Are you ready to stand out in your next interview? Understanding and preparing for Materials and Resources Sourcing interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Materials and Resources Sourcing Interview

Q 1. Describe your experience in negotiating contracts with suppliers.

Negotiating contracts with suppliers is a crucial aspect of materials sourcing, requiring a strategic approach that balances cost-effectiveness with risk mitigation. My process involves thorough preparation, skillful communication, and a keen understanding of market dynamics. I begin by clearly defining our needs and desired outcomes in the contract, including specifications, quantities, delivery timelines, and payment terms. I then research the supplier’s capabilities and market position to establish a strong negotiating baseline. During negotiations, I focus on building a collaborative relationship while firmly advocating for our company’s interests. This often involves exploring alternative solutions and compromises to achieve a mutually beneficial agreement. For example, I successfully negotiated a longer payment term with a key supplier during a period of raw material price volatility, thereby mitigating our financial risk while maintaining a positive relationship. Furthermore, I always ensure that the contract includes clear clauses addressing quality control, dispute resolution, and potential breaches of contract.

Q 2. Explain your process for identifying and selecting new suppliers.

Identifying and selecting new suppliers is a multi-stage process that prioritizes due diligence and risk assessment. I begin by defining our specific requirements, including material specifications, quality standards, and desired delivery times. Then, I leverage a combination of methods to identify potential suppliers. This includes market research, online databases, industry events, and referrals from existing partners. Once a list of potential suppliers is compiled, a thorough vetting process is initiated. This involves assessing their financial stability, manufacturing capabilities, quality control systems, and environmental practices. Site visits are frequently conducted to directly assess their facilities and operations. Finally, a comparative analysis is performed, considering factors such as price, lead times, quality, and reliability, before making a final selection. For example, when sourcing a new type of specialized polymer, I conducted extensive online research, attended a relevant industry trade show, and requested samples from several potential suppliers to thoroughly evaluate their offerings before awarding the contract.

Q 3. How do you manage supplier relationships to ensure timely delivery and quality?

Managing supplier relationships is paramount for ensuring timely delivery and consistent quality. I prioritize open communication and collaboration, regularly engaging with key suppliers to monitor performance and address any emerging issues proactively. We establish clear Key Performance Indicators (KPIs) that measure delivery performance, quality metrics, and responsiveness. Regular performance reviews are conducted, offering constructive feedback and identifying areas for improvement. A collaborative approach fosters trust and encourages mutual problem-solving. For instance, when a supplier experienced unexpected delays due to a natural disaster, we worked collaboratively to find alternative solutions, such as expedited shipping from a secondary facility, to mitigate the impact on our production schedule. This proactive approach strengthens the supplier relationship and ensures project continuity.

Q 4. What are your preferred methods for cost reduction in materials sourcing?

Cost reduction in materials sourcing involves a multi-pronged approach that balances cost savings with quality and reliability. My strategies include negotiating favorable pricing terms with suppliers, exploring alternative materials with comparable performance at lower costs, optimizing order quantities to benefit from economies of scale, and consolidating purchasing across different departments to leverage greater bargaining power. Furthermore, I frequently explore opportunities for value engineering, collaborating with suppliers to identify cost-effective design modifications without compromising product functionality. For example, by switching from a premium grade steel to a slightly less expensive but still suitable alternative, we achieved significant cost savings without impacting product quality. Continuous monitoring of market trends and commodity prices allows for proactive adjustments in our sourcing strategies to further reduce costs.

Q 5. Describe your experience with different sourcing strategies (e.g., global sourcing, local sourcing).

My experience encompasses both global and local sourcing strategies, each offering unique advantages and challenges. Global sourcing allows access to a wider range of suppliers, potentially leading to lower costs and access to specialized materials. However, it presents challenges associated with longer lead times, higher transportation costs, and potential geopolitical risks. Local sourcing, on the other hand, benefits from shorter lead times, reduced transportation costs, and improved collaboration with suppliers. However, it may limit access to specialized materials and potentially result in higher costs. The optimal sourcing strategy depends on a careful evaluation of various factors, including cost, lead times, quality requirements, risk tolerance, and the specific characteristics of the materials being sourced. For instance, we utilize global sourcing for some commodity materials where cost is a primary concern, while local sourcing is preferred for specialized components that require close collaboration with the supplier and fast turnaround times.

Q 6. How do you handle supplier performance issues?

Handling supplier performance issues requires a systematic approach that prioritizes clear communication and collaborative problem-solving. I begin by clearly defining the issue and gathering relevant data, such as delivery delays, quality defects, or non-compliance with contract terms. Then, I engage with the supplier to understand the root cause of the problem. This typically involves open communication, joint problem-solving sessions, and a review of the supplier’s processes. Based on the severity and root cause of the issue, corrective actions are implemented, which may include implementing improved quality control measures, revised delivery schedules, or financial penalties as stipulated in the contract. For instance, when a supplier consistently failed to meet delivery deadlines, we initiated a comprehensive review of their production processes, collaborated on implementing improved scheduling practices, and provided technical assistance to help them streamline their operations. This collaborative approach led to significant improvements in their delivery performance.

Q 7. What are some key metrics you use to evaluate the effectiveness of your sourcing strategies?

Evaluating the effectiveness of sourcing strategies involves tracking key metrics that reflect cost, quality, and efficiency. Key metrics I utilize include total cost of ownership (TCO), which encompasses all costs associated with acquiring and managing materials; supplier delivery performance, measured by on-time delivery rates and lead times; material quality, assessed through defect rates and customer feedback; and supplier responsiveness, reflecting how effectively suppliers address inquiries and resolve issues. Furthermore, I track the efficiency of the sourcing process itself, measuring time to market, procurement cycle times, and the number of suppliers used. Regular analysis of these metrics allows for continuous improvement of our sourcing strategies, ensuring we achieve optimal cost, quality, and efficiency in our material acquisition processes.

Q 8. How do you manage risk in the supply chain?

Managing risk in the supply chain is paramount. It’s like building a house – you wouldn’t skip the foundation! My approach is multifaceted, focusing on identifying, assessing, and mitigating potential disruptions. This involves:

- Supplier Diversification: Instead of relying on a single supplier, I work with multiple vendors to reduce dependence on any one source. This protects against production delays or price hikes from a single supplier failure. For example, if one semiconductor manufacturer faces a plant closure, having alternative suppliers ensures continued production.

- Risk Assessment & Mapping: I use a structured approach to identify potential risks – geopolitical instability, natural disasters, pandemics, economic downturns, etc. – and map their impact on our supply chain. This helps prioritize mitigation efforts.

- Contract Negotiation & Clauses: Contracts should include provisions for force majeure (unforeseeable circumstances), supply guarantees, and dispute resolution mechanisms. For instance, a contract might specify penalties for late deliveries or include a price escalation clause to account for inflation.

- Inventory Management & Buffer Stock: Maintaining strategic inventory levels provides a buffer against supply shortages. This is a balancing act – too much stock ties up capital, while too little exposes you to disruptions. Sophisticated inventory management systems help optimize this.

- Regular Monitoring & Communication: Continuous monitoring of supplier performance, market trends, and geopolitical events is crucial. Open communication with suppliers fosters collaboration and early warning of potential problems.

Ultimately, proactive risk management is about building resilience into the supply chain, so it can withstand inevitable shocks.

Q 9. Explain your understanding of Total Cost of Ownership (TCO).

Total Cost of Ownership (TCO) goes beyond the initial purchase price of a material. It encompasses all direct and indirect costs associated with acquiring, using, and disposing of that material throughout its lifecycle. Think of buying a car – you pay the sticker price, but also factor in fuel, insurance, maintenance, and eventual resale value or disposal costs. Similarly, for materials, TCO includes:

- Acquisition Costs: Purchase price, transportation, customs duties, inspection costs.

- Operating Costs: Energy consumption during processing, labor costs, maintenance, downtime due to defects.

- Disposal Costs: Recycling, waste management, environmental remediation.

Understanding TCO allows for informed decision-making. A material with a lower initial price might have higher operating or disposal costs, making it ultimately more expensive than a seemingly pricier alternative with a longer lifespan and better recyclability. We utilize TCO analysis to make strategic sourcing decisions, optimizing value for money across the entire lifecycle.

Q 10. How do you use technology (e.g., ERP systems, procurement platforms) to improve sourcing efficiency?

Technology plays a vital role in improving sourcing efficiency. We leverage various systems, including:

- Enterprise Resource Planning (ERP) Systems: These systems integrate various business processes, providing a single source of truth for inventory levels, purchasing orders, and supplier performance data. This eliminates data silos and streamlines workflows. For example, an ERP system can automatically trigger a purchase order when inventory falls below a pre-defined threshold.

- Procurement Platforms: These platforms automate the sourcing process, facilitating online bidding, supplier selection, contract management, and purchase order processing. This accelerates the procurement cycle and reduces manual effort. Some platforms offer features such as supplier performance rating and analytics dashboards.

- Data Analytics & Business Intelligence Tools: Analyzing sourcing data helps identify trends, optimize pricing strategies, and improve supplier relationships. For example, we can use data analytics to forecast demand, optimize inventory levels, and identify potential supply chain bottlenecks.

By integrating these technologies, we achieve greater transparency, efficiency, and cost savings in our sourcing operations. The goal is not just automation but leveraging data to make informed, strategic decisions.

Q 11. Describe your experience with different types of contracts (e.g., fixed-price, cost-plus).

Different contract types cater to various project needs and risk profiles. I’ve extensive experience with:

- Fixed-Price Contracts: The supplier agrees to a fixed price for delivering goods or services. This is ideal for projects with well-defined specifications and low uncertainty. However, it can be risky for suppliers if unforeseen circumstances arise that increase their costs.

- Cost-Plus Contracts: The supplier’s costs are reimbursed, plus a predetermined markup (e.g., a percentage of costs or a fixed fee). This is suitable for projects with high uncertainty or complex specifications where the scope might evolve. However, it requires robust cost tracking and control to avoid cost overruns.

- Time and Materials Contracts: The supplier is paid for the time spent and materials used. This provides flexibility but necessitates careful tracking of time and materials to ensure efficient use of resources.

The choice of contract depends on several factors, including project complexity, risk tolerance, supplier capabilities, and the level of detail available in the initial specifications. We carefully analyze these factors to select the most appropriate contract type for each situation.

Q 12. How do you ensure compliance with ethical sourcing practices?

Ethical sourcing is non-negotiable. We adhere to strict ethical guidelines, including:

- Supplier Audits: Regular audits ensure suppliers meet our standards for labor practices, environmental protection, and business ethics. This includes verifying compliance with labor laws, fair wages, safe working conditions, and environmental regulations.

- Traceability & Transparency: We strive for full traceability of materials, from origin to final product, to identify and address potential ethical issues throughout the supply chain. This allows us to identify and mitigate potential risks associated with unethical practices.

- Conflict Minerals Compliance: We ensure our materials are free from conflict minerals, such as tantalum, tin, tungsten, and gold, sourced from conflict zones. We utilize due diligence procedures to ensure responsible sourcing.

- Sustainability Initiatives: We prioritize suppliers committed to sustainable practices, reducing their environmental footprint and promoting responsible resource management.

- Collaboration & Continuous Improvement: We actively collaborate with suppliers to improve ethical sourcing practices across the supply chain, fostering a culture of continuous improvement.

Our commitment to ethical sourcing extends beyond compliance. We view it as a core value that enhances our reputation, strengthens stakeholder relationships, and creates a more sustainable future.

Q 13. How do you forecast future materials needs?

Forecasting future materials needs is crucial for efficient sourcing and inventory management. We employ a combination of quantitative and qualitative methods:

- Demand Forecasting Techniques: We use statistical methods such as time series analysis, moving averages, and exponential smoothing to project future demand based on historical data. This accounts for seasonality and trends.

- Market Research & Analysis: We monitor market trends, economic indicators, and industry forecasts to identify potential shifts in demand. This gives a broader context to our quantitative forecasts.

- Sales & Production Plans: Close collaboration with sales and production teams ensures our forecasts align with business plans and anticipated production volumes. This provides a ground-up view of expected material needs.

- Collaboration with Suppliers: Open communication with key suppliers helps in validating forecasts and anticipating potential supply chain disruptions. Suppliers often have valuable insights into market dynamics and future availability.

- Scenario Planning: We develop multiple scenarios – best-case, worst-case, and most-likely – to prepare for various potential outcomes. This helps us adjust our sourcing strategies and inventory levels accordingly.

A robust forecasting process isn’t just about accuracy; it’s about flexibility and responsiveness to changing circumstances.

Q 14. Describe your experience with inventory management.

Effective inventory management is essential for minimizing costs and ensuring timely supply. My approach is based on:

- Inventory Control Systems: We use robust inventory management systems to track inventory levels, monitor stock movements, and generate reports on stock turnover rates. This gives a real-time view of our inventory position.

- ABC Analysis: We categorize inventory items based on their value and consumption rates. High-value items receive closer monitoring and more sophisticated control measures, while low-value items require less attention.

- Just-in-Time (JIT) Inventory: Where feasible, we implement JIT strategies to minimize inventory holding costs by receiving materials only when needed. This requires close collaboration with suppliers and reliable delivery schedules.

- Safety Stock Management: We maintain safety stock levels to buffer against unexpected demand fluctuations or supply disruptions. The optimal safety stock level is determined by balancing the cost of holding excess inventory against the risk of stockouts.

- Regular Inventory Reviews: Periodic reviews of inventory levels, turnover rates, and obsolescence help identify areas for improvement and optimization. This ensures inventory levels align with demand forecasts and business objectives.

Successful inventory management is a continuous process of optimization, balancing the need for sufficient inventory to meet demand with the desire to minimize holding costs and reduce waste.

Q 15. How do you prioritize sourcing projects?

Prioritizing sourcing projects requires a strategic approach that balances urgency, impact, and risk. I typically use a weighted scoring system, considering factors like:

- Business Criticality: How vital is this material to our operations? A critical component for a flagship product will naturally rank higher than a less essential part.

- Cost Savings Potential: What’s the potential for reducing costs through better sourcing? Projects with significant cost-reduction opportunities are prioritized.

- Supply Risk: How vulnerable is our current supply chain for this material? Materials with limited suppliers or geopolitical risks are prioritized to mitigate potential disruptions.

- Project Complexity: Does the sourcing project involve complex negotiations, regulatory hurdles, or technological challenges? This impacts resource allocation and project timeline.

Once each project is scored across these criteria, I use a weighted average to establish a ranked list. This ensures that we focus our resources on the initiatives that deliver the most value and minimize risk to the business. For example, if a project has a high impact on profitability but presents significant supply risk, it would be prioritized over a project with moderate cost savings and low risk.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle unexpected supply chain disruptions?

Handling unexpected supply chain disruptions requires a proactive and multi-faceted approach. My strategy involves:

- Immediate Response Team: Activation of a dedicated team to assess the impact and identify immediate mitigation steps. This could involve leveraging existing safety stock or exploring expedited shipping options.

- Supplier Relationship Management: Direct communication with the affected supplier to understand the root cause of the disruption and collaboratively explore solutions. This includes negotiating alternative delivery schedules or sourcing from secondary suppliers.

- Alternative Sourcing Strategies: Identifying and evaluating potential alternative suppliers, which might require a rapid qualification process. This involves assessing their capacity, quality, and lead times.

- Risk Mitigation Planning: Post-incident review to identify weaknesses in the supply chain and implement preventive measures. This could include diversification of suppliers, building strategic inventory, or developing contingency plans.

For example, during a recent semiconductor shortage, we quickly activated our response team, identified alternative suppliers with overlapping capabilities, and negotiated price premiums to secure the required components. This prevented significant production delays and maintained our customer commitments.

Q 17. What is your experience with supplier audits?

I have extensive experience conducting and managing supplier audits, covering both financial and operational aspects. My approach is based on a comprehensive checklist encompassing:

- Quality Management Systems (QMS): Assessment of the supplier’s adherence to ISO 9001 or similar standards, including process control, quality checks, and corrective actions.

- Environmental, Social, and Governance (ESG): Evaluation of the supplier’s environmental compliance, labor practices, and ethical standards – increasingly critical for maintaining a responsible and sustainable supply chain.

- Financial Stability: Review of the supplier’s financial health, including creditworthiness, debt levels, and profitability, to assess their long-term viability.

- Capacity and Capability: Evaluation of the supplier’s production capacity, technology, and workforce to ensure they can meet our needs.

- Security and Compliance: Assessment of security protocols to protect intellectual property and ensure compliance with relevant regulations.

The audit process typically involves site visits, document reviews, and interviews with key personnel. The findings are documented in a detailed report, which is then used to inform supplier selection and performance management decisions.

Q 18. Explain your understanding of different purchasing methods (e.g., competitive bidding, reverse auctions).

Different purchasing methods serve distinct purposes and are chosen based on the specific requirements of a sourcing project. Here’s a breakdown of common methods:

- Competitive Bidding: A formal process where multiple suppliers submit sealed bids for a specific requirement. This is suitable for standardized products or services where price is a major factor.

- Reverse Auctions: An online auction where suppliers compete to offer the lowest price. This approach can be effective for high-volume purchases with clearly defined specifications. It’s important to note that focusing solely on price can compromise quality.

- Negotiation: A more collaborative approach where the buyer and supplier engage in discussions to reach a mutually acceptable agreement. This works best for complex or customized products or services where factors beyond price are important, such as quality, lead time, and technical support.

- Cost-Plus Contracts: The supplier’s costs are reimbursed plus a predetermined markup. This is suitable when the scope of work is unclear or involves high risk and uncertainty.

The choice of method depends on factors such as market conditions, product complexity, and the buyer-supplier relationship. Sometimes, a combination of methods might be employed.

Q 19. How do you measure the success of your sourcing initiatives?

Measuring the success of sourcing initiatives requires a multi-dimensional approach, focusing on both quantitative and qualitative metrics. Key performance indicators (KPIs) include:

- Cost Savings: Did we achieve the targeted cost reductions? This is often measured as a percentage reduction in the cost of goods sold.

- Supplier Performance: How well did the suppliers perform in terms of on-time delivery, quality, and responsiveness? This is tracked through metrics such as on-time delivery rate and defect rate.

- Risk Mitigation: Did our sourcing strategy successfully reduce supply chain risks? This could involve tracking the number of disruptions or the availability of alternative sources.

- Lead Time Reduction: Were we able to shorten the time it takes to acquire materials? This enhances efficiency and responsiveness to market demand.

- Supplier Relationship Strength: Have we built strong relationships with key suppliers? This is assessed through qualitative factors such as communication, trust, and collaboration.

Regular monitoring and reporting of these KPIs are essential to track progress and identify areas for improvement.

Q 20. Describe a time you had to resolve a conflict with a supplier.

In one instance, we experienced a significant delay in the delivery of critical components from a key supplier. The delay threatened to disrupt our production schedule and impact customer commitments. To resolve the conflict, I employed the following steps:

- Open Communication: I initiated a series of meetings with the supplier’s management team to clearly understand the reasons for the delay and their proposed solutions.

- Collaborative Problem-Solving: We worked together to identify alternative solutions, including expedited shipping and adjusting our production schedule to minimize the impact of the delay.

- Fair Negotiation: We reached a mutually acceptable agreement on compensation for the disruption, acknowledging the supplier’s efforts and recognizing the impact on our business.

- Documentation and Follow-Up: The entire process was meticulously documented to ensure accountability and prevent similar issues in the future. Regular follow-up ensured that the agreed-upon solutions were implemented effectively.

Through transparent communication and collaborative problem-solving, we successfully resolved the conflict and maintained a strong working relationship with the supplier.

Q 21. How do you build strong relationships with key stakeholders?

Building strong relationships with key stakeholders – both internal and external – is fundamental to successful sourcing. My approach involves:

- Active Listening and Empathy: Understanding the needs and perspectives of internal stakeholders such as engineering, production, and finance, as well as external stakeholders such as suppliers and logistics providers.

- Transparent Communication: Keeping stakeholders informed of sourcing activities, challenges, and progress. This includes regular updates and open channels for feedback.

- Collaboration and Teamwork: Engaging stakeholders in the decision-making process to foster a sense of ownership and collaboration.

- Building Trust and Respect: Treating all stakeholders with respect and fairness, building relationships based on mutual trust and understanding.

- Value Creation: Demonstrating the value that sourcing brings to the organization through cost savings, quality improvements, and risk mitigation.

For example, I regularly meet with our engineering team to discuss material specifications and anticipate potential supply chain challenges, ensuring that our sourcing strategies align with their needs. This proactive approach builds trust and ensures a smooth flow of information.

Q 22. What are your strengths and weaknesses in materials sourcing?

My greatest strength in materials sourcing lies in my strategic approach to supplier relationship management. I excel at building long-term partnerships with vendors, negotiating favorable contracts, and ensuring consistent supply chain performance. For example, in my previous role at Acme Corp, I successfully negotiated a 15% reduction in material costs by leveraging my understanding of market dynamics and implementing a multi-sourcing strategy. This not only saved the company significant money but also mitigated risks associated with single-source reliance.

However, I recognize that a potential weakness is my tendency to get deeply involved in the details of every project. While this ensures high quality, it can sometimes impact my time management across multiple projects. I am actively working on improving this by using project management tools and delegating tasks effectively. I’m currently learning Agile methodologies to further enhance my project management skills and improve time efficiency.

Q 23. How do you stay current with industry trends and best practices in procurement?

Staying current in procurement requires a multi-pronged approach. I regularly attend industry conferences like the Institute for Supply Management (ISM) events and webinars offered by leading procurement platforms. I also actively subscribe to industry publications such as Supply Chain Digest and Procurement Leaders. To stay on top of emerging technologies, I actively follow thought leaders on platforms like LinkedIn and engage in online professional development courses focused on topics such as digital procurement and AI in supply chain management. I find that engaging in online forums and communities further broadens my perspective and allows for peer learning.

Q 24. What is your experience with sustainable sourcing initiatives?

Sustainable sourcing is a core principle in my procurement philosophy. I have extensive experience implementing environmentally and socially responsible practices. At Beta Industries, I spearheaded an initiative to transition our manufacturing process to utilize recycled materials, resulting in a 20% reduction in our carbon footprint. This involved meticulous supplier vetting to ensure compliance with environmental standards and ethical labor practices. We implemented a robust tracking system, using ISO 14001 compliant procedures to ensure traceability and transparency across the supply chain. Another example involved collaborating with suppliers to develop more sustainable packaging alternatives, reducing waste and improving recyclability.

Q 25. Describe your experience with managing complex projects.

Managing complex projects is a key part of my expertise. My experience at Gamma Inc. involved sourcing components for a new product launch under tight deadlines and budgetary constraints. This demanded effective project planning, risk assessment, and stakeholder management. I used a phased approach, breaking down the project into manageable tasks with clearly defined milestones and deliverables. Regular communication with all stakeholders, including engineering, marketing and finance, ensured alignment and prevented bottlenecks. We successfully launched the product on time and within budget, demonstrating my ability to handle complexity effectively. I frequently use Gantt charts and project management software like Microsoft Project to maintain organization and track progress.

Q 26. What are your salary expectations?

My salary expectations are commensurate with my experience and skills within the industry. Based on my research and understanding of similar roles, I am targeting a salary range between $X and $Y. I am open to discussing this further and aligning my expectations with the specifics of this role and the company’s compensation structure.

Q 27. What are your long-term career goals?

My long-term career goals involve progressing into a leadership role in procurement. I aim to leverage my expertise to optimize supply chain operations for a company committed to innovation and sustainability. I envision myself leading and mentoring a team, shaping procurement strategies that enhance both business performance and social responsibility. I’m particularly interested in exploring the application of cutting-edge technologies like blockchain and AI to further improve efficiency and transparency within the supply chain.

Q 28. Do you have any questions for me?

I have a few questions for you. First, could you elaborate on the company’s current procurement challenges and how this role will contribute to addressing them? Second, what opportunities exist for professional development and growth within the company? Finally, can you describe the team dynamics and work culture within the procurement department?

Key Topics to Learn for Materials and Resources Sourcing Interview

- Supplier Relationship Management (SRM): Understand the strategies and processes involved in building and maintaining strong relationships with suppliers, including negotiation, contract management, and performance evaluation. Consider practical applications like developing key performance indicators (KPIs) for supplier performance.

- Supply Chain Optimization: Explore techniques for streamlining the sourcing process, reducing costs, and improving efficiency. Think about case studies involving lean principles and inventory management strategies.

- Sourcing Strategies: Learn about various sourcing approaches, such as global sourcing, strategic partnerships, and e-procurement. Analyze the advantages and disadvantages of each strategy and how to choose the optimal approach based on specific needs.

- Risk Management in Sourcing: Understand potential risks in the supply chain, such as geopolitical instability, supplier bankruptcy, and disruptions due to natural disasters. Discuss mitigation strategies and contingency planning.

- Cost Analysis and Negotiation: Master the techniques for analyzing costs, identifying cost-saving opportunities, and negotiating favorable terms with suppliers. Consider real-world scenarios involving total cost of ownership (TCO) calculations.

- Sustainability and Ethical Sourcing: Explore the importance of incorporating environmental and social responsibility into sourcing decisions. Consider the practical application of fair trade practices and sustainable material selection.

- Technology in Sourcing: Familiarize yourself with technologies used in materials and resources sourcing, such as procurement software, data analytics, and AI-powered tools. Discuss how these technologies improve efficiency and decision-making.

- Contract Law and Procurement Regulations: Understand the legal frameworks and regulations governing procurement processes. Consider the implications of compliance and potential legal issues related to sourcing.

Next Steps

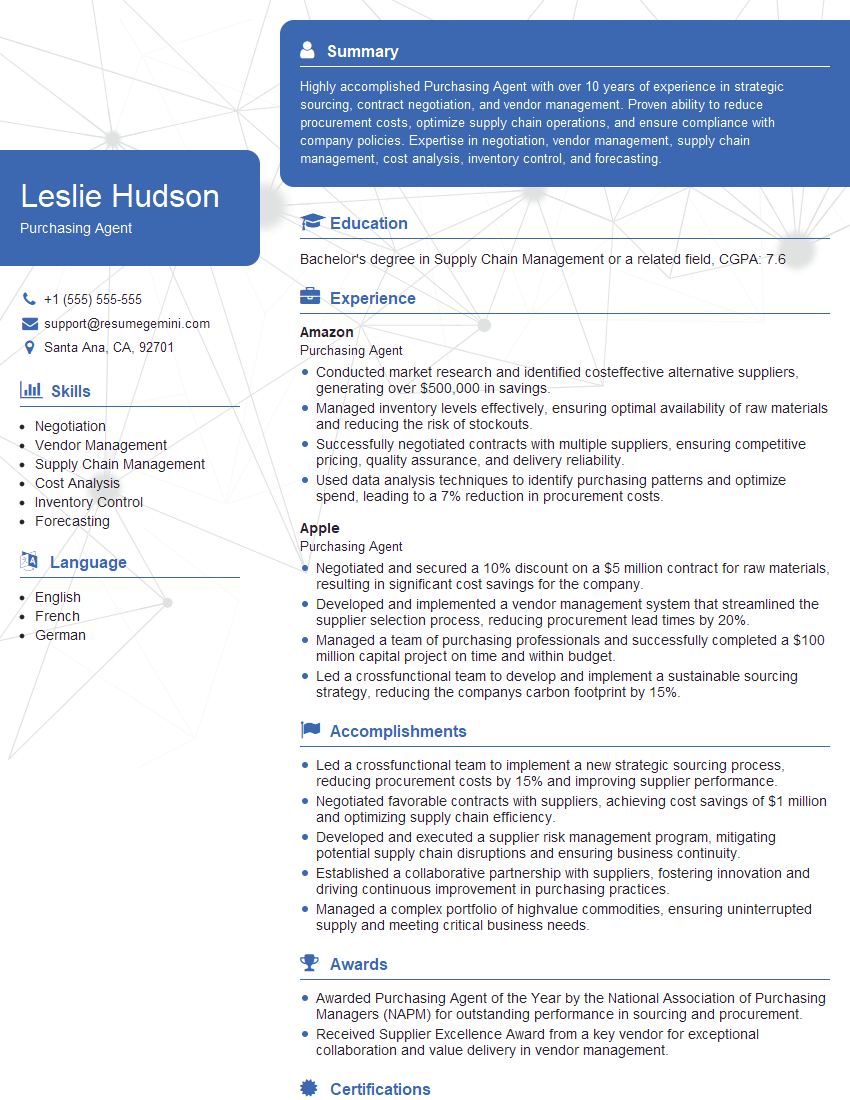

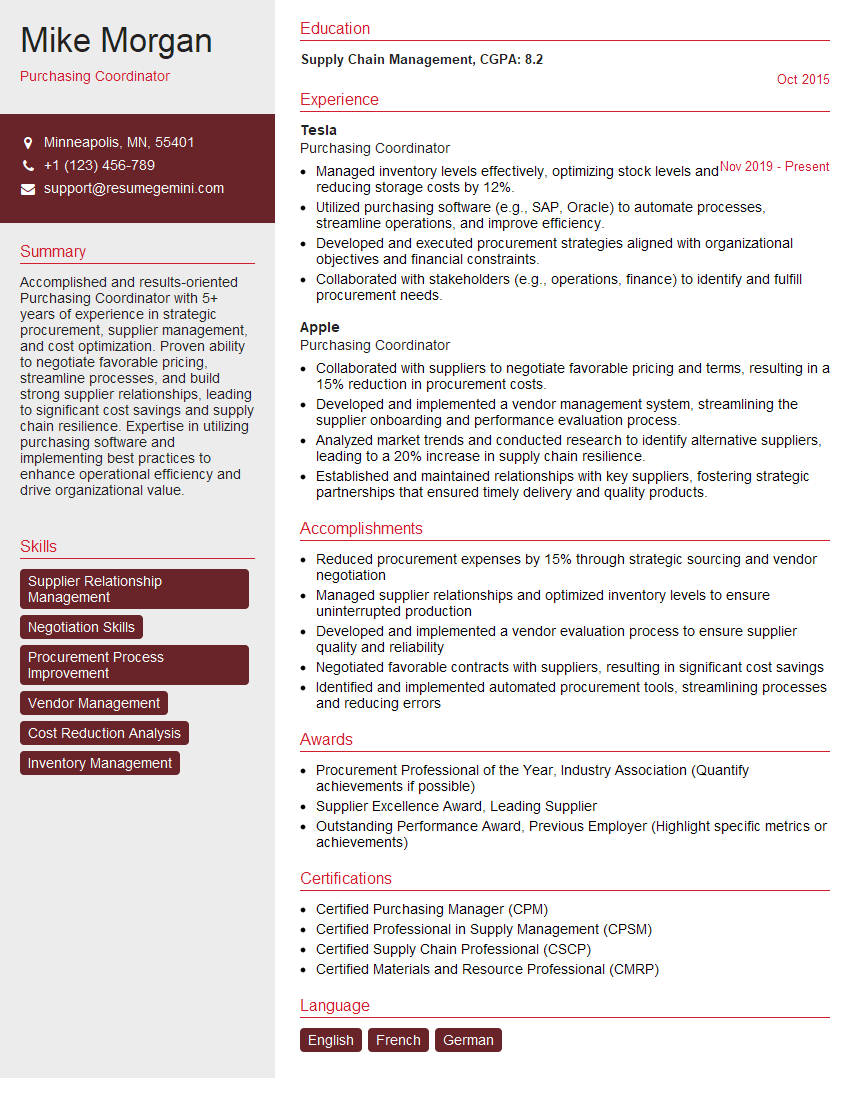

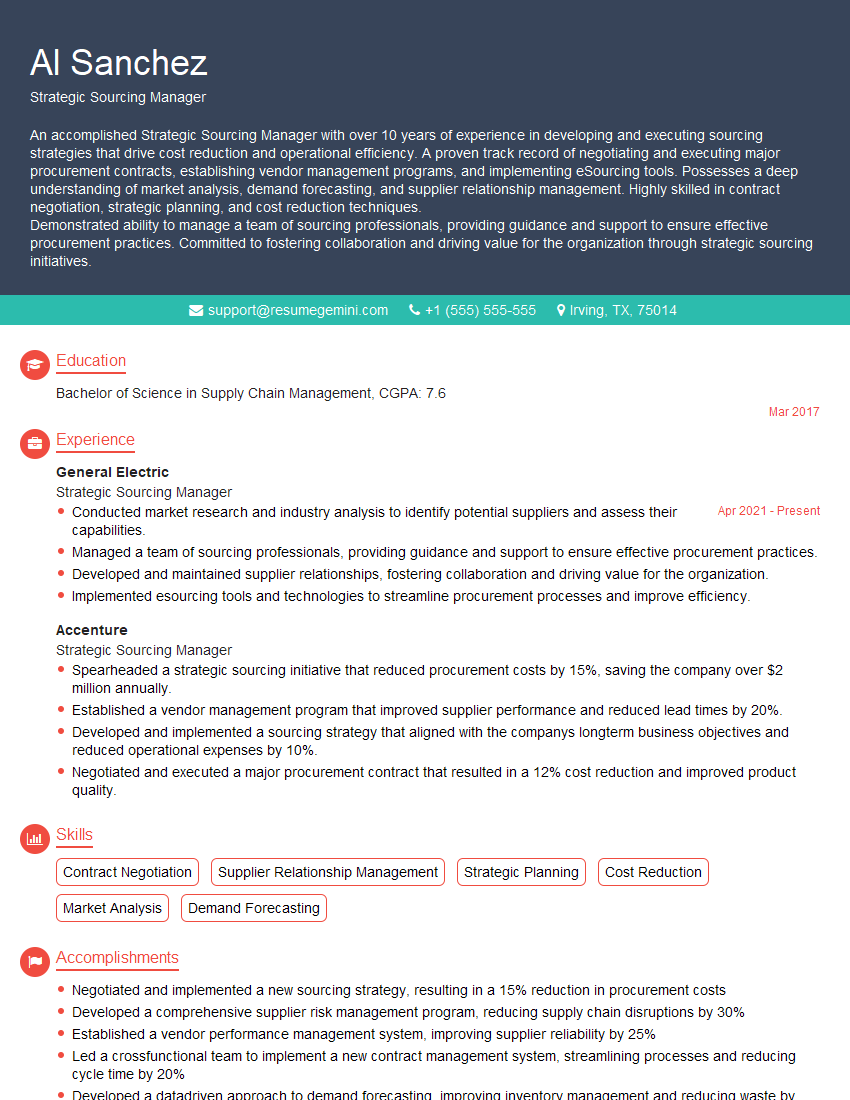

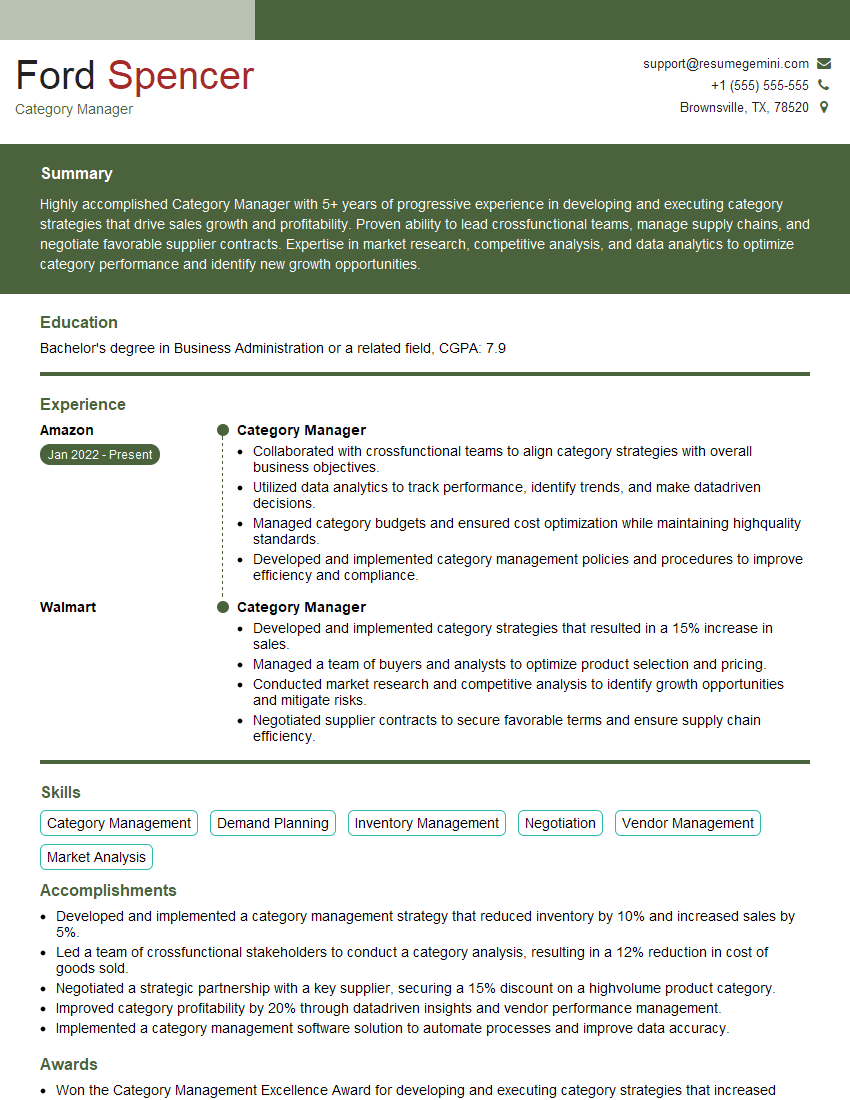

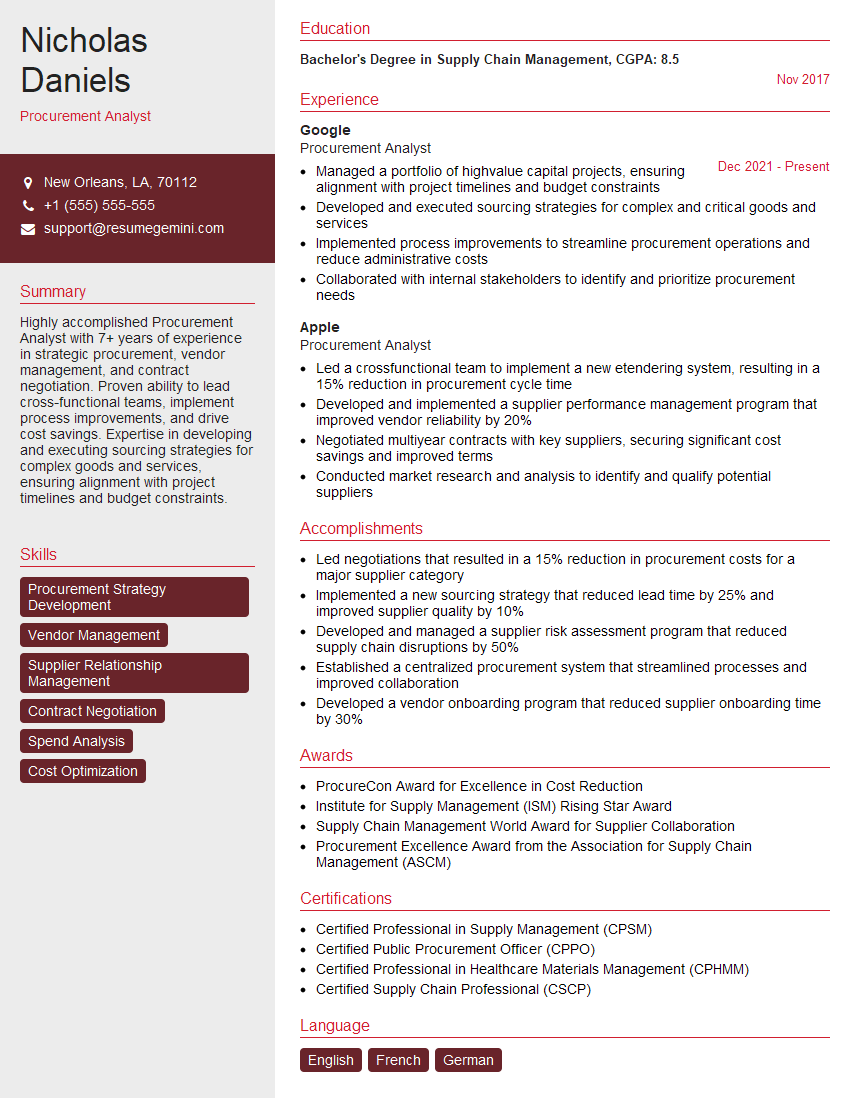

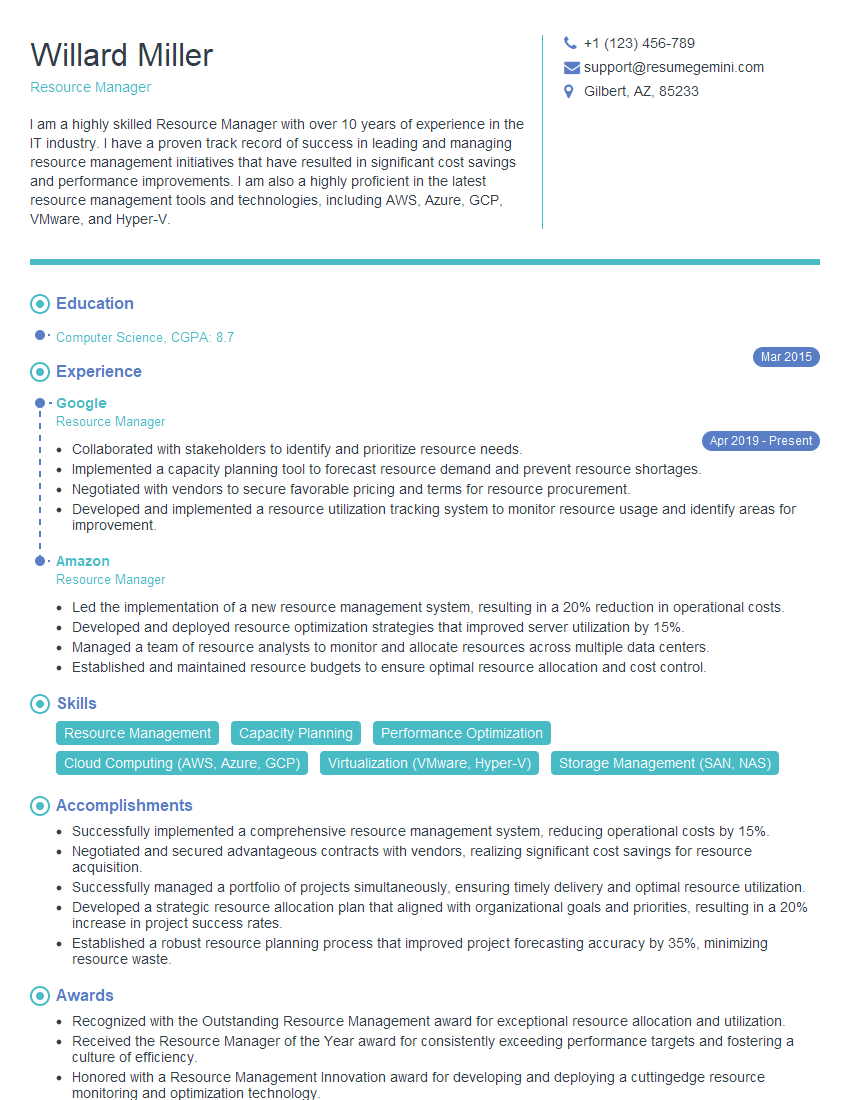

Mastering Materials and Resources Sourcing is crucial for a rewarding and successful career in procurement and supply chain management. It opens doors to diverse roles offering significant professional growth and impact. To maximize your job prospects, create a strong, ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume, ensuring your application stands out. Examples of resumes tailored to Materials and Resources Sourcing are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO