Cracking a skill-specific interview, like one for Drilling Fluids Rheology, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Drilling Fluids Rheology Interview

Q 1. Explain the importance of rheological properties in drilling fluids.

The rheological properties of drilling fluids are absolutely critical for successful drilling operations. Rheology, simply put, is the study of how fluids flow and deform. In drilling, this translates to how easily the drilling fluid moves through the wellbore, how well it carries cuttings (rock fragments) to the surface, and how it interacts with the formation itself. Understanding and controlling the rheological properties is essential for optimizing drilling efficiency, minimizing wellbore instability issues, and ensuring the safety of the operation.

For example, a fluid that’s too thick can cause excessive pressure loss, slow drilling rates, and increase the risk of equipment damage. Conversely, a fluid that’s too thin may not effectively carry cuttings to the surface, leading to poor hole cleaning and potential pipe sticking. The right rheological profile is a delicate balance, tailored to the specific geological conditions and drilling parameters.

Q 2. Describe the different types of drilling fluid rheometers and their applications.

Several types of rheometers are used to measure drilling fluid rheology. The most common are:

- Marsh Funnel Viscometer: This is a simple, low-cost device that measures the time it takes for a specific volume of fluid to flow through a funnel. It provides a quick assessment of the fluid’s viscosity but doesn’t offer detailed rheological information. Think of it as a quick temperature check; it provides a general idea, but not precise detail.

- Rotary Viscometer: This instrument uses a rotating bob immersed in the fluid to measure the torque required to maintain a constant rotational speed. This allows for determination of plastic viscosity and yield point, giving a much more comprehensive profile than the Marsh Funnel. This is like getting a detailed blood panel – offering much more specific and useful data.

- Fann Viscometer: A sophisticated rotary viscometer that measures the fluid’s viscosity at different shear rates. It is widely used in the drilling industry to determine yield point, gel strength, and plastic viscosity, providing crucial information for optimizing drilling fluid performance. It’s the gold standard in the industry for rheological characterization.

The choice of rheometer depends on the level of detail required and the budget available. Quick assessments might use a Marsh Funnel, while detailed analyses necessitate a Fann or rotary viscometer.

Q 3. How do you determine the yield point and gel strength of a drilling fluid?

The yield point and gel strength are crucial indicators of a drilling fluid’s ability to suspend cuttings and prevent settling. They’re determined using a rotary or Fann viscometer.

- Yield Point: This is the minimum shear stress required to initiate fluid flow. It represents the fluid’s resistance to movement when at rest. It’s measured using a rotary viscometer at a very low shear rate (e.g., 3 rpm). A higher yield point indicates a greater ability to suspend cuttings. The value is obtained from the rheogram (a graph plotting shear stress versus shear rate).

- Gel Strength: This refers to the force required to break the structure that forms when the fluid is at rest. It’s measured by allowing the fluid to rest for 10 and 30 minutes and then measuring the shear stress needed to initiate flow. It represents the fluid’s ability to retain its structure and hold cuttings in suspension when circulation is stopped. Higher gel strength improves cuttings suspension and prevents settling, reducing the risk of pipe sticking.

The measurement process involves carefully preparing the fluid sample, running the test according to industry standards (API standards are commonly followed), and interpreting the results from the viscometer readings. Specialized software often accompanies modern viscometers to simplify data analysis and rheogram generation.

Q 4. What are the effects of temperature and pressure on drilling fluid rheology?

Temperature and pressure significantly impact drilling fluid rheology. Increasing temperature generally reduces viscosity, while increasing pressure usually increases viscosity. This is because higher temperatures increase the kinetic energy of the fluid molecules, making them more mobile and reducing the internal friction, hence reducing viscosity. Conversely, higher pressures reduce the fluid’s volume and increase intermolecular forces, leading to higher viscosity. The extent of these changes depends on the type of drilling fluid and its composition.

For instance, in high-temperature wells, the drilling fluid may become significantly thinner than expected, requiring adjustments to the formulation (e.g., adding polymers that maintain viscosity at higher temperatures) to maintain adequate cuttings carrying capacity and prevent wellbore instability. Similarly, in high-pressure formations, the increase in viscosity can lead to increased pressure losses during circulation, necessitating formulations with lower inherent viscosity.

Understanding these effects is vital in selecting and optimizing drilling fluid formulations for various well conditions. Careful analysis of the expected temperature and pressure profiles is crucial for ensuring the rheological properties remain within the acceptable range.

Q 5. Explain the concept of plastic viscosity and its significance in drilling operations.

Plastic viscosity is a measure of the resistance to flow of a drilling fluid after the yield point has been overcome. It reflects the internal friction within the fluid when it’s actively moving. It’s determined from the slope of the flow curve (the linear portion of the rheogram) in a rotary viscometer or Fann viscometer. A lower plastic viscosity indicates easier flow, while a higher plastic viscosity indicates greater resistance to flow.

Plastic viscosity is significant because it directly affects the pressure losses during drilling. A high plastic viscosity can lead to increased pump pressure, reduced drilling rates, and higher energy consumption. Controlling the plastic viscosity is vital in optimizing drilling efficiency and minimizing operational costs. Think of it like the friction in an engine; lower friction (plastic viscosity) means less energy wasted.

Q 6. How does the rheology of drilling fluids affect wellbore stability?

The rheology of drilling fluids plays a crucial role in maintaining wellbore stability. An appropriately designed drilling fluid exerts sufficient pressure against the formation walls to prevent collapse or fracturing. The yield point and gel strength are particularly important here. A fluid with sufficient yield point and gel strength will provide the necessary pressure support to prevent formation collapse in unconsolidated or weak formations.

Conversely, a fluid that is too viscous or has an excessively high yield point may induce fracturing of the wellbore in stronger formations, potentially causing problems like lost circulation or formation damage. Thus, careful consideration of the formation’s strength and pressure is critical in selecting the appropriate rheological profile to ensure stability and avoid costly issues.

For instance, in shale formations prone to swelling, a fluid with proper rheological properties can help to mitigate this issue by providing sufficient pressure support to the formation. This prevents the swelling shale from invading the wellbore and causing problems such as pipe sticking.

Q 7. Describe the different types of drilling fluids and their rheological characteristics.

Several types of drilling fluids exist, each with distinct rheological characteristics tailored to specific drilling environments:

- Water-Based Muds: These are the most common type, using water as the continuous phase. Their rheology is easily modified by adding various additives like clay, polymers, and weighting agents. They are generally less expensive but can be sensitive to temperature and salinity changes.

- Oil-Based Muds: These utilize oil as the continuous phase, offering better lubricity, shale inhibition, and high-temperature stability than water-based muds. Their rheology is typically more stable across a wider range of temperatures and pressures. However, they are more expensive and pose environmental concerns.

- Synthetic-Based Muds: These use synthetic oils as the continuous phase, combining the advantages of oil-based muds with reduced environmental impact. They exhibit good lubricity, stability, and shale inhibition, but cost significantly more than water-based muds.

- Air and Gas Drilling Fluids: These are used in specific applications and lack the traditional rheological properties described above; they behave according to gas dynamics.

The rheological characteristics, such as viscosity, yield point, and gel strength, vary greatly depending on the type of drilling fluid and the additives used. The selection of the appropriate drilling fluid type and its rheological profile depends on factors like formation type, temperature, pressure, and environmental regulations.

Q 8. How do you interpret and analyze rheological data from a drilling fluid report?

Interpreting rheological data from a drilling fluid report involves understanding the key parameters and their implications for drilling operations. The report typically includes measurements obtained using a rheometer, such as plastic viscosity (PV), yield point (YP), and gel strengths (10 sec and 10 min). These parameters describe the fluid’s resistance to flow under different shear rates and at rest. We look for trends in these parameters over time, to identify changes in the fluid’s properties during the drilling process.

For example, a consistently increasing yield point might indicate that the fluid is thickening excessively, potentially leading to increased pump pressure and reduced drilling efficiency. Similarly, a decrease in plastic viscosity could signal that the fluid is becoming too thin and may not adequately suspend cuttings or maintain wellbore stability. We analyze these data points in conjunction with other parameters such as mud weight, filtration properties, and the geological formation being drilled to draw meaningful conclusions and make necessary adjustments to the drilling fluid.

Furthermore, we often use rheological models, like the Bingham plastic or Power law model (explained later), to fit the data and extract key parameters for quantitative analysis. This helps predict the fluid’s behavior under different conditions and to optimize drilling parameters.

Q 9. What are the common additives used to modify the rheology of drilling fluids?

Many additives are used to tailor drilling fluid rheology to specific well conditions. These additives can increase or decrease viscosity, control gel strength, and improve other properties. Some common examples include:

- Clay (bentonite): A natural thickening agent, crucial for viscosity and gel strength. The type and amount of bentonite are carefully selected.

- Polymers (e.g., xanthan gum, guar gum): These provide excellent viscosifying properties, particularly at low shear rates, enhancing cuttings carrying capacity.

- Weighting materials (e.g., barite): Increase the density of the mud to control formation pressure and prevent wellbore instability. While not directly rheology modifiers, they influence the overall rheological behavior.

- Deflocculants (e.g., sodium carbonate, potassium carbonate): Reduce the viscosity of clay-based fluids by dispersing clay particles, preventing flocculation.

- Fluid loss control agents (e.g., lignite, polymers): Reduce the loss of water from the mud into the formation, improving wellbore stability. They indirectly affect rheology by influencing fluid structure.

The choice and concentration of additives depend heavily on the specific drilling conditions (e.g., formation type, temperature, pressure) and the desired rheological properties.

Q 10. Explain the relationship between rheology and the hydraulics of drilling fluids.

Rheology and hydraulics are intrinsically linked in drilling fluids. Rheological properties dictate how the fluid behaves under pressure and shear, directly impacting its hydraulic behavior. The rheology defines the pressure drop across the drillstring and annulus, affecting pump pressure, flow rate, and ultimately, the efficiency of cuttings transport.

Imagine trying to pump honey (high viscosity) through a straw versus water (low viscosity). The honey requires significantly more pressure due to its higher resistance to flow. Similarly, a high-viscosity drilling fluid will require higher pump pressure to achieve the desired flow rate, leading to increased operational costs. On the other hand, a fluid that’s too thin may not effectively carry cuttings to the surface.

The equations governing fluid flow in pipes (e.g., Darcy-Weisbach equation) depend on rheological parameters (e.g., viscosity, yield stress) to calculate the pressure drop. Accurate rheological characterization is vital for designing the optimal drilling fluid system and predicting hydraulic performance.

Q 11. How do you troubleshoot high-pressure/high-temperature (HPHT) drilling fluid rheological issues?

Troubleshooting HPHT rheological issues requires a systematic approach. High temperatures can severely degrade the performance of many drilling fluid additives, leading to thickening, gelation, or fluid loss. The first step is to identify the specific problem: excessive viscosity, gelation, or inadequate fluid loss control. Then, we analyze the rheological data and mud chemistry to determine the root cause.

For example, if the fluid is thickening excessively, it might be due to thermal degradation of polymers. We might need to switch to more thermally stable polymers or incorporate thermal stabilizers. Similarly, if we encounter gelation, we might need to adjust the concentration of deflocculants or use different types of clay. We might also consider using high-temperature mud systems (e.g., oil-based muds, synthetic-based muds).

A methodical approach involving laboratory tests, mud logging data, and analysis of wellbore conditions is crucial for identifying the underlying cause and implementing an effective solution. Careful selection of high-temperature-tolerant additives and optimized fluid formulations are essential to manage HPHT challenges.

Q 12. Describe the methods for controlling and managing drilling fluid rheology in different drilling conditions.

Controlling and managing drilling fluid rheology involves adapting the fluid system to different drilling conditions. This requires real-time monitoring and adjustments based on the geological formation, depth, and operational goals.

In soft formations, a lower-viscosity fluid might be preferred to minimize friction and pump pressure. However, in harder formations, higher viscosity might be needed to carry heavier cuttings. Similarly, highly deviated or horizontal wells require fluids with good shear thinning properties to minimize frictional losses. We might utilize different additives or adjust their concentrations to achieve the desired properties, ensuring optimal cuttings transport and maintaining wellbore stability.

Regular rheological measurements during drilling are essential to track the fluid’s performance and make timely adjustments. Furthermore, regular quality control checks of the mud system and proactive treatment based on anticipated conditions are crucial for maintaining optimum drilling fluid rheology across different drilling phases.

Q 13. What is the significance of the power law model in describing drilling fluid rheology?

The power law model is a non-Newtonian fluid model frequently used to describe the rheological behavior of drilling fluids, particularly those exhibiting shear-thinning behavior. Unlike Newtonian fluids (like water), whose viscosity remains constant, the apparent viscosity of shear-thinning fluids (like many drilling muds) decreases with increasing shear rate.

The power law model mathematically expresses this relationship as: τ = K * γn, where:

τis the shear stressγis the shear rateKis the consistency index (related to viscosity)nis the flow behavior index (0 < n < 1 for shear-thinning)

The power law model provides a simple yet effective way to represent the relationship between shear stress and shear rate for many drilling fluids. It’s helpful for designing drilling operations because it allows us to predict the pressure drop in the drillstring and annulus at various flow rates. The parameters K and n can be obtained by fitting experimental rheological data to the power law equation.

Q 14. How does the rheology of drilling fluids affect cuttings transport?

The rheology of drilling fluids significantly affects cuttings transport. The fluid’s ability to lift and carry drill cuttings to the surface is directly related to its viscosity, yield point, and shear thinning properties.

A fluid with sufficient viscosity and yield point can suspend cuttings effectively, preventing them from settling and potentially causing problems such as pipe sticking or differential sticking. Shear-thinning behavior allows the fluid to become less viscous at higher shear rates (e.g., near the pump), enhancing flow efficiency and minimizing energy consumption. Conversely, a fluid that’s too thin may not effectively lift the cuttings, resulting in poor hole cleaning, increased risk of pipe damage, and reduced drilling efficiency.

For optimal cuttings transport, the drilling fluid needs to have a balance of viscosity and shear-thinning behavior: high enough viscosity to suspend cuttings but low enough to minimize pump pressure. Therefore, careful rheological design and control are crucial for efficient hole cleaning and drilling operations.

Q 15. Explain the impact of solids content on drilling fluid rheology.

Solids content significantly impacts drilling fluid rheology, influencing its viscosity, yield point, and gel strength. Imagine trying to stir honey (low solids) versus peanut butter (high solids). Peanut butter is much more resistant to flow due to the higher concentration of solid particles.

Increased solids content generally leads to higher viscosity and yield point. This is because the solid particles create friction and interparticle forces, resisting flow. The type of solids also matters; clay particles, for example, can hydrate and significantly increase viscosity more than inert solids like barite. Too many solids can lead to problems like pump pressure increases, reduced rate of penetration (ROP), and difficulties in cuttings transport. Conversely, insufficient solids can result in poor wellbore stability and inadequate filter cake formation.

For instance, in a shale formation, a high solids content might be necessary to provide sufficient wall-building properties, preventing shale swelling and wellbore collapse. However, in a highly permeable sandstone, excessive solids could cause formation damage, reducing permeability and hindering hydrocarbon production. Careful control of solids content is crucial for optimal drilling performance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the role of rheology in preventing wellbore instability.

Rheology plays a critical role in preventing wellbore instability by creating a fluid system capable of providing sufficient pressure against the formation and preventing fluid invasion into the wellbore. Think of it as a protective barrier.

Properly designed drilling fluids with appropriate rheological properties exert a pressure on the wellbore walls that counteracts the formation pore pressure. This prevents the formation from collapsing (in formations with low pore pressure) or fracturing (in formations with high pore pressure). The fluid’s viscosity and yield point are particularly important here; a higher yield point creates a more stable fluid that can better support the wellbore, preventing caving or sloughing.

For example, in a highly fractured shale formation, a fluid with a high viscosity and yield point, potentially containing specialized shale inhibitors, is crucial to prevent shale swelling and wellbore instability. This is achieved by preventing fluid invasion that causes the shale to hydrate and swell, thereby creating instability.

Q 17. How do you optimize drilling fluid rheology for specific well conditions?

Optimizing drilling fluid rheology for specific well conditions involves a systematic approach considering formation type, pressure, temperature, and desired rate of penetration (ROP). It’s like tailoring a suit – one size doesn’t fit all.

- Formation Evaluation: Thoroughly analyze the geological formation to determine its mechanical properties, such as the strength and type of rock, potential for instability (shale swelling, etc.), and permeability.

- Pressure Management: Select a mud weight (density) that appropriately balances formation pressure to prevent wellbore collapse or fracturing (formation pressure tests are crucial).

- Temperature Considerations: Ensure the fluid maintains its desired rheological properties at the expected bottomhole temperature. Some additives degrade or lose effectiveness at higher temperatures.

- Rheological Modifier Adjustment: Adjust the concentrations of rheological modifiers (clays, polymers, weighting agents) to achieve the target viscosity, yield point, and gel strength while considering factors such as hole cleaning efficiency, cuttings transport, and minimizing formation damage. This typically involves laboratory testing and field adjustments.

- ROP Optimization: Balance the need for wellbore stability and sufficient pressure against the formation with the need for a sufficiently low viscosity to facilitate a high ROP.

For example, drilling through a highly pressured, unconsolidated sandstone may require a lower viscosity fluid with good hole cleaning capabilities to maintain a high ROP without causing formation fracture. Conversely, drilling through a weak, unstable shale may necessitate a high-viscosity, high-yield point fluid to prevent wellbore collapse.

Q 18. Explain the importance of rheological measurements in monitoring wellbore integrity.

Rheological measurements are vital for continuous monitoring of wellbore integrity. Regular monitoring allows for early detection of potential problems, preventing costly complications.

By continuously measuring parameters like viscosity, yield point, and gel strength, we can detect changes that may indicate wellbore instability. For example, a sudden increase in viscosity could signal that solids are accumulating or that the fluid is interacting with the formation in an unexpected way. This prompts an investigation into possible wellbore issues, such as shale swelling or a potential lost circulation zone. Similarly, a decrease in viscosity might indicate mud degradation or fluid loss.

The data obtained from these measurements provides early warning signals of potential problems and enables proactive adjustments to the drilling fluid system. This proactive approach minimizes risks and enhances the overall efficiency and safety of the drilling operation.

Q 19. What are the safety considerations associated with handling drilling fluids with specific rheological properties?

Handling drilling fluids with specific rheological properties involves several safety considerations. Some fluids contain hazardous materials, and their specific rheological properties can contribute to hazards.

- Toxicity: Some drilling fluid additives are toxic and require careful handling and disposal. Proper personal protective equipment (PPE), including gloves, respirators, and eye protection, is essential.

- High Viscosity/Yield Point: Fluids with very high viscosity or yield point can create significant pressure on equipment, posing risks to personnel and potentially causing equipment failure. Operators need to understand the pressure limitations of the system.

- High Density: High-density fluids (e.g., those with high barite content) require specialized handling to prevent injury during mixing and transfer. The weight of the fluid creates additional strain on equipment.

- Flammability/Reactivity: Some additives may be flammable or reactive, requiring appropriate safety measures during storage, handling, and disposal. Proper ventilation and precautions against ignition sources are critical.

- Environmental Impact: The environmental impact of drilling fluid disposal must be carefully considered. Regulations on disposal must be followed to protect soil and water resources. Rheological properties can influence how effectively the fluid is treated before disposal.

Q 20. How do changes in rheological properties affect the rate of penetration (ROP)?

Changes in rheological properties directly affect the rate of penetration (ROP). Imagine trying to dig a hole with thick mud versus water – water would make it much easier.

High viscosity and yield point increase the frictional resistance between the drill bit and the formation, reducing ROP. This is because the fluid hinders the bit’s ability to penetrate the rock efficiently. Excessive viscosity also inhibits the efficient removal of cuttings from the wellbore, further reducing ROP and potentially causing bit balling.

Conversely, a fluid with appropriately low viscosity facilitates efficient cuttings transport and allows for higher ROP. However, if the viscosity is too low, it might not provide adequate wellbore stability and may lead to instability issues. Therefore, optimizing rheological properties is crucial for maximizing ROP while maintaining wellbore stability.

Q 21. Describe the influence of rheology on the formation of filter cake.

The rheological properties of the drilling fluid significantly influence the formation of the filter cake. The filter cake is a layer of solids that forms on the wellbore wall as fluid filters into the formation, similar to how a coffee filter retains grounds.

High viscosity fluids tend to form thicker filter cakes because more solids are deposited near the borehole wall. This thickness affects the permeability and the integrity of the cake. A very thin cake provides minimal wellbore protection, while an excessively thick cake could lead to increased pressure drops and reduced ROP. The yield point also plays a crucial role; a higher yield point reduces fluid filtration into the formation and, therefore, reduces filter cake thickness.

The type of clay in the fluid also affects cake properties, with some clays generating stronger cakes. In formations with high permeability, we need a fluid that generates a relatively low-permeability filter cake to minimize fluid loss and formation damage. In low permeability formations, we may seek a thinner filter cake to avoid creating unnecessary friction.

Q 22. How do you use rheological data to predict and prevent problems in drilling operations?

Rheological data, specifically measurements of viscosity, yield point, and gel strength, are crucial for predicting and preventing drilling problems. Think of it like this: the drilling fluid is the ‘blood’ of the well; its properties directly impact the health and efficiency of the operation.

Predicting Problems: High viscosity can indicate potential problems with pump pressure and circulation, potentially leading to pump failures or stuck pipe. Low viscosity, on the other hand, might suggest inadequate carrying capacity for cuttings, leading to hole instability and potential wellbore collapse. Analyzing rheological data allows us to anticipate these issues before they become major problems.

Preventing Problems: By monitoring rheological parameters throughout the drilling process, we can adjust the mud properties proactively. For example, if the viscosity starts to increase significantly, we can add thinners to maintain optimal flow characteristics. Conversely, if the viscosity is too low, we can add weighting materials or polymers to enhance its carrying capacity and prevent cuttings bed formation. Regular rheological testing provides early warning signs, allowing for timely corrective actions and minimizing costly downtime.

Example: During a drilling operation, a sudden increase in pump pressure is observed. Analyzing the rheological data reveals a significant increase in viscosity. This indicates a potential problem with the mud’s properties, such as excessive clay swelling or contamination. Immediate action, such as adding a dispersant to reduce clay swelling or performing a mud clean-up, prevents a stuck pipe situation and ensures continued drilling efficiency.

Q 23. Explain the relationship between rheology and the efficiency of drilling fluid filtration.

The rheology of a drilling fluid is intrinsically linked to its filtration properties. Filtration refers to the loss of fluid into the permeable formations surrounding the wellbore. A fluid with high viscosity and a strong gel structure will exhibit lower filtration rates compared to a fluid with low viscosity.

High Viscosity and Gel Strength: These properties create a more resistant barrier against the fluid’s tendency to filter into the formation. The higher viscosity creates a thicker, more cohesive filter cake, reducing the amount of filtrate loss. The gel structure prevents the immediate flow of water from the mud. Think of it like a thick, strong gel acting as a seal.

Low Viscosity and Weak Gel: Fluids with low viscosity and weak gel structures will filter more readily, resulting in excessive filtrate loss. This leads to instability around the wellbore, potential formation damage, and loss of drilling fluid, increasing overall operational costs.

Practical Application: We use filtration tests, like the API filter press test, to quantitatively assess the filtration characteristics of the mud. By adjusting the rheological properties, we can control the filtration rate and maintain wellbore stability. For instance, adding filter cake enhancing agents to the drilling fluid can create a more effective filter cake, significantly reducing filtrate loss and improving the overall drilling efficiency.

Q 24. Discuss the various factors influencing the rheological behavior of water-based muds.

The rheological behavior of water-based muds is influenced by a complex interplay of various factors. Imagine a water-based mud as a complex soup with many ingredients, each affecting the overall consistency and flow.

- Clay Type and Concentration: Clays are the primary rheology modifiers in water-based muds. Different clays exhibit different rheological behaviors. Bentonite, for example, is known for its high viscosity and gel strength, while other clays might have lower impacts. The concentration of clay directly affects the viscosity and gel strength.

- pH: The pH of the mud significantly influences clay hydration and dispersion. An optimal pH range ensures proper clay dispersion, minimizing viscosity and preventing gelation.

- Temperature: Temperature affects the viscosity of water and the hydration of clay particles. Higher temperatures generally lead to lower viscosity, while lower temperatures can increase it.

- Salinity: The presence of salts in the mud influences clay hydration and flocculation. High salinity can cause clay particles to flocculate, increasing the viscosity and gel strength.

- Polymer Additives: Polymers are frequently added to control rheology, improve filtration, and enhance other mud properties. Different polymers provide different rheological effects, allowing for fine-tuning of the mud’s properties.

- Contaminants: The introduction of contaminants like calcium or magnesium ions can significantly change the rheological behavior of the mud, often leading to increased viscosity and gel strength.

Careful control and monitoring of these factors are essential for maintaining the optimal rheological properties of the water-based mud and for successful drilling operations.

Q 25. How do you assess the effectiveness of a drilling fluid treatment based on rheological data?

Assessing the effectiveness of a drilling fluid treatment involves comparing rheological data before and after the treatment. It’s like comparing before-and-after photos to see the results of a beauty treatment.

Step-by-step Approach:

- Baseline Data: Before implementing any treatment, collect comprehensive rheological data, including viscosity, yield point, gel strength, and plastic viscosity. This provides a benchmark against which to evaluate the treatment’s effectiveness.

- Treatment Implementation: Introduce the chosen treatment (e.g., adding a polymer, dispersant, or weighting material).

- Post-Treatment Data: After sufficient mixing and equilibration time, collect rheological data again. Compare this data with the baseline measurements.

- Data Analysis: Analyze the changes in rheological properties. For example, if the treatment aims to reduce viscosity, a significant decrease in viscosity values after the treatment indicates its effectiveness. A lack of significant change may suggest the treatment wasn’t effective or that the wrong treatment was used.

- Interpretation: Interpret the changes in the context of the wellbore conditions and drilling requirements. The desired rheological profile may vary depending on the geological formation and other wellbore parameters.

Example: A drilling fluid exhibits high viscosity, hindering drilling efficiency. A dispersant is added to break down clay aggregates and reduce viscosity. Post-treatment rheological data shows a significant decrease in viscosity to the desired range. This confirms the treatment’s effectiveness in optimizing the drilling fluid for improved operational efficiency.

Q 26. Explain the concept of apparent viscosity and its implications in drilling operations.

Apparent viscosity is a measure of the resistance of a fluid to flow under a given shear rate. It’s not a constant property but varies with the shear rate. Think of it like squeezing toothpaste from a tube: the resistance is higher when you squeeze slowly (low shear rate) compared to when you squeeze hard (high shear rate).

Implications in Drilling:

- Pumping Pressure: High apparent viscosity at low shear rates (near the wellbore) indicates higher pump pressure requirements, impacting operational efficiency and potentially causing pump failure.

- Cuttings Transport: High apparent viscosity at higher shear rates (in the annulus) ensures effective cuttings transport to the surface, preventing build-up in the wellbore.

- Hole Cleaning: The balance between low apparent viscosity at low shear rates to minimize pump pressure, and high apparent viscosity at high shear rates for good cuttings transport, is crucial for efficient hole cleaning.

- Formation Damage: Excessive filtration due to low apparent viscosity can lead to formation damage, affecting reservoir productivity.

Practical Application: Rheometers measure the apparent viscosity at various shear rates, allowing us to characterize the fluid’s behavior under different flow conditions. This information is critical for selecting appropriate mud types, optimizing pumping parameters, and predicting potential drilling problems. Apparent viscosity data assists in creating a comprehensive picture of the drilling fluid’s suitability for specific drilling environments.

Q 27. What are some common challenges faced in managing drilling fluid rheology in deviated wells?

Managing drilling fluid rheology in deviated wells presents unique challenges. In deviated wells, the drilling fluid must effectively transport cuttings upward against gravity and potentially around tight curves. This adds complexity to rheological control. Think of it as navigating a complex maze with a viscous fluid.

Challenges:

- Increased Pressure Drop: The longer and more tortuous flow path in a deviated well can lead to significantly increased pressure drops, requiring higher pump pressures and potentially exceeding equipment limitations.

- Cuttings Bed Formation: Cuttings can settle out more easily in low-velocity sections of the wellbore, particularly in inclined sections and along curves. This leads to potential hole instability and stuck pipe incidents.

- Enhanced Gel Strength Requirements: Higher gel strength might be required to suspend cuttings effectively throughout the wellbore, but excessively high gel strength could lead to pump pressure problems.

- Difficulties in Maintaining Homogeneity: It becomes challenging to maintain the homogeneity of the drilling fluid throughout the wellbore due to variations in flow patterns.

Mitigation Strategies:

- Optimized Mud Design: Careful selection of mud rheology modifiers and additives can help mitigate these challenges. For instance, specialized polymers and weighting materials can be used to enhance cuttings transport and minimize settling.

- Improved Circulation Procedures: Implementing optimized circulation programs and techniques can help prevent cuttings bed formation and promote effective cuttings transport.

- Advanced Rheological Modeling: Using advanced computational fluid dynamics (CFD) simulations and rheological models can assist in predicting flow patterns and optimizing drilling fluid properties for specific wellbore trajectories.

Q 28. Describe the impact of different drilling fluid rheological properties on environmental concerns.

The rheological properties of drilling fluids have significant implications for environmental concerns. The discharge of drilling fluids into the environment must be carefully managed to minimize potential impacts on water resources and ecosystems.

Environmental Impacts:

- Filtrate Loss: Excessive filtrate loss can contaminate groundwater resources, potentially affecting water quality and impacting local ecosystems. High viscosity and effective filter cake can mitigate this risk.

- Mud Disposal: The disposal of spent drilling fluids poses significant environmental challenges. The volume and the properties of the discarded mud must be carefully considered to ensure safe and environmentally sound disposal practices.

- Toxicity: Certain additives in drilling fluids can be toxic to aquatic life, so choosing environmentally friendly additives is crucial. Minimizing the use of harmful chemicals is a key goal.

- Soil Contamination: Spills or improper handling of drilling fluids can contaminate soil, affecting soil quality and potentially impacting plant life. Best practices for handling and storing fluids are critical.

Mitigation Strategies:

- Minimizing Filtrate Loss: Employing drilling fluids with optimized rheological properties that minimize filtrate loss is crucial for protecting groundwater resources.

- Sustainable Mud Systems: Using environmentally benign mud systems, such as water-based muds with biodegradable additives, is a step towards minimizing environmental impact.

- Wastewater Treatment: Implementing effective wastewater treatment processes before discharge can reduce the concentration of pollutants in drilling waste.

- Responsible Disposal: Strict adherence to regulations and best practices for the disposal of drilling fluids is essential for reducing environmental risks.

Key Topics to Learn for Drilling Fluids Rheology Interview

- Fluid Rheology Fundamentals: Understanding viscosity, yield point, gel strength, and their measurement techniques (e.g., rheometer principles).

- Rheological Models: Applying the Bingham plastic, power-law, and Herschel-Bulkley models to describe drilling fluid behavior and predict performance.

- Practical Applications: Connecting rheological properties to drilling operations, such as hole cleaning, cuttings transport, and wellbore stability. Analyze how different rheological parameters influence these processes.

- Influence of Fluid Additives: Discuss the impact of various additives (e.g., clays, polymers, weighting agents) on rheological properties and their optimization for specific drilling conditions.

- Temperature and Pressure Effects: Understanding how changes in temperature and pressure affect the rheological behavior of drilling fluids and the implications for downhole performance.

- Rheological Testing and Interpretation: Familiarize yourself with standard rheological tests (e.g., API, ISO) and be able to interpret the results, including identifying potential issues and suggesting solutions.

- Problem-Solving Approaches: Develop your ability to troubleshoot rheological problems encountered during drilling operations and propose effective solutions based on sound theoretical understanding.

- Advanced Rheological Concepts (Optional): Explore thixotropy, viscoelasticity, and their relevance to drilling fluid behavior. This demonstrates a deeper understanding and proactive learning.

Next Steps

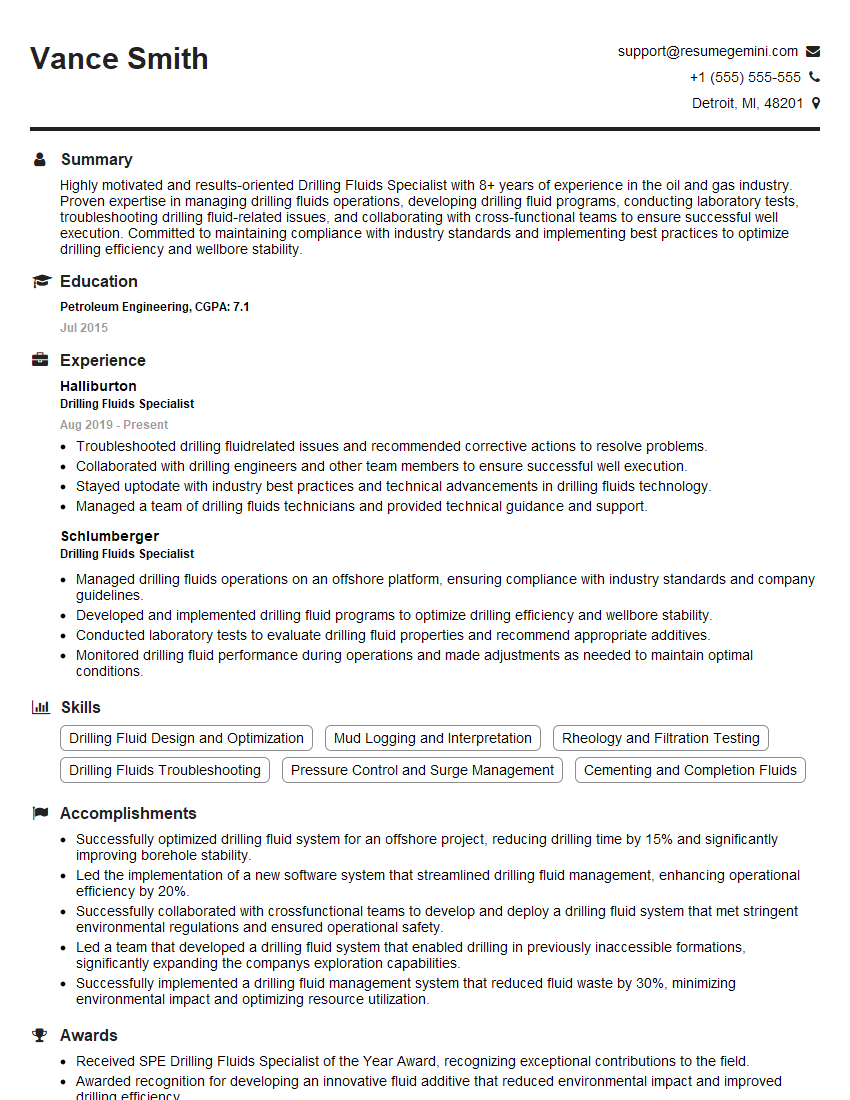

Mastering Drilling Fluids Rheology is crucial for career advancement in the oil and gas industry, opening doors to specialized roles and higher earning potential. A strong understanding of these concepts demonstrates technical expertise and problem-solving capabilities highly valued by employers. To maximize your job prospects, invest time in creating an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the energy sector. Examples of resumes specifically tailored to Drilling Fluids Rheology expertise are available to guide you. Take advantage of these resources to present yourself as the ideal candidate.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO