The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to ADR/CDL Regulations interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in ADR/CDL Regulations Interview

Q 1. Explain the difference between ADR and CDL regulations.

ADR and CDL are both crucial for the safe transportation of hazardous materials, but they operate at different levels and address distinct aspects of the process. ADR (Accord européen relatif au transport international des marchandises dangereuses par route) is a European agreement concerning the international carriage of dangerous goods by road. It dictates the classification, packaging, labeling, and documentation requirements for these goods. Think of ADR as the comprehensive rulebook. CDL (Commercial Driver’s License), on the other hand, is a North American license required to operate commercial motor vehicles, including those carrying hazardous materials. It focuses on the driver’s qualifications and certifications for safely transporting these materials. In essence, ADR establishes the regulations for *what* is being transported, while CDL regulates *who* can transport it and ensures the driver is adequately trained to do so. A driver needs a CDL endorsement (like the HAZMAT endorsement) to legally transport hazardous materials even if the goods themselves comply with ADR.

Q 2. What are the classes of hazardous materials under ADR/CDL regulations?

Hazardous materials under ADR/CDL regulations are categorized into classes based on their inherent hazards. These classes aren’t mutually exclusive; a single material might fall under multiple classes. Here’s a simplified overview:

- Class 1: Explosives (e.g., dynamite, fireworks): Materials capable of mass explosion or projection of fragments.

- Class 2: Gases (e.g., propane, oxygen): Compressed, liquefied, or dissolved gases posing fire, explosion, or toxic hazards.

- Class 3: Flammable Liquids (e.g., gasoline, paint thinner): Liquids that readily ignite.

- Class 4: Flammable Solids (e.g., magnesium, matches): Solids that readily ignite.

- Class 5: Oxidizing Substances and Organic Peroxides (e.g., hydrogen peroxide, bleach): Substances that cause or contribute to combustion.

- Class 6: Toxic and Infectious Substances (e.g., pesticides, medical waste): Materials that are poisonous or cause disease.

- Class 7: Radioactive Materials (e.g., nuclear isotopes): Materials that emit ionizing radiation.

- Class 8: Corrosive Substances (e.g., acids, bases): Materials that cause destruction of living tissue.

- Class 9: Miscellaneous Dangerous Goods (e.g., lithium batteries, dry ice): Materials not fitting into other classes but presenting a hazard during transport.

Understanding these classes is fundamental for proper handling and transportation.

Q 3. Describe the process for classifying hazardous materials.

Classifying hazardous materials is a crucial step in ensuring safe transportation. It involves a systematic process, often involving reference to a comprehensive classification system like the United Nations Globally Harmonized System of Classification and Labelling of Chemicals (GHS). The process typically includes:

- Identifying the Material: Determine the chemical composition and physical properties of the substance.

- Reviewing Safety Data Sheets (SDS): SDS provides crucial information regarding the hazards associated with the material.

- Consulting Classification Guides: Utilize official guides like the ADR or UN recommendations to match the material’s properties to hazard classes.

- Testing (If Necessary): Some materials require laboratory testing to determine their precise hazard classification.

- Assigning the Hazard Class and Division: Once the hazards are identified, assign the correct hazard class and division (e.g., Class 1.1, Class 3, etc.).

- Determining Packing Group: The packing group (I, II, or III) indicates the degree of hazard associated with the material – I being the most dangerous and III the least.

The classification process ensures that every hazardous material is appropriately labeled, packaged, and handled during transport.

Q 4. What are the requirements for packaging hazardous materials?

Packaging hazardous materials is critical to preventing leaks, spills, and other incidents during transport. The packaging must be compatible with the material being transported and meet specific strength and design requirements based on its hazard classification and packing group. Key aspects include:

- Material Compatibility: The packaging must be resistant to the chemical properties of the contained material. For example, corrosive substances require packaging that won’t be damaged by acids or bases.

- Strength and Integrity: Packaging must withstand typical transport stresses, like vibrations and impacts, preventing leaks or ruptures.

- UN-approved Packaging: Many hazardous materials require packaging that has been tested and approved by the UN or other relevant regulatory bodies, according to ADR regulations.

- Proper Closures and Seals: Secure closures and seals are necessary to prevent leaks or spills.

- Marking and Labeling: Packages must be clearly marked and labeled with the correct hazard information.

Using incorrect or damaged packaging can lead to serious accidents and environmental damage.

Q 5. Explain the placarding requirements for transporting hazardous materials.

Placarding is the process of displaying warning signs (placards) on the outside of vehicles transporting hazardous materials. These placards communicate the class of hazardous material being transported, providing crucial information to emergency responders and other drivers. The size and type of placard depend on the class of hazardous material and the quantity being transported. For example, a tanker truck carrying gasoline will display a flammable liquid placard. The placards must be placed at specific locations on the vehicle, typically in a highly visible area, ensuring they are easily spotted.

Failure to properly placard a vehicle carrying hazardous materials is a serious violation and can result in significant fines and penalties. It can also severely compromise emergency response efforts should an incident occur.

Q 6. What are the driver requirements for transporting hazardous materials?

Drivers transporting hazardous materials must meet stringent requirements to ensure safe handling and transportation. These include:

- Possessing a CDL with HAZMAT Endorsement: This demonstrates they have undergone specialized training on handling hazardous materials.

- Understanding the Transportation Regulations: Drivers must know and follow ADR/CDL regulations, including proper handling, securing, and emergency procedures.

- Security Awareness: They should be aware of security threats and procedures to prevent theft or tampering.

- Emergency Response Training: Drivers need training on handling spills, leaks, or other emergency situations.

- Proper Documentation: Drivers must carry and maintain the necessary shipping papers and other documentation.

These requirements are essential to prevent accidents and protect the public.

Q 7. What are the emergency response procedures for hazardous material incidents?

Emergency response procedures for hazardous material incidents are critical for minimizing harm to people and the environment. A successful response relies on several key elements:

- Immediate Notification: Report the incident to emergency services immediately. This allows for prompt dispatch of trained personnel.

- Scene Security: Establish a safety perimeter around the incident to prevent further exposure.

- Evacuation: Evacuate people from the immediate area if necessary.

- Hazard Identification: Identify the type and quantity of hazardous material involved to determine the appropriate response strategy. This often requires reviewing shipping documents and placards.

- Containment and Cleanup: Employ appropriate containment measures to prevent further spread, followed by specialized cleanup procedures.

- Decontamination: Decontaminate affected individuals and equipment as needed.

- Investigation: Conduct a thorough investigation to determine the cause of the incident and prevent future occurrences.

Effective emergency response requires coordination between various agencies and trained professionals and relies on accurate information gathered before, during, and after the incident. Regular training and drills are essential to ensure readiness for such events.

Q 8. Describe the documentation required for transporting hazardous materials.

Transporting hazardous materials requires meticulous documentation to ensure safety and compliance. The specific documents needed vary depending on the material, mode of transport, and destination, but generally include:

- Shipper’s Declaration for Dangerous Goods (DG): This crucial document details the hazardous materials being shipped, their classification, packaging, quantity, and any special handling instructions. Think of it as the ‘passport’ for your hazardous cargo. It’s the primary document checked by authorities.

- Emergency Response Information: This includes contact details for the shipper, carrier, and emergency response teams. In case of an accident, this is vital for swift and informed action.

- Safety Data Sheets (SDS): Also known as Material Safety Data Sheets (MSDS), these sheets provide detailed information about the hazards of the specific material, including its physical and chemical properties, health risks, and emergency procedures. These are essential for anyone handling the material.

- Packing Lists: These lists detail the contents of each package, ensuring accurate tracking and accountability throughout the transportation process. They are especially important for verifying that hazardous goods are properly packaged and labelled.

- Transport Documents: These are the standard shipping documents (e.g., bills of lading, waybills) that accompany the shipment. They will clearly identify the hazardous nature of the goods and any specific transport requirements.

- Certificates of Compliance (COCs): These certify that the packaging and the materials themselves meet the required safety standards.

Imagine a shipment of corrosive chemicals. Without the proper documentation, authorities wouldn’t know how to handle the goods safely in case of an accident, potentially leading to a much bigger incident. Each document plays a vital role in ensuring safe and legal transportation.

Q 9. What are the penalties for non-compliance with ADR/CDL regulations?

Penalties for non-compliance with ADR/CDL regulations can be severe and vary depending on the severity of the violation and the jurisdiction. They can include:

- Heavy Fines: Significant financial penalties can be imposed, sometimes reaching tens of thousands of dollars, especially for repeated or serious offenses.

- Vehicle Impoundment: The vehicle transporting the hazardous materials may be impounded until the violations are rectified.

- Criminal Charges: In cases of gross negligence or intentional misconduct, criminal charges can be filed, resulting in imprisonment.

- Suspension or Revocation of Licenses: Drivers and carriers can face suspension or permanent revocation of their operating licenses, effectively ending their careers in the transport industry.

- Civil Lawsuits: In case of accidents or environmental damage caused by non-compliance, companies can face costly civil lawsuits from injured parties or affected communities.

- Reputational Damage: Non-compliance can severely damage a company’s reputation, making it difficult to secure future contracts and clients.

For example, a company failing to properly label hazardous materials might face significant fines and even criminal prosecution if their negligence causes an accident or harm. The consequences are far-reaching and highlight the importance of strict adherence to these regulations.

Q 10. Explain the role of the shipper and the carrier in ensuring compliance.

Both the shipper and the carrier share responsibility for ensuring compliance with ADR/CDL regulations. Their roles are interconnected and crucial for maintaining safety throughout the transportation process:

- Shipper’s Responsibilities: The shipper is responsible for classifying the hazardous materials correctly, selecting appropriate packaging, ensuring accurate labeling and marking, preparing the required documentation (Shipper’s Declaration, SDS), and providing the carrier with all necessary information for safe transportation.

- Carrier’s Responsibilities: The carrier is responsible for ensuring the hazardous materials are transported according to the shipper’s instructions and applicable regulations. This includes having properly trained drivers, using appropriate vehicles and equipment, adhering to transport routes and restrictions, and responding correctly in emergency situations.

Consider a scenario where a shipper incorrectly classifies a hazardous material. The carrier, relying on the shipper’s declaration, may unknowingly transport the material inappropriately. Both parties would then be held accountable for any resulting consequences. Effective communication and collaboration are paramount.

Q 11. How do you ensure the safety of hazardous materials during transportation?

Ensuring the safety of hazardous materials during transportation requires a multi-faceted approach:

- Proper Packaging and Labeling: Using UN-approved packaging and clear, accurate labeling is fundamental. This ensures the materials are contained securely and their identity is readily apparent.

- Trained Personnel: Drivers and handlers must receive adequate training on hazardous materials handling, transportation regulations, and emergency procedures. Regular refresher training is crucial.

- Secure Vehicle Transport: Using vehicles specifically designed for hazardous materials transportation, with features like secure fastenings and containment systems, is essential.

- Route Planning: Choosing appropriate routes that avoid populated areas, sensitive environments, and challenging terrains is critical. This minimizes the risk of accidents.

- Regular Inspections: Vehicles and their cargo should undergo regular inspections to detect and address potential issues before they escalate.

- Emergency Preparedness: Having clear emergency response plans and well-trained personnel is crucial for managing incidents swiftly and effectively.

Think of it like this: transporting hazardous materials is like carrying a loaded gun. You need careful handling, proper training, and a well-defined safety plan at every step.

Q 12. How do you handle a spill or accident involving hazardous materials?

Handling a spill or accident involving hazardous materials requires a swift and coordinated response, prioritizing safety:

- Immediate Evacuation: Evacuate the immediate area, ensuring the safety of people and animals.

- Emergency Services Notification: Contact emergency services immediately, providing them with detailed information about the material, location, and extent of the spill.

- Containment: Attempt to contain the spill using appropriate methods to prevent further spread.

- Protection: Use appropriate personal protective equipment (PPE) to protect yourself from exposure.

- Decontamination: Once the spill is contained, initiate decontamination procedures for affected personnel and equipment.

- Cleanup and Disposal: Engage specialized cleanup crews with the necessary expertise and equipment to safely clean up and dispose of the hazardous materials according to regulations.

- Documentation: Thoroughly document the incident, including actions taken, material involved, and any injuries or damage.

A coordinated response, from immediate action to detailed documentation, is paramount in limiting damage and ensuring the safety of all involved.

Q 13. What are the different types of hazardous materials containers?

Hazardous materials containers are categorized according to their construction, design, and performance capabilities. Different container types are designed to meet specific requirements depending on the hazard class of the materials being transported. Examples include:

- Drums: Metal or plastic drums are commonly used for liquids and solids, offering varying levels of strength and durability.

- Tanks: Bulk transport tanks, either portable or fixed on vehicles, are used for large volumes of liquid hazardous materials.

- Intermediate Bulk Containers (IBCs): These reusable containers, often made of plastic or metal, are designed for the transport of both liquid and solid materials.

- Cylinders: High-pressure cylinders are used for compressed gases, ensuring safe containment under pressure.

- Boxes and Crates: These containers are used for solid hazardous materials, with the design varying depending on the material’s physical and chemical properties.

The selection of a container is determined by various factors, including the physical and chemical properties of the hazardous material, the quantity to be transported, and the mode of transport. Selecting the incorrect container can lead to leakage or damage during transport, posing significant safety risks.

Q 14. What are the requirements for training hazardous materials handlers?

Training for hazardous materials handlers is crucial for ensuring safe and compliant transportation. Requirements vary by jurisdiction but generally include:

- Initial Training: Initial training covers the fundamentals of hazardous materials, their classification, and proper handling procedures. It typically includes both classroom instruction and practical demonstrations.

- Refresher Training: Regular refresher training is essential to keep handlers up-to-date on regulations, best practices, and any changes in procedures. This ensures knowledge remains current and handling techniques remain safe and efficient.

- Hazard-Specific Training: Handlers may require additional training specific to the particular hazardous materials they work with. This ensures in-depth understanding of the unique hazards and handling requirements.

- Emergency Response Training: Training on emergency response procedures, including spill management and first aid for hazardous material exposure, is essential.

- Certification: Many jurisdictions require handlers to receive certification demonstrating their competence in hazardous materials handling. This ensures a minimum standard of skill and knowledge across the industry.

A lack of proper training can lead to accidents, environmental damage, and severe health consequences. Continuous training and certification demonstrate a commitment to safety and adherence to regulations.

Q 15. Explain the significance of the Emergency Response Guidebook (ERG).

The Emergency Response Guidebook (ERG) is a crucial resource for first responders and transportation personnel dealing with hazardous materials incidents. It provides a quick guide to identify hazardous materials based on their UN/NA numbers or proper shipping names, and then outlines immediate actions to take during an emergency. Think of it as a first aid manual, but for hazardous materials. It’s not exhaustive, but it gives vital initial instructions until more specialized resources arrive.

The ERG is organized by sections, allowing for quick identification of the hazard and appropriate response. For example, if a tanker truck overturns and displays UN number 1202 (Gasoline), the ERG will immediately indicate potential hazards (fire, explosion), recommended evacuation distances, and initial protective actions. This information is critical in minimizing harm to people and the environment.

In short, the ERG is the first line of defense in a hazardous materials incident. Its importance lies in its accessibility and ease of use in high-pressure emergency situations where time is of the essence.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the limitations on transporting hazardous materials by specific modes?

Transportation of hazardous materials is tightly regulated, varying by mode (road, rail, air, sea). For example, the amount of flammable materials allowed on a passenger aircraft is significantly less than what might be permitted on a dedicated cargo vessel. Each mode has specific packaging requirements, documentation needs, and operational restrictions.

- Road: Limits might include weight restrictions, routing limitations (avoiding populated areas or tunnels), and specialized vehicle requirements (tanker trucks with specific safety features).

- Rail: Stricter regulations exist concerning the type of railcars allowed, their maintenance, and the volume of hazardous materials that can be transported in a single train. Placarding requirements are more stringent.

- Air: The most restrictive, with limits on the quantity, type, and packaging of hazardous materials permitted on both passenger and cargo flights. Specific certifications for handling personnel are often required.

- Sea: International Maritime Dangerous Goods (IMDG) Code governs sea transport, detailing classifications, packaging, and stowage requirements for hazardous materials shipped by sea. These regulations are arguably the most extensive.

Exceeding these limits can lead to severe penalties, including hefty fines and even criminal charges. Accurate planning and adherence to regulations are paramount.

Q 17. How do you maintain accurate records and documentation for compliance?

Maintaining accurate records and documentation is crucial for compliance with ADR/CDL regulations. This involves meticulous record-keeping of every step of the hazardous materials transportation process.

- Shipping Papers: Complete and accurate shipping papers (Bill of Lading, etc.) must accompany the shipment, detailing the hazardous materials being transported, their classification, and handling instructions.

- Driver Logs: Drivers must maintain accurate logs of their driving hours and activities, adhering to hours-of-service regulations.

- Inspection Reports: Regular vehicle inspections and maintenance records must be kept, demonstrating that the vehicles used are in safe working condition.

- Training Records: Documentation of driver and handler training programs is essential, proving that all personnel involved are properly trained to handle the specific hazardous materials being transported.

- Incident Reports: Any incidents or accidents involving hazardous materials must be thoroughly documented and reported to the appropriate authorities.

Utilizing electronic logging devices (ELDs) and transport management systems (TMS) can simplify and improve the accuracy of record-keeping. The key is having a robust system in place to ensure all documentation is readily available for audits.

Q 18. Explain the process of obtaining necessary permits and licenses.

The process of obtaining necessary permits and licenses for hazardous materials transportation varies depending on the jurisdiction and the type of hazardous material being transported. It generally involves several steps:

- Identify Required Permits and Licenses: Determine the specific permits and licenses required based on the type of hazardous materials, the routes involved, and the regulations in the jurisdictions where the transport will take place.

- Application Submission: Complete and submit the required applications to the appropriate regulatory agencies (e.g., Department of Transportation). This often includes providing details about the hazardous materials, the vehicles to be used, the proposed routes, and the personnel involved.

- Background Checks and Security Clearance: Depending on the nature of the hazardous materials, background checks and security clearances may be required for drivers and handlers.

- Compliance Audits and Inspections: Regulatory agencies may conduct audits and inspections to verify compliance with the regulations before issuing permits and licenses.

- License Renewal: Permits and licenses usually have expiration dates and need periodic renewal, requiring ongoing compliance demonstrations.

Failure to obtain or maintain the necessary permits and licenses can result in severe penalties and operational disruption. It’s critical to proactively engage with the relevant agencies to ensure all requirements are met.

Q 19. Describe your experience with hazard communication and safety data sheets (SDS).

Hazard communication and Safety Data Sheets (SDS) are fundamental components of safe hazardous materials handling. SDSs provide comprehensive information about the physical, chemical, and health hazards of a specific chemical, including handling procedures, emergency response measures, and personal protective equipment (PPE) required. My experience involves training employees on proper SDS interpretation and use.

For example, I’ve trained teams on how to recognize hazard pictograms, understand the different sections of an SDS, and identify appropriate PPE based on the hazard information provided. I’ve also developed and implemented emergency response plans based on the information provided in the SDSs for various hazardous materials we handle. This includes procedures for spills, leaks, and exposures. We conduct regular drills and refreshers to ensure that everyone understands their roles and responsibilities.

In addition to training, my role involves ensuring that SDSs are readily accessible to all personnel, properly updated, and translated as needed. I’ve managed the electronic and hard-copy storage and organization of SDSs, adhering to all applicable regulatory requirements. Effective hazard communication and a well-managed SDS system are pivotal for maintaining a safe working environment.

Q 20. How do you stay updated on changes in ADR/CDL regulations?

Staying updated on changes in ADR/CDL regulations requires a proactive approach. I utilize several strategies:

- Subscription to Regulatory Updates: I subscribe to newsletters and publications from relevant regulatory bodies (e.g., DOT, UN, IMO) to receive notifications of upcoming changes and updates.

- Participation in Industry Conferences and Workshops: Attending conferences and workshops helps me stay informed about the latest industry best practices and regulatory changes discussed by peers and experts.

- Monitoring Government Websites: I regularly check the websites of relevant regulatory agencies for updated guidance, new rules, and amendments to existing regulations.

- Professional Development Courses and Training: I actively pursue professional development courses and training programs focused on ADR/CDL regulations to gain deeper knowledge and expertise.

- Networking with Industry Professionals: Maintaining relationships with other professionals in the field allows for the exchange of knowledge and insights on regulatory changes.

Continuous learning is critical in this field; regulatory changes are frequent, and staying abreast of these is essential to maintain compliance and operational efficiency.

Q 21. How would you handle a situation where a driver is not following procedures?

If a driver is not following established procedures, I’d follow a structured approach:

- Immediate Intervention: If a safety violation is observed, immediate intervention is necessary. I’d instruct the driver to cease the non-compliant activity.

- Investigate the Reason: Understanding the root cause is crucial. Was it a misunderstanding of procedures, lack of training, or a deliberate disregard for safety rules? I’d conduct a thorough investigation, gathering evidence and talking to the driver.

- Corrective Action: Depending on the severity of the violation, corrective action could range from additional training and retraining to disciplinary measures. I would document the incident and any corrective actions taken.

- Reinforce Training: If the issue stems from a lack of understanding or training, I would reinforce the relevant training materials and ensure the driver understands the correct procedures.

- Report and Documentation: A detailed report would be filed documenting the incident, the investigation, and the corrective actions taken. This ensures that similar incidents can be prevented in the future.

The goal is not just to punish, but to prevent future incidents through education, retraining, and improved communication. Safety is paramount in hazardous materials transport, and maintaining a culture of compliance is crucial.

Q 22. How do you ensure compliance with international regulations for ADR?

Ensuring compliance with international ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) regulations requires a multifaceted approach. It’s not just about ticking boxes; it’s about embedding a culture of safety and understanding.

- Documentation and Training: We begin with meticulous documentation – ensuring all shipping papers, including the dangerous goods declaration, are correctly completed and comply with the latest ADR provisions. This includes accurate classification of goods according to the UN hazard classes and proper packaging according to the instructions provided by the manufacturer. Comprehensive training for all personnel involved in the handling, transport, and storage of dangerous goods is crucial. This training covers aspects like emergency response procedures and proper handling techniques.

- Vehicle Inspections and Maintenance: Regular vehicle inspections are essential to ensure that vehicles meet the ADR requirements for carrying dangerous goods, such as proper signage, emergency equipment, and tank integrity for tankers. Maintaining accurate maintenance logs is also key to demonstrate ongoing compliance.

- Route Planning and Emergency Preparedness: Careful route planning to avoid sensitive areas and adherence to speed restrictions for dangerous goods is vital. Emergency response plans should be in place, detailing procedures in case of accidents, spills, or other incidents. Driver training includes simulated emergency scenarios and regular drills to enhance their preparedness.

- Staying Updated: ADR regulations are constantly updated, so continuous monitoring of changes and timely implementation of updates is crucial. Subscribing to relevant newsletters, attending industry conferences, and participating in training programs helps us stay abreast of changes and best practices.

For example, I once prevented a shipment from leaving our facility because the dangerous goods declaration incorrectly stated the UN number for the transported substance. This seemingly small mistake could have had serious consequences.

Q 23. What is your experience with various hazardous materials transport modes (road, rail, sea, air)?

My experience spans all major modes of hazardous materials transport: road, rail, sea, and air. Each mode presents unique challenges and regulatory requirements.

- Road Transport: This is the most common mode, and I have extensive experience with managing road transport, including driver training, vehicle compliance, and route planning to mitigate risks. This often involves detailed understanding of ADR regulations as well as national legislation.

- Rail Transport: Rail transport of hazardous materials requires a different set of regulations and considerations, focusing on securing the cargo within specialized railcars and adhering to stringent safety protocols. I have experience ensuring compliance with railway-specific regulations, such as those covering tank car inspections and securing the load within railcars.

- Sea Transport: Maritime transport involves compliance with the IMDG Code (International Maritime Dangerous Goods Code) and adherence to safety procedures related to seafaring and port handling. My knowledge here includes documentation requirements for international shipments and emergency response procedures on board vessels.

- Air Transport: Air transport is the most regulated mode, given the potential consequences of an incident at high altitudes. I’m familiar with IATA (International Air Transport Association) regulations, including the handling of dangerous goods at airports and the preparation of shipping documents required for air freight.

Understanding the nuances of each mode ensures we utilize appropriate safety measures and select suitable transport options, minimizing potential hazards.

Q 24. Describe your experience with different types of hazardous material incidents and how you managed them.

I’ve dealt with various hazardous material incidents, from minor spills to more serious accidents. My approach prioritizes immediate response, containment, and investigation.

- Minor Spills: I have managed numerous minor spills, involving prompt cleanup using appropriate safety measures and disposal methods. These incidents always lead to a thorough review of our processes to prevent recurrence.

- Accidents Involving Injuries: In more serious incidents involving injuries, immediate first aid and contacting emergency services were paramount. Post-incident investigation and reporting to relevant authorities, including thorough documentation of the incident, root-cause analysis, and corrective actions, were undertaken to prevent similar accidents in the future.

- Large-Scale Incidents: For large-scale incidents, coordinated response with emergency services and regulatory bodies is crucial. This includes evacuation procedures, and containment of the spill. Detailed investigation and reporting according to the requirements of the various regulatory agencies are mandatory.

Each incident reinforces the importance of meticulous planning, rigorous training, and ongoing risk assessment. For example, one incident involving a chemical reaction within a container highlighted the need for more stringent temperature control during transport.

Q 25. How do you identify and mitigate risks associated with transporting hazardous materials?

Identifying and mitigating risks associated with hazardous materials transport involves a proactive, multi-layered approach.

- Hazard Identification and Risk Assessment: This starts with a thorough understanding of the hazardous materials being transported – their properties, potential hazards, and associated risks. We use risk assessment methodologies to identify potential hazards during handling, transportation, and storage.

- Proper Packaging and Labeling: Ensuring proper packaging and labeling according to UN standards is critical. This minimizes the likelihood of leaks, spills, and exposure to hazardous materials.

- Route Selection and Security Measures: Choosing the safest routes and implementing security measures to prevent theft or sabotage are also essential considerations.

- Emergency Response Planning: Having well-defined emergency response plans ensures that we’re prepared to handle incidents swiftly and effectively. This includes training drivers in emergency procedures and providing them with the necessary equipment.

- Continuous Monitoring: Using technology such as GPS tracking allows monitoring of shipments in real time and provides early warning of any potential issues.

For instance, in one project, we identified a higher risk of accidents during nighttime transport due to reduced visibility. We mitigated this by restricting nighttime transport of the most hazardous materials.

Q 26. Describe your experience working with various regulatory bodies (e.g., DOT, EPA).

I have extensive experience working with various regulatory bodies including the Department of Transportation (DOT), Environmental Protection Agency (EPA), and other international counterparts. This includes:

- DOT Compliance: I’ve worked extensively to ensure compliance with DOT regulations for hazardous materials transport within the US, including proper documentation, vehicle certification, and driver training requirements.

- EPA Compliance: I’ve collaborated with the EPA to ensure that our handling and disposal of hazardous materials conform to environmental regulations. This has included working on spill response plans and appropriate waste management protocols.

- International Regulatory Bodies: My experience encompasses working with international agencies to navigate the complexities of global hazardous materials transport, ensuring compliance with various international regulations and standards.

Building strong relationships with these bodies and maintaining open communication is essential for proactive compliance and addressing any challenges that may arise. For example, I successfully navigated a complex regulatory change by working closely with the DOT, resulting in a timely and compliant solution.

Q 27. How familiar are you with the use of technology in managing ADR/CDL compliance?

Technology plays a pivotal role in modern ADR/CDL compliance management. I am highly familiar with using various technological solutions to enhance safety and efficiency.

- GPS Tracking and Telematics: Real-time tracking of hazardous materials shipments allows for proactive risk management, enabling swift responses to potential incidents and providing valuable data for route optimization and risk analysis.

- Electronic Documentation and Data Management Systems: Digital solutions for managing shipping documents, training records, and vehicle maintenance logs streamline compliance processes and ensure accurate data management. This minimizes paperwork and reduces the risk of errors.

- Hazmat Management Software: Dedicated hazmat management software solutions automate many aspects of compliance, assisting in route planning, hazmat classification, and document generation. This simplifies operations and improves overall efficiency.

- Driver Training Apps and Simulations: Using technology for driver training enhances the learning experience and provides access to updated regulations and best practices, increasing preparedness.

For instance, we implemented a GPS tracking system that alerted us to a vehicle that had deviated from the approved route, allowing immediate intervention and preventing a potential security breach.

Q 28. Explain your approach to continuous improvement in hazmat safety and regulatory compliance.

Continuous improvement in hazmat safety and regulatory compliance is a journey, not a destination. My approach involves a cyclical process of review, analysis, and implementation.

- Regular Audits and Inspections: Conducting regular internal audits and inspections helps identify areas for improvement, ensuring our processes and procedures are up to date and efficient.

- Data Analysis and Trend Identification: Analyzing incident data, transport statistics, and compliance records identifies patterns and trends that can inform improvements and prevent future problems.

- Feedback Mechanisms: Encouraging feedback from drivers, staff, and other stakeholders provides valuable insights into potential issues and areas for improvement.

- Benchmarking and Best Practices: Regularly benchmarking our performance against industry best practices and keeping abreast of new technologies and techniques allows us to learn from others and identify opportunities for improvement.

- Training and Education: Consistent training and education programs ensure our personnel stay updated with the latest regulations, technologies, and best practices.

For example, after a minor incident, we reviewed our emergency response procedures, adding a new step that significantly improved our reaction time. This iterative approach fosters a culture of continuous improvement and ensures our commitment to hazmat safety.

Key Topics to Learn for ADR/CDL Regulations Interview

- Classification of Dangerous Goods: Understand the different classes of dangerous goods and their associated hazard labels and identification numbers. Be prepared to discuss practical examples of how to classify various substances.

- Packaging and Containerization: Learn the regulations surrounding the packaging and securement of dangerous goods for transport. Be ready to explain the importance of choosing appropriate packaging and the consequences of incorrect packaging.

- Transport Documentation: Master the requirements for completing and maintaining accurate shipping papers, including the correct completion of relevant forms and declarations. Understand the implications of missing or inaccurate documentation.

- Emergency Response: Familiarize yourself with emergency procedures in case of accidents involving dangerous goods. This includes understanding safety procedures, spill response, and communication protocols.

- Driver Responsibilities: Understand the specific responsibilities of drivers transporting dangerous goods, including pre-trip inspections, route planning, and adherence to regulations throughout the transportation process.

- Vehicle Requirements: Learn the specific requirements for vehicles used to transport dangerous goods, including placards, markings, and equipment necessary for safe transport.

- Segregation and Compatibility: Understand the rules concerning the segregation of incompatible dangerous goods during transport and the potential consequences of improper segregation.

- International Regulations (if applicable): If your role involves international transport, familiarize yourself with relevant international regulations and their interplay with local laws.

- Practical Problem Solving: Prepare to analyze hypothetical scenarios involving dangerous goods transport and apply your knowledge to find compliant solutions.

Next Steps

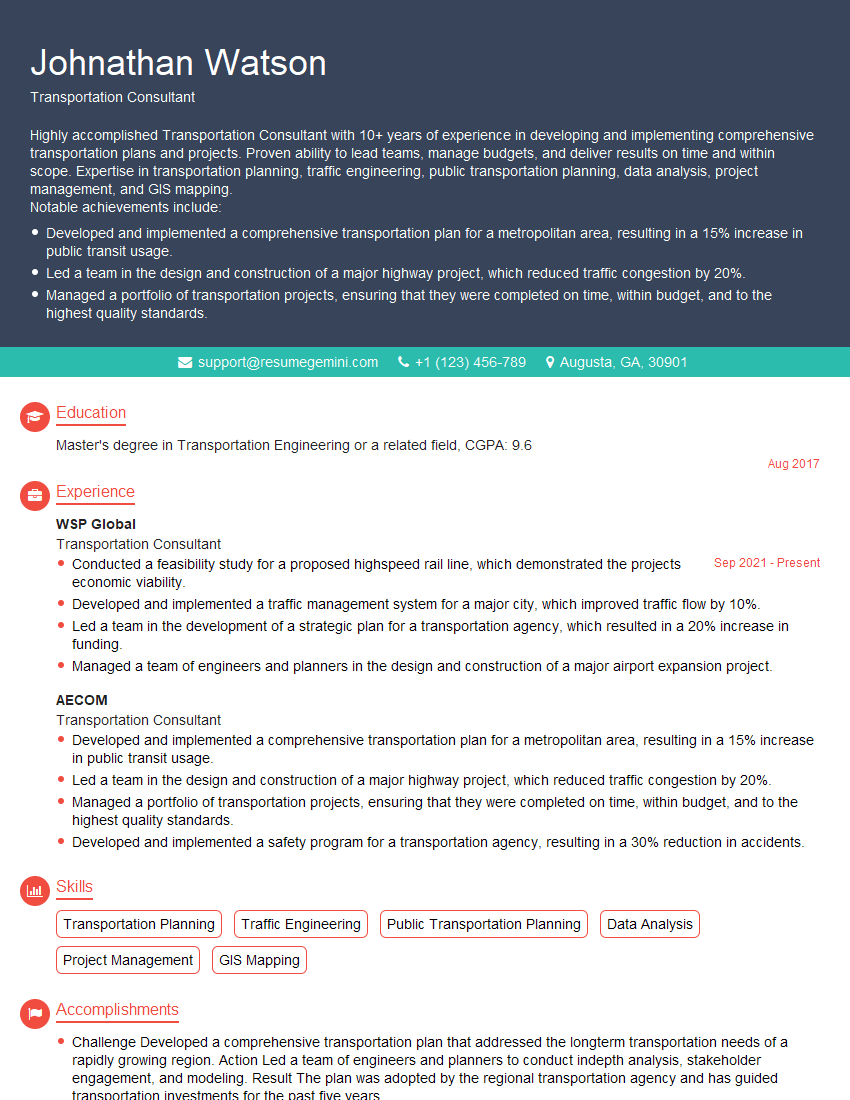

Mastering ADR/CDL regulations is crucial for career advancement in the transportation industry, demonstrating your commitment to safety and compliance. A strong understanding of these regulations will significantly enhance your job prospects and open doors to higher-level roles with increased responsibility and compensation. Creating an ATS-friendly resume is key to getting your application noticed. To make your resume stand out, we encourage you to use ResumeGemini, a trusted resource for building professional and effective resumes. ResumeGemini provides examples of resumes tailored specifically to the ADR/CDL Regulations field, helping you showcase your skills and experience effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO