The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Scheduling Software (e.g., JDA, Orbis, Kinaxis) interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Scheduling Software (e.g., JDA, Orbis, Kinaxis) Interview

Q 1. Explain the difference between MRP and APS.

Material Requirements Planning (MRP) and Advanced Planning and Scheduling (APS) are both crucial for production planning, but they operate at different levels of sophistication and scope. MRP is a foundational system focusing on dependent demand – the demand for components needed to manufacture a finished product. It uses a bill of materials (BOM) and a master production schedule (MPS) to calculate the required quantities of raw materials and components needed at each stage of production. Think of it as a recipe: if you need to bake 10 cakes, MRP calculates how much flour, sugar, and eggs you need.

APS, on the other hand, is a more advanced system that encompasses MRP and extends it to include independent demand forecasting, capacity planning, and optimization across the entire supply chain. It considers factors like market demand, resource constraints, and supplier lead times to create a more holistic and optimized production plan. It’s like having a sophisticated kitchen manager who not only knows the recipes but also manages inventory, staffing, and customer orders to ensure everything runs smoothly and efficiently. APS provides a more comprehensive view, allowing for what-if analysis and proactive adjustments to minimize disruptions and maximize profitability.

- MRP: Primarily focuses on dependent demand, relies on a BOM and MPS, simpler to implement.

- APS: Includes MRP functionalities, handles independent demand, integrates capacity planning and optimization, more complex, provides greater visibility and control.

Q 2. Describe your experience with demand planning and forecasting.

My experience with demand planning and forecasting spans over eight years, encompassing diverse industries including consumer packaged goods and manufacturing. I’ve extensively utilized statistical forecasting methods such as ARIMA, exponential smoothing, and regression analysis within various APS systems like JDA and Kinaxis. I’m proficient in using both qualitative and quantitative methods, understanding that combining historical data with expert opinions often yields the most accurate predictions.

For instance, in a previous role, we were tasked with forecasting demand for a seasonal product. By combining historical sales data with market research insights, such as upcoming marketing campaigns and competitor activities, we were able to significantly improve our forecast accuracy, leading to a 15% reduction in inventory holding costs and a 10% increase in on-time delivery.

Furthermore, I’m experienced in incorporating external factors into my forecasts, such as economic indicators, weather patterns, and geopolitical events. I understand that static forecasts are insufficient and regularly review and update my models to reflect changing market conditions.

Q 3. How would you handle a sudden disruption to the supply chain?

Handling a sudden supply chain disruption requires a swift and coordinated response. My approach involves a structured process, prioritizing communication and collaboration across all relevant departments.

- Assess the Impact: First, I’d determine the severity and scope of the disruption, identifying the affected products, production lines, and suppliers.

- Communicate Effectively: Clear and timely communication is vital. I’d inform all stakeholders – internal teams, suppliers, and potentially customers – about the situation and the potential consequences.

- Identify Mitigation Strategies: Depending on the nature of the disruption, potential strategies include finding alternative suppliers, adjusting production schedules, prioritizing critical products, and engaging in collaborative problem-solving with affected parties.

- Implement and Monitor: Selected mitigation strategies are immediately implemented and closely monitored for effectiveness.

- Post-Incident Review: After the immediate crisis is resolved, a thorough post-incident review is conducted to identify root causes, areas for improvement in supply chain resilience, and prevent future occurrences.

For example, during a supplier factory fire that impacted a crucial component, we quickly identified alternative suppliers, prioritized production of essential products, and communicated the situation to our customers. Though the initial impact was felt, our proactive measures limited long-term disruptions and maintained customer trust.

Q 4. What are the key performance indicators (KPIs) you use to measure scheduling effectiveness?

Key performance indicators (KPIs) for measuring scheduling effectiveness depend on the specific business goals, but common metrics include:

- On-Time Delivery (OTD): The percentage of orders delivered on or before the scheduled delivery date. This is a crucial metric reflecting customer satisfaction and operational efficiency.

- Inventory Turnover Rate: Measures how efficiently inventory is managed. A higher rate indicates faster sales and lower holding costs.

- Production Schedule Adherence: The extent to which the actual production schedule matches the planned schedule, indicating planning accuracy and execution effectiveness.

- Capacity Utilization Rate: The percentage of available capacity being used. This helps to identify potential bottlenecks and optimize resource allocation.

- Order Fulfillment Cycle Time: The time it takes to process an order from placement to delivery, reflecting the overall efficiency of the supply chain.

- Customer Satisfaction: Direct feedback from customers on their experience with order fulfillment and delivery. This is a vital metric, tying operational efficiency to business success.

By tracking and analyzing these KPIs, we can identify areas for improvement and fine-tune our scheduling strategies to enhance efficiency and profitability.

Q 5. Explain your understanding of capacity planning within a scheduling system.

Capacity planning within a scheduling system involves determining the available resources and their capacity to meet the production demands. It’s crucial for preventing over-scheduling, maximizing resource utilization, and ensuring on-time delivery. This involves analyzing various resources such as machines, labor, materials, and storage space.

A typical capacity planning process involves:

- Resource Identification: Identifying all relevant resources and their individual capacity.

- Demand Forecasting: Predicting future demand for products and services.

- Capacity Calculation: Determining the total capacity of each resource and comparing it to the forecasted demand.

- Capacity Gaps Identification: Identifying any potential shortfalls or over-capacities.

- Capacity Optimization: Developing strategies to address capacity gaps, such as investing in new equipment, optimizing production processes, or adjusting scheduling policies.

For example, in a manufacturing plant, capacity planning might involve analyzing the production capacity of assembly lines, considering machine downtime, employee availability, and material supply. The APS system would then utilize this information to create a production schedule that efficiently utilizes available resources and minimizes production delays.

Q 6. How familiar are you with different scheduling algorithms (e.g., FIFO, LIFO, etc.)?

I’m very familiar with various scheduling algorithms, including FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and more sophisticated methods such as shortest processing time, earliest due date, and critical ratio.

FIFO is simple and straightforward but may not be optimal in situations with varying priorities or processing times. LIFO can be useful for managing perishable goods but can lead to long wait times for items that have been waiting longer. The shortest processing time algorithm prioritizes jobs with the shortest processing times, leading to higher throughput. Earliest due date aims to minimize the number of late jobs. The critical ratio algorithm prioritizes jobs based on their urgency and remaining processing time.

The choice of algorithm depends on the specific context and objectives. In some cases, a hybrid approach combining multiple algorithms might be the most effective strategy. For example, a manufacturing facility might use a combination of earliest due date and shortest processing time algorithms to balance the need for timely delivery with maximizing overall throughput.

Q 7. Describe your experience using JDA’s demand planning module.

I have extensive experience using JDA’s demand planning module, specifically versions 9.1 and 10.0. I’ve utilized its various features, including statistical forecasting methods, collaborative forecasting workflows, and scenario planning capabilities.

In a past project, we used JDA’s demand planning module to improve forecast accuracy for a large retail chain. By leveraging its advanced statistical models and incorporating promotional activities into the forecasts, we achieved a 20% reduction in forecast error, resulting in substantial savings in inventory costs and improved customer service levels.

My expertise extends to configuring and customizing JDA’s demand planning module to meet specific business requirements, such as integrating it with other systems, defining custom metrics, and developing automated reporting processes.

I’m also familiar with the data management aspects, including data cleansing, validation, and visualization, crucial for ensuring the accuracy and reliability of the forecasts generated by the JDA system.

Q 8. How would you optimize inventory levels using Kinaxis RapidResponse?

Optimizing inventory levels in Kinaxis RapidResponse involves leveraging its powerful forecasting and simulation capabilities. It’s not just about finding the ‘right’ number, but about finding the optimal balance between minimizing holding costs and maximizing service levels. This requires a multi-faceted approach:

Accurate Forecasting: RapidResponse’s advanced forecasting algorithms, incorporating various data sources like historical sales, market trends, and promotions, provide a crucial foundation. We can refine these models using techniques like causal forecasting to account for external factors influencing demand.

Demand Sensing: We actively monitor real-time sales data and incorporate early signals of changing demand to proactively adjust inventory plans. This reduces the risk of stockouts or excess inventory due to unforeseen events.

Supply Chain Visibility: RapidResponse’s integrated supply chain model allows us to visualize the entire flow of materials, identifying potential bottlenecks and delays that might impact inventory needs. This proactive approach ensures we have the right inventory at the right place at the right time.

Simulation and What-If Analysis: Before implementing any changes, we run simulations to test different inventory strategies, evaluating their impact on key performance indicators (KPIs) like inventory turnover, fill rate, and service levels. This reduces the risk of unintended consequences.

Inventory Optimization Rules: We can define specific rules within RapidResponse to automatically adjust inventory based on pre-defined parameters. For example, we might set rules for safety stock levels based on demand variability and lead times.

For example, in a previous role, we used RapidResponse to optimize inventory for a seasonal product. By incorporating weather forecasts into the demand model and running simulations, we were able to significantly reduce inventory holding costs while maintaining a 99% service level during peak season.

Q 9. Explain your experience with Orbis’s simulation and what-if analysis tools.

My experience with Orbis’s simulation and what-if analysis tools centers around leveraging its capabilities to model complex supply chains and assess the impact of various scenarios. Orbis excels at creating detailed, dynamic models that reflect the intricate relationships between different parts of a supply chain. This allows for sophisticated scenario planning and risk mitigation.

Scenario Planning: I’ve used Orbis to model various ‘what-if’ scenarios, such as disruptions to key suppliers, changes in demand, or unexpected transportation delays. This proactive approach helps identify potential vulnerabilities and develop contingency plans.

Capacity Planning: Orbis’s simulation capabilities allow for accurate capacity planning, ensuring that production capacity aligns with forecasted demand. This prevents bottlenecks and ensures efficient resource utilization.

Optimization: By running various simulations and analyzing the results, we can identify optimal configurations for inventory levels, production schedules, and transportation networks. This leads to significant cost savings and improved efficiency.

In a past project involving a global manufacturing company, we used Orbis to simulate the impact of a potential port strike. The simulations revealed critical vulnerabilities and enabled the company to proactively secure alternative shipping routes, preventing significant production delays and financial losses. The visualizations and reporting features in Orbis were particularly useful in communicating the findings to stakeholders.

Q 10. How do you handle conflicting priorities in scheduling?

Handling conflicting priorities in scheduling requires a structured approach that prioritizes tasks based on factors like urgency, importance, and dependencies. I utilize a combination of techniques:

Prioritization Matrix: I often employ a prioritization matrix (like Eisenhower Matrix) to categorize tasks based on urgency and importance. This helps focus on critical tasks first while delegating or postponing less critical ones.

Dependency Analysis: Before scheduling, I identify task dependencies, determining the order in which tasks must be completed. This ensures a logical workflow and prevents delays.

Negotiation and Communication: When conflicts arise, open communication with stakeholders is crucial. It’s about finding mutually acceptable solutions through negotiation, perhaps involving trade-offs or re-prioritization based on updated information.

Resource Allocation: Effective allocation of resources (people, machines, materials) is essential in resolving scheduling conflicts. This involves optimizing resource utilization to meet the highest priority tasks first.

Project Management Software: Tools like MS Project or Jira allow for visual representation of tasks and dependencies, facilitating the identification and resolution of scheduling conflicts.

For instance, I once faced a scenario where a high-priority order required resources already allocated to a less urgent project. Through negotiation with the project manager, we agreed to slightly delay the less urgent project, allowing us to complete the high-priority order on time without jeopardizing both projects entirely.

Q 11. How would you address production bottlenecks using scheduling software?

Addressing production bottlenecks using scheduling software involves a systematic approach focusing on identifying the root cause and implementing corrective actions. The software plays a crucial role in visualizing bottlenecks and exploring solutions.

Bottleneck Identification: The scheduling software allows visualization of the entire production process, highlighting areas where tasks are delayed or resources are overutilized. This often involves analyzing metrics like machine utilization, work-in-progress (WIP), and cycle times.

Root Cause Analysis: Once a bottleneck is identified, a root cause analysis is performed to understand the underlying reasons for the delay. This might involve investigating machine breakdowns, material shortages, process inefficiencies, or skill gaps in the workforce.

Solution Implementation: Depending on the root cause, solutions can range from adjusting machine schedules to improve resource allocation, implementing process improvements to reduce cycle times, procuring additional materials or equipment, or providing additional training to improve worker efficiency.

Simulation and Optimization: The scheduling software’s simulation capabilities allow for testing various solutions before implementing them. This helps in selecting the most effective strategy and minimizing the risk of unintended consequences.

In one project, we identified a bottleneck at a specific assembly station. Using the scheduling software, we simulated different scenarios, including adding another machine, adjusting the work schedule, and streamlining the assembly process. The simulation revealed that streamlining the process was the most effective solution, resulting in a 20% increase in throughput.

Q 12. What are your strategies for mitigating supply chain risks?

Mitigating supply chain risks requires a proactive and multi-layered approach. My strategies include:

Diversification: Reducing reliance on a single supplier by working with multiple vendors reduces vulnerability to disruptions from a single source.

Risk Assessment: Regularly assessing potential risks, including political instability, natural disasters, and supplier financial difficulties, allows for proactive planning and mitigation strategies.

Inventory Management: Maintaining strategic inventory levels provides a buffer against unexpected disruptions. This involves balancing the cost of holding inventory against the risk of stockouts.

Supply Chain Visibility: Utilizing technologies that provide real-time visibility into the supply chain allows for early detection of potential problems. This enables proactive intervention to prevent disruptions.

Contingency Planning: Developing contingency plans for various scenarios, such as supplier defaults or transportation delays, ensures the business can continue operating even during disruptions.

Collaboration: Strong relationships with suppliers and logistics partners foster open communication and collaboration, enabling early identification and resolution of potential problems.

For example, during a period of geopolitical instability, we proactively diversified our sourcing for a critical component, establishing relationships with multiple suppliers in different regions. This minimized the impact of potential disruptions to our production schedule.

Q 13. Describe your experience with data analysis in the context of scheduling.

Data analysis is integral to effective scheduling. I use various techniques to extract actionable insights from scheduling data:

Performance Monitoring: Tracking key performance indicators (KPIs) such as on-time delivery, machine utilization, and inventory turnover provides insights into the efficiency of the scheduling process and identifies areas for improvement.

Trend Analysis: Analyzing historical data to identify trends in demand, lead times, and production efficiency helps in predicting future performance and making proactive adjustments to the schedule.

Root Cause Analysis: Investigating data related to production delays or other issues helps pinpoint the underlying causes, enabling targeted interventions to address them.

Predictive Analytics: Using statistical modeling and machine learning techniques to predict future demand and production bottlenecks allows for proactive scheduling adjustments to optimize resource utilization.

Data Visualization: Tools like Tableau or Power BI allow for effective visualization of scheduling data, providing stakeholders with clear insights into performance and helping to identify potential issues.

In a recent project, we used data analysis to identify a seasonal pattern in demand, enabling us to proactively adjust our production schedule to meet increased demand during peak periods and minimize inventory buildup during off-peak periods.

Q 14. How do you ensure data accuracy and integrity in scheduling systems?

Ensuring data accuracy and integrity in scheduling systems is paramount. My approach involves several key steps:

Data Validation: Implementing data validation rules to check for inconsistencies and errors before data is entered into the system. This involves checks for data type, range, and format.

Data Cleansing: Regularly cleansing the data to remove duplicates, inconsistencies, and outdated information ensures the data used for scheduling is reliable and accurate.

Data Governance: Establishing clear data governance policies and procedures defines roles and responsibilities for data management, ensuring data quality is maintained throughout the process.

Regular Audits: Periodic audits of the data and processes involved in scheduling help to identify and address any issues related to data accuracy and integrity.

Data Reconciliation: Regularly reconciling data between different systems and sources ensures consistency and reduces errors caused by data discrepancies.

Version Control: Maintaining version control of scheduling data helps to track changes and revert to previous versions if necessary.

For example, we implemented a data validation process that automatically checks for inconsistencies in order quantities and delivery dates, preventing errors from propagating through the scheduling system and impacting production schedules.

Q 15. What are the benefits of using cloud-based scheduling software?

Cloud-based scheduling software offers numerous advantages over on-premise solutions. Primarily, it eliminates the need for significant upfront investment in hardware and infrastructure. Think of it like renting an apartment versus buying a house – you pay a recurring fee for access to powerful resources instead of a large initial outlay. This also reduces IT maintenance overhead; the vendor handles updates, security patches, and system maintenance, freeing up your internal IT team to focus on other strategic initiatives.

Scalability is another key benefit. Cloud solutions easily adapt to changing business needs. If you experience a sudden surge in demand, the cloud provider can quickly allocate additional resources to handle the increased workload. Conversely, if demand dips, you can scale down your usage, avoiding wasted resources. This flexibility is invaluable in unpredictable market conditions.

- Cost Savings: Reduced hardware and IT maintenance costs.

- Scalability: Easily adapt to fluctuating demand.

- Accessibility: Access scheduling data and tools from anywhere with an internet connection.

- Enhanced Collaboration: Easier collaboration among team members and departments.

- Automatic Updates: Always working with the latest version of the software.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you collaborate with different departments (e.g., procurement, production) for effective scheduling?

Effective scheduling requires seamless collaboration across departments. In my experience, this starts with establishing clear communication channels and shared goals. For instance, with procurement, I’d use the software to share production schedules, enabling them to proactively manage material availability. Regular meetings (perhaps weekly or bi-weekly) to review upcoming production needs and potential supply chain bottlenecks are crucial. We’d jointly analyze material lead times and inventory levels to prevent production delays.

With production, the focus is on real-time updates and feedback loops. The scheduling system should provide real-time visibility into production progress, allowing for immediate adjustments if necessary. This might involve daily stand-up meetings to discuss any issues or deviations from the schedule. Using a collaborative platform within the scheduling software itself—where everyone can see the same data and track progress simultaneously— significantly improves communication efficiency.

I advocate for utilizing the software’s reporting capabilities to track key performance indicators (KPIs) across departments. This data-driven approach helps us to identify areas for improvement and ensures that everyone is working towards the same objectives. For example, tracking on-time delivery rates and inventory turnover helps gauge overall efficiency.

Q 17. Describe your experience with integrating scheduling software with other enterprise systems (e.g., ERP).

I have extensive experience integrating scheduling software with various enterprise systems, most notably ERPs (Enterprise Resource Planning) like SAP and Oracle. The integration process typically involves using APIs (Application Programming Interfaces) to exchange data between the scheduling software and the ERP. This allows for a seamless flow of information, ensuring that all systems are working from a single source of truth. For example, I’ve worked on projects where the ERP system provides the master data (bill of materials, inventory levels) to the scheduling software, which then generates a production schedule. The completed schedule is then sent back to the ERP to update production orders and inventory projections.

Challenges during integration can arise from data mapping inconsistencies or differences in data formats between systems. Careful planning and thorough testing are essential to ensure a successful integration. I usually employ a phased approach, starting with a pilot project to test the integration before rolling it out company-wide. This helps identify and resolve any issues early on.

Q 18. How do you handle changes in customer demand?

Handling changes in customer demand is a core function of any effective scheduling system. The key is to have a system that’s both flexible and responsive. I typically utilize a demand management process, where changes are analyzed for their impact on capacity and resources. We might use forecasting tools within the scheduling software to predict future demand based on historical data and market trends. When changes occur, the system should ideally provide what-if analysis capabilities, allowing us to evaluate different scenarios and choose the best response.

For example, a sudden increase in demand for a specific product might require us to prioritize production of that product, potentially delaying other orders. The system should help us to identify the optimal solution, minimizing disruptions and delays. This might involve rescheduling production runs, adjusting workforce allocation, or even outsourcing some production to meet the increased demand.

Transparency is key. Communication with customers is essential to manage expectations, particularly if delays are unavoidable. Providing accurate and timely updates keeps customers informed and fosters stronger relationships.

Q 19. What is your experience with different scheduling horizons (short-term, medium-term, long-term)?

My experience encompasses all scheduling horizons: short-term, medium-term, and long-term. Each horizon requires a different approach and level of detail. Short-term scheduling (typically daily or weekly) focuses on detailed resource allocation and production sequencing to meet immediate demands. I might use techniques like finite capacity scheduling to optimize resource utilization within the constraints of available capacity.

Medium-term scheduling (weekly to monthly) typically involves capacity planning and material procurement. I would focus on ensuring sufficient resources are available to meet forecasted demand. Long-term scheduling (months to years) involves strategic capacity planning and investment decisions. This often involves analyzing market trends, identifying potential bottlenecks, and making informed decisions about capacity expansion or technology upgrades.

The ability to seamlessly integrate these different horizons is critical. Long-term strategic plans should inform medium-term capacity planning, which, in turn, influences short-term scheduling decisions. The software should facilitate this integrated view, ensuring consistent planning across all horizons.

Q 20. Explain your understanding of master production scheduling (MPS).

Master Production Scheduling (MPS) is a high-level production plan that specifies what products will be manufactured, in what quantities, and when. Think of it as the blueprint for the entire manufacturing process. It’s a crucial component of Material Requirements Planning (MRP) and drives all downstream scheduling activities. It takes into consideration customer orders, forecasts, and available inventory. The MPS is typically created based on long-term business goals and market forecasts, considering factors like production capacity and resource availability. It provides a framework for creating more detailed schedules for individual production lines or work centers. Discrepancies between the MPS and actual production are constantly monitored and addressed through adjustments to the schedule or procurement plans.

A well-defined MPS is critical for minimizing inventory costs, optimizing production capacity, and meeting customer demand. Effective MPS relies on accurate demand forecasting and a clear understanding of production capabilities. In practical terms, a poorly defined MPS can lead to production bottlenecks, stockouts, and increased costs.

Q 21. How would you improve the efficiency of an existing scheduling process?

Improving the efficiency of an existing scheduling process requires a systematic approach. I’d begin by conducting a thorough assessment of the current process, identifying bottlenecks and inefficiencies. This might involve analyzing data from the scheduling system, conducting interviews with key stakeholders, and reviewing relevant documentation. I would look at areas like:

- Data Accuracy: Ensuring the accuracy of input data such as demand forecasts, production lead times, and resource availability.

- Process Automation: Identifying opportunities to automate manual tasks and reduce human error. Could we integrate more systems or leverage AI-driven optimization tools?

- Real-time Visibility: Improving real-time visibility into production progress to enable proactive adjustments. Are our dashboards effective, and are we monitoring the right KPIs?

- Resource Utilization: Optimizing the use of resources such as equipment and labor. Are there any idle resources or bottlenecks?

- Collaboration: Enhancing collaboration among departments and teams. Are our communication channels efficient?

Once the areas for improvement have been identified, I would develop and implement solutions, using a phased approach. Regular monitoring and adjustments are crucial to ensure that the improvements are sustainable and effective. Continuous improvement should be a core principle in any scheduling process.

Q 22. What are the limitations of the scheduling software you have used?

Even the most sophisticated scheduling software like JDA, Orbis, and Kinaxis have limitations. One common constraint is data accuracy and completeness. Inaccurate input data, whether it’s lead times, demand forecasts, or resource availability, directly impacts the quality of the schedule generated. The software is only as good as the data it receives. For example, if a supplier consistently fails to deliver on time, the schedule will be unreliable even with the most advanced algorithms. Another limitation is the inherent complexity of real-world supply chains. These systems often involve numerous unpredictable factors— unexpected equipment failures, raw material shortages, or sudden spikes in demand – which are difficult to model perfectly within the software. Finally, there’s the challenge of integrating diverse systems. Many companies have legacy systems that don’t easily integrate with modern scheduling software, leading to data silos and a lack of holistic visibility.

Another example of limitations is in the handling of highly variable and uncertain demands. While advanced forecasting techniques are used, unforeseen events can render even the best schedules obsolete. This necessitates frequent rescheduling, which can be time-consuming and resource-intensive.

Q 23. How do you prioritize tasks and projects in a fast-paced environment?

In a fast-paced environment, effective prioritization is crucial. I use a combination of techniques. First, I employ a prioritization matrix, often using a MoSCoW method (Must have, Should have, Could have, Won’t have). This categorizes tasks based on their urgency and importance, providing a clear roadmap. For example, resolving a critical supply chain bottleneck that’s impacting production would be a ‘Must have’, while implementing a minor process improvement would fall into ‘Could have’.

Secondly, I leverage the scheduling software’s inherent capabilities. Features like what-if analysis and scenario planning allow me to simulate the impact of prioritizing different tasks. This data-driven approach allows for informed decision-making. Finally, I focus on clear communication and collaboration. Regular meetings with stakeholders are vital to ensure everyone is aligned on priorities and aware of potential challenges.

Q 24. Describe your experience with reporting and dashboarding within scheduling software.

My experience with reporting and dashboarding in scheduling software is extensive. I’m proficient in extracting key performance indicators (KPIs) like on-time delivery, inventory turnover, and production efficiency. I use these KPIs to monitor the performance of the schedule and identify areas for improvement. For instance, if on-time delivery consistently falls below target, I can investigate the root causes— whether it’s supplier issues, capacity constraints, or transportation delays. This analysis helps me fine-tune the scheduling parameters or implement corrective actions.

I’ve utilized various dashboarding techniques including creating custom reports to visualize key data points. For example, I’ve developed dashboards showing projected inventory levels over time, highlighting potential stockouts or overstocking situations. This helps anticipate problems and proactively adjust the schedule.

Q 25. How do you stay updated with the latest trends and technologies in supply chain scheduling?

Staying current in supply chain scheduling requires a multi-pronged approach. I regularly attend industry conferences and webinars, subscribe to relevant journals (like the Journal of Business Logistics), and actively participate in online communities and forums. This exposure keeps me abreast of emerging trends such as AI-powered forecasting, blockchain technology for enhancing transparency, and the increasing use of digital twins for supply chain simulation.

I also follow key industry influencers and thought leaders on social media platforms such as LinkedIn, which provides valuable insights into innovative solutions and best practices. Furthermore, I proactively seek out opportunities for professional development, including online courses and certifications, to deepen my knowledge of new tools and techniques.

Q 26. Explain your approach to problem-solving in a scheduling context.

My approach to problem-solving in a scheduling context is systematic and data-driven. I typically follow a structured process: First, I clearly define the problem. This includes identifying the symptoms, the root cause (often using the 5 Whys technique), and the impact on the overall schedule. For example, if a production line is experiencing delays, I would investigate the reason behind these delays – is it a machine malfunction, material shortages, or unskilled labor?

Next, I gather data to support my analysis. This may involve reviewing historical data, conducting interviews with stakeholders, or utilizing the scheduling software’s analytical tools. Then, I brainstorm and evaluate potential solutions. This involves considering the feasibility, cost, and impact of each solution. After selecting the best option, I implement it, monitor its effectiveness, and make necessary adjustments based on the results. This iterative process ensures continuous improvement.

Q 27. What are your salary expectations?

My salary expectations are in line with my experience and skills in supply chain scheduling, specifically with my expertise in JDA, Orbis, and Kinaxis. Considering my years of experience and accomplishments, I am seeking a compensation package in the range of [Insert Salary Range]. I am open to discussing this further, taking into consideration the specific responsibilities and benefits offered.

Key Topics to Learn for Scheduling Software (e.g., JDA, Orbis, Kinaxis) Interview

- Demand Forecasting & Planning: Understanding different forecasting methodologies and their application within the software. Learn how to analyze historical data, identify trends, and build accurate forecasts to optimize schedules.

- Capacity Planning & Resource Allocation: Mastering the techniques for effectively allocating resources (labor, equipment, materials) based on forecasted demand. Explore different scheduling algorithms and their impact on efficiency and cost.

- Constraint Management: Understand how to identify and address various constraints (e.g., material availability, labor limitations, machine capacity) within the scheduling process. Learn to use the software’s tools to find optimal solutions.

- Order Management & Sequencing: Learn how to effectively manage and sequence orders within the software, considering factors such as due dates, priorities, and resource availability. Understand how different sequencing rules impact overall performance.

- Simulation & What-If Analysis: Learn to leverage the simulation capabilities of the software to test different scenarios and assess their impact on the schedule. This involves understanding how to interpret simulation results and make data-driven decisions.

- Reporting & Analytics: Understand the reporting features of the software and how to extract key performance indicators (KPIs) to monitor schedule performance and identify areas for improvement. Learn to effectively communicate insights from data analysis.

- Software Specific Features: Familiarize yourself with the unique features and functionalities of the specific scheduling software you are interviewing for (JDA, Orbis, Kinaxis). Focus on understanding their strengths and how they can be applied in various scenarios.

- Problem-Solving & Troubleshooting: Practice identifying and resolving common scheduling issues. Be prepared to discuss your approach to problem-solving and your ability to think critically under pressure.

Next Steps

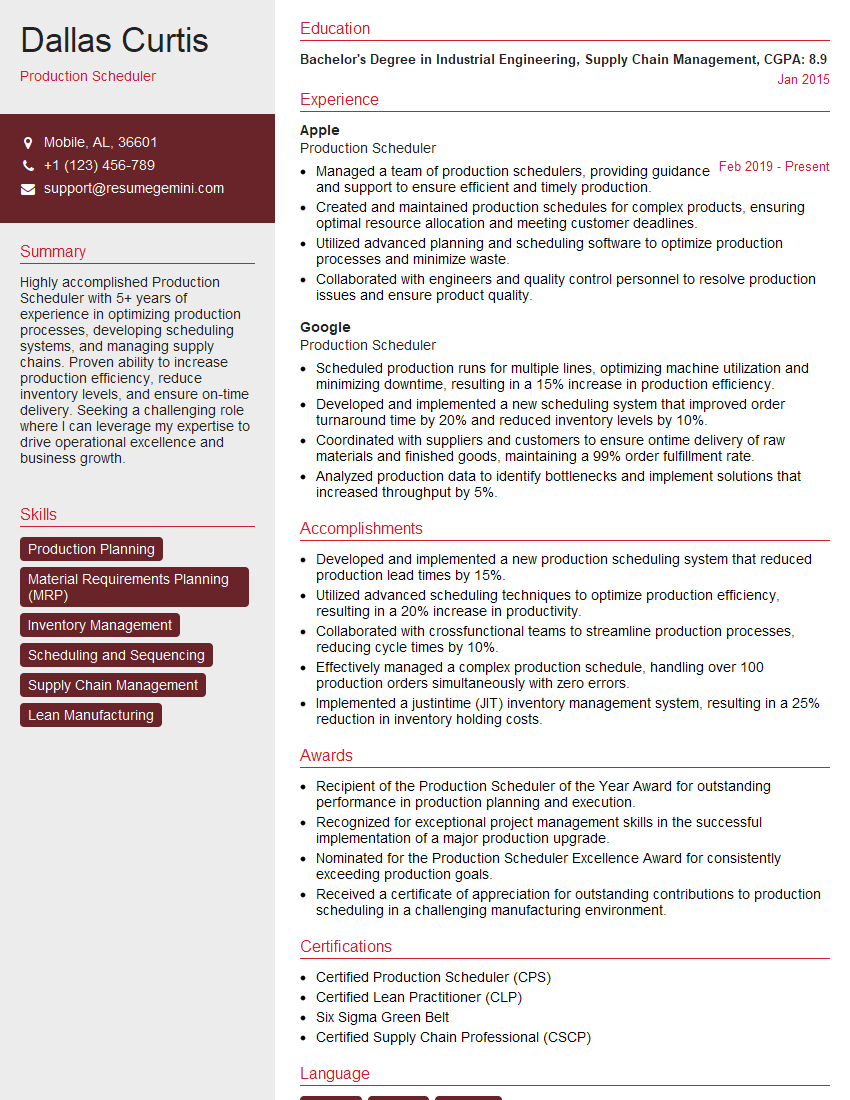

Mastering scheduling software like JDA, Orbis, or Kinaxis is crucial for career advancement in supply chain and operations management, opening doors to exciting opportunities and higher earning potential. To significantly enhance your job prospects, focus on creating an ATS-friendly resume that clearly highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to showcasing experience with JDA, Orbis, and Kinaxis, helping you stand out from the competition.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO