Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Materials Requirement Planning (MRP) interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Materials Requirement Planning (MRP) Interview

Q 1. Explain the core principles of Materials Requirements Planning (MRP).

Materials Requirements Planning (MRP) is a production planning and inventory control system. At its core, MRP ensures that the right materials are available at the right time and in the right quantity to meet production demands. It achieves this by meticulously scheduling the procurement and production of components, considering factors like lead times, production capacity, and inventory levels. Think of it like a highly organized recipe book for manufacturing, making sure you have all the ingredients (materials) at the right time to bake your final product (finished goods).

The fundamental principles revolve around:

- Dependent Demand: MRP focuses on the dependent demand of components, meaning the need for a particular part is dependent on the demand for the finished goods it contributes to.

- Bill of Materials (BOM): A detailed list of all the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product.

- Master Production Schedule (MPS): A detailed plan that indicates the quantity of finished goods to be produced and when.

- Inventory Records: Accurate tracking of current inventory levels to avoid shortages or excessive stock.

- Lead Times: Precisely accounting for the time it takes to procure materials or produce components.

Q 2. What are the key inputs required for an effective MRP system?

An effective MRP system relies on several crucial inputs:

- Master Production Schedule (MPS): This is the top-level plan specifying the quantity and timing of finished goods production. Think of it as the overall production roadmap.

- Bill of Materials (BOM): The recipe of materials required for each product, outlining all components and sub-assemblies. Inaccurate BOMs lead to incorrect material planning.

- Inventory Records: An up-to-date record of all on-hand materials, work-in-progress (WIP), and finished goods. This forms the baseline for calculating requirements.

- Lead Times: The time required to procure or manufacture each item. Accurate lead times are critical for timely production. If you underestimate the baking time, you will be late serving cake!

- Capacity Planning Data: Information on available production capacity—machinery, labor, etc.—to assess production feasibility and potential bottlenecks.

Q 3. Describe the Bill of Materials (BOM) and its role in MRP.

The Bill of Materials (BOM) is a structured list detailing all the components required to manufacture a product. It’s hierarchical, showing the relationship between finished goods, sub-assemblies, and raw materials. For example, a BOM for a bicycle would list the frame, wheels, handlebars, etc., and then further break down each component – the wheel would be comprised of spokes, rim, tire, etc.

In MRP, the BOM is essential because it allows the system to ‘explode’ the demand for the finished product into demands for all its component parts. If the MPS calls for 100 bicycles, the MRP system, using the BOM, will automatically calculate the required quantity of each component, like frames, wheels, seats, etc., taking into account any existing inventory.

Q 4. How does MRP handle dependent and independent demand?

MRP expertly handles both dependent and independent demand:

- Independent Demand: This refers to the demand for finished goods. It’s independent because it’s directly driven by customer orders or sales forecasts and isn’t dependent on any other item. This is the starting point of the MRP calculations.

- Dependent Demand: This is the demand for components and raw materials. It’s dependent because it’s directly determined by the independent demand for the finished goods. The demand for bicycle wheels is dependent on the demand for bicycles.

MRP uses the BOM to calculate the dependent demand. It starts with the independent demand (finished goods) and ‘explodes’ it down through the BOM to determine the required quantities of all the components at each level.

Q 5. What are the differences between MRP I and MRP II?

MRP I and MRP II are closely related but distinct systems:

- MRP I (Manufacturing Resource Planning): Focuses primarily on materials planning, scheduling production, and managing inventory. It’s a tactical system focused on the efficient flow of materials.

- MRP II (Manufacturing Resource Planning II): Extends MRP I by incorporating broader business functions beyond materials management. It integrates production planning, purchasing, financial planning, and other business processes. MRP II is a strategic system that integrates different departments and perspectives for a holistic view of the business.

Essentially, MRP II builds upon MRP I by adding capabilities for financial planning, capacity requirements planning, sales and operations planning, and shop floor control. It provides a more comprehensive view of the entire manufacturing operation.

Q 6. Explain the concept of lead time in MRP and its impact on planning.

Lead time in MRP is the time it takes to acquire a material or manufacture a part. This includes procurement time (for purchased parts) and manufacturing time (for in-house production). It’s a crucial factor because it determines when orders need to be placed or production initiated to meet the required delivery date.

For example, if the lead time for a specific component is 2 weeks, the MRP system will calculate the order release date 2 weeks before the component is needed in the production process. Inaccurate lead times can lead to delays, stockouts, or excessive inventory. A realistic lead time estimation is crucial.

Q 7. How does safety stock factor into MRP calculations?

Safety stock is extra inventory held to buffer against unexpected events like supplier delays, production issues, or sudden spikes in demand. It’s a crucial element in MRP to avoid stockouts and disruptions. The amount of safety stock is usually determined by a combination of factors, including:

- Demand Variability: Higher demand variability necessitates higher safety stock.

- Lead Time Variability: Longer and more variable lead times also require more safety stock.

- Service Level: The desired probability of meeting demand. A higher service level necessitates a larger safety stock.

The MRP system incorporates safety stock into its calculations by adding it to the net requirements, ensuring enough inventory is available even under uncertain conditions. It’s a balancing act – too much safety stock ties up capital, while too little risks stockouts.

Q 8. Describe the process of generating a master production schedule (MPS).

The Master Production Schedule (MPS) is a detailed plan specifying the quantity of each product to be produced within a given timeframe. Think of it as the company’s production roadmap. Creating an effective MPS involves several key steps:

Demand Forecasting: Accurately predict future customer demand for your products. This often involves analyzing historical sales data, market trends, and seasonal variations. For example, a toy company might expect higher demand during the holiday season.

Sales and Operations Planning (S&OP): Align the MPS with overall business objectives and available resources. This collaborative process brings together sales, marketing, production, and other departments to reconcile demand forecasts with production capacity and inventory levels. Consider a scenario where the sales team predicts high demand but the factory lacks the capacity to meet it; S&OP helps to find a solution.

Capacity Planning: Ensure that sufficient production capacity exists to meet the MPS. This involves assessing available equipment, labor, and materials. If capacity is limited, you may need to adjust the MPS or invest in additional resources. A furniture manufacturer might need to add a second shift to meet a large order.

MPS Development: Translate the demand forecast and capacity plan into a concrete MPS. This usually involves specifying the quantity of each product to be produced in each time period (e.g., weekly, monthly). The MPS will usually be presented in a table format, detailing product, quantity, and due date.

Review and Adjustment: Continuously monitor and adjust the MPS based on actual production results, changes in demand, and other factors. The MPS is not a static document; it’s a living plan that adapts to evolving conditions.

Q 9. How do you handle capacity constraints within an MRP system?

Capacity constraints are a common challenge in MRP. They occur when the available resources (machinery, labor, space) are insufficient to meet the planned production. Handling these constraints requires a multi-pronged approach:

Finite Capacity Scheduling (FCS): This technique explicitly considers capacity limitations when scheduling production. Instead of just calculating what *should* be produced, FCS determines what *can* be produced given the available resources. It may involve using specialized software to create a detailed production schedule that respects capacity limits.

Capacity Requirements Planning (CRP): CRP forecasts the capacity needed to meet the MPS and identifies potential bottlenecks. It allows you to proactively address capacity issues before they impact production. For example, if CRP shows a shortage of skilled welders, you can implement training programs or hire additional staff.

Level Scheduling: This strategy aims to maintain a consistent production rate over time, minimizing fluctuations that can strain capacity. While this might increase inventory, it avoids the peaks and valleys associated with chasing demand, reducing the likelihood of exceeding capacity.

Overtime/Subcontracting: If capacity is consistently constrained, consider using overtime or subcontracting to increase production capacity temporarily. However, this should be a well-considered decision as it can increase costs.

Adjusting the MPS: In some cases, the most effective solution is to adjust the MPS to align with available capacity. This might involve prioritizing certain products or delaying others.

Q 10. Explain the concept of lot sizing and its various techniques.

Lot sizing determines the order quantity for each item. Producing in larger lots can reduce setup costs, but it increases inventory holding costs. Finding the optimal lot size is crucial for minimizing total costs. Several techniques exist:

Economic Order Quantity (EOQ): A classic model that balances setup costs and holding costs to determine the optimal order quantity. It assumes constant demand and setup costs. While a fundamental model, its limitations should be considered in the context of dynamic demand environments.

Economic Production Quantity (EPQ): An extension of EOQ that considers the fact that production may occur over a period of time, rather than instantaneously. This is particularly relevant for manufacturing environments.

Lot-for-Lot (L4L): This simple method orders exactly the quantity needed to meet demand for each period. It minimizes inventory but can lead to higher setup costs.

Fixed Order Quantity (FOQ): Orders a fixed quantity regardless of demand. It simplifies planning but may result in excess inventory.

Wagner-Whitin Algorithm: A dynamic programming approach that finds the optimal lot sizing policy considering variable demand and setup costs. It’s computationally more intensive but produces more accurate results than simpler methods.

Q 11. What are some common challenges encountered in implementing MRP?

Implementing MRP effectively presents several challenges:

Data Accuracy: MRP relies heavily on accurate data about inventory levels, lead times, and demand forecasts. Inaccurate data leads to inaccurate plans and potentially significant problems.

System Complexity: MRP systems can be complex, requiring specialized software and trained personnel. This adds to implementation costs and the time required to achieve full operational efficiency.

Lead Time Variability: Unpredictable lead times for materials and production can disrupt the MRP plan. This necessitates robust planning processes to anticipate and mitigate the impact of delays.

Demand Fluctuations: Changes in customer demand can necessitate frequent adjustments to the MRP plan, requiring flexibility and responsiveness.

Integration Challenges: Integrating MRP with other supply chain systems (e.g., ERP, CRM) can be difficult, requiring careful planning and execution.

Lack of User Adoption: Without the buy-in and active participation of employees, the MRP system is unlikely to achieve its full potential. Training and communication are crucial aspects of successful implementation.

Q 12. How do you address discrepancies between planned and actual production?

Discrepancies between planned and actual production highlight areas needing improvement. Addressing these requires a systematic approach:

Root Cause Analysis: Identify the reasons for the discrepancies. Was it due to inaccurate demand forecasts, production delays, material shortages, or other issues? Utilize tools like 5 Whys to delve into the underlying causes.

Data Reconciliation: Ensure that the MRP system’s data reflects reality. This might involve adjusting inventory levels, updating lead times, or correcting demand forecasts.

Process Improvement: Implement changes to address the root causes. This might involve improving the accuracy of demand forecasting, streamlining production processes, or improving communication and collaboration.

Performance Monitoring: Continuously monitor performance to identify emerging discrepancies and take corrective action before they become major problems. Regularly review key metrics and adapt strategies as necessary.

Exception Reporting: Set up alerts to notify managers of significant discrepancies promptly. This allows for timely intervention and reduces the potential for large-scale problems.

Q 13. How does MRP integrate with other supply chain management systems?

MRP is not a standalone system; it integrates seamlessly with other supply chain management systems:

Enterprise Resource Planning (ERP): MRP is often a module within a larger ERP system. This allows for a unified view of the entire business, facilitating data sharing and efficient planning.

Customer Relationship Management (CRM): Integrating with CRM systems provides real-time insights into customer demand, enabling more accurate demand forecasting.

Warehouse Management Systems (WMS): Integration with WMS ensures that the MRP system has accurate inventory data, improving planning accuracy.

Supply Chain Planning (SCP): SCP systems use MRP data to optimize the entire supply chain, from procurement to delivery. This enhances overall efficiency and responsiveness.

This integration allows for a holistic and efficient management of the entire supply chain. Data is shared effortlessly, leading to better decision-making and reduced inefficiencies.

Q 14. What are the key performance indicators (KPIs) used to evaluate MRP effectiveness?

Several KPIs assess MRP effectiveness:

Inventory Turnover: Measures how efficiently inventory is used. A high turnover rate indicates effective inventory management.

On-Time Delivery Rate: Indicates the percentage of orders delivered on time. A high rate suggests efficient production planning and execution.

Production Schedule Adherence: Measures the degree to which actual production aligns with the planned schedule. High adherence indicates accurate planning and effective execution.

Lead Time: Measures the time required to produce a product from order placement to delivery. Short lead times are desirable.

Inventory Holding Costs: Represents the costs associated with storing inventory. Lower costs signify efficient inventory management.

Production Efficiency: Measures the ratio of actual output to planned output. High efficiency reflects effective production planning and execution.

By tracking these KPIs, businesses can identify areas for improvement and optimize their MRP processes.

Q 15. Explain the role of forecasting in MRP.

Forecasting is the cornerstone of Materials Requirement Planning (MRP). It provides the demand prediction that drives the entire MRP system. Without accurate forecasts of customer demand for finished goods, MRP cannot effectively determine the quantities and timing of materials needed for production. Think of it as the roadmap – a good forecast ensures we’re planning the right journey.

MRP uses various forecasting techniques, from simple moving averages to more sophisticated exponential smoothing and causal models. The choice depends on the product’s demand pattern, data availability, and forecasting horizon. For example, a company selling seasonal clothing will use a forecasting model that accounts for the cyclical nature of demand, while a company selling staple items might use a simpler moving average. The accuracy of the forecast directly impacts the efficiency of the entire MRP process; inaccurate forecasts lead to excess inventory, stockouts, and lost sales.

In practice, regular review and adjustment of forecasts are vital. Using real-time sales data and market intelligence helps refine forecasts, keeping the MRP system responsive to changing market conditions. This iterative approach ensures that the plan remains relevant and minimizes potential disruptions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you deal with unexpected changes in demand or supply?

Unexpected changes in demand or supply are inevitable. The key is to have a robust MRP system with contingency plans. When faced with sudden surges in demand, the system needs to be able to quickly adjust production schedules, prioritize critical materials, and explore options like expedited shipping or subcontracting. Imagine a sudden increase in orders for your product due to a positive news story. Your MRP system needs to seamlessly react to this.

For supply disruptions, such as a supplier delay or a natural disaster affecting a key resource, having alternative sources of materials is crucial. The MRP system should highlight these risks and trigger alerts, prompting the team to proactively search for alternative suppliers or substitute materials. This could involve leveraging strategic partnerships or revisiting purchasing agreements.

Regularly reviewing the MRP system’s parameters and actively monitoring key performance indicators (KPIs) is essential for early detection of potential problems. This allows for timely intervention and minimizes the impact of these unexpected events. The flexibility of the MRP system to adapt to these changes is critical to its effectiveness.

Q 17. What are the benefits of using an MRP software system?

MRP software systems offer numerous advantages over manual planning. They streamline the entire process, improving efficiency and accuracy significantly. Think of it as upgrading from pen and paper to a sophisticated navigation system.

- Improved Accuracy: Manual calculations are prone to errors, whereas software minimizes these chances. It ensures consistency and reliability across the entire process.

- Reduced Lead Times: By optimizing scheduling and material procurement, MRP software helps reduce production lead times and improve delivery performance.

- Better Inventory Control: The software optimizes inventory levels, minimizing storage costs and preventing stockouts or excess inventory.

- Enhanced Planning & Visibility: Real-time visibility into materials, capacity, and scheduling facilitates better planning and decision-making.

- Increased Profitability: Through improved efficiency, reduced waste, and better inventory control, MRP software ultimately contributes to increased profitability.

Q 18. Describe your experience with different MRP software packages.

Throughout my career, I’ve worked extensively with various MRP software packages, including SAP, Oracle, and Infor. Each has its strengths and weaknesses. SAP, for instance, is renowned for its comprehensive functionality and scalability, suitable for large enterprises with complex supply chains. However, it can be more expensive and requires specialized training. Oracle offers a robust solution with strong integration capabilities, while Infor provides flexible options suited to specific industries.

My experience spans from implementing these systems in manufacturing environments to customizing them to meet unique business requirements. I’m comfortable navigating the intricacies of each package, understanding their data structures, and configuring them to optimize material planning and resource allocation. My focus is always on selecting the right software to meet the specific needs of the organization and ensuring seamless integration with existing systems.

Q 19. Explain the concept of rough-cut capacity planning (RCCP).

Rough-Cut Capacity Planning (RCCP) is a high-level capacity planning technique used in conjunction with MRP. Unlike detailed scheduling, RCCP focuses on verifying whether sufficient capacity exists to meet the master production schedule (MPS) demands. Think of it as a preliminary check to see if the project is even feasible before delving into the fine details.

RCCP uses aggregate data – like total machine hours or labor hours – to assess capacity against the MPS. If RCCP reveals capacity constraints, it prompts adjustments to the MPS or resource allocation before proceeding with detailed scheduling. This prevents the creation of unrealistic schedules that cannot be executed. For example, RCCP might show that the planned production volume exceeds the available machine hours, leading to revisions in the MPS or the need to acquire additional capacity.

RCCP is typically performed before detailed capacity planning and MRP execution, helping to avoid costly and time-consuming re-planning later in the process. It helps ensure that the master plan is realistic and achievable, saving time and resources in the long run.

Q 20. How does MRP contribute to improved inventory management?

MRP significantly improves inventory management by optimizing inventory levels to meet demand while minimizing holding costs. It achieves this through accurate forecasting, efficient scheduling, and precise tracking of materials. Think of it as a sophisticated system for managing your store’s inventory—making sure you have enough stock without wasting space or money.

By accurately predicting demand, MRP reduces the risk of stockouts and the associated lost sales opportunities. Simultaneously, it prevents overstocking, minimizing storage costs, obsolescence, and waste. The system continuously monitors inventory levels, triggering purchase orders for materials when necessary to maintain optimal stock levels. This reduces the chances of production delays due to material shortages, while the optimized inventory levels free up capital.

Q 21. How can MRP help reduce production lead times?

MRP contributes to reduced production lead times through several mechanisms: improved planning, optimized scheduling, and efficient material procurement. By creating a detailed plan that accounts for all necessary materials and resources, potential bottlenecks are identified and addressed proactively.

Efficient scheduling within the MRP system ensures that materials and resources are available when needed, eliminating delays caused by material shortages or machine downtime. The system also helps optimize the flow of materials through the production process, reducing waiting times and accelerating the overall production cycle. For instance, if a material has a long lead time, MRP will signal the need for early ordering, preventing delays later in the process. This proactive approach is critical in minimizing overall lead times and ensuring on-time delivery.

Q 22. What are some common errors in MRP implementation and how to avoid them?

Implementing MRP successfully requires meticulous planning and execution. Common errors often stem from inaccurate or incomplete data, poor system configuration, and a lack of user training.

- Inaccurate Data: Incorrect lead times, inaccurate inventory counts, and flawed bill of materials (BOMs) are frequent culprits. This leads to inaccurate forecasts and scheduling issues. Imagine ordering raw materials based on a BOM that’s missing a crucial component – disaster!

- Poor System Configuration: Improperly setting parameters like safety stock levels, lot sizing rules, or planning horizons can severely impact the MRP’s effectiveness. For example, setting safety stock too low can lead to frequent shortages, while setting it too high ties up unnecessary capital.

- Lack of User Training and Buy-in: MRP systems are only as good as the people who use them. Inadequate training leads to data entry errors, misinterpretations of reports, and ultimately, inefficient planning.

- Ignoring Capacity Planning: An MRP system should consider the available production capacity. Failing to do so leads to unrealistic schedules and missed deadlines. The system may generate a plan that looks great on paper, but it’s impossible to execute because the machines simply aren’t available.

Avoiding these errors involves:

- Data Cleansing and Validation: Regular audits and data verification are essential to maintain data accuracy.

- Proper System Configuration: Carefully define parameters based on historical data, industry best practices, and expert knowledge. Use a phased approach, starting with a pilot project to refine settings before full-scale implementation.

- Comprehensive Training: Provide thorough training to all users, ensuring they understand the system’s functionality and their role in data accuracy.

- Integrated Capacity Planning: Integrate capacity planning with the MRP system to ensure feasibility and avoid over-scheduling.

- Regular System Reviews and Optimization: Continuously monitor the system’s performance, identifying areas for improvement and making necessary adjustments.

Q 23. Describe your experience with data analysis in the context of MRP.

My experience with data analysis in MRP centers around using historical data to improve forecasting accuracy and optimize inventory levels. I leverage various techniques, including:

- Demand Forecasting: I utilize statistical methods like moving averages, exponential smoothing, and ARIMA models to predict future demand for finished goods. This involves analyzing historical sales data, seasonal trends, and external factors that may influence demand.

- Inventory Optimization: Analyzing inventory turnover rates, safety stock levels, and carrying costs helps to determine optimal inventory levels to minimize costs while ensuring sufficient stock to meet demand. This involves identifying slow-moving items and potential obsolescence.

- Lead Time Analysis: I analyze lead times for raw materials and components to identify potential bottlenecks and opportunities for improvement. This data helps to refine the MRP system’s calculations and improve overall planning accuracy.

- Exception Reporting: I develop reports to highlight potential issues such as upcoming shortages, excessive inventory, or significant deviations from planned schedules. This allows for proactive intervention to mitigate risks.

For example, in a previous role, I identified a seasonal spike in demand for a particular product that wasn’t captured by the existing forecasting model. By incorporating this seasonal factor into a more sophisticated model, we were able to significantly reduce stockouts during peak season and improve overall customer satisfaction.

Q 24. How do you ensure data accuracy within an MRP system?

Data accuracy is paramount in MRP. Ensuring it requires a multi-faceted approach encompassing data governance, validation, and continuous monitoring.

- Data Governance: Establish clear data ownership and responsibility. Define data entry procedures, validation rules, and data quality metrics.

- Data Validation: Implement checks and balances throughout the data entry process. This can include automated checks for inconsistencies or out-of-range values, as well as regular manual audits to identify and correct errors. Using barcode scanners and RFID technology can significantly reduce manual data entry errors.

- Regular Reconciliation: Regularly compare MRP system data with physical inventory counts and purchase orders to identify discrepancies. Addressing these discrepancies promptly prevents them from propagating and creating inaccurate forecasts and schedules.

- Data Cleansing: Regularly cleanse the database by removing outdated, duplicate, or erroneous records.

- Master Data Management: Maintain accurate and up-to-date master data, including bills of materials (BOMs), routing information, and lead times. Any change to these should be carefully reviewed and approved to prevent downstream inaccuracies.

Think of it like building a house: if your foundation (data) is weak, the entire structure (MRP plan) will be unstable.

Q 25. Explain your understanding of closed-loop MRP.

Closed-loop MRP is an advanced form of MRP that incorporates feedback from the shop floor to continuously refine the production plan. It moves beyond the traditional closed-loop system by actively monitoring actual performance against the planned schedule and adjusting accordingly.

In a typical MRP system, the plan is generated based on forecasts and historical data. However, in a closed-loop system, actual production output, material consumption, and other real-time data are fed back into the system. This feedback allows for the system to dynamically adjust the plan to reflect the current situation and minimize deviations from the schedule. This continuous feedback loop ensures the plan remains accurate and responsive to changes in the production environment.

For example, if a machine breaks down and delays production, the closed-loop MRP system will detect this delay and automatically adjust the subsequent schedules and material requirements. This prevents cascading delays and ensures the final product is delivered on time. It helps create a more agile and responsive manufacturing process.

Q 26. How do you handle material shortages in an MRP environment?

Material shortages are a major concern in any MRP environment. Handling them effectively requires a proactive and systematic approach.

- Identify the Shortage: The first step is to identify the specific material in short supply, the quantity of the shortage, and the impact on the production schedule. The MRP system itself should highlight these shortages through exception reports.

- Investigate the Cause: Determine the root cause of the shortage. Is it due to inaccurate demand forecasting, supplier delays, quality issues, or unexpected spikes in demand? Understanding the cause is crucial for developing effective solutions.

- Implement Corrective Actions: Depending on the cause and severity of the shortage, several corrective actions can be taken:

- Expedite Delivery: Contact the supplier to expedite the delivery of the missing material. This might involve paying a premium for faster shipping.

- Substitute Materials: If a suitable substitute is available, consider using it to continue production. This requires careful evaluation to ensure the substitute meets quality standards.

- Reschedule Production: If the shortage cannot be resolved quickly, reschedule production to prioritize items that are not affected by the shortage. This requires careful prioritization to minimize the overall impact on the schedule.

- Adjust Safety Stock Levels: Evaluate whether safety stock levels are adequate to prevent future shortages. It might need to be increased to ensure sufficient buffer stock.

- Prevent Future Shortages: Analyze the shortage to identify areas for improvement in the MRP system or supply chain. This might involve improving demand forecasting accuracy, diversifying suppliers, or implementing better inventory management practices.

It’s like managing a restaurant: if you run out of a key ingredient, you need to quickly find a replacement, adjust the menu, or inform customers about the delay. A proactive approach minimizes disruption.

Q 27. Describe your experience with MRP in a specific industry.

I have extensive experience implementing and optimizing MRP systems in the automotive industry. This is a sector known for its complex supply chains, stringent quality requirements, and just-in-time manufacturing practices.

In my previous role, I was involved in the implementation of a new MRP system for a major automotive parts supplier. This involved:

- Data Migration: Migrating historical data from the legacy system to the new MRP system, ensuring data accuracy and consistency.

- Process Mapping: Mapping out existing manufacturing processes and integrating them into the new MRP system to ensure smooth operations.

- System Configuration: Configuring the system to meet the specific needs of the automotive industry, including integrating with supplier portals and quality management systems. This included optimizing parameters such as lot sizing, safety stock, and lead times specific to the constraints of automotive production.

- Training and Support: Providing training to users and ongoing support to ensure smooth adoption of the new system.

- Performance Monitoring: Monitoring the system’s performance and making necessary adjustments to optimize its efficiency. This includes addressing bottlenecks, analyzing inventory turnover, and improving forecasting accuracy.

The project was a success, resulting in significant improvements in inventory management, reduced lead times, and improved on-time delivery performance. The automotive industry’s demand for precision and efficiency made this experience particularly challenging but also incredibly rewarding. The application of MRP in this environment highlighted the importance of meticulous data management and the ability to respond rapidly to changing production needs.

Key Topics to Learn for Materials Requirement Planning (MRP) Interview

- Bill of Materials (BOM) Management: Understanding how to create, maintain, and analyze BOMs, including handling revisions and engineering changes. Practical application: Scenario-based questions on BOM explosion and optimization.

- Master Production Schedule (MPS): Developing and managing the MPS, considering factors like demand forecasting, capacity planning, and inventory levels. Practical application: Analyzing a given MPS and identifying potential bottlenecks or scheduling conflicts.

- Inventory Control: Implementing strategies to minimize inventory costs while ensuring sufficient stock to meet production demands. Practical application: Evaluating different inventory control methods (e.g., EOQ, safety stock) and their impact on overall costs.

- Capacity Requirements Planning (CRP): Assessing the capacity needed to meet the MPS, identifying potential capacity constraints, and developing strategies to address them. Practical application: Analyzing resource utilization and suggesting solutions to optimize capacity utilization.

- MRP System Implementation and Software: Familiarity with different MRP software systems and the process of implementing an MRP system within an organization. Practical application: Discussing the benefits and challenges of implementing an MRP system.

- Demand Forecasting Techniques: Understanding various forecasting methods (e.g., moving average, exponential smoothing) and their application in MRP. Practical application: Evaluating the accuracy of different forecasting methods and choosing the most appropriate one based on specific data.

- Problem-Solving and Optimization: Troubleshooting common MRP issues, such as material shortages, production delays, and inventory discrepancies. Practical application: Analyzing case studies involving MRP problems and developing effective solutions.

Next Steps

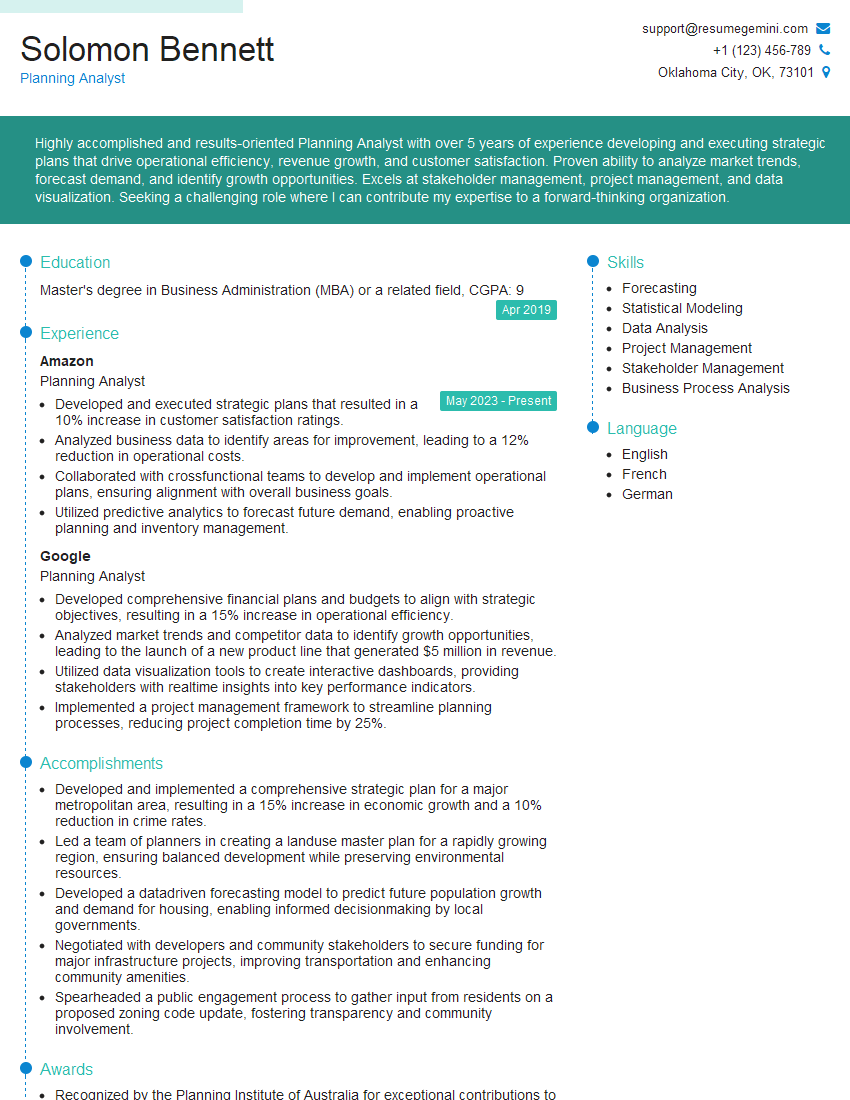

Mastering Materials Requirement Planning (MRP) is crucial for a successful career in supply chain management and operations. A strong understanding of MRP principles and their practical application opens doors to exciting opportunities and higher earning potential. To maximize your job prospects, crafting a well-structured, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your MRP skills effectively. Examples of resumes tailored to Materials Requirement Planning (MRP) are available to guide you in showcasing your expertise. Invest time in building a compelling resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO