Preparation is the key to success in any interview. In this post, we’ll explore crucial Hazardous Materials Transportation Endorsement (HAZMAT) interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Hazardous Materials Transportation Endorsement (HAZMAT) Interview

Q 1. Explain the classification of hazardous materials according to the Hazardous Materials Regulations (HMR).

The Hazardous Materials Regulations (HMR) classify hazardous materials based on their inherent dangers. This classification system is crucial for ensuring safe transportation and handling. Think of it like sorting laundry – different types of clothing need different washing instructions, just as different hazardous materials need specific handling procedures.

The classification isn’t arbitrary; it’s based on the material’s properties and how it could pose a risk during transport. The HMR uses a nine-class system, each representing a specific hazard category, along with various divisions within those classes to further refine the risk assessment. This meticulous categorization allows for the development of appropriate safety regulations and emergency response protocols.

Q 2. Describe the different hazard classes and divisions within the HMR.

The HMR’s nine hazard classes, with examples and divisions where applicable, are:

- Class 1: Explosives (Divisions 1.1-1.6, based on the explosive’s mass explosion hazard and fire hazard): Think dynamite or fireworks.

- Class 2: Gases (Divisions 2.1-2.3, based on flammability, toxicity, and reactivity): Examples include propane, oxygen, and chlorine.

- Class 3: Flammable Liquids: Gasoline, paint thinner.

- Class 4: Flammable Solids (Divisions 4.1-4.3, based on flammability and water reactivity): Matches, magnesium.

- Class 5: Oxidizers and Organic Peroxides (Divisions 5.1 and 5.2): Bleach, hydrogen peroxide.

- Class 6: Toxic and Infectious Substances (Divisions 6.1 and 6.2): Pesticides, biological materials.

- Class 7: Radioactive Materials: Nuclear fuel, medical isotopes.

- Class 8: Corrosive Materials: Battery acid, drain cleaner.

- Class 9: Miscellaneous Hazardous Materials: Materials that don’t fit into other classes but pose a significant hazard during transport; this class is a catch-all for various materials that present unique risks.

Understanding these classes and divisions is paramount for proper packaging, labeling, and transportation.

Q 3. What are the requirements for marking and labeling hazardous materials packages?

Marking and labeling hazardous materials packages are non-negotiable safety measures. Imagine a grocery store without labels – chaos! Similarly, clear labeling on hazardous materials is crucial for immediate identification of the hazards. The HMR mandates specific requirements for marking and labeling, which include:

- Labels: These diamond-shaped labels clearly identify the hazard class and division using standardized colors and symbols. Each package must have a label corresponding to its contents’ hazard classification.

- Marking: This involves adding additional information beyond the label, such as the proper shipping name, UN number (a unique identification code for each hazardous material), and other necessary details.

For example, a package containing gasoline would require a Class 3 (Flammable Liquid) label and be marked with the proper shipping name (‘Gasoline’), UN number, and other relevant information. The proper placement of labels and markings on the package is also critical.

Q 4. What are the requirements for shipping papers for hazardous materials?

Shipping papers, also known as the Shipper’s Declaration for Dangerous Goods, are essential documents accompanying hazardous materials during transport. They are like a passport for the shipment, providing essential information to emergency responders and transportation personnel. Key requirements include:

- Accurate description of the hazardous material: Using the proper shipping name and UN number.

- Quantity of hazardous material: Precisely stated in the appropriate units.

- Hazard class and division: Clearly indicated.

- Shipper and consignee information: Contact details of the sender and receiver.

- Emergency contact information: Details of someone available 24/7 in case of an incident.

The completeness and accuracy of shipping papers are crucial for effective emergency response and prevention of accidents. Inconsistent or missing information can lead to delays and complicate emergency response.

Q 5. Explain the different types of placards used for hazardous materials transportation.

Placards are large, diamond-shaped signs displayed on the outside of vehicles transporting hazardous materials. They are crucial for alerting emergency responders and other drivers to the presence of hazardous materials. The placard color and symbol correspond to the hazard class of the material being transported, ensuring quick recognition of the potential hazards. Multiple placards might be needed if the shipment contains multiple hazard classes.

For instance, a truck carrying flammable liquids would display a red placard with the flame symbol. The size of the placard depends on the size of the vehicle and the quantity of hazardous materials being transported.

Proper placarding is crucial for accident prevention and response. Improper or missing placards can result in serious consequences, such as delayed emergency response and increased risk of accidents.

Q 6. What are the requirements for the emergency response information for hazardous materials shipments?

Emergency response information is critical for handling incidents involving hazardous materials. This information must be readily available to first responders and other relevant personnel. Key requirements include:

- Emergency response guidebook: A readily accessible guide providing information on the specific hazards of the materials being transported and appropriate response procedures.

- Emergency contact numbers: 24/7 contact details for the shipper, carrier, and emergency response professionals.

- Safety Data Sheets (SDS): Detailed information about the chemical properties, hazards, and handling procedures for each hazardous material.

Imagine a situation where a truck carrying hazardous materials is involved in an accident. The quick availability of emergency response information would allow first responders to assess the situation, take appropriate measures to mitigate risks, and ensure the safety of themselves and the public.

Q 7. What are the requirements for the training of hazardous materials employees?

Training for hazardous materials employees is paramount for safe transportation. It’s not enough to simply understand the regulations; employees need practical knowledge and skills to handle hazardous materials responsibly. The HMR mandates specific training requirements based on the employee’s role and responsibilities, which often involves both initial and recurrent training. This training must cover topics such as:

- Hazard communication: Understanding safety data sheets, labels, and placards.

- Proper handling and packaging procedures: Safe practices for loading, securing, and unloading hazardous materials.

- Emergency response procedures: Knowing how to react in case of spills, leaks, or other incidents.

- Regulations and compliance: Understanding the relevant HMR requirements and documentation.

Regular refresher training is crucial to maintain competency and adapt to changes in regulations and best practices. Well-trained employees are the first line of defense against accidents involving hazardous materials.

Q 8. Describe the different types of hazardous materials containers and their applications.

Hazardous materials containers are designed and manufactured to specific standards to ensure the safe containment and transport of dangerous goods. The type of container used depends heavily on the properties of the hazardous material being transported. Think of it like choosing the right tool for a job – you wouldn’t use a hammer to screw in a screw!

- Cylinders: These are pressure vessels, typically made of steel or aluminum, used for compressed gases, liquefied gases, and some other materials. Imagine a propane tank for your grill – that’s a cylinder.

- Drums: Steel, plastic, or fiber drums are commonly used for liquids and solids. These are the large barrels you might see carrying chemicals in industrial settings.

- Carboys: Glass or plastic carboys are used for smaller quantities of liquids, often corrosive materials. They’re essentially large, robust bottles.

- Bags: Flexible intermediate bulk containers (FIBCs), also known as ‘big bags,’ are used for granular solids. You’ve likely seen these large fabric containers used for things like cement or fertilizers.

- Tank Trucks and Tank Cars: These are bulk transport options for larger quantities of liquids and gases. Think of the large tanker trucks you see on highways carrying fuel.

The selection of the appropriate container involves considering factors like the material’s physical and chemical properties (flammability, corrosivity, reactivity), its quantity, and the mode of transport. Incorrect packaging can lead to serious consequences, including leaks, fires, or explosions.

Q 9. What are the requirements for transporting hazardous materials by different modes of transportation (e.g., highway, rail, air, sea)?

Transporting hazardous materials requires adherence to stringent regulations that vary based on the mode of transport. This is crucial for preventing accidents and protecting the public and environment.

- Highway: Requires the use of properly marked vehicles, a hazardous materials endorsement on the driver’s license, and compliance with Department of Transportation (DOT) regulations including proper placarding and shipping papers. This includes specifications for the vehicle’s construction and maintenance.

- Rail: Hazardous materials are transported in specialized tank cars or other containers designed to withstand the rigors of rail transport. Rail transport is governed by the Federal Railroad Administration (FRA) and necessitates strict adherence to packaging, labeling, and handling requirements.

- Air: Air transport of hazardous materials is governed by the International Civil Aviation Organization (ICAO) and the International Air Transport Association (IATA) regulations. This is highly regulated due to safety concerns related to passenger safety and potential damage in flight. Only certain materials are allowed, and packaging requirements are exceptionally rigorous.

- Sea: Maritime transport of hazardous materials is regulated by the International Maritime Organization (IMO) and the U.S. Coast Guard. This involves strict documentation, special packaging, and labeling requirements depending on the material’s properties and the type of vessel.

Each mode has specific requirements for documentation, emergency response plans, and safety training for personnel involved. Failure to comply can result in severe penalties and legal repercussions.

Q 10. Explain the role of the shipper, carrier, and receiver in hazardous materials transportation.

The shipper, carrier, and receiver each play a critical role in the safe transportation of hazardous materials. They share responsibility for ensuring compliance with all applicable regulations.

- Shipper: The shipper is responsible for properly classifying the hazardous material, selecting appropriate packaging, preparing the shipping papers (including the Safety Data Sheet), and marking and labeling the package accurately. They are essentially the source of the shipment.

- Carrier: The carrier, such as a trucking company or railroad, is responsible for transporting the materials safely and according to regulations. This includes ensuring that the driver is properly trained and the vehicle is compliant, as well as having plans for dealing with any emergencies that may arise. They’re responsible for the ‘middle-man’ aspect.

- Receiver: The receiver is responsible for safely receiving the hazardous materials and handling them properly. They need to be aware of the hazards associated with the material and follow procedures for storage, handling, and disposal. They receive the final product and are responsible for its post-transport handling.

Effective communication and collaboration between all three parties are essential to minimize risks and ensure the safe and legal transport of hazardous materials.

Q 11. What are the consequences of non-compliance with hazardous materials regulations?

Non-compliance with hazardous materials regulations can have severe consequences, ranging from fines and legal penalties to injuries, environmental damage, and even fatalities.

- Fines and Penalties: Significant fines can be levied against shippers, carriers, and receivers for violations. These fines can reach hundreds of thousands of dollars, depending on the severity of the violation.

- Criminal Charges: In cases of gross negligence or willful violations resulting in serious harm, criminal charges can be filed.

- Civil Lawsuits: Individuals injured or businesses suffering losses due to hazardous materials incidents can sue those responsible for non-compliance.

- Reputational Damage: Non-compliance can severely damage an organization’s reputation and trust among clients, partners, and the public.

- Operational Disruptions: Investigations, legal proceedings, and corrective actions can disrupt operations and increase costs significantly.

The potential for catastrophic consequences emphasizes the importance of strict adherence to regulations and responsible hazardous materials management.

Q 12. How do you handle a hazardous materials incident or spill?

Handling a hazardous materials incident or spill requires a swift, coordinated response. Safety is paramount.

- Prioritize Safety: Immediately secure the area, evacuate personnel, and call emergency services (911 in the US). Establish a safe perimeter based on the material’s properties.

- Identify the Material: If possible, identify the spilled material using shipping papers or labels. This is crucial for choosing the appropriate response measures.

- Contain the Spill: Use appropriate containment methods such as absorbent materials, booms, or dikes to prevent further spread. The goal is to prevent the material from entering water bodies or harming the environment.

- Decontamination: If personnel are exposed, decontaminate them following established protocols. This might involve washing with water or using specialized decontamination agents.

- Cleanup and Disposal: Employ qualified personnel to clean up the spill according to regulations. Improper cleanup can lead to further risks.

- Post-Incident Reporting: Thoroughly document the incident, including the nature of the material, the extent of the spill, and actions taken. Report the incident to relevant authorities, as required.

Remember, using the proper personal protective equipment (PPE) is critical throughout the entire process. Every situation is unique; adapt your response to the specific hazards involved.

Q 13. What is the role of the Safety Data Sheet (SDS) in hazardous materials transportation?

The Safety Data Sheet (SDS), formerly known as the Material Safety Data Sheet (MSDS), is a crucial document containing comprehensive information about a hazardous chemical. It’s the single most important document related to the safe handling and transport of hazardous materials. It’s like a comprehensive instruction manual for the material.

During transportation, the SDS provides vital information to responders in case of an emergency or spill. It details the material’s hazards, handling precautions, first aid measures, and emergency procedures. The shipper is responsible for providing the SDS to the carrier and ensuring its accessibility.

Information included in the SDS includes:

- Identification of the substance

- Hazard identification

- Composition/information on ingredients

- First-aid measures

- Fire-fighting measures

- Accidental release measures

- Handling and storage

- Exposure controls/personal protection

- Physical and chemical properties

- Stability and reactivity

- Toxicological information

- Ecological information

- Disposal considerations

- Transport information

- Regulatory information

- Other information

Without the SDS, emergency responders and handlers are significantly hampered in their ability to respond safely and effectively to incidents.

Q 14. Explain the process of selecting the appropriate packaging for hazardous materials.

Selecting appropriate packaging for hazardous materials is a critical step in ensuring safe transportation. It’s not a one-size-fits-all process; each material requires careful consideration.

The process involves:

- Identify the Hazardous Material: Determine the material’s classification (e.g., flammable, corrosive, toxic) according to the appropriate regulatory framework (DOT, IMO, IATA, etc.).

- Determine the Packaging Requirements: Based on the material’s classification, determine the required packaging type and specifications. Regulations specify packaging requirements for each hazard class.

- Select the Appropriate Container: Choose a container that meets the required standards for strength, leak resistance, and compatibility with the material. Consider factors like material compatibility, temperature sensitivity, and potential for pressure buildup.

- Verify Compliance: Ensure that the chosen packaging complies with all relevant regulations and is properly marked and labeled. This includes using approved materials, having adequate strength tests, and correct labeling.

- Perform Packaging Tests (if necessary): Some materials require specific packaging integrity tests to ensure that the package can withstand typical transport conditions.

Incorrect packaging selection can lead to leaks, spills, and other hazardous situations. Always prioritize safety and regulatory compliance when choosing packaging for hazardous materials.

Q 15. What are the limitations and restrictions on transporting hazardous materials?

Transporting hazardous materials is heavily regulated due to the inherent risks involved. Limitations and restrictions vary depending on the specific material, its hazard class, and the mode of transport (road, rail, air, sea). However, some common restrictions include:

- Quantity Limits: There are often maximum quantities of a hazardous material allowed per shipment, package, or vehicle. Exceeding these limits is strictly prohibited.

- Packaging Requirements: Specific packaging types, materials, and designs are mandated to ensure containment and prevent leaks or spills. Improper packaging can lead to serious incidents.

- Placarding and Labeling: Clear and accurate placarding (large signs on the vehicle) and labeling (on individual packages) are crucial for emergency responders to quickly identify the hazards present. Incorrect labeling is a major violation.

- Routing Restrictions: Some hazardous materials may be prohibited from certain routes, especially those passing through populated areas, schools, or hospitals, due to the increased risk to the public.

- Vehicle Requirements: Specific vehicle types, equipped with appropriate safety features (e.g., emergency shut-off valves, spill containment), might be necessary for transporting certain hazardous materials. For instance, transporting flammable liquids often requires a tanker truck with specialized safety features.

- Driver Training and Qualifications: Drivers must possess the necessary training and endorsements (like the HAZMAT endorsement) to legally transport hazardous materials. This ensures they understand the risks and proper handling procedures.

For example, transporting explosives will have far stricter regulations than transporting a relatively less hazardous material like batteries. These regulations are designed to minimize the risk of accidents and protect public safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure compliance with the latest updates and changes in HAZMAT regulations?

Staying current with HAZMAT regulations requires a multi-pronged approach. The regulations are constantly evolving, so passive learning isn’t enough. My strategy involves:

- Subscription to Regulatory Updates: I subscribe to official newsletters and publications from agencies like the Department of Transportation (DOT) in the US or equivalent agencies in other countries. This ensures I receive timely notifications of changes.

- Professional Development Courses and Seminars: Attending regular training courses and seminars keeps my knowledge sharp and ensures I’m up-to-date on best practices and recent legal interpretations.

- Networking with Industry Professionals: Regular communication with colleagues and participation in industry events allows for the exchange of information and insights on practical challenges and regulatory updates.

- Review of Regulatory Documents: I regularly review the main regulatory documents and related guidance documents from the DOT to ensure my understanding aligns with the latest versions.

- Use of Reputable Online Resources: I utilize trusted online resources and databases that provide updated information on regulations and hazardous materials classifications.

For instance, I recently learned about a change in the packaging requirements for a specific class of flammable liquids through a regulatory update email, allowing me to immediately update our company’s procedures to maintain compliance.

Q 17. Explain the concept of segregation of incompatible hazardous materials during transportation.

Segregation of incompatible hazardous materials is crucial for preventing dangerous reactions during transport. Incompatible materials, when mixed, can react violently, causing fires, explosions, or the release of toxic fumes. Segregation involves separating these materials to minimize the risk of interaction. This is achieved through:

- Physical Separation: Maintaining a sufficient distance between incompatible materials during transportation. This might involve loading them in different compartments of a vehicle or using separate transport vehicles altogether.

- Packaging Separation: Using separate packaging to prevent direct contact. This is especially important for materials that react through packaging failure.

- Compliance with Segregation Tables: Following the specific segregation guidelines laid out in regulatory documents (e.g., the DOT’s Hazardous Materials Regulations). These tables outline which materials should never be transported together.

Example: Oxidizers (like hydrogen peroxide) and flammable materials (like gasoline) should never be placed near each other. A small spark or leak could initiate a violent reaction. Proper segregation prevents such catastrophic events.

Q 18. Describe the requirements for hazardous materials transportation security.

Hazardous materials transportation security focuses on protecting shipments from theft, sabotage, or unauthorized access. Requirements vary based on the specific material and its security sensitivity level. Key aspects include:

- Security Plans: Companies transporting high-risk materials must develop comprehensive security plans outlining procedures to safeguard shipments throughout the transportation process.

- Background Checks and Training: Personnel involved in handling and transporting hazardous materials often undergo thorough background checks and security-related training.

- Vehicle Security Measures: Vehicles might be equipped with GPS tracking devices, tamper-evident seals, and other security features to deter theft or unauthorized access. They might even require escorts for particularly sensitive materials.

- Tracking and Monitoring: Real-time tracking systems help monitor the location and status of shipments, enabling rapid response to any security incidents.

- Reporting Requirements: Strict reporting protocols are in place to ensure that any security breaches or suspicious activities are promptly reported to relevant authorities.

For instance, the transportation of radioactive materials involves extremely stringent security measures, including armed escorts and constant surveillance, due to their potential for misuse.

Q 19. How do you determine if a material is considered hazardous?

Determining if a material is hazardous involves referring to official hazard classification systems. In the US, the DOT’s Hazardous Materials Regulations (HMR) provides the framework. A material is considered hazardous if it exhibits one or more of the following characteristics:

- Toxicity: Can cause harm through ingestion, inhalation, or skin contact.

- Flammability: Can easily ignite and burn.

- Reactivity: Can undergo violent chemical reactions, potentially causing explosions or fire.

- Corrosivity: Can cause damage to materials or living tissue through chemical reaction.

- Radioactivity: Emits ionizing radiation.

The classification process often involves laboratory testing and analysis to determine a material’s properties and assign it to the appropriate hazard class and division. Each hazard class has specific regulations regarding handling, packaging, and transportation.

Example: Acetone is classified as a flammable liquid, requiring specific packaging, labeling, and transportation methods to prevent fires. A Safety Data Sheet (SDS) is used to define the hazards of a specific material.

Q 20. What are the key differences between hazardous materials and dangerous goods?

While the terms “hazardous materials” and “dangerous goods” are often used interchangeably, there are subtle differences in their context and usage.

- Hazardous Materials: The term typically refers to substances transported within a specific country or region under that nation’s regulatory framework (like the DOT’s HMR in the United States).

- Dangerous Goods: This term is more commonly used in international transport under regulations like the International Air Transport Association (IATA) Dangerous Goods Regulations or the International Maritime Dangerous Goods (IMDG) Code. It encompasses a broader range of substances that pose a risk during transportation, regardless of the mode of transport.

Essentially, dangerous goods is a more globally-applicable term, while hazardous materials is often tied to specific national regulations.

Q 21. Explain the process of obtaining and maintaining a HAZMAT endorsement.

Obtaining and maintaining a HAZMAT endorsement involves several steps, differing slightly by jurisdiction. The process generally involves:

- Meeting Eligibility Requirements: This usually includes possessing a valid commercial driver’s license (CDL) and passing a written and possibly a practical test demonstrating knowledge of HAZMAT regulations.

- Completing a HAZMAT Training Course: This training covers various aspects of hazardous materials handling, including proper identification, packaging, placarding, emergency response, and security. A certificate will be provided upon successful completion.

- Applying for the Endorsement: An application is submitted to the relevant licensing authority (e.g., the Department of Motor Vehicles). The application will involve providing the completed training certificate.

- Passing the HAZMAT Knowledge Test: This test covers various regulations and procedures. Failure necessitates further training and retaking the test.

- Maintaining the Endorsement: Regular refresher training is usually required to maintain the validity of the endorsement. The frequency of this refresher training will depend on local guidelines and policies.

Failure to maintain the HAZMAT endorsement can result in serious consequences, including fines and suspension or revocation of driving privileges. Continuous learning and adhering to the latest regulatory updates are key to successful maintenance.

Q 22. What are the responsibilities of a HAZMAT employee?

The responsibilities of a HAZMAT employee are multifaceted and crucial for ensuring public safety and environmental protection. They encompass the entire lifecycle of hazardous materials, from initial packaging and labeling to final disposal. This includes:

- Proper Packaging and Labeling: Ensuring materials are packaged according to regulations, clearly labeled with appropriate hazard symbols and classifications (e.g., UN numbers), and secured to prevent leakage or damage during transport.

- Documentation and Manifest Preparation: Accurately completing shipping papers, including the hazardous materials manifest, which details the contents, quantity, and hazard class of each shipment. This is vital for emergency responders.

- Route Planning and Selection: Choosing the safest and most efficient routes, considering factors like weather conditions, traffic patterns, and proximity to populated areas or sensitive environments. This may involve using specialized routing software.

- Emergency Response Planning: Being prepared for accidents or incidents, including knowing how to handle spills, leaks, or fires involving hazardous materials. This includes having appropriate safety equipment and emergency contact information readily available.

- Compliance with Regulations: Staying up-to-date on all relevant federal, state, and local regulations governing hazardous materials transportation, including those established by the Department of Transportation (DOT).

- Employee Training and Safety: Ensuring all personnel involved in handling and transporting hazardous materials receive the necessary training and understand safety protocols. This includes regular refresher courses.

- Security Measures: Implementing security measures to prevent theft or unauthorized access to hazardous materials, especially those classified as dangerous goods.

Failure to adhere to these responsibilities can lead to serious consequences, including environmental damage, injury, and even death.

Q 23. What are the common causes of hazardous materials transportation incidents?

Incidents in hazardous materials transportation stem from a variety of causes, often involving a combination of factors. Some common causes include:

- Improper Packaging and Labeling: Damaged or inadequately secured containers can lead to spills or releases. Inaccurate or missing labels can hinder emergency responders’ ability to identify the hazard and take appropriate action.

- Driver Error: This encompasses speeding, reckless driving, fatigue, and a lack of awareness of hazardous materials handling procedures. For example, improper braking techniques can cause a container to shift and potentially rupture.

- Equipment Failure: Mechanical issues such as brake failure or a faulty container closure can result in accidents. Regular vehicle maintenance is essential.

- Adverse Weather Conditions: Severe weather, such as heavy rain, snow, or ice, can compromise vehicle control and increase the risk of accidents. Poor visibility further exacerbates these risks.

- Lack of Training: Insufficient or outdated training for drivers and handlers can lead to mistakes in handling, loading, and securing hazardous materials.

- Security Breaches: Theft or sabotage of hazardous materials shipments can have devastating consequences. Robust security protocols are essential to mitigate this risk.

Understanding these root causes is crucial for developing effective preventative measures.

Q 24. How do you identify and mitigate risks associated with hazardous materials transportation?

Identifying and mitigating risks involves a proactive, multi-layered approach. It begins with a thorough hazard assessment, considering the properties of the material being transported and the potential consequences of an incident. Key steps include:

- Hazard Identification: Classifying the hazardous materials according to their properties (flammable, corrosive, toxic, etc.) and referring to the Safety Data Sheet (SDS) for detailed information.

- Risk Assessment: Evaluating the likelihood and potential severity of different types of incidents (e.g., spill, fire, explosion). This often involves using a quantitative risk assessment methodology.

- Mitigation Strategies: Implementing measures to reduce the likelihood and impact of incidents. Examples include choosing appropriate containment systems, using specialized vehicles, employing trained personnel, and selecting safe routes.

- Emergency Preparedness: Developing emergency response plans that outline procedures for handling spills, leaks, fires, and other incidents. This typically includes training, equipment, and communication protocols.

- Regular Inspections and Maintenance: Conducting routine inspections of vehicles, containers, and equipment to identify and address potential problems before they lead to accidents.

- Continuous Improvement: Regularly reviewing safety procedures and incident reports to identify areas for improvement and implement corrective actions.

The goal is to establish a safety culture where risk management is an ongoing process, not just a one-time activity.

Q 25. Describe your experience with the handling and transportation of specific hazardous materials (e.g., explosives, flammable liquids, corrosive materials).

My experience encompasses the handling and transportation of a wide range of hazardous materials. For instance, I’ve been involved in the transportation of flammable liquids such as gasoline and solvents, where meticulous attention to detail is paramount. Properly securing containers, ensuring ventilation, and utilizing specialized tankers are essential to prevent fires or spills. I’ve also worked with corrosive materials like acids and bases, requiring the use of compatible containers, protective gear, and careful handling to avoid chemical burns or reactions. My experience with explosives, although limited to overseeing the transportation aspects under strict regulatory oversight, emphasized the importance of secure packaging, specialized vehicles, and adherence to stringent security protocols. Each material presents unique challenges and necessitates a deep understanding of its properties and associated risks.

In one specific instance, I supervised the transport of a shipment of highly reactive chemicals. This necessitated the use of temperature-controlled containers, specialized safety equipment, and a detailed risk assessment addressing potential scenarios, including unexpected temperature changes during transit. The successful completion of this project demonstrated my capability to adapt to the unique challenges posed by diverse hazardous materials.

Q 26. How do you use technology (e.g., tracking systems, electronic manifests) to improve hazardous materials transportation safety and compliance?

Technology plays a significant role in improving hazardous materials transportation safety and compliance. Real-time tracking systems provide continuous monitoring of shipments, allowing for immediate response in case of deviations from planned routes or unexpected events. Electronic manifests eliminate the need for paper-based documentation, reducing the risk of errors and streamlining the process. Furthermore, these systems can integrate with other safety management systems to provide comprehensive oversight of the entire transportation process. For instance:

- GPS Tracking: Provides real-time location information, enabling proactive responses to potential problems.

- Telematics: Offers data on vehicle performance, driver behavior, and environmental conditions, helping to identify and prevent unsafe practices.

- Electronic Logging Devices (ELDs): Ensure compliance with hours-of-service regulations, reducing driver fatigue and improving safety.

- Data Analytics: Analyzing data from tracking systems and other sources allows for the identification of trends and patterns that can be used to improve safety procedures.

By leveraging these technologies, we can significantly enhance the efficiency and safety of hazardous materials transportation, ultimately reducing the risk of accidents and ensuring compliance with regulations.

Q 27. Describe a situation where you had to handle a complex hazardous materials transportation problem. What was the challenge, and how did you resolve it?

During the transportation of a shipment of highly flammable solvents, an unexpected incident occurred when the primary transport vehicle experienced a significant mechanical failure approximately halfway through its journey. The challenge was to quickly transfer the solvents to a replacement vehicle without compromising safety or regulatory compliance. This required immediate coordination with the emergency response team, the relevant authorities, and the receiving facility. The solution involved:

- Emergency Stop and Assessment: The vehicle was safely secured, and an assessment of the situation was conducted to ascertain the extent of the mechanical damage and the potential risks involved.

- Alternative Transportation Arrangements: A suitable replacement vehicle was sourced, ensuring it met the necessary safety and regulatory standards for transporting flammable materials. This included securing the necessary documentation and ensuring the driver was properly trained.

- Safe Transfer Procedures: Following a detailed risk assessment, a secure transfer of the solvents was executed, adhering to strict safety protocols and minimizing the risk of spills or ignition.

- Communication and Documentation: Continuous communication with relevant parties was maintained throughout the process. Detailed records were kept, documenting all actions taken and any deviations from the original plan.

The successful resolution of this situation highlighted the importance of preparedness, effective communication, and adherence to safety protocols in managing unforeseen challenges during hazardous materials transportation.

Key Topics to Learn for Hazardous Materials Transportation Endorsement (HAZMAT) Interview

- Hazard Classes and Divisions: Understanding the classification system for hazardous materials and the specific regulations for each class. Practical Application: Being able to identify the hazard class of various materials and determine the appropriate handling and transportation procedures.

- Packaging Requirements: Knowing the different types of packaging and their suitability for various hazardous materials. Practical Application: Determining the correct packaging for a shipment based on the material’s properties and regulations.

- Placarding and Labeling: Understanding the proper placarding and labeling requirements for hazardous materials shipments. Practical Application: Accurately placarding and labeling a vehicle or container transporting hazardous materials.

- Shipping Papers and Documentation: Familiarity with the required documentation for hazardous materials shipments, including shipping papers and emergency response information. Practical Application: Completing shipping papers accurately and ensuring all necessary documentation is present.

- Emergency Response Procedures: Knowing the steps to take in case of an accident or incident involving hazardous materials. Practical Application: Describing your actions in a hypothetical accident scenario, including communication, containment, and evacuation procedures.

- Regulations and Compliance: Staying updated on the latest regulations and compliance requirements for hazardous materials transportation. Practical Application: Demonstrating awareness of current regulations and their impact on transportation practices.

- Security and Safe Handling Practices: Understanding security protocols and best practices for safe handling and transportation of hazardous materials. Practical Application: Describing procedures to prevent theft or accidental release.

Next Steps

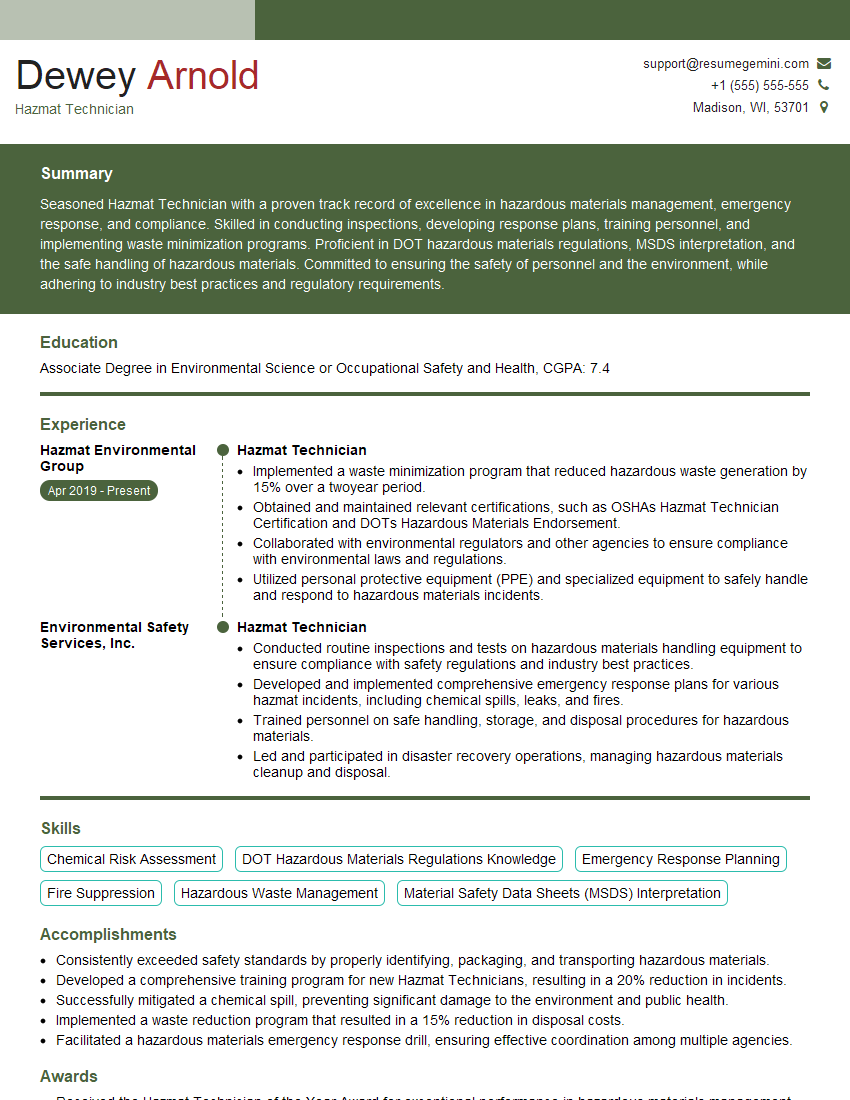

Mastering the Hazardous Materials Transportation Endorsement (HAZMAT) opens doors to exciting career opportunities in logistics, transportation, and safety. A strong understanding of HAZMAT regulations is highly sought after, significantly increasing your employability and earning potential. To maximize your job prospects, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the HAZMAT industry. Examples of resumes specifically designed for HAZMAT endorsement holders are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO