Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Ability to operate and maintain waste collection vehicles interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Ability to operate and maintain waste collection vehicles Interview

Q 1. Describe your experience operating waste collection vehicles.

I have over eight years of experience operating various types of waste collection vehicles, ranging from rear-load trucks to automated side loaders and roll-off trucks. My experience encompasses diverse operational environments, including residential areas, commercial districts, and industrial sites. I’m proficient in navigating tight streets, managing traffic safely, and operating the vehicle’s specialized equipment, such as the packer arm, hopper, and compactor. For example, in my previous role, I consistently exceeded daily collection targets while maintaining a perfect safety record. I’ve also worked in challenging conditions like snowy weather and heavy traffic, adapting my driving and collection techniques to maintain efficiency and safety.

Q 2. What safety procedures do you follow when operating a refuse truck?

Safety is my top priority. Before starting my route, I always conduct a thorough pre-trip inspection (as detailed in the next answer). While operating the vehicle, I strictly adhere to traffic laws, using signals appropriately and maintaining a safe following distance. I am highly aware of blind spots, using mirrors diligently and checking surroundings before any maneuver, especially when reversing or near pedestrians and other vehicles. I prioritize pedestrian safety, slowing down in residential areas and being extra cautious around schools and playgrounds. I also wear high-visibility clothing, follow load securement procedures, and report any mechanical issues immediately to prevent accidents. Furthermore, I’ve completed several safety training courses, including defensive driving and hazard recognition.

Q 3. How do you perform pre-trip inspections on a waste collection vehicle?

My pre-trip inspection is a systematic process. I start by checking fluid levels (engine oil, coolant, transmission fluid, hydraulic fluid), ensuring they are within the acceptable ranges. I then inspect tires for proper inflation and any signs of damage, like cuts or wear. Next, I check the lights, turn signals, brakes, wipers, and horn to ensure they are functioning correctly. I also examine the body of the truck for any dents, leaks, or damage that might compromise safety. The packer arm and compactor mechanism are checked for proper operation and any signs of leakage. Finally, I carefully inspect the safety equipment, like emergency lights and fire extinguishers, to ensure they are in place and functional. A thorough inspection prevents costly downtime and maintains vehicle safety. I always document my findings and report any issues immediately to prevent further problems.

Q 4. Explain the different types of waste collection vehicles you’re familiar with.

I’m familiar with various waste collection vehicles, including:

- Rear-load trucks: These are the most common type, featuring a hopper at the rear where containers are emptied. The waste is then compacted into the truck body.

- Side-load trucks (automated): These use an automated arm to lift and empty containers from the curbside, improving efficiency and worker safety.

- Front-load trucks: Waste is loaded from the front, usually using a claw-like mechanism to pick up large containers.

- Roll-off trucks: These carry large dumpsters which are lifted and emptied into a larger container at a transfer station.

- Compactors: These are mainly used for larger scale collection from businesses.

Q 5. What are the common mechanical issues you encounter with waste collection vehicles?

Common mechanical issues include hydraulic system leaks (leading to reduced compaction or arm function), problems with the packer blade (causing jams or inefficient compaction), tire punctures or blowouts, brake issues, engine problems (like overheating or low oil pressure), and electrical faults (affecting lights, signals, or the compaction system). Dealing with these issues promptly minimizes downtime and reduces safety risks. For example, I once encountered a hydraulic leak which I reported immediately preventing further damage and downtime. Regular maintenance, as described below, plays a key role in minimizing these issues.

Q 6. How do you troubleshoot hydraulic system problems in a garbage truck?

Troubleshooting hydraulic system problems requires systematic checking. First, I would identify the problem; is it a leak, a lack of pressure, or a malfunctioning component? Then, I’d check fluid levels and look for leaks. A visual inspection can reveal external leaks while listening for unusual noises might pinpoint internal problems. If a leak is present, I would identify the source. If a component is faulty, replacement might be necessary. Checking pressure gauges is critical to understanding the system’s performance. If there’s low pressure, I’d inspect filters, pumps, and valves. The troubleshooting process often involves checking hydraulic lines, hoses and connectors for damage. I’ve found that keeping a detailed maintenance log helps in pinpointing potential problems early on.

Q 7. Describe your experience with preventative maintenance on waste collection vehicles.

Preventative maintenance is crucial for the longevity and safe operation of waste collection vehicles. My experience encompasses regular checks and lubrication of moving parts, including the packer arm and hydraulic components. I’m involved in regular fluid changes (engine oil, transmission fluid, hydraulic fluid), as well as tire pressure checks and inspections. I also monitor the condition of brakes, lights, and other safety-related components, making sure these undergo regular maintenance. This proactive approach significantly reduces the risk of breakdowns, improves fuel efficiency, and extends the lifespan of the vehicle. Detailed records of all maintenance performed are kept, facilitating better tracking and anticipating potential future issues.

Q 8. How do you handle hazardous waste during collection?

Handling hazardous waste requires strict adherence to safety protocols and regulations. It’s crucial to identify the waste correctly first. This often involves checking labels, manifests, and consulting with the client if there’s any ambiguity. We segregate hazardous waste from regular waste using clearly marked containers, often color-coded according to the type of hazard (e.g., red for flammables, yellow for corrosives).

Once segregated, hazardous waste requires special handling. This includes using personal protective equipment (PPE) like gloves, eye protection, and sometimes respirators depending on the hazard. The waste is loaded into designated compartments within the vehicle, often sealed containers to prevent spills or leaks. These compartments are clearly labeled and secured to prevent accidental release during transit. Finally, the hazardous waste is transported to a licensed hazardous waste facility, where its disposal is carefully monitored and documented.

For example, I once encountered a situation involving improperly labeled medical waste. By meticulously examining the contents and contacting the source, I was able to correctly classify and handle the waste, preventing potential contamination.

Q 9. What are the regulations regarding waste disposal in your area?

Waste disposal regulations in my area are quite stringent, encompassing various aspects from collection to final disposal. They dictate the types of waste allowed for curbside collection, the frequency of collection, the required labeling of hazardous materials, and the permitted disposal methods. These regulations are closely linked to environmental protection laws and aim to minimize the environmental impact of waste management. Specifically, there are regulations concerning the proper handling of recyclables, organic waste, and hazardous materials such as batteries and chemicals. Failure to comply with these regulations can result in hefty fines and legal repercussions.

Beyond local ordinances, we must also adhere to state and federal regulations concerning the transportation and disposal of hazardous materials. This includes maintaining accurate records of waste collected and transported, ensuring proper containerization, and complying with all relevant permits and licenses. Regular training and updates ensure we stay current on all applicable regulations.

Q 10. Explain the proper procedure for loading and unloading waste containers.

The loading and unloading procedure is designed for efficiency and safety. It starts with a pre-trip inspection of the vehicle and the containers to ensure they are in good condition and free of any obstructions. Then we begin with the loading process. We use mechanical arms or manual methods to lift and place containers onto the truck, always being mindful of the weight and balance of the load. The containers are secured to prevent shifting or tipping during transit. Each type of container has a specific loading method; for instance, wheeled bins are carefully rolled in while bulk containers might require a more complex lifting mechanism.

Unloading is a reverse process. We use the same equipment to carefully remove the containers from the truck at the disposal site, again ensuring balance and safety. Once unloaded, we perform a post-trip inspection of the vehicle and ensure that the unloading area is clear of debris. Efficient loading and unloading maximizes time and efficiency for our daily routes.

Q 11. How do you manage your route efficiently?

Efficient route management is key to maximizing productivity. This involves careful planning and execution, taking into consideration several factors: the number of stops, the location of each stop, the type and volume of waste at each stop, and traffic conditions. We often use GPS-based route optimization software to plan the most efficient routes. This software helps to avoid unnecessary detours, prioritize high-volume locations, and adjust routes in response to changing conditions like traffic jams or unexpected delays.

On the ground, we also utilize good communication to manage unforeseen delays or changes in waste collection requirements. Reporting any problems or changes to the central dispatch allows for adjustments to the route in real time, minimizing disruption to the schedule. My experience has shown that proactive route management leads to significant improvements in fuel efficiency and time utilization.

Q 12. How do you ensure the safety of pedestrians and other vehicles while operating a waste collection vehicle?

Safety is paramount when operating a waste collection vehicle. We prioritize safety through a combination of defensive driving techniques and adherence to traffic laws. This includes maintaining a safe following distance, using turn signals well in advance, and being extra vigilant around pedestrians and cyclists. Regular vehicle maintenance is essential for safe operation. This includes checking brakes, lights, and other critical components. We’re trained to perform pre-trip and post-trip inspections to identify and address potential mechanical issues promptly.

In addition to driving safely, we’re trained in proper procedures for backing up the truck and using warning devices like flashing lights and backup alarms to alert pedestrians and other vehicles. Continuous training and adherence to company safety protocols are vital to ensuring both our safety and the safety of those around us. I’ve always found that proactive safety measures are more effective than reactive ones.

Q 13. Describe your experience with different types of waste containers (e.g., bins, carts).

I have extensive experience handling various types of waste containers, including residential bins, large commercial dumpsters, and specialized containers for hazardous waste. Residential bins, typically ranging in size, require careful maneuvering and efficient emptying. Commercial dumpsters present different challenges due to their size and weight, often requiring specialized equipment like hooklifts or roll-off containers. Each container type necessitates a different approach to ensure safe and efficient loading and unloading. Specialized containers for hazardous waste require extra caution due to the risks involved.

For example, I’ve handled everything from the standard 96-gallon wheeled bins common in residential areas to large 30-yard dumpsters used by restaurants and businesses. Understanding the variations in weight, shape, and construction of these containers is crucial for efficient and safe operations. This experience translates directly into reduced risks and improved operational efficiency.

Q 14. What is your experience with GPS navigation systems in waste collection vehicles?

GPS navigation systems are invaluable in modern waste collection. They significantly improve route efficiency and reduce fuel consumption. The systems provide real-time updates on traffic, enabling us to reroute if needed and avoid congested areas. They also provide precise location data, ensuring that we don’t miss any stops and cover the entire assigned route. Moreover, some systems allow for data collection on factors such as the number of containers serviced and the duration of each stop, providing valuable operational data for performance analysis and improvement.

My experience with GPS navigation includes using various systems from different manufacturers. Each system has its own set of features, but all contribute to better route planning and overall operational efficiency. I’ve used GPS to identify the shortest routes, track the progress of my work, and improve communication with the dispatch center.

Q 15. How do you maintain accurate records of your daily operations?

Maintaining accurate records is crucial for efficiency and accountability in waste collection. I utilize a combination of digital and physical methods. Daily route sheets are meticulously filled out, noting start and end times, locations serviced, volume of waste collected (often estimated using pre-defined volume indicators on the truck), and any incidents or challenges encountered. These sheets are then digitally scanned and uploaded to our fleet management system. This system allows for real-time tracking of vehicle location and performance, providing data for route optimization and resource allocation. Additionally, we maintain detailed logs of fuel consumption, vehicle maintenance, and any repairs or replacements. This comprehensive approach allows for easy reporting, identifying trends, and planning for future needs.

For example, if a particular area consistently requires more frequent collections than anticipated, the data allows us to adjust the route schedule accordingly. Or, if a truck consistently requires more maintenance than others, this signals a potential underlying mechanical issue that needs attention.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle unexpected mechanical breakdowns on the road?

Unexpected breakdowns are a reality in this line of work. My first priority is safety – securing the vehicle safely off the road, activating hazard lights, and ensuring the safety of myself and any bystanders. Then, I immediately contact our dispatch center, providing them with the location, a description of the problem, and the truck’s identification number. They can then assess the situation, dispatch a mechanic if needed, and arrange for alternative collection services for that route section if the breakdown is significant. Depending on the nature of the issue and my level of mechanical understanding, I might attempt minor troubleshooting (like checking fluids or addressing a simple electrical fault), but I prioritize safety and avoid attempting repairs beyond my capabilities.

For instance, I once experienced a sudden loss of hydraulic pressure. I safely stopped the vehicle, contacted dispatch, and waited for a mechanic. They diagnosed a hydraulic line leak and repaired it onsite, minimizing disruption to the collection route.

Q 17. What is your experience with vehicle maintenance logs and reporting?

I have extensive experience maintaining accurate and detailed vehicle maintenance logs. These logs detail all scheduled maintenance, such as oil changes, filter replacements, and tire rotations, as well as any unscheduled repairs, including the date, nature of the repair, parts used, and labor costs. This documentation is crucial for warranty claims, budgeting, and identifying patterns in vehicle maintenance needs. Our fleet management system usually handles this digitally, but I always ensure a physical copy of the report is available and kept in the truck’s paperwork file. Using such data, we can track the overall health and efficiency of the fleet, identifying any trends and opportunities for preventative maintenance, thereby reducing downtime and overall maintenance costs. Regular reporting on this data is provided to my supervisors, and the reports can highlight potential issues or areas needing immediate action.

Q 18. Explain your understanding of load balancing and its importance in waste collection.

Load balancing is the strategic distribution of waste across the collection route to optimize efficiency and reduce wear and tear on the vehicle. It involves strategically planning the route to ensure even distribution of weight. An unevenly balanced load can lead to increased fuel consumption, premature tire wear, and potentially damage to the vehicle’s chassis and suspension.

Imagine you’re carrying groceries. If you put all the heavy items on one side of the bag, it’ll be awkward to carry and the bag might even tear. Similarly, if a waste truck is heavily loaded on one side, it impacts fuel efficiency and increases the strain on components. I strive for even distribution, utilizing knowledge of the volume and density of waste in different collection points to strategically plan the order of stops and loading sequence.

Q 19. Describe your experience with different types of compaction mechanisms in waste trucks.

I’m familiar with various compaction mechanisms, including packer trucks with their oscillating, rectangular, or circular chambers, as well as side-loading and rear-loading systems. Packer trucks use a ram to compress waste, maximizing the amount of waste that can be collected before the truck needs to be emptied. The choice of compaction mechanism depends on factors such as the type of waste being collected (residential vs. commercial), and the volume to be collected. I have experience operating trucks with different types of compaction mechanisms and understand the maintenance requirements specific to each system. For example, I know that regular lubrication is essential for proper functioning of the packer ram and that timely inspection of the seals and packing system is critical to prevent leakage and contamination.

Q 20. How do you comply with weight limits and regulations?

Compliance with weight limits and regulations is paramount. I regularly check the weight of the vehicle using the onboard weighing system or by using a weighbridge. Exceeding weight limits can result in hefty fines, vehicle damage, and safety hazards. Before starting the route, I assess the anticipated load based on past experience and adjust my loading strategy to prevent overloading. I also ensure that the load is distributed evenly across the axles. If I approach the weight limit, I may make fewer stops or coordinate with dispatch to send another truck for overflow waste. Strict adherence to these regulations is crucial for maintaining a safe and efficient operation and is something I consistently prioritize.

Q 21. What is your experience working with various lifting mechanisms on the truck?

Waste collection vehicles utilize various lifting mechanisms, such as hydraulic hoists for lifting bins, and automated arms for handling large commercial containers. I am proficient in operating these mechanisms safely and efficiently. Regular inspections and maintenance of these systems are crucial to prevent malfunctions and accidents. This includes checking hydraulic fluid levels, inspecting hoses and cylinders for leaks, and regularly lubricating moving parts. Proper operation ensures both efficiency and safety. I always follow the manufacturer’s instructions and the company’s safety procedures when operating any of these lifting mechanisms. I understand the importance of appropriate safety precautions such as ensuring that the load is securely held and that no personnel are near the moving parts during operation.

Q 22. How do you deal with difficult customers or situations on the route?

Dealing with difficult customers requires patience, empathy, and a professional demeanor. My approach is to listen actively to their concerns, validate their feelings, and then clearly explain the situation from my perspective. For example, if a customer is upset about missed collection, I’d first apologize for the inconvenience. Then, I’d explain the reason for the delay – perhaps a mechanical issue or an unexpected volume of waste – and offer a solution, like scheduling a special pick-up. If the issue is about incorrect waste disposal, I’d calmly explain the local regulations and provide educational materials. The key is de-escalation – remaining calm and respectful even when faced with anger. Sometimes, a simple, “I understand your frustration, and I’ll do my best to help” can go a long way.

Difficult situations might include traffic accidents or unexpected road closures. In such instances, I’d prioritize safety, reporting the incident to my supervisor immediately and following their instructions. I’d also alert other drivers and ensure the safety of the public. Effective communication with dispatch and colleagues is crucial in these scenarios.

Q 23. How do you ensure the cleanliness and hygiene of your vehicle?

Maintaining a clean and hygienic vehicle is paramount for both safety and professionalism. My routine includes a thorough cleaning after each route. This involves emptying all waste containers, sweeping the cab and cargo area, and wiping down all surfaces. I pay special attention to areas that can easily accumulate bacteria, like the handles and controls. I use appropriate cleaning solutions, ensuring they’re environmentally friendly and safe for use. Regular maintenance includes checking fluid levels, lubricating moving parts, and reporting any potential issues immediately. Consider it like this: a clean vehicle is a safe vehicle. A well-maintained vehicle is efficient and reliable, preventing breakdowns and delays. It also reflects positively on the company’s image.

Q 24. Explain your knowledge of environmental regulations related to waste collection.

I possess a comprehensive understanding of environmental regulations concerning waste collection. This includes knowledge of local ordinances regarding waste sorting, disposal methods, and hazardous waste handling. For example, I’m familiar with regulations around recycling programs, the proper disposal of electronic waste, and the restrictions on accepting certain materials. I’m also aware of the regulations concerning vehicle emissions and fuel efficiency, ensuring our vehicles meet or exceed environmental standards. Staying updated on these regulations is crucial through continuous professional development, including online courses and attending industry conferences. Non-compliance can result in hefty fines and environmental damage, which is unacceptable.

Q 25. How do you stay current with changes in waste management technology?

The waste management industry is constantly evolving, so staying updated is crucial. I actively seek out new information through various channels. This includes subscribing to industry publications, attending workshops and training sessions, and networking with other professionals. I regularly explore online resources and utilize the resources provided by my employer to learn about new technologies and best practices. For instance, I’ve recently learned about the implementation of smart bins with sensors that monitor fill levels, optimizing collection routes and reducing fuel consumption. Staying updated translates to improved efficiency and environmental responsibility.

Q 26. What are your strengths and weaknesses as a waste collection vehicle operator?

My strengths as a waste collection vehicle operator include my meticulous attention to detail, my commitment to safety, and my ability to work independently and as part of a team. I’m adept at problem-solving, efficiently handling unexpected situations, and prioritizing tasks effectively. My driving skills are excellent, ensuring safe and efficient route completion. However, like everyone, I have areas for improvement. I sometimes struggle with managing interruptions during the workday, which can impact my schedule. To address this, I’m practicing time management techniques and prioritizing tasks more effectively to handle disruptions more smoothly.

Q 27. Describe a time you had to solve a mechanical problem on your own.

One day, while on my route, I experienced a sudden loss of hydraulic pressure in the compactor. This meant I couldn’t compact the waste, significantly delaying my route. Instead of panicking, I systematically checked the hydraulic fluid levels and noticed a significant leak. Using my knowledge of basic hydraulic systems, I located the leak and, utilizing a temporary repair kit I always carry, managed to stem the leak enough to complete my route, though at a slower pace. This highlights the importance of preventative maintenance and proactive problem-solving skills. Upon my return, I reported the issue and the vehicle was properly repaired.

Q 28. How do you prioritize tasks during a busy workday?

Prioritizing tasks during a busy workday involves a combination of planning and adaptability. I begin by reviewing my route schedule, identifying high-priority areas and any potential challenges. I then assess the volume of waste at each location, factoring in any potential delays due to traffic or access issues. I follow a systematic approach, prioritizing residential areas with larger waste volumes first, working my way to smaller commercial or industrial clients. Flexibility is key; if an unexpected issue arises, I adjust my priorities accordingly, ensuring safety and efficiency remain top priorities. Think of it as a dynamic puzzle; the pieces may change, but the goal remains consistent – efficient and timely waste collection.

Key Topics to Learn for Ability to Operate and Maintain Waste Collection Vehicles Interview

- Vehicle Operation: Safe and efficient driving techniques, including maneuvering large vehicles in tight spaces and adhering to traffic regulations. Understanding route optimization and efficient waste collection strategies.

- Vehicle Maintenance: Daily pre-trip inspections, identifying and reporting mechanical issues, basic preventative maintenance procedures (e.g., checking fluids, tire pressure). Understanding the importance of regular servicing and its impact on vehicle longevity and safety.

- Waste Handling Procedures: Safe and proper loading and unloading of waste materials, following regulations for hazardous waste handling, adhering to company safety protocols.

- Emergency Procedures: Responding to mechanical breakdowns, handling minor repairs on the road, communicating effectively with dispatch and support teams in case of emergencies. Understanding appropriate safety protocols in various situations.

- Regulations and Compliance: Understanding and adhering to all relevant health and safety regulations, waste disposal regulations, and traffic laws. Knowing your responsibilities concerning environmental protection.

- Problem-solving and Troubleshooting: Diagnosing common mechanical issues, applying practical solutions to operational challenges, prioritizing tasks effectively during a busy workday.

- Customer Service and Communication: Interacting professionally with residents and businesses, handling customer complaints effectively, and maintaining a positive public image for the company.

Next Steps

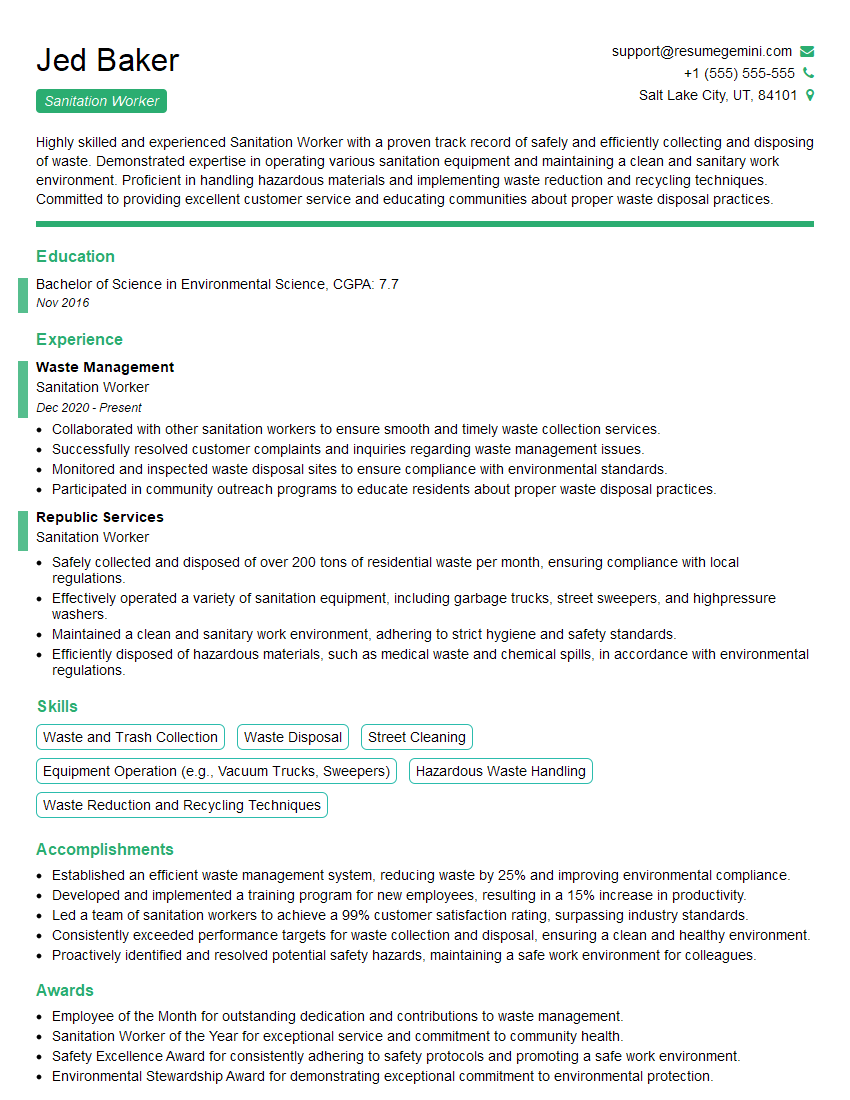

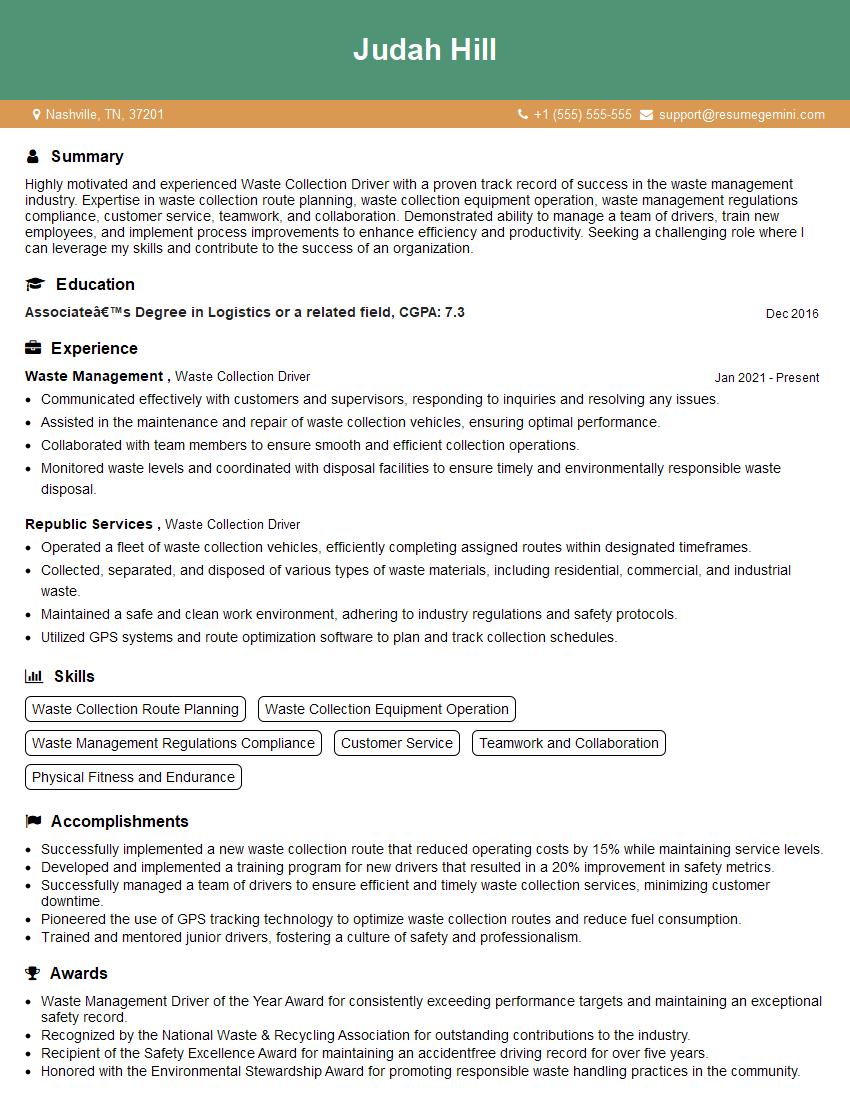

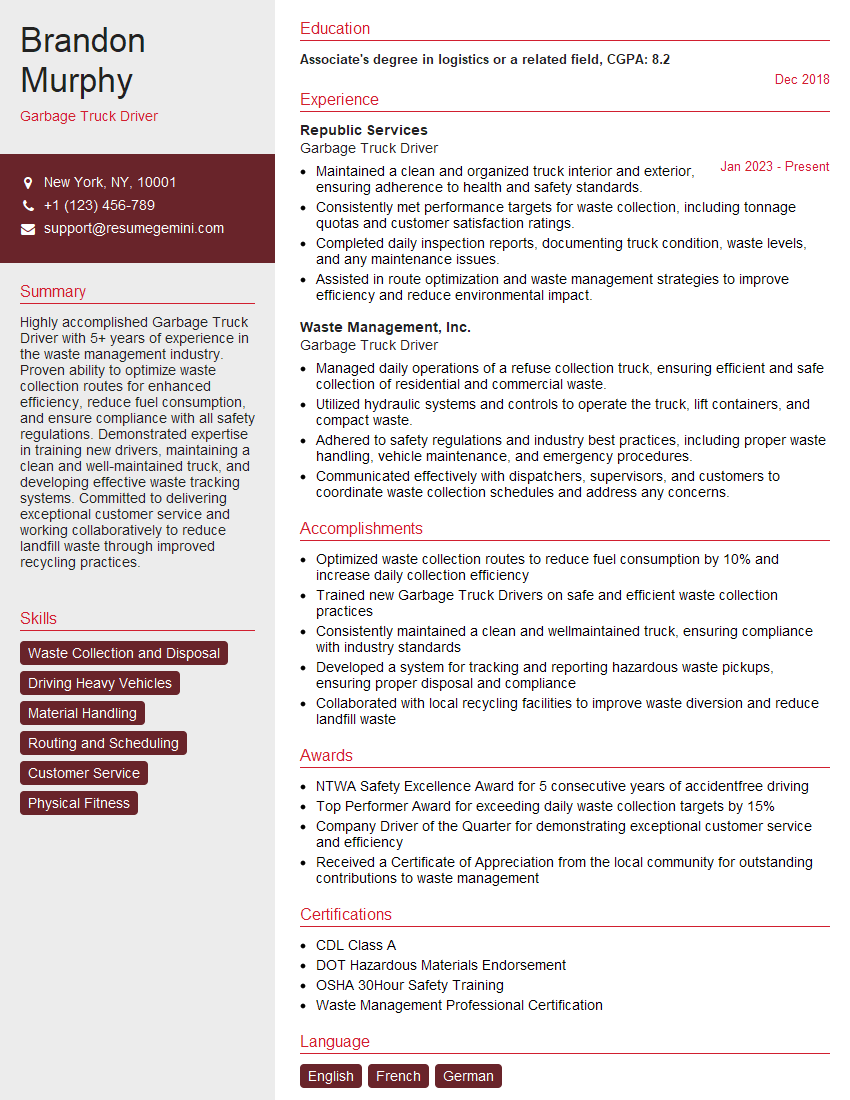

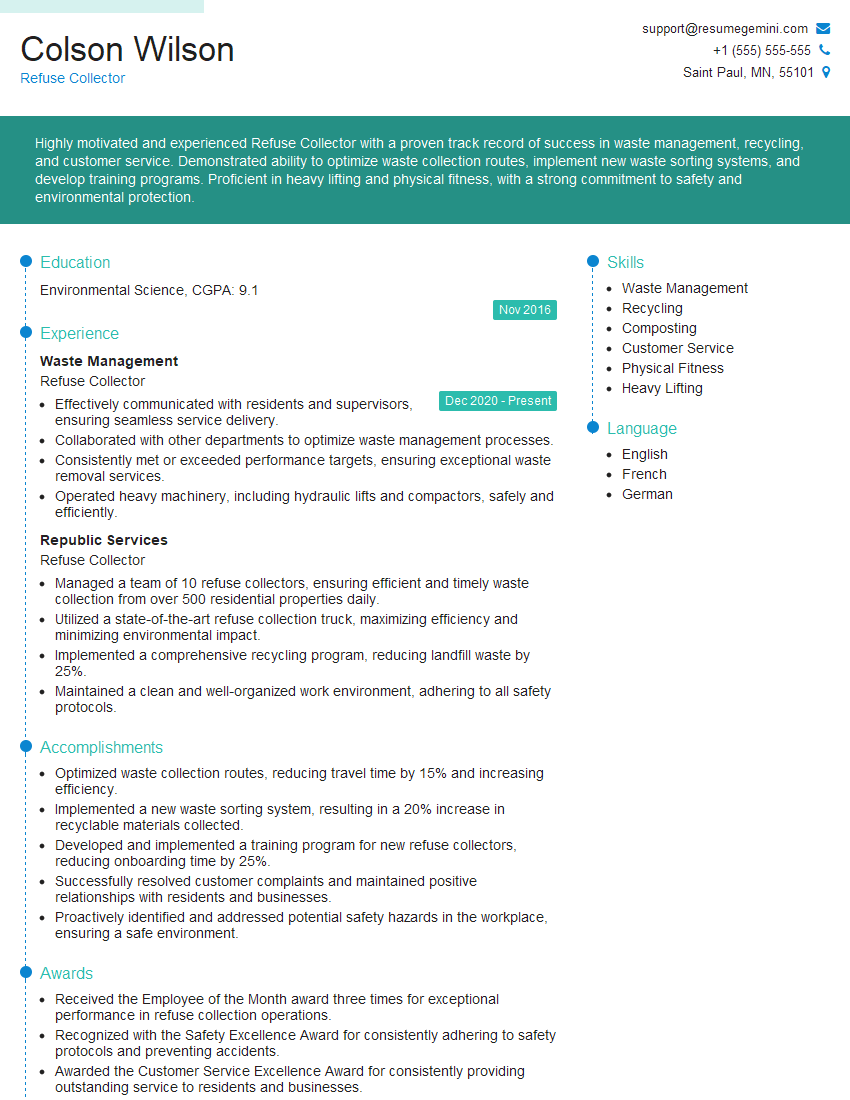

Mastering the ability to operate and maintain waste collection vehicles opens doors to a stable and rewarding career with opportunities for advancement. A strong foundation in these skills demonstrates commitment and reliability, essential qualities for long-term success in this field. To significantly boost your job prospects, create an ATS-friendly resume that highlights your expertise effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to this specific role. Examples of resumes specifically designed for Ability to operate and maintain waste collection vehicles are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO