Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Supply Chain Management (SCM) Systems interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Supply Chain Management (SCM) Systems Interview

Q 1. Explain the concept of bullwhip effect and how to mitigate it.

The bullwhip effect is a phenomenon in supply chains where demand variability is amplified as you move upstream in the supply chain. Imagine a simple chain – retailer, distributor, manufacturer. A small increase in demand at the retailer level can lead to a much larger order placed with the distributor, who in turn orders a significantly larger quantity from the manufacturer. This distortion causes inefficiencies like excess inventory, lost sales due to stockouts, and increased costs.

Mitigating the bullwhip effect requires collaborative efforts across the supply chain. Key strategies include:

- Improved information sharing: Implementing systems that provide real-time visibility into demand and inventory levels across the entire chain. This allows for better forecasting and more accurate ordering.

- Demand forecasting techniques: Using advanced forecasting methods that consider seasonality, trends, and external factors, reducing reliance on simple extrapolations of past data.

- Vendor Managed Inventory (VMI): Allowing key suppliers to manage inventory levels at your facilities, leveraging their expertise and insights into demand patterns.

- Reducing lead times: Streamlining processes and optimizing logistics to shorten the time it takes to fulfill orders. Shorter lead times reduce the need for large safety stocks.

- Everyday low pricing (EDLP): Reducing price fluctuations can smooth demand and lessen the bullwhip effect.

- Collaborative planning, forecasting, and replenishment (CPFR): Working closely with supply chain partners to share forecasts, plans, and inventory data, leading to a more coordinated and responsive supply chain.

For example, I worked with a food retailer that implemented CPFR with its major suppliers. This resulted in a 20% reduction in inventory holding costs and a 15% improvement in on-time delivery.

Q 2. Describe your experience with different inventory management techniques (e.g., FIFO, LIFO, EOQ).

I have extensive experience with various inventory management techniques. First-In, First-Out (FIFO) is ideal for perishable goods, ensuring that older items are sold first to minimize waste. Last-In, First-Out (LIFO) is less commonly used for physical inventory due to accounting implications but can be relevant in certain contexts. Economic Order Quantity (EOQ) is a model that helps determine the optimal order size to minimize the total cost of inventory, considering ordering costs and holding costs.

In a previous role, we used FIFO for managing fresh produce in a grocery chain. This minimized spoilage and maintained product quality. We also applied EOQ to optimize the ordering of non-perishable items like canned goods, reducing warehousing costs significantly. I’ve also worked with more advanced techniques like just-in-time (JIT) inventory management, aiming for minimal inventory levels by coordinating production and delivery very closely. The success of these methods depends greatly on reliable suppliers and accurate demand forecasting. Furthermore, I’ve incorporated ABC analysis to prioritize inventory management efforts on high-value items, ensuring optimal control over critical stock.

Q 3. What are the key performance indicators (KPIs) you would use to measure supply chain efficiency?

Measuring supply chain efficiency involves tracking several key performance indicators (KPIs). These KPIs provide insights into different aspects of the supply chain’s performance, allowing for identification of areas for improvement.

- On-time delivery rate: The percentage of orders delivered on or before the promised delivery date.

- Inventory turnover rate: The number of times inventory is sold and replaced over a specific period. A higher rate generally indicates efficient inventory management.

- Lead time: The time it takes to fulfill an order, from order placement to delivery. Shorter lead times are generally preferred.

- Order fulfillment cycle time: The total time from order placement to customer receipt. This encompasses order processing, picking, packing, and shipping.

- Perfect order rate: The percentage of orders delivered completely and accurately, without any errors or delays.

- Customer order cycle time: Time from customer order placement to order receipt. It measures the responsiveness of the supply chain.

- Total supply chain cost: The sum of all costs associated with the supply chain, including procurement, manufacturing, logistics, and warehousing.

- Return on assets (ROA): Measures the profitability relative to total assets invested in the supply chain.

By monitoring these KPIs, we can identify bottlenecks and areas that need improvement, leading to a more efficient and cost-effective supply chain.

Q 4. How do you handle supply chain disruptions?

Handling supply chain disruptions requires a proactive and well-defined strategy. My approach involves:

- Risk assessment and mitigation: Identifying potential disruptions (natural disasters, geopolitical instability, supplier failures) and developing contingency plans to minimize their impact.

- Diversification of suppliers: Reducing reliance on a single supplier to mitigate the risk of supply shortages due to disruptions at one supplier.

- Inventory management: Holding appropriate safety stock levels for critical items to buffer against unexpected demand fluctuations or supply disruptions.

- Alternative sourcing strategies: Having backup suppliers or alternative sourcing options readily available in case of disruptions.

- Real-time monitoring and communication: Using technology to monitor supply chain events and communicate effectively with suppliers and customers.

- Agile response and adaptation: Having the ability to quickly adapt to changing circumstances and make necessary adjustments to the supply chain plan.

For instance, during a recent pandemic-related disruption, we leveraged our existing relationships with secondary suppliers to secure critical components. This prevented significant production delays and maintained customer service levels.

Q 5. Explain your experience with different transportation modes and their selection criteria.

My experience encompasses various transportation modes, including road, rail, air, and sea freight. The selection of the optimal mode depends on several factors:

- Cost: Each mode has different cost structures, with road freight generally being the least expensive for shorter distances, while sea freight is often the most economical for long distances.

- Speed: Air freight offers the fastest delivery but is significantly more expensive. Rail and sea freight are slower but often more cost-effective for large volumes.

- Reliability: Reliability can vary depending on factors like weather conditions and infrastructure.

- Capacity: Sea freight has the highest capacity, followed by rail, then road, and finally air freight.

- Product characteristics: Fragile or perishable goods may necessitate faster and more reliable modes like air freight.

- Distance: Distance plays a key role in mode selection, with shorter distances often favoring road freight, and longer distances favoring sea or rail freight.

In one project, we optimized a global supply chain by utilizing a combination of sea freight for bulk shipments and air freight for expedited delivery of critical components. This strategy reduced overall transportation costs while ensuring timely delivery.

Q 6. What is your experience with Warehouse Management Systems (WMS)?

My experience with Warehouse Management Systems (WMS) is extensive. I’ve implemented and managed several WMS across different organizations. A well-designed WMS is crucial for optimizing warehouse operations and minimizing costs. Key functionalities I’ve worked with include:

- Inventory tracking and management: Accurately tracking inventory levels, location, and movement within the warehouse.

- Order management: Processing and managing orders, including picking, packing, and shipping.

- Receiving and put-away: Managing the receipt of goods and their efficient placement in the warehouse.

- Labor management: Optimizing labor productivity by assigning tasks and tracking employee performance.

- Warehouse layout optimization: Using the WMS to improve the warehouse layout and optimize material flow.

- Integration with other systems: Seamlessly integrating the WMS with other systems, such as ERP and TMS, to create a holistic supply chain solution.

In a previous role, we implemented a new WMS that resulted in a 15% reduction in order fulfillment time and a 10% improvement in warehouse space utilization.

Q 7. Describe your experience with Transportation Management Systems (TMS).

My experience with Transportation Management Systems (TMS) includes selection, implementation, and optimization. TMS are critical for efficient transportation planning and execution. Key features I’ve utilized include:

- Route optimization: Planning efficient routes to minimize transportation costs and delivery times.

- Carrier selection: Identifying and selecting the most suitable carriers based on cost, reliability, and capacity.

- Shipment tracking and monitoring: Tracking shipments in real-time and providing visibility into their status.

- Dock scheduling: Optimizing the loading and unloading process at warehouses to improve efficiency and reduce delays.

- Yard management: Managing the movement of trucks and trailers within the warehouse yard.

- Freight auditing: Verifying freight invoices for accuracy and identifying potential cost savings.

By implementing a robust TMS, we were able to reduce transportation costs by 12% and improve on-time delivery by 8% in a previous logistics project. I have experience with both cloud-based and on-premise TMS solutions and understand the integration needs with other systems.

Q 8. How do you leverage data analytics to improve supply chain performance?

Data analytics is the backbone of modern supply chain optimization. We leverage it to gain actionable insights from the massive amounts of data generated throughout the supply chain – from procurement to delivery. This allows us to identify bottlenecks, predict disruptions, and improve efficiency.

- Predictive Analytics for Demand Forecasting: By analyzing historical sales data, market trends, and external factors (weather, economic indicators), we build predictive models to forecast demand more accurately. This minimizes stockouts and overstocking, saving significant costs. For example, analyzing past sales data alongside weather patterns allowed a retailer to accurately predict increased demand for umbrellas during hurricane season, enabling them to proactively increase inventory.

- Prescriptive Analytics for Optimization: We use advanced analytics to suggest optimal solutions for complex supply chain problems. This includes optimizing transportation routes, warehouse locations, and inventory levels. For instance, using linear programming techniques, we can find the most cost-effective way to distribute goods from multiple warehouses to various retail locations, taking into account transportation costs, delivery times, and warehouse capacities.

- Real-time Monitoring and Anomaly Detection: Data analytics allows us to monitor key performance indicators (KPIs) in real-time, such as inventory levels, delivery times, and supplier performance. Anomaly detection algorithms can flag unusual patterns, allowing us to react quickly to potential issues, such as supplier delays or unexpected demand surges. Imagine a system alerting us to a sudden drop in a specific product’s sales, hinting at a potential issue like a competitor’s new product launch, allowing for a timely marketing response.

Q 9. Explain your understanding of different forecasting methods.

Forecasting methods are crucial for accurate demand prediction. They range from simple to sophisticated techniques, each with its strengths and weaknesses.

- Qualitative Methods: These rely on expert judgment and opinion, suitable when historical data is scarce. Examples include market research surveys and Delphi methods.

- Quantitative Methods: These use mathematical models and historical data. Common techniques include:

- Moving Average: A simple method averaging demand over a specific period. Useful for stable demand patterns.

- Exponential Smoothing: Assigns exponentially decreasing weights to older data, better for detecting trends.

- ARIMA (Autoregressive Integrated Moving Average): A more complex statistical model capable of handling seasonality and trends.

- Machine Learning (ML) Models: Advanced techniques like time series analysis with ML algorithms (e.g., LSTM networks) provide highly accurate forecasts by considering complex patterns and external factors.

The choice of method depends on factors like data availability, demand pattern complexity, and forecasting horizon. Often, a hybrid approach combining qualitative and quantitative methods yields the most accurate results.

Q 10. What is your experience with Supply Chain Planning (SCP) software?

I have extensive experience with various Supply Chain Planning (SCP) software solutions, including SAP SCM, Oracle SCM Cloud, and Blue Yonder. My experience encompasses implementing, configuring, and optimizing these systems to improve planning accuracy and efficiency. This involves defining planning parameters, customizing workflows, integrating with ERP systems, and training users. For example, in a previous role, I successfully implemented SAP SCM to optimize our production planning process, resulting in a 15% reduction in lead times and a 10% decrease in inventory holding costs.

My expertise extends to leveraging the advanced analytical capabilities of these systems for demand planning, production scheduling, and inventory optimization. I’m proficient in configuring rules and algorithms to automate key planning tasks, reducing manual effort and improving decision-making.

Q 11. How do you ensure supply chain visibility?

Supply chain visibility is achieved through real-time tracking and monitoring of goods and information across the entire supply chain network. Think of it like having a GPS tracking system for every item and every step of the process. This requires a combination of technologies and strategies:

- Real-time Tracking Technologies: RFID, GPS, barcode scanners, and IoT sensors provide real-time data on product location and condition.

- Data Integration and Analytics Platforms: Centralized platforms integrate data from various sources (ERP, TMS, WMS) to provide a holistic view of the supply chain. Advanced analytics then transform raw data into actionable intelligence.

- Collaborative Platforms: Sharing real-time data with suppliers, customers, and logistics partners ensures transparency and facilitates proactive problem-solving. Collaboration platforms enable open communication and real-time visibility of the supply chain status.

- Supply Chain Mapping: Creating a visual representation of the entire supply chain helps identify potential vulnerabilities and areas for improvement.

Effective supply chain visibility enables quicker reaction to disruptions, better inventory management, and enhanced customer service. For example, during a recent transportation disruption, our real-time tracking system allowed us to reroute shipments and minimize delays, avoiding a significant loss of revenue and maintaining customer satisfaction.

Q 12. Describe your experience with Supplier Relationship Management (SRM).

Supplier Relationship Management (SRM) is all about building and maintaining strong relationships with key suppliers. It’s not just about procurement; it’s about collaboration, trust, and mutual benefit. Effective SRM requires a systematic approach:

- Supplier Selection and Qualification: Rigorous processes ensure we select reliable and capable suppliers who align with our quality and ethical standards.

- Performance Monitoring and Evaluation: Regularly tracking supplier performance using KPIs helps identify areas for improvement and potential risks.

- Collaboration and Communication: Open communication channels ensure efficient information flow and collaborative problem-solving.

- Risk Management: Identifying and mitigating potential risks (e.g., supply disruptions, quality issues) is crucial for supply chain resilience.

- Technology Integration: Using SRM software to manage supplier information, contracts, and performance data streamlines processes and improves efficiency.

In a previous role, I implemented a comprehensive SRM program that resulted in a 10% reduction in supplier lead times and a 5% decrease in procurement costs. This involved establishing clear communication protocols, implementing a standardized performance evaluation system, and leveraging SRM software to automate various tasks.

Q 13. What is your experience with demand forecasting and planning?

Demand forecasting and planning are critical functions within supply chain management. Accurate forecasting is the foundation for effective inventory management, production scheduling, and resource allocation. My experience spans various forecasting techniques and planning methodologies.

- Demand Forecasting: I’ve used a range of methods, from simple moving averages to sophisticated machine learning models, tailoring the approach to the specific product and market characteristics. This includes considering seasonality, trends, and external factors (economic indicators, promotions, etc.).

- Demand Planning: This involves translating the forecast into actionable plans, considering production capacity, inventory levels, and customer service requirements. This includes sales and operations planning (S&OP) processes to align demand forecasts with supply capabilities across the organization. I’ve facilitated numerous S&OP meetings, driving collaboration between sales, marketing, and operations teams.

- Software Usage: My experience includes utilizing specialized demand planning software (e.g., Demand Solutions, Anaplan) to build and manage forecasting models, analyze data, and create actionable plans. This also included the implementation of various statistical methods for forecasting accuracy improvement, resulting in the reduction of forecasting errors in several product lines.

Q 14. How do you manage inventory levels to optimize costs and service levels?

Managing inventory levels is a balancing act between minimizing costs and ensuring sufficient stock to meet customer demand. Finding the optimal balance requires a strategic approach:

- Inventory Control Systems: Implementing robust inventory management systems (WMS – Warehouse Management Systems) provides real-time visibility into inventory levels and facilitates accurate tracking. This system will give up-to-the-minute information on location and quantity of inventory, alerting us to potentially running low on stock.

- Inventory Optimization Techniques: Various techniques, such as Economic Order Quantity (EOQ) and safety stock calculations, help determine optimal order quantities and safety stock levels to buffer against demand variability and lead time uncertainty. These calculations are based on factors like demand, lead time, storage costs, and desired service level.

- Demand Forecasting Accuracy: Accurate demand forecasting is crucial for minimizing excess inventory. More accurate forecasts lead to less waste from overstocking and less risk of stockouts.

- Supplier Relationships: Strong relationships with suppliers enable more efficient inventory management through reliable and timely deliveries.

- Continuous Improvement: Regularly reviewing inventory levels, order quantities, and lead times helps identify opportunities for optimization and cost reduction.

In my experience, optimizing inventory management through these methods has resulted in significant cost savings and improved service levels. For instance, by implementing EOQ calculations and optimizing our supplier relationships, we achieved a 7% reduction in inventory holding costs and a 5% increase in on-time delivery.

Q 15. Explain your understanding of different supply chain strategies (e.g., agile, lean).

Supply chain strategies are approaches companies use to manage the flow of goods and services from origin to consumption. Two prominent strategies are Lean and Agile. Lean focuses on eliminating waste and maximizing efficiency throughout the entire supply chain. Think of it like a well-oiled machine—every movement is purposeful, minimizing inventory and maximizing speed. This works best for products with stable, predictable demand, such as staple food items. Agile, on the other hand, prioritizes flexibility and responsiveness to changes in demand. It’s like a nimble dancer, adapting quickly to market fluctuations. This is ideal for products with unpredictable demand, such as fashion items or electronics with short product lifecycles.

- Lean: Emphasizes waste reduction (muda) through techniques like Kaizen (continuous improvement), Just-in-Time (JIT) inventory management, and value stream mapping. Example: Toyota’s production system is a prime example of lean principles in action.

- Agile: Focuses on rapid response to changing customer demands and market conditions. This involves close collaboration with suppliers, flexible manufacturing processes, and postponement of final product configuration until orders are received. Example: A company selling personalized t-shirts online uses an agile approach, printing only when an order is placed.

Other strategies include Risk-Hedging (focused on mitigating disruptions), Responsiveness (emphasizing speed and flexibility), and Relationship-Based (prioritizing strong supplier partnerships).

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What experience do you have with implementing or improving SCM systems?

In my previous role at ABC Corp, I led the implementation of a new Warehouse Management System (WMS). This involved a complete overhaul of their existing system, which was outdated and inefficient. My team and I followed a phased approach:

- Needs Assessment: We started by conducting thorough interviews with warehouse staff to understand their pain points and identify areas for improvement.

- System Selection: We evaluated different WMS solutions based on functionality, scalability, and integration capabilities, eventually selecting a cloud-based solution from XYZ Software.

- Implementation: We managed the project timeline, coordinated with vendors, and oversaw the data migration process. This included extensive training for warehouse personnel on the new system.

- Post-Implementation Support: We provided ongoing support and addressed any issues that arose after the go-live. We also tracked key performance indicators (KPIs) to measure the system’s effectiveness.

The result was a significant reduction in order fulfillment times, improved inventory accuracy, and a considerable decrease in operational costs. We also saw a boost in employee satisfaction thanks to the more user-friendly and efficient system. In another project, I helped optimize a company’s supply chain network by leveraging advanced analytics to identify inefficiencies and optimize transportation routes, leading to a 15% reduction in shipping costs.

Q 17. How do you measure the ROI of a supply chain improvement project?

Measuring the ROI of a supply chain improvement project requires a comprehensive approach. We need to compare the costs incurred with the benefits achieved, both tangible and intangible.

- Cost Calculation: This includes project implementation costs (software, consultants, training), operational changes, and any initial investment in new equipment or technology.

- Benefit Identification: Tangible benefits might be reduced inventory holding costs, lower transportation expenses, or improved on-time delivery. Intangible benefits could include improved customer satisfaction and brand reputation.

- ROI Calculation: A simple ROI calculation is:

(Total Benefits - Total Costs) / Total Costs. For example, if a project costs $100,000 and yields $150,000 in benefits, the ROI is 50%. However, it’s crucial to consider the time horizon, possibly using Net Present Value (NPV) or Internal Rate of Return (IRR) for more sophisticated analysis.

It’s essential to track KPIs like inventory turnover, order fulfillment cycle time, and customer satisfaction levels both before and after the project to accurately measure its impact.

Q 18. Describe a time you had to solve a complex supply chain problem.

During a major port strike, a critical component for our manufacturing process was delayed, threatening production and potentially significant financial losses. My team and I immediately convened an emergency meeting. We implemented a three-pronged strategy:

- Identify Alternative Suppliers: We quickly researched and qualified alternative suppliers for the affected component, negotiating expedited shipping terms.

- Adjust Production Schedule: We adjusted our production schedule to prioritize the assembly of products that didn’t require the delayed component, minimizing downtime.

- Communicate with Stakeholders: We proactively communicated the situation to our customers, managing expectations and ensuring transparency.

Through effective collaboration and quick decision-making, we successfully mitigated the impact of the strike, minimizing production disruption and averting significant financial losses. This experience highlighted the importance of having robust contingency plans and maintaining strong relationships with diverse suppliers.

Q 19. What are your experience with different types of supply chain software?

My experience encompasses various supply chain software solutions, including:

- Enterprise Resource Planning (ERP) systems: Such as SAP, Oracle, and Infor. I’ve worked extensively with these systems to manage inventory, track orders, and plan production.

- Warehouse Management Systems (WMS): Including Blue Yonder and Manhattan Associates. I’ve utilized these to optimize warehouse operations, improve inventory accuracy, and streamline order fulfillment.

- Transportation Management Systems (TMS): Like Oracle Transportation Management. I’ve used these to plan and optimize transportation routes, manage carriers, and track shipments.

- Supply Chain Planning (SCP) software: I have experience using such tools to forecast demand, optimize inventory levels, and plan production schedules.

My expertise isn’t limited to using these systems; I also have experience in integrating different software systems to ensure seamless data flow across the supply chain. I’m comfortable with both cloud-based and on-premise solutions.

Q 20. Explain your understanding of different types of demand patterns.

Demand patterns describe how customer demand for a product changes over time. Understanding these patterns is vital for accurate forecasting and efficient inventory management. Some common types include:

- Seasonal: Demand fluctuates predictably throughout the year (e.g., increased demand for ice cream in summer).

- Trend: A long-term increase or decrease in demand (e.g., steadily growing demand for electric vehicles).

- Cyclical: Demand fluctuates over longer periods, often influenced by economic cycles (e.g., fluctuations in housing construction during economic booms and busts).

- Random: Unpredictable fluctuations that cannot be explained by any pattern (e.g., sudden spikes in demand due to unexpected events).

- Level (or Stable): Demand remains relatively constant over time (e.g., demand for basic necessities).

Accurate forecasting requires identifying the dominant patterns and using appropriate forecasting techniques to predict future demand. This knowledge is crucial for effective inventory management, production planning, and resource allocation.

Q 21. How do you ensure compliance with relevant regulations and standards within a supply chain?

Ensuring compliance within a supply chain involves a multifaceted approach. It’s not just about meeting legal requirements; it also encompasses ethical considerations and corporate social responsibility. Key aspects include:

- Understanding Relevant Regulations: Thorough knowledge of laws and regulations, such as those related to product safety, environmental protection, labor standards (e.g., Fair Labor Standards Act, California Transparency in Supply Chains Act), and import/export controls (e.g., tariffs, sanctions) is essential.

- Supplier Audits and Due Diligence: Regular audits of suppliers to ensure they adhere to the required standards. This includes assessing their environmental practices, labor conditions, and business ethics.

- Traceability and Transparency: Implementing systems to track products and materials throughout the supply chain, enabling efficient recall management and demonstrating compliance to stakeholders.

- Documentation and Record Keeping: Maintaining comprehensive documentation to demonstrate compliance with all relevant regulations and internal policies. This might include certificates, licenses, and audit reports.

- Training and Awareness: Providing training to employees on relevant regulations and ethical guidelines to foster a culture of compliance.

By integrating compliance into every aspect of the supply chain, from sourcing to delivery, organizations can minimize risks, enhance reputation, and build trust with consumers and other stakeholders.

Q 22. Describe your experience using ERP systems in a supply chain context.

My experience with ERP systems in supply chain management spans over eight years, primarily working with SAP and Oracle systems. I’ve utilized these systems across various roles, from supply planning to procurement and inventory management. For example, in my previous role at XYZ Corporation, I leveraged SAP’s integrated planning capabilities to significantly reduce our inventory holding costs by 15% within a year. This involved optimizing our forecasting models, integrating them with our production planning module, and improving data accuracy throughout the system. I also have extensive experience using these systems to manage supplier relationships, track shipments, and monitor key performance indicators (KPIs) like on-time delivery and fill rates. Beyond the standard functionalities, I’ve been involved in custom report development and system enhancements to better address specific business needs, such as implementing a customized dashboard for real-time visibility into key supply chain metrics.

In another project, we used Oracle’s advanced analytics capabilities to predict potential supply disruptions based on historical data and external factors like weather patterns and geopolitical events. This proactive approach allowed us to mitigate risks and avoid significant production delays.

Q 23. How would you design a robust supply chain risk management framework?

A robust supply chain risk management framework requires a multi-faceted approach. Think of it like building a house – you need a solid foundation, strong walls, and a protective roof. First, we need a strong foundation of risk identification. This involves analyzing potential disruptions across the entire supply chain, from raw material sourcing to final product delivery. This includes identifying risks like supplier failures, natural disasters, geopolitical instability, and pandemics. Techniques include SWOT analysis, PESTLE analysis, and scenario planning.

Next, we build the ‘walls’ with risk assessment and prioritization. We evaluate the likelihood and potential impact of each identified risk using qualitative and quantitative methods. This helps us focus on the most critical risks first. For instance, a low-likelihood but high-impact risk like a pandemic requires different mitigation strategies than a high-likelihood, low-impact risk like minor supplier delays.

Finally, the ‘roof’ comes in the form of risk mitigation and response planning. This phase involves developing specific strategies to reduce the likelihood or impact of each identified risk. These strategies can include diversification of suppliers, establishing robust inventory buffers, developing contingency plans, and implementing technology solutions like real-time tracking and predictive analytics. Regular monitoring and review are crucial to adapt to changing circumstances and ensure the framework remains effective. For example, following a disruption, a post-incident review helps improve future response plans.

Q 24. What is your experience with blockchain technology in supply chain management?

My experience with blockchain technology in supply chain management is still developing, but I’m actively exploring its potential. I’ve participated in workshops and training sessions focused on the practical applications of blockchain for enhancing traceability and transparency. I understand its potential to revolutionize supply chain operations by providing immutable records of transactions and product movements. Imagine a system where every step of a product’s journey – from origin to consumer – is recorded on a secure, distributed ledger. This offers significant improvements in terms of product authenticity, fraud prevention, and improved efficiency in tracking and recall management.

For example, blockchain can be used to track the origin of food products, ensuring consumers have confidence in their authenticity and ethical sourcing. Similarly, it can track the movement of pharmaceuticals, preventing counterfeiting and ensuring product integrity. However, the widespread adoption of blockchain in supply chain management requires addressing challenges related to scalability, interoperability, and the need for widespread industry standardization. My interest lies in understanding how we can overcome these hurdles to maximize blockchain’s potential in improving efficiency and transparency.

Q 25. How do you balance cost optimization with customer service expectations?

Balancing cost optimization with customer service expectations is a delicate act of juggling. It’s not about choosing one over the other, but finding the optimal balance that maximizes overall profitability and customer satisfaction. This requires a deep understanding of both cost drivers and customer needs. Think of it as finding the sweet spot on a seesaw – too much weight on one side (cost or customer service) will tip the scales.

Strategies to achieve this balance include: utilizing data-driven decision-making to identify areas for cost reduction without compromising service levels; employing lean manufacturing principles to streamline processes and eliminate waste; investing in technology to improve efficiency and reduce operational costs; and proactively managing customer expectations through transparent communication and setting realistic service level agreements (SLAs). For example, offering expedited shipping at a premium price caters to customers willing to pay for faster delivery while maintaining cost-effective standard shipping options. Regularly reviewing customer feedback and market trends helps ensure alignment with evolving customer expectations and adapt accordingly.

Q 26. Describe your experience with different sourcing strategies.

My experience encompasses a range of sourcing strategies, including single sourcing, multiple sourcing, and global sourcing. Each strategy has its advantages and disadvantages, and the best choice depends on various factors, such as the nature of the product, the supplier landscape, and risk tolerance. Single sourcing, for example, can lead to strong supplier relationships and economies of scale, but it also increases the risk of supply disruptions if the sole supplier encounters problems. In contrast, multiple sourcing diversifies risk but can lead to higher administrative costs and potentially lower quality consistency.

I’ve successfully implemented multiple sourcing strategies for commodity items, leveraging competitive bidding to secure the best prices while ensuring sufficient supply. For critical components, I’ve focused on dual sourcing or even triple sourcing to mitigate risks. In other scenarios, global sourcing has been essential for accessing specialized suppliers or lower-cost manufacturing locations. However, global sourcing introduces complexities related to logistics, regulatory compliance, and potential geopolitical risks. In each case, the selection of a sourcing strategy requires a careful evaluation of the trade-offs and consideration of potential risks and opportunities.

Q 27. Explain your understanding of the concept of supply chain resilience.

Supply chain resilience refers to a supply chain’s ability to withstand and recover quickly from disruptions. It’s the ability to bounce back from unforeseen events, whether it’s a natural disaster, a pandemic, or geopolitical instability. A resilient supply chain minimizes the impact of these disruptions on its operations and continues to deliver products or services to customers without significant delays or quality compromises.

Building resilience requires a proactive approach, including diversifying sources of supply, building strategic inventories, developing contingency plans, and investing in flexible and adaptable infrastructure and technology. Think of a forest – individual trees can be susceptible to damage, but a diverse forest with strong root systems is far more resilient to a storm. Similarly, a resilient supply chain needs diversity, redundancy, and robust planning to withstand various shocks.

For example, a company might establish multiple manufacturing facilities in different geographical locations to avoid over-reliance on a single location. This redundancy allows them to continue production even if one facility is affected by a disaster. Furthermore, investing in real-time visibility tools and technologies enables quicker responses to disruptions, minimizing their impact.

Q 28. What are your thoughts on the future of supply chain management and technology?

The future of supply chain management will be heavily shaped by technological advancements and evolving global dynamics. We’ll see an increasing adoption of technologies like artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) to optimize operations, predict disruptions, and enhance decision-making. AI-powered forecasting models, for example, will provide more accurate demand predictions, enabling more efficient inventory management and reducing waste. IoT sensors embedded in products and throughout the supply chain will provide real-time visibility into product location and condition, enhancing traceability and improving responsiveness to disruptions.

Sustainability will also play a major role, with companies facing increasing pressure to reduce their environmental footprint and adopt more ethical and responsible sourcing practices. We’ll likely see more focus on circular economy models, emphasizing reuse, recycling, and reducing waste throughout the supply chain. Finally, the rise of e-commerce and the growth of omnichannel retail will continue to reshape supply chain networks, demanding greater agility and responsiveness to meet ever-changing customer expectations. The supply chain professionals of tomorrow will need to be technologically adept, data-driven, and possess a keen understanding of sustainability and ethical sourcing principles.

Key Topics to Learn for Supply Chain Management (SCM) Systems Interview

- Demand Forecasting & Planning: Understanding various forecasting methods (e.g., moving average, exponential smoothing) and their application in optimizing inventory levels and production schedules. Practical application: Analyzing historical sales data to predict future demand and mitigate stockouts or overstocking.

- Inventory Management: Exploring different inventory control techniques (e.g., EOQ, ABC analysis) and their impact on cost optimization and service levels. Practical application: Developing an inventory management strategy for a specific product line, considering factors like lead times, storage costs, and demand variability.

- Supply Chain Network Design: Analyzing different network structures (e.g., centralized vs. decentralized) and their implications for efficiency and resilience. Practical application: Evaluating the costs and benefits of establishing new distribution centers or outsourcing logistics operations.

- Supply Chain Technology: Familiarity with Enterprise Resource Planning (ERP) systems, Warehouse Management Systems (WMS), Transportation Management Systems (TMS), and their integration within the broader supply chain. Practical application: Describing how a specific technology solution can improve efficiency or visibility in a supply chain process.

- Supply Chain Risk Management: Identifying potential disruptions (e.g., natural disasters, supplier failures) and developing strategies for mitigation and resilience. Practical application: Developing a contingency plan to address a potential supply chain disruption, considering alternative suppliers or transportation modes.

- Supply Chain Analytics & Optimization: Utilizing data analysis techniques to identify inefficiencies and improve decision-making. Practical application: Analyzing key performance indicators (KPIs) to identify areas for improvement in a supply chain process and proposing data-driven solutions.

- Logistics & Transportation Management: Understanding different transportation modes, routing optimization, and warehouse operations. Practical application: Designing a cost-effective transportation plan for a specific shipment, considering factors like delivery time, cost, and mode of transport.

- Procurement & Sourcing: Understanding strategic sourcing, supplier relationship management, and contract negotiation. Practical application: Developing a sourcing strategy for a specific component, considering factors like cost, quality, and supplier reliability.

Next Steps

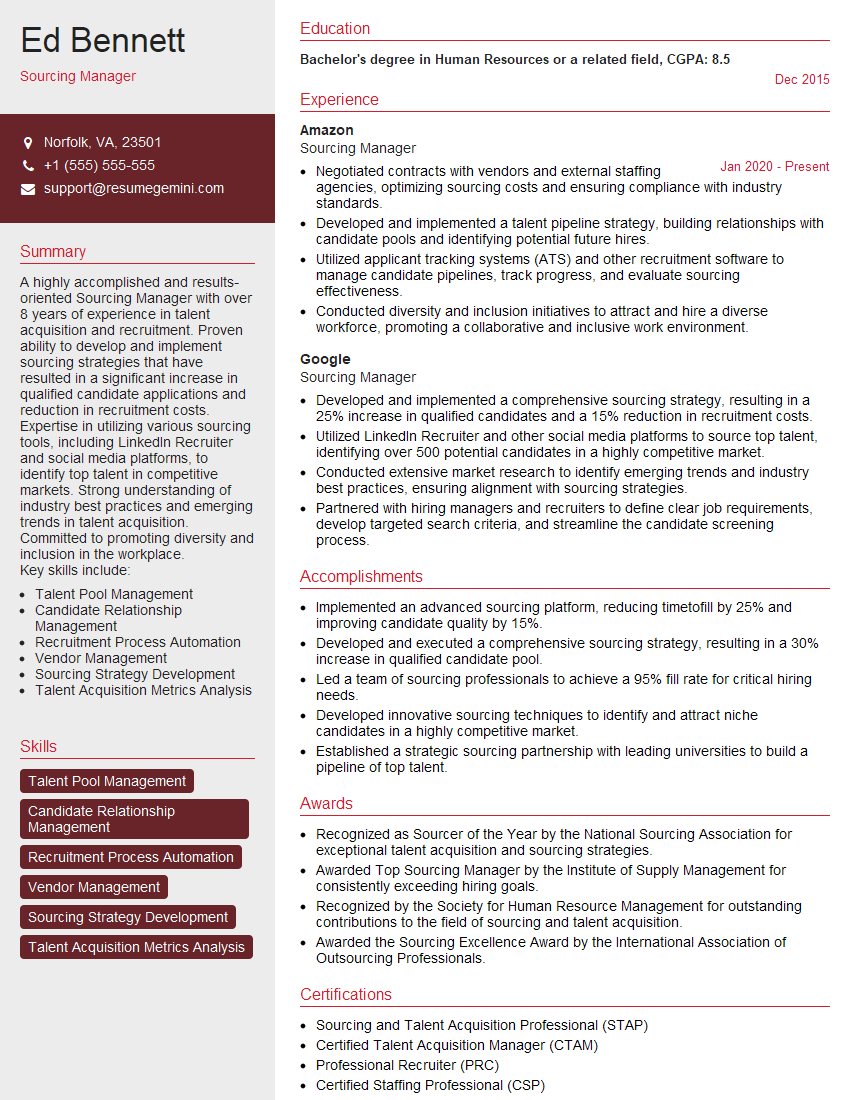

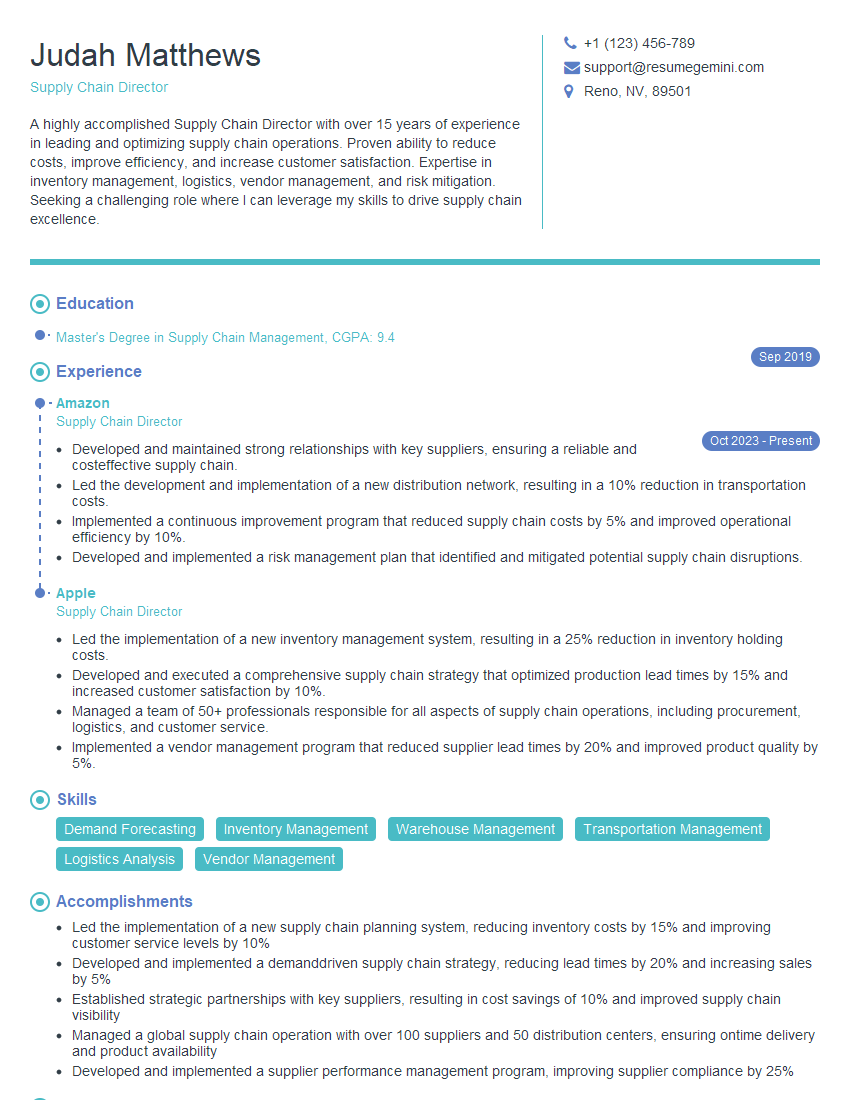

Mastering Supply Chain Management (SCM) Systems is crucial for a successful and rewarding career in today’s dynamic business environment. It opens doors to challenging roles with high growth potential and competitive compensation. To maximize your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to Supply Chain Management (SCM) Systems, ensuring your application stands out from the competition. Take the next step towards your dream career – build a compelling resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO