The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Key Duplication interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Key Duplication Interview

Q 1. Explain the difference between a bitted key and a dimple key.

Bitted keys and dimple keys are both types of pin tumbler keys, but they differ significantly in their design and how they interact with the lock mechanism. A bitted key features a series of parallel cuts of varying depths along its blade. These cuts determine the position of pins within the lock cylinder. Think of it like a simple, stepped profile. A dimple key, on the other hand, has a series of indentations or dimples of varying sizes and depths along the blade. These dimples create a more complex interaction with the lock cylinder, offering potentially higher security. The difference lies in the method of key-cutting – bitted keys are easier to duplicate since the cuts are simpler, whereas dimple keys need more precise tooling due to their intricate dimple patterns.

Example: A standard house key is typically a bitted key, while many car keys and high-security residential keys might employ dimple technology.

Q 2. Describe the process of duplicating a standard house key.

Duplicating a standard house key is a relatively straightforward process. First, the original key is inserted into a key duplicating machine. This machine usually has a clamp to hold the key securely. The machine then uses a cutting mechanism, often a rotating cutter, to precisely cut a blank key based on the profile of the original key. The depth and position of each cut on the blank are determined by the profile of the original key. The process involves multiple passes of the cutter to create the exact shape of the original key. Finally, the duplicated key is removed from the machine and tested in the lock to ensure it works correctly.

Important Note: Always use high-quality key blanks appropriate for the original key’s type and lock. Poor quality blanks can lead to poorly functioning duplicates.

Q 3. What are the common types of key blanks used for residential locks?

The most common types of key blanks for residential locks are those designed for pin tumbler locks. These blanks come in various profiles, sizes, and cuts to accommodate different lock manufacturers and security levels. Some common types include:

- Standard house keys: These are the most common and come in a wide variety of sizes and cuts.

- High security keys: These have more complex cuts or features that make them more difficult to duplicate.

- Tubular keys: These have a cylindrical shape and a series of pins running along their length. Used less frequently than pin tumbler keys.

The specific blank needed depends entirely on the original key and the lock it operates. An experienced key cutter will identify the correct blank based on the original key’s profile.

Q 4. How do you identify a key’s bitting?

Identifying a key’s bitting refers to determining the exact pattern of cuts or dimples on the key blade. This pattern is crucial for duplicating a key accurately. For a bitted key, bitting is often expressed as a series of numbers representing the depth of the cuts. For example, 1-2-3-4-5 might represent the depth of the cuts on a bitted key. For dimple keys, the bitting might be a more complex code, including information on the size and shape of each dimple.

To identify a key’s bitting, you can use a key code chart specific to the key’s manufacturer (if known). Or, a key duplicating machine that includes a bitting measurement system can automatically read and display the bitting information. In less advanced situations, it is often read visually using a gauge that measures the depth of each cut.

Q 5. What safety precautions should be taken when operating key cutting machines?

Safety precautions when operating key cutting machines are paramount to avoid injury. Key cutting machines use sharp cutting tools and moving parts. Here’s a breakdown of essential safety measures:

- Always wear safety glasses: To protect your eyes from flying debris.

- Keep hands clear of the cutting area: Never attempt to adjust the key while the machine is running.

- Use the machine only as instructed: Familiarize yourself with the operator’s manual and follow all safety guidelines.

- Properly clamp the key blank: Ensure the blank is securely held to prevent it from moving during the cutting process.

- Regular maintenance: Keep the machine clean and lubricated according to the manufacturer’s instructions.

- Never operate a faulty machine: Report any mechanical issues to a qualified technician.

Ignoring these precautions can lead to serious injuries. Safety is the top priority when using any power tool.

Q 6. Explain the procedure for duplicating a car key using a code.

Duplicating a car key using a code typically involves using a specialized key cutting machine and a code reader. The code, often obtained from the car’s manufacturer or a dealership, represents the specific bitting of the key. This code is then entered into the key cutting machine, which will automatically cut a new key based on the provided information. This is often a more secure process than directly duplicating from an existing key, as it bypasses the potential for unauthorized copying. The key cutting machine usually has the ability to match the transponder chip to the vehicle’s system to allow the key to start and drive the vehicle. This process often requires specialized equipment and expertise.

Important Note: Unauthorized duplication of car keys can be illegal and may lead to serious consequences.

Q 7. How do you handle a customer request for a key to a lock you suspect is compromised?

If a customer requests a key to a lock I suspect is compromised – perhaps due to signs of tampering or a previous reported incident – I would handle the situation with caution. I would first politely but firmly inquire about the circumstances of their request. If there is any ambiguity about their ownership of the property or legitimacy of the request, I would decline to duplicate the key. I would explain that my professional responsibility includes preventing unauthorized key duplication that could facilitate illegal activity. I might suggest they contact a locksmith or law enforcement for assistance to gain legitimate access to the property.

Protecting my business reputation and upholding safety standards require careful consideration of these ethical and legal aspects. A professional locksmith will handle these situations carefully to avoid possible legal repercussions.

Q 8. What are the legal implications of duplicating keys without authorization?

Duplicating keys without authorization carries significant legal ramifications. It’s essentially trespassing into someone else’s property rights, potentially leading to criminal charges. The severity depends on the context. For instance, duplicating a house key for unauthorized entry is a much more serious offense than making a copy of a generic office key. You could face charges like burglary, theft, or even more serious felonies if the duplicated key is used to commit crimes. Civil lawsuits for damages and compensation are also possible. Always obtain explicit consent before duplicating any key that isn’t yours. Think of it like this: you wouldn’t copy someone’s credit card, and keys offer access, similarly a valuable asset.

In short, always confirm ownership and obtain permission before duplicating a key. The legal consequences can be severe and far-reaching.

Q 9. Describe the different types of key machines you’ve worked with.

Over my career, I’ve worked with a range of key machines, from simple manual key cutting machines to sophisticated, computerized systems. Manual machines are great for basic keys, requiring precision and skill. They are typically less expensive but demand more expertise from the operator. I’ve used many different models of Silca, Ilco, and Codemax manual machines over the years. These machines use different types of cutting bits that have to be swapped out depending on the type of key that is being cut. These machines need regular maintenance and sharpening of the bits. The computerized systems are incredibly precise and efficient. They often incorporate laser guidance systems that cut keys exactly to specification. Many of these machines can program transponder keys, which have become extremely common. These programmed machines, such as those from JMA and Xhorse, automate many of the processes involved in cutting keys, and often include digital databases of key cuts.

The choice of machine depends on the volume of work, the types of keys being duplicated, and the desired level of precision.

Q 10. How do you troubleshoot a malfunctioning key machine?

Troubleshooting a malfunctioning key machine requires a systematic approach. First, I’d check the most basic things: power supply, proper connection of all the components, and the condition of the cutting bits. Dull or damaged bits are a common culprit. If the issue persists, I’d refer to the machine’s manual. Many modern machines provide error codes that can pinpoint the problem. For instance, a ‘bit error’ indicates a problem with the cutting bit. If there is no manual or clear error code, I would begin a process of elimination. I’d systematically inspect each component checking for loose connections, malfunctions in the control panel and motor, and anything that might indicate a mechanical issue.

Sometimes the problem lies in the key blank itself. A warped or damaged blank can jam the machine. If the problem continues after attempting all of the troubleshooting measures, I would then contact the manufacturer of the key machine for assistance and potentially send it in for repairs.

Q 11. Explain the concept of a master key system.

A master key system is a hierarchical arrangement of keys where one key (the master key) can unlock multiple locks, while other keys can only open specific subsets of those locks. This is extremely useful for managing access in large buildings, such as apartment complexes or office buildings. Imagine an apartment complex; each apartment will have a unique key. Then there will be a floor key that can open all apartments on that floor, and then there is a master key that will open all of the doors in the entire building. This system allows for controlled access: a building manager has the master key, floor supervisors have floor keys, and tenants have their individual apartment keys. The design and implementation of a master key system require careful planning to ensure security and prevent unauthorized access. Poor design of this system can create vulnerability.

Q 12. How do you program a transponder key?

Programming a transponder key involves using specialized equipment to write a unique electronic code into the key’s chip. This chip communicates with the car’s immobilizer system, allowing the car to start. The process varies slightly depending on the car make and model and the type of key programmer used. Generally, it involves connecting a key programmer to the car’s diagnostic port (OBD-II port), reading the car’s existing transponder codes, and then writing those codes (or creating a new one) into the new transponder key. Some advanced systems require specific software and databases. Many modern key programmers can also perform key learning, where the vehicle is taught the new transponder keys as part of the programming process. Improperly programming a transponder key can render it unusable or even potentially damage the vehicle’s system. It’s crucial to have the correct tools and knowledge to program transponder keys correctly. It’s best done by trained professionals to avoid damaging the vehicle’s electronic system.

Q 13. What are the different types of keyways?

Keyways are the patterns cut into a key blank’s edge. These patterns determine which locks the key can open. There’s a huge variety, with each manufacturer and even specific lock models using their own keyways. Some common examples include Schlage SC1, Kwikset KW1, and Yale Y1. These keyways differ in their depth, spacing, and overall shape of the cuts into the key. Think of them as unique fingerprints for locks. Knowing the keyway is essential for accurate key duplication, as the correct blank must be selected to create a functional copy. Each keyway requires a specific cutting profile that may differ even within the same keyway type.

Q 14. How do you deal with a damaged key requiring duplication?

Duplicating a damaged key presents a challenge, but often solvable. The approach depends on the extent of the damage. If only a small portion is broken, the existing undamaged portions can often be used to guide the duplication process on a computerized machine. If the key is severely damaged, with many broken bits or significant wear, it might be necessary to create a new key from scratch with no reference to an existing key. This requires identifying the lock cylinder (often by the number found on the lock casing) and then ordering a key blank that matches the keyway. Then, using the specific type of lock cylinder, a new key is cut from the blank. If possible, it’s always best to have an undamaged, functional key as a model to use as a reference for creating copies. In some cases, it’s more cost-effective to have the entire lock cylinder replaced. Sometimes, the cost of reconstructing a key from a severely damaged key will be more expensive than just purchasing a new key.

Q 15. Describe your experience with key control systems.

My experience with key control systems spans over ten years, encompassing various applications from simple master key systems in small businesses to complex access control solutions for large commercial buildings. I’ve worked with both mechanical and electronic key systems, including those utilizing proximity cards and biometric technologies. My expertise extends to the implementation, maintenance, and troubleshooting of these systems, ensuring optimal security and efficiency. For instance, I helped a local hospital implement a new key control system that reduced key-related security breaches by 40% within the first year. This involved a thorough assessment of their existing infrastructure, designing a customized solution, and providing comprehensive training to their staff.

- Experience with various keying systems (e.g., Bitting, Master Key Systems, Access Control Systems)

- Proficient in installing, maintaining, and troubleshooting key control systems

- Strong understanding of security protocols and best practices

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the process of making a key from a lock cylinder?

Making a key from a lock cylinder is a precise process requiring specialized tools and expertise. It’s not simply copying the shape; it involves decoding the lock’s internal mechanism. First, the lock cylinder is carefully disassembled to expose the pins. A key code is then determined by measuring the height of each pin using a depth gauge. This code, which represents the precise measurements for each bit, is then input into a key cutting machine. The machine utilizes this code to precisely cut the teeth of the blank key, creating a duplicate that should operate identically to the original.

Think of it like building with LEGOs. The lock cylinder’s pins are like the LEGO studs, and the key’s cuts match the studs’ heights. If the heights aren’t precisely matched, the LEGO structure (the lock) won’t assemble (unlock) properly. The process requires precision and attention to detail.

Q 17. Explain the function of different key components like the bitting and the shank.

A key’s components work together to unlock a specific lock. The shank is the main body of the key, providing the structural support and handle. The bitting, however, is the crucial part; it’s the pattern of cuts along the key’s edge that interacts with the pins inside the lock cylinder. Different bitting patterns create different keys, ensuring only the correctly cut key will work. For example, a common flat key has a simple bitting pattern, while a complex dimple key has a series of deeper cuts.

Imagine a lock as a puzzle, and the bitting as the key’s unique shape that matches the puzzle pieces inside the lock. The shank is simply the handle that you hold to manipulate the puzzle pieces.

Q 18. How do you maintain and clean key cutting machines?

Maintaining key cutting machines is crucial for accurate and efficient duplication. Regular cleaning involves removing metal shavings and debris from the cutting mechanism using a brush and compressed air. Lubrication is equally important to reduce friction and wear. The machine’s cutting blades should be regularly inspected for sharpness and replaced when necessary. Failure to maintain the machine can lead to inaccurate cuts, damaging the key blanks, or even causing the machine to malfunction.

Think of it like maintaining a precision instrument; regular care ensures it functions as intended. Neglecting this maintenance can lead to costly repairs or replacements.

Q 19. What are the common problems encountered during key duplication?

Common problems during key duplication include incorrect bitting measurements leading to keys that don’t work, damaged key blanks due to dull or improperly adjusted cutting blades, and machine malfunctions due to lack of maintenance. Additionally, encountering unusual or uncommon lock types can pose challenges. For example, I once encountered a key with a unique patented design that required special tools and techniques to duplicate accurately.

These problems highlight the importance of experience and precision in key duplication. Each situation requires thorough assessment and careful application of specific techniques.

Q 20. How do you handle customer complaints about duplicated keys?

Handling customer complaints about duplicated keys requires a calm, professional approach. First, I actively listen to the customer’s concern to fully understand the issue. Then, I carefully examine the duplicated key and the original lock to identify the cause of the problem. If the error is on my end, I offer a sincere apology and immediately make a new duplicate key, ensuring its functionality this time. If the issue arises from an unexpected incompatibility (for instance, a lock that is unusually worn or damaged), I explain this clearly and transparently to the customer, offering alternative solutions if possible.

Building trust and maintaining a positive customer relationship are crucial aspects of my job. A straightforward, honest approach helps resolve even the most challenging complaints.

Q 21. What is your experience with different types of lock mechanisms?

My experience covers a wide range of lock mechanisms, including pin tumbler locks (the most common type), wafer locks, lever locks, and various types of electronic locks. I understand the internal workings of each mechanism and the specific techniques required for key duplication. This includes recognizing the differences in keyways, pin configurations, and security features, which are crucial for successful key duplication. For instance, high-security locks often have unique features that require specialized tools and knowledge to duplicate accurately.

Familiarity with different lock mechanisms allows me to provide efficient and effective key duplication services to customers with a variety of needs. It’s like knowing various types of puzzles—each requires a different approach to solve.

Q 22. Describe your experience with various key materials.

My experience encompasses a wide range of key materials, each with its own unique properties and challenges for duplication. I’ve worked extensively with brass, nickel silver, and steel keys, understanding their varying levels of durability and resistance to wear. Brass keys, for instance, are relatively soft and easier to duplicate, while steel keys require more precision and specialized tools due to their hardness. I’m also familiar with keys made from more advanced materials like composite metals and specialized alloys found in high-security systems, each demanding a different approach to duplication.

- Brass: Common, relatively soft, easily duplicated.

- Nickel Silver: Durable, harder than brass, requires slightly more precise tools.

- Steel: Hardest, most durable, needs specialized machines and techniques.

- Composite Metals/Alloys: Used in high-security keys; duplication requires specialized knowledge and equipment.

Understanding these material properties is crucial for selecting the right tools and techniques to ensure a precise and durable duplicate key.

Q 23. How do you handle requests for restricted keys?

Requests for restricted keys, such as those for access to secure buildings or vehicles, are handled with the utmost care and in strict adherence to legal and ethical guidelines. I always verify the requester’s identity through multiple forms of identification and cross-reference their request with the provided documentation to prevent unauthorized duplication. If the required documentation isn’t complete or there’s any doubt about the legitimacy of the request, I refuse the duplication. Maintaining a secure and responsible process is paramount to preventing misuse.

Think of it like this: I’m a gatekeeper, safeguarding access to secure locations. My responsibility goes beyond just making keys; it’s about ensuring that only authorized individuals can access restricted areas.

Q 24. Explain your understanding of key codes and their importance.

Key codes are essential alphanumeric representations of a key’s cutting profile. They provide a standardized method for accurately reproducing keys without relying solely on the physical key itself. Understanding key codes is crucial for efficient and accurate key duplication, particularly for high-security keys. Each number or letter corresponds to a specific cut depth and position on the key blank. For instance, a code like 00123456 represents a specific sequence of cuts. These codes allow for the creation of identical duplicates even if the original key is lost or damaged.

The importance of key codes lies in their precision and standardization. They reduce errors in the duplication process, helping to ensure a perfect fit and functionality. They’re especially critical when dealing with complex key systems, preventing potential security breaches.

Q 25. Describe your proficiency in using various key duplication tools.

My proficiency spans a range of key duplication tools, from basic manual key machines to sophisticated computerized systems. I’m adept at using both manual and electric key cutting machines, capable of handling various key types and blanks. I’m also experienced with specialized equipment for high-security keys, including those requiring laser cutting or specialized milling. Furthermore, I’m proficient with code-reading devices which decode the key information from the key’s physical profile.

- Manual Key Machines: Excellent for simple keys, requiring manual skill and precision.

- Electric Key Machines: Faster and more efficient for higher volume duplication.

- High-Security Key Cutting Machines: Specialized equipment for complex and intricate key designs.

- Code Readers: Used to extract key codes from existing keys for duplication.

Regular maintenance and calibration of these tools are essential for ensuring their accuracy and precision in producing perfect key duplicates.

Q 26. How do you ensure the accuracy and precision of key duplication?

Accuracy and precision in key duplication are paramount. I achieve this through a combination of meticulous technique, regular equipment calibration, and quality control checks. Before starting, I always inspect the original key for any damage or wear that could affect the duplication. After cutting, I thoroughly test the duplicated key in the corresponding lock to ensure a smooth, accurate operation. If there are any issues, I re-cut the key until a perfect fit is achieved.

Think of it as fine woodworking – precision is essential. A slight miscalculation can render a key unusable. My attention to detail and quality control procedures guarantee accuracy every time.

Q 27. What is your experience with high-security key systems?

I have significant experience with high-security key systems, which incorporate advanced features to enhance security and prevent unauthorized access. These systems often utilize specialized key blanks with complex cuts, patented designs, and anti-picking mechanisms. My experience includes working with systems such as Mul-T-Lock, Abloy, and Medeco. Duplicating these keys requires specialized knowledge, tools, and authorization processes to maintain security integrity.

Duplicating a high-security key is like solving a complex puzzle. You need to understand the intricate mechanics of the key and lock to create a perfect, functional duplicate without compromising security.

Q 28. Describe a situation where you had to solve a challenging key duplication problem.

One challenging case involved a severely damaged high-security key. Only a small fragment remained, making it impossible to use standard code-reading methods. The client needed the key duplicated urgently for access to a crucial facility. To solve this, I used a combination of techniques. First, I carefully examined the remaining fragment under magnification to identify as many cut depths and positions as possible. Then, I leveraged my experience with the specific high-security key system to deduce the likely missing cuts based on the remaining profile and the system’s known patterns. Finally, I used a specialized key-cutting machine capable of precision adjustments, making incremental cuts and constantly testing the key against a blank lock cylinder until it achieved perfect operation. Solving this problem required a blend of technical skill, deductive reasoning, and patience. The successful outcome underscored the importance of possessing a holistic understanding of key systems and their intricacies.

Key Topics to Learn for Key Duplication Interview

- Key Types and Cutting Techniques: Understanding different key types (e.g., flat, tubular, dimple, laser-cut), their unique features, and appropriate cutting methods. This includes recognizing key blanks and their compatibility.

- Key Duplication Machinery and Equipment: Familiarize yourself with various key cutting machines, their operation, maintenance, and safety protocols. This includes understanding the differences between manual and automated systems.

- Code Cutting and Keyways: Learn about decoding keyways from existing keys and using that information to accurately duplicate keys. Understand the importance of precision and potential challenges in this process.

- Troubleshooting and Problem-Solving: Develop your ability to identify and resolve common issues encountered during key duplication, such as misaligned cuts, broken key blanks, or machine malfunctions. This includes preventative maintenance practices.

- Security and Ethical Considerations: Understand the legal and ethical implications of key duplication, including the importance of verifying customer identification and avoiding unauthorized duplication of restricted keys.

- Customer Service and Communication: Practice clear and effective communication with customers, answering their questions confidently and professionally. This includes handling difficult situations with grace and professionalism.

- Inventory Management: Learn about the importance of maintaining an organized and well-stocked inventory of key blanks and related supplies.

Next Steps

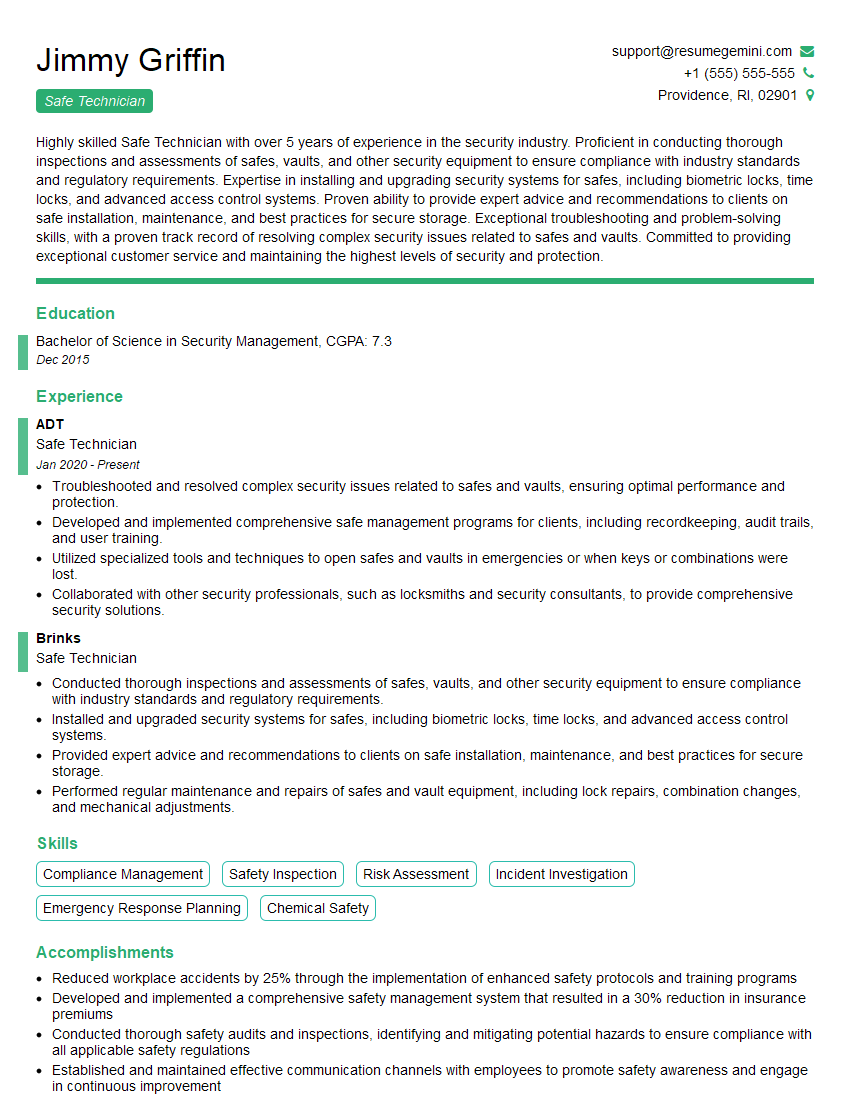

Mastering key duplication skills opens doors to a rewarding career with opportunities for growth and specialization. A strong understanding of key types, cutting techniques, and customer service will set you apart. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional resume that showcases your qualifications. Examples of resumes tailored to the key duplication field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO