Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential IEC Standards interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in IEC Standards Interview

Q 1. Explain the significance of IEC 61508 in functional safety.

IEC 61508 is the foundational standard for functional safety of electrical/electronic/programmable electronic safety-related systems (E/E/PES). It doesn’t specify what to do but provides a framework for determining what *needs* to be done to achieve a required level of safety. Think of it as the blueprint for building a safe system; it doesn’t supply the bricks and mortar but dictates how they should be arranged to ensure structural integrity. Its significance lies in its systematic approach to hazard analysis, risk reduction, and the implementation of safety requirements throughout the lifecycle of a system. This ensures that risks associated with potential failures are properly mitigated, protecting people, equipment, and the environment.

The standard’s influence is widespread, forming the basis for many industry-specific standards like IEC 62061 (machinery safety) and ISO 26262 (automotive safety). It’s a crucial document for anyone involved in designing and developing safety-critical systems.

Q 2. Describe the different levels of safety integrity levels (SILs) in IEC 61508.

IEC 61508 defines four Safety Integrity Levels (SILs), ranging from SIL 1 (lowest) to SIL 4 (highest). These levels represent the probability of a safety function failing to perform its required safety function on demand. A higher SIL implies a lower probability of failure and thus a higher level of safety. The allocation of a SIL depends on the severity of the potential hazard and is determined through a rigorous risk assessment.

- SIL 1: Represents a lower risk, with a higher probability of failure on demand. Think of a simple safety device with a relatively minor consequence of failure.

- SIL 2: Indicates a moderate risk, with a lower probability of failure than SIL 1.

- SIL 3: Represents a high risk, requiring a very low probability of failure on demand. Failures have more severe consequences here.

- SIL 4: Represents the highest risk level, demanding an extremely low probability of failure. The consequences of failure are potentially catastrophic.

The selection of a SIL is not arbitrary; it’s based on a thorough risk assessment that carefully considers the potential hazards, their severity, and the probability of occurrence. For example, a safety system for a simple machine might require only SIL 1, whereas a safety-critical system in a nuclear power plant might require SIL 4.

Q 3. What are the key differences between IEC 61508 and IEC 62304?

While both IEC 61508 and IEC 62304 deal with safety, they address different domains. IEC 61508 is a general standard for functional safety of E/E/PES systems across various industries, whereas IEC 62304 specifically addresses the software lifecycle processes within medical devices.

- IEC 61508: Focuses on the overall functional safety of E/E/PES systems. It covers the entire lifecycle, from hazard analysis to verification and validation.

- IEC 62304: Deals exclusively with the software aspects within medical devices, aiming to ensure the safety and reliability of the software used in these devices. It defines different software development lifecycle processes based on risk levels.

Essentially, IEC 62304 is a more specialized standard built upon the foundational principles laid out by IEC 61508. A medical device manufacturer might use IEC 61508 as a general safety framework, but they would also need to comply with IEC 62304’s specific requirements for software safety within their devices. Imagine IEC 61508 as the overarching safety plan for a building, and IEC 62304 as the specific regulations for the electrical systems within that building.

Q 4. How does IEC 61000 relate to electromagnetic compatibility (EMC)?

IEC 61000 is a comprehensive series of standards focusing on electromagnetic compatibility (EMC). EMC deals with the ability of electrical and electronic equipment to function satisfactorily in its electromagnetic environment without introducing unacceptable electromagnetic disturbances to that environment. Think of it as ensuring that devices don’t interfere with each other or cause malfunctions due to electromagnetic interference.

The IEC 61000 series covers various aspects of EMC, including:

- Emission limits: Standards defining the maximum levels of electromagnetic energy a device can emit.

- Immunity requirements: Standards specifying the minimum levels of electromagnetic disturbances a device must withstand without malfunctioning.

- Testing methods: Procedures for testing and verifying compliance with emission and immunity standards.

Compliance with IEC 61000 standards is crucial to ensuring the reliability and proper functioning of electronic devices. Failures to comply can lead to malfunctions, data corruption, and even safety hazards. For instance, interference from a nearby radio transmitter could disrupt the operation of a medical device if it isn’t adequately shielded, and that is where the IEC 61000 standards guide manufacturers and testing houses.

Q 5. Explain the process of IEC certification for a medical device.

The IEC certification process for a medical device is complex and varies depending on the specific device’s classification and intended use. It typically involves a series of steps:

- Device Classification: The device is classified based on its risk level and intended use (Class I, II, or III).

- Risk Management: A thorough risk assessment is conducted to identify potential hazards and mitigate risks.

- Design and Development: The device is designed and developed according to relevant IEC standards (e.g., IEC 60601-1 for general requirements, IEC 62304 for software).

- Testing and Verification: The device undergoes rigorous testing to verify its safety, performance, and compliance with relevant standards. This includes EMC testing based on IEC 61000, and safety testing based on IEC 60601-1.

- Documentation: Extensive documentation is prepared, including design files, test results, and risk management reports.

- Auditing and Inspection: A Notified Body (an independent organization authorized by the relevant regulatory authority) audits the manufacturer’s quality management system and inspects the device to verify compliance.

- Certification: If all requirements are met, the Notified Body issues a certificate of conformity, allowing the manufacturer to affix the CE mark, indicating compliance with EU directives.

The process is rigorous to ensure patient safety, and the involvement of a Notified Body adds an extra layer of independent verification to the certification process.

Q 6. What is the role of risk assessment in IEC standards?

Risk assessment is fundamental to all relevant IEC standards. It’s a systematic process for identifying potential hazards, analyzing their risks, and determining appropriate control measures to mitigate those risks. It’s not a one-time event, but an iterative process that continues throughout the lifecycle of a product or system.

In IEC standards, risk assessment helps to:

- Identify hazards: Determine potential sources of harm.

- Analyze risks: Evaluate the likelihood and severity of each hazard.

- Determine safety requirements: Define the necessary safety measures to reduce risks to an acceptable level.

- Verify and validate safety measures: Ensure the effectiveness of the implemented safety measures.

The output of a risk assessment often influences design choices, safety requirements, and the selection of appropriate Safety Integrity Levels (SILs) or other safety classification systems. Without a thorough risk assessment, it’s impossible to ensure that a system meets the required safety standards.

Q 7. Describe your experience with hazard analysis and risk assessment techniques.

Throughout my career, I’ve extensively utilized various hazard analysis and risk assessment techniques. I’m proficient in using methods such as Failure Mode and Effects Analysis (FMEA), Fault Tree Analysis (FTA), and Hazard and Operability Studies (HAZOP).

For example, in a project involving the development of a safety-critical industrial control system, we employed FMEA to systematically identify potential failure modes within each component of the system and assess their impact on overall safety. This allowed us to prioritize mitigation efforts and allocate resources effectively. In another project, involving medical device design, we used FTA to trace potential causes of a specific hazard—an unintended device malfunction—back to their root causes. This helped us to identify weaknesses in the design and implement corrective measures. HAZOP was also used to systematically review various operating scenarios and identify potential hazards related to process deviations.

My experience extends to different industries including medical devices, industrial automation, and automotive sectors; this broad exposure has provided me with diverse perspectives and honed my ability to adapt different techniques to various settings. I also have experience leading risk assessment teams, which involves facilitating collaborative sessions with engineers, designers, and safety professionals to ensure thorough hazard identification and risk mitigation.

Q 8. How do you ensure compliance with IEC standards throughout the product lifecycle?

Ensuring IEC compliance throughout a product’s lifecycle requires a proactive and systematic approach, starting from the initial design phase and continuing through manufacturing, testing, and post-market surveillance. It’s not a one-time activity, but an integral part of the entire process.

- Design Phase: We begin by identifying all applicable IEC standards relevant to the product’s function and intended use. This involves a thorough hazard analysis and risk assessment to pinpoint potential safety and electromagnetic compatibility (EMC) concerns. We then incorporate these standards into the design specifications, ensuring that every component and subsystem adheres to the requirements.

- Manufacturing Phase: Strict quality control measures are implemented during manufacturing to ensure consistent adherence to the design specifications and IEC standards. This includes regular audits of the manufacturing processes and testing of components and finished products.

- Testing and Verification: Rigorous testing is crucial. This goes beyond internal testing; we often engage independent third-party laboratories accredited to perform conformity assessment to ensure objectivity and credibility. Tests cover various aspects, including safety, EMC, and performance.

- Post-Market Surveillance: Even after product launch, ongoing monitoring and analysis of field performance is essential. Feedback from customers and any reported incidents are carefully evaluated to identify potential issues and ensure that any necessary corrective actions are taken promptly. This is vital for continuous improvement and maintaining compliance.

Imagine building a house – you wouldn’t just start constructing without blueprints and building codes (like IEC standards). Similarly, a systematic approach ensures that the final product meets all safety and regulatory requirements.

Q 9. What are the common challenges in achieving IEC compliance?

Achieving IEC compliance presents several challenges. These can range from technical hurdles to logistical and economic constraints.

- Keeping up with evolving standards: IEC standards are regularly updated to reflect technological advancements and improved safety practices. Staying current requires continuous learning and adaptation.

- Complexity of standards: Some IEC standards are highly complex and technical, requiring specialized expertise to interpret and implement correctly. Misinterpretation can lead to non-compliance.

- Cost of compliance: Meeting IEC standards often involves significant investments in testing, certification, and documentation. This can be a major barrier, particularly for smaller companies.

- Global variations in regulations: While IEC standards provide a global framework, individual countries may have additional or stricter regulations that need to be considered.

- Supply chain management: Ensuring that all components and materials used in a product comply with relevant IEC standards requires careful management of the supply chain.

For example, a company might struggle with EMC compliance due to unforeseen electromagnetic interference from a specific component, necessitating redesign or shielding solutions.

Q 10. How would you handle a situation where a product fails to meet IEC standards?

If a product fails to meet IEC standards, a structured problem-solving approach is essential. This involves a thorough investigation to identify the root cause of the non-compliance. Transparency and communication with relevant stakeholders are critical.

- Immediate Action: The first step is to halt any further production or distribution of the non-compliant product to prevent potential harm or risks.

- Root Cause Analysis: A detailed investigation is conducted to determine why the product failed to meet the standards. This may involve reviewing design specifications, manufacturing processes, and testing data.

- Corrective Actions: Based on the root cause analysis, appropriate corrective actions are implemented. This might include redesigning the product, modifying the manufacturing process, or improving the testing procedures.

- Verification: After implementing corrective actions, rigorous testing is performed to verify that the product now meets the IEC standards. This may require re-certification.

- Communication and Reporting: Any necessary notifications to regulatory bodies or customers need to be made promptly and transparently. This is critical for maintaining trust and reputation.

Imagine a car manufacturer discovering a brake failure issue – immediate recall and rectification are mandatory, mirroring the urgency required in such situations.

Q 11. Explain your understanding of IEC conformity assessment procedures.

IEC conformity assessment procedures are formal processes used to demonstrate that a product meets the requirements of relevant IEC standards. These procedures vary depending on the specific standard and the level of assurance required. They often involve a combination of testing, inspection, and certification.

- Self-declaration: The manufacturer declares that their product complies with the relevant standard based on their own testing and assessment. This approach is suitable for products with lower risk levels.

- Third-party certification: An independent, accredited laboratory tests and assesses the product to verify compliance. This provides higher assurance of conformity and is typically required for products with higher safety or regulatory implications. This involves audits of the manufacturer’s quality management system and product testing to ensure consistent compliance. The final step is the issuance of a certificate confirming compliance.

- Type testing: A representative sample of the product is rigorously tested by a certified laboratory to verify that its design meets the specified standards. This is usually followed by production testing and inspections.

The choice of conformity assessment procedure depends on various factors, such as the product’s risk profile, applicable regulations, and market requirements. A higher-risk medical device, for instance, would require a more robust third-party certification process than a simple household appliance.

Q 12. What are the key clauses in IEC 62304 that you find most critical?

IEC 62304, the standard for medical device software, is crucial for ensuring the safety and effectiveness of software used in medical devices. Several clauses are particularly critical:

- Clause 4 (Life Cycle Data): This section emphasizes the importance of documenting the entire software lifecycle, from planning and development to maintenance and retirement. Detailed records are essential for traceability and risk management.

- Clause 5 (Software Safety Requirements): This clause outlines the process for defining and managing safety requirements for medical device software. Identifying and mitigating potential hazards is paramount.

- Clause 7 (Software Verification and Validation): This section details the procedures for verifying that the software meets its specified requirements and validating that it satisfies its intended purpose. Thorough testing is key.

- Clause 8 (Software Configuration Management): This covers how to control the evolution of the software throughout its lifecycle. Proper version control and change management procedures prevent uncontrolled modifications that could compromise safety and functionality.

Missing comprehensive documentation in these areas can lead to significant problems during audits and increase the risks associated with the medical device.

Q 13. How do you interpret and apply IEC standards to specific product designs?

Interpreting and applying IEC standards to specific product designs requires a thorough understanding of both the product and the relevant standards. It’s a process of careful mapping and integration.

- Identify applicable standards: Begin by identifying all applicable IEC standards based on the product’s function, intended use, and any relevant regulatory requirements.

- Hazard analysis and risk assessment: Conduct a thorough hazard analysis to identify potential hazards associated with the product. This involves considering various scenarios and potential failures.

- Requirements traceability: Map the IEC requirements to specific design elements and ensure that all aspects of the design meet the specified standards. A traceability matrix is invaluable for this process.

- Design verification and validation: Rigorous testing and validation procedures are required to ensure that the design meets the IEC requirements and performs as intended.

- Documentation: Maintain detailed documentation of all aspects of the design process, including the rationale for design choices, test results, and any deviations from the standards.

For instance, if designing a power supply, IEC 60950-1 (now largely superseded by IEC 62368-1) dictates requirements for safety, specifying clearances, insulation, and creepage distances. The design must incorporate these parameters to comply.

Q 14. Describe your experience with different IEC standards related to your field.

My experience with IEC standards spans a variety of areas, including safety, EMC, and software development. I have worked extensively with standards such as:

- IEC 60950-1 / IEC 62368-1: These standards define safety requirements for information technology equipment, which are crucial for ensuring the safety of electronic devices.

- IEC 61000 series (EMC): I’ve handled projects involving the design and testing of electronic devices for electromagnetic compatibility, addressing issues such as emissions and immunity to interference.

- IEC 62304: As previously discussed, I have significant experience applying this standard in the development of medical device software, ensuring that the software meets its safety and regulatory requirements.

- IEC 60601-1: This standard covers the basic safety and essential performance of medical electrical equipment, impacting the design and testing of medical devices.

In each case, my work involved a deep dive into the specifics of the standards, applying the principles to product designs, managing testing processes, and ensuring regulatory compliance. This included working with third-party certification bodies to obtain necessary approvals.

Q 15. What are the differences between type testing and routine testing in IEC standards?

Type testing and routine testing are both crucial parts of verifying the conformity of electrical equipment to IEC standards, but they differ significantly in scope and purpose.

Type testing is a comprehensive series of tests performed on a representative sample of a specific equipment design. Think of it as a rigorous examination of the design’s blueprint. It verifies that the design meets all the specified requirements of the relevant IEC standard. Results apply to the entire production run of that specific type of equipment, assuming no significant design changes occur. These tests are often performed by independent, accredited testing laboratories and documented extensively. For example, type testing for a circuit breaker might include tests for short-circuit withstand, thermal endurance, and dielectric strength.

Routine testing, on the other hand, is a more limited set of tests performed on each individual piece of equipment produced. It focuses on confirming that the manufacturing process consistently delivers products matching the type-tested design. Think of it as a quality check during mass production to ensure that no defects slipped through. It’s a sampling process, not exhaustive like type testing. For the same circuit breaker, routine testing might only include a functional test and a simple insulation resistance test.

In essence, type testing validates the design, while routine testing confirms the manufacturing process’s consistency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure traceability to specific requirements in an IEC compliant design?

Ensuring traceability to specific requirements in an IEC-compliant design is paramount for demonstrating compliance and facilitating any necessary investigations. It’s like building a house with a detailed blueprint – you need to be able to clearly see which part of the structure corresponds to which specification.

This traceability is achieved through a robust requirements management system. This typically involves:

- Clear Requirements Documentation: All requirements, derived from the relevant IEC standard and any additional customer or internal requirements, must be clearly documented, ideally using a requirements management tool. Each requirement should have a unique identifier.

- Design Traceability Matrix: A matrix is created that links each requirement to the specific design elements, components, or software modules that satisfy it. This is crucial for demonstrating compliance and also for debugging later if needed.

- Test Case Linking: Each requirement should have associated test cases designed to verify its fulfillment. The test results should be directly linked back to both the test cases and the original requirements.

- Version Control: The use of version control software is vital to track changes and ensure that the traceability links remain valid throughout the development lifecycle. This allows you to easily determine which version of the design corresponds to which set of requirements and test results.

For example, if an IEC standard requires a minimum insulation resistance value, the requirements document would state this, a design element would specify the chosen insulation material, the test plan would outline the insulation resistance measurement, and the test report would record the results. All of these elements are linked through the traceability matrix, providing a complete audit trail.

Q 17. Explain your understanding of safety integrity levels (SIL) and their determination.

Safety Integrity Levels (SILs) are a crucial concept in functional safety, quantifying the risk reduction provided by safety-related systems. They’re essentially a classification of the required safety performance. Imagine a traffic light: a higher SIL is like having more redundancy and robust safeguards to ensure its reliable operation.

SILs are defined according to IEC 61508 and related standards (e.g., IEC 61511 for process industries). They range from SIL 1 (lowest) to SIL 4 (highest), with each level representing a progressively higher level of safety and risk reduction. The assignment of a SIL is based on a risk assessment which considers the:

- Severity: How serious would the consequences of a failure be (e.g., minor injury, major injury, fatality)?

- Probability: How likely is it that the hazardous event will occur (frequency of operation, chance of failure)?

- Exposure: How many people are exposed to the hazard (frequency of people being in the area)?

A risk assessment determines a risk level which then dictates the required SIL. A higher risk level mandates a higher SIL. To achieve a specific SIL, the safety functions must meet specific requirements for probability of failure on demand (PFD) and hardware fault tolerance, based on the chosen architecture and components.

For instance, a simple safety system with low risk (e.g., a minor fault in a low voltage appliance) might require only SIL 1, while a safety system in a chemical plant controlling a potentially explosive process would likely need a much higher SIL, like SIL 3 or SIL 4, requiring more rigorous design and verification processes.

Q 18. Describe your experience with safety lifecycle management according to IEC standards.

Safety lifecycle management, according to IEC standards, involves a systematic approach to managing safety-related aspects throughout a product’s entire lifespan. It’s akin to a comprehensive healthcare plan for your product, ensuring it remains safe and reliable from its conception to its eventual decommissioning.

My experience encompasses all phases of this lifecycle, including:

- Concept and Feasibility: Identifying potential hazards and conducting preliminary risk assessments.

- Requirements Specification: Defining safety requirements based on the risk assessment and the relevant IEC standard(s).

- Design: Implementing safety functions and choosing components suitable for the target SIL.

- Verification and Validation: Conducting tests, analysis, and reviews to verify that the safety requirements are met.

- Production and Operation: Ensuring that the manufacturing process and operational procedures maintain safety levels.

- Maintenance and Decommissioning: Providing guidelines and procedures for safe maintenance and eventual decommissioning of the equipment.

In practice, I’ve been involved in projects where we used V-model and Agile methodologies, tailoring the safety lifecycle management process to suit each project’s specific context and complexity. I have experience with using tools to manage safety cases, track requirements and design changes, and document evidence to support claims of compliance.

Q 19. What is your experience with documentation for IEC compliance?

Documentation is the cornerstone of IEC compliance. Think of it as the detailed history of your project, meticulously recording every step of the journey. Without proper documentation, proving compliance is virtually impossible.

My experience includes creating and managing a wide variety of IEC-compliant documents, including:

- Safety Case: A comprehensive document that justifies the safety of the system, demonstrating that all necessary safety requirements have been met.

- Hazard and Operability Studies (HAZOP): Systematic hazard identification and risk assessment techniques used during the design phase.

- Failure Modes and Effects Analysis (FMEA): Identifying potential failures and their effects on the system.

- Functional Safety Requirements Specification: Details on safety functions and their performance requirements.

- Test Plans and Reports: Comprehensive documentation of testing activities and results.

- Technical Files: A complete record of all design, manufacturing, and verification activities.

I’m proficient in using various document management systems and ensuring that all documentation is clearly structured, consistently formatted, and easily searchable. I understand the importance of version control and maintain a rigorous process for document review and approval.

Q 20. How do you stay up-to-date with the latest changes and revisions of IEC standards?

Keeping abreast of the latest changes and revisions in IEC standards is crucial for maintaining compliance and leveraging the latest best practices in safety engineering. It’s a bit like staying updated with medical advances; you must constantly learn to provide the best and safest solutions.

My strategies for staying current include:

- Subscriptions to IEC newsletters and publications: I receive regular updates on new standards, revisions, and interpretations.

- Active participation in industry events and conferences: Attending conferences and workshops allows me to network with other experts and learn about the latest developments.

- Membership in professional organizations: Engaging with professional bodies offers access to expert resources and training.

- Monitoring IEC’s website: Regularly checking for updates and notifications regarding standard revisions.

- Following industry experts and journals: Staying informed about the latest trends and challenges in the field.

I also maintain a personal library of relevant IEC standards and utilize online databases for quick access to the latest information. This proactive approach ensures I’m always equipped with the knowledge needed to ensure the safety and compliance of my projects.

Q 21. Explain your understanding of the harmonization of IEC standards with other international standards.

Harmonization of IEC standards with other international standards, such as ISO and ANSI, is vital for creating a globally consistent approach to safety and technical regulations. It’s like having a universal language in the field of engineering, making it easier to collaborate internationally and to ensure that products meet consistent standards around the world.

This harmonization reduces duplication of efforts, minimizes trade barriers, and facilitates the wider acceptance of products globally. Many IEC standards are developed collaboratively with other standards bodies. This collaboration ensures that there is alignment and consistency to avoid conflicting requirements. For example, there is significant alignment between IEC 61508 (functional safety) and ISO 26262 (functional safety for automotive applications). While the application areas differ, they share similar principles and methodologies, minimizing the need for duplicate development efforts.

The harmonization isn’t always perfect, but the goal is to converge on common principles and methodologies wherever possible, to reduce the complexities of dealing with different regulatory frameworks. This fosters better communication between engineers around the world and facilitates the creation of safer and more reliable products.

Q 22. Describe your experience with the interpretation of IEC diagrams and specifications.

Interpreting IEC diagrams and specifications requires a methodical approach combining technical understanding with careful attention to detail. I’ve spent years working with various IEC standards, from those defining safety requirements for electrical appliances (like IEC 60335) to those specifying communication protocols (like IEC 61850). My experience encompasses understanding schematic diagrams, functional block diagrams, timing diagrams, and detailed technical specifications. For example, in one project involving IEC 61850, I had to interpret complex sequence diagrams to understand the communication between Intelligent Electronic Devices (IEDs) in a power substation. This involved not just understanding the individual messages but also the timing and sequence of those messages to ensure proper functionality and compliance. I’m proficient in using tools like specialized software for reviewing and analyzing these diagrams and specifications, ensuring accuracy and thoroughness in my interpretation.

I find success comes from breaking down complex diagrams into smaller, manageable parts. This helps to understand each component’s function and how it interacts with other parts of the system. I also rely heavily on cross-referencing information across multiple sections of the standard to ensure a comprehensive understanding.

Q 23. How would you approach investigating a non-compliance issue identified during testing?

Investigating a non-compliance issue requires a systematic approach. First, I’d meticulously reproduce the failure, documenting the exact conditions under which it occurred. This involves checking the test setup, the equipment used, and the procedure followed to rule out any errors in testing. Then, I’d carefully review the relevant sections of the IEC standard to pinpoint the specific requirement that wasn’t met. This often involves cross-referencing multiple clauses and interpreting potentially ambiguous wording. After clearly identifying the non-compliance, I would analyze the design and implementation to find the root cause. This might involve inspecting schematics, reviewing code, and conducting further targeted testing. Consider, for example, a situation where a device failed an EMC test according to IEC 61000-4-2 (ESD immunity). I would systematically check the circuit design for ESD protection components, verify their correct placement and values, and potentially run simulations to identify weaknesses.

Once the root cause is identified, I’d propose solutions and verification methods. This could involve circuit modifications, firmware updates, or even a change in the test methodology if the initial testing proved flawed. Finally, I’d document the entire investigation process thoroughly, including the findings, proposed solutions, and verification results to prevent similar occurrences.

Q 24. Explain your experience using IEC related testing equipment.

My experience with IEC-related testing equipment is extensive and covers a wide range of instruments. This includes oscilloscopes, spectrum analyzers, power meters, and specialized equipment like surge generators and ESD guns, all used for testing compliance to standards such as IEC 61000 (EMC), IEC 60335 (safety), and IEC 60950 (safety of IT equipment). I am proficient in operating and calibrating these instruments, understanding their limitations, and interpreting the results accurately. For instance, when performing EMC testing according to IEC 61000-4-x standards, I use spectrum analyzers to measure conducted and radiated emissions, and surge generators to test immunity to transient disturbances. I am familiar with the various calibration procedures required to ensure the accuracy of measurements.

Beyond the basic operation, I understand the importance of selecting the right equipment for the specific test, adhering to correct measurement techniques, and troubleshooting any equipment malfunctions that may arise during testing. I also possess experience with automated test systems, significantly improving efficiency and repeatability during testing.

Q 25. What are some common pitfalls when working with IEC standards and how do you avoid them?

Working with IEC standards presents several common pitfalls. One is misinterpreting the standard’s requirements. The language can be dense and technical, leading to incorrect implementation. For instance, the difference between ‘shall’ and ‘should’ in a standard carries significant weight regarding compliance. Another common mistake is overlooking amendments or errata. Standards are often updated, and using an outdated version can lead to non-compliance. A third pitfall is a lack of consideration for all applicable standards. A product might need to comply with multiple IEC standards, and overlooking one can have serious consequences. Finally, poor test planning and inadequate documentation can result in inaccurate testing and inconclusive results.

To avoid these issues, I always ensure to utilize the latest versions of the relevant standards. I cross-reference information from various sections to eliminate ambiguities, and I pay close attention to the nuances of the language used. Comprehensive test planning is crucial, and meticulous record-keeping ensures traceability and reproducibility of results. Using checklists and standardized procedures reduces the likelihood of human error and helps maintain consistency across projects.

Q 26. How would you explain the concepts of IEC standards to a non-technical audience?

Explaining IEC standards to a non-technical audience requires simple analogies and avoiding technical jargon. I often describe IEC standards as a set of globally recognized rules and guidelines ensuring safety, interoperability, and quality of electrical equipment and systems. They’re like the building codes for electronics, making sure that appliances are safe to use and that different devices can work together seamlessly. For example, the standards specify requirements for safe operation of a washing machine (avoiding electric shocks) or ensuring that a smart home device can communicate properly with other devices in the network. These standards help protect consumers and foster a stable and reliable marketplace for electronic products.

I use real-world examples to illustrate the impact of IEC standards. I might explain how the standards ensure the safety of household appliances by preventing electrical shocks or fires. Or I could explain how standardization enables interoperability, allowing different brands of devices to communicate and work together in a home network.

Q 27. Describe your experience in contributing to the development or revision of IEC standards.

While I haven’t directly contributed to the formal development or revision of IEC standards, my experience includes active participation in industry working groups and forums that influence the direction and interpretation of these standards. This involvement has allowed me to provide feedback on the clarity, feasibility, and practical application of existing standards and propose modifications based on real-world experiences. For example, I’ve participated in discussions regarding the practical challenges of implementing certain EMC requirements in specific product categories, contributing to a better understanding of the industry’s needs and potential adjustments to the standards. This indirect contribution is vital in ensuring the relevance and effectiveness of these crucial documents.

My contributions focus primarily on the practical application of standards and identifying potential ambiguities or areas requiring further clarification. This ensures that the standards are not only technically sound but also realistically achievable for manufacturers.

Q 28. What are some of the limitations or challenges associated with IEC standards?

Despite their importance, IEC standards do have limitations. One is that they may not always be fully up-to-date with rapid technological advancements. New technologies sometimes emerge faster than the standards can adapt, creating gaps in coverage. Another challenge is the potential for ambiguity in interpretation. The wording in standards can sometimes be open to different interpretations, leading to inconsistencies in implementation. Also, the sheer number of standards and their complexity can make compliance a daunting task for manufacturers, especially for smaller companies. Finally, enforcing compliance globally can be difficult, particularly in regions with less stringent regulatory oversight. This can lead to products that don’t meet the safety and interoperability standards set by the IEC entering the market.

Despite these limitations, IEC standards remain essential for ensuring the safety and interoperability of electrical products and systems worldwide. The ongoing efforts by the IEC to update and clarify standards address many of these challenges, albeit imperfectly.

Key Topics to Learn for IEC Standards Interview

- IEC 60050 International Electrotechnical Vocabulary (IEV): Understanding the standardized terminology and definitions is crucial for clear communication and comprehension of other IEC standards.

- Safety Standards (e.g., IEC 60950, IEC 62368): Learn about the practical application of these standards in ensuring product safety and compliance, including risk assessment methodologies and testing procedures.

- Electromagnetic Compatibility (EMC) Standards (e.g., IEC 61000): Explore the principles of EMC, including emission and immunity testing, and how to design products that meet these requirements. Understand the implications of non-compliance.

- Specific Standards for Your Field: Identify the IEC standards most relevant to your specialization (e.g., power systems, medical devices, industrial automation) and delve deeper into their specific requirements and implications.

- Standard Development Process: Familiarize yourself with how IEC standards are developed, reviewed, and updated. This provides valuable context for understanding the rationale behind specific requirements.

- Problem-Solving with IEC Standards: Practice applying your knowledge to hypothetical scenarios involving compliance issues, design challenges, or interpretation of standard clauses. Consider how to approach conflicting requirements.

- Certification and Compliance: Understand the various certification bodies and processes involved in demonstrating compliance with IEC standards. This includes the role of testing laboratories and conformity assessment procedures.

Next Steps

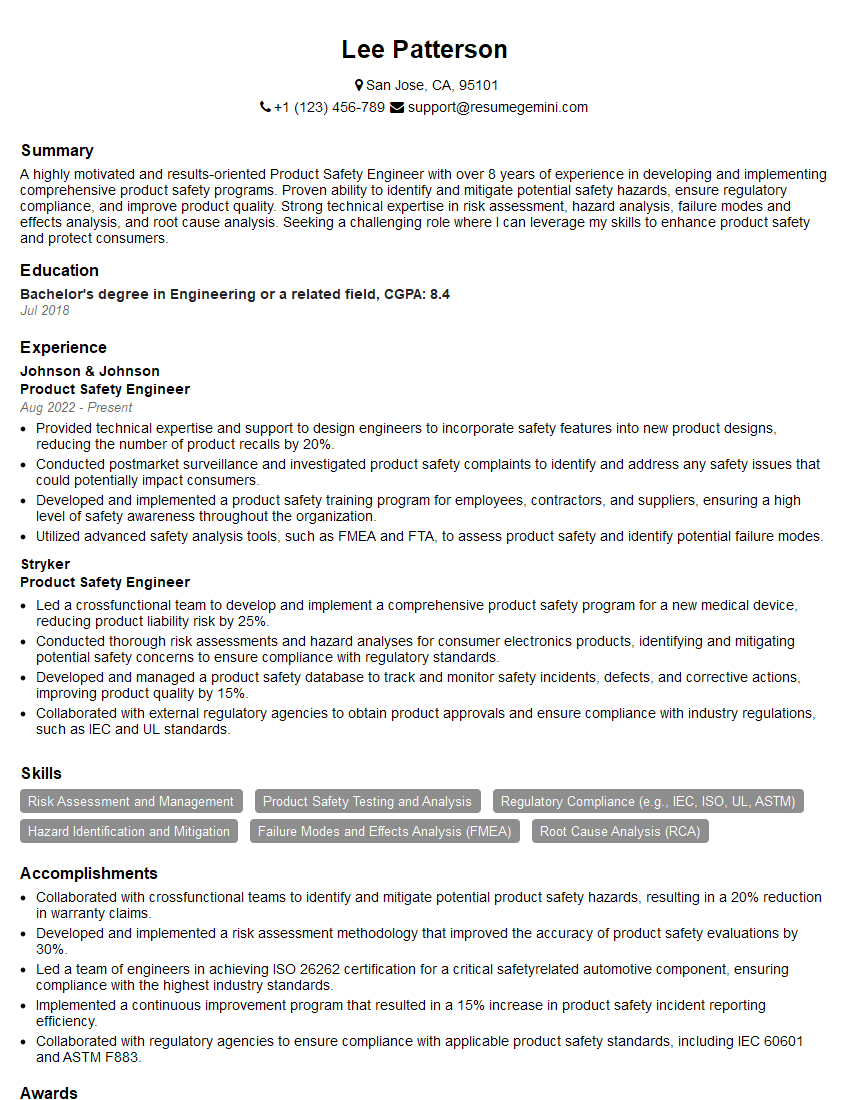

Mastering IEC Standards significantly enhances your career prospects in electrical engineering and related fields, opening doors to advanced roles and increased earning potential. A strong understanding of these standards demonstrates competence and commitment to safety and quality, highly valued by employers. To maximize your job search success, it’s essential to create an ATS-friendly resume that effectively showcases your skills and experience. We highly recommend using ResumeGemini to build a professional and impactful resume tailored to your specific field. ResumeGemini provides valuable resources and examples of resumes optimized for keywords related to IEC Standards, ensuring your application gets noticed. Examples of resumes tailored to IEC Standards are available.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO