The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Experience in using preventive maintenance techniques interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Experience in using preventive maintenance techniques Interview

Q 1. Describe your experience with different preventive maintenance techniques.

Preventive maintenance techniques aim to avoid equipment failures by performing regular inspections and servicing. My experience encompasses a wide range of techniques, tailored to the specific equipment and its operating environment. These include:

- Lubrication: Regularly lubricating moving parts like bearings and gears minimizes friction, extending their lifespan and preventing premature wear. For example, in a manufacturing plant, I implemented a scheduled lubrication program for conveyor belts, resulting in a 20% reduction in belt replacements.

- Inspection: Visual inspections, often using checklists, identify potential issues like cracks, corrosion, or loose connections before they escalate. I’ve used this extensively in HVAC systems, catching minor refrigerant leaks before they led to major system failures.

- Cleaning: Removing dust, debris, and other contaminants from equipment improves performance and reduces the risk of overheating or malfunctions. A prime example is cleaning the filters of air compressors to prevent overheating and ensure consistent air pressure.

- Functional Testing: Periodically testing equipment under operating conditions confirms its functionality and identifies subtle performance degradation. This is crucial for critical systems like generators, where regular load tests prevent unexpected power outages.

- Component Replacement: Proactive replacement of components nearing the end of their useful life prevents catastrophic failures. This is particularly effective for parts with predictable wear-and-tear patterns, like belts, filters, and seals. For instance, strategically replacing worn-out pump seals in a water treatment plant prevented costly emergency shutdowns.

Q 2. How do you prioritize preventive maintenance tasks?

Prioritizing preventive maintenance tasks requires a structured approach. I typically use a risk-based prioritization system, considering factors such as:

- Criticality: Equipment critical to production receives higher priority. For example, a production line’s main motor is prioritized over a less critical ventilation system.

- Failure consequences: The potential impact of a failure (safety hazards, production downtime, financial losses) dictates priority. A machine posing a safety risk gets immediate attention.

- Failure rate: Equipment with a history of frequent failures receives more frequent maintenance. For instance, a pump with a history of leaks would be inspected and serviced more regularly.

- Maintenance cost: Balancing maintenance costs with the cost of potential failures is essential. A cost-benefit analysis can guide this process.

Often, I utilize a CMMS (explained in the next answer) to manage and track these priorities, generating automated schedules based on these criteria.

Q 3. Explain your experience with Computerized Maintenance Management Systems (CMMS).

My experience with Computerized Maintenance Management Systems (CMMS) is extensive. I’ve used various CMMS software to manage preventive maintenance programs, scheduling tasks, tracking work orders, managing inventory, and generating reports. A good CMMS is the backbone of an effective preventive maintenance program.

Specific functionalities I leverage include:

- Work order management: Creating, assigning, and tracking work orders for preventive maintenance tasks, ensuring timely completion.

- Inventory control: Managing spare parts inventory to ensure availability for timely repairs, minimizing downtime.

- Preventative maintenance scheduling: Automatically scheduling maintenance tasks based on equipment usage, time intervals, or other parameters.

- Reporting and analytics: Generating reports on maintenance costs, equipment uptime, and other key performance indicators (KPIs) to assess program effectiveness and identify areas for improvement.

For instance, in a previous role, I implemented a CMMS that reduced maintenance costs by 15% and improved equipment uptime by 10% within a year. This system allowed for better data-driven decision-making regarding maintenance strategies.

Q 4. What are some common indicators that preventive maintenance is needed?

Several indicators point towards the need for preventive maintenance. These can be broadly categorized as:

- Unusual Sounds or Vibrations: Unusual noises like grinding, squealing, or excessive vibrations often indicate wear or misalignment.

- Performance Degradation: Reduced output, increased energy consumption, or slower operating speeds signal potential problems.

- Leaks: Fluid leaks (oil, water, refrigerant) indicate potential seal failures or damage.

- Temperature Changes: Unexpectedly high or low operating temperatures can point to overheating, insufficient cooling, or other issues.

- Increased Wear and Tear: Visible wear and tear on components (e.g., frayed belts, corroded surfaces) require immediate attention.

- Error Messages: Modern equipment often provides error messages or fault codes that can pinpoint the source of problems.

Regular visual inspections and monitoring key performance indicators can help catch these early warning signs.

Q 5. How do you identify and address potential maintenance issues before they become major problems?

Identifying and addressing potential maintenance issues before they escalate requires proactive strategies. This includes:

- Regular Inspections: Frequent visual inspections, utilizing checklists, help identify minor issues before they become major problems.

- Predictive Maintenance Techniques: Employing vibration analysis, oil analysis, or thermal imaging can help detect early signs of wear or potential failures.

- Data Monitoring: Using sensors to monitor equipment parameters (temperature, pressure, vibration) and analyzing the data for anomalies can proactively identify developing problems.

- Operator Feedback: Encouraging operators to report unusual observations or performance changes is crucial for early problem detection.

For example, using vibration analysis on a motor, I detected an imbalance before it caused significant damage, preventing a costly shutdown. Early detection allows for scheduled repairs, minimizing disruption.

Q 6. Describe your experience with root cause analysis in relation to maintenance issues.

Root cause analysis (RCA) is crucial for preventing recurring maintenance issues. My approach involves systematic investigation to identify the underlying cause of a problem, not just the symptoms. I commonly use techniques like:

- 5 Whys: Repeatedly asking “Why?” to drill down to the root cause of a problem. This helps uncover the underlying factors contributing to the issue.

- Fishbone Diagram (Ishikawa Diagram): A visual tool to brainstorm potential causes categorized by factors like people, materials, methods, machines, environment, and measurements.

- Fault Tree Analysis: A top-down approach to systematically identifying the potential causes of a failure, analyzing their probabilities and interdependencies.

By identifying the root cause, we can implement corrective actions to prevent recurrence. For instance, using 5 Whys on a recurring pump failure, we discovered a faulty valve which was consistently damaging the pump. Replacing the valve completely eliminated the issue.

Q 7. How do you ensure the accuracy and reliability of maintenance records?

Ensuring the accuracy and reliability of maintenance records is vital for effective preventive maintenance. I use several strategies to achieve this:

- Standardized Forms and Checklists: Using predefined forms and checklists ensures consistency and completeness of recorded information. This avoids ambiguity and ensures all necessary data is captured.

- Digital Record Keeping: Utilizing CMMS software for digital record keeping minimizes errors, improves accessibility, and facilitates data analysis.

- Regular Audits: Periodic audits of maintenance records ensure accuracy, consistency, and compliance with established procedures. This identifies discrepancies and helps improve data quality.

- Training and Procedures: Properly trained maintenance personnel are crucial for accurate record keeping. Clear procedures guide them in collecting and recording data.

- Data Validation: Implementing checks and balances in the data entry process helps identify and correct errors early on.

A well-maintained and accurate record-keeping system is essential for evidence-based decision-making, improving the efficiency and effectiveness of the preventive maintenance program.

Q 8. What are your methods for tracking and reporting maintenance KPIs?

Tracking and reporting maintenance KPIs (Key Performance Indicators) is crucial for optimizing maintenance strategies and demonstrating the value of preventive maintenance. My approach involves a multi-faceted system. First, I rely on a Computerized Maintenance Management System (CMMS), a software solution that allows for centralized data collection and analysis. This CMMS tracks various metrics, including:

- Mean Time Between Failures (MTBF): This tells us the average time between equipment failures, a key indicator of preventive maintenance effectiveness.

- Mean Time To Repair (MTTR): This measures how long it takes to repair a piece of equipment, highlighting areas for improvement in our corrective maintenance processes.

- Overall Equipment Effectiveness (OEE): This combines availability, performance, and quality rate to give a holistic view of equipment productivity. A higher OEE indicates better maintenance practices.

- Maintenance Costs: Tracking both preventive and corrective maintenance costs helps identify cost-saving opportunities.

- Number of Preventive Maintenance Tasks Completed: This shows our adherence to the established preventive maintenance schedule.

The CMMS generates reports that visually represent these KPIs, often using charts and graphs. These reports are shared regularly with stakeholders, including management and operations teams. I also use data visualization tools to create customized dashboards that allow for quick identification of trends and potential issues. For instance, a sudden spike in MTTR might indicate a need for improved training or parts management.

Q 9. Describe your experience with developing and implementing preventive maintenance schedules.

Developing and implementing preventive maintenance schedules requires a systematic approach. It begins with a thorough understanding of the equipment involved. This includes reviewing manufacturer’s recommendations, studying historical maintenance data, and performing risk assessments to identify critical components or potential failure points.

For example, in a previous role managing a packaging line, we analyzed past repair records to determine the frequency of belt replacements. We found that belts typically needed replacement after 6 months of continuous operation. Based on this, we scheduled preventative belt replacements every 5 months to create a buffer and minimize the risk of unexpected downtime.

Once the maintenance tasks are identified, I create a detailed schedule, taking into account factors such as equipment downtime windows, resource availability, and potential disruptions. The schedule is then entered into the CMMS, which automatically generates work orders and sends notifications to the appropriate maintenance personnel. The schedule should be regularly reviewed and adjusted as needed based on performance data and equipment condition.

Q 10. How do you manage your workload and prioritize urgent vs. preventive maintenance?

Managing workload and prioritizing maintenance tasks requires a structured approach. I use a prioritization matrix that considers the severity and urgency of each task. Urgent tasks (e.g., equipment failure causing production stoppage) always take precedence. For preventive maintenance tasks, I use a risk-based approach, prioritizing tasks that have the potential for causing significant downtime or safety hazards.

Imagine a scenario where a conveyor belt requires preventive lubrication (a routine task) and a critical pump is exhibiting unusual vibrations (a potential failure). I would prioritize addressing the pump issue first because its failure would have a much larger impact on production. I use the CMMS to schedule and track these tasks, ensuring visibility and accountability.

Workload management also involves effective communication with the maintenance team. This includes regular team meetings to discuss workload, address challenges, and coordinate efforts. A well-defined escalation process is also essential to ensure that urgent issues are addressed promptly.

Q 11. How do you handle unexpected maintenance needs?

Unexpected maintenance needs are a reality in any operational environment. My response involves a well-defined process. First, I ensure the immediate safety of personnel and equipment. Then, I assess the problem’s severity and its impact on operations. A quick assessment often involves visual inspection, equipment diagnostic tools, or consulting experienced technicians. Based on this assessment, I prioritize the issue within the existing workload.

For example, if a critical machine suddenly fails, halting production, I immediately dispatch a qualified technician to diagnose and repair the issue. Meanwhile, I communicate the disruption to the relevant stakeholders, providing updates and estimated time for restoration. Once the issue is resolved, a root cause analysis (RCA) is conducted to prevent similar incidents in the future. This often involves reviewing operational procedures, equipment design, and maintenance history.

Q 12. What is your experience with different types of maintenance (predictive, preventative, corrective)?

I have extensive experience with all three types of maintenance: corrective, preventive, and predictive. Corrective maintenance addresses equipment failures after they occur. Preventive maintenance aims to prevent failures through scheduled tasks. Predictive maintenance utilizes data analysis and technology (sensors, vibration analysis) to predict potential failures *before* they happen.

In my experience, a balanced approach is most effective. Corrective maintenance is unavoidable, but its costs and downtime should be minimized through effective preventive and predictive strategies. Preventive maintenance forms the backbone of reliability, while predictive maintenance helps optimize the preventive schedule and target resources more efficiently. For example, using vibration analysis on a critical motor can predict bearing wear before it leads to a costly breakdown, allowing for a timely preventive replacement.

Q 13. How familiar are you with different types of machinery and equipment?

My experience encompasses a wide range of machinery and equipment, including but not limited to: conveyors, pumps, compressors, HVAC systems, packaging machines, and various types of industrial motors. I’m proficient in understanding their operational principles, common failure modes, and effective maintenance techniques. My experience also extends to understanding electrical systems, pneumatic systems, and hydraulic systems. I’m comfortable working with both mechanical and electrical equipment and readily adapt to new technologies and systems.

My approach is always to thoroughly research and familiarize myself with the specifics of any new equipment before commencing maintenance tasks. Safety data sheets (SDS) are meticulously reviewed before handling any chemicals or hazardous materials. Manufacturer’s manuals and technical documentation are essential resources in my work.

Q 14. What is your experience with safety protocols in a maintenance environment?

Safety is paramount in any maintenance environment. My experience includes strict adherence to OSHA (or equivalent) regulations and company-specific safety protocols. This involves using appropriate personal protective equipment (PPE), following lockout/tagout procedures (LOTO) for electrical and mechanical isolation, and conducting regular safety inspections. I’m trained in hazard identification and risk assessment techniques and actively participate in safety training and refresher courses.

Beyond the formal processes, fostering a safety-conscious culture is vital. This involves leading by example, actively promoting safe work practices, and encouraging open communication regarding any safety concerns among team members. Regular safety meetings, incident reporting and investigation, and continual improvement are integral to maintaining a safe work environment.

Q 15. How do you communicate maintenance needs and issues to management?

Effective communication is the cornerstone of successful preventive maintenance. I utilize a multi-pronged approach, tailoring my communication to the audience and the urgency of the issue. For routine updates, I leverage regular reports, using clear, concise language and visualizations like charts and graphs to showcase key performance indicators (KPIs) such as equipment uptime and maintenance costs. These reports highlight trends and potential problems, allowing management to proactively allocate resources.

For urgent issues, I immediately inform the relevant managers via email or phone, providing a concise summary of the problem, its potential impact, and proposed solutions. I always follow up with a more detailed written report documenting the event, actions taken, and lessons learned. Finally, I participate in regular meetings to discuss maintenance plans, budgets, and address any concerns or questions management may have. For example, if a critical piece of equipment shows signs of accelerated wear, I’ll immediately alert the plant manager, outlining the potential downtime costs and outlining a prioritized repair schedule.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What tools and technologies do you utilize for preventive maintenance?

My toolkit for preventive maintenance is a blend of software and hardware. On the software side, I rely heavily on Computerized Maintenance Management Systems (CMMS). These systems, such as IBM Maximo or SAP PM, allow for scheduling, tracking, and analysis of maintenance activities. They help me manage work orders, track inventory, and generate reports. We also use data analytics tools to identify patterns in equipment failures and optimize maintenance schedules. For instance, we might analyze vibration data from a pump to predict potential bearing failures before they occur.

On the hardware side, we utilize a range of diagnostic tools depending on the equipment. This includes infrared cameras for thermal imaging (to detect overheating), vibration analyzers for early detection of mechanical issues, and ultrasonic detectors for leak detection. Regularly calibrated tools are crucial for accurate readings and reliable maintenance decisions. For example, I routinely use a calibrated vibration analyzer to monitor the health of our critical compressors, which helps us to proactively schedule maintenance based on the data.

Q 17. Explain your experience with spare parts management.

Efficient spare parts management is critical for minimizing downtime. My experience involves implementing a robust system that combines inventory management software with a well-defined ordering process. We utilize the CMMS to track parts usage, predict demand based on historical data and equipment age, and set optimal inventory levels using techniques like ABC analysis (classifying parts based on their value and criticality). This ensures we have enough critical parts on hand while avoiding unnecessary storage costs for low-usage items.

Furthermore, we maintain a detailed database of parts, including specifications, suppliers, and lead times. Regular inventory audits are conducted to verify stock levels and identify discrepancies. We also employ a ‘just-in-time’ inventory strategy for certain parts, ensuring we order them only when needed to avoid obsolescence and minimize storage space. In one instance, we streamlined our ordering process by negotiating contracts with key suppliers, reducing lead times and improving our overall responsiveness to maintenance needs.

Q 18. How do you ensure that your maintenance team adheres to safety regulations?

Safety is paramount in any maintenance operation. I ensure compliance by implementing a comprehensive safety program that includes regular safety training for all team members, covering topics such as lockout/tagout procedures, hazard communication, and personal protective equipment (PPE) use. We conduct toolbox talks before each job, reinforcing safe work practices and addressing specific hazards relevant to the task. Our team also participates in regular safety audits, identifying potential hazards and correcting unsafe conditions.

We use a permit-to-work system for high-risk tasks, requiring detailed risk assessments and authorization before any work begins. The system also includes documented verification of the completion of the task safely. All accidents and near misses are thoroughly investigated to identify root causes and prevent recurrence. For example, we recently implemented a new training program on confined space entry, significantly improving the team’s awareness and skills in this high-risk area.

Q 19. Describe your experience in conducting maintenance audits.

Maintenance audits are crucial for assessing the effectiveness of our maintenance strategies and identifying areas for improvement. My experience involves conducting both planned and unplanned audits. Planned audits involve a systematic review of our maintenance procedures, documentation, and records against established standards and best practices. We use checklists and standardized forms to ensure consistency and objectivity. We also conduct interviews with maintenance personnel to gather their feedback and identify any potential challenges.

Unplanned audits, or ‘spot checks’, are conducted randomly to assess real-time compliance with safety regulations and maintenance procedures. Audits findings are documented, and corrective actions are implemented to address any deficiencies. I have used audit results to identify bottlenecks in the maintenance process, leading to improved scheduling and reduced downtime. For instance, a recent audit revealed an inconsistency in the calibration of our vibration analyzers leading to unreliable data—this was corrected immediately, improving the accuracy of our predictive maintenance tasks.

Q 20. How do you improve the efficiency of preventive maintenance processes?

Improving the efficiency of preventive maintenance is an ongoing process. I focus on several key areas: optimizing maintenance schedules using predictive and condition-based maintenance techniques, leveraging technology like CMMS and sensor data to improve scheduling accuracy, and streamlining work orders through clear instructions and standardized procedures. I also focus on improving team communication and collaboration, and regularly seeking out and implementing best practices from other organizations and relevant industries.

For example, we recently implemented a predictive maintenance program for our critical pumps using vibration analysis. This allowed us to shift from time-based maintenance to condition-based maintenance, reducing unnecessary interventions and extending the lifespan of the pumps. This resulted in reduced maintenance costs and enhanced equipment reliability. Another strategy involved improving our parts management system; optimizing inventory levels and streamlining the procurement process resulted in a significant reduction in downtime caused by parts shortages.

Q 21. What metrics do you use to measure the effectiveness of preventive maintenance?

Measuring the effectiveness of preventive maintenance requires a set of key performance indicators (KPIs). I utilize several metrics to assess our success. These include: Mean Time Between Failures (MTBF) – the average time between equipment failures, which indicates improved reliability due to preventive maintenance; Mean Time To Repair (MTTR) – the average time it takes to repair a piece of equipment, signifying the efficiency of our repair processes; Equipment Uptime – the percentage of time equipment is operational, reflecting the overall effectiveness of our maintenance program; Maintenance Cost per Unit of Production – which highlights the cost-effectiveness of our maintenance efforts; and Safety Incident Rate – the number of safety incidents per employee-hours worked, showing the effectiveness of our safety program. Regularly tracking and analyzing these KPIs allows us to identify trends, pinpoint areas needing attention, and justify investment in improvements to our preventive maintenance program.

Q 22. How do you handle disagreements or conflicts within the maintenance team?

Disagreements within a team are inevitable, but addressing them constructively is crucial for effective preventive maintenance. My approach centers around open communication and collaborative problem-solving. First, I ensure everyone feels comfortable expressing their concerns. Then, I facilitate a discussion where we objectively analyze the root cause of the disagreement, focusing on the facts and potential solutions rather than assigning blame. We brainstorm together, exploring different perspectives and weighing the pros and cons of each approach. For example, if there’s a disagreement about the optimal schedule for inspecting a critical piece of equipment, we might review historical data on failure rates, analyze the potential impact of delaying the inspection, and ultimately decide on a schedule that minimizes risk and maximizes efficiency. Finally, we agree on a clear action plan and assign responsibilities, ensuring everyone understands their roles and the expected outcome. Regular team meetings and feedback sessions help prevent future conflicts by fostering open dialogue and shared understanding.

Q 23. How do you stay up-to-date on the latest maintenance techniques and technologies?

Staying current in the rapidly evolving field of preventive maintenance requires a multi-pronged approach. I actively participate in professional organizations like the Society for Maintenance & Reliability Professionals (SMRP), attending conferences and webinars to learn about new technologies and best practices. Industry publications, both print and online, are invaluable sources of information, keeping me abreast of new research and innovations. I also participate in online forums and communities where maintenance professionals share their experiences and insights. Furthermore, I encourage continuous learning within my team, regularly updating our standard operating procedures (SOPs) and training programs to reflect the latest advancements. For example, we recently integrated predictive maintenance techniques using vibration analysis software, drastically improving our ability to predict equipment failures and optimize maintenance schedules.

Q 24. What is your experience with budget management for preventive maintenance?

Budget management for preventive maintenance is a critical aspect of my role. It requires careful planning, accurate forecasting, and efficient resource allocation. I start by creating a detailed budget proposal that outlines all anticipated costs, including labor, materials, software subscriptions, and training expenses. This proposal is supported by a comprehensive analysis of equipment criticality, historical maintenance data, and predicted failure costs. Regular monitoring and reporting are crucial to ensuring the budget remains on track. We use a computerized maintenance management system (CMMS) to track maintenance activities, costs, and resource utilization, enabling us to identify potential overspending early on. If we encounter unexpected expenses, I work collaboratively with management to explore alternative solutions, such as prioritizing tasks or seeking cost-effective alternatives. For example, we recently negotiated a bulk discount on spare parts, leading to significant cost savings over the year.

Q 25. How do you train junior maintenance staff on preventive maintenance procedures?

Training junior maintenance staff is a high priority, as it ensures the continuity and effectiveness of our preventive maintenance program. My training approach is a blend of classroom instruction, hands-on experience, and on-the-job mentoring. We use a structured curriculum that covers all aspects of preventive maintenance, from understanding equipment schematics and safety procedures to executing specific maintenance tasks. Classroom sessions are supplemented by practical demonstrations and simulations. I emphasize the importance of safety protocols, using real-world examples of accidents to highlight the consequences of negligence. Mentorship plays a vital role, pairing junior staff with experienced technicians for on-the-job training and guidance. Regular quizzes and performance evaluations ensure staff members acquire and retain the necessary skills and knowledge. We also use a CMMS to track their progress and provide feedback.

Q 26. Describe a time when a preventive maintenance task prevented a major equipment failure.

During a routine inspection of a critical compressor in our manufacturing plant, we discovered a significant crack in a pressure vessel. This was identified during a scheduled visual inspection, well before it could lead to a catastrophic failure. Had this crack gone unnoticed, the compressor would have likely experienced a major failure, resulting in significant production downtime, costly repairs, and potential safety hazards. By addressing the issue proactively, we performed a timely repair at minimal cost, preventing a potentially disastrous scenario. This exemplifies the importance of adhering to our preventive maintenance schedule and highlights the cost-effectiveness of proactive maintenance versus reactive repair.

Q 27. How do you assess the risk associated with postponing preventive maintenance?

Assessing the risk of postponing preventive maintenance requires a systematic approach. I begin by evaluating the criticality of the equipment – how essential is it to the overall operation? Next, I consider the potential consequences of failure – what is the potential for downtime, production loss, safety hazards, and environmental damage? Then, I analyze the equipment’s history – have there been previous failures, and what was the cost of those failures? Finally, I weigh the cost of preventive maintenance against the potential cost of failure. This risk assessment is often documented using a Failure Modes and Effects Analysis (FMEA) or a similar risk matrix. For instance, postponing maintenance on a crucial production line might lead to a high likelihood of significant downtime and lost revenue, making it a high-risk decision. By quantifying the risks, we can make data-driven decisions regarding maintenance prioritization.

Q 28. Describe your experience working with cross-functional teams on maintenance projects.

Collaboration with cross-functional teams is essential for successful preventive maintenance. I have extensive experience working with operations, engineering, procurement, and safety teams. For example, during a recent project to upgrade our facility’s HVAC system, I collaborated closely with the engineering team to design the maintenance procedures, with the procurement team to source replacement parts, and with the operations team to schedule downtime for the upgrades. Effective communication, clearly defined roles, and shared goals were crucial for the project’s success. Regular meetings, shared documentation, and a collaborative problem-solving approach ensured all teams were aligned and worked towards the common objective. This cross-functional collaboration resulted in a smoother upgrade process, minimized downtime, and improved the overall efficiency of the HVAC system.

Key Topics to Learn for Experience in using Preventive Maintenance Techniques Interview

- Understanding Preventive Maintenance Strategies: Explore different preventive maintenance approaches (e.g., time-based, condition-based, predictive) and their respective advantages and disadvantages. Consider the factors influencing the selection of a specific strategy.

- Practical Application of Preventive Maintenance: Discuss your experience implementing preventive maintenance schedules, conducting inspections, performing routine tasks (lubrication, cleaning, adjustments), and documenting findings. Provide specific examples showcasing your contributions.

- Data Analysis and Interpretation: Explain how you use data collected during preventive maintenance (e.g., equipment performance data, sensor readings) to identify potential issues and optimize maintenance procedures. Demonstrate your ability to interpret data and make informed decisions.

- Troubleshooting and Problem-Solving: Describe your approach to resolving unexpected equipment issues identified during preventive maintenance. Highlight your problem-solving skills, ability to diagnose problems, and implement effective solutions.

- Compliance and Safety Regulations: Discuss your understanding and adherence to relevant safety regulations and industry standards during preventive maintenance activities. Showcase your commitment to a safe working environment.

- Cost Optimization and ROI: Explain how you contribute to cost reduction and improved return on investment through effective preventive maintenance strategies. Quantify your achievements whenever possible.

- Technology and Tools: Discuss your experience using various tools and technologies (CMMS software, diagnostic equipment) to support preventive maintenance activities. Highlight your proficiency with relevant software and hardware.

Next Steps

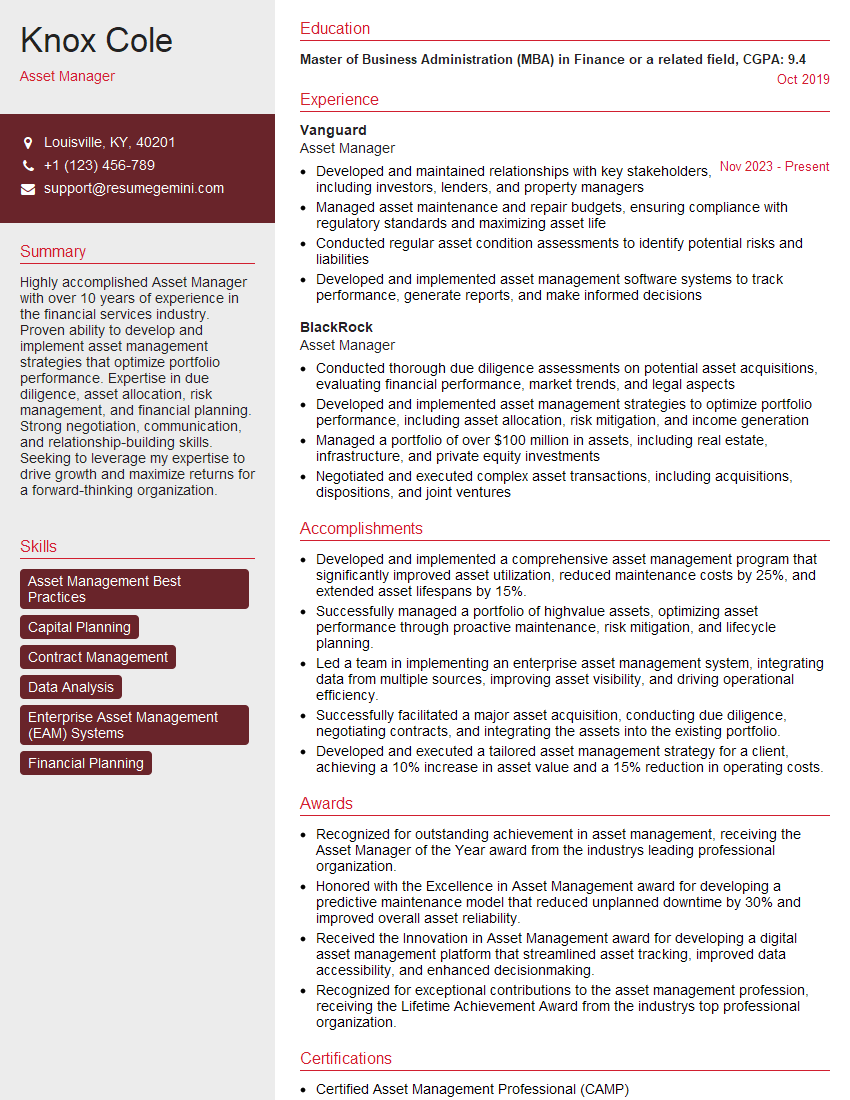

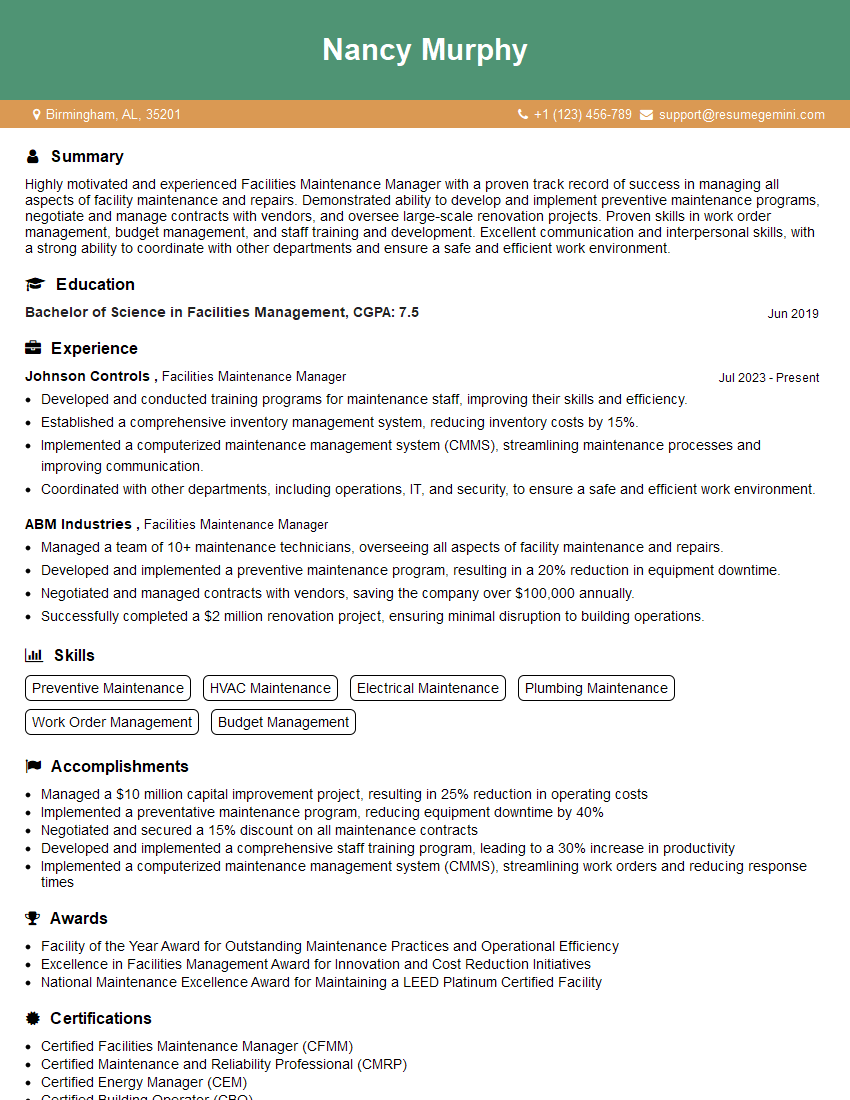

Mastering preventive maintenance techniques is crucial for career advancement in many industries. A strong understanding of these techniques demonstrates your commitment to efficiency, reliability, and safety. To increase your job prospects, focus on building an ATS-friendly resume that highlights your skills and achievements. ResumeGemini is a trusted resource that can help you create a professional and impactful resume tailored to your experience. Examples of resumes tailored to showcasing experience in preventive maintenance techniques are available [link to examples – remove for this code example]. Invest time in crafting a compelling resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO