Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Experience in Failure Analysis and Corrective Action interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Experience in Failure Analysis and Corrective Action Interview

Q 1. Describe your experience with various failure analysis techniques (e.g., microscopy, chemical analysis, etc.).

My experience encompasses a wide range of failure analysis techniques, crucial for pinpointing the root cause of product or process failures. I’m proficient in various microscopy methods, including optical microscopy for initial visual inspection, scanning electron microscopy (SEM) for high-resolution imaging of surfaces and microstructures, and transmission electron microscopy (TEM) for analyzing the internal structure of materials at the nanoscale. These techniques help identify defects like cracks, inclusions, or corrosion.

Chemical analysis plays a vital role. I’ve utilized techniques such as energy-dispersive X-ray spectroscopy (EDS) coupled with SEM to determine the elemental composition of materials, identifying unexpected elements or compositional variations that contribute to failure. Other methods I’ve employed include X-ray diffraction (XRD) for identifying crystalline phases and their orientations, and inductively coupled plasma mass spectrometry (ICP-MS) for highly sensitive trace element analysis.

Beyond these, I’m experienced with mechanical testing techniques like tensile testing to determine material strength and fracture toughness, and thermal analysis (DSC/TGA) to study material degradation under temperature changes. The selection of the appropriate technique depends heavily on the nature of the failure and the material in question. For example, analyzing a cracked plastic component might involve optical microscopy, SEM, and mechanical testing, while a failed electronic component may require SEM, EDS, and cross-sectional analysis.

Q 2. Explain your process for identifying the root cause of a failure.

Identifying the root cause of a failure is a systematic process. I typically follow a structured approach, starting with a thorough understanding of the failure itself. This includes gathering information from various sources – visual inspection of the failed component, reviewing operational data logs, interviewing operators, and reviewing any relevant documentation.

Next, I perform a detailed physical examination using the appropriate failure analysis techniques (as described in the previous answer). This helps pinpoint the location and nature of the failure. Then, I develop a hypothesis about the root cause based on the evidence gathered. This involves considering all possible contributing factors, from material defects to design flaws and operational issues.

This hypothesis is then rigorously tested using various analytical tools and techniques. The process often involves iterative testing and refinement of the hypothesis until a convincing explanation of the failure is found. Finally, I document all findings, including the root cause, contributing factors, and supporting evidence, ensuring a clear and traceable record of the failure analysis process.

Q 3. How do you differentiate between a systemic failure and a random failure?

The distinction between systemic and random failures is crucial for effective corrective action. A systemic failure is one that results from a flaw in the system itself – a design weakness, a process defect, or an underlying issue affecting multiple units. Think of it as a weakness in the system’s design or operation that allows failure to occur repeatedly.

A random failure, on the other hand, occurs due to chance or unpredictable events. It’s an isolated incident, not indicative of a broader problem with the design or process. An example would be a single component failing due to a manufacturing defect that didn’t affect other units.

The key to differentiating them lies in the frequency and pattern of failures. A high failure rate across multiple units, particularly under similar operating conditions, strongly suggests a systemic issue. Conversely, isolated failures with no apparent commonality point to random failures. Statistical methods like control charts can be used to analyze failure data and distinguish between random variations and systematic shifts indicating systemic issues.

Q 4. Describe your experience with Failure Mode and Effects Analysis (FMEA).

Failure Mode and Effects Analysis (FMEA) is a proactive tool, utilized to anticipate potential failure modes and their consequences before they occur. My experience involves conducting both design FMEAs (DFMEA) and process FMEAs (PFMEA). In a DFMEA, we systematically review a design’s potential failure modes, their effects, severity, likelihood of occurrence, and detectability during manufacturing or operation. We then assign risk priority numbers (RPNs) to prioritize mitigation efforts.

Similarly, in a PFMEA, we analyze the potential failures within a manufacturing process, evaluating each step for possible defects and their impact on the final product. The focus is on identifying potential process variations and their consequences. This helps to anticipate and prevent problems before they lead to actual failures, saving time and resources in the long run. I have consistently used FMEA to improve designs and manufacturing processes by proactively addressing potential weaknesses and implementing robust preventative measures.

Q 5. How do you develop and implement corrective and preventive actions (CAPA)?

Developing and implementing Corrective and Preventive Actions (CAPA) is crucial after failure analysis. The process begins with a clear understanding of the root cause identified through the failure analysis. Based on this, we develop specific, measurable, achievable, relevant, and time-bound (SMART) corrective actions to address the immediate issue and prevent its recurrence. This might involve redesigning a component, modifying a process parameter, or implementing new training for operators.

For preventive actions, we look beyond the immediate failure to identify any underlying weaknesses in the system that might contribute to future failures. These actions might include implementing improved quality control procedures, upgrading equipment, or modifying design specifications to enhance robustness. The implementation phase involves careful planning, documentation, and communication to ensure that the corrective and preventive actions are effectively implemented throughout the organization. Regular monitoring is critical to ensure that the actions are effective and achieving the desired results.

Q 6. What metrics do you use to track the effectiveness of CAPA?

Tracking the effectiveness of CAPA is critical to ensure continuous improvement. I use several metrics to gauge this effectiveness. One key metric is the reduction in failure rate after implementation of CAPA. This involves tracking the frequency of similar failures before and after the corrective actions. A significant reduction demonstrates the effectiveness of the implemented measures.

Another useful metric is the reduction in customer complaints or warranty claims related to the addressed failure mode. This provides a direct measure of the impact of CAPA on customer satisfaction and product quality. We also track the time required for implementing the CAPA and the associated costs. This helps to identify areas for process optimization in future CAPA implementations. These metrics are regularly reviewed and analyzed to refine our CAPA process and ensure continuous improvement in product quality and reliability.

Q 7. Describe a situation where a failure analysis led to a significant process improvement.

During an analysis of recurring failures in a high-volume manufacturing process for a critical component, we initially identified surface cracks as the main cause of failure. Initial analysis pointed towards a material defect. However, a deeper investigation using SEM and EDS revealed that the cracks originated from microscopic stress concentrations arising from a poorly designed tooling fixture used in the manufacturing process. This was initially overlooked because the surface cracks initially appeared to be a material problem.

The CAPA involved redesigning the tooling fixture to eliminate the stress concentrations. This led to a significant reduction in the failure rate (from approximately 5% to less than 0.1%), a substantial improvement in product quality, and significant cost savings due to reduced scrap and rework. This example highlights the importance of thorough failure analysis to pinpoint the true root cause, rather than relying on surface-level observations. The process improvement here was not only in the product itself, but also in the overall manufacturing process and the company’s approach to failure analysis itself, leading to a much more rigorous investigative process.

Q 8. How familiar are you with statistical process control (SPC) techniques?

Statistical Process Control (SPC) is crucial for proactively identifying and preventing failures. I’m highly familiar with various SPC techniques, including control charts (like Shewhart, CUSUM, EWMA), process capability analysis (Cp, Cpk), and acceptance sampling. These help monitor process stability and identify shifts or trends indicating potential problems. For instance, a sudden increase in points outside the control limits on a Shewhart X-bar and R chart might signal a machine malfunction necessitating immediate investigation. Similarly, a low Cpk value suggests the process isn’t meeting specifications, indicating a need for corrective actions like adjusting machine settings or improving raw material quality.

My experience includes using SPC to monitor the production of automotive components, where we tracked critical dimensions using X-bar and R charts. Early detection of process variation through these charts prevented a significant number of out-of-specification parts, resulting in substantial cost savings and improved customer satisfaction.

Q 9. Explain your understanding of different types of failure modes (e.g., fatigue, corrosion, wear).

Failure modes represent the ways in which a product or process can fail. Understanding them is fundamental to effective failure analysis. Some common failure modes include:

- Fatigue: This occurs when a material is subjected to repeated cyclic loading, eventually leading to crack initiation and propagation. Think of a repeatedly bending paperclip until it breaks. In engineering, fatigue failures are often analyzed using S-N curves to determine the relationship between stress amplitude and fatigue life.

- Corrosion: This involves the deterioration of a material due to chemical or electrochemical reactions with its environment. Rust on a car is a classic example. Corrosion analysis often involves examining the corrosion products and the environment to identify the root cause.

- Wear: This refers to the gradual loss of material due to friction or abrasion. Imagine the wear on the soles of your shoes after prolonged use. Wear analysis often involves measuring the wear rate and identifying the mechanisms of wear.

- Creep: This is a time-dependent deformation under constant stress, often seen at high temperatures. Think of a sagging power line over time.

- Fracture: This involves the sudden separation of a material into two or more pieces, often due to excessive stress or impact. A broken bone is a biological example.

Understanding these modes allows for targeted investigations and the implementation of appropriate preventative measures.

Q 10. How do you determine the severity and probability of failure?

Determining the severity and probability of failure is crucial for prioritizing corrective actions. We often use Failure Mode and Effects Analysis (FMEA) for this. FMEA involves a structured approach to identify potential failure modes, their effects, severity, probability of occurrence, and the detectability of the failure. Each factor is typically rated on a scale (e.g., 1-10), and a Risk Priority Number (RPN) is calculated by multiplying these ratings (Severity x Probability x Detectability).

For example, a high-severity, high-probability failure with low detectability would have a high RPN, requiring immediate attention. A low-severity, low-probability failure with high detectability would have a low RPN and may not require immediate action. We regularly use FMEA in product design and process improvement to identify and mitigate potential risks before they lead to failures.

Q 11. Describe your experience with using data analysis tools for failure analysis.

Data analysis is the backbone of effective failure analysis. I’m proficient in using various statistical and visualization techniques to analyze failure data. This includes using descriptive statistics (mean, standard deviation, histograms) to summarize data, inferential statistics (hypothesis testing, regression analysis) to draw conclusions, and graphical techniques (scatter plots, box plots) to visualize relationships and patterns. For example, I’ve used regression analysis to identify a correlation between the operating temperature of a component and its failure rate. This allowed us to implement temperature control measures to extend the component’s lifespan.

I’ve also used root cause analysis methodologies such as the ‘5 Whys’ and fishbone diagrams to systematically identify the underlying causes of failures. These techniques help move beyond the symptoms of a problem to its root causes. For instance, using the 5 Whys technique on a repetitive production defect helped us uncover a faulty calibration procedure for a key manufacturing machine.

Q 12. What software or tools are you proficient in for failure analysis (e.g., Minitab, JMP)?

I am proficient in several software packages for failure analysis. My expertise includes:

- Minitab: For statistical process control, data analysis, and design of experiments.

- JMP: For robust statistical analysis and visualization, especially useful for exploring complex datasets.

- Excel: For data management, basic statistical analysis, and creating reports.

- Specialized Engineering Software: Experience with FEA (Finite Element Analysis) software for simulating material behavior under stress, and other specialized tools depending on the product and failure mode.

The choice of software depends on the complexity of the data and the specific analysis required. For simple datasets, Excel may suffice; however, for more complex analyses, Minitab or JMP provide more powerful tools.

Q 13. How do you manage a large number of simultaneous failure investigations?

Managing numerous simultaneous failure investigations requires a structured approach. I utilize a prioritization system based on the severity and urgency of each failure, often employing the RPN from FMEA. Critical failures requiring immediate attention are tackled first, while less urgent ones are addressed systematically. This involves clear task delegation to team members, regular progress updates, and effective communication channels. We also utilize a centralized database to track all ongoing investigations, ensuring consistent data management and reducing redundancy.

For example, during a period of increased field failures, I implemented a triage system where each failure report was categorized by severity and assigned to the most appropriate team member. This ensured efficient resource allocation and timely resolution of critical issues.

Q 14. How do you communicate complex technical information to non-technical audiences?

Communicating complex technical information to non-technical audiences requires clear, concise language and effective visualization. I avoid jargon and technical terms whenever possible, using analogies and real-world examples to explain concepts. Visual aids such as charts, graphs, and diagrams are crucial for conveying complex data effectively. Storytelling is also a powerful technique, presenting technical findings within a narrative context that is relatable and engaging.

For example, when presenting findings to senior management regarding a product failure, I avoided using statistical terms and instead focused on the impact on the company’s reputation and bottom line. I used a simple bar graph to show the cost of the failures and a flowchart to explain the sequence of events leading to the failure. This approach ensured everyone understood the issue and the proposed solutions.

Q 15. Describe your experience with documenting failure analysis findings.

Documenting failure analysis findings is crucial for traceability, continuous improvement, and legal compliance. My approach involves a structured report, typically following a standard format. This includes a detailed description of the failed component, the failure mode observed, the symptoms leading to discovery, and a comprehensive root cause analysis. I use clear, concise language, avoiding jargon whenever possible, and include copious visuals like photographs, schematics, and micrographs to support my findings.

For instance, when analyzing a failed circuit board, my report would include high-resolution images of the affected area, a schematic highlighting the failed component, measurements of key parameters before and after failure, and a description of the testing procedures performed. The report also incorporates a detailed explanation of the root cause, supported by evidence from the investigation, and finally, the proposed corrective actions.

I always maintain version control of the documents, ensuring that all changes are tracked and that the latest version is readily available. This not only facilitates communication across teams but also serves as a valuable resource for future investigations of similar failures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize multiple failure investigations?

Prioritizing multiple failure investigations requires a systematic approach. I use a risk-based prioritization matrix considering factors like safety implications, production downtime, financial impact, and customer satisfaction. Failures posing significant safety risks or causing substantial production halts take precedence.

For example, a failure in a safety-critical system would always be prioritized over a minor cosmetic defect. I utilize a simple scoring system, assigning weights to each factor, to objectively compare different failure investigations. This allows for a transparent and data-driven decision-making process, ensuring that resources are allocated effectively. Regular review meetings help to monitor progress and adjust priorities as needed, adapting to any emerging critical situations.

Q 17. Explain your understanding of design of experiments (DOE).

Design of Experiments (DOE) is a powerful statistical technique used to efficiently identify the key factors influencing a process or product’s performance. It helps determine the optimal settings for these factors to achieve desired outcomes. I have extensive experience applying DOE methodologies like factorial designs, response surface methodology (RSM), and Taguchi methods.

Imagine we’re trying to optimize the yield of a chemical process. Instead of randomly changing parameters, a DOE approach allows us to systematically vary temperature, pressure, and reactant concentration in a planned manner. By analyzing the resulting data statistically, we can identify which factors have the most significant impact on yield and determine the optimal combination of settings to maximize it. This is significantly more efficient than trial-and-error methods.

DOE is invaluable in failure analysis because it helps pinpoint the root cause of failures by systematically testing different hypotheses. It reduces the time and resources required compared to a haphazard approach.

Q 18. How do you ensure that implemented corrective actions are effective and sustainable?

Ensuring the effectiveness and sustainability of corrective actions involves a multi-step process that extends beyond implementation. Firstly, I verify the implemented correction through rigorous testing and validation to ensure it resolves the identified root cause. I utilize a combination of simulations, accelerated life testing, and in-situ testing depending on the nature of the failure and the implemented solution.

Secondly, I establish effective monitoring mechanisms to track the performance of the corrected component or system over time. This includes implementing relevant metrics and establishing review checkpoints. This helps catch any potential recurrences of the failure before they escalate. Thirdly, I leverage the findings from the failure analysis and corrective action implementation to update related procedures, training materials, and design specifications to prevent similar failures in the future. This involves documenting the lessons learned and sharing them effectively across relevant teams.

Finally, regular audits and reviews ensure long-term effectiveness and compliance with updated standards and processes. This proactive approach ensures that the corrective actions are not only effective in the short term but also contribute to building a more robust and reliable system.

Q 19. What is your experience with 8D problem-solving methodology?

The 8D problem-solving methodology is a structured approach for identifying, analyzing, and resolving problems. I’ve successfully applied it numerous times. It’s a systematic process that guides investigation from initial problem definition to permanent corrective action.

Each ‘D’ represents a specific step: D0 (Plan) defines the problem and team; D1 (Describe) details the problem; D2 (Contain) implements immediate containment actions; D3 (Correct) identifies the root cause; D4 (Verify) validates the correction; D5 (Prevent) implements preventative measures; D6 (Document) documents the entire process; and D7 (Congratulate) recognizes the team’s effort. This structured approach helps prevent overlooking crucial aspects and ensures a complete and thorough resolution.

For instance, in a case involving a recurring software bug, I utilized the 8D process. ‘D3’ (Correct) involved code reviews, debugging, and software testing. ‘D5’ (Prevent) included updating coding standards and implementing automated testing procedures. The 8D methodology provides a framework to systematically address complex issues, allowing for efficient resolution and improved product quality.

Q 20. Describe a time you had to deal with a challenging failure analysis case.

One particularly challenging case involved a series of unexplained failures in a high-voltage power supply. Initial investigations yielded no clear cause. The failures were intermittent, and the affected components showed no consistent damage patterns.

To address this, I employed a combination of techniques. We started with a thorough review of the design specifications, manufacturing processes, and operating conditions. Then, we conducted detailed failure mode and effects analysis (FMEA) and a thorough environmental stress screening (ESS) test. This revealed a previously unanticipated resonance frequency within the power supply that was causing excessive stress under specific operating conditions. This frequency was only activated under particular environmental conditions and load profiles, making it extremely difficult to detect. We implemented a redesign incorporating damping materials and altered the circuit to mitigate the resonance, solving the problem. This case highlighted the importance of considering all potential contributing factors, even those that might seem unlikely.

Q 21. How do you handle disagreements with engineers or management during failure analysis?

Disagreements are inevitable in failure analysis, as different engineers might have varying perspectives and interpretations of the data. My approach emphasizes collaborative problem-solving and respectful communication. I start by actively listening to all viewpoints, ensuring everyone feels heard. I then facilitate open discussions, focusing on the data and evidence to support or refute different hypotheses.

If a consensus cannot be reached, I present a structured, evidence-based argument supported by data analysis and established engineering principles. If necessary, I might involve a more senior engineer or a cross-functional team to mediate and help reach a conclusion. Transparency and a focus on finding the true root cause, rather than winning an argument, are paramount. Maintaining professional respect, even during disagreements, is critical for preserving team morale and achieving effective problem resolution.

Q 22. How do you stay updated on the latest advancements in failure analysis techniques?

Staying current in the rapidly evolving field of failure analysis requires a multi-pronged approach. I actively participate in professional organizations like the American Society for Quality (ASQ) and attend their conferences and webinars, which often feature cutting-edge research and techniques. I also subscribe to several key journals, such as Materials Characterization and Reliability Engineering & System Safety, ensuring I’m aware of the latest publications. Furthermore, I actively engage with online communities and forums dedicated to failure analysis, participating in discussions and learning from the collective experience of experts around the world. Finally, I make it a point to regularly review industry standards and best practices to ensure my methods remain aligned with the highest levels of professional competence.

For instance, recently I learned about advancements in using AI-powered image analysis for microstructural examination, significantly speeding up the process and improving accuracy in identifying defects. This is something I am actively exploring for implementation in my workflow.

Q 23. Explain your understanding of reliability prediction methods.

Reliability prediction involves estimating the probability of a system or component failing within a specified time frame. This is crucial for proactive maintenance, design improvement, and life-cycle cost analysis. Several methods exist, each with its own strengths and limitations.

- Failure Rate Models: These models, like the exponential distribution, assume a constant failure rate over time. They’re simple but often insufficient for complex systems with wear-out mechanisms.

- Weibull Distribution: A more versatile model capable of capturing different failure patterns, including infant mortality, constant failure rate, and wear-out. It’s widely used for analyzing time-to-failure data.

- Fault Tree Analysis (FTA): A top-down, deductive approach identifying potential failure events and their combinations that lead to system failure. It helps visualize failure pathways and probabilities.

- Finite Element Analysis (FEA): Used for predicting structural failure based on stress, strain, and material properties. It’s particularly useful for complex mechanical systems.

Choosing the appropriate method depends heavily on the context. For instance, for simple components with relatively constant failure rates, an exponential model might suffice. However, for complex electronic systems exhibiting infant mortality, a Weibull analysis would provide a more accurate prediction. I have experience applying all these methods and selecting the most appropriate one based on the available data and the specific system.

Q 24. How do you balance the need for speed in failure analysis with the need for accuracy?

Balancing speed and accuracy in failure analysis is a critical skill. While quick turnaround times are often crucial, especially when production lines are affected, compromising accuracy can lead to ineffective corrective actions and recurring failures. My approach is to establish clear priorities and use a tiered approach.

Initially, I focus on a rapid preliminary assessment using non-destructive techniques like visual inspection, simple electrical measurements, or basic microscopy to quickly pinpoint the most likely area of failure. This provides a starting point for targeted, more in-depth analysis. As I gather more data, I refine my analysis, progressively employing more sophisticated and time-consuming techniques like SEM (Scanning Electron Microscopy), chemical analysis, or destructive physical testing only when necessary. This targeted strategy allows me to achieve a balance between speed and accuracy, addressing urgent issues quickly while ensuring a thorough understanding of the root cause for lasting solutions.

For example, in a recent case involving a malfunctioning circuit board, preliminary visual inspection revealed a burnt component. This immediately pointed to an overcurrent issue. Further investigations with electrical testing and then detailed component analysis were focused only on that area of the board to quickly pinpoint the cause of the overcurrent.

Q 25. What is your experience with different types of testing and inspection methods?

My experience encompasses a wide range of testing and inspection methods, both destructive and non-destructive.

- Non-destructive: Visual inspection, X-ray inspection, ultrasonic testing, eddy current testing, infrared thermography, and electrical measurements (resistance, capacitance, inductance).

- Destructive: Tensile testing, impact testing, fatigue testing, cross-sectioning, chemical analysis (e.g., EDS, XPS), microscopy (optical, SEM, TEM).

I am proficient in using specialized equipment and interpreting the results obtained from these tests. The choice of method depends on factors such as the type of component, material, suspected failure mode, and the information required. I am experienced in properly documenting all testing procedures and results for traceability and compliance.

For instance, I recently used infrared thermography to quickly identify a localized overheating in a power supply, leading to a cost-effective resolution without requiring disassembly. In a different case, destructive cross-sectioning and SEM analysis were vital in determining a microscopic crack formation at the solder joint of a critical component.

Q 26. How do you assess the risk associated with a particular failure mode?

Assessing the risk associated with a particular failure mode involves a combination of quantitative and qualitative analyses.

Risk = Probability of Failure × Severity of Consequences

I use various techniques to assess these two factors:

- Probability of Failure: This can be estimated using historical data, reliability models (like Weibull analysis), simulation, or expert judgment. For instance, a high failure rate in previous batches of a certain component suggests a high probability of future failures.

- Severity of Consequences: This considers the impact of failure on safety, environment, cost, reputation, and production schedule. A failure in a critical safety system obviously has much higher severity than a failure in a non-critical system.

Once both probability and severity are assessed, a risk matrix can be used to prioritize failure modes. Those with high probability and high severity require immediate attention, while those with low probability and low severity can be addressed later. This allows for focusing resources effectively on the most critical failure modes.

For example, a low probability of a catastrophic failure (e.g., high-severity) might still need immediate attention, while a high-probability minor failure (low severity) may only require minor adjustments in the short term.

Q 27. Describe your experience with using Weibull analysis.

Weibull analysis is a powerful statistical method used to analyze time-to-failure data and estimate the reliability of a product or component. It’s particularly useful when the failure rate is not constant over time, which is common in many real-world applications. The Weibull distribution has two key parameters: the shape parameter (β) and the scale parameter (η).

The shape parameter indicates the failure pattern: β < 1 indicates infant mortality, β = 1 indicates a constant failure rate, and β > 1 indicates wear-out. The scale parameter represents the characteristic life of the component. I have extensive experience in fitting Weibull distributions to failure data using statistical software packages. This allows me to estimate the reliability function, failure rate function, and other critical metrics. The results are crucial for predicting the future reliability of a product, determining optimal maintenance strategies, and improving product design.

In a recent project involving the analysis of hard drive failures, Weibull analysis revealed a wear-out pattern, allowing us to predict the remaining useful life of the drives and implement a proactive replacement schedule, minimizing downtime and cost.

Q 28. How do you handle situations where the root cause of a failure is unclear?

When the root cause of a failure remains unclear, a systematic and methodical approach is essential. I typically employ the following steps:

- Review all available data: This includes the initial failure report, test results, maintenance logs, and any relevant design documentation.

- Conduct brainstorming sessions: Involve a diverse team with different perspectives to generate a wide range of potential root causes.

- Develop a hypothesis: Based on the available data and brainstorming, formulate testable hypotheses about the potential root causes.

- Design and conduct experiments: Conduct targeted experiments to test each hypothesis. This might involve additional testing, simulations, or further analysis.

- Iterative process: This is an iterative process; as new information becomes available, hypotheses are refined and experiments are adjusted.

- Elimination process: Once a root cause is identified, implement corrective actions to eliminate the failure.

The key is to remain persistent, methodical, and open-minded, constantly challenging assumptions until the true root cause is identified. Sometimes, advanced analytical techniques, such as Design of Experiments (DOE), may be necessary to isolate the root cause among multiple potential factors. Documenting each step rigorously is also crucial to ensure transparency and allow for future reference.

For example, I recently encountered a situation where a complex system was failing intermittently. Through a structured approach involving logging of operational parameters, detailed data analysis, and targeted testing, we were able to identify a subtle software bug interacting with environmental factors as the root cause of this perplexing failure.

Key Topics to Learn for Experience in Failure Analysis and Corrective Action Interview

- Root Cause Analysis Techniques: Understanding and applying methodologies like 5 Whys, Fishbone diagrams, and Fault Tree Analysis to identify the underlying causes of failures.

- Failure Modes and Effects Analysis (FMEA): Proficiently conducting FMEAs to proactively identify potential failure points and mitigate risks before they occur. Practical application includes demonstrating experience in creating and implementing FMEA plans.

- Data Analysis and Interpretation: Skillfully analyzing data from various sources (e.g., test results, field reports, manufacturing data) to identify trends and patterns indicative of failures. This includes using statistical tools and software for data analysis.

- Corrective Action Implementation and Verification: Developing and implementing effective corrective actions to prevent recurrence of failures. This includes describing methods for verifying the effectiveness of implemented solutions.

- Documentation and Reporting: Clearly and concisely documenting failure analysis findings, corrective actions, and verification results in professional reports. This involves utilizing appropriate templates and adhering to company standards.

- Problem-Solving Methodologies: Demonstrating a structured approach to problem-solving, including defining problems, brainstorming solutions, and evaluating their effectiveness. Lean methodologies (e.g., Kaizen) are valuable additions.

- Communication and Collaboration: Effectively communicating technical information to both technical and non-technical audiences, and collaborating effectively with cross-functional teams to resolve complex issues.

- Specific Industry Knowledge: Tailoring your preparation to the specific industry and technologies relevant to the target role. Understanding industry-specific standards and regulations is crucial.

Next Steps

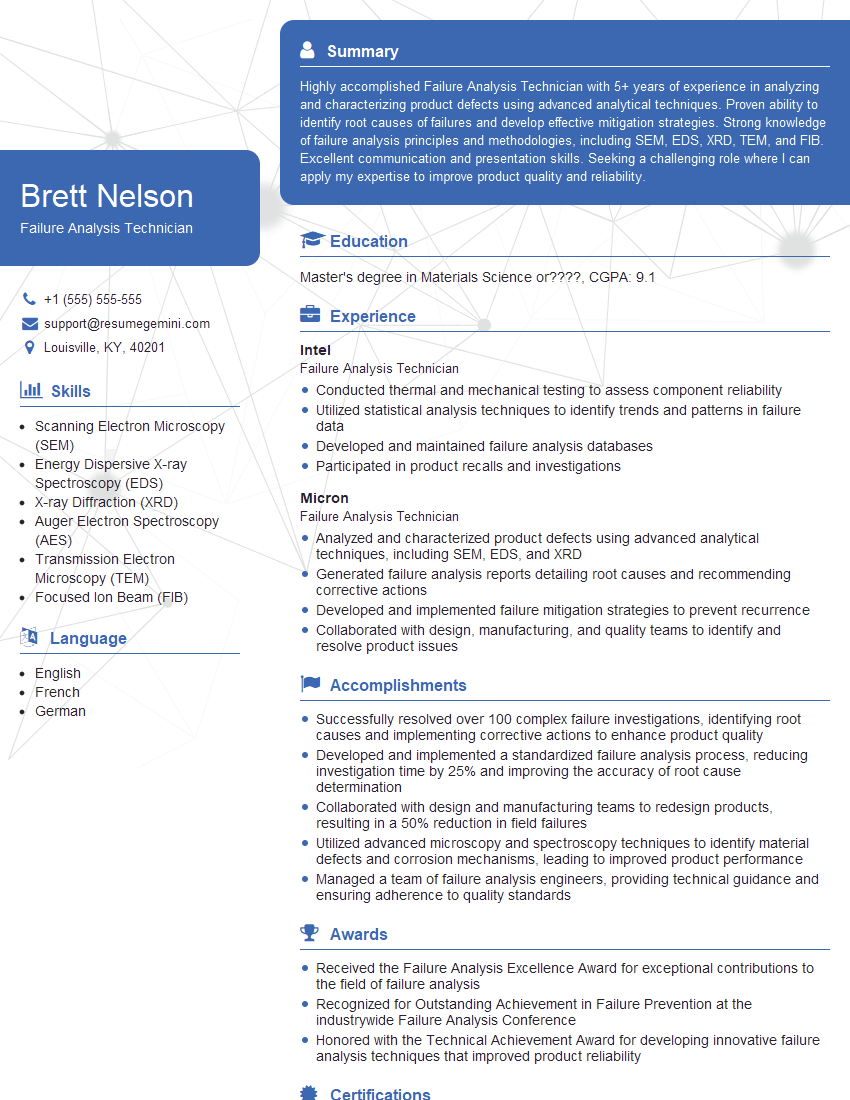

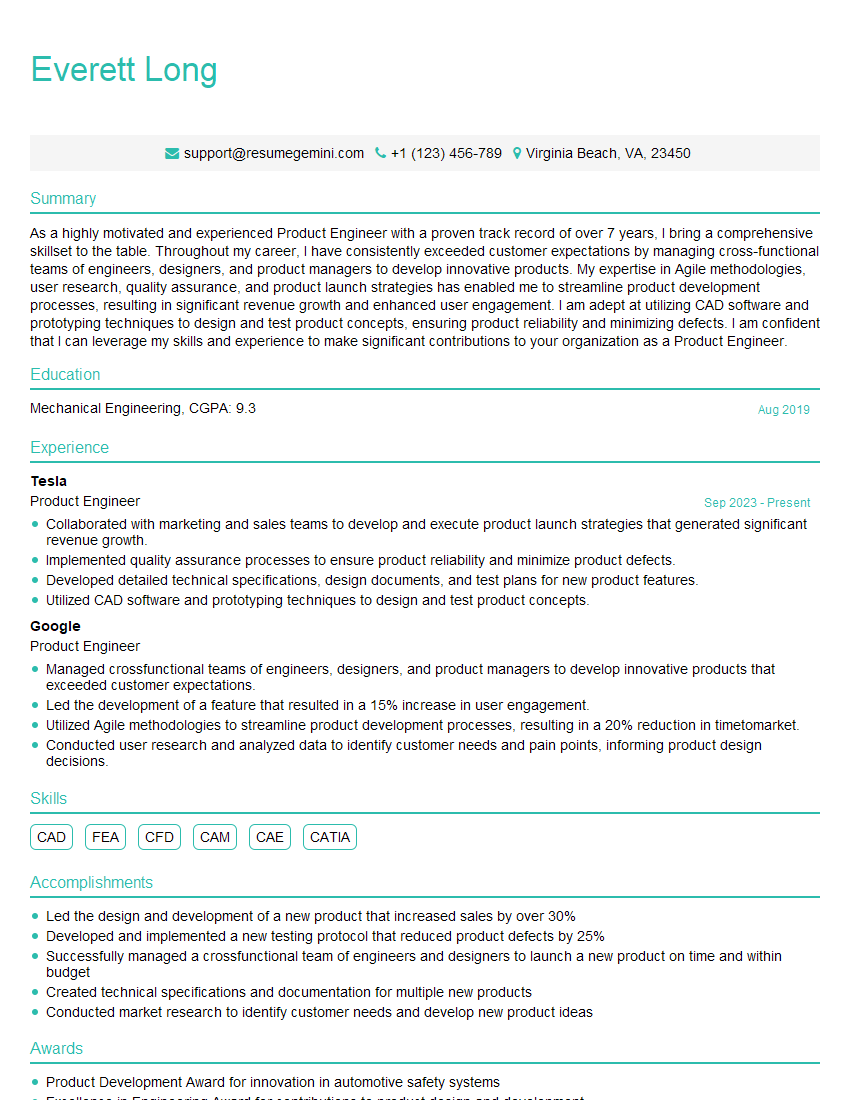

Mastering Failure Analysis and Corrective Action is vital for career advancement in many technical fields. It demonstrates critical thinking, problem-solving skills, and a proactive approach to quality and efficiency. To maximize your job prospects, create an ATS-friendly resume that showcases your expertise effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume, ensuring your skills and experience are clearly highlighted for recruiters. Examples of resumes tailored to Experience in Failure Analysis and Corrective Action are available to further guide your resume development.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO