Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Experience in lifting and handling heavy objects interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Experience in lifting and handling heavy objects Interview

Q 1. Describe your experience with different lifting techniques (e.g., proper lifting posture, using assistive devices).

Proper lifting techniques are paramount to prevent injury. My experience encompasses various methods, prioritizing safety and efficiency. The fundamental principle is to keep the load close to the body, minimizing strain on the back. This involves bending at the knees and hips, not the waist, maintaining a straight back, and lifting with leg muscles rather than back muscles. I’ve utilized several techniques, including:

- The Power Lift: This involves getting a firm grip, keeping the object close, and lifting smoothly using leg power, maintaining a neutral spine. Think of it like lifting a heavy suitcase: you wouldn’t just yank it up.

- Stoop Lift: For objects that are slightly lower, I would partially bend at the knees and hips, maintaining a straight back, and then lift smoothly using leg and core strength. This is great for picking things off the floor without overextending.

- Using Assistive Devices: I am proficient in using a wide range of equipment including dollies, hand trucks, pallet jacks, and even cranes depending on the weight and type of object. These significantly reduce strain and potential injury. The key is selecting the right tool for the job.

Throughout my career, I’ve consistently adapted my lifting technique depending on the size, shape, and weight of the object, always prioritizing safety first.

Q 2. Explain how you assess the weight and stability of an object before lifting.

Assessing weight and stability is crucial before any lift. I always start by visually inspecting the object. Is it uniform in weight distribution? Are there any weak points or damage? Then, I try to estimate the weight by feeling its heft, or if possible using a scale. If unsure, I’ll always err on the side of caution and treat it as heavier than it might appear. Stability is assessed by checking the object’s base and ensuring it’s not precarious. I look for potential hazards – is the ground even? Are there any obstructions? I might even gently rock the object to feel its stability. This comprehensive assessment prevents accidents caused by unexpected shifts or instability.

Q 3. What safety precautions do you take when lifting heavy objects?

Safety is paramount. My standard precautions include:

- Proper Lifting Technique: Always using the techniques mentioned previously.

- Clear Path: Ensuring a clear path to the destination, free from obstacles.

- Proper Footwear: Wearing appropriate footwear with good grip.

- Communication: If working with others, clear communication about the lift is crucial to coordinate movements and avoid collisions.

- Personal Protective Equipment (PPE): Using appropriate PPE such as gloves or back supports where necessary.

- Mechanical Aids: Utilizing appropriate lifting equipment like hand trucks, dollies, and hoists when lifting objects beyond my capabilities.

It’s also crucial to know one’s physical limitations and never attempt a lift that feels unsafe or beyond my capabilities.

Q 4. How do you determine the appropriate lifting equipment for a given task?

Choosing the right lifting equipment depends entirely on the object’s size, weight, shape, and the environment. For example:

- Small, lightweight objects: Often require no special equipment beyond good lifting technique.

- Heavy, bulky objects: Might need pallet jacks, hand trucks, or even forklifts depending on the weight and distance.

- Awkwardly shaped objects: Might require specialized slings, straps, or other rigging equipment to ensure secure and stable transport.

- Overhead lifting: Requires hoists, cranes, or other overhead lifting mechanisms.

My experience allows me to assess the situation and select the most suitable equipment, ensuring both efficiency and safety.

Q 5. Have you ever experienced a lifting-related injury? If so, describe the incident and what you learned from it.

Yes, early in my career, I strained my back lifting a heavy box improperly. I was rushing and didn’t use proper lifting techniques – I bent at the waist instead of the knees. This resulted in significant pain and time off work. The experience taught me the critical importance of following safety protocols, regardless of time constraints. It reinforced the need for thorough assessment before lifting and the use of appropriate equipment whenever possible. This incident profoundly impacted my approach to lifting, solidifying my commitment to safe lifting practices.

Q 6. Describe your experience using lifting aids like dollies, hand trucks, or hoists.

I have extensive experience using various lifting aids. I am proficient with:

- Dollies: Excellent for moving heavy, bulky items over short distances on flat surfaces. I’ve used them for moving furniture, equipment, and supplies.

- Hand Trucks: Ideal for transporting heavier loads over longer distances. I’m experienced in securing loads properly to prevent slippage.

- Hoists: For lifting heavy objects to significant heights, I’ve worked with various types of hoists ensuring proper safety protocols were followed including load testing.

My proficiency extends to understanding the limitations of each device and choosing the correct one for the specific task.

Q 7. How do you handle situations where you need to lift an object beyond your capabilities?

If an object is beyond my capabilities, I never attempt to lift it alone. My first step is to accurately assess the weight and difficulty of the lift. I would then:

- Seek Assistance: Get help from colleagues or use a mechanical aid.

- Utilize Equipment: Employ the appropriate lifting equipment – forklifts, cranes, etc. – depending on the object and situation.

- Request Professional Help: If the object is exceptionally heavy or requires specialized equipment, I would seek the assistance of trained professionals.

Safety is paramount, and it’s always better to seek assistance than to risk injury by attempting a lift beyond my capacity.

Q 8. What is your understanding of workplace safety regulations related to manual handling?

Workplace safety regulations concerning manual handling are paramount to preventing injuries. These regulations typically focus on minimizing risk through assessment, training, and the provision of appropriate equipment. They often mandate risk assessments to identify hazards like awkward postures, repetitive movements, and excessive force. Training programs educate workers on proper lifting techniques, emphasizing posture, grip, and the importance of teamwork. Regulations might also specify the maximum weight limits for manual handling, encouraging the use of mechanical aids for heavier loads. For example, regulations might stipulate that loads exceeding 25kg should not be lifted manually unless a thorough risk assessment justifies it. Failure to comply can lead to fines and legal action for employers.

- Risk Assessment: A systematic process to identify and evaluate hazards associated with manual handling tasks.

- Training: Proper instruction on safe lifting techniques, including posture, grip, and teamwork.

- Mechanical Aids: Using equipment such as hand trucks, pallet jacks, or hoists to reduce manual effort.

- Weight Limits: Regulations often specify maximum permissible weights for manual lifting.

Q 9. How do you communicate with colleagues when working together to lift heavy objects?

Effective communication is critical when lifting heavy objects collaboratively. Before initiating a lift, we establish clear communication channels. This usually involves a designated leader who gives instructions – ‘Ready? Lift!’. We confirm everyone understands their role and the weight distribution. Verbal cues are essential, such as describing the object’s weight and center of gravity, confirming readiness, and signaling any issues or changes in the plan. Non-verbal cues, like maintaining eye contact, also ensure coordination. For example, if one person feels strain, they should immediately signal this to the team so adjustments can be made.

Clear and concise communication prevents mishaps and injuries. Imagine a team trying to move a large cabinet. If one person starts lifting before the others are ready, the imbalance can lead to injury. A simple ‘Ready?’ and ‘Lift!’ prevents this.

Q 10. Describe a time you had to improvise a lifting solution due to unexpected circumstances.

During a warehouse move, we needed to shift a heavy, unusually shaped piece of machinery that was too large for our standard pallet jack. The regular lifting equipment couldn’t maneuver it safely due to its unique shape and size. We improvised by using a combination of heavy-duty straps, a come-along winch, and a sturdy wooden platform. We securely fastened the straps to the machine, attached the winch to a secure anchor point, and used the platform as a base for stability and leverage. We carefully coordinated the winch operation and lifting, ensuring even distribution of weight to move the machine without damage. This required careful planning and a strong understanding of physics and weight distribution. The success hinged on teamwork, adapting to the situation, and applying our knowledge of leverage and safety precautions.

Q 11. How familiar are you with different types of lifting equipment (e.g., forklifts, cranes)?

I’m highly familiar with various lifting equipment, including forklifts, cranes, and their associated safety procedures. My experience encompasses operating and overseeing the use of forklifts, including pre-operational checks (checking fluid levels, tire pressure, and mast functionality), safe operation, and load securing. With cranes, I understand the critical role of load charts, rigging techniques (selecting appropriate slings and chains), and the importance of adhering to strict safety protocols and communication between crane operator and ground crew. I also have experience with other equipment, such as pallet jacks, hand trucks, and hoists, always selecting and using them according to their operational limits and safety guidelines.

Q 12. What are the signs of a potential lifting injury, and what actions should be taken?

Signs of a potential lifting injury can range from immediate to subtle. Immediate signs include sharp pain, difficulty moving, or obvious swelling or bruising. More subtle signs might include persistent muscle aches, stiffness, or reduced range of motion in the back, neck, or limbs. Other potential signs include numbness, tingling, or weakness. If any of these signs appear, immediate action is required. This includes stopping the activity, reporting the incident to a supervisor, and seeking medical attention. Early intervention is key to preventing long-term problems. It’s also important to consider cumulative trauma—repeated micro-injuries over time can result in significant problems.

Q 13. How do you ensure the safety of yourself and others while lifting heavy objects in a busy warehouse?

Safety in a busy warehouse requires a multi-faceted approach. Firstly, maintaining awareness of surroundings is crucial—avoiding collisions with other equipment or personnel. Secondly, we adhere strictly to traffic rules and designated pathways. Thirdly, the use of appropriate PPE (Personal Protective Equipment), such as safety shoes and gloves, is essential. Fourthly, employing appropriate lifting techniques and using available mechanical aids are vital. Lastly, clear communication with colleagues is paramount – warning others of movements, ensuring clear pathways, and coordinating lifts. For instance, placing warning cones around a lifting operation, ensuring clear communication, and utilizing proper signaling and hand signals helps avoid accidents.

Q 14. Explain your experience with load balancing and securing heavy objects during transport.

Load balancing and securing are vital aspects of safe transport. My experience involves assessing the weight and center of gravity of objects to prevent instability. This includes using appropriate lifting and securing equipment – choosing slings and straps based on the load’s weight and characteristics to distribute the weight evenly, preventing damage or tipping. When securing loads during transportation, I ensure that the object is properly restrained to prevent movement, potentially using multiple securing points and tie-down straps. The choice of securing method depends on the mode of transport and the nature of the load. For example, shipping a heavy container requires more robust tie-down procedures than transporting a smaller pallet on a forklift. Proper documentation of the securing process is also important for liability and insurance purposes.

Q 15. Describe your experience with working at heights while handling heavy objects.

Working at heights while handling heavy objects significantly increases the risk of injury. It requires meticulous planning, adherence to safety protocols, and the use of appropriate equipment. My experience includes extensive work on scaffolding and elevated platforms, always employing fall protection systems like harnesses and lifelines. Before lifting anything at height, I perform a thorough risk assessment, checking the stability of the working platform, ensuring sufficient lighting and clear communication with colleagues, and always using appropriate lifting aids like hoists or cranes whenever possible. For instance, during a recent project involving the installation of heavy HVAC units on a multi-story building, we used a crane and a designated rigging crew to lift and position each unit, meticulously following safety checklists at every stage. Each lift was double-checked by two experienced riggers, minimizing the risk of accidents.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How would you handle a situation where a colleague is using unsafe lifting techniques?

Witnessing unsafe lifting techniques is unacceptable. My approach is to intervene promptly but professionally. I’d start by approaching my colleague privately and gently pointing out the unsafe practice, explaining the potential risks involved and referring to specific safety guidelines or company policies. For instance, if they’re bending at the waist instead of using their legs, I’d explain how this strains the back. I’d demonstrate the correct lifting technique, emphasizing the importance of maintaining a straight back and using leg power. If the unsafe practice persists, I’d escalate the concern to a supervisor or safety officer, ensuring the safety of my colleague and myself. My priority is always safety, and I believe in a proactive, collaborative approach to ensure workplace safety.

Q 17. What is your understanding of ergonomic principles related to lifting?

Ergonomic principles focus on designing workplaces and tasks to minimize physical strain and injury. When lifting, this translates to optimizing posture, using appropriate lifting techniques, and utilizing mechanical aids whenever possible. Understanding load center and minimizing twisting or reaching are crucial. For instance, keeping the load close to the body, bending the knees, and lifting with leg muscles instead of back muscles prevents back injuries. Using equipment like lifting straps, dollies, or forklifts can significantly reduce strain. Proper lifting techniques combined with regular breaks and stretching can considerably improve safety and reduce the risk of musculoskeletal disorders like back pain or carpal tunnel syndrome.

Q 18. How do you prioritize safety when working under pressure or tight deadlines?

Even under pressure or tight deadlines, safety remains non-negotiable. I apply a risk management approach. First, I prioritize the tasks that pose the highest safety risks, ensuring these are completed with extra caution. I’ll also communicate clearly with my team, emphasizing the importance of maintaining safety standards and seeking assistance if needed. If I feel unsafe about a task due to time constraints, I’ll directly communicate my concerns to my supervisor, explaining the potential risks and advocating for additional resources or time to perform the task safely. Safety should never be sacrificed for speed; compromising it ultimately costs more in the long run.

Q 19. What is your understanding of different types of personal protective equipment (PPE) for lifting?

Personal Protective Equipment (PPE) for lifting includes various items depending on the task. This might include safety shoes with steel toes to protect against dropped objects, gloves to improve grip and protect hands, back supports to provide lumbar support during lifting, and safety harnesses and lifelines when working at heights. Depending on the material being lifted, specialized gloves or protective clothing might be necessary to protect against cuts, abrasions, or chemical exposure. The correct selection and use of PPE are vital, and understanding the limitations of each item is critical to ensuring maximum protection.

Q 20. Describe your experience with lifting objects in different environments (e.g., confined spaces, uneven terrain).

My experience encompasses lifting in diverse environments, each presenting unique challenges. In confined spaces, maneuverability is limited, requiring careful planning and potentially specialized equipment like smaller hoists or pneumatic lifts. Uneven terrain necessitates extra caution, using sure footing, avoiding twisting, and potentially using lifting aids with wider bases for stability. For instance, while working on a construction site with uneven ground, we utilized a specialized forklift with larger, stabilized tires to transport heavy materials safely. Similarly, when moving equipment in a confined basement area, we used smaller, more maneuverable hand trucks and a system of ropes and pulleys to lift and position the equipment.

Q 21. How do you maintain your physical fitness to handle the demands of heavy lifting?

Maintaining physical fitness is crucial for heavy lifting. I prioritize regular exercise focusing on strength training, particularly for my back, legs, and core muscles, as these are vital for safe lifting. Cardiovascular exercise enhances stamina, which is important for endurance during prolonged lifting tasks. Stretching before and after work helps improve flexibility and prevent muscle soreness or injury. A healthy diet rich in protein and nutrients supports muscle repair and recovery. Regular visits to a physical therapist can provide guidance on proper lifting techniques and address any muscle imbalances or postural issues. This proactive approach ensures I’m physically capable of handling the demands of my work safely and efficiently.

Q 22. What are the key factors to consider when planning a heavy lifting operation?

Planning a heavy lifting operation requires a meticulous approach to ensure safety and efficiency. Key factors include:

- Weight of the object: Accurately determine the object’s weight using scales or lifting charts. Overestimating is safer than underestimating.

- Object dimensions and shape: Irregular shapes or unusually large dimensions necessitate specialized lifting techniques and equipment.

- Distance to be lifted: Longer distances increase strain; plan for breaks and adequate support if necessary.

- Lifting path and environment: Ensure a clear, unobstructed path free of obstacles, uneven surfaces, or slippery conditions. Adequate lighting is crucial.

- Available equipment and personnel: Determine if manual lifting is feasible or if mechanical aids like cranes, forklifts, or hoists are required. Sufficient trained personnel are essential.

- Risk assessment: A thorough risk assessment should identify and mitigate potential hazards, including slips, trips, falls, and strains.

For example, moving a heavy engine requires a different approach compared to lifting a box of files. The former might necessitate a crane and a team, while the latter could be managed manually with the proper technique.

Q 23. Explain your understanding of weight distribution principles when lifting heavy objects.

Weight distribution is paramount for safe lifting. The goal is to keep the load as close to the body as possible and distribute its weight evenly. Lifting with your back straight and bending at the knees reduces strain on the spine.

Imagine trying to carry a heavy suitcase. If you hold it away from your body, it requires significantly more effort and places undue stress on your back. Holding it close and keeping your back straight makes the task far easier and safer. This same principle applies to all heavy lifting. Keeping the center of gravity close to your body reduces torque and strain on your muscles and joints.

Using lifting aids like dollies or hand trucks can also improve weight distribution by allowing you to roll or wheel the load instead of lifting it. This reduces strain and avoids back injuries.

Q 24. How do you identify potential hazards before starting a heavy lifting task?

Identifying hazards is a crucial first step. My approach involves a systematic check of the environment and the object itself:

- Inspect the lifting path: Check for uneven ground, obstacles, spills, or slippery surfaces that could cause slips, trips, or falls.

- Assess the object’s condition: Is it stable? Are there any sharp edges or unstable parts that could cause injury? Is the object properly secured or packaged?

- Check for environmental hazards: Are there overhead obstructions? Are there any potential pinch points?

- Evaluate lighting: Sufficient lighting is essential for safe maneuvering.

- Consider weather conditions: Rain or snow can create slippery conditions increasing risk.

I’ve encountered situations where a seemingly simple lift turned hazardous due to hidden issues like a loose floorboard or an unstable stack. A careful visual inspection and risk assessment can often prevent accidents.

Q 25. Describe your experience with using lifting charts or other weight estimation tools.

I have extensive experience using lifting charts and weight estimation tools. These are invaluable for determining the safe lifting capacity for a given object and for selecting the appropriate lifting equipment. Lifting charts typically provide weight limits based on the object’s dimensions and weight, taking into account factors like the distance lifted and posture.

I am proficient in using both physical charts and digital applications that can automate calculations based on the object’s dimensions and material density. These tools help determine whether manual lifting is appropriate or if mechanical assistance is needed. For example, if a chart shows that a particular object exceeds the safe manual lifting limit, I would immediately look for mechanical assistance.

Q 26. Explain your experience in following and enforcing company safety policies related to manual handling.

Enforcing and following company safety policies related to manual handling is non-negotiable. My experience includes:

- Adherence to safe lifting techniques: I always use proper body mechanics, keeping my back straight, bending at the knees, and keeping the load close to my body.

- Using appropriate equipment: I select and use lifting aids like hand trucks, dollies, or hoists when appropriate to reduce manual strain.

- Teamwork and communication: For heavy lifts, I always work with a team, ensuring clear communication and coordination to prevent accidents.

- Reporting near misses: I report any near misses or potentially unsafe situations to my supervisor so corrective action can be taken.

- Training others: I help train new employees on safe lifting techniques and company safety policies.

I firmly believe that a culture of safety is paramount and actively participate in promoting safe work practices among colleagues.

Q 27. How do you ensure proper documentation of heavy lifting tasks and any potential incidents?

Proper documentation is crucial for accountability and continuous improvement. My approach involves:

- Pre-lift checklists: Completing checklists that document the object’s weight, dimensions, and potential hazards before any lifting begins.

- Incident reports: If any incidents occur, regardless of severity, I complete a detailed incident report, including date, time, location, description of the event, injuries sustained, and any contributing factors.

- Near-miss reporting: Near misses are reported promptly, allowing for preventative measures to be implemented.

- Maintenance logs: For any equipment used in the lift (cranes, hoists etc.), I ensure proper maintenance logs are up-to-date.

This meticulous record-keeping helps in identifying trends, improving safety practices, and ensuring compliance with regulations.

Q 28. Describe a situation where you had to adapt your lifting technique based on the object’s shape or size.

I once had to lift a large, oddly shaped piece of machinery—it was a customized metal component with uneven weight distribution. A standard lifting technique would have been precarious and potentially dangerous.

My solution involved using a combination of lifting straps and a hand truck. I carefully positioned the straps to distribute the weight evenly, mitigating the risk of the object tipping or shifting during the lift. The hand truck provided support, preventing strain and allowing a more controlled movement. This demonstrated my adaptability and problem-solving skills in challenging situations.

Key Topics to Learn for Experience in lifting and handling heavy objects Interview

- Understanding Weight Limits and Lifting Techniques: Learn the proper techniques for lifting and carrying heavy objects safely, considering weight limits and ergonomic principles. This includes understanding the risks associated with improper lifting.

- Equipment Usage and Safety Procedures: Familiarize yourself with different types of lifting equipment (e.g., forklifts, cranes, hoists) and the safety protocols involved in their operation. Be prepared to discuss your experience with any relevant equipment.

- Workplace Safety Regulations and Best Practices: Demonstrate knowledge of relevant health and safety regulations and best practices related to manual handling. This includes understanding risk assessments and hazard identification.

- Physical Fitness and Injury Prevention: Discuss your physical fitness level and its relevance to the job, and highlight your understanding of injury prevention strategies, such as stretching and proper posture.

- Problem-Solving and Adaptability: Be ready to describe situations where you had to adapt your lifting techniques or use of equipment to overcome challenges, emphasizing safe and efficient problem-solving.

- Teamwork and Communication: Highlight your ability to work effectively as part of a team when lifting and moving heavy objects, emphasizing clear communication to ensure safety.

- Documentation and Reporting: Discuss your experience with documenting lifting procedures, near misses, or incidents, and the importance of accurate reporting for safety improvements.

Next Steps

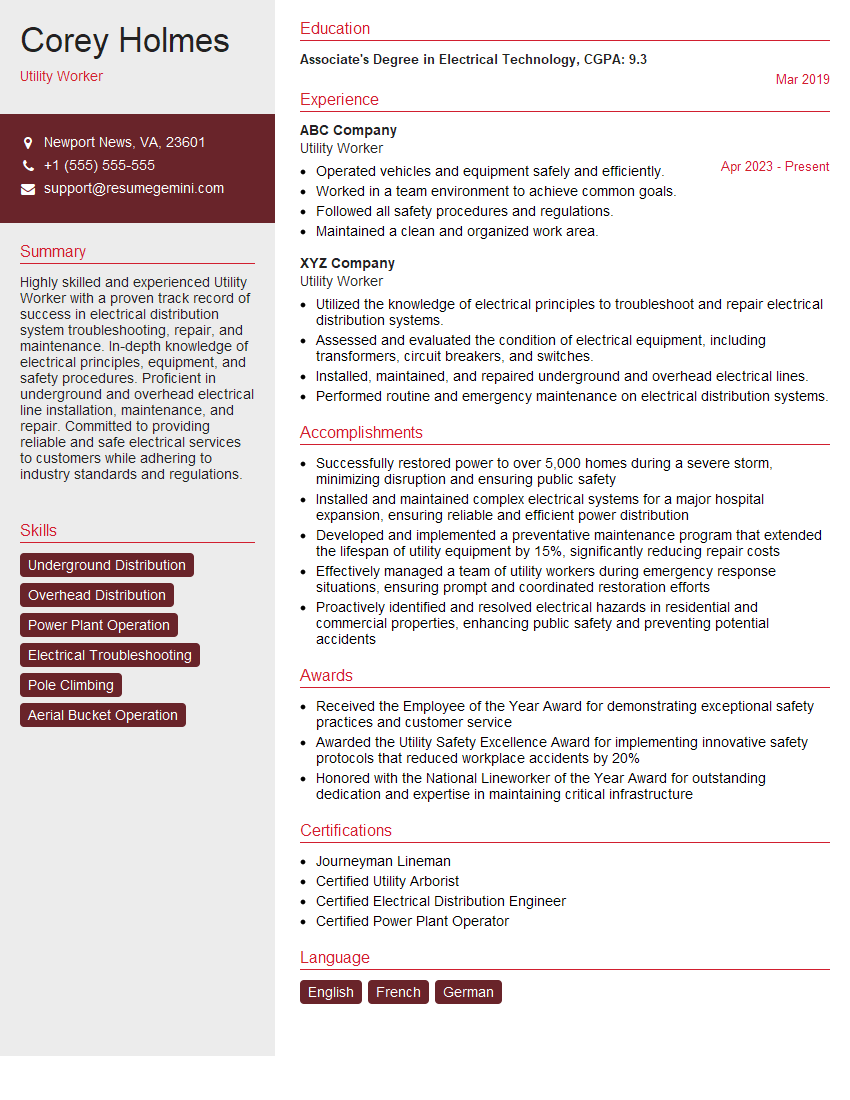

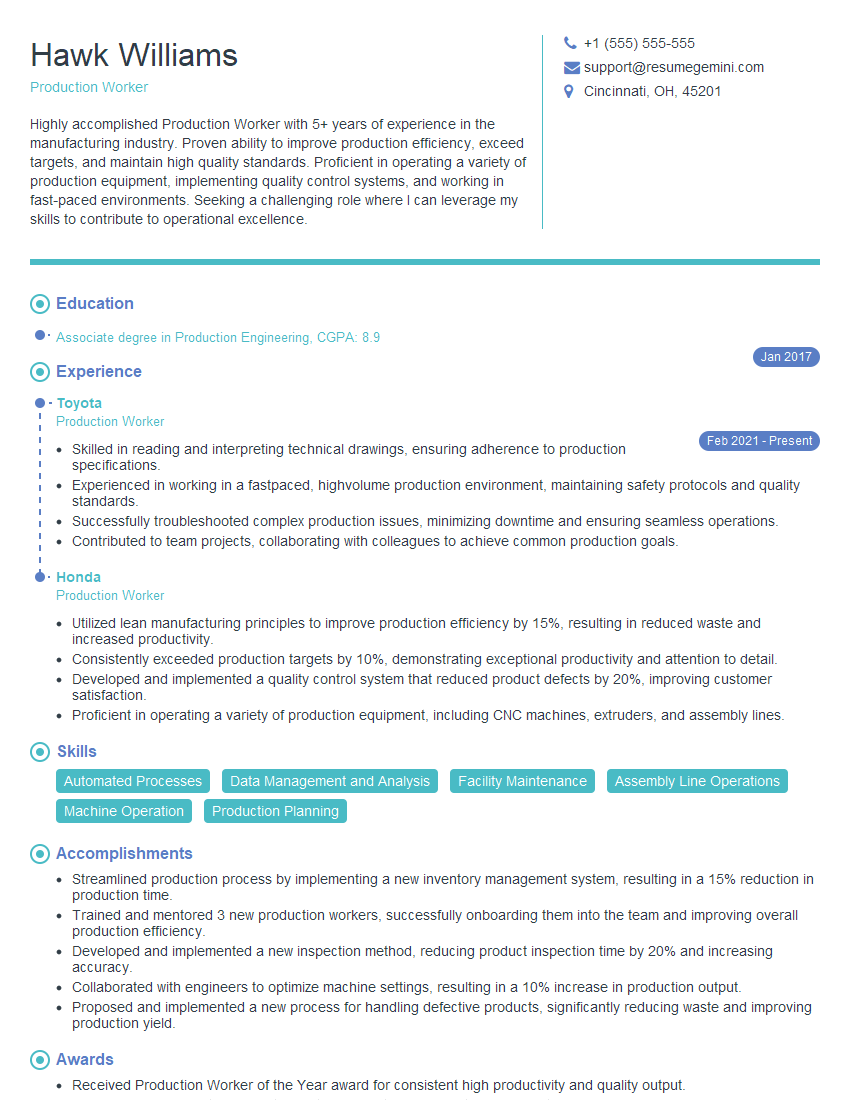

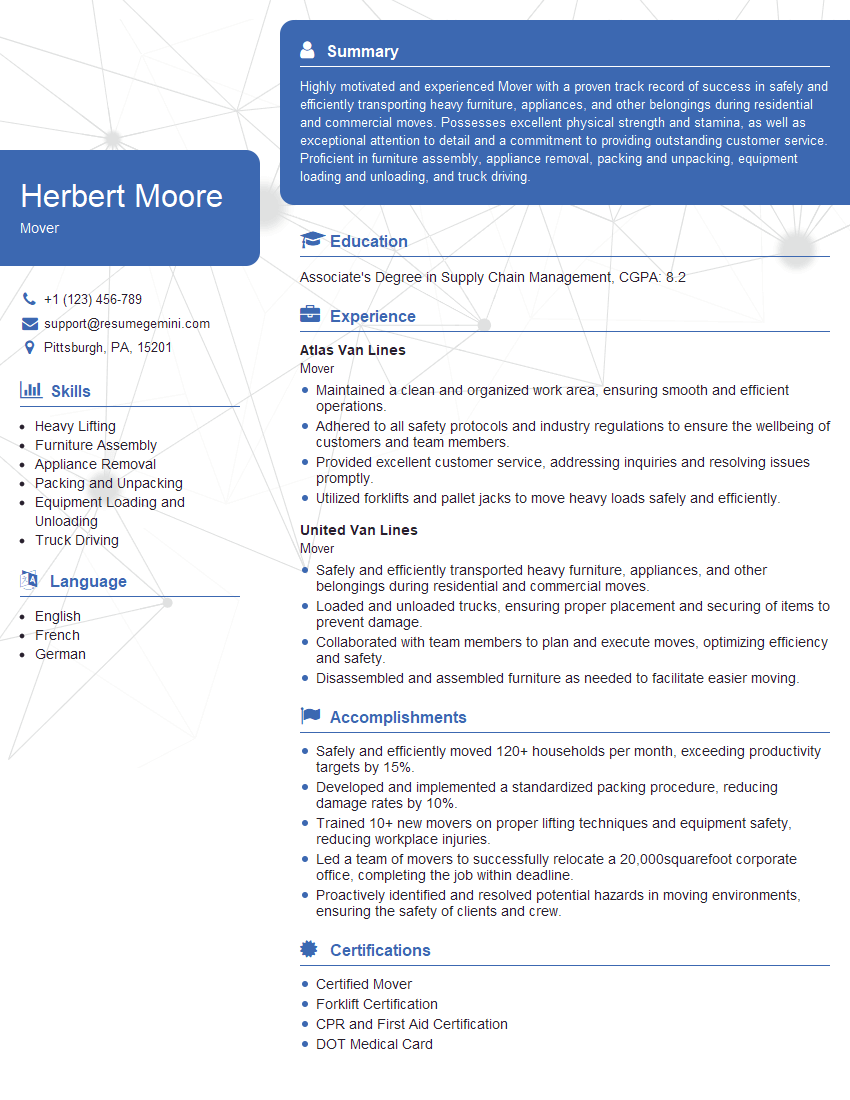

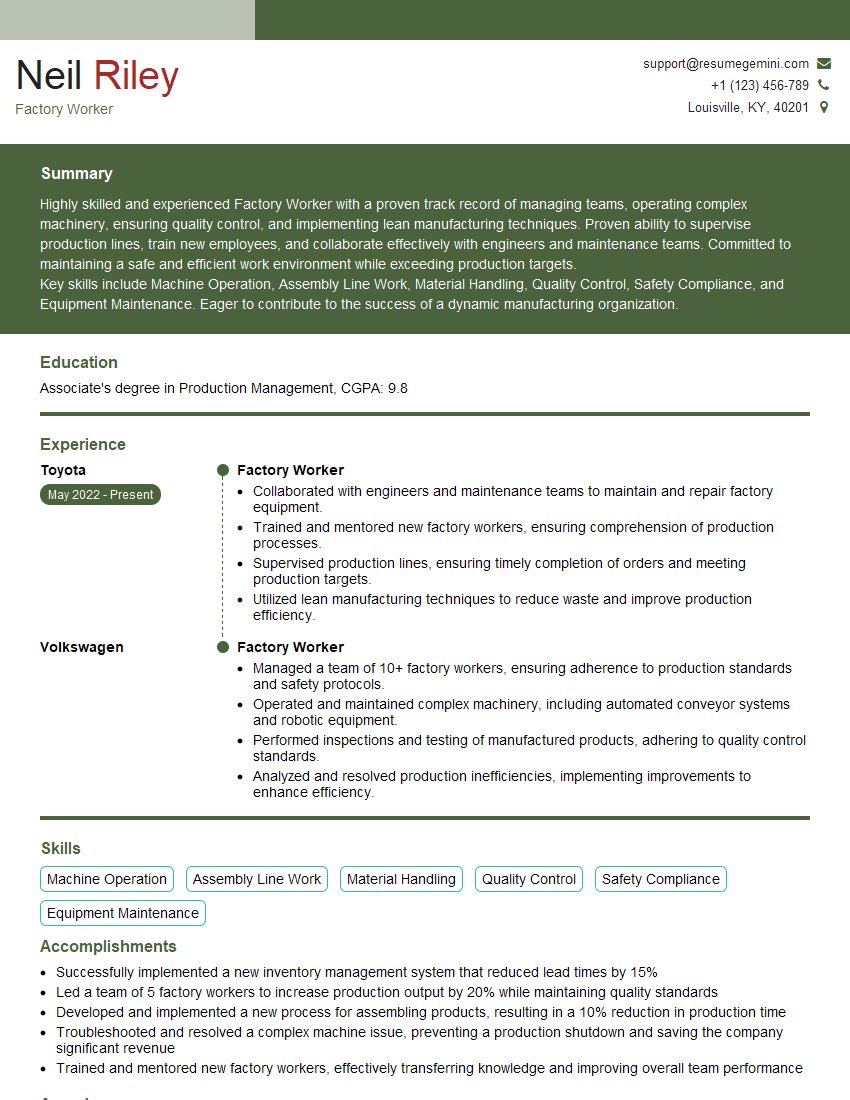

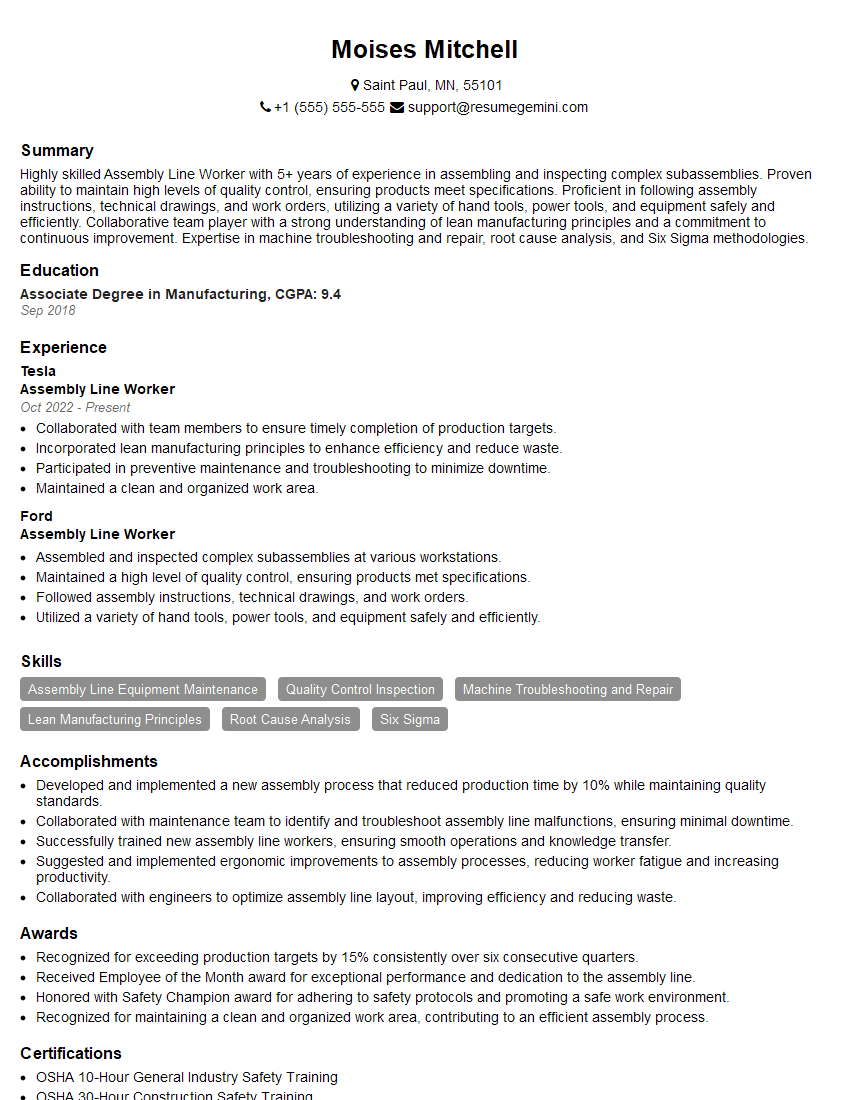

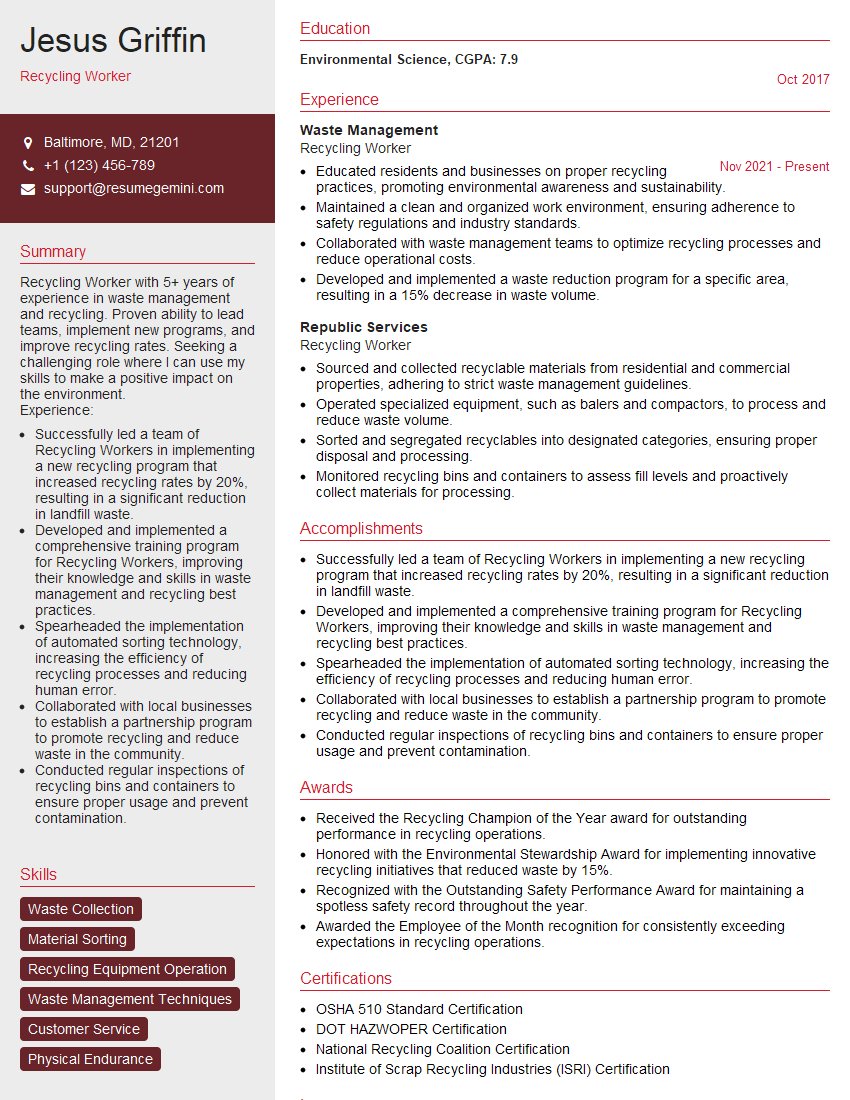

Mastering safe and efficient lifting and handling techniques is crucial for career advancement in many industries, significantly reducing the risk of workplace injuries and improving overall productivity. A well-crafted resume is your key to unlocking opportunities. Creating an ATS-friendly resume significantly increases your chances of getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your skills and experience effectively. Examples of resumes tailored to highlight experience in lifting and handling heavy objects are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO