Unlock your full potential by mastering the most common Commercial Vehicle Safety Alliance (CVSA) Brake Inspection Certification interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Commercial Vehicle Safety Alliance (CVSA) Brake Inspection Certification Interview

Q 1. Describe the components of an air brake system.

A commercial vehicle’s air brake system is a complex network of components working together to safely stop the vehicle. Think of it like a sophisticated plumbing system, but instead of water, it uses compressed air to apply the brakes. Key components include:

- Air Compressor: This is the heart of the system, compressing atmospheric air to build pressure.

- Air Tanks (Reservoirs): These store the compressed air, providing a reserve for braking even if the compressor temporarily fails.

- Air Lines and Hoses: These carry the compressed air throughout the system to various components.

- Pressure Gauge: This indicates the amount of compressed air pressure available in the system – crucial for safe operation.

- Control Valves: These regulate the flow of compressed air to the brake chambers.

- Brake Chambers: These convert the compressed air pressure into mechanical force to actuate the brakes.

- S-Cams and Push Rods: These translate the movement from the brake chambers to the brake shoes or calipers.

- Brake Shoes/Pads and Drums/Discs: These are the friction components that create braking force.

- Parking Brake System: This is usually a spring-applied, air-released system that ensures the vehicle remains stationary when parked.

- Air Dryer: Removes moisture from the compressed air to prevent freezing and corrosion.

- Safety Valves and Relays: Prevent over-pressurization and ensure fail-safe operation.

Understanding each component’s function is crucial for effective brake inspection.

Q 2. Explain the procedure for conducting a Level I, II, and III brake inspection.

CVSA brake inspections are categorized into three levels, each progressively more in-depth:

Level I: Walk-Around Inspection: This is a quick visual check, primarily looking for obvious issues like leaks, damage to air lines, and loose components. It’s analogous to a quick visual check of your car’s tires before a trip. You’re looking for anything glaringly wrong. It doesn’t involve getting under the vehicle.

Level II: Detailed Inspection: This goes deeper, requiring more hands-on examination. This level includes checking air pressure, inspecting brake linings and drums, testing the parking brake, and verifying proper function of air system components (air compressor, tanks, valves, etc.). You will need to get under the vehicle.

Level III: Full Inspection: This is a thorough, comprehensive check of the entire braking system, including detailed examination of all components identified in Level II, with a focus on identifying potential failures or weaknesses which could lead to brake failure. This will involve disassembling and/or testing individual components.

The specific steps for each level are detailed in the CVSA Brake System Inspection Manual. This manual contains detailed instructions and illustrations for each step, and should always be consulted before conducting any inspection.

Q 3. What are the key indicators of brake system leaks?

Brake system leaks are serious safety hazards. Key indicators include:

- Low air pressure: The air pressure gauge will show a gradual or sudden drop in pressure.

- Air leaks around components: You’ll hear a hissing sound or see air escaping from joints, valves, or lines.

- Wet spots under the vehicle: If the leak involves moisture from the air dryer, you might notice wet spots.

- Reduced braking effectiveness: A softer brake pedal or reduced stopping power indicates a possible leak.

- Visible cracks or damage: Inspect air lines and hoses for cracks, chafing, or other damage that may lead to leakage.

Imagine a punctured tire – the air pressure drops, and the tire loses its ability to support the weight of the vehicle. Similarly, leaks in the air brake system reduce braking effectiveness and jeopardize safety.

Q 4. How do you inspect brake linings and drums for wear?

Inspecting brake linings and drums for wear involves a careful visual examination and sometimes measurement. For linings, look for:

- Thickness: Linings should meet minimum thickness requirements as specified by the manufacturer. Use a brake lining thickness gauge for accurate measurement.

- Cracks or glazing: Cracks indicate weakening, and glazed linings have lost their friction material.

- Uneven wear: Significant uneven wear suggests potential problems with brake adjustment, wheel bearings, or other components.

For brake drums, check for:

- Grooving or scoring: Deep grooves or scores reduce braking effectiveness and can damage brake linings.

- Cracks or scoring: These indicate potential drum failure.

- Excessive wear: Overly thin drums should be replaced.

Always refer to the manufacturer’s specifications for acceptable wear limits. Think of it like checking tire tread depth – you wouldn’t drive on tires with dangerously low tread, and similarly, worn-out brake components pose a risk.

Q 5. Explain the function of an anti-lock braking system (ABS).

An Anti-lock Braking System (ABS) prevents wheel lockup during braking, allowing the driver to maintain steering control. Imagine driving on ice: if your wheels lock, you lose steering control and skid uncontrollably. ABS prevents this by rapidly pumping the brakes, keeping the wheels rotating and maintaining traction. This allows the driver to steer around obstacles while braking.

ABS uses sensors to monitor wheel speed. If a wheel starts to lock up, the ABS system reduces brake pressure to that specific wheel, allowing it to regain rotation. This process happens very quickly, often unnoticed by the driver except for a pulsating brake pedal.

Q 6. How do you test an ABS system?

Testing an ABS system requires specialized equipment. A simple visual inspection can check for obvious signs of damage to wiring, sensors, or the ABS module itself. However, a complete functional test involves using an ABS diagnostic tool to:

- Retrieve diagnostic trouble codes (DTCs): These codes identify any malfunctions within the system.

- Monitor sensor data: Check if the wheel speed sensors are functioning correctly and reporting data.

- Conduct an active test: The tool can initiate an ABS activation test, simulating a lockup condition to verify proper system operation.

It’s important to note that incorrectly performing an ABS test can potentially damage the system. This work is typically performed using professional-grade tools and requires specialized training.

Q 7. What are the common causes of brake fade?

Brake fade, the reduction in braking effectiveness due to overheating, can be caused by several factors:

- Overuse of brakes during prolonged downhill driving: Continuously applying the brakes generates significant heat, leading to brake fade.

- Inadequate brake cooling: Insufficient airflow around brake components prevents heat dissipation.

- Worn or contaminated brake linings: Worn linings have less friction material, and contaminants reduce their effectiveness, increasing heat generation.

- Brake fluid boiling: Extreme heat can cause the brake fluid to boil, creating vapor bubbles that reduce braking force.

- Improper brake adjustment: Poorly adjusted brakes may cause unequal distribution of braking force across the wheels, leading to overheating of specific components.

Think of it like rubbing your hands together – the more you rub, the hotter they get. Similarly, continuous brake use generates heat that can reduce braking performance. Preventing brake fade requires proper brake maintenance, downhill driving techniques, and attention to system cooling.

Q 8. How do you inspect slack adjusters for proper adjustment?

Inspecting slack adjusters is crucial for brake safety. They control the amount of travel in the brake pushrod, ensuring the brakes engage correctly. Improper adjustment leads to inefficient braking or brake drag. To inspect them, you need to:

- Visually inspect for damage: Look for cracks, corrosion, or missing parts. Think of them as the ‘fine-tuners’ of your brake system – any damage compromises their function.

- Measure the pushrod travel: Use a ruler or specialized tool to measure the amount the pushrod moves when the brakes are released. This measurement should fall within the manufacturer’s specifications, often found in the vehicle’s maintenance manual. For example, if the manual states a range of 1-2 inches, it should be within that range.

- Check for proper adjustment: With the brakes released, the slack adjuster should have a small amount of play (slack). If the brakes are dragging, the slack adjuster is too tight. If they are not engaging effectively, it’s too loose. This is like the ‘sweet spot’ on a guitar – find the right tension for optimum performance.

- Listen for unusual sounds: While adjusting, pay attention to unusual noises like grinding, squealing, or clicking. These sounds indicate potential issues requiring further investigation. It’s like listening to your car’s engine; certain sounds can tell you if everything is okay.

Always refer to the vehicle manufacturer’s specifications for exact adjustment procedures and limits. Failure to properly adjust slack adjusters can lead to brake failure, causing accidents and potentially serious injury.

Q 9. What are the requirements for brake system documentation?

Brake system documentation is vital for safety and compliance. It proves you’re following regulations and maintaining your vehicle’s braking system. Documentation requirements vary by jurisdiction but generally include:

- Repair records: Detailed records of all brake repairs, including the date, type of repair, parts replaced, and the technician’s signature. Think of this as a medical history for your brakes.

- Inspection reports: Regular reports detailing the results of brake inspections, noting any defects or issues found. These act as a snapshot of the brake system’s health.

- Driver’s vehicle inspection reports (DVIRs): Drivers should complete daily inspections and document any brake system issues, which are then reviewed by management. This ensures everyone is aware of the brake system’s condition.

- Proof of maintenance: Documentation showing regular maintenance, such as air compressor oil changes and filter replacements. This is like a service record for your car, showing that regular maintenance is carried out.

Accurate and thorough documentation helps prevent accidents and ensures compliance with regulations. It’s crucial for audits and investigations in case of accidents or malfunctions.

Q 10. Describe the procedure for inspecting air compressor components.

Inspecting air compressor components is essential for a functioning air brake system. The air compressor provides the air pressure needed for braking. Here’s a step-by-step procedure:

- Check the air compressor’s oil level: Low oil levels can damage the compressor. Ensure it’s within the manufacturer’s specified range. Similar to how you’d check your car’s engine oil.

- Inspect the air compressor’s belts: Check for wear, damage, or slippage. Worn or damaged belts can lead to compressor failure. If the belts are damaged, replace them promptly.

- Examine the air compressor’s intake filter: A clogged filter restricts airflow and reduces the compressor’s efficiency. It needs to be replaced regularly.

- Check the governor: The governor regulates the air compressor’s output. If malfunctioning, it can cause problems with air pressure. Check that it functions within the specified parameters.

- Listen for unusual noises: Unusual sounds such as knocking, squealing, or excessive noise during operation often indicate a problem. Similar to how you might recognize if a car engine makes an unusual sound.

- Check the pressure switch: The pressure switch controls the compressor’s on/off cycle. It should cut the compressor off once the tank reaches a preset pressure and turn it back on when the pressure drops. A faulty pressure switch will likely indicate itself via irregular pressure readings.

Regular inspection and maintenance of the air compressor are crucial for preventing brake system failures. Neglecting maintenance can lead to serious consequences.

Q 11. Explain the difference between a parking brake and a service brake.

Service brakes and parking brakes serve distinct purposes:

- Service brakes: Used for slowing down and stopping the vehicle while driving. They’re the brakes you use regularly while operating your vehicle.

- Parking brakes: Used to hold the vehicle stationary when parked. They’re used after the vehicle has already come to a complete stop.

Think of it this way: service brakes are for active stopping, while parking brakes are for passive holding. Both are critical for safe vehicle operation, and proper function of both is necessary for CVSA compliance.

Q 12. How do you check the air pressure in the brake system?

Checking air pressure in a brake system involves using an air pressure gauge. Here’s how to do it:

- Locate the pressure gauge: Most vehicles have a gauge mounted on the dashboard displaying the air pressure in the system’s air tanks. It is usually displayed in PSI (pounds per square inch).

- Note the pressure reading: The gauge shows the current air pressure in the system. This pressure should be within the specified range for the specific vehicle and generally above a specified minimum pressure for safe operation.

- Compare to manufacturer’s specifications: Refer to the vehicle’s specifications to see what the appropriate operating pressure should be. If the pressure is too low, investigate the cause of the leak or pressure loss.

- If using an external gauge: If necessary, connect an external pressure gauge to the system’s test port to verify pressure readings.

Low air pressure indicates a leak or problem within the brake system requiring immediate attention. Never operate a vehicle with insufficient air pressure in the brake system.

Q 13. What are the regulations regarding brake system maintenance?

Regulations regarding brake system maintenance vary depending on jurisdiction and vehicle type but generally involve:

- Regular inspections: Frequent and thorough visual inspections of all brake components.

- Preventative maintenance: Scheduled maintenance tasks such as air filter replacements, oil changes, and leak repairs to prevent larger issues.

- Repairing defects promptly: Any identified defects or malfunctions must be addressed immediately. This ensures the vehicle stays safe to operate.

- Record keeping: Maintaining detailed records of all inspections and repairs performed, as previously mentioned.

- Compliance with relevant standards: Adherence to the standards set by the FMCSA and other applicable agencies.

Neglecting brake system maintenance not only jeopardizes safety but also carries significant legal penalties. Think of it as preventative care – regularly maintaining your braking system avoids costly repairs and potential accidents.

Q 14. How do you interpret brake system diagnostic trouble codes?

Interpreting brake system diagnostic trouble codes (DTCs) requires understanding the vehicle’s electronic control system. DTCs are stored in the vehicle’s computer and provide clues about malfunctions. The process involves:

- Retrieving DTCs: Using a diagnostic tool or scanner to access and read the stored DTCs from the vehicle’s computer. There are many commercial and even open-source options for this.

- Consulting a diagnostic chart: Using a manufacturer-specific diagnostic chart or manual to understand the meaning of each DTC. This is essential as DTCs can vary from manufacturer to manufacturer.

- Troubleshooting based on DTC: Once the meaning of the DTC is understood, you can use that information to troubleshoot and pinpoint the source of the problem. This often involves visual checks of the implicated system components.

- Repairing the identified issue: After identifying the problem, repair the faulty component and clear the DTC using the scanner. A simple repair such as replacing a sensor or tightening a connection might resolve the error.

Properly interpreting DTCs enables efficient diagnosis and repair of brake system issues, preventing costly downtime and ensuring vehicle safety.

Q 15. What are the safety precautions when inspecting brakes?

Safety is paramount during brake inspections. Before you even begin, ensure the vehicle is parked on a level, stable surface, and the engine is turned off. Always engage the parking brake. Wear appropriate safety gear, including gloves and safety glasses, to protect yourself from potential hazards like sharp edges or brake fluid. Never work under a vehicle supported only by a jack; use jack stands for added safety. Be aware of your surroundings and avoid distractions. If you encounter any leaks or suspect a component failure, take extra precautions and potentially flag the vehicle out of service until it’s repaired. Think of it like this: your safety is the foundation upon which a thorough and accurate inspection is built.

- Secure the Vehicle: Always use wheel chocks in addition to the parking brake.

- Personal Protective Equipment (PPE): Gloves protect your hands from brake fluid and grease, while safety glasses shield your eyes from debris.

- Proper Lifting and Support: Never work under a vehicle solely supported by a jack.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the use of a brake adjustment tool.

A brake adjustment tool is used to fine-tune the clearance between the brake shoes or pads and the drum or rotor. This ensures optimal braking performance and prevents premature wear. Different tools exist for various brake systems; some are simple hand tools, while others are more specialized. The goal is to achieve a specified clearance, typically measured in thousandths of an inch, ensuring the brakes engage effectively without dragging. Incorrect adjustment can lead to reduced braking efficiency, squealing brakes, or even brake failure. Think of it as precisely setting the distance between the drummer and the sticks – too close and they’ll clash, too far and they won’t produce sound. For example, an automatic slack adjuster automatically adjusts brake shoe clearance, eliminating the need for manual adjustment.

Using the tool involves following the manufacturer’s instructions precisely. This often involves turning a wheel to visually check for the appropriate clearances and making minor adjustments until the specification is met.

Q 17. What are the signs of a faulty brake chamber?

A faulty brake chamber can manifest in several ways. Leaks are a common sign, either around the diaphragm or the push rod. You might see fluid seeping out, or notice a significant reduction in brake pressure. The chamber might also be physically damaged, showing cracks, dents, or rust. In some cases, the diaphragm itself might be torn or worn, leading to inconsistent braking. A stuck-in-place push rod could prevent the brake from releasing completely, causing a dragging brake. You may also notice that the air pressure in the chamber doesn’t hold correctly. If you imagine the brake chamber as a balloon, a leak is like a small hole letting the air escape, affecting its inflation and ability to function.

Q 18. How do you check for brake fluid leaks?

Checking for brake fluid leaks involves a thorough visual inspection of all components within the braking system. Focus on the brake lines, hoses, wheel cylinders, calipers, and master cylinder. Look for any signs of fluid dripping, staining, or discoloration on these components. Brake fluid will usually have a very distinct wet appearance. A leak might be slow and subtle, leaving only a small residue. Use clean rags or paper towels to gently wipe down suspect areas; the presence of brake fluid will be easily observable. Pay special attention to the areas where the components connect – leaking often occurs at joints or seals.

Q 19. Describe the procedure for bleeding brakes.

Bleeding brakes is the process of removing air from the brake lines. Air in the lines compromises braking performance. The procedure typically involves opening a bleeder valve on each brake caliper or wheel cylinder while an assistant pumps the brake pedal or operates the brake system actuator. This allows air to escape as fluid is forced through the lines. A clear hose attached to the bleeder valve collects the escaping fluid. The process is repeated until the fluid runs clear, indicating that all air is purged from the line. It’s crucial to maintain the brake fluid reservoir level throughout the process. Different brake systems may require slightly different procedures, so always consult the manufacturer’s guidelines. Think of it as slowly forcing the air bubbles out of a water pipe with fluid.

- Prepare: Gather tools (bleeder wrench, hose, container), and have a helper.

- Position: Secure vehicle, engage parking brake, and add fresh fluid to the master cylinder reservoir.

- Open Bleeder: Crack open the bleeder valve on the most distant wheel first.

- Pump Brake: Have your helper gently pump the brakes several times.

- Close Bleeder: Close the bleeder valve and check for leaks, before repeating process at other brakes.

- Repeat: Continue until clear fluid flows from the bleeder.

Q 20. What are the different types of brake systems used in commercial vehicles?

Commercial vehicles use various brake systems, including:

- Hydraulic Brakes: These use brake fluid pressure to actuate the brakes. They are common in trailers and can be found on some tractors.

- Air Brakes: These are the most common type in heavy-duty trucks, using compressed air to activate brake chambers. They offer superior stopping power for heavier vehicles. Subtypes include S-cam brakes and air disc brakes.

- Anti-lock Braking Systems (ABS): These are electronic systems that prevent wheel lockup during braking, improving vehicle control.

- Electronic Braking Systems (EBS): These advanced systems control braking electronically, offering features like automatic slack adjusters and enhanced stability control.

- Exhaust Brakes (Jake Brakes): These use engine exhaust to create braking force, especially helpful in descending grades. They slow the vehicle with exhaust pressure which will improve fuel economy on long trips.

The choice of brake system depends on the vehicle’s size, weight, and intended application. For instance, a heavier vehicle might require air brakes for greater stopping power while smaller vehicles might utilize hydraulic brakes

Q 21. How do you inspect brake hoses and lines for damage?

Inspecting brake hoses and lines for damage requires a careful visual examination of their entire length. Look for any signs of chafing, cuts, kinks, bulges, or corrosion. Pay close attention to the areas where the hoses connect to the fittings, as these are common points of failure. Any cracks, leaks, or signs of weakness should immediately flag the component as needing repair or replacement. A damaged brake hose or line can lead to brake failure, resulting in dangerous situations. Remember, these are critical components ensuring the integrity of your braking system.

Using your hands, you can gently feel along the hose and line for any unusual swelling or softness which can indicate internal damage. Pay special attention to areas that may experience higher wear such as areas near the chassis or other components which can rub against them.

Q 22. What are the requirements for brake system repairs?

Brake system repairs must adhere to stringent standards to ensure roadworthiness and safety. This involves using only approved parts, following manufacturer specifications, and performing thorough testing after the repair. The specific requirements depend on the nature of the repair. For example, replacing brake shoes necessitates verifying proper adjustment and ensuring even wear across all shoes. Replacing brake lines demands careful bleeding to remove air from the system and checking for leaks. Always refer to the vehicle’s service manual for precise instructions and torque specifications. Improper repairs can lead to brake failure, putting lives at risk and resulting in hefty fines.

- Use OEM or equivalent parts: Using substandard parts compromises brake performance and safety.

- Follow manufacturer’s specifications: This includes torque settings, adjustment procedures, and bleeding techniques.

- Thorough testing post-repair: This involves road testing and visual inspection for leaks or other issues.

Q 23. Explain the importance of proper brake maintenance.

Proper brake maintenance is paramount for preventing accidents and ensuring the longevity of the braking system. Think of your brakes like the tires on your vehicle; regular maintenance prevents catastrophic failure. Neglecting maintenance leads to premature wear and tear, reduced braking efficiency, and ultimately, brake failure. A comprehensive maintenance schedule includes regular inspections of brake pads, rotors, calipers, lines, and fluid levels. It also includes promptly addressing any issues identified during inspections, such as replacing worn components or flushing the brake fluid.

- Regular Inspections: Visual checks for wear, leaks, and damage should be performed regularly.

- Fluid Changes: Brake fluid absorbs moisture over time, reducing its effectiveness and causing corrosion. Regular fluid flushes are essential.

- Component Replacements: Worn brake pads, rotors, and other components should be replaced promptly to maintain braking efficiency.

For instance, I once worked with a fleet that prioritized brake maintenance, resulting in fewer accidents and significant cost savings in the long run compared to a similar fleet that neglected maintenance.

Q 24. Describe the consequences of failing a brake inspection.

Failing a brake inspection has severe consequences, ranging from being placed out of service to facing significant fines. The severity depends on the nature and extent of the brake deficiencies. A minor violation might lead to a temporary out-of-service order until the issue is rectified, while a serious violation could result in a lengthy out-of-service period and substantial fines. Furthermore, repeated violations can lead to license suspension or revocation. This not only impacts the driver and the company but also endangers public safety. The consequences can extend beyond just fines; damage to reputation and insurance implications can significantly impact a trucking company’s bottom line.

- Out-of-Service Orders: Immediate removal from service until repairs are completed.

- Fines: Substantial financial penalties depending on the severity of the violation.

- License Suspension/Revocation: Repeated violations could lead to the loss of operating licenses.

- Insurance Implications: Increased premiums or policy cancellation.

Q 25. How do you document brake inspection findings?

Accurate documentation of brake inspection findings is crucial for maintaining compliance and providing a clear record of the vehicle’s condition. This usually involves completing a standardized inspection report that details all aspects of the inspection, including the date, time, vehicle identification number, inspector’s name, and a comprehensive list of findings. Any deficiencies identified should be meticulously documented, noting their severity and location. Photographs or videos of significant defects are often included to provide visual evidence. This documentation serves as a crucial record for regulatory compliance, insurance purposes, and potential legal proceedings.

- Standardized Inspection Report: A detailed form outlining all aspects of the inspection.

- Clear Documentation of Deficiencies: Specific details about the nature, location, and severity of any issues.

- Visual Evidence (Photos/Videos): Supporting documentation for major defects.

Q 26. What are the common violations found during brake inspections?

Common violations during brake inspections include issues like low brake fluid, leaking brake lines, worn brake pads or shoes, damaged brake drums or rotors, and inadequate brake adjustment. Air brake system violations are particularly prevalent, encompassing issues such as low air pressure, leaks in the air system, faulty air compressor, and malfunctioning air dryer. These violations often stem from inadequate maintenance, improper repairs, or a lack of regular inspections. Addressing these common violations proactively through regular maintenance significantly reduces the risk of failures and ensures safe operation. A proactive approach to maintenance often prevents these issues from escalating into serious safety hazards.

- Low Brake Fluid: Indicates potential leaks or system degradation.

- Leaking Brake Lines: Compromises braking efficiency and can cause complete failure.

- Worn Brake Pads/Shoes: Reduced braking performance and potential rotor/drum damage.

- Air Brake System Issues: Leaks, low pressure, faulty components – a major safety concern.

Q 27. How do you handle a situation where a vehicle fails a brake inspection?

When a vehicle fails a brake inspection, the immediate priority is to take the vehicle out of service and prevent it from operating until the necessary repairs are completed. The driver and the company should be notified of the findings and the required repairs. Depending on the severity, a temporary or permanent out-of-service order may be issued. A detailed report should be filed, documenting all deficiencies. The vehicle is permitted back on the road only after thorough repairs and a successful reinspection demonstrate that the identified issues have been properly addressed. Proper communication between the inspector, driver, and maintenance team is key to ensuring a swift and efficient resolution.

- Out-of-Service Order: Immediate removal from service.

- Detailed Report: Comprehensive documentation of all findings.

- Necessary Repairs: Addressing all identified deficiencies.

- Reinspection: Verification that repairs are satisfactory.

Q 28. How do you stay updated on the latest CVSA regulations?

Staying updated on the latest CVSA regulations is critical for maintaining compliance and ensuring safety. The CVSA regularly updates its standards and guidelines, so continuous learning is essential. I regularly review the CVSA website, subscribe to their newsletters and alerts, and actively participate in industry events and training sessions. Participating in CVSA-sponsored workshops and training programs offers valuable insights into regulatory changes and best practices. Keeping abreast of these changes is not just about compliance but also about enhancing safety and improving operational efficiency.

- CVSA Website: Regular review of the official website for updates and announcements.

- Newsletters and Alerts: Subscribing to receive timely updates on regulatory changes.

- Industry Events and Training: Participating in conferences and workshops to learn from experts.

Key Topics to Learn for Commercial Vehicle Safety Alliance (CVSA) Brake Inspection Certification Interview

- Brake System Components: Understand the function and inspection procedures for all major brake system components, including air compressors, air tanks, brake chambers, slack adjusters, and valves. Be prepared to discuss their interaction within the entire braking system.

- Air Brake System Diagnostics: Master troubleshooting techniques for common air brake system malfunctions. Practice diagnosing problems based on symptoms and using diagnostic tools effectively. This includes understanding leak-down tests and low-pressure situations.

- ABS (Anti-lock Braking System) Inspection: Know how to inspect and test ABS systems, including identifying malfunctions and understanding the importance of ABS functionality for safety.

- Brake Adjustment and Maintenance: Demonstrate understanding of proper brake adjustment procedures and routine maintenance tasks to ensure optimal brake performance and longevity. This includes identifying wear and tear.

- Safety Regulations and Compliance: Be thoroughly familiar with relevant CVSA regulations and standards pertaining to brake inspections and maintenance. Understand the consequences of non-compliance.

- Documentation and Reporting: Know how to accurately document inspection findings and report any deficiencies found during an inspection. Practice clear and concise reporting.

- Practical Application: Be ready to explain how your theoretical knowledge translates into real-world scenarios. For example, describe how you would handle a specific brake system failure or a challenging inspection situation.

- Problem-Solving: Prepare to articulate your problem-solving methodology when faced with complex brake system issues. Highlight your ability to systematically identify problems and implement effective solutions.

Next Steps

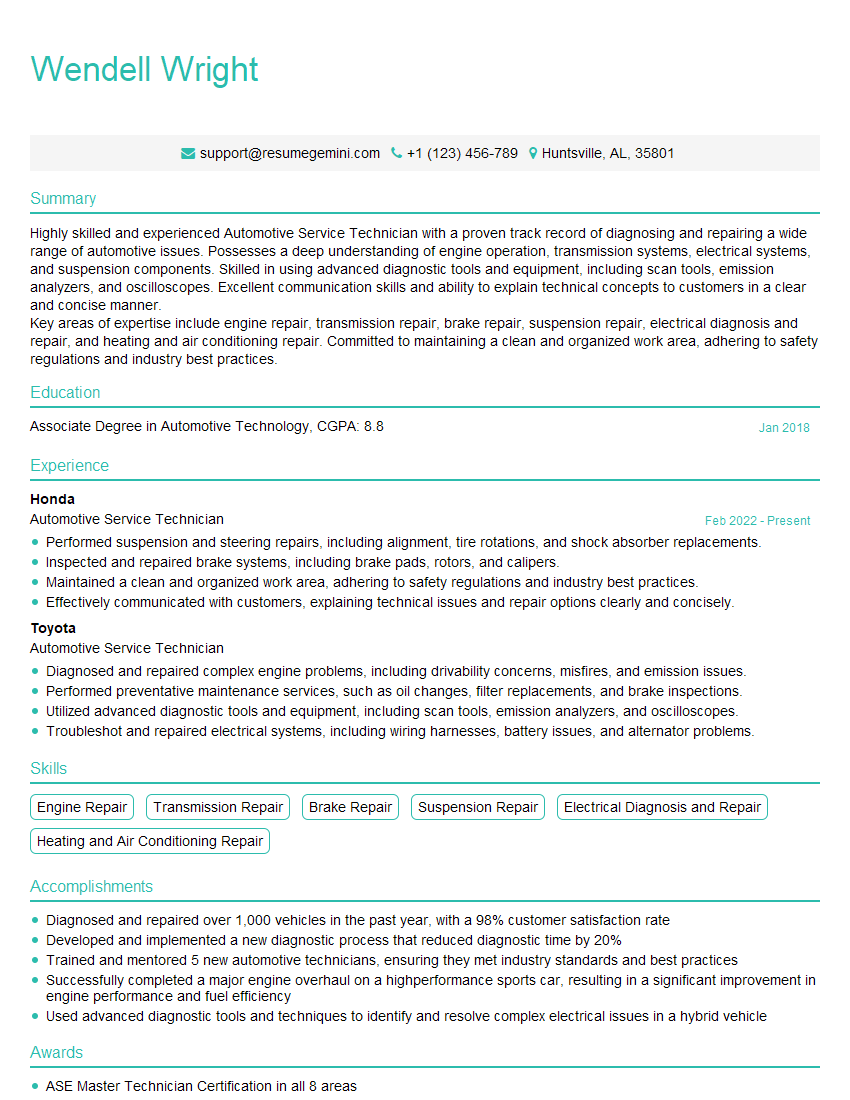

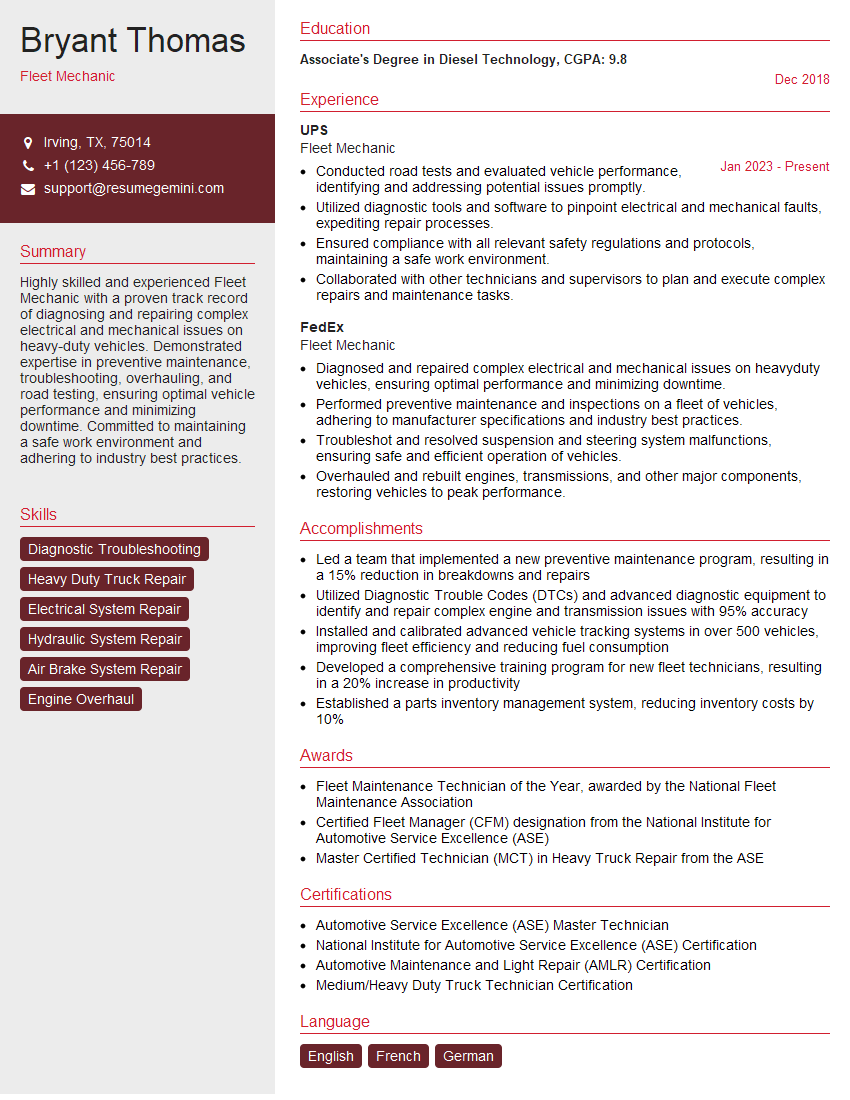

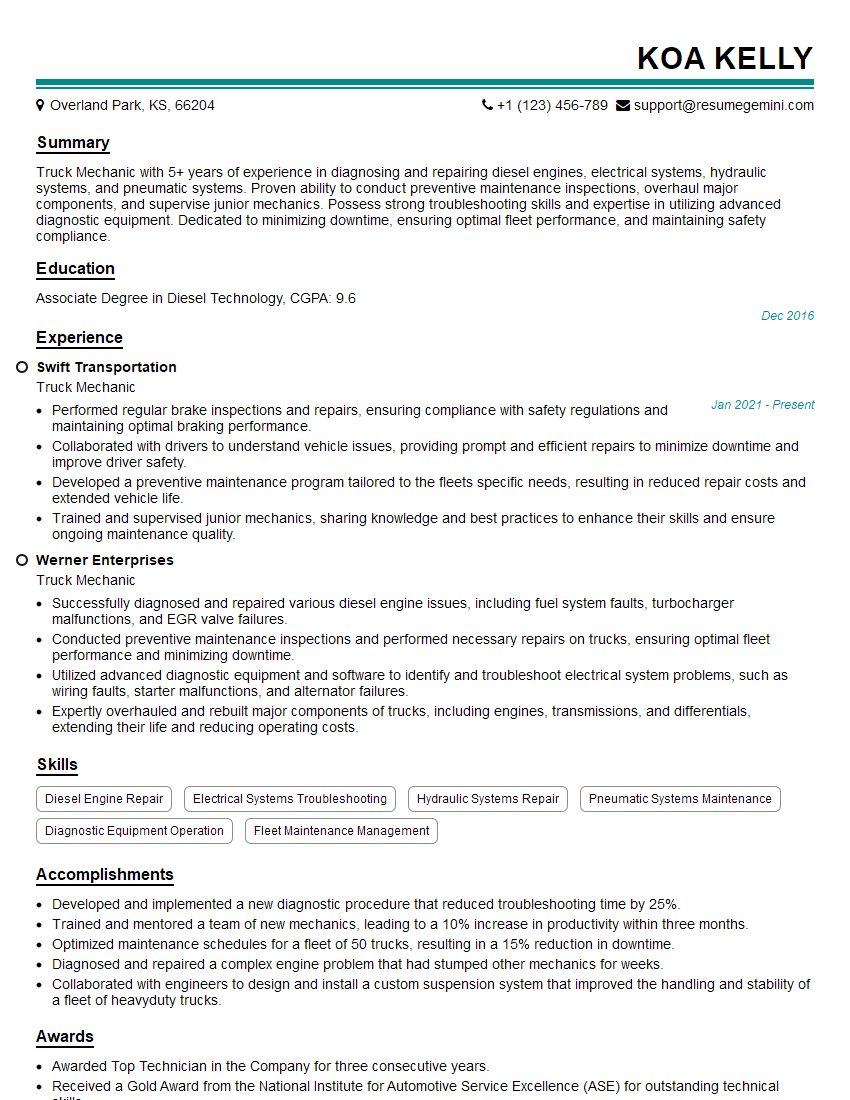

Mastering the Commercial Vehicle Safety Alliance (CVSA) Brake Inspection Certification significantly enhances your career prospects, opening doors to higher-paying roles and increased job security within the transportation industry. To maximize your chances of landing your dream job, crafting an ATS-friendly resume is crucial. ResumeGemini is a trusted resource to help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to the CVSA Brake Inspection Certification are provided to help guide you. Take the next step in your career journey – invest in your future with a powerful resume.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO