The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Drafting and Design interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Drafting and Design Interview

Q 1. Explain your experience with various CAD software (AutoCAD, Revit, MicroStation, etc.).

My CAD software experience is extensive, encompassing a range of industry-standard programs. I’m highly proficient in AutoCAD, using it daily for 2D drafting, detailing, and creating precise drawings for construction projects. My experience includes creating everything from site plans to detailed shop drawings. I’m also adept at Revit, which I utilize for building information modeling (BIM). This involves creating 3D models and extracting 2D drawings from them, allowing for better coordination and clash detection among disciplines. My Revit skills include family creation, parameter management, and sheet creation and management. Finally, I have experience with MicroStation, primarily for large-scale infrastructure projects where its handling of large datasets and precise geospatial data is invaluable. I’ve used it for road design, surveying data integration, and creating detailed plans for utility infrastructure. Each software has its strengths, and I choose the most appropriate tool based on project requirements.

For example, on a recent commercial building project, I used Revit to model the entire structure, allowing me to identify and resolve potential clashes between MEP (Mechanical, Electrical, Plumbing) systems and structural elements before construction began, saving significant time and cost.

Q 2. Describe your proficiency in 2D and 3D drafting.

My proficiency in both 2D and 3D drafting is a cornerstone of my skillset. 2D drafting forms the foundation of my work, encompassing the creation of precise plans, sections, elevations, and details. I’m highly skilled in using various drafting techniques and tools to produce clear, concise, and accurate drawings suitable for construction. My 3D modeling skills complement my 2D abilities, allowing me to create realistic representations of projects, facilitating better visualization and communication among stakeholders. This helps to identify potential design flaws or construction challenges early in the process.

For instance, I recently utilized 3D modeling to create a walkthrough for a client for a complex residential renovation. This allowed them to fully grasp the design before any construction began and led to more informed decisions about finishes and layout.

Q 3. How do you ensure accuracy and precision in your drawings?

Accuracy and precision are paramount in drafting and design. I employ several methods to ensure the highest level of accuracy in my drawings. These include utilizing model-based workflows whenever possible, leveraging the built-in constraints and features of CAD software, employing dimensional referencing, and meticulously checking my work using various tools and techniques. I always verify dimensions against project specifications and architectural plans and utilize layers effectively to maintain organization and prevent accidental modifications to essential elements.

One strategy I often use is to perform several independent checks on critical dimensions, comparing them to calculations and on-site measurements where feasible. I also frequently use external reference drawings and models to ensure consistency and accuracy.

Q 4. What are your preferred methods for creating detailed drawings?

My preferred methods for creating detailed drawings revolve around a structured approach incorporating best practices. I start with a clear understanding of the project requirements and design intent. I then begin with a preliminary sketch or conceptual model to refine design ideas and then move to a detailed digital model using appropriate CAD software. I utilize layers efficiently to manage the complexity of the drawings, focusing on clear annotation and labeling to ensure every component is clearly identified and detailed. I always follow a standardized template, ensuring all drawings comply with industry best practices and company standards.

For example, when creating shop drawings for custom millwork, I will create detailed sections and elevations, including dimensions, materials, finishes, and assembly instructions. This ensures the fabrication process is smooth and error-free.

Q 5. Explain your understanding of different drawing scales and units.

Understanding different drawing scales and units is crucial for creating accurate and easily interpretable drawings. Scales are crucial for representing large projects within a manageable drawing size. Common scales include 1:100, 1:50, and 1:20, reducing real-world dimensions proportionally. Units are equally important; whether working in millimeters, inches, or feet, consistency is paramount to prevent errors. I’m proficient in converting between different unit systems and employing the appropriate scale for each drawing element to maintain accuracy and clarity. Mismatched units or incorrect scales can lead to significant construction errors, so meticulous attention to this aspect of drafting is a top priority.

For example, while working on a large-scale site plan, I’d use a scale of 1:500 to show the overall site layout, then use a larger scale of 1:100 for detailed building plans. I always ensure my units match the project specifications and communicate clearly on the drawing what the scale represents and the units being used.

Q 6. Describe your experience with creating construction documents.

I have significant experience in creating construction documents, which includes preparing a comprehensive set of drawings and specifications that guide the construction process. This involves preparing various types of drawings, including site plans, floor plans, sections, elevations, details, schedules, and specifications. My work encompasses all phases of a project, from schematic design to construction completion. I’m familiar with the latest building codes and standards, ensuring that the documents accurately reflect the design and meet regulatory requirements. I’ve worked on projects of various scales and complexities, from small residential renovations to large commercial developments.

On a recent project, I coordinated with structural, mechanical, electrical, and plumbing engineers to integrate their drawings into a comprehensive set of construction documents that enabled seamless construction. Careful coordination ensures a smoothly-running construction process.

Q 7. How do you manage revisions and updates to drawings?

Managing revisions and updates to drawings effectively is critical to maintain accuracy and prevent confusion throughout the project lifecycle. I utilize version control within CAD software, utilizing revision clouds to highlight changes and maintaining a detailed revision history log. All changes are clearly documented and communicated to the relevant stakeholders. This typically includes numbered revisions, date stamps, and descriptions of the modifications. For larger projects, I might use a dedicated document management system that tracks every change and ensures that everyone is working with the most up-to-date drawings. The use of cloud-based collaborative tools also helps in streamlining communication among team members and ensuring a centralized repository for the most current versions.

For example, during a recent renovation project, I used Revit’s version control to manage revisions effectively, notifying all relevant stakeholders promptly whenever changes were made. This prevented confusion and ensured everyone was working with the latest versions of the drawings.

Q 8. How do you collaborate with other team members on design projects?

Collaboration is the cornerstone of successful design projects. I leverage various methods depending on the project and team dynamics. For instance, we frequently use cloud-based platforms like BIM 360 or similar tools for centralized model access and version control. This ensures everyone works on the latest iteration and reduces the risk of conflicts. We also utilize regular team meetings – both in-person and virtual – for brainstorming, design reviews, and issue resolution. During these meetings, we utilize visual aids like screen sharing and annotated drawings to facilitate clear communication. I also believe strongly in open communication and proactively seek feedback from colleagues, valuing their expertise and perspectives to ensure the best possible outcome. For example, on a recent school renovation project, daily check-ins with the structural and MEP (Mechanical, Electrical, Plumbing) engineers ensured that our architectural designs were compatible and efficiently integrated within the existing building envelope.

Q 9. Describe your experience with BIM (Building Information Modeling).

My experience with BIM is extensive. I’ve been proficient in Revit for over eight years, using it to model complex buildings from initial conceptual design through to construction documentation. I’m not only skilled in creating 3D models but also in leveraging BIM’s capabilities for quantity take-offs, clash detection, and energy analysis. For example, on a recent high-rise residential project, BIM enabled us to identify and resolve clashes between the HVAC system and structural elements during the design phase, preventing costly rework during construction. The collaborative features of BIM were crucial in coordinating with the various consultants involved. Further, I have experience utilizing Navisworks for model review and coordination, ensuring seamless integration of all building systems. My understanding goes beyond software proficiency; I comprehend the underlying principles of BIM and its role in improving efficiency and reducing errors throughout the project lifecycle.

Q 10. Explain your understanding of different drafting standards and codes.

Understanding drafting standards and codes is fundamental to producing compliant and constructible drawings. I’m familiar with various standards, including those published by ANSI (American National Standards Institute), AIA (American Institute of Architects), and local building codes. This knowledge extends to understanding different drawing scales, line weights, annotation conventions, and sheet organization. For example, I understand the importance of adhering to specific requirements for dimensioning, section details, and material specifications to ensure clarity and minimize ambiguity. My experience working on projects across different jurisdictions necessitates adapting to varying local codes, including accessibility regulations (ADA), fire codes, and seismic requirements. This adaptability requires meticulous attention to detail and consistent referencing of the appropriate codes and standards throughout the design process.

Q 11. How do you handle conflicting design requirements?

Conflicting design requirements are inevitable in complex projects. My approach involves a systematic process. First, I clearly document all requirements, highlighting the areas of conflict. Then, I collaborate with the relevant stakeholders (architects, engineers, clients) to understand the priorities and constraints associated with each requirement. This often involves a series of meetings and discussions to identify potential compromises or alternative solutions. We prioritize requirements based on their impact on the overall project goals, budget, and schedule. For example, on a recent project, a conflict arose between the client’s desire for a specific material and the structural engineer’s concerns about its load-bearing capacity. We explored alternative materials and structural solutions to meet both the aesthetic and structural requirements. Successful conflict resolution often requires clear communication, compromise, and a collaborative spirit.

Q 12. Describe your experience with creating detailed sections and elevations.

Creating detailed sections and elevations is a crucial aspect of my work, ensuring accuracy and clarity for construction. My approach involves using precise measurements and detailed annotations to clearly illustrate the construction methodology, material specifications, and relationships between building components. I often utilize callouts and details to highlight specific features or construction techniques that require further clarification. For example, when detailing a complex roof assembly, I would create multiple sections at different scales to show the layers of insulation, waterproofing, and structural framing. This meticulous approach minimizes the possibility of misinterpretations and ensures a smooth construction process. I’m proficient in generating these drawings using various CAD software, ensuring professional presentation and easy understanding by contractors and other stakeholders.

Q 13. How do you ensure your drawings are compliant with building codes?

Ensuring drawing compliance with building codes is a paramount concern. I employ a multi-faceted approach. First, I carefully review the applicable building codes and standards relevant to the project’s location and type. Throughout the design process, I regularly check the drawings against these codes, ensuring all aspects—from structural elements to egress paths and accessibility features—conform to the requirements. This often involves collaborating with structural, mechanical, electrical, and plumbing engineers to ensure that the designs are coordinated and compliant. Secondly, I incorporate code references into the drawings themselves, annotating key details and specifications where relevant. Finally, I participate in design reviews with other team members and with building officials to address any potential code violations early in the design process. This proactive approach greatly reduces the risk of delays and rework during construction.

Q 14. What are some common challenges you face in drafting, and how do you overcome them?

Common challenges in drafting include managing large datasets, resolving conflicts between different design disciplines, and ensuring consistent drawing standards across a large team. To overcome these challenges, I leverage BIM software’s collaborative features and efficient data management tools. For example, using Revit’s worksharing capabilities ensures a collaborative workflow where multiple team members can work concurrently on the same model without data loss. For large datasets, I implement a structured file management system and regularly back up all project files. To ensure consistent drawing standards, we create and adhere to in-house templates and style guides. Additionally, I regularly attend professional development courses to stay abreast of the latest software advancements and design methodologies. Finally, clear communication and proactive problem-solving are crucial in effectively navigating any challenges that arise.

Q 15. Describe your experience working with different material specifications.

My experience spans a wide range of material specifications, from common construction materials like steel, concrete, and wood to more specialized materials such as composites and advanced alloys. Understanding material properties is crucial for successful drafting and design. For instance, when designing a steel structure, I consider factors like yield strength, tensile strength, and weldability to ensure structural integrity and safety. Similarly, for a concrete structure, I account for compressive strength, slump, and durability requirements. I’m proficient in interpreting material datasheets and specifications, ensuring that the chosen materials meet project requirements and building codes. In one project, I had to specify high-strength, corrosion-resistant steel for a coastal bridge, requiring meticulous research to ensure longevity and withstand harsh environmental conditions. This involved a deep dive into material selection based on the client’s budget and the project’s life-cycle considerations.

I often utilize material libraries within CAD software to streamline the process of specifying materials and accessing their properties. This ensures consistency and accuracy throughout the project. The selection process often involves balancing factors like cost, performance, availability, and sustainability.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your understanding of design principles and best practices.

My understanding of design principles centers around several key concepts: functionality, aesthetics, ergonomics, and sustainability. Functionality ensures the design meets its intended purpose efficiently and effectively. Aesthetics involve creating a visually appealing and harmonious design. Ergonomics focuses on user comfort and ease of use. Sustainability incorporates environmentally friendly practices and materials. Best practices include thorough research, adherence to building codes and standards, and effective communication with clients and stakeholders.

For example, when designing a building, I consider factors like natural light, ventilation, and accessibility to ensure a comfortable and functional space. I use principles of proportion, balance, and rhythm to create a visually appealing design. I also ensure that the building’s construction is environmentally friendly, using sustainable materials and energy-efficient systems.

Iterative design processes and incorporating feedback are crucial. I often create multiple design iterations, refining each based on feedback and analysis before finalizing the design. This ensures the final product effectively addresses all stakeholder concerns and industry best practices.

Q 17. How do you stay up-to-date with the latest drafting and design technologies?

Staying current in drafting and design technologies is vital. I achieve this through several methods:

- Industry Publications and Conferences: I regularly read industry publications, such as magazines and online journals, and attend industry conferences to stay abreast of the latest trends and advancements.

- Online Courses and Webinars: Numerous online platforms offer courses and webinars covering new CAD software features and design techniques. I actively participate in these to enhance my skills.

- Professional Networking: Networking with colleagues through professional organizations allows for the sharing of knowledge and experience in new technologies.

- Software Updates and Training: I consistently update my CAD software and participate in vendor-provided training to master new features and functionalities.

For instance, I recently completed a course on Building Information Modeling (BIM), which has significantly improved my ability to create and manage complex building projects. Keeping up-to-date with these technologies improves efficiency, accuracy and facilitates collaboration within project teams. It’s a continuous learning process that is key to remaining competitive and delivering high-quality designs.

Q 18. Describe your experience with creating presentation drawings.

Creating presentation drawings is a key part of my role. These drawings need to be clear, concise, and visually appealing to effectively communicate the design to clients and stakeholders. I focus on using high-quality visuals, clear annotations, and a consistent design style to ensure professionalism and ease of understanding. I use various techniques to enhance the visual appeal, including appropriate use of color, shading, and perspective views. For example, I’ll use 3D renderings to provide a more realistic representation of the final product. I pay attention to the layout and organization of the drawings, making sure that the information is presented logically and clearly. My goal is to create drawings that are not only technically accurate but also persuasive and engaging, helping clients visualize the final outcome.

Different projects require different levels of detail. For initial client presentations, I might focus on general layout and key features, while for final approvals, I’ll provide detailed drawings including specifications and material information. I always tailor the presentation to the specific audience and their needs.

Q 19. How do you handle complex design details?

Handling complex design details requires a methodical and organized approach. I break down the design into smaller, manageable components, focusing on each element individually before integrating them into the overall design. This includes using detailed section views, enlarged details, and 3D modeling to clarify intricate aspects. I leverage the power of parametric modeling in CAD to ensure that changes in one area of the design automatically update related components, preventing errors and inconsistencies. I meticulously check for clashes and interferences between different components using clash detection tools, ensuring the design is feasible and buildable. Effective communication with the engineering team is critical for resolving any conflicts or uncertainties. I often create detailed schedules and spreadsheets to manage information and track the progress of complex details. This structured method minimizes errors and ensures that all components work seamlessly together.

A recent example involved designing a complex intersection of structural elements in a high-rise building. By breaking it down into smaller sections and using 3D modeling with clash detection, we were able to identify and resolve potential issues early in the design process, avoiding costly changes later on.

Q 20. Explain your understanding of different types of drawing formats (PDF, DWG, etc.).

Understanding different drawing formats is essential for effective collaboration and data exchange within the drafting and design process. Common formats include:

- DWG (Drawing): The native file format for AutoCAD and other CAD software. It allows for full editing and modification of the drawing.

- PDF (Portable Document Format): A universal format for sharing drawings, ensuring compatibility across different software and platforms. It is primarily used for viewing and printing; direct editing is limited.

- DXF (Drawing Exchange Format): A neutral file format allowing for data transfer between different CAD software applications.

- DWF (Design Web Format): A format optimized for viewing and collaboration online.

The choice of format depends on the intended purpose. DWG is ideal for active design work, while PDF is preferred for sharing finalized drawings with clients or contractors. I ensure that all drawings are saved in appropriate formats to maintain consistency and facilitate collaboration throughout the project lifecycle. Understanding the limitations and capabilities of each format is vital for error-free project delivery.

Q 21. How do you utilize layers and blocks effectively in CAD?

Effective use of layers and blocks significantly enhances efficiency and organization in CAD. Layers allow for the separation of different aspects of a drawing, such as structural elements, MEP systems, and architectural details. This enables selective display and editing of specific elements, preventing confusion and improving design clarity. For example, I’ll use separate layers for walls, doors, windows, and electrical systems. This is also useful for controlling the visual appearance of the drawing by setting layer properties such as color, linetype, and lineweight.

Blocks are reusable components that can be inserted into a drawing multiple times. They help standardize design elements, minimizing repetitive tasks and ensuring consistency. For instance, I’ll create blocks for standard doors, windows, and fixtures. This not only saves time but also guarantees consistency in design. Using attributes within blocks allows me to easily modify parameters of the block instance without needing to modify the block definition itself, increasing flexibility and simplifying design modifications.

Proper management of layers and blocks is crucial for maintaining a clean, well-organized drawing that’s easy to navigate and modify. A well-structured drawing with effective layer and block management simplifies the design process, enhances collaboration, and reduces the risk of errors.

Q 22. Describe your experience with creating and managing drawing templates.

Creating and managing drawing templates is fundamental to ensuring consistency and efficiency in any drafting and design project. A well-crafted template establishes a standard format for all drawings, including title blocks, layer organization, text styles, and annotation settings. This not only streamlines the design process but also minimizes errors and facilitates collaboration.

My experience encompasses developing templates for various CAD software, including AutoCAD, Revit, and MicroStation. For instance, when working on a large-scale residential development, I developed a Revit template that incorporated pre-defined families for doors, windows, and structural elements. This allowed the team to quickly populate models with accurate components, reducing manual input and ensuring consistency across all building designs. Another example is creating a template for AutoCAD including pre-set line types, text styles, and layers for architectural, structural, and MEP drawings. This significantly speeds up the drawing creation process and ensures uniform presentation. I regularly review and update templates to incorporate new standards, improving efficiency and accuracy. The management aspect includes version control, ensuring everyone is using the latest template and training team members on its proper usage.

Q 23. How do you troubleshoot technical issues in CAD software?

Troubleshooting technical issues in CAD software requires a systematic approach. My strategy involves first identifying the nature of the problem. Is it a software crash, a file corruption issue, a rendering error, or a problem with specific functionalities? I start by checking the simplest solutions first: ensuring the software is updated to the latest version, checking system resources (memory and disk space), and restarting the computer.

If the problem persists, I delve into more specific troubleshooting steps. For instance, if a file is corrupted, I might try opening it in a previous version of the software, or using file recovery tools. If a specific command or function isn’t working correctly, I consult the software’s help documentation, online forums, or the software vendor’s support channels. I also utilize the software’s diagnostic tools to identify underlying issues. For example, in Revit, I frequently use the ‘Diagnostic Utility’ to identify and address performance bottlenecks. Documenting these issues and solutions is crucial for future reference and for collaboration with the team. A methodical approach, combined with resourcefulness and access to relevant support channels, is key to efficient problem-solving in CAD.

Q 24. Explain your understanding of dimensioning and annotation techniques.

Dimensioning and annotation are crucial for conveying design intent accurately and unambiguously. It involves precisely indicating the size, location, and other characteristics of design elements. My understanding encompasses various dimensioning standards, including ANSI, ISO, and architectural standards. I’m proficient in creating different types of dimensions, including linear, angular, radial, and ordinate dimensions, using appropriate dimension styles to maintain consistency and clarity.

Beyond basic dimensions, I’m skilled in employing advanced annotation techniques, such as using leader lines to call out specific details, creating detailed sections and elevations, and using tags and symbols to identify materials and construction methods. For example, specifying material types (e.g., ‘Concrete – 3000 psi’) directly on the drawings through annotations is critical. Maintaining uniformity, including using consistent text styles, arrowheads, and dimensioning practices, ensures that drawings are easy to understand and interpret. I also use callouts and detailed views to clarify complex design features and avoid potential ambiguities.

Q 25. Describe your experience with creating shop drawings.

Creating shop drawings is a critical aspect of my work, bridging the gap between design and fabrication. These detailed drawings provide contractors with the precise information needed to construct components or assemblies accurately. My experience involves producing shop drawings for various disciplines, including structural steel, mechanical, electrical, and plumbing (MEP) systems, and architectural components.

The process typically involves extracting relevant data from the design model, creating detailed sections and elevations, and annotating dimensions, tolerances, and material specifications. I carefully review the shop drawings for accuracy and completeness, often coordinating with fabricators or contractors to address any questions or discrepancies. A real-world example is creating shop drawings for custom metal fabrication. This involved detailed dimensions, material specifications, and finish requirements. Clear communication and attention to detail are crucial in this phase to avoid costly errors during construction.

Q 26. How do you interpret and apply design specifications?

Interpreting and applying design specifications requires a thorough understanding of various design documents, including architectural plans, structural drawings, engineering specifications, and client requirements. I begin by reviewing all relevant documents to fully grasp the project’s scope and objectives. This includes understanding codes, regulations, and industry standards applicable to the project.

Next, I systematically extract relevant information, paying close attention to details like material specifications, tolerances, and construction methods. For instance, if the specifications call for a specific type of concrete, I ensure the model and drawings accurately reflect that requirement, paying particular attention to the concrete’s compressive strength and slump requirements. Any ambiguities or conflicts in the specifications are addressed through collaboration with the design team and client to ensure a common understanding. Applying these specifications involves incorporating them into the design, ensuring every aspect of the design adheres to the given parameters. This detailed approach minimizes misunderstandings and errors, leading to a more efficient and successful project.

Q 27. How do you handle design changes during a project?

Handling design changes efficiently and effectively is critical for successful project completion. My approach involves a structured process that begins with documenting the change request clearly, including its rationale and impact on other aspects of the design. This involves a thorough impact assessment, determining the extent of the changes needed in the drawings and models.

Next, I implement the changes using the appropriate CAD software, ensuring consistency with existing design elements and standards. I then update the affected drawings and models, meticulously tracking all revisions using a version control system. For instance, using revision clouds in CAD to highlight modified areas, along with revision logs, is vital for clarity. Finally, I communicate the changes to relevant stakeholders, providing updated drawings and documenting the modifications in the project records. This organized approach minimizes confusion and ensures all parties are informed of the latest design iteration, preventing costly errors and misunderstandings.

Q 28. Explain your experience with quantity takeoffs.

Quantity takeoffs are crucial for accurate cost estimation and material procurement. My experience includes performing quantity takeoffs from both 2D drawings and 3D models, using various methods including manual takeoff, utilizing takeoff software, and leveraging the capabilities of BIM software. For example, Revit allows for automated quantity takeoffs for elements such as concrete, steel, and lumber.

The process starts with a thorough review of the drawings and specifications to identify all required quantities of materials and labor. This is followed by the actual takeoff, carefully measuring dimensions and calculating quantities. In a typical project, I might perform takeoffs for different building components, such as concrete foundations, framing members, roofing materials, and finishes. Accurate takeoffs are essential for accurate cost estimates and efficient procurement of materials, directly impacting the project’s budget and schedule. The results are meticulously documented, cross-checked for accuracy, and often presented in tabular form for easy understanding and review by the project team.

Key Topics to Learn for Drafting and Design Interview

- CAD Software Proficiency: Mastering industry-standard software like AutoCAD, Revit, SolidWorks, or similar is crucial. Focus on demonstrating your skills in 2D and 3D modeling, drafting techniques, and annotation.

- Blueprint Reading and Interpretation: Practice interpreting complex blueprints, understanding symbols, dimensions, specifications, and tolerances. Be prepared to explain your approach to deciphering technical drawings.

- Design Principles and Standards: Familiarize yourself with relevant design standards, codes, and best practices. Understand concepts like scale, proportion, and spatial relationships.

- Material Selection and Properties: Demonstrate knowledge of various materials used in design projects, their properties (strength, durability, cost), and suitability for different applications. Be prepared to discuss material selection criteria.

- Construction Methods and Processes: Develop a foundational understanding of construction techniques and their impact on design decisions. This includes aspects like structural integrity, building codes, and safety regulations.

- Problem-Solving and Design Thinking: Showcase your ability to approach design challenges systematically. Practice articulating your design process, including problem definition, ideation, and solution implementation.

- Collaboration and Communication: Highlight your ability to work effectively in teams, communicate technical information clearly, and contribute to a positive collaborative environment.

- Project Management Fundamentals: Demonstrate understanding of project timelines, resource allocation, and the ability to manage your time efficiently to meet deadlines.

Next Steps

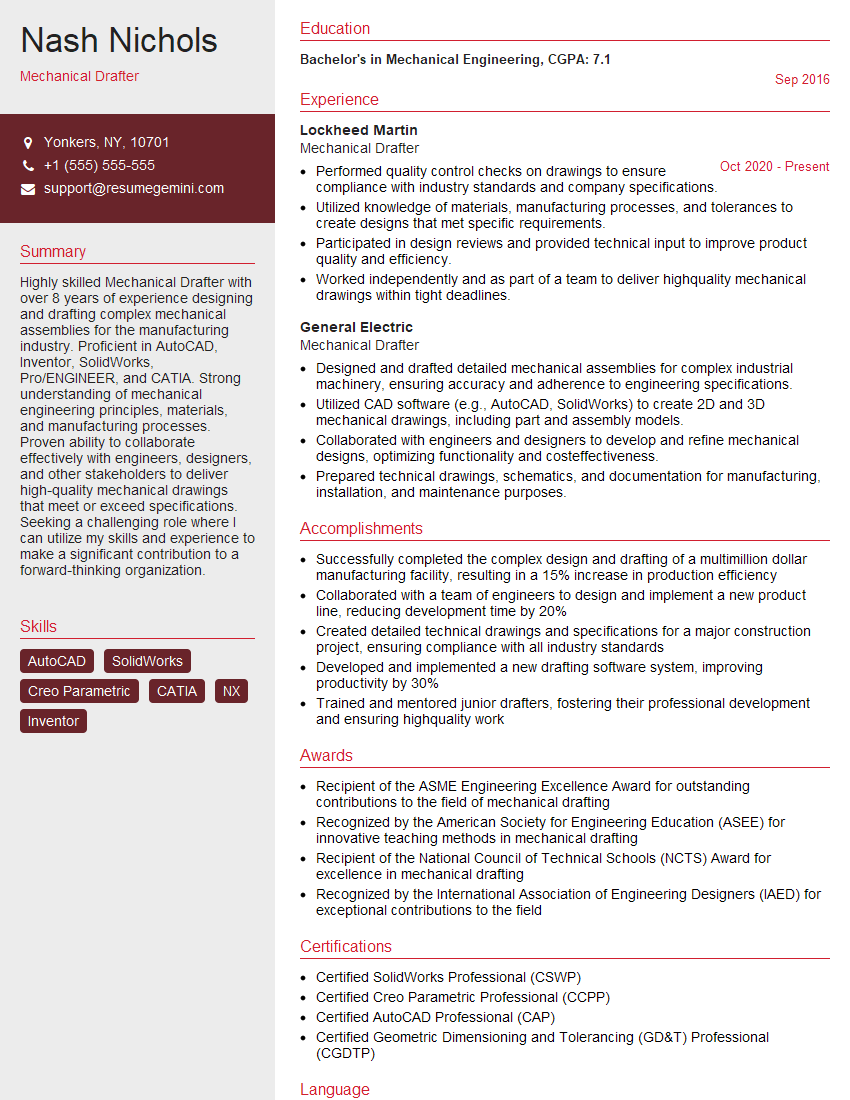

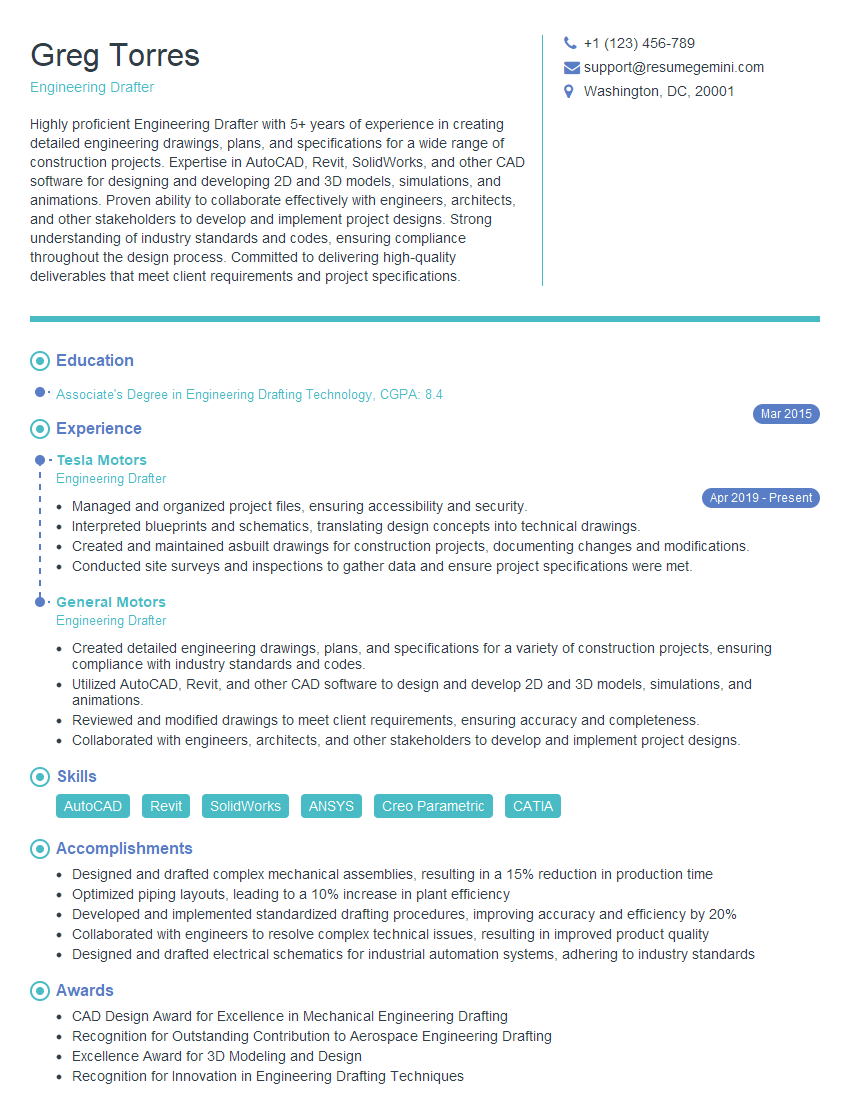

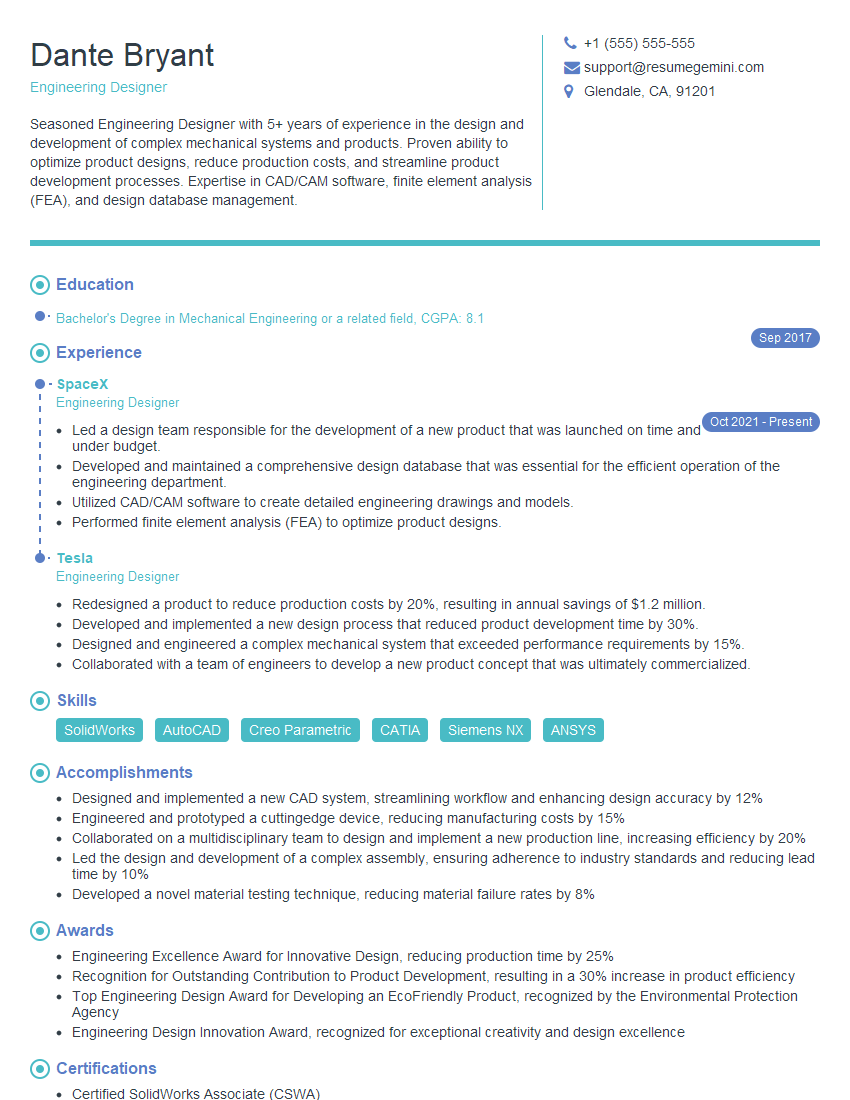

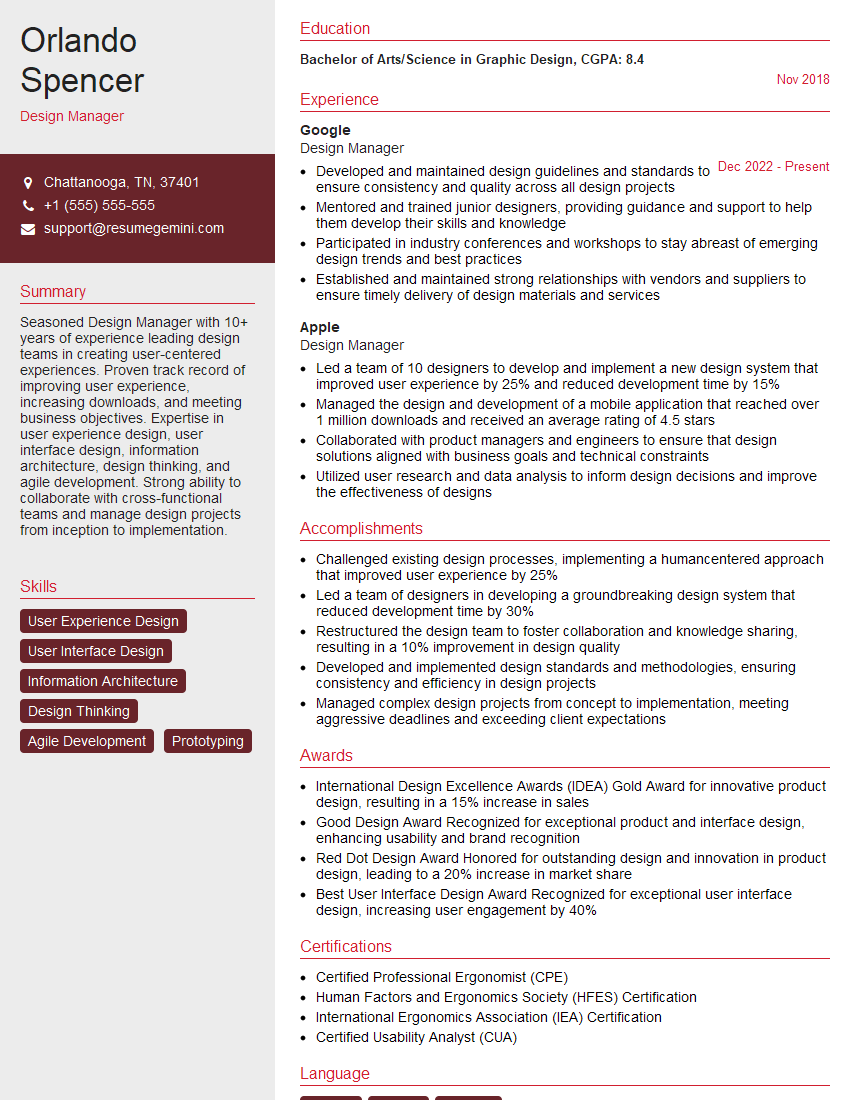

Mastering Drafting and Design opens doors to exciting and rewarding careers in architecture, engineering, construction, and manufacturing. To maximize your job prospects, it’s essential to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your abilities. Examples of resumes tailored to Drafting and Design are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO