Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Moulding Saw Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Moulding Saw Operation Interview

Q 1. Explain the different types of moulding saws and their applications.

Moulding saws come in various types, each suited for different applications. The most common are:

- Horizontal Spindle Moulding Machines: These are workhorses in many woodworking shops, ideal for high-volume production of consistent moulding profiles. They use a rapidly spinning horizontal spindle with a variety of interchangeable cutters to create complex shapes. Think of them as the ‘assembly line’ of moulding saws.

- Vertical Spindle Moulding Machines: These offer greater flexibility in handling larger and more awkward pieces of wood. The spindle is vertical, making it easier to manage larger stock. They are commonly used for larger-scale projects or custom designs.

- Shapers: These are more versatile than spindle moulders, capable of performing various operations beyond moulding, such as shaping edges and creating decorative patterns. They often have a more open design, allowing for a wider range of workpieces. Think of these as the ‘Swiss Army Knife’ of moulding machines.

- Hand-held Routers with Moulding Bits: While not strictly a ‘moulding saw,’ hand-held routers equipped with specific moulding bits allow for smaller-scale, more intricate work and are useful for repairs or custom projects. They are great for detail work and difficult-to-reach areas.

The choice depends heavily on the scale of production, complexity of the moulding profile, and the size and type of wood being worked. For example, a large-scale production of simple window trim would be efficiently done on a horizontal spindle moulder, while creating a complex, one-off decorative piece might best be handled with a shaper or router.

Q 2. Describe the safety procedures you follow when operating a moulding saw.

Safety is paramount when operating a moulding saw. My routine always includes:

- Pre-operation checks: Thoroughly inspecting the machine for loose parts, ensuring all guards are in place and functioning correctly, and checking the blade for damage or dullness before starting. I always double-check the blade is securely mounted and tightened according to the manufacturer’s instructions.

- Personal Protective Equipment (PPE): I never operate the machine without wearing appropriate PPE: safety glasses, hearing protection, dust mask, and cut-resistant gloves. A shop apron adds an extra layer of protection.

- Feed Rate and Pressure: Maintaining a consistent and appropriate feed rate is crucial to avoid kickback and ensure clean cuts. Excessive pressure can lead to blade breakage or injury. The machine should be properly adjusted to suit the material and profile being cut.

- Clear Work Area: Keeping the area around the machine clear of debris and obstructions is crucial for safe operation. A tidy and organized workspace minimizes the risk of accidents.

- Emergency Stop: I always know the location of the emergency stop button and understand how to use it. I regularly check that the button is functioning correctly.

- Proper Training and Knowledge: It’s essential to have received proper training on the specific machine and to fully understand the operation and safety procedures before use. If there is any uncertainty, I won’t hesitate to ask for assistance from experienced colleagues.

Following these safety protocols diligently is not just a matter of compliance; it’s a commitment to personal well-being and the safety of my fellow workers.

Q 3. How do you ensure the accuracy and precision of cuts on a moulding saw?

Accuracy and precision are achieved through a combination of factors:

- Blade Sharpness: A sharp blade is essential for clean, accurate cuts. A dull blade will cause tear-out and inaccurate cuts. Regular sharpening or replacement is crucial.

- Proper Setup: Accurate setup of the fence, the workpiece, and the blade is crucial. The fence should be square to the blade and properly adjusted for the desired cut. The workpiece should be firmly held and aligned correctly.

- Machine Calibration: The machine itself must be properly calibrated. This often involves checking and adjusting the alignment of the blade, fence, and other critical components. Regular maintenance and calibration are vital.

- Material Selection and Preparation: The type of wood and its moisture content can significantly affect the accuracy of the cuts. The workpiece should be free of knots or other defects that might cause the blade to bind or deviate from the desired path. Proper drying and planing of wood significantly reduce these issues.

- Test Cuts: Before starting a large production run, I always perform test cuts on scrap material. This allows me to fine-tune the settings and verify the accuracy of the cuts before working on the final piece. It’s much better to learn from a scrap piece than from a ruined workpiece.

By meticulously addressing each of these aspects, I can consistently achieve highly accurate and precise cuts.

Q 4. What are the common causes of blade breakage or malfunction, and how do you troubleshoot them?

Blade breakage or malfunction usually stems from a few common issues:

- Dull Blades: Forcing a dull blade through the material is the most common cause of breakage. The blade will overheat and eventually shatter or deform.

- Improper Setup: Incorrect fence alignment, improper blade height, or loose blade mounting can all contribute to blade breakage. It’s imperative that the machine is properly set up and maintained.

- Overfeeding: Pushing the material too quickly through the blade generates excessive heat and stress, leading to breakage.

- Knots and Defects in the Wood: Hidden knots or other defects in the wood can cause the blade to bind and break. Careful inspection of the wood prior to cutting is paramount.

- Incorrect Blade Type: Using the wrong type of blade for the material or application can also lead to breakage. Each blade is designed for a specific purpose.

Troubleshooting involves careful inspection of the blade, the machine’s setup, and the wood itself. Replacing a damaged blade, tightening loose components, adjusting the feed rate, and selecting the correct blade type for the material are all part of effective troubleshooting.

Q 5. Explain the process of setting up a moulding saw for a specific moulding profile.

Setting up a moulding saw for a specific profile involves several steps:

- Select the correct cutter or blade: Each moulding profile requires a specific cutter or blade. This is typically chosen based on the dimensions and shape of the desired profile.

- Mount the cutter or blade securely: The cutter or blade must be securely mounted on the spindle. This typically involves using appropriate tooling and tightening the spindle nut to the manufacturer’s specifications. Incorrect mounting can lead to inaccurate cuts or even dangerous accidents.

- Adjust the fence: The fence needs to be adjusted to a position that allows for the correct amount of stock to be removed. This is typically done using measuring tools to ensure accuracy and avoid cutting into the workpiece more than intended.

- Adjust the blade height: This step ensures that the correct portion of the cutter or blade is engaged in the cutting process. Incorrect height may result in an incomplete or uneven profile. Always consult the manufacturer’s guidelines for the specific tooling being used.

- Test Cut: Before starting a full production run, always run a test cut on scrap wood. This allows you to verify the accuracy of the setup and make any adjustments before cutting the final materials.

Each of these steps is critical for accurate moulding; overlooking any one of them can result in unsatisfactory or potentially dangerous results. Precision and attention to detail are crucial throughout the process.

Q 6. How do you maintain the sharpness and condition of moulding saw blades?

Maintaining the sharpness and condition of moulding saw blades is crucial for producing high-quality work and preventing accidents. Here’s how I do it:

- Regular Inspection: I regularly inspect blades for signs of wear, damage, or dullness. This includes checking for chips, cracks, or other defects. Any damaged blades must be replaced immediately.

- Sharpening: Depending on the type of blade (carbide-tipped or high-speed steel), sharpening techniques vary. Carbide-tipped blades generally require specialized equipment and often aren’t sharpened by hand; they are replaced when dull. High-speed steel blades can be sharpened using grinding wheels or honing stones, however, this should be performed by a skilled individual experienced in blade sharpening to maintain proper angles.

- Cleaning: Regular cleaning of the blades is essential to remove sawdust and resin buildup. This helps prevent dulling and ensures the blade remains free of obstructions. Appropriate cleaning agents should be used to prevent further damage to the blade.

- Storage: Proper blade storage is vital for maintaining their longevity. Blades should be stored in a clean, dry place away from moisture and potential damage.

- Rotation: For multiple blades, rotating them through use can extend their overall lifespan by preventing excessive wear on any one blade.

Following these guidelines ensures the blades remain sharp, efficient, and safe to use, significantly impacting the quality and efficiency of the work.

Q 7. Describe your experience with different types of moulding saw blades (e.g., carbide, high-speed steel).

I have extensive experience working with both carbide-tipped and high-speed steel (HSS) moulding saw blades. Each has its advantages and disadvantages:

- Carbide-tipped blades: These are incredibly durable and retain their sharpness for a significantly longer period than HSS blades. This makes them ideal for high-volume production work where frequent sharpening is impractical. However, they are more expensive to replace when ultimately dull.

- High-speed steel (HSS) blades: HSS blades are more readily sharpened than carbide blades, making them cost-effective for smaller shops or jobs that don’t require the extreme durability of carbide. They are also generally less expensive initially but require more frequent sharpening. However, their sharpness can degrade quicker, requiring more frequent attention.

The selection between carbide and HSS depends on factors such as the scale of the project, the type of wood being used, and the budget. For instance, a large production run of simple moulding would likely utilize carbide-tipped blades for their longevity, whereas a small-scale project or a material prone to dulling the blade quickly might necessitate the use of HSS blades, allowing for more frequent sharpening in between use.

Q 8. How do you identify and address common defects in moulding produced by the saw?

Identifying and addressing defects in moulding starts with a keen eye and understanding of the sawing process. Common defects include splintering, tear-out, inaccurate dimensions, and surface imperfections. Let’s break down how to address these:

- Splintering and Tear-Out: Often caused by dull blades, improper feed rate, or the wood’s grain direction. Solution: Sharpen or replace the blade, adjust the feed speed (slower for harder woods or intricate profiles), and carefully orient the wood to minimize cutting against the grain. For example, I once had a batch of cherry moulding with significant tear-out. By slowing the feed rate and slightly adjusting the blade angle, we eliminated the problem.

- Inaccurate Dimensions: This can result from misalignment of the saw blade, incorrect setup of the fence, or blade wear. Solution: Regularly check and adjust the blade alignment, ensure the fence is correctly positioned and securely fastened, and maintain sharp blades. A precise measuring tool is crucial for regular checks and adjustments.

- Surface Imperfections: These can be caused by vibrations, dull blades, or inconsistent material. Solution: Tighten all machine components to reduce vibrations, maintain sharp blades, and ensure consistent material moisture content. Proper blade selection is also vital—a fine-toothed blade is often needed for smoother finishes.

Ultimately, defect identification is proactive. Regular inspections throughout the process, from material selection to the finished product, are crucial for quality control.

Q 9. What are the key performance indicators (KPIs) for a moulding saw operator?

Key Performance Indicators (KPIs) for a moulding saw operator focus on both quality and efficiency. The metrics I prioritize include:

- Production Rate (pieces/hour): Measures the efficiency of the operation. This KPI helps identify bottlenecks and areas for improvement in the process flow.

- Defect Rate (%): Represents the percentage of defective pieces produced. A lower defect rate indicates better quality control and operator skill.

- Downtime (minutes/hour): Tracks the time the saw is not producing due to jams, maintenance, or other issues. Minimizing downtime improves overall productivity.

- Material Waste (%): Measures the amount of material lost due to defects or improper cutting. Reducing waste is crucial for cost-effectiveness.

- Blade Life (hours): Indicates the operational life of a blade before requiring sharpening or replacement. This metric helps optimize blade usage and reduce costs.

By tracking these KPIs, I can identify areas for improvement and consistently maintain high-quality output while optimizing resource usage.

Q 10. How do you handle material jams or other operational issues?

Handling material jams or operational issues requires a systematic approach, prioritizing safety first. Here’s my process:

- Safety First: Immediately shut down the machine and ensure the area is safe before attempting any intervention.

- Identify the Problem: Carefully examine the cause of the jam, looking for obstructions, misaligned components, or material defects.

- Clear the Jam: Use appropriate tools and techniques to carefully remove the obstruction, avoiding damage to the machine or injury to myself. Never force anything.

- Inspect for Damage: Once cleared, check for any damage to the machine, blades, or material. Repair or replace as needed.

- Restart and Monitor: Carefully restart the machine, closely monitoring its operation to ensure the issue doesn’t recur.

- Root Cause Analysis: Once the immediate issue is resolved, I investigate the underlying cause to prevent future occurrences. For example, frequent jams might indicate a problem with the feed system or material quality.

Documentation is crucial; I maintain a log of all issues, their resolution, and preventative measures taken. This data is valuable for continuous improvement.

Q 11. Explain your experience with different types of wood and their impact on cutting techniques.

Different wood types require adjustments to cutting techniques due to varying hardness, grain structure, and moisture content. My experience includes working with a wide range of hardwoods and softwoods:

- Hardwoods (e.g., Oak, Maple, Cherry): These require sharper blades, slower feed rates, and sometimes a slight change in the blade angle to minimize tear-out. The denser grain structure demands more power and careful control.

- Softwoods (e.g., Pine, Fir, Cedar): Generally easier to cut, allowing for faster feed rates. However, they can be more prone to splintering if the blade is dull or the feed rate is too high. Proper blade selection and attention to grain direction are crucial.

- Exotic Woods: Each exotic wood presents unique challenges. Researching the specific properties of the wood—its density, hardness, and grain pattern—is essential for determining the optimal cutting parameters.

I always test cutting parameters on scrap material first to ensure the best settings before working with the final pieces. This is especially important with rarer or expensive wood types.

Q 12. How do you ensure the consistent quality of moulding throughout a production run?

Consistent moulding quality relies on a multi-faceted approach:

- Regular Blade Maintenance: Sharpening or replacing blades at the right intervals is crucial. Dull blades lead to poor quality cuts and increased defects.

- Material Consistency: Using wood with a uniform moisture content is vital. Variations in moisture can lead to warping and inconsistencies in the final product.

- Machine Calibration: Regularly checking and adjusting machine settings ensures accuracy and precision throughout the production run. This includes blade alignment, fence position, and feed rate.

- Operator Skill and Training: Experienced operators are essential for maintaining consistent quality. Regular training and adherence to established procedures are key.

- Quality Checks: Regular quality checks throughout the production run—at the beginning, middle, and end—ensure consistent quality and prompt identification of any issues.

By implementing these measures, I can help maintain high standards throughout a production run, minimizing variations and maximizing the consistency of the finished product.

Q 13. Describe your experience with preventative maintenance on moulding saws.

Preventative maintenance is vital for extending the life of moulding saws and preventing costly downtime. My experience includes:

- Daily Inspections: Checking for loose components, blade alignment, and overall machine cleanliness. Addressing minor issues promptly prevents them from escalating into larger problems.

- Regular Lubrication: Proper lubrication of moving parts prevents wear and tear, ensuring smooth operation and extending the lifespan of the machine.

- Blade Sharpening/Replacement: Maintaining sharp blades is crucial for both quality and safety. I follow a schedule based on usage and observe for signs of dulling.

- Scheduled Maintenance: Performing more thorough maintenance checks at regular intervals (e.g., monthly, quarterly) addresses more complex issues and ensures the machine is operating at peak efficiency.

- Record Keeping: Meticulously documenting all maintenance activities is critical for tracking performance, identifying trends, and scheduling future maintenance.

A well-maintained machine is a safer and more productive machine. My approach is proactive, aiming to prevent problems before they occur rather than reacting to breakdowns.

Q 14. What is your experience with different types of moulding saw feeds (e.g., infeed, outfeed)?

My experience encompasses various moulding saw feed systems, understanding their strengths and limitations:

- Infeed Systems: These systems control how the wood enters the cutting area. I’ve worked with various types, including roller conveyors, chain feeds, and push-feed systems. Each requires adjustments for different materials and profiles to ensure smooth and consistent feed.

- Outfeed Systems: These handle the cut moulding after it exits the saw. I’ve used roller conveyors, stackers, and transfer systems. Selecting the right system depends on the production volume and the required handling of the finished product. Efficient outfeed is crucial to avoid bottlenecks and maintain a smooth workflow.

- Understanding System Interplay: The optimal performance of a moulding saw relies on the coordinated function of both the infeed and outfeed systems. A properly adjusted and maintained system minimizes jams, ensures consistent feed rates, and protects the final product.

Understanding and maintaining these systems is key to efficient and high-quality moulding production. I regularly check alignment, tension, and lubrication to ensure optimal performance.

Q 15. How do you interpret and follow operational instructions and safety guidelines?

Interpreting and following operational instructions and safety guidelines is paramount in moulding saw operation. It’s not just about reading the manual; it’s about understanding the why behind each instruction. I approach this systematically. First, I carefully read all instructions, paying close attention to diagrams and warnings. Then, I mentally walk through the process, anticipating potential hazards. For example, if the instructions mention using a specific type of blade for a particular material, I understand that using the wrong blade could lead to breakage, kickback, or inaccurate cuts. I always perform a pre-operational inspection of the machine, checking for loose parts, damaged components, and proper safety guard functionality. Finally, I treat safety guidelines not as suggestions but as non-negotiable rules. This includes wearing appropriate Personal Protective Equipment (PPE), like safety glasses, hearing protection, and dust masks, and ensuring the work area is clear and well-lit. I always remember that a moment’s lapse in safety can have serious consequences.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of moulding saw controls (e.g., manual, automated).

My experience encompasses both manual and automated moulding saw controls. With manual controls, I’m adept at precise adjustments of feed rate and cutting speed, crucial for achieving accurate cuts in various materials and profiles. This requires a good understanding of the machine’s mechanics and the material’s properties. I’ve worked with machines requiring hand-crank feed adjustments and those with more sophisticated lever-based systems. In contrast, automated controls, such as CNC (Computer Numerical Control) moulding saws, offer programmable settings for consistent cuts and high production rates. I’m experienced in programming these machines using CAD/CAM software to create intricate moulding patterns. I’m also proficient in troubleshooting issues and performing routine maintenance on both manual and automated systems, ensuring optimum performance and safety. For example, in one project, we used a CNC saw to achieve extremely precise cuts for a large volume of intricate crown moulding, something impossible to achieve efficiently with manual controls alone.

Q 17. How do you calculate the optimal cutting speed and feed rate for different materials?

Calculating the optimal cutting speed and feed rate is crucial for efficiency and preventing damage to the blade or the material. This calculation depends on several factors: the type of material (hardwoods require slower speeds than softwoods), the type of blade (teeth per inch, tooth profile), and the desired finish. Generally, harder materials require slower cutting speeds and feed rates to avoid overheating and blade damage. Softwoods, conversely, can tolerate higher speeds. I often refer to manufacturers’ recommendations for specific blade types and materials, but I also rely on my experience to fine-tune these settings based on the specific job. For instance, if I notice a rough finish, I’ll slightly reduce the feed rate. If the blade is overheating, I’ll reduce the speed. It’s a balancing act between speed, accuracy, and the longevity of the blade. Over time, you develop an intuition for optimal settings for various materials and blade types.

Q 18. Explain your experience with blade alignment and adjustments.

Blade alignment and adjustments are critical for accurate cuts and blade longevity. Improper alignment leads to uneven cuts, increased wear on the blade, and potential for kickback. My process begins with a visual inspection of the blade for any damage or wear. Then, I carefully use precision tools such as a square and feeler gauges to check the blade’s alignment in relation to the fence and the miter gauge. Minor adjustments are usually made using the appropriate adjustment screws on the saw. For significant misalignments, I consult the machine’s manual for proper procedures. I also understand the importance of maintaining correct blade tension – insufficient tension can lead to blade wander, while excessive tension can cause blade breakage. Regular checks and adjustments are essential to ensuring precise and safe cutting. I always remember a time when a slightly misaligned blade resulted in several spoiled pieces; that reinforced the importance of meticulous blade alignment checks.

Q 19. How do you manage and dispose of waste materials from the moulding saw operation?

Managing and disposing of waste materials is crucial for maintaining a clean and safe workspace and complying with environmental regulations. My approach involves a multi-step process. Firstly, I separate different types of waste, such as wood scraps, metal shavings, and packaging materials. Wood scraps are typically collected in designated containers. Metal shavings are often swept and collected in a separate container for recycling. I always ensure that any sharp or dangerous waste is handled safely, using appropriate protective equipment. Secondly, I follow the company’s procedures for waste disposal. This usually involves separating recyclable materials from non-recyclable materials and arranging for their appropriate disposal. Finally, I regularly clean the work area to prevent accidents and maintain a safe and efficient working environment. Adherence to proper disposal practices is not only environmentally responsible but also crucial for workplace safety.

Q 20. Describe your experience working with different types of moulding profiles.

My experience extends to a wide variety of moulding profiles. I’m proficient in cutting everything from simple rectangular profiles to complex crown mouldings, baseboards, and decorative trims. Each profile has its unique cutting requirements, and my experience enables me to select the appropriate blade, cutting speed, and feed rate to achieve the desired results. I’m familiar with various profile designations and understand how slight adjustments in blade angle or feed rate can significantly affect the final product. I can interpret blueprints and drawings accurately to produce consistent and accurate cuts. I also understand the nuances of material selection for different profiles; for instance, a harder wood might be better suited for complex, intricate profiles to withstand wear and tear.

Q 21. What is your experience with using measuring instruments (calipers, rulers) to ensure accuracy?

Accuracy is paramount in moulding saw operation, and measuring instruments are essential tools for ensuring it. I routinely use calipers and rulers to check dimensions and ensure cuts are to specification. Calipers are invaluable for precise measurements of thickness and width, especially when dealing with intricate profiles. Rulers are used for measuring overall lengths and verifying angles. I am meticulous in my measurements and understand the importance of using the correct instruments for the task. For instance, using a ruler to measure a small, intricate profile wouldn’t provide the same accuracy as using a caliper. My experience includes using both digital and analog versions of these tools and understanding their limitations. This attention to detail minimizes waste and ensures that the final product meets the required standards. I regularly check my tools for accuracy, recalibrating them as needed to maintain consistency.

Q 22. How do you adjust saw settings to account for variations in material thickness or density?

Adjusting saw settings for varying material thickness and density is crucial for achieving accurate cuts and preventing damage to the blade or workpiece. Think of it like adjusting the pressure on a knife – a thicker piece of bread needs more force than a thin slice. On a moulding saw, this adjustment primarily involves modifying the feed rate and potentially the blade height.

Thickness Adjustment: For thicker material, you’ll typically reduce the feed rate. This allows the saw blade more time to cut through the material cleanly, preventing excessive strain and potential breakage. Conversely, thinner material can be fed at a faster rate.

Density Adjustment: Denser materials, like hardwoods, require a slower feed rate and sometimes a sharper blade to avoid dulling or overheating. Softer woods, on the other hand, can tolerate a slightly faster feed rate. You might also need to slightly adjust the blade’s depth of cut for optimal performance.

Practical Example: When switching from cutting soft pine to dense oak, I would first reduce the feed rate by approximately 20-30%. I’d then carefully monitor the cut quality. If the cut isn’t clean, I might need to consider using a fresh blade designed for hardwoods or slightly increase the blade’s depth of cut, while maintaining the slower feed rate.

Q 23. How do you troubleshoot blade chatter or vibration issues?

Blade chatter and vibration are common problems on moulding saws that significantly affect cut quality and can even cause damage. These issues usually stem from several potential causes, requiring systematic troubleshooting.

Blade Issues: A dull blade, a blade with damaged teeth, or a blade with incorrect tension are prime suspects. Check for any chips, cracks, or uneven wear on the teeth. Ensure the blade is correctly tensioned according to the manufacturer’s specifications.

Machine Alignment: Misalignment of the saw arbor, guides, or fences can lead to significant vibration. Carefully inspect the alignment of these components using measuring tools like dial indicators or straight edges to ensure they are perfectly straight and parallel.

Material Issues: Knots, internal stresses, or moisture variations in the wood can induce vibration. Inspect the wood for these imperfections and try to feed the problematic area slowly and carefully.

Speed and Feed Rate: Incorrect cutting speeds and feed rates can also trigger vibration. Experiment with adjusting these settings to find an optimal balance for the specific material and blade being used.

Troubleshooting Strategy: I usually start by checking the blade’s condition. If it’s in good shape, I move on to checking the machine alignment, and then the material quality and finally the cutting parameters. This systematic approach helps isolate the problem quickly.

Q 24. What is your experience with diagnosing and repairing minor mechanical issues on moulding saws?

My experience includes diagnosing and resolving various minor mechanical issues on moulding saws. This includes everything from replacing worn bearings and belts to adjusting fence alignment and lubricating moving parts. I approach each issue methodically, following safety procedures and always starting with a thorough inspection.

Bearing Replacement: Identifying a worn bearing usually involves listening for unusual noises, such as grinding or squealing, during operation. Once a bad bearing is identified, the procedure involves safely disassembling the relevant component, carefully removing the old bearing, and installing a new one with the correct specifications, ensuring proper lubrication.

Belt Replacement: Worn or broken belts result in decreased power transmission. I replace worn belts by carefully removing the old belt and installing a new one with the same size and specifications, ensuring proper tension.

Fence Alignment: I’ve resolved many issues related to fence alignment using alignment tools and procedures to correct squaring issues.

I always prioritize safety and ensure that the saw is completely shut down and unplugged before carrying out any repairs. Detailed records are kept of all maintenance and repairs.

Q 25. Describe your experience with using different types of lubrication for the saw and its components.

Proper lubrication is vital for the longevity and performance of a moulding saw. Different components require different types of lubricants, chosen based on their operating conditions and materials.

Saw Blade: While blades themselves typically don’t require lubrication, the arbor bearings do. I use a high-quality grease specifically designed for high-speed applications, ensuring consistent lubrication to minimise friction and extend the lifespan of the bearings.

Moving Parts: Ways, feed mechanisms, and other moving parts often require oil-based lubrication. I typically use a light-weight machine oil with good anti-wear properties. The type and viscosity of the oil can be chosen based on environmental conditions and operating speeds.

Chains and Gears: If the saw has chains or gears, they also require lubrication. I’d use a specialised chain lubricant to help minimize wear and maintain efficient operation.

Over-lubrication can be as detrimental as under-lubrication, leading to excessive build-up of grease or oil which can attract dust and other contaminants and cause further issues. Regular inspection and appropriate lubrication are crucial for preventative maintenance.

Q 26. How do you prioritize tasks and manage your time effectively during a production run?

Prioritizing tasks and managing time effectively during a production run is essential for meeting deadlines and ensuring efficiency. I utilize a combination of planning, prioritization techniques, and efficient workflow strategies.

Production Schedule Review: At the start of a run, I carefully review the production schedule to identify priorities and potential bottlenecks. This involves understanding order quantities, deadlines, and the complexity of each moulding profile.

Prioritization Matrix: I apply a prioritization matrix, considering factors like urgency and importance to rank tasks. This ensures that critical tasks are completed first and that resources are allocated efficiently.

Workflow Optimization: I continually look for ways to streamline the workflow, reducing idle time and improving the flow of materials. This might involve optimizing blade changes, improving material handling, or adjusting machine settings for better efficiency.

Continuous Monitoring: Throughout the production run, I monitor progress, identify any delays, and adjust priorities as needed. This adaptive approach allows for flexibility and helps to mitigate unforeseen challenges.

By proactively planning and continuously monitoring the production process, I ensure efficient and timely completion of all tasks.

Q 27. Describe a time you had to resolve a challenging problem on the moulding saw. What was the outcome?

During a large-scale production run, we experienced consistent chipping on the finished mouldings, particularly on sharp corners. Initially, we suspected blade dullness and replaced the blade, but the problem persisted. After careful examination, I noticed slight misalignment in the outfeed rollers, causing the moulding to be slightly bent just before exiting, leading to the chipping.

To resolve this, I carefully adjusted the outfeed rollers using precision shims and measuring tools, ensuring perfect alignment. After this adjustment, the chipping issue was completely eliminated. The outcome was a significant improvement in product quality, preventing waste, meeting customer expectations and maintaining our high production standards. It taught me the importance of meticulous attention to detail and the need to consider all potential sources of problems, rather than focusing solely on the most obvious ones.

Q 28. How do you ensure compliance with health and safety regulations in your work?

Compliance with health and safety regulations is paramount in my work. I adhere to all company policies and relevant legislation, incorporating safety considerations into every aspect of my daily routine.

Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, hearing protection, and work gloves. This is essential for safeguarding against potential hazards like flying debris, loud noises, and sharp edges.

Machine Guarding: I ensure that all machine guards are in place and functioning correctly before operating the moulding saw. This prevents accidental contact with moving parts, minimizing the risk of injury.

Regular Inspections: I perform regular inspections of the machine and its surroundings to identify and rectify any potential hazards, ensuring a safe working environment.

Lockout/Tagout Procedures: Before performing any maintenance or repair, I meticulously follow lockout/tagout procedures, ensuring the power is disconnected and the machine is secured to prevent accidental activation.

Training and Awareness: I’m always up-to-date with the latest safety guidelines and actively participate in safety training sessions to stay informed about best practices and potential hazards.

Safety isn’t just a set of rules; it’s a mindset. I consistently prioritize safety to create a secure and productive working environment for myself and others.

Key Topics to Learn for Moulding Saw Operation Interview

- Moulding Saw Operation Safety Procedures: Understanding and applying safety regulations, including lockout/tagout procedures, proper personal protective equipment (PPE) use, and emergency response protocols.

- Machine Operation & Maintenance: Practical knowledge of setting up, operating, and maintaining moulding saws, including blade changes, tension adjustments, and basic troubleshooting.

- Material Handling & Selection: Understanding different wood types and their properties, proper material handling techniques to prevent damage and ensure efficient operation.

- Quality Control & Inspection: Identifying and addressing common defects in moulding, understanding quality standards, and performing accurate inspections.

- Troubleshooting & Problem Solving: Diagnosing common machine malfunctions, identifying causes of defects, and implementing effective solutions to minimize downtime.

- Production Efficiency & Optimization: Understanding techniques to maximize output while maintaining quality, including optimizing cutting speeds and feed rates.

- Reading & Interpreting Blueprints/Technical Drawings: Accurately interpreting technical drawings to understand moulding specifications and dimensions.

- Understanding of different types of moulding saws and their applications: Familiarize yourself with various saw types and their suitability for different moulding tasks.

- Preventive Maintenance Schedules and Procedures: Knowing the importance of regular maintenance and the procedures involved in keeping the machine in optimal condition.

Next Steps

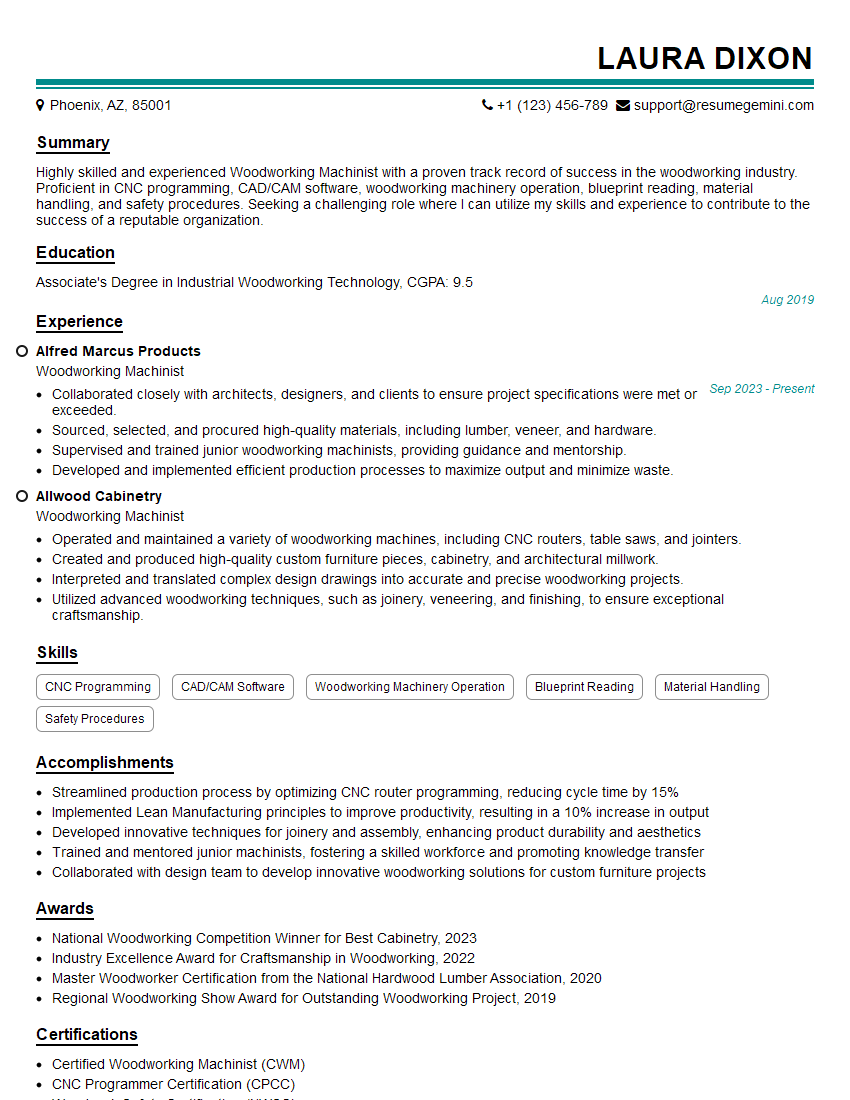

Mastering Moulding Saw Operation opens doors to rewarding careers in woodworking and manufacturing, offering opportunities for advancement and specialization. A strong resume is crucial for securing your dream role. Creating an ATS-friendly resume significantly increases your chances of getting noticed by employers. To build a compelling and effective resume, we highly recommend using ResumeGemini, a trusted resource for crafting professional resumes. Examples of resumes tailored to Moulding Saw Operation are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO