The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Understanding of Material Properties and Characteristics interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Understanding of Material Properties and Characteristics Interview

Q 1. Explain the difference between tensile strength and yield strength.

Tensile strength and yield strength are both crucial measures of a material’s resistance to deformation under tensile loading, but they represent different stages of the material’s response.

Tensile strength, also known as ultimate tensile strength (UTS), represents the maximum stress a material can withstand before it begins to fracture. Imagine pulling on a rubber band – the tensile strength is the point at which the rubber band snaps. It’s determined by the highest point on a stress-strain curve.

Yield strength, on the other hand, is the stress at which a material begins to deform permanently. This is the point where the material transitions from elastic deformation (where it returns to its original shape after the load is removed) to plastic deformation (permanent deformation). Think of bending a paperclip; once you exceed the yield strength, it stays bent. This is often marked by a noticeable deviation from linearity on the stress-strain curve.

The difference is key in engineering design. While tensile strength indicates the maximum load a component can endure before failure, yield strength is crucial for ensuring that a component doesn’t undergo unacceptable permanent deformation under service loads.

Example: A steel bridge must be designed to not only withstand the maximum anticipated load (related to tensile strength) but also avoid permanent deformation (related to yield strength) under normal traffic conditions.

Q 2. Describe the various types of material failure.

Material failure encompasses a variety of mechanisms by which a material ceases to function as intended under stress. These can be broadly categorized as:

- Ductile Failure: This involves significant plastic deformation before fracture. It’s often characterized by necking (reduction in cross-sectional area) prior to rupture. Think of pulling taffy – it stretches considerably before breaking. Many metals exhibit ductile failure.

- Brittle Failure: This occurs suddenly with little or no plastic deformation. Fracture surfaces are typically flat and perpendicular to the applied stress. Glass shattering is a classic example of brittle failure.

- Fatigue Failure: This results from repeated cyclical loading, even at stresses below the yield strength. Microscopic cracks initiate and propagate until the material fails. Think of a constantly bent paperclip eventually breaking.

- Creep Failure: This occurs under sustained high temperatures and stresses. The material slowly deforms over time, leading to eventual failure. This is a concern in high-temperature applications like power plant turbines.

- Corrosion Failure: This is caused by chemical or electrochemical reactions that degrade the material’s properties, leading to weakening and failure. Rusting of iron is a common example.

Understanding the type of failure is critical for selecting the appropriate material and designing against potential failure modes.

Q 3. What are the factors affecting the fatigue life of a material?

The fatigue life of a material – the number of cycles it can withstand before failure – is influenced by several factors:

- Stress amplitude: Higher stress amplitudes lead to shorter fatigue lives. A higher stress level means more damage per cycle.

- Mean stress: A higher mean stress (average stress over a cycle) reduces fatigue life. The material is already stressed, even before the cyclic loading begins.

- Frequency of loading: Higher frequencies can increase fatigue damage accumulation. More cycles in a given time mean more opportunities for damage.

- Material properties: Yield strength, tensile strength, and ductility significantly impact fatigue resistance. Stronger materials generally have higher fatigue resistance.

- Surface finish: Surface imperfections act as stress concentrators, initiating cracks and thus reducing fatigue life. A smooth surface is better than a rough one.

- Temperature: High temperatures can lower fatigue strength and accelerate crack growth.

- Environment: Corrosive environments can accelerate crack initiation and propagation, significantly reducing fatigue life.

Example: Aircraft components experience cyclic loading during flight. Understanding these factors is crucial for designing parts that can withstand millions of cycles without failure.

Q 4. How does temperature affect the mechanical properties of materials?

Temperature significantly impacts the mechanical properties of materials. Generally:

- Yield strength and tensile strength: These often decrease with increasing temperature. At higher temperatures, atoms have more energy and are more likely to move past each other, making plastic deformation easier.

- Ductility: This usually increases with increasing temperature, as higher temperatures facilitate atomic movement and deformation.

- Hardness: This typically decreases with increasing temperature, for similar reasons to the changes in strength.

- Elastic modulus: This may also decrease with temperature, indicating a reduction in material stiffness.

- Creep: The rate of creep increases significantly with rising temperatures.

Example: Consider a metal used in a jet engine. The high operating temperatures would necessitate using a material with exceptional high-temperature strength and creep resistance. Conversely, a material for cryogenic applications (very low temperatures) would need different properties tailored to its low-temperature environment.

Q 5. Explain the concept of creep in materials.

Creep is the time-dependent permanent deformation of a material under a constant load and elevated temperature. Imagine a plastic ruler bending slightly over a long time under its own weight at room temperature; this is a slow form of creep. However, creep becomes significantly more important at high temperatures. At these temperatures, atomic diffusion is enhanced which allows for the material to deform even under modest stresses.

Creep occurs in three stages:

- Primary Creep: The creep rate decreases with time. The material is initially strengthening under the stress but slowly yielding.

- Secondary Creep: The creep rate is relatively constant. This stage is often used in creep-testing to measure the materials creep characteristics.

- Tertiary Creep: The creep rate increases rapidly until failure. This is the stage when necking starts to occur, and the material begins to fracture.

Practical application: Creep is a critical consideration in the design of high-temperature components such as gas turbine blades and nuclear reactor components. Materials must be selected and designed to withstand creep deformation to ensure long-term structural integrity.

Q 6. Describe different methods for characterizing material microstructure.

Several techniques are used to characterize material microstructure, providing insights into the arrangement of grains, phases, and defects:

- Optical Microscopy: This involves polishing and etching a sample to reveal the microstructure, which is then observed under an optical microscope. It’s relatively simple and inexpensive, providing general information about grain size and phase distribution.

- Scanning Electron Microscopy (SEM): SEM uses a focused beam of electrons to scan the surface of a sample, providing high-resolution images with greater magnification than optical microscopy. It’s useful for observing fine details and surface features.

- Transmission Electron Microscopy (TEM): TEM transmits electrons through a thin sample, allowing for observation of internal structures at the atomic level. This is a powerful technique for identifying crystal defects and precipitates.

- X-ray Diffraction (XRD): XRD uses X-rays to identify the crystalline phases present in a material. It provides information about crystal structure, lattice parameters, and phase composition.

- Electron Backscatter Diffraction (EBSD): EBSD is a technique used in conjunction with SEM to determine the crystallographic orientation of individual grains in a polycrystalline material. This allows for the study of grain boundaries and texture.

The choice of method depends on the specific information required and the scale of features to be observed. A combination of techniques is often used to obtain a comprehensive understanding of the microstructure.

Q 7. What are the advantages and disadvantages of using different material testing methods (e.g., tensile, compression, impact)?

Different material testing methods provide complementary information about material behavior. Each has its advantages and disadvantages:

- Tensile Testing:

- Advantages: Provides data on tensile strength, yield strength, elastic modulus, and ductility. Relatively simple and standardized.

- Disadvantages: Doesn’t directly assess behavior under compressive or shear loading.

- Compression Testing:

- Advantages: Evaluates compressive strength, useful for brittle materials.

- Disadvantages: More complex sample preparation than tensile testing. May be difficult to achieve uniform stress distribution.

- Impact Testing (e.g., Charpy, Izod):

- Advantages: Assesses material toughness, resistance to fracture under impact loading. Important for evaluating fracture behavior at low temperatures.

- Disadvantages: Provides limited information on material behavior under other loading conditions.

- Fatigue Testing:

- Advantages: Determines fatigue life and endurance limit. Crucial for designing components subjected to cyclic loading.

- Disadvantages: Time-consuming and expensive. Test parameters need careful consideration.

- Creep Testing:

- Advantages: Measures creep strain under constant stress and temperature, critical for high-temperature applications.

- Disadvantages: Very time-consuming, requires specialized equipment and precise temperature control.

The selection of appropriate testing methods depends on the application and the type of information needed. Often, a combination of tests is necessary for a thorough characterization of material behavior. For instance, impact testing might be crucial in addition to tensile testing for a material intended for use in a cold climate to understand its fracture toughness.

Q 8. Explain the principles of stress-strain curves and their interpretation.

A stress-strain curve is a graphical representation of a material’s response to an applied force. The curve plots stress (force per unit area) against strain (deformation per unit length). It reveals crucial information about the material’s mechanical properties.

Interpreting the Curve: The initial linear portion represents the elastic region, where the material deforms elastically and returns to its original shape upon removal of the load. The slope of this region is Young’s modulus (E), a measure of stiffness. The yield point marks the transition to plastic deformation, where permanent deformation occurs. Beyond the yield point, the material undergoes plastic deformation, becoming permanently altered. The ultimate tensile strength represents the maximum stress the material can withstand before failure. Finally, the fracture point indicates the stress at which the material breaks.

Example: Imagine stretching a rubber band. Initially, it stretches and returns to its original length (elastic). However, if you stretch it too far, it remains elongated (plastic). The stress-strain curve for a rubber band would show a significant elastic region followed by a gradual transition to plastic deformation.

Practical Application: Engineers use stress-strain curves to select appropriate materials for specific applications. For example, a bridge requires a material with high yield strength and ultimate tensile strength to ensure structural integrity. In contrast, a rubber gasket needs high elasticity and resilience, rather than high strength.

Q 9. How do you select materials for a specific application considering cost, performance, and environmental impact?

Material selection is a critical step in engineering design, balancing cost, performance, and environmental impact. It’s not just about finding the strongest or cheapest option; it’s about finding the optimal material for a given application.

- Cost: Consider raw material costs, manufacturing processes, and lifecycle costs (maintenance, replacement).

- Performance: This includes mechanical properties (strength, toughness, hardness, fatigue resistance), thermal properties (melting point, thermal conductivity), electrical properties (conductivity, resistivity), and chemical properties (corrosion resistance).

- Environmental Impact: This encompasses the material’s carbon footprint (energy consumption during production and transportation), recyclability, biodegradability, and potential toxicity.

Decision-Making Framework: A systematic approach might involve:

- Define Requirements: Clearly specify the necessary performance characteristics, operating conditions, and lifespan of the component.

- Material Screening: Identify potential candidate materials based on the requirements. Databases and handbooks can be helpful here.

- Comparative Analysis: Evaluate the shortlisted materials based on cost, performance, and environmental criteria. Life Cycle Assessment (LCA) can be valuable in evaluating environmental impact.

- Testing and Validation: Conduct experiments to verify that the selected material meets the specified performance requirements under actual operating conditions.

- Selection: Choose the optimal material that best balances cost, performance, and environmental considerations.

Example: Choosing a material for a car’s chassis. Steel is strong, but heavier and less fuel-efficient. Aluminum is lighter and better for fuel economy, but more expensive. Advanced high-strength steels offer a balance, but their manufacturing process may have a higher environmental cost. A thorough analysis is needed to make the best choice.

Q 10. What are the common types of non-destructive testing methods used for materials evaluation?

Non-destructive testing (NDT) methods allow evaluation of material properties without causing damage to the material. This is crucial for ensuring quality control and safety in various applications.

- Visual Inspection: A simple and widely used technique involving visual examination for surface defects.

- Liquid Penetrant Testing: Uses a dye to detect surface cracks and flaws.

- Magnetic Particle Testing: Detects surface and near-surface defects in ferromagnetic materials using magnetic fields.

- Ultrasonic Testing: Employs high-frequency sound waves to detect internal flaws and measure material thickness.

- Radiographic Testing (X-ray or Gamma-ray): Uses penetrating radiation to reveal internal defects.

- Eddy Current Testing: Utilizes electromagnetic induction to detect surface and subsurface defects in conductive materials.

Practical Application: Ultrasonic testing is commonly used to inspect welds in pipelines and pressure vessels for cracks, while radiographic testing is used to detect flaws in castings and forgings. Visual inspection is a preliminary step in many NDT procedures.

Q 11. Explain the concept of hardness and different hardness testing methods.

Hardness is a material’s resistance to localized plastic deformation, typically indentation. A harder material resists indentation more effectively than a softer one. Various methods exist to quantify hardness.

- Brinell Hardness Test: A hardened steel or carbide ball indents the material under a specified load. Hardness is calculated from the indentation diameter.

- Rockwell Hardness Test: Measures the depth of penetration of an indenter (diamond cone or steel ball) under a major load, following a minor preload. Several scales exist (e.g., Rockwell A, B, C) depending on the material and indenter used.

- Vickers Hardness Test: Uses a diamond pyramid indenter, providing a more precise measurement than Brinell or Rockwell for hard materials.

- Shore Durometer: Measures the hardness of elastomers (rubbers and plastics) using a needle that indents the material.

Practical Application: Hardness testing is frequently used for quality control in manufacturing. For instance, a manufacturer might check the hardness of a heat-treated steel component to ensure it meets the required strength and durability specifications. Selecting the appropriate hardness testing method depends on the material’s hardness range and the desired level of precision.

Q 12. Describe different types of bonding in materials (ionic, covalent, metallic).

The type of bonding in a material significantly influences its properties. Three main types are:

- Ionic Bonding: Involves the electrostatic attraction between oppositely charged ions. One atom loses electrons (becoming a positively charged cation), while another atom gains electrons (becoming a negatively charged anion). This results in a strong bond, but the materials are often brittle. Example: Sodium chloride (NaCl), table salt.

- Covalent Bonding: Atoms share electrons to achieve a stable electron configuration. This leads to strong bonds and high melting points. Materials can be hard or soft depending on the structure. Example: Diamond (carbon atoms share electrons in a strong, three-dimensional network).

- Metallic Bonding: Electrons are delocalized and form a ‘sea’ of electrons surrounding positively charged metal ions. This allows for good electrical and thermal conductivity, ductility, and malleability. Example: Copper (Cu), a good conductor of electricity.

Note: Many materials exhibit a combination of bonding types.

Q 13. How do grain size and grain boundaries affect material properties?

Grain size and grain boundaries significantly affect a material’s properties. Grains are small, crystalline regions within a polycrystalline material. Grain boundaries are the interfaces between these grains.

- Grain Size: Smaller grain sizes generally lead to increased strength and hardness due to more grain boundaries hindering dislocation movement (dislocations are defects in the crystal lattice that contribute to plastic deformation). However, smaller grains can also reduce ductility. Larger grains can result in lower strength but better ductility.

- Grain Boundaries: Grain boundaries act as barriers to dislocation movement, affecting the material’s strength, ductility, and creep resistance. They can also influence corrosion behavior and diffusion processes.

Example: Heat treatment can be used to control grain size. Annealing (heating to a high temperature followed by slow cooling) can increase grain size, resulting in a softer, more ductile material. Conversely, rapid cooling (quenching) can produce a finer grain structure, leading to a stronger, harder material.

Practical Application: Controlling grain size is important in many applications. For example, in aerospace alloys, fine-grained structures are preferred to improve strength and fracture toughness. In some applications, however, a larger grain size may be desirable for improved formability (ability to be shaped).

Q 14. What are the effects of alloying elements on the properties of metals?

Alloying elements are added to metals to modify their properties, often improving strength, corrosion resistance, or other characteristics. The effect depends on the base metal and the alloying elements. Alloying can involve solid solution strengthening, precipitation hardening, or the formation of intermetallic compounds.

- Solid Solution Strengthening: Alloying atoms dissolve in the base metal’s crystal lattice, hindering dislocation movement and increasing strength and hardness. Example: Adding carbon to iron (steel) significantly increases its strength.

- Precipitation Hardening: Alloying elements form small, dispersed precipitates within the base metal. These precipitates obstruct dislocation motion, enhancing strength and hardness. Example: Aluminum alloys containing copper or magnesium are precipitation hardened for aircraft applications.

- Formation of Intermetallic Compounds: Certain alloying elements react with the base metal to form new compounds with distinct properties. These compounds can affect strength, hardness, corrosion resistance, or other characteristics. Example: Adding chromium to iron forms chromium carbides, improving steel’s high-temperature strength and corrosion resistance.

Example: Stainless steel is an alloy of iron, chromium, and nickel. Chromium improves corrosion resistance, while nickel enhances ductility and toughness.

Practical Application: Alloying is critical for tailoring metal properties to meet specific application requirements. High-strength steels, superalloys, and aluminum alloys are prime examples of engineered materials with enhanced properties due to strategic alloying.

Q 15. Explain the concept of phase diagrams and their use in material selection.

Phase diagrams are graphical representations of the equilibrium relationships between different phases of a material, typically as a function of temperature and composition (or pressure). Think of it like a map showing which form a substance takes – solid, liquid, gas, or even different solid structures – under various conditions.

In material selection, phase diagrams are invaluable because they allow engineers and scientists to predict the microstructure and thus the properties of a material under specific processing conditions. For example, a phase diagram can tell you the optimal temperature and cooling rate to achieve a specific grain size in a metal alloy, which directly affects its strength and ductility. They’re essential for understanding phase transformations, such as the formation of specific phases during heat treatments, which are used to tailor the material’s properties for a specific application.

Example: The iron-carbon phase diagram is crucial in steel manufacturing. By understanding the different phases (austenite, ferrite, pearlite, cementite) and their temperature ranges, metallurgists can control the heat treatment process to achieve specific steel grades with varying strength, hardness, and toughness properties, suitable for applications from construction beams to surgical instruments.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of polymers and their properties?

Polymers are large molecules composed of repeating structural units called monomers. They’re categorized into several types based on their structure and properties:

- Thermoplastics: These can be repeatedly melted and solidified without undergoing significant chemical change. Think of plastic bottles or LEGO bricks – they can be melted down and reshaped. Examples include polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC). They are generally less strong than thermosets but are recyclable.

- Thermosets: These undergo irreversible chemical changes upon heating, forming a cross-linked network structure. Once cured, they cannot be melted and reshaped. Think of epoxy resins or fiberglass. They are typically stronger and more heat-resistant than thermoplastics, but they cannot be recycled easily.

- Elastomers: These are polymers that exhibit significant elasticity, returning to their original shape after deformation. Rubber is the prime example, used in tires, seals, and many other applications. Their flexibility and resilience make them well-suited for applications requiring shock absorption or sealing.

The properties of polymers vary widely depending on their chemical structure, molecular weight, and degree of crystallinity. Factors such as flexibility, strength, melting point, and chemical resistance are all influenced by these characteristics.

Q 17. Describe the properties of ceramics and their applications.

Ceramics are inorganic, non-metallic materials typically composed of metallic and non-metallic elements bonded together primarily by ionic or covalent bonds. This strong bonding results in materials with high hardness, high melting points, and excellent chemical resistance.

Properties: High strength and hardness, excellent wear resistance, high melting points, good electrical insulation, chemical inertness (resistance to corrosion). However, they are generally brittle, meaning they lack ductility and are prone to fracture under tensile stress.

Applications: Their diverse properties make them suitable for a wide range of applications, including:

- Structural components: Bricks, tiles, and advanced ceramics in aerospace and automotive applications.

- Cutting tools: Due to their hardness, ceramics are used in cutting tools and abrasives.

- Electrical insulators: Their insulating properties make them valuable in electrical and electronic components.

- Biomedical applications: Biocompatible ceramics are used in implants and dental applications.

Example: Alumina (Al2O3) is a common ceramic used in high-strength components due to its excellent hardness and wear resistance. Silicon carbide (SiC) finds use in high-temperature applications because of its exceptional thermal stability.

Q 18. Explain the concept of composite materials and their advantages.

Composite materials are made by combining two or more distinct materials with significantly different properties to create a new material with enhanced characteristics. The goal is to synergistically combine the strengths of each component, resulting in a material superior to its individual constituents.

Examples: Fiberglass (glass fibers in a polymer matrix), carbon fiber reinforced polymers (CFRP) (carbon fibers in a polymer matrix), concrete (aggregate in a cement matrix).

Advantages:

- High strength-to-weight ratio: Composites often exhibit superior strength and stiffness compared to their individual components, making them ideal for lightweight applications like aerospace and automotive industries.

- Tailored properties: The properties of composites can be tailored by adjusting the type and amount of reinforcement and matrix materials.

- Corrosion resistance: Certain composites, like those with polymer matrices, offer excellent corrosion resistance.

- Design flexibility: Composites can be molded and shaped into complex geometries.

Application example: CFRP is extensively used in the aerospace industry to manufacture lightweight and strong aircraft components, reducing fuel consumption and increasing efficiency. The high strength-to-weight ratio is crucial for maximizing payload capacity.

Q 19. What are the different types of corrosion and how can they be prevented?

Corrosion is the deterioration of a material, usually a metal, due to a chemical or electrochemical reaction with its environment. There are several types:

- Uniform corrosion: Even degradation across the entire surface area. Think of a rusty iron fence.

- Galvanic corrosion: Occurs when two dissimilar metals are in electrical contact in the presence of an electrolyte (like saltwater). The more active metal corrodes preferentially. Think of steel bolts in a brass fitting exposed to moisture.

- Pitting corrosion: Localized corrosion resulting in small holes or pits on the surface. This is often difficult to detect early.

- Crevice corrosion: Corrosion within confined spaces such as gaps, cracks, or under deposits. The stagnant environment within the crevice promotes localized corrosion.

- Stress corrosion cracking: Combined effect of tensile stress and corrosive environment, leading to cracking.

Prevention: Corrosion prevention methods include:

- Protective coatings: Paints, polymers, and metallic coatings (e.g., galvanizing) can create a barrier between the metal and the environment.

- Corrosion inhibitors: Chemicals added to the environment to slow down the corrosion rate.

- Cathodic protection: Applying a protective current to make the metal less susceptible to corrosion (e.g., sacrificial anodes).

- Material selection: Choosing corrosion-resistant materials, like stainless steel, for specific applications.

- Design considerations: Avoiding crevices, ensuring good drainage, and using appropriate joint designs.

Q 20. Explain the concept of thermal conductivity and its significance in material selection.

Thermal conductivity is a measure of a material’s ability to conduct heat. It quantifies how easily heat can flow through a material. A high thermal conductivity indicates that heat flows easily, while a low thermal conductivity means the material resists heat flow.

Significance in material selection: Thermal conductivity is a critical factor in many engineering applications:

- Heat exchangers: Materials with high thermal conductivity are preferred for heat exchanger components (like pipes and fins) to efficiently transfer heat between fluids.

- Electronics: Heat dissipation is crucial in electronics; materials with high thermal conductivity are used in heat sinks to prevent overheating.

- Insulation: In applications requiring thermal insulation (like building walls or ovens), materials with low thermal conductivity are chosen to minimize heat transfer.

- Engines: Materials with high thermal conductivity might be used in engine components to efficiently manage heat transfer, minimizing wear and improving efficiency.

Example: Copper has a very high thermal conductivity and is widely used in heat sinks and heat exchangers. Conversely, materials like fiberglass and aerogel have very low thermal conductivities and are used as insulators.

Q 21. What are the challenges and opportunities in using nanomaterials?

Nanomaterials are materials with at least one dimension sized between 1 and 100 nanometers (a nanometer is one billionth of a meter). Their unique properties arise from their high surface area-to-volume ratio and quantum effects.

Challenges:

- Synthesis and characterization: Producing nanomaterials with controlled size, shape, and properties is often challenging and expensive.

- Toxicity and environmental impact: The potential toxicity of certain nanomaterials to humans and the environment is a major concern requiring careful study and mitigation strategies.

- Scale-up and manufacturing: Scaling up nanomaterial production from laboratory to industrial levels is a significant hurdle.

- Long-term stability and durability: Ensuring the long-term stability and durability of nanomaterials in different environments is crucial for many applications.

Opportunities:

- Enhanced mechanical properties: Nanomaterials can exhibit significantly improved strength, stiffness, and toughness compared to bulk materials.

- Improved electronic and optical properties: Nanomaterials often possess unique electrical and optical properties not found in their bulk counterparts, leading to applications in electronics, photonics, and sensors.

- Biomedical applications: Nanomaterials are showing promise in drug delivery, diagnostics, and tissue engineering.

- Energy applications: Nanomaterials are being explored for use in batteries, solar cells, and fuel cells to improve efficiency and performance.

Example: Carbon nanotubes, with their exceptional strength and electrical conductivity, show promise in various applications from reinforced composites to advanced electronics.

Q 22. Describe different methods for improving the mechanical properties of materials.

Improving the mechanical properties of materials is crucial for tailoring them to specific applications. This can be achieved through various methods, broadly categorized as processing techniques and alloying/compositional modifications.

Processing Techniques: These methods alter the material’s microstructure without changing its chemical composition. Examples include:

Heat Treatment: Processes like annealing, quenching, and tempering modify a material’s strength, hardness, and ductility by controlling the grain size and phase distribution. For instance, steel’s strength can be significantly increased through quenching and tempering.

Cold Working: Deforming a material at room temperature increases its strength and hardness but reduces its ductility. This is commonly used in processes like rolling and drawing to create stronger wires or sheets.

Strain Hardening (Work Hardening): Repeated deformation increases dislocation density, leading to increased strength. Think of hammering a piece of metal—it becomes harder and less malleable.

Alloying and Compositional Modifications: This involves adding other elements to the base material to enhance its properties. For example:

Adding carbon to iron creates steel, significantly increasing its strength and hardness compared to pure iron.

Adding alloying elements like chromium and nickel to steel improves its corrosion resistance (stainless steel).

The choice of method depends on the desired properties and the material itself. Often, a combination of techniques is employed to achieve optimal performance.

Q 23. Explain how material properties relate to processing methods.

Material properties are intrinsically linked to processing methods. The way a material is processed directly impacts its microstructure and, consequently, its macroscopic properties. Imagine baking a cake; the ingredients (material composition) and baking method (processing) determine the final product’s texture, taste, and overall quality.

For example, the grain size of a metal significantly influences its strength and ductility. Slow cooling during solidification results in larger grains, leading to lower strength but higher ductility. Conversely, rapid cooling (quenching) produces finer grains, enhancing strength but reducing ductility. Similarly, the forging process can refine the grain structure and increase the strength of a metal component. In polymer processing, techniques like injection molding or extrusion directly influence the final part’s shape, strength, and crystallinity.

Understanding this relationship is vital for materials scientists and engineers. By controlling the processing parameters, we can tailor the material’s microstructure and achieve the desired properties for a given application.

Q 24. Describe the importance of material safety data sheets (MSDS).

Material Safety Data Sheets (MSDS), now often called Safety Data Sheets (SDS), are crucial documents providing comprehensive information on the hazards associated with a particular material. They are essential for workplace safety and environmental protection.

An SDS typically includes:

Chemical composition and properties: This helps identify potential hazards.

Physical and chemical hazards: Details on flammability, reactivity, toxicity, etc.

Health hazards: Information on potential health effects upon exposure.

First aid measures: Instructions on how to handle exposure incidents.

Fire-fighting measures: Guidelines for extinguishing fires involving the material.

Accidental release measures: Procedures for cleaning up spills.

Handling and storage: Safe practices for handling and storage.

Exposure controls/personal protection: Recommended personal protective equipment (PPE).

Physical and chemical properties: Melting point, boiling point, density, etc.

Stability and reactivity: Information on potential instability and reactions.

Toxicological information: Details on toxicity and health effects.

Ecological information: Environmental impact.

Disposal considerations: Safe disposal methods.

Transport information: Regulations for transportation.

Regulatory information: Compliance with regulations.

Ignoring SDS information can lead to serious accidents, health problems, and environmental damage. They are a fundamental tool for responsible material handling and usage.

Q 25. How does the microstructure of a material relate to its macroscopic properties?

The microstructure of a material—its internal structure at a microscopic level—directly influences its macroscopic properties, which are the properties we observe at a larger scale.

Consider the example of steel. At the microscopic level, the arrangement of iron atoms and the presence of carbon atoms determine the formation of different phases (ferrite, pearlite, cementite). These phases have different properties, affecting the overall strength, hardness, and ductility of the steel. A fine-grained microstructure generally leads to higher strength and hardness due to increased dislocation density, while a coarse-grained microstructure leads to higher ductility and toughness.

Similarly, in polymers, the degree of crystallinity and the arrangement of polymer chains affect the material’s stiffness, strength, and toughness. A highly crystalline polymer will be stiffer and stronger than an amorphous polymer.

Techniques like microscopy (optical, electron, etc.) are crucial for characterizing the microstructure and correlating it with macroscopic properties. This understanding is essential for materials selection and processing optimization.

Q 26. What are some common material degradation mechanisms?

Material degradation is the process by which a material’s properties deteriorate over time due to various factors. Common mechanisms include:

Corrosion: The deterioration of a material due to chemical or electrochemical reactions with its environment. Rusting of iron is a classic example of corrosion.

Oxidation: A type of corrosion where a material reacts with oxygen, often leading to the formation of oxides. The tarnishing of silver is an example.

Creep: Time-dependent deformation under sustained stress at high temperatures. This can lead to failure of components under constant load, particularly in high-temperature applications like gas turbines.

Fatigue: Failure under cyclic loading, even at stresses below the material’s yield strength. This is a significant concern in components experiencing repeated loading and unloading cycles.

Erosion: Material loss due to the impact of solid particles or liquids. Erosion can be observed in pipes carrying abrasive fluids or in turbine blades subjected to high-velocity gas streams.

Stress Corrosion Cracking (SCC): Crack formation and propagation under combined stress and corrosive environment. This is a serious concern in many engineering applications.

Biodegradation: Breakdown of materials by biological organisms, such as bacteria or fungi. This is important for biodegradable polymers and implants.

Understanding these mechanisms is critical for designing materials and structures that can withstand the expected operating conditions and have a long lifespan.

Q 27. How would you determine the appropriate material for a high-temperature application?

Selecting a material for a high-temperature application requires considering several crucial factors:

Melting Point: The material should have a melting point significantly higher than the operating temperature to prevent melting or softening.

Creep Resistance: High creep resistance is essential to avoid time-dependent deformation under load at elevated temperatures.

Oxidation Resistance: The material should resist oxidation and other high-temperature degradation mechanisms.

Thermal Shock Resistance: Ability to withstand rapid temperature changes without cracking or fracturing is crucial.

Strength and Stiffness at High Temperatures: The material should retain sufficient strength and stiffness at the operating temperature.

Step-by-step approach for material selection:

Define operating conditions: Determine the exact temperature range, stress levels, and environmental conditions.

Identify candidate materials: Consider materials known for their high-temperature properties, such as superalloys, ceramics, or refractory metals.

Consult material databases and literature: Access data on the materials’ high-temperature properties (creep, oxidation resistance, etc.).

Perform simulations and experiments: If necessary, conduct simulations or experiments to validate the material’s performance under the specific operating conditions.

Consider cost and manufacturability: Evaluate the cost-effectiveness and feasibility of manufacturing with the selected material.

Examples of materials used in high-temperature applications include nickel-based superalloys for gas turbine blades and ceramic composites for heat shields.

Q 28. Explain the concept of viscoelasticity.

Viscoelasticity describes the behavior of materials that exhibit both viscous (fluid-like) and elastic (solid-like) properties. These materials deform elastically under load but also exhibit time-dependent deformation (creep) and energy dissipation (similar to a fluid).

Imagine a silly putty: If you pull it slowly, it stretches like a viscous liquid, and if you pull it quickly, it behaves more like an elastic solid. It exhibits both properties to varying degrees depending on the rate of loading.

Key characteristics of viscoelastic materials:

Creep: Continuous deformation under constant stress.

Stress Relaxation: Decrease in stress over time under constant strain.

Hysteresis: Energy dissipation during loading and unloading cycles.

Viscoelasticity is observed in a wide range of materials, including polymers, rubbers, biological tissues, and some metals at high temperatures. Understanding viscoelastic behavior is crucial in designing components that experience time-dependent loads or cyclic loading, such as seals, shock absorbers, and biomedical implants.

Mathematical models, such as the Maxwell and Kelvin-Voigt models, are used to describe the viscoelastic behavior of materials. These models help predict material response under various loading conditions.

Key Topics to Learn for Understanding of Material Properties and Characteristics Interview

- Mechanical Properties: Stress-strain relationships, elasticity, plasticity, yield strength, tensile strength, fatigue, creep, hardness, impact resistance. Consider practical applications in structural design and material selection.

- Thermal Properties: Thermal conductivity, specific heat capacity, thermal expansion, melting point, glass transition temperature. Explore how these properties influence material behavior in high-temperature or cryogenic environments.

- Electrical Properties: Conductivity, resistivity, dielectric strength, piezoelectric effect. Understand the applications in electronics, energy storage, and sensor technologies.

- Optical Properties: Refractive index, reflectivity, transparency, absorption. Consider applications in optics, photonics, and solar energy.

- Magnetic Properties: Permeability, susceptibility, hysteresis. Discuss applications in magnetic storage, sensors, and actuators.

- Chemical Properties: Corrosion resistance, reactivity, oxidation, degradation. Analyze the impact of environmental factors on material performance and longevity.

- Material Selection and Processing: Learn how to choose appropriate materials based on required properties and understand the effects of processing techniques (casting, forging, machining, etc.) on final material characteristics. Practice solving problems involving material selection for specific applications.

- Failure Analysis: Understanding common failure mechanisms (fracture, fatigue, creep, corrosion) and methods for investigating material failures. This is crucial for problem-solving and ensuring product reliability.

Next Steps

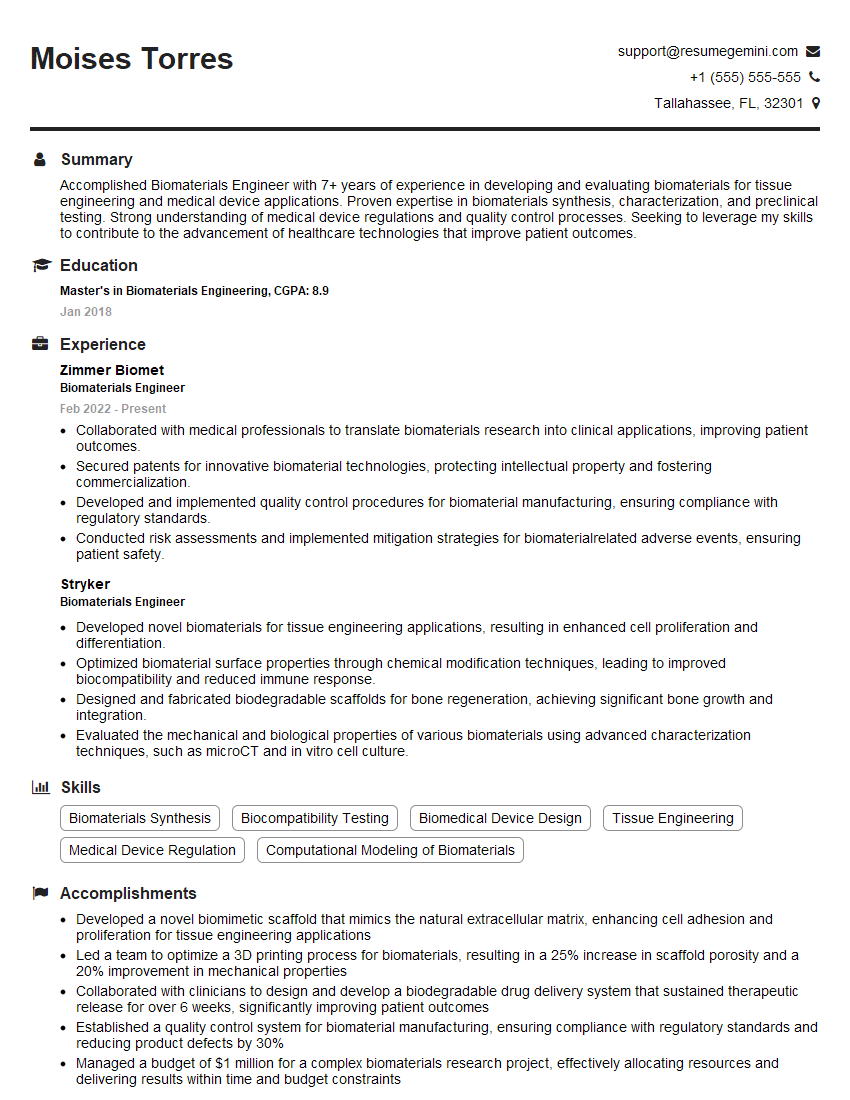

Mastering the understanding of material properties and characteristics is paramount for career advancement in numerous engineering and scientific fields. A strong foundation in this area opens doors to exciting opportunities and positions you as a valuable asset to any team. To maximize your job prospects, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. ResumeGemini provides examples of resumes tailored to roles requiring a strong understanding of material properties and characteristics, giving you a head start in crafting your own.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO