Cracking a skill-specific interview, like one for Waste Compaction, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Waste Compaction Interview

Q 1. What are the different types of waste compactors?

Waste compactors come in various types, each designed for specific waste streams and operational needs. The most common categories include:

- Baler Compactors: These machines compress waste into dense, manageable bales, often using hydraulic pressure. They are ideal for cardboard, paper, plastics, and textiles. Think of them like giant, automated versions of a clothes press. There are horizontal and vertical balers, each with its advantages in terms of space and material handling.

- Compactor Containers: These are self-contained units that compact waste directly inside a large container. They’re commonly seen at commercial and industrial sites. These are great for places with limited space, as the compaction and storage happen in one unit.

- Stationary Compactors: These are larger, fixed-in-place machines that process a high volume of waste. They often feed into larger transportation containers for efficient removal. Imagine a heavy-duty version of a garbage disposal, built for large-scale waste management.

- Mobile Compactors: These compactors can be moved around a facility or site as needed. Their portability makes them versatile for different applications and locations.

- Self-Contained Compactors:These compactors have their own power source and don’t require external connections like stationary models.

The choice of compactor depends heavily on factors such as the type and volume of waste generated, available space, budget, and environmental considerations.

Q 2. Explain the principles of waste compaction.

Waste compaction relies on the principle of reducing the volume of waste material through the application of pressure. This pressure forces air out of the waste, bringing the material closer together. Think of it like squeezing a sponge—you reduce its size by removing the water (air) inside. Different types of compactors achieve this through various methods: hydraulic pressure (most common), mechanical compression, or even a combination of both. The goal is to maximize the density of the waste, making it easier and more cost-effective to transport and dispose of. Higher compaction ratios translate to fewer trips to the landfill or recycling facility, reducing transportation costs and environmental impact.

Q 3. Describe the maintenance procedures for a baler.

Regular maintenance is crucial for ensuring the longevity and safe operation of a baler. A comprehensive maintenance schedule should include:

- Daily Inspection: Check for leaks in the hydraulic system, unusual noises, and obstructions in the chamber. This is like a quick health check for your machine.

- Weekly Lubrication: Lubricate moving parts according to the manufacturer’s recommendations. This keeps everything running smoothly and prevents wear and tear.

- Monthly Cleaning: Remove accumulated waste and debris from the compaction chamber and other areas. Think of it as spring cleaning for your baler.

- Quarterly Inspections: Conduct thorough inspections of hydraulic lines, hoses, and electrical components, looking for wear or damage. This is more in-depth than the daily check.

- Annual Maintenance: Schedule a professional service visit for a complete inspection, replacement of worn parts, and preventative maintenance. This prevents potential breakdowns.

Maintaining accurate records of all maintenance activities is critical for tracking performance, troubleshooting issues, and ensuring compliance with safety regulations.

Q 4. What safety precautions are crucial when operating compaction equipment?

Safety is paramount when operating compaction equipment. Crucial precautions include:

- Lockout/Tagout Procedures: Before performing any maintenance or repairs, always follow proper lockout/tagout procedures to prevent accidental starts. This is a critical safety measure to prevent injuries.

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, steel-toed boots, and hearing protection. Never underestimate the importance of protection.

- Proper Training: Operators must receive comprehensive training on the safe operation and maintenance of the equipment. Knowing how to operate safely is crucial.

- Clear Work Area: Ensure the area around the compactor is clear of obstructions to prevent accidents. A clean workspace prevents tripping hazards and other accidents.

- Emergency Shut-off Procedures: All operators should be thoroughly familiar with the location and operation of emergency shut-off switches. This ensures a quick response in case of emergencies.

- Regular Inspections: Regular equipment inspections are crucial to identify and address potential hazards before they lead to accidents. Preventative maintenance prevents accidents.

Compaction equipment can be dangerous if not handled correctly. Adhering to these safety precautions is essential to prevent injuries and ensure a safe working environment.

Q 5. How do you calculate compaction ratios?

The compaction ratio is calculated by comparing the volume of the waste *before* compaction to its volume *after* compaction. The formula is:

Compaction Ratio = (Initial Volume / Final Volume)For example, if you start with 10 cubic meters of waste and, after compaction, the volume is reduced to 2 cubic meters, the compaction ratio is 5:1 (10/2 = 5).

Accurate measurement of initial and final volumes is crucial for an accurate ratio. This often involves using calibrated containers or measuring devices.

Q 6. What are the common causes of compaction equipment malfunctions?

Malfunctions in compaction equipment can stem from various causes:

- Hydraulic System Issues: Leaks, worn seals, or contaminated hydraulic fluid are common culprits. Think of it as the blood circulation of the compactor; if that is flawed, the whole system suffers.

- Mechanical Failures: Wear and tear on moving parts like rams, pistons, and bearings can lead to breakdowns. Regular lubrication and maintenance are key in addressing this.

- Electrical Problems: Faulty wiring, malfunctioning sensors, or motor problems can disrupt operation. Regular electrical checks are necessary.

- Overloading: Exceeding the compactor’s rated capacity can strain components and lead to damage. Operating within the limits of the equipment is critical.

- Improper Maintenance: Lack of regular maintenance is often the root cause of many malfunctions. This underlines the importance of following a detailed maintenance plan.

Careful attention to preventative maintenance, regular inspections, and prompt repairs can minimize downtime and ensure the smooth operation of compaction equipment.

Q 7. Explain the importance of proper waste segregation before compaction.

Proper waste segregation before compaction is essential for several reasons:

- Improved Compaction Efficiency: Separating different materials (e.g., recyclables from non-recyclables) allows for more efficient compaction. Mixing materials often leads to poor compaction, wasted space, and inefficient use of resources.

- Increased Recycling Rates: Segregation allows for easy separation of recyclable materials, leading to increased recycling rates and a reduced environmental footprint. It maximizes resource recovery.

- Reduced Landfill Burden: By removing recyclable and reusable materials, the amount of waste sent to landfills is significantly reduced, saving space and reducing environmental pollution.

- Safety Enhancement: Segregation prevents the mixing of hazardous materials with other waste streams, ensuring safer handling and preventing potential hazards.

- Cost Savings: Proper segregation often results in cost savings through increased recycling revenue and reduced landfill disposal fees. It’s an economically sound practice.

In essence, proper segregation is a cornerstone of effective and sustainable waste management practices, maximizing resource recovery, minimizing environmental impacts, and enhancing the overall efficiency and safety of the compaction process.

Q 8. How do you optimize waste compaction efficiency?

Optimizing waste compaction efficiency is crucial for cost savings and environmental responsibility. It involves a multi-pronged approach focusing on several key areas.

- Proper Waste Segregation: Before compaction, separating materials like recyclables from general waste significantly improves compaction ratios. Imagine trying to compact a mix of fluffy pillows and bricks – the result is less efficient than compacting each separately.

- Equipment Selection: Choosing the right compactor for the waste stream is vital. A baler is perfect for cardboard, while a shear compactor handles mixed waste effectively. The wrong equipment leads to lower compaction rates and potential breakdowns.

- Regular Maintenance: Scheduled maintenance prevents breakdowns and ensures optimal performance. Think of it like a car – regular servicing keeps it running smoothly and efficiently. Neglecting maintenance leads to decreased compaction ratios and increased downtime.

- Operator Training: Well-trained operators understand best practices for loading, operating, and maintaining the compactor. Proper loading techniques, avoiding overloading, and understanding the compactor’s limitations are all key.

- Waste Characterization: Understanding the composition of the waste stream allows for selecting the most efficient compaction methods and technologies. This includes analyzing the density, moisture content, and size of the materials. For example, wet waste needs different handling than dry waste.

By focusing on these factors, businesses can significantly improve their waste compaction efficiency, reducing disposal costs and their environmental footprint.

Q 9. Describe your experience with different types of waste materials (e.g., cardboard, plastics, etc.)

My experience spans a wide range of waste materials. I’ve worked with everything from highly compressible materials like cardboard and paper to less compressible ones like plastics and mixed municipal solid waste (MSW).

- Cardboard: Cardboard compacts exceptionally well, often achieving high density bales ideal for recycling. The key is proper baling techniques to prevent blockages.

- Plastics: Plastics present more challenges. Different plastic types have varying densities and compressibility. Film plastics, for example, are notoriously difficult to compact effectively. Strategies often involve pre-processing, such as shredding, to increase compaction efficiency.

- Mixed MSW: Compacting mixed MSW requires robust equipment designed to handle diverse material types. Issues like sharp objects and liquids need careful consideration to ensure operator safety and prevent equipment damage.

- Food Waste: Food waste presents unique challenges due to its high moisture content. This can lead to reduced compaction ratios and potential odor issues. Proper pre-treatment, like dewatering, can be necessary.

Understanding the specific properties of each material type is crucial to selecting the appropriate compaction technology and optimizing the process for maximum efficiency and safety.

Q 10. What are the environmental benefits of waste compaction?

Waste compaction offers numerous environmental benefits. It significantly reduces the volume of waste requiring transportation and disposal, thus leading to several positive outcomes.

- Reduced Landfill Space: Compacting waste reduces its volume, extending the lifespan of landfills. Landfills are a major source of greenhouse gas emissions; reducing their size helps mitigate this issue.

- Lower Transportation Costs: Less volume means fewer trucks needed for transportation, resulting in lower fuel consumption and reduced greenhouse gas emissions associated with transportation.

- Improved Recycling Efficiency: Efficient compaction of materials like cardboard and plastics makes them easier to handle and process in recycling facilities, boosting recycling rates.

- Reduced Greenhouse Gas Emissions: Less transportation and less landfill space contribute to lower overall greenhouse gas emissions compared to uncompacted waste disposal.

Ultimately, waste compaction promotes a more sustainable waste management approach, minimizing environmental impact and preserving natural resources.

Q 11. How do you address compaction issues related to different material types?

Addressing compaction issues related to different material types requires a tailored approach. It’s about understanding the specific challenges each material presents.

- Inconsistent Material Sizes: For materials with varying sizes, pre-processing such as shredding or size reduction can significantly improve compaction efficiency.

- High Moisture Content: For wet materials, dewatering or pre-drying is often necessary to achieve optimal compaction. This prevents problems like blockages and reduces the overall weight for transportation.

- Non-Compressible Materials: Materials like certain plastics or bulky items require different compaction techniques or even separate disposal methods to avoid damaging equipment or hindering the compaction process.

- Sharp Objects: Sharp objects pose a safety risk and can damage equipment. Proper pre-sorting and the use of appropriate safety measures are essential.

A thorough understanding of the waste stream and selection of the appropriate equipment and pre-processing techniques are essential to overcome material-specific compaction challenges.

Q 12. What are the regulatory requirements for waste compaction in your region?

Regulatory requirements for waste compaction vary by region. In my region, key regulations often focus on:

- Waste Characterization and Segregation: Strict guidelines exist on the proper separation of different waste streams before compaction to ensure compliance with recycling and disposal regulations.

- Compactor Safety Standards: Regulations mandate regular inspections and maintenance to ensure the safe operation of compaction equipment. This includes measures to protect operators from hazards such as entanglement and crushing.

- Environmental Permits: Depending on the scale of the operation, environmental permits may be required to ensure compliance with emission standards and waste disposal regulations.

- Record Keeping: Detailed records of waste generation, compaction activities, and disposal are required for auditing and regulatory compliance.

- Transportation Regulations: Regulations govern the transport of compacted waste, including weight limits, vehicle specifications, and waste manifest requirements.

Staying up-to-date on these regulations and ensuring full compliance is paramount to avoid penalties and maintain a responsible waste management practice.

Q 13. Describe your experience with different compaction technologies (e.g., horizontal, vertical, etc.)

My experience encompasses various compaction technologies, each with its strengths and weaknesses.

- Horizontal Balers: Ideal for high-volume, easily compressible materials like cardboard and paper. They create dense, rectangular bales suitable for storage and transportation.

- Vertical Balers: More versatile, handling a wider variety of materials than horizontal balers, although typically with lower compaction ratios. They are also suitable for smaller spaces.

- Shear Compactors: Designed for mixed waste streams, they use shear forces to compact materials, often handling a wider range of materials including bulky items and difficult-to-compact materials. However, they tend to produce a less dense compacted mass.

- Self-Contained Compactors: Compactors designed for on-site waste reduction, ideal for locations with limited space or access to frequent waste collection services.

The choice of technology depends on the specific waste stream, available space, budget, and desired compaction density. Often a combination of technologies is used to achieve optimal waste management results.

Q 14. How do you troubleshoot a jammed compactor?

Troubleshooting a jammed compactor requires a systematic approach, prioritizing safety.

- Safety First: Always ensure the compactor is turned off and locked out before attempting any repairs. Never attempt to manually clear a blockage while the machine is running.

- Identify the Jam: Carefully inspect the compactor to locate the source of the blockage. This may involve checking the hopper, the compaction chamber, and the ejection system.

- Remove the Blockage: Depending on the nature of the blockage, use appropriate tools to carefully remove the jammed material. Avoid using excessive force, which could damage the equipment.

- Check for Foreign Objects: Look for any foreign objects that may have caused the jam, such as oversized items or materials that are not meant to be compacted.

- Inspect for Damage: Once the jam is cleared, thoroughly inspect the compactor for any damage caused by the blockage. This could include bent components or damaged sensors.

- Restart and Monitor: After clearing the jam and performing any necessary repairs, restart the compactor and carefully monitor its operation to ensure it’s functioning correctly.

- Preventive Maintenance: Regular maintenance, including routine inspections and cleaning, can help prevent future jams.

If the jam persists or you are unsure how to proceed, always contact a qualified technician for assistance.

Q 15. What are the key performance indicators (KPIs) for a waste compaction system?

Key Performance Indicators (KPIs) for a waste compaction system are crucial for monitoring efficiency and effectiveness. They help us understand if the system is meeting its goals and identify areas for improvement. Think of them as the vital signs of your compaction operation.

- Compaction Ratio: This measures the volume reduction achieved. A higher ratio means more efficient compaction. For instance, a ratio of 4:1 indicates that 1 cubic yard of waste is reduced to 0.25 cubic yards after compaction.

- Throughput: This represents the volume of waste processed per unit of time (e.g., tons per hour). A higher throughput indicates greater efficiency and capacity.

- Downtime: This measures the percentage of time the equipment is not operational due to maintenance, repairs, or other issues. Minimizing downtime is key to maximizing productivity.

- Operating Costs: This encompasses energy consumption, maintenance, labor, and repair costs. Tracking these helps optimize resource allocation and reduce overall expenses. For example, monitoring energy usage can reveal opportunities for switching to more efficient equipment or operating procedures.

- Safety Incidents: A critical KPI is the number of safety incidents related to the compaction process. A robust safety program is paramount.

- Maintenance Costs: Regular maintenance prevents unexpected breakdowns. Tracking maintenance costs helps optimize schedules and predict future expenses.

By regularly tracking these KPIs, we can identify trends, make data-driven decisions, and continuously improve the waste compaction process. For example, a sudden increase in downtime might signal the need for preventive maintenance or staff training.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of selecting appropriate compaction equipment for a specific application.

Selecting the right compaction equipment involves a careful assessment of several factors. It’s like choosing the right tool for a specific job – you wouldn’t use a hammer to screw in a screw!

- Waste Type and Characteristics: The type of waste (e.g., municipal solid waste, industrial waste, recyclables) significantly influences equipment selection. The density, moisture content, and size of the waste will determine the required compaction force and equipment type.

- Volume of Waste: The amount of waste generated daily or weekly directly impacts the capacity and throughput requirements of the equipment. A small business might need a small baler, while a large manufacturing plant requires a high-capacity compactor.

- Available Space: The available space for equipment placement and waste storage is crucial. Compactors come in various sizes and configurations to suit different spaces.

- Budget: Compaction equipment comes with a range of price tags. The budget dictates the type and features that are feasible.

- Environmental Regulations: Compliance with local, state, and federal environmental regulations regarding waste disposal is paramount. This includes choosing equipment that meets emission standards.

- Maintenance and Support: Consider the availability of parts, service, and technical support for the chosen equipment. Downtime due to equipment failure can be very costly.

Often, a thorough site assessment and consultation with equipment suppliers are necessary to ensure the optimal selection. For example, a facility processing a large volume of bulky cardboard might choose a horizontal baler, while a facility with limited space might opt for a self-contained compactor.

Q 17. How do you ensure the safe disposal of compacted waste?

Safe disposal of compacted waste involves adherence to strict protocols and regulations. This is not just about environmental responsibility, it’s also about worker safety and community well-being.

- Proper Labeling: Compacted waste should be clearly labeled according to its contents (e.g., hazardous waste, recyclable materials, general waste) to facilitate safe handling and disposal.

- Compliance with Regulations: All disposal activities must comply with local, state, and federal regulations regarding waste transportation, storage, and disposal. This often involves obtaining permits and following specific procedures.

- Secure Transportation: Compacted waste must be transported securely to prevent spills or leaks during transit. This often involves using appropriate containers or vehicles.

- Designated Disposal Sites: Waste should be transported to legally permitted landfills or recycling facilities. Improper disposal can lead to significant environmental and legal ramifications.

- Waste Tracking and Documentation: Maintaining detailed records of waste generation, compaction, and disposal is essential for compliance and auditing purposes. This documentation serves as proof of adherence to regulations.

- Employee Training: All employees handling compacted waste must receive thorough training on safe handling procedures, emergency protocols, and regulatory compliance.

A well-defined waste management plan, including emergency procedures, is crucial for ensuring the safe disposal of compacted waste. Neglecting these steps can lead to serious consequences, including environmental damage, legal penalties, and safety hazards.

Q 18. What are the cost considerations associated with waste compaction?

Cost considerations in waste compaction are multifaceted and should be carefully evaluated before implementing a system. Think of it like budgeting for any large project – you need to account for all the costs involved.

- Initial Investment: This includes the cost of purchasing or leasing compaction equipment. This can vary significantly depending on the type, size, and features of the equipment.

- Installation Costs: This may include site preparation, electrical work, and installation of the equipment.

- Operating Costs: These are ongoing costs that include energy consumption, maintenance, repairs, labor, and transportation to disposal sites. Energy costs, for instance, can be significantly reduced by using energy-efficient compactors.

- Maintenance and Repair Costs: Regular preventative maintenance can significantly reduce repair costs in the long run. Unexpected breakdowns can lead to substantial downtime and expenses.

- Disposal Fees: Costs associated with transporting and disposing of compacted waste at landfills or recycling facilities vary based on location and waste type.

- Labor Costs: The cost of labor depends on the size of the operation and the level of automation. Automated systems can reduce labor costs but involve a higher initial investment.

A comprehensive cost-benefit analysis, considering both upfront and ongoing costs, is essential before making a decision on waste compaction systems. This will help optimize the investment and ensure a sustainable solution.

Q 19. How do you manage waste compaction in a large-scale operation?

Managing waste compaction in large-scale operations requires a well-structured and systematic approach. It’s like orchestrating a complex symphony – each instrument (process) must work in harmony to achieve the desired outcome.

- Centralized Waste Management System: A centralized system with designated collection points and clearly defined routes optimizes waste flow and reduces transportation costs.

- Optimized Equipment Selection: Deploying a mix of compactors, balers, and other equipment tailored to different waste streams ensures efficient processing.

- Regular Maintenance Schedules: Implementing a preventative maintenance schedule minimizes downtime and reduces repair costs. This includes regular inspections, lubrication, and parts replacement.

- Automated Systems: Incorporating automated systems, where appropriate, increases efficiency and reduces labor costs. Automated compactors, for example, require less manual intervention.

- Data Monitoring and Analysis: Employing a robust data tracking system allows for real-time monitoring of key performance indicators (KPIs) and aids in identifying areas for improvement.

- Employee Training and Safety Protocols: Comprehensive training programs and stringent safety protocols are essential for a safe and efficient operation.

Large-scale operations often benefit from sophisticated waste management software that helps track waste streams, optimize routes, and manage equipment maintenance. For example, real-time data on equipment performance can help predict potential problems before they lead to major downtime.

Q 20. What are the best practices for minimizing downtime in waste compaction operations?

Minimizing downtime in waste compaction operations is crucial for maintaining efficiency and profitability. Think of it as keeping your production line running smoothly.

- Preventative Maintenance: Implementing a rigorous preventative maintenance program is paramount. This involves regular inspections, lubrication, and timely replacement of parts.

- Predictive Maintenance: Utilizing sensor technology and data analysis to predict potential equipment failures allows for proactive interventions, minimizing unexpected downtime.

- Spare Parts Inventory: Maintaining a sufficient inventory of commonly used spare parts reduces downtime associated with part replacements.

- Skilled Technicians: Having a team of skilled technicians who are well-trained on equipment repair and maintenance is vital for quick and efficient repairs.

- Equipment Redundancy: In large operations, having backup equipment can mitigate the impact of unexpected breakdowns.

- Regular Inspections: Frequent visual inspections by trained personnel can help identify potential issues before they escalate into major problems.

By investing in these preventative measures, businesses can significantly reduce downtime and ensure the smooth operation of their waste compaction systems. For example, a well-maintained compactor will need fewer emergency repairs, which directly translates to reduced downtime and cost savings.

Q 21. Describe your experience with data analysis related to waste compaction (e.g., volume reduction, cost savings).

Data analysis plays a crucial role in optimizing waste compaction operations. It’s like having a crystal ball that helps you foresee trends and make informed decisions.

In my experience, I’ve used data analysis to:

- Measure Volume Reduction: By tracking the input and output volumes of waste, I’ve determined the actual compaction ratios achieved by different equipment and processes. This data helps optimize compaction strategies and select the most efficient equipment.

- Calculate Cost Savings: Analyzing data on energy consumption, maintenance costs, and disposal fees allows for precise calculation of cost savings achieved through improved compaction techniques or equipment upgrades. For instance, a switch to a more energy-efficient compactor yielded significant savings in energy costs.

- Identify Trends and Patterns: Analyzing historical data reveals trends in waste generation, compaction performance, and downtime. This helps in predictive maintenance and resource allocation.

- Improve Operational Efficiency: By identifying bottlenecks and inefficiencies in the waste compaction process, I’ve proposed changes that improved throughput and reduced operational costs. This often involved process improvements or equipment optimization.

- Optimize Equipment Utilization: Data analysis helped determine the optimal utilization of equipment, leading to better scheduling and reduced idle time.

Using statistical software and data visualization tools, I’ve presented compelling reports and dashboards to illustrate the results of these analyses and guide decision-making. For example, I’ve used data to demonstrate the ROI of investing in new, more efficient equipment.

Q 22. How do you handle emergency situations related to compaction equipment?

Handling emergency situations with compaction equipment requires a swift and methodical approach. My first priority is always safety. This involves immediately securing the area, ensuring all personnel are clear of the malfunctioning equipment, and then assessing the nature of the emergency.

For example, if a compactor malfunctions due to a hydraulic leak, I would first shut down the machine completely, using the emergency stop button if necessary. I would then contact maintenance personnel, following established protocols for reporting equipment failures. Depending on the severity, this might involve isolating the power supply and preventing further operation until repairs are made. If there’s a fire, the procedure shifts to immediate evacuation and calling emergency services, prioritizing personnel safety above all else. Following the incident, a thorough investigation is undertaken to identify the root cause and prevent future occurrences. This often includes reviewing maintenance logs, operator training records, and the equipment’s service history.

In another scenario, a jammed compactor might require a more hands-on approach – after ensuring safety, using appropriate tools (following lockout/tagout procedures) to clear the blockage, ensuring that all safety protocols are observed during this process. Proper training and adherence to manufacturer guidelines are crucial in effective emergency response.

Q 23. Explain your experience with different types of waste containers used in conjunction with compaction.

My experience encompasses a wide range of waste containers used in conjunction with compaction systems. This includes roll-off containers of varying sizes, front-load containers (the familiar large bins often seen in commercial areas), and self-contained compacting units like those found in many restaurants and office buildings. I’ve also worked with specialized containers designed for specific waste streams, such as those for recycling (often color-coded for different materials) or hazardous waste, which require enhanced safety features.

The choice of container is heavily influenced by the type and volume of waste generated, the available space, and the type of compactor used. For instance, high-volume waste generators may use large roll-off containers that are emptied less frequently by large-capacity compactors. Smaller businesses might opt for smaller, front-load containers emptied by a smaller, mobile compactor, or even self-contained compacting units that reduce the frequency of external pick-ups. In every case, careful consideration of container size, compatibility with the compactor, and durability are essential to optimize the efficiency and safety of the waste management process.

Q 24. What are the differences between stationary and mobile compactors?

Stationary and mobile compactors serve different needs based on waste volume and location. Stationary compactors are typically larger, permanently installed units often found in central locations like waste transfer stations or large industrial sites. They offer higher compaction ratios and larger capacities, resulting in significant space savings and reduced transportation costs. However, they require a dedicated space and cannot be moved easily.

Mobile compactors, on the other hand, are smaller and mounted on trailers or chassis, making them highly versatile. They can be moved around a facility or even between different sites, making them suitable for various applications, such as construction sites or events with fluctuating waste volumes. While their compaction ratios might be slightly lower than stationary units, their mobility is a key advantage. They are also often more economical for businesses with moderate waste generation needing infrequent servicing and lower initial investment. Think of it like the difference between a large stationary industrial press and a smaller, portable hydraulic jack – each has its strengths and appropriate uses.

Q 25. What are some common challenges faced in waste compaction and how do you overcome them?

Waste compaction presents various challenges. One common issue is dealing with materials that are difficult to compact, such as bulky items or irregularly shaped objects. These can reduce compaction efficiency or even jam the equipment. To overcome this, we implement strategies like pre-processing the waste (e.g., breaking down large items) or utilizing compactors designed to handle a range of materials.

Another challenge is maintaining optimal equipment performance. Regular maintenance, including lubrication, inspections, and timely repairs, is crucial to prevent breakdowns and extend the lifespan of the equipment. We address this with preventative maintenance schedules and a well-defined maintenance plan. Finally, maximizing compaction efficiency requires optimizing the waste flow and handling procedures. This often involves employee training, careful waste segregation, and adjusting operational processes for maximum efficiency. For example, introducing improved sorting methods can remove non-compactable items before compaction, improving the overall efficiency of the system.

Q 26. How do you ensure compliance with all relevant safety regulations and environmental standards?

Compliance with safety and environmental regulations is paramount. I ensure this through rigorous adherence to OSHA standards (or equivalent local regulations), which includes regular safety training for personnel, proper use of personal protective equipment (PPE), and implementing lockout/tagout procedures for maintenance activities.

Environmentally, we comply with local and national regulations related to waste disposal and recycling. This involves proper handling and disposal of hazardous waste, tracking waste generation, and working with licensed waste haulers. Maintaining detailed records of maintenance, inspections, and waste disposal activities is essential for demonstrating compliance during audits. We also actively seek ways to improve our environmental footprint through efficient compaction, waste reduction initiatives, and recycling programs. A commitment to continuous improvement is essential in maintaining compliance and minimizing our environmental impact.

Q 27. Describe your experience with implementing or improving waste compaction processes.

In a previous role, I implemented a new waste compaction system at a large manufacturing facility. The existing system was inefficient, resulting in high disposal costs and inadequate space for waste storage.

My approach involved a thorough assessment of the facility’s waste generation patterns, the types of waste produced, and the available space. I then designed a new system incorporating a larger, more efficient stationary compactor complemented by strategically placed smaller, mobile compactors for areas further from the main waste processing area. This reduced transportation costs and improved efficiency. Additionally, I introduced a comprehensive employee training program emphasizing proper waste segregation and safe handling procedures. The result was a significant reduction in disposal costs, increased space efficiency, and improved workplace safety. The project also involved regular monitoring and analysis to continually optimize the system’s performance and adapt to changing waste generation patterns.

Key Topics to Learn for Waste Compaction Interview

- Waste Stream Characterization: Understanding the composition and properties of different waste types (organic, recyclable, hazardous, etc.) and their impact on compaction processes.

- Compaction Technologies: Familiarize yourself with various compaction methods (baling, shredding, densification) and their respective advantages and disadvantages. Consider the energy efficiency and environmental impact of each.

- Equipment Operation and Maintenance: Develop a strong understanding of the mechanics of compaction equipment, including troubleshooting common issues and performing routine maintenance.

- Safety Regulations and Procedures: Demonstrate knowledge of relevant safety standards and best practices related to waste handling and compaction equipment operation.

- Waste Volume Reduction and Optimization: Explore strategies for maximizing compaction efficiency, minimizing waste volume, and optimizing the entire waste management process.

- Environmental Impact: Understand the environmental implications of waste compaction, including landfill space reduction, greenhouse gas emissions, and leachate generation.

- Data Analysis and Reporting: Learn how to collect, analyze, and interpret data related to compaction performance, identifying areas for improvement and reporting key metrics.

- Economic Considerations: Analyze the cost-effectiveness of different compaction methods, considering factors like equipment costs, operating expenses, and disposal fees.

Next Steps

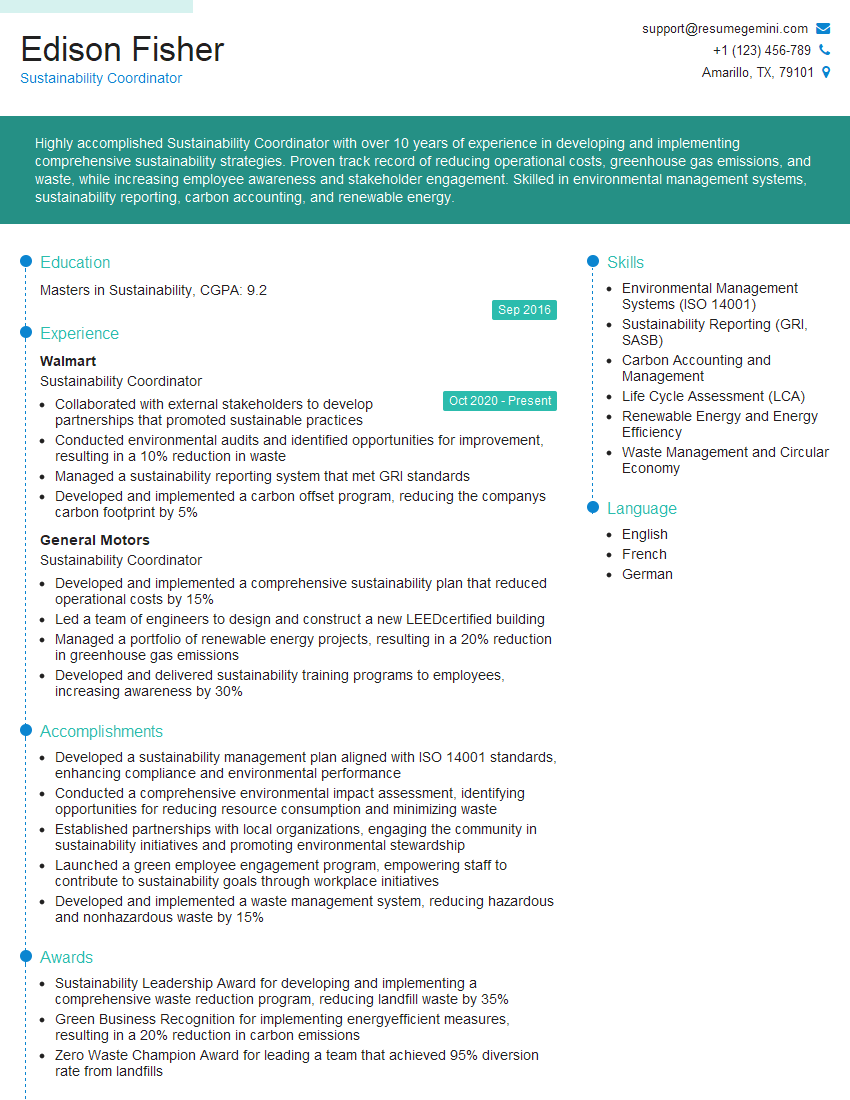

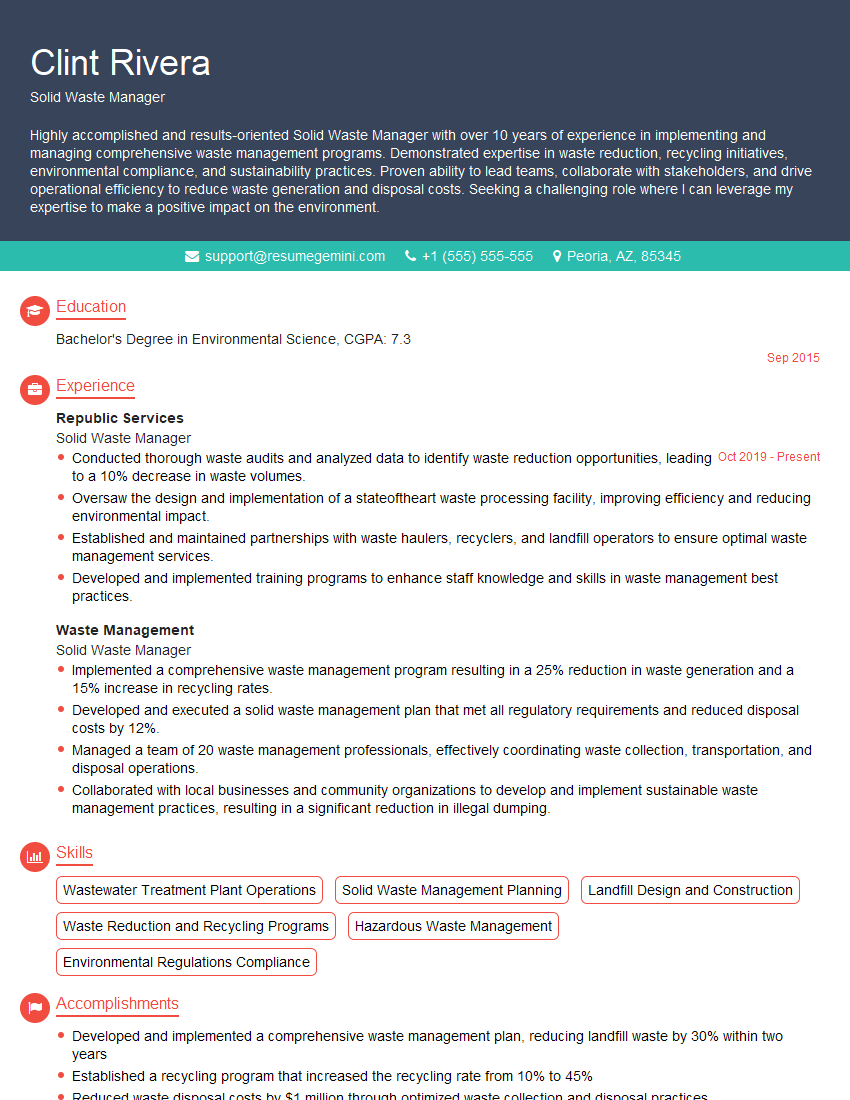

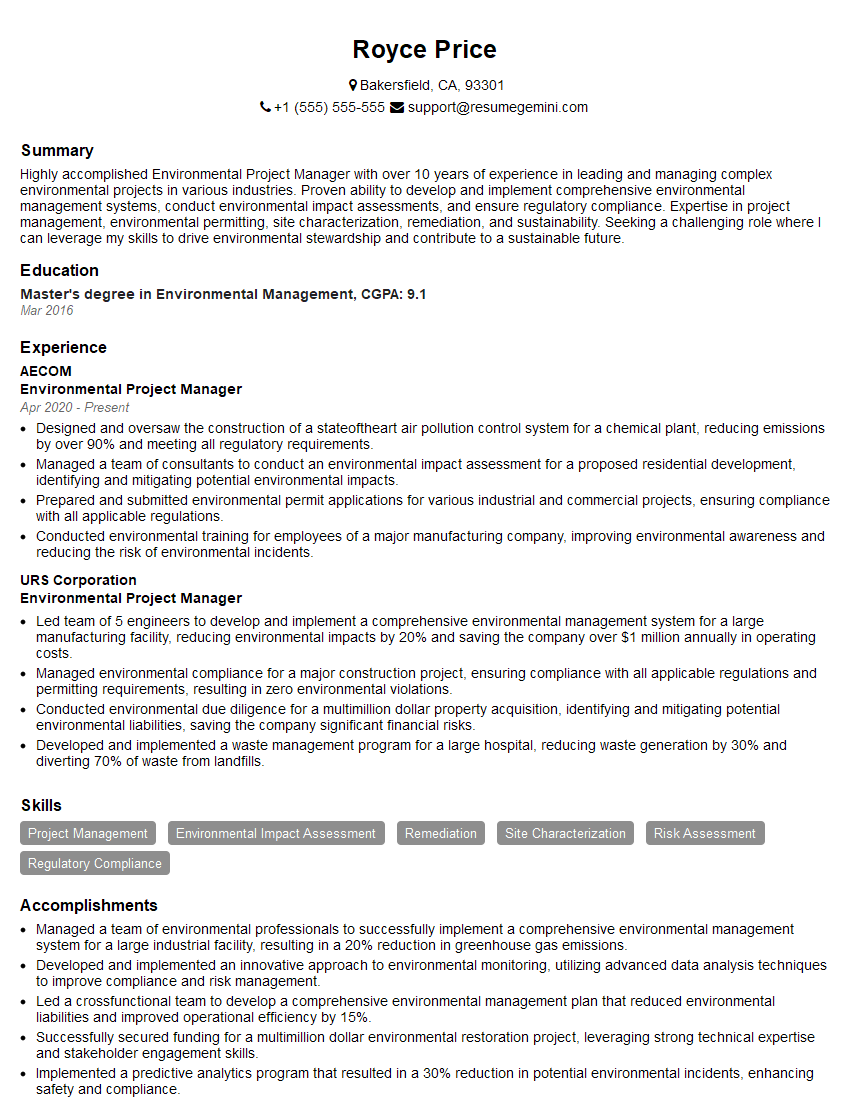

Mastering waste compaction opens doors to a rewarding career in a field crucial for environmental sustainability and resource management. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini can help you build a professional and impactful resume that highlights your skills and experience effectively. We offer examples of resumes tailored specifically to the Waste Compaction industry to give you a head start. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO