Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Linen Management interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Linen Management Interview

Q 1. Describe your experience with linen inventory management systems.

My experience with linen inventory management systems spans over 10 years, encompassing various technologies from simple spreadsheet-based systems to sophisticated RFID-integrated solutions. I’ve worked with both on-premise and cloud-based systems, managing inventories ranging from small boutique hotels to large healthcare facilities. My expertise includes implementing and optimizing these systems to ensure accuracy, efficiency, and cost-effectiveness. For example, in a previous role at a large hospital, I successfully transitioned the linen inventory system from a manual, paper-based process to a real-time, automated system using RFID tags. This resulted in a 20% reduction in linen loss and a 15% improvement in inventory accuracy.

I’m proficient in using systems to track various linen types (sheets, towels, gowns, etc.), their locations (soiled linen rooms, clean linen storage, patient rooms), and their status (in use, in laundry, lost). I can also generate reports on linen consumption, usage patterns, and costs. This data is crucial for informed decision-making related to linen purchasing and resource allocation.

Q 2. How do you ensure accurate linen tracking and reporting?

Accurate linen tracking and reporting are paramount for efficient linen management. My approach involves a multi-pronged strategy. First, a robust inventory management system, as described above, is essential. This system needs to be seamlessly integrated with the laundry process and ideally use real-time tracking technologies like RFID or barcodes to eliminate manual counting and reduce human error. Second, regular physical stock counts should be conducted, ideally using cyclical counting techniques rather than a complete inventory count at once. This reduces downtime and improves accuracy. Discrepancies between the physical count and the system record trigger investigations to identify and resolve the cause of the error (e.g., misplacement, loss, theft). Finally, comprehensive reporting capabilities are vital. Regularly generated reports on linen usage, loss rates, and costs help identify trends, highlight areas for improvement, and inform purchasing decisions. These reports are also crucial for demonstrating operational efficiency and justifying investments in new technologies or processes.

Q 3. Explain your process for handling damaged or soiled linen.

Handling damaged or soiled linen is a critical aspect of maintaining hygiene and extending linen lifespan. My process begins with clear segregation. Soiled linen is collected in designated containers and transported to the laundry facility using appropriate procedures to prevent cross-contamination. Damaged linen is separately identified and assessed. Minor damage, like small tears, may be repaired in-house, while severely damaged linens are discarded responsibly, following proper waste disposal guidelines. The handling process always adheres to safety protocols and infection control measures, especially in healthcare settings. Regular audits of the process ensure compliance and identify potential issues early on. For instance, if we see a sudden increase in damaged linen from a specific department, we investigate the root cause, which might include staff training on proper linen handling or replacing worn-out equipment.

Q 4. What methods do you use to optimize linen usage and reduce waste?

Optimizing linen usage and reducing waste requires a holistic approach. It starts with accurate forecasting of linen needs based on historical data and occupancy rates. This helps avoid overstocking, which ties up capital and increases storage costs. Implementing a linen rotation system ensures even wear and tear, extending the lifespan of each item. Regular preventative maintenance on laundry equipment minimizes linen damage during the washing process. Staff training plays a crucial role in promoting responsible linen handling and reducing accidental damage. Finally, exploring sustainable laundry practices, such as using eco-friendly detergents and reducing water consumption, contributes to overall cost savings and environmental responsibility. For example, in a previous role, I implemented a program that reduced water usage in the laundry process by 15%, resulting in significant cost savings and environmental benefits.

Q 5. How do you manage linen par levels and reorder points?

Managing linen par levels (the ideal quantity of linen on hand) and reorder points (the inventory level at which a reorder should be placed) is critical for preventing stockouts and overstocking. These levels are determined through careful analysis of historical data, forecasting future demand, and considering factors such as linen usage rates, laundry cycle times, and lead times for new orders. A good inventory management system simplifies the task by automatically calculating reorder points based on pre-defined parameters. Safety stock is added to the par level to account for unexpected demand fluctuations or delays in delivery. Regular review and adjustment of par levels and reorder points are necessary to adapt to changes in occupancy rates, linen usage patterns, and external factors. For instance, during peak seasons, we adjust the par levels upwards to meet increased demand, while during off-peak seasons we lower them to optimize inventory levels.

Q 6. Describe your experience with linen distribution and delivery systems.

My experience with linen distribution and delivery systems includes working with both internal and external logistics providers. Internal systems typically involve dedicated linen carts and staff responsible for delivering clean linen to various departments and collecting soiled linen. External providers are usually employed for larger operations or when outsourcing laundry services. Efficient distribution systems require clear communication channels, well-defined delivery routes, and tracking mechanisms to ensure timely delivery and minimize delays. For example, in a previous role, we implemented a barcoding system that tracked linen from the laundry to its final destination, enabling real-time monitoring and improving delivery efficiency. Regular review of the distribution process helps identify bottlenecks and optimize routes for cost-effectiveness and timely service.

Q 7. How do you maintain linen quality and extend its lifespan?

Maintaining linen quality and extending its lifespan requires a combination of best practices. This starts with selecting high-quality linen made from durable fabrics that can withstand frequent washing and drying. Proper laundry procedures, including using appropriate detergents, water temperatures, and drying cycles, are essential. Regular inspection of linen for damage and prompt repair of minor issues prevents further deterioration. Implementing a linen rotation system ensures that all linens get used evenly, reducing wear and tear on individual items. Careful handling by staff, through proper training, also minimizes damage. Proper storage conditions – maintaining a clean, dry, and well-ventilated storage area – also protects the linen quality. Finally, investing in high-quality laundry equipment and regular preventative maintenance minimizes linen damage during the washing process. A well-maintained linen inventory not only reduces costs through extended lifespan but also improves the overall quality of service.

Q 8. Explain your approach to managing linen budgets and costs.

Managing linen budgets effectively requires a multi-pronged approach focusing on cost reduction and efficient resource allocation. It’s not just about slashing expenses; it’s about optimizing the entire linen lifecycle.

Detailed Inventory Tracking: Implementing a robust inventory management system allows for precise tracking of linen usage, identifying areas of waste and potential cost savings. For instance, identifying items with high loss rates prompts investigation into the cause – is it due to damage, theft, or simply inaccurate counting?

Strategic Purchasing: Negotiating favorable contracts with linen suppliers, exploring bulk discounts, and evaluating the long-term cost of different linen fabrics are crucial. For example, while higher-quality linens might have a higher upfront cost, their durability can significantly reduce replacement costs over time.

Efficient Laundry Practices: Optimizing laundry procedures – including water and energy consumption, detergent usage, and proper handling to minimize damage – directly impacts operational costs. A simple example is ensuring that the laundry is properly sorted to prevent mixing colors and fabrics which could lead to damage and replacement.

Regular Maintenance and Repair: Implementing a proactive linen repair program can extend the lifespan of linens, reducing the need for frequent replacements. This could involve assigning a dedicated team member to repair minor tears and stains, extending their usable lifespan.

Employee Training: Properly trained staff handle linens with care, reducing accidental damage and extending the life of the inventory. This translates into significant cost savings in the long run.

By combining these strategies, we can create a sustainable linen management system that minimizes costs without compromising quality or service.

Q 9. How do you handle linen shortages or unexpected demand?

Linen shortages can be disruptive, but a well-planned response can mitigate the impact. My approach involves a combination of proactive measures and reactive strategies.

Predictive Analysis: Analyzing historical data on linen usage patterns helps anticipate potential shortages and allows for proactive ordering. For example, if we notice a consistent spike in demand during specific events or seasons, we can adjust our stock levels accordingly.

Emergency Stockpiles: Maintaining a reserve of commonly used linens serves as a buffer against unexpected surges in demand. This is like having a safety net for unexpected guests in a hotel.

Outsourcing: In cases of extreme shortage, outsourcing to a reliable linen rental service can provide a temporary solution. This provides immediate relief without long-term commitments.

Prioritization: During shortages, prioritizing the needs of critical areas, like operating rooms or patient rooms in a hospital setting, ensures essential services are not compromised.

Communication: Open and transparent communication with relevant stakeholders – staff, management, and clients (if applicable) – helps manage expectations during a shortage.

This multi-faceted approach ensures we’re prepared for virtually any scenario, minimizing disruption and maintaining a high level of service.

Q 10. What are your preferred methods for training linen room staff?

Effective training is paramount in linen room management. My preferred method combines practical, hands-on training with theoretical knowledge, using a multi-step approach:

On-the-Job Training: New employees shadow experienced staff, learning practical skills like sorting, washing, folding, and storing linens. This provides immediate, practical experience.

Formal Instruction: Structured sessions cover linen types, care instructions, hygiene protocols, safety procedures, and inventory management systems. This ensures a thorough understanding of the theoretical aspects.

Regular Refresher Training: Periodic refresher courses keep employees updated on best practices, new technologies, and changes in regulations. This maintains a high standard of performance and reinforces good habits.

Interactive Workshops: Hands-on workshops focus on specific skills, like stain removal or operating specialized laundry equipment. This allows for targeted skill development and practice.

Performance Feedback: Regular performance reviews provide constructive feedback, identifying areas for improvement and reinforcing successful practices. This creates a continuous improvement cycle.

By integrating these methods, we ensure our linen room staff are well-equipped to handle their duties efficiently and safely.

Q 11. Describe your experience with different types of linen fabrics and their care requirements.

My experience encompasses a wide range of linen fabrics, each with unique properties and care requirements. Understanding these nuances is crucial for extending linen lifespan and maintaining quality.

Cotton: A versatile and widely used fabric, known for its absorbency and softness. Different cotton weaves (percale, sateen) impact durability and feel. Proper washing temperatures and avoidance of harsh chemicals are key to maintaining its quality.

Linen: A luxurious natural fiber, known for its strength and breathability. It’s more prone to wrinkling but becomes softer with each wash. Gentle washing and ironing are recommended.

Polyester: A synthetic fiber offering high durability and wrinkle resistance. It’s less absorbent than natural fibers and requires appropriate detergent and drying temperatures to prevent damage.

Blends: Many linens are blends of natural and synthetic fibers, combining the benefits of each. For example, a cotton-polyester blend offers the softness of cotton with the durability of polyester. Care instructions will vary depending on the blend composition.

I’ve also worked with specialty linens like microfiber (highly absorbent and quick-drying) and bamboo (soft, sustainable, and naturally antimicrobial). Understanding the specific care instructions for each type is crucial for maintaining the quality and longevity of the linen inventory.

Q 12. How do you ensure compliance with hygiene and safety regulations regarding linen handling?

Maintaining hygiene and safety is paramount in linen handling. My approach combines stringent procedures with regular monitoring and staff training.

Strict Hygiene Protocols: Implementing strict protocols for handling soiled linens, including the use of appropriate personal protective equipment (PPE) such as gloves, and following proper procedures for sorting, washing, and disinfection are crucial.

Regular Cleaning and Disinfection: Frequent cleaning and disinfection of linen carts, storage areas, and laundry equipment prevent cross-contamination and the spread of infection. This includes regular sterilization of laundry machinery.

Proper Waste Disposal: Following strict protocols for the disposal of contaminated linens and waste ensures environmental safety and prevents the spread of pathogens.

Employee Training on Safety and Hygiene: Regular training sessions emphasizing proper handling techniques, hygiene standards, and safety regulations are critical. This includes training on the use and disposal of PPE.

By adhering to these measures, we ensure compliance with all relevant regulations and maintain a safe and hygienic environment. We also conduct regular audits to ensure compliance and identify any areas needing improvement.

Q 13. What software or technology have you used for linen management?

I have extensive experience using various software and technologies for linen management, enhancing efficiency and accuracy.

Inventory Management Systems (IMS): I’ve worked with several IMS, including cloud-based solutions that enable real-time tracking of linen inventory, predicting potential shortages, and generating reports on linen usage and costs. Examples include systems that utilize barcodes or RFID tags for item tracking.

Laundry Management Software: I’m proficient in using software that optimizes laundry processes, monitors machine usage, and tracks energy and water consumption. This helps in identifying areas for improvement in efficiency and cost reduction.

Spreadsheet Software (Excel): While more basic, spreadsheets remain a valuable tool for tracking data, creating reports, and managing smaller-scale linen inventories. Functions like pivot tables and charting are invaluable for data analysis.

My experience across different systems allows me to adapt to new technologies and leverage their capabilities to streamline linen management practices.

Q 14. How do you prioritize tasks and manage your workload in a busy linen room?

Prioritizing tasks and managing workload in a busy linen room requires a systematic approach. I use a combination of techniques to ensure smooth operations.

Task Prioritization: I employ methods like the Eisenhower Matrix (urgent/important) to categorize tasks and focus on high-priority items first. For example, processing soiled linens from operating rooms would take priority over routine laundry.

Workflow Optimization: Analyzing the current workflow identifies bottlenecks and areas for improvement, leading to a more efficient process. This could involve rearranging the layout of the linen room or streamlining the sorting process.

Teamwork and Delegation: Effectively delegating tasks based on team members’ skills and experience optimizes workload distribution. This ensures a fair distribution of workload and prevents burnout.

Time Management Techniques: Utilizing techniques like time blocking and Pomodoro help manage time efficiently and maintain focus. This helps to prevent being overwhelmed by a large volume of tasks.

Regular Review and Adjustment: Periodically reviewing the workflow and task management strategies ensures that the system remains efficient and adaptable to changing needs.

By implementing these strategies, I maintain a high level of productivity and efficiency in even the busiest of linen rooms.

Q 15. Describe your experience with linen procurement and vendor management.

Linen procurement and vendor management are critical for maintaining a consistent supply of high-quality linens while optimizing costs. My experience encompasses the entire process, from identifying needs and sourcing vendors to negotiating contracts and managing ongoing relationships.

Firstly, I meticulously analyze linen requirements based on occupancy rates, usage patterns, and anticipated growth. This informs the type and quantity of linens needed—everything from sheets and towels to pillowcases and uniforms. Then, I research and evaluate potential vendors, considering factors like quality, pricing, delivery reliability, and sustainability practices. I’ve found that requesting samples and conducting on-site visits are crucial for assessing quality and operational capabilities.

Once a vendor is selected, I negotiate contracts that detail specifications, pricing, delivery schedules, and penalty clauses for non-compliance. Ongoing management involves regular communication, performance monitoring (tracking on-time delivery, quality issues, and pricing adjustments), and proactive problem-solving. For instance, if a vendor consistently experiences delays, I’d explore alternative solutions, possibly using a secondary vendor to ensure continuity of supply. Maintaining strong relationships with vendors fosters collaboration and helps navigate challenges effectively. I use a robust system for tracking inventory levels, purchase orders, and vendor performance, which allows for data-driven decision making and cost optimization.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you resolve conflicts or disagreements among linen room staff?

Resolving conflicts among linen room staff requires a proactive, fair, and consistent approach. My strategy focuses on open communication, clear expectations, and a supportive team environment. I start by actively listening to each individual’s perspective, ensuring everyone feels heard and understood. This often helps uncover the root cause of the disagreement, which might be anything from workload imbalances to personality clashes.

If the conflict involves a procedural issue, I clearly outline the established processes and expectations. For example, if there’s a disagreement about how linens should be folded, I review the standard operating procedures and provide additional training if necessary. In cases of personality clashes, I facilitate a constructive dialogue, focusing on finding common ground and promoting mutual respect. Mediation techniques, such as encouraging active listening and compromise, are often beneficial. If the conflict persists or involves serious misconduct, I will follow established disciplinary procedures. Ultimately, my goal is to create a collaborative and positive workplace where staff members can work together efficiently and respectfully.

Q 17. How do you stay up-to-date with the latest linen management best practices?

Staying current with linen management best practices is crucial for maintaining efficiency and optimizing resources. I utilize a multi-pronged approach to ensure I am always up-to-date.

- Professional Associations: I actively participate in professional organizations like the Textile Rental Services Association (TRSA) which offer training, conferences, and networking opportunities. This provides access to the latest industry trends and innovative solutions.

- Industry Publications and Journals: Regularly reading trade publications and journals keeps me informed about new technologies, management techniques, and regulatory changes.

- Webinars and Online Courses: Online learning platforms offer a wealth of courses and webinars on linen management, sustainability, and technology.

- Networking: Attending industry conferences and connecting with other professionals in the field allows me to exchange knowledge and learn from others’ experiences.

- Vendor Partnerships: Maintaining strong relationships with vendors keeps me informed about new products and services that can improve efficiency and reduce costs.

This continuous learning process ensures I am applying the most effective strategies and technologies to my work.

Q 18. What are the key performance indicators (KPIs) you use to measure linen room efficiency?

Key Performance Indicators (KPIs) are vital for measuring the efficiency and effectiveness of a linen room. I use a combination of metrics to gain a holistic view of performance.

- Par Stock Levels: Maintaining optimal stock levels minimizes shortages while avoiding excessive inventory. This is measured by tracking the number of each linen item on hand compared to the established par level.

- Linen Loss Rate: Tracking the number of linens lost or damaged per unit of laundry processed helps identify areas for improvement in handling and laundry processes. A lower loss rate indicates better efficiency.

- Inventory Turnover Rate: This indicates how quickly linens are being used and replaced. A healthy turnover rate suggests efficient inventory management.

- Laundry Cycle Time: Measuring the time it takes from the moment linen enters the laundry process to when it’s ready for distribution indicates efficiency of the laundry processes themselves.

- Staff Productivity: Measuring linen processed per staff hour helps evaluate staff efficiency and identify potential training needs.

- Cost Per Clean Linen Item: This KPI tracks the overall cost of processing a single linen item, encompassing labor, materials, and utilities. A lower cost per item indicates better cost control.

Regularly monitoring these KPIs allows for timely identification of areas needing improvement, ultimately leading to a more efficient and cost-effective linen operation.

Q 19. How do you handle customer complaints related to linen services?

Handling customer complaints related to linen services requires a calm, empathetic, and professional approach. My first step is to actively listen to the customer’s concern without interruption, acknowledging their frustration and validating their experience. This shows that I care and am taking their complaint seriously.

Next, I gather all relevant information, including dates, times, specific items, and the nature of the complaint. Then, I thoroughly investigate the situation, reviewing relevant records and consulting with staff involved. Once I have a clear understanding of what happened, I communicate my findings to the customer, explaining the situation in a straightforward manner. Even if the complaint is unfounded, I maintain a respectful and understanding tone.

Finally, I work with the customer to find a resolution, which may involve replacing damaged items, issuing a refund, or offering a discount on future services. In most situations, a sincere apology and a proactive approach to rectifying the issue are sufficient to resolve customer complaints. I also document all complaints and their resolutions to identify recurring issues and implement preventative measures.

Q 20. Describe your experience with linen recycling and sustainability initiatives.

Linen recycling and sustainability initiatives are crucial for minimizing environmental impact and reducing operational costs. My experience includes implementing several strategies to promote sustainability within linen management.

- Partnering with Eco-Friendly Laundries: Selecting laundry vendors committed to sustainable practices, such as water conservation, energy efficiency, and the use of eco-friendly detergents.

- Implementing Linen Recycling Programs: Partnering with textile recycling facilities to repurpose worn-out linens, diverting them from landfills and reducing waste.

- Investing in Durable, High-Quality Linens: Choosing linens made from sustainable materials and designed for longevity reduces the frequency of replacement, decreasing waste and resource consumption.

- Optimizing Laundry Processes: Implementing efficient laundry practices, such as optimizing wash cycles and reducing water and energy usage. This often involves upgrading to energy-efficient equipment.

- Promoting Reusable Items: Encouraging the use of reusable items, such as cloth napkins and towels instead of disposable options.

- Employee Training: Educating staff on sustainable practices, emphasizing responsible linen handling and waste reduction.

By implementing these strategies, we can significantly reduce our environmental footprint and achieve cost savings in the long run. Measuring the success of these initiatives involves tracking key metrics such as water and energy consumption, waste reduction, and the quantity of linens diverted from landfills.

Q 21. What is your understanding of different laundry methods and their impact on linen?

Understanding different laundry methods and their impact on linen is essential for maintaining quality and extending the lifespan of linens. Various methods exist, each with its own pros and cons.

- On-Premise Laundry: This involves having your own laundry facilities. It provides greater control over the process and quality but requires significant investment in equipment and staffing.

- Off-Premise Laundry (Commercial Laundry): Outsourcing to a commercial laundry saves on capital expenditure and staffing but reduces control over the process and might affect quality if not managed well.

- Different Wash Cycles: Various wash cycles (e.g., delicate, heavy-duty) are chosen based on the linen type and soiling level. Improper cycle selection can lead to premature wear and tear.

- Water Temperature and Detergents: Using appropriate water temperatures and eco-friendly detergents is important for hygiene and linen preservation. High temperatures can cause shrinkage and damage, while harsh detergents can degrade fabric fibers.

- Drying Methods: Different drying methods—high heat, low heat, air drying—affect shrinkage and fabric lifespan. Over-drying can damage fibers and reduce linen longevity.

Understanding these factors and choosing appropriate methods for each linen type is critical. It allows me to optimize the cleaning process while minimizing damage and maximizing the life of the linens, ultimately saving costs and ensuring customer satisfaction.

Q 22. How do you ensure the cleanliness and hygiene of the linen room itself?

Maintaining a clean and hygienic linen room is paramount to preventing contamination and ensuring the quality of the linen. Think of it like a sterile operating room for textiles; the environment itself impacts the final product.

- Regular Cleaning: Daily cleaning is essential. This includes sweeping or vacuuming the floor, wiping down surfaces (shelves, counters, equipment), and emptying trash receptacles. We use hospital-grade disinfectants to kill bacteria and viruses.

- Pest Control: Regular pest control inspections and treatments are vital. Pests can contaminate linen and compromise hygiene. We have a scheduled preventative pest control program.

- Ventilation: Proper ventilation is crucial to prevent mold and mildew growth, especially in humid climates. Our linen room has excellent ventilation and air conditioning.

- Organization: Maintaining an organized linen room prevents clutter and makes cleaning easier. We use color-coded shelving and clear labeling to easily locate and manage linen inventory.

- Staff Training: All staff are trained on proper hygiene protocols, including handwashing, the use of personal protective equipment (PPE) like gloves, and proper handling of soiled linen.

For example, in a previous role, we implemented a color-coded system for cleaning supplies, clearly distinguishing between disinfectants, detergents, and general cleaning agents. This reduced the risk of cross-contamination and improved efficiency.

Q 23. Explain your experience with different linen sorting and processing techniques.

Linen sorting and processing techniques are crucial for efficient and hygienic linen management. The methods used vary depending on the scale and type of facility, but the core principles remain the same: segregation, sorting, and processing.

- Segregation: Soiled linen is initially segregated based on type (e.g., towels, sheets, uniforms) and level of soiling (e.g., light, moderate, heavy). This helps optimize the washing process and prevents cross-contamination.

- Sorting: After segregation, linen undergoes detailed sorting by color and fabric type. This prevents color bleeding and ensures proper washing temperatures and cycles are utilized.

- Processing: This involves pre-treatment (stain removal, sorting), washing, drying, folding, and storage. We utilize advanced laundry equipment that includes stain removal technology and high-capacity washers and dryers to manage large volumes efficiently. We also regularly review our wash formulas and cycle times to adjust to the type and level of soiling.

In my experience, I’ve worked with both manual and automated sorting systems. In a smaller setting, manual sorting and identification were sufficient; however, in larger facilities, automated systems significantly improve efficiency and accuracy.

Q 24. How do you calculate the cost per use of a linen item?

Calculating the cost per use of a linen item involves factoring in all associated expenses over its lifespan. Think of it like calculating the cost per mile for a car, but with towels and sheets.

The formula is relatively straightforward: (Total Cost / Total Uses) = Cost Per Use

Total Cost includes:

- Initial purchase price of the linen

- Cost of laundry (detergents, water, electricity, labor)

- Cost of repairs and replacements

- Cost of storage

Total Uses is determined by the item’s estimated lifespan and frequency of use. We typically estimate the lifespan of a linen item based on its material and the washing frequency.

Example: A sheet costing $10 with an estimated lifespan of 200 uses and a laundry cost of $1 per wash would have a cost per use of: ($10 + ($1 x 200)) / 200 = $1.05

Regularly analyzing the cost per use helps in optimizing linen purchasing strategies, identifying areas for cost reduction, and making informed decisions about linen replacement schedules.

Q 25. How would you address a sudden increase in linen demand due to an unexpected event?

A sudden increase in linen demand, say due to a natural disaster or large-scale event, requires a rapid and flexible response. It’s about thinking strategically and leveraging all available resources.

- Assess the Demand: First, accurately determine the extent and duration of the increased demand. This is vital for planning.

- Inventory Check: Immediately assess existing inventory to identify available linen that can be deployed.

- External Sourcing: Explore the possibility of renting or borrowing additional linen from external suppliers. This is a quick solution for short-term needs.

- Prioritization: Prioritize the allocation of available linen to areas with the highest need. This might involve temporarily reducing linen changes in less critical areas.

- Staffing: If necessary, increase staffing levels in laundry and linen distribution to handle the increased workload. Overtime or temporary staff may be required.

- Communication: Maintain clear communication with all stakeholders (staff, management, clients) to keep everyone informed and manage expectations.

In a previous situation, we faced a sudden increase in demand during a major convention. By leveraging our existing relationships with linen suppliers and implementing a prioritized allocation plan, we successfully met the increased demand without compromising quality or service.

Q 26. What is your experience with preventative maintenance of laundry equipment?

Preventative maintenance of laundry equipment is crucial to minimize downtime, extend equipment lifespan, and ensure consistent performance. Think of it as regularly servicing your car – it’s far cheaper and more efficient than dealing with major breakdowns.

- Regular Inspections: Scheduled inspections of all equipment (washers, dryers, folders, etc.) to identify potential problems early on.

- Cleaning: Regular cleaning of equipment to remove lint, soap residue, and other debris. This prevents blockages and ensures optimal performance.

- Lubrication: Proper lubrication of moving parts to reduce friction and wear.

- Belt and Roller Checks: Regular checks and replacements of belts and rollers to prevent breakdowns.

- Calibration: Periodic calibration of temperature and other settings to ensure consistent and efficient operation.

- Record Keeping: Maintain detailed records of all maintenance activities, including dates, tasks performed, and any parts replaced.

We use a computerized maintenance management system (CMMS) to schedule and track all maintenance activities. This helps ensure that preventative maintenance tasks are completed on time and facilitates easy access to maintenance records.

Q 27. How do you ensure linen is properly identified and labeled?

Proper linen identification and labeling is vital for efficient tracking, inventory management, and preventing mix-ups. Think of it as the addressing system for your textiles.

- Barcoding or RFID Tagging: We use barcodes or RFID tags to digitally track linen items throughout their lifecycle. This enables precise inventory management and efficient tracking.

- Departmental Labels: Color-coded labels or printed labels indicating the department or area where the linen is used (e.g., operating room, patient rooms). This improves efficiency in distribution and collection.

- Size and Type Labels: Labels indicating the size and type of the linen item (e.g., queen sheet, bath towel). This improves efficient sorting and inventory control.

- Durability of Labels: Use durable and wash-resistant labels to ensure that identification is maintained throughout the linen’s lifespan.

- Label Placement: Labels are placed in a prominent and easily accessible location, without compromising the aesthetic quality of the linen.

In my previous role, we implemented an RFID system for high-value linen items, which dramatically improved accuracy in tracking and reduced linen loss.

Q 28. Describe your experience with implementing new linen management procedures.

Implementing new linen management procedures requires a structured approach to ensure a smooth transition and maximize effectiveness. It’s a project management exercise applied to textiles.

- Needs Assessment: Clearly define the goals and objectives of the new procedures. This ensures that the implementation aligns with strategic goals.

- Procedure Development: Develop clear, concise, and easy-to-understand procedures. Involve staff in the development process to ensure buy-in and smooth implementation.

- Training: Provide comprehensive training to all staff on the new procedures. This is crucial for successful adoption.

- Pilot Testing: Implement the new procedures on a small scale (pilot test) before full-scale deployment. This allows for identification and resolution of any potential issues early on.

- Monitoring and Evaluation: Monitor the effectiveness of the new procedures and make adjustments as needed. Regularly evaluate the impact on efficiency, cost, and quality.

- Communication: Maintain clear and consistent communication throughout the implementation process. Keep staff informed of progress and address any concerns.

In one instance, we implemented a new linen tracking system. By using a phased approach, starting with a pilot test in one department, we successfully identified and resolved minor glitches before a full-scale rollout. This minimized disruption and ensured a smooth transition.

Key Topics to Learn for Linen Management Interview

- Inventory Management: Understanding stock levels, tracking linen usage, and implementing efficient inventory control systems. Practical application: Analyzing data to predict linen needs and prevent shortages.

- Linen Processing and Handling: Familiarize yourself with the entire lifecycle of linen, from cleaning and sorting to storage and distribution. Practical application: Developing and optimizing workflows to ensure hygiene and efficiency.

- Quality Control and Maintenance: Implementing processes to ensure linen quality, identifying and addressing damage, and implementing preventative maintenance strategies. Practical application: Establishing quality standards and inspection procedures.

- Cost Control and Budgeting: Analyzing linen expenses, identifying cost-saving opportunities, and managing budgets effectively. Practical application: Negotiating contracts with suppliers and implementing resource-efficient practices.

- Technology and Software: Understanding the role of technology in linen management, including inventory management software and data analysis tools. Practical application: Implementing and utilizing technology to streamline operations and improve efficiency.

- Hygiene and Infection Control: Knowledge of sanitation procedures, relevant regulations, and best practices to ensure hygiene and prevent the spread of infection. Practical application: Implementing and maintaining a robust hygiene program.

- Team Management and Communication: Effective leadership, delegation, and communication skills to manage a team effectively. Practical application: Motivating staff and ensuring smooth workflow within the linen department.

- Compliance and Regulations: Understanding relevant health and safety regulations and industry standards. Practical application: Ensuring compliance with all relevant regulations and best practices.

Next Steps

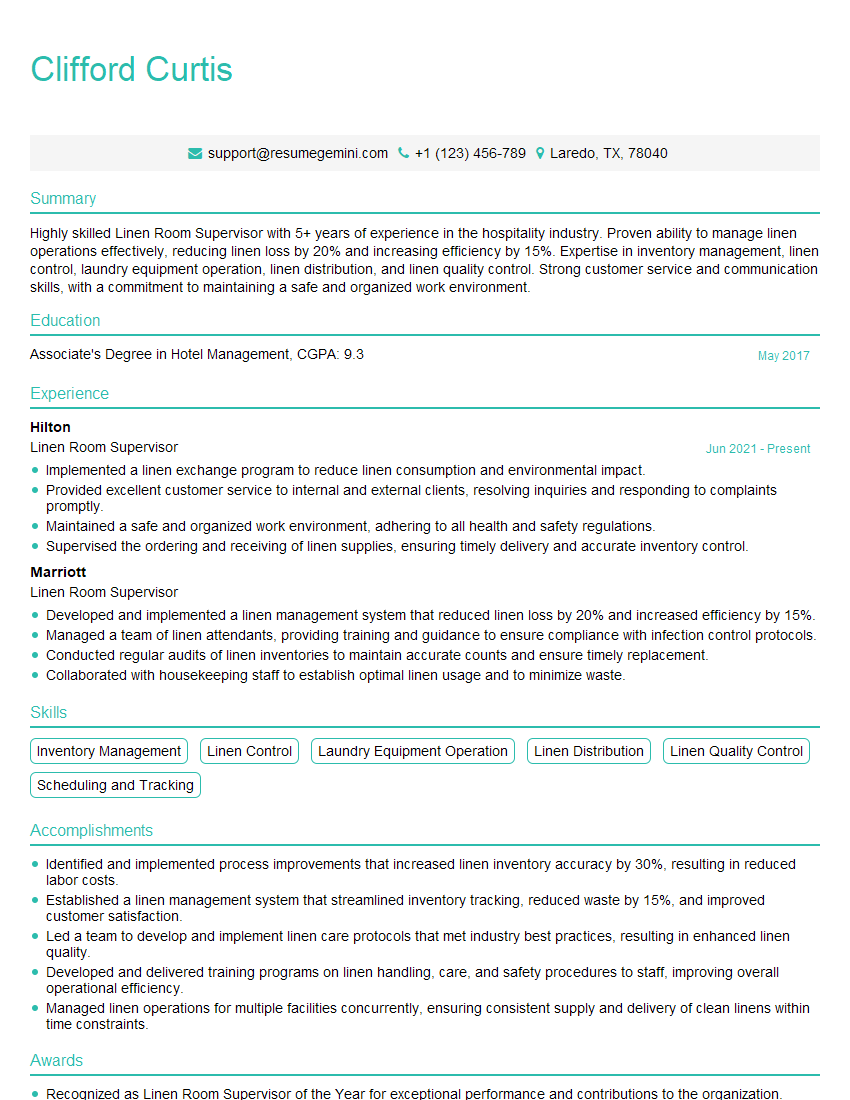

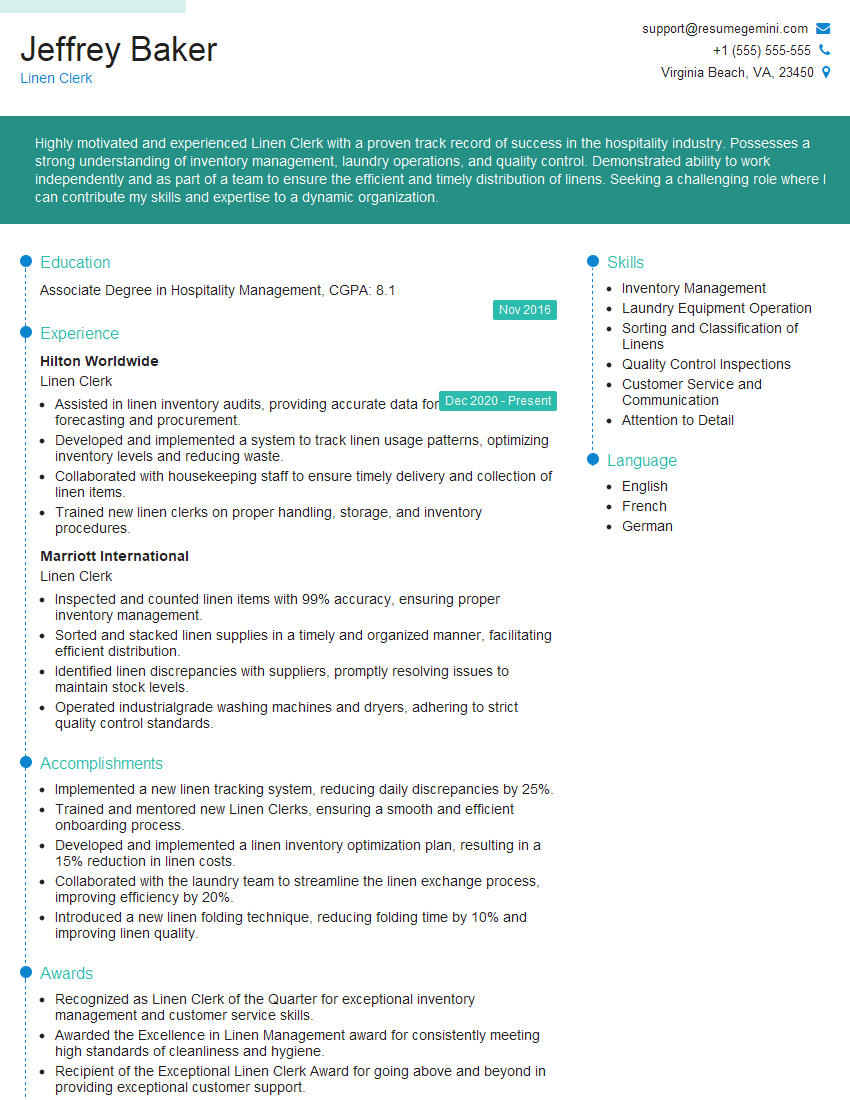

Mastering linen management opens doors to exciting career opportunities within the hospitality, healthcare, and industrial sectors. A strong understanding of these concepts is crucial for advancement and demonstrates your value to potential employers. To significantly increase your chances of landing your dream role, focus on crafting a compelling, ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored specifically to Linen Management are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO