Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Conduct inspections of rail cars and couplers interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Conduct inspections of rail cars and couplers Interview

Q 1. Describe the different types of railcar couplers and their functionalities.

Railcar couplers are the crucial connection points between railcars, enabling the formation of trains. There are primarily two main types: the Janney coupler (most common in North America) and the Scharfenberg coupler (more prevalent in Europe and other parts of the world).

- Janney Coupler: This is a knuckle-type coupler, characterized by its distinctive knuckle and locking mechanism. It’s designed for automatic coupling and uncoupling, making it efficient and relatively safe. Think of it like a strong, mechanical handshaking mechanism. The knuckle’s movement allows for some flexibility in aligning the cars, even if they’re not perfectly positioned.

- Scharfenberg Coupler: This is a more complex, automatic coupler system featuring a central buffer and a rotating mechanism to create the connection. It provides a stronger and more robust connection than the Janney coupler, often incorporating pneumatic and electrical connections alongside the mechanical coupling. It’s like a sophisticated, multi-function connector that handles both physical connection and transfer of resources.

Both types have variations in design and strength ratings depending on the type of cargo and the operating conditions.

Q 2. Explain the visual inspection procedures for railcar wheels and axles.

Visual inspection of railcar wheels and axles is paramount for safety. It involves a thorough examination for various forms of damage and wear. I typically follow a checklist which includes:

- Wheel condition: Checking for cracks, flats, shelling (loss of surface material), flange wear (the wheel’s inner edge), and damage caused by collisions or derailments. I look for anything that departs from the smooth, round profile of the wheel. A visible flat spot, for instance, can significantly affect ride stability and safety.

- Axle condition: This involves checking for cracks, fractures, bends, corrosion, or any signs of excessive wear. Since the axle bears the weight of the entire car, even small cracks can be extremely dangerous. I pay close attention to the axle journals (the cylindrical portions that rotate within the bearings).

- Bearing condition: Observing for overheating, leaks, or any signs of impending failure. Overheated bearings are often indicated by discoloration or even burning. This is a critical observation since bearing failure can lead to catastrophic derailment.

I use a flashlight, often with a magnifying lens, to closely inspect hard-to-see areas, and any issues are always thoroughly documented and reported using standardized forms. A digital camera is useful for recording any noteworthy defects.

Q 3. How do you identify and report damaged or worn-out couplers?

Damaged or worn-out couplers are identified through both visual inspection and sometimes gauge measurements. Look for:

- Broken or cracked parts: This includes fractures in the knuckle, locking pin, or other coupler components. Even small cracks can compromise the integrity of the connection.

- Excessive wear: This often manifests as significant wear on the striking faces, where the couplers meet, or excessive play in the locking mechanism.

- Bent or deformed parts: This indicates a significant impact that could have affected the coupler’s structural integrity. A bent coupler won’t provide a secure connection.

- Missing or damaged components: Any missing pins, cotters, or other parts signal a critical failure that needs immediate repair.

Reporting involves detailed documentation including photographs, and exact location and type of damage. A standardized report is crucial, noting the severity of the issue so that appropriate actions are taken – removal from service and repair, or even replacement.

Q 4. What are the key safety regulations related to railcar inspections?

Railcar inspection safety regulations are stringent and vary slightly by country and regulatory body but generally center around ensuring the safe operation of trains and the prevention of accidents. Key areas include:

- Compliance with industry standards: Adherence to standards set by organizations like the Association of American Railroads (AAR) in North America or similar bodies in other regions. These standards dictate the frequency and thoroughness of inspections.

- Qualified personnel: Inspections must be conducted by trained and certified personnel who possess the knowledge and skills to identify potential hazards. Certification ensures proper competency.

- Documentation: Meticulous record-keeping is essential for tracking maintenance, repairs, and any identified defects. Documentation helps in preventing future incidents and aids investigation if something does go wrong.

- Immediate reporting: Any safety-critical defects or failures must be reported immediately to the appropriate authorities. This often involves a chain of reporting up through supervisors and maintenance departments.

- Personal Protective Equipment (PPE): Inspectors must always use appropriate PPE, including safety glasses, gloves, and high-visibility clothing.

Failure to adhere to these regulations can result in significant penalties, ranging from fines to operational shutdowns, and in extreme cases, criminal charges depending on the circumstances and potential impact.

Q 5. Explain the process of inspecting air brakes on railcars.

Inspecting air brakes on railcars involves a systematic approach to ensure the safe and reliable operation of this critical safety system. It includes:

- Visual inspection: Check air hoses for damage, leaks, and proper connections. Examine the brake cylinders, reservoirs, and related components for any signs of leakage, corrosion, or damage. I pay close attention to any fittings for signs of leakage or corrosion.

- Pressure test: Using appropriate gauges, I verify the air pressure within the system, ensuring it’s within the specified operational range. This is a critical check to make sure the braking system will function properly.

- Brake pipe testing: Checking the integrity of the brake pipe, the main line that carries compressed air throughout the train. This involves testing the ability to charge and maintain the pressure within the system.

- Operational testing: By using the train’s brake system, I conduct an operational test to ensure that all brakes respond correctly to the application and release of air pressure. This validates that the system functions as intended.

Documentation is key throughout this process, noting any observed discrepancies or repairs needed. All steps must be carefully documented for both safety and regulatory compliance.

Q 6. How do you check for leaks in the railcar’s air brake system?

Checking for leaks in the railcar’s air brake system is a vital part of the inspection process. Leaks can significantly impair braking performance and create safety hazards. I use several methods:

- Visual inspection: I carefully examine all connections, hoses, valves, and cylinders for any signs of leaking air. I look for bubbles in standing water or moisture around fittings which indicates air leakage.

- Listening for leaks: A trained ear can often detect escaping compressed air, especially around valves or fittings under pressure. A hissing sound is a clear indicator.

- Soap solution test: Applying a soapy water solution to connections and joints creates visible bubbles if a leak is present, making smaller leaks easier to locate. This is a very effective way to detect even minor leaks that might be otherwise difficult to find.

- Pressure gauge monitoring: Observing the air pressure gauge over time while the system is charged can indicate a slow leak if the pressure slowly decreases.

If leaks are found, their locations and severity are carefully documented for prompt repair. Even seemingly minor leaks can escalate into serious problems over time, affecting system reliability and safety.

Q 7. What are the common causes of coupler malfunctions?

Coupler malfunctions stem from a variety of causes, often related to wear and tear, accidents, or lack of proper maintenance.

- Wear and tear: This is a significant factor, leading to components wearing out or becoming damaged over time. This can affect the knuckle’s ability to engage and disengage, or cause damage to the locking pin.

- Impact damage: Collisions, derailments, or other impacts can severely damage couplers, causing bending, cracking, or complete failure. Even minor impacts can lead to degradation over time.

- Improper maintenance: Lack of regular inspection and lubrication can lead to accelerated wear and tear and increase the risk of malfunction. Grease and lubrication are crucial for preventing premature damage.

- Corrosion: Exposure to environmental elements, especially moisture and salt, can cause corrosion that weakens the coupler’s structural integrity. Corrosion often goes undetected unless a regular inspection is performed.

- Improper operation: Forcing a coupler to engage or disengage under unfavorable conditions, such as misalignment, can damage components. This can create considerable stress on the components, leading to failure. The use of proper coupling procedures is essential.

Understanding these common causes allows for preventative maintenance measures and enhances the ability to promptly detect and address problems before they escalate into safety hazards.

Q 8. How would you handle a situation where a railcar is found to have a critical safety violation?

Discovering a critical safety violation on a railcar demands immediate and decisive action. My first step would be to immediately secure the railcar, preventing further movement or potential accidents. This might involve placing warning flags, contacting the relevant dispatchers and switching crews to isolate the car, and ensuring the area around the car is clear of personnel. Then, I would thoroughly document the violation, taking detailed photographs and notes describing the exact nature of the problem, its location on the car, and any contributing factors. This documentation is crucial for follow-up repairs and investigation. Finally, I would report the violation through the established channels – typically using a standardized reporting system – to the appropriate supervisors and maintenance personnel. Depending on the severity (e.g., a broken coupler, severely damaged tank car), the railcar might require immediate out-of-service status until repairs are completed by certified professionals. I’ve personally dealt with a case involving a severely cracked brake cylinder on a tanker; immediate action prevented potential catastrophe.

Q 9. What is your experience with AAR (Association of American Railroads) standards?

My experience with AAR standards is extensive. I’m intimately familiar with the various AAR standards related to railcar construction, maintenance, and inspection, including those pertaining to couplers, brakes, tank cars, and other crucial components. These standards serve as the industry benchmark for safety, and understanding them is fundamental to my job. For example, I regularly use the AAR M-1001 standard for coupler inspection, verifying the proper functioning of knuckle locking mechanisms, yoke integrity, and the overall condition of the coupler assembly. I’m also proficient in interpreting the AAR’s regulations on tank car testing and repair, ensuring that hazardous materials are safely transported. My training includes regular updates on revisions to these standards, ensuring I’m always up-to-date on the latest safety protocols.

Q 10. Describe your experience documenting railcar inspection findings.

Documenting railcar inspection findings is a meticulous process. I typically use a combination of digital and physical methods. Each inspection generates a detailed report, often using a pre-printed form or a dedicated software application, that includes the railcar number, date and time of inspection, inspector’s name, and a comprehensive description of the railcar’s condition. For each finding, I detail the specific location, severity, and type of damage using standardized terminology. Photographs and sketches are crucial supplements to the written descriptions. For example, when documenting a crack on a bolster, I’ll specify its length, depth, location, and its orientation (e.g., longitudinal, transverse). This rigorous documentation ensures accuracy, provides a historical record of the railcar’s condition, and facilitates effective maintenance planning. The reports also include recommendations for repairs or further investigation.

Q 11. Explain your process for identifying and classifying different types of railcar damage.

Identifying and classifying railcar damage involves a systematic approach. First, I conduct a visual inspection, noting any visible defects such as dents, cracks, corrosion, or missing parts. I then use appropriate tools, like ultrasonic testing equipment for detecting hidden cracks, to further assess the severity of any damage. Damage is then categorized based on its severity (e.g., minor, major, critical) and its potential impact on safety and operational efficiency. For example, a small dent on a sidewall would be classified as minor, whereas a major crack on a coupler would be critical and require immediate action. This classification system aligns with AAR standards and internal company procedures. I also document the type of damage, for instance, specifying whether the damage is due to impact, corrosion, or fatigue. Understanding the cause of the damage helps in preventing future occurrences.

Q 12. How do you ensure the accuracy and completeness of your inspection reports?

Ensuring the accuracy and completeness of my inspection reports is paramount. I utilize several strategies. First, I follow a standardized checklist during every inspection, ensuring that all key components are examined. Second, I employ various inspection tools and techniques, such as visual inspection, ultrasonic testing, and gauging, to verify findings. I cross-reference my findings with previous inspection reports to track damage progression and identify potential maintenance issues. My reports include clear, concise language and multiple supporting documents such as photographs and sketches. A crucial step is a peer review process, where another inspector can verify the findings independently. This dual check helps catch errors and ensure comprehensive documentation, leading to high-quality, accurate reporting. Finally, I always maintain detailed records of calibration and maintenance of the inspection equipment used to support report validity.

Q 13. What is your experience with using different types of inspection tools and equipment?

My experience encompasses a wide array of inspection tools and equipment. I’m proficient in using basic tools like hammers, calipers, and levels for visual inspections and dimensional checks. For more detailed assessments, I utilize sophisticated equipment such as ultrasonic flaw detectors to identify hidden cracks in metal components, magnetic particle inspection systems for surface flaws, and specialized gauges for precise measurements. I’m also trained in the use of thermal cameras for detecting overheating components and leak detection equipment for tank cars. The selection of tools depends heavily on the type of railcar and the specific inspection requirements. Regular calibration and maintenance of these tools are crucial for accuracy and reliability, contributing significantly to safe and precise inspections.

Q 14. How do you prioritize inspections based on the urgency and risk levels?

Prioritizing inspections involves a risk-based approach. Critical components and those known to have a higher failure rate – such as couplers, brakes, and tank car valves – naturally receive higher priority. Railcars carrying hazardous materials also demand more frequent and thorough inspections due to the increased risk associated with accidents involving these materials. Urgency plays a significant role; if a car shows signs of immediate danger, it’s taken out of service immediately. Inspection frequency is tailored according to the railcar type, usage pattern, and regulatory requirements. A risk matrix is often employed to rank various factors and determine which inspections need to be performed sooner rather than later. This allows me to allocate time and resources effectively, ensuring that the highest-risk railcars are inspected most frequently, minimizing the likelihood of accidents.

Q 15. What are some common signs of railcar fatigue or structural damage?

Railcar fatigue and structural damage manifest in various ways, often subtle at first. Identifying these signs requires a trained eye and thorough inspection. Common indicators include:

Cracks: These can range from hairline fractures to significant cracks in the car body, underframe, or couplers. Location is crucial; cracks near welds or stress points are particularly concerning.

Dents and Gouges: While minor dents might be acceptable, significant damage that compromises structural integrity is unacceptable. Deep gouges, especially in load-bearing areas, require immediate attention.

Corrosion: Rust and corrosion weaken the metal, reducing its load-bearing capacity. Pitting, scaling, and significant rust buildup are all serious concerns.

Misalignment: Components like wheels, trucks, and couplers should be properly aligned. Significant misalignment indicates potential damage or wear.

Excessive Wear: Look for signs of wear and tear on critical components such as brake systems, bearings, and wheels. Excessive wear suggests a need for maintenance or replacement.

Abnormal Sounds: During movement, unusual noises like squealing, grinding, or banging can indicate underlying problems. These warrant further investigation.

Think of it like inspecting a bridge: a single crack might not be immediately catastrophic, but its presence necessitates further evaluation to determine the extent of the underlying damage and potential risk.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you determine whether a railcar is fit for service after inspection?

Determining a railcar’s fitness for service involves a multi-step process following a thorough inspection. I use a combination of visual inspection, measurement, and sometimes specialized testing. My decision is based on several factors:

Severity of Damage: The extent of any identified damage is crucial. Minor cosmetic issues are different from structural compromises.

Location of Damage: Damage in critical load-bearing areas is more serious than damage in less critical areas.

Applicable Regulations and Standards: All inspections adhere strictly to AAR (Association of American Railroads) standards and relevant federal regulations. These regulations specify acceptable limits for various types of damage.

Documentation: Comprehensive documentation, including photographs and detailed reports, supports my decisions and ensures accountability.

Engineering Judgment: Sometimes, I need to exercise professional judgment, considering the overall condition of the car and weighing the risks. If there’s any doubt, the railcar is taken out of service until a thorough repair and reassessment are completed.

Essentially, I’m ensuring the safety and integrity of the railcar, considering both immediate and long-term risks. A railcar deemed unfit for service will be clearly marked and removed from operation.

Q 17. Describe your understanding of different types of railcar repairs.

Railcar repairs span a wide spectrum, from minor maintenance to major structural overhauls. Here are some examples:

Minor Repairs: These include fixing small dents, welding minor cracks, replacing worn brake shoes, and lubricating components. These are often done on-site.

Major Repairs: This category includes replacing damaged sections of the car body, repairing or replacing trucks and couplers, and extensive welding or straightening. These often require specialized equipment and a workshop setting.

Overhauls: A complete overhaul is a comprehensive restoration, addressing many areas of wear and tear. This ensures the railcar is returned to ‘as new’ condition.

Specialized Repairs: Specific repairs depending on the type of railcar and its cargo, such as specialized tank car cleaning or the repair of refrigeration systems.

The type of repair required depends entirely on the severity and location of damage identified during the inspection. The choice is driven by safety considerations, cost-effectiveness, and the required regulatory compliance.

Q 18. How do you communicate your findings effectively to other members of the team?

Effective communication is critical for safety and efficiency. I utilize several methods:

Detailed Inspection Reports: I create comprehensive reports that include photographs, detailed descriptions of the damage, and recommendations for repairs. These reports are clear, concise, and easy to understand.

Verbal Communication: I hold regular briefings with team members to discuss findings and potential issues, fostering collaborative problem-solving.

Digital Communication: I use digital tools to share photographs and other relevant data quickly and efficiently.

Clear Prioritization: I prioritize findings based on safety and urgency, ensuring that critical issues are addressed immediately.

Imagine a scenario where a critical crack is found. Clear, concise communication ensuring the immediate removal of the car from service is paramount to prevent accidents. This is where clear and consistent communication, both written and verbal, becomes crucial.

Q 19. Describe a situation where you had to make a difficult decision during an inspection.

During an inspection of a tanker car, I discovered a significant crack near a weld on the bottom of the tank. The crack was subtle, but its location near a crucial structural point raised serious concerns. The car was carrying hazardous materials.

The decision was difficult because repairing the crack on-site would have been time-consuming and potentially risky given the hazardous materials. However, allowing the car to continue operation could have resulted in a catastrophic failure. I ultimately chose to recommend immediate removal from service, prioritizing safety even at the cost of temporary operational disruption. The car was repaired in a controlled environment, following rigorous safety protocols, proving the prioritization of safety was the correct decision.

Q 20. Explain how you maintain your knowledge of railcar safety regulations and best practices.

Maintaining up-to-date knowledge in this field is an ongoing process. I utilize several methods:

AAR Standards and Publications: I regularly review updates and revisions to AAR standards and publications to remain current with best practices and regulatory changes.

Professional Development Courses: I participate in professional development courses and seminars to expand my knowledge and skills.

Industry Conferences and Workshops: Attending industry conferences and workshops provides valuable insights into the latest trends and techniques.

Networking: I actively network with other inspectors and industry professionals to share knowledge and stay informed about emerging issues.

Staying current with regulations is not just a professional requirement; it’s crucial for ensuring the safety of railway operations and preventing accidents. This continuous learning ensures I can effectively identify and address potential hazards.

Q 21. What is your experience working in various weather conditions?

I have extensive experience working in various weather conditions, from extreme heat and cold to heavy rain, snow, and ice. My inspections adhere to safety protocols for each weather type, ensuring both my safety and the integrity of my work.

Working in adverse weather often requires adjustments to the inspection procedure. For example, in heavy rain or snow, visibility can be reduced, necessitating the use of additional lighting and extra caution. In extremely cold conditions, I have to account for potential material embrittlement, which can make some types of damage more difficult to detect. My experience allows for the adaptation of techniques to ensure that inspections are thorough and safe, regardless of weather conditions.

Q 22. How familiar are you with different types of freight car lading?

My familiarity with freight car lading is extensive. I understand that the type of lading dictates the necessary safety precautions and inspection procedures. For example, handling hazardous materials like flammable liquids requires a much more rigorous inspection than transporting grain. I’m proficient in identifying different types of lading through the use of shipping papers and visual inspection.

- Bulk Commodities: These include grains, coal, and ores, often requiring inspections for proper loading and securing to prevent shifting during transit.

- Intermodal Containers: These standardized containers can house a vast array of goods, requiring attention to securing mechanisms and potential damage to the container itself.

- Liquid Products: This necessitates checking for leaks, proper tank car labeling, and ensuring valves and fittings are secure. For example, I’ve inspected tank cars carrying gasoline and had to report a faulty valve once.

- Manufactured Goods: This encompasses everything from automobiles to packaged goods, requiring an inspection focused on securement to prevent shifting and damage during transit.

Understanding the type of lading allows me to anticipate potential issues and ensures the safe transportation of the goods.

Q 23. Describe your experience with using Computerized Maintenance Management Systems (CMMS).

I have extensive experience using Computerized Maintenance Management Systems (CMMS), specifically [Mention Specific CMMS software used, e.g., IBM Maximo, SAP PM]. I’ve used these systems to schedule preventative maintenance, track repairs, manage inventory of parts, and generate reports. In my previous role, I was responsible for inputting inspection data directly into the CMMS, which facilitated efficient tracking of railcar conditions and improved overall maintenance planning.

For example, I used the CMMS to create and track work orders for repairing a coupler on a damaged railcar. The system generated notifications to the relevant mechanics, recorded parts used, and tracked labor costs, improving both accountability and efficiency.

My proficiency with CMMS extends to generating reports to demonstrate compliance with regulations and identify recurring issues with specific railcar types or components.

Q 24. What is your understanding of the various types of defects that can be found in railcar underframes?

Railcar underframes are critical for structural integrity and safety. Defects can range from minor to catastrophic. I’m familiar with a wide array of potential problems:

- Cracks: These can develop in the frame members due to stress, fatigue, or corrosion. I’m trained to identify cracks using visual inspection and, when necessary, utilize non-destructive testing (NDT) methods.

- Corrosion: Rust and other forms of corrosion weaken the structural integrity of the underframe, potentially leading to failure. Regular inspections, including detailed visual checks, are crucial for early detection.

- Broken or Damaged Components: This includes broken or missing bolting, damaged bolster assemblies, and broken side frames. These often necessitate immediate repairs.

- Misalignment: Misalignment of wheels, axles, or the entire underframe can significantly impact operational safety and stability. Detection often requires precise measurements and specialized tools.

- Wear and Tear: General wear and tear on components such as bearings, springs, and brake systems can lead to functionality issues or safety hazards.

The severity of the defect determines the appropriate course of action – from minor repairs to complete replacement of the underframe component or the entire railcar. I am trained to assess the severity and recommend appropriate action.

Q 25. How would you handle a situation where a coworker is not following safety procedures?

Safety is paramount in this industry. If I observe a coworker not following established safety procedures, my first step would be a direct and private conversation. I’d explain the specific safety violation, its potential consequences, and refer to the relevant safety regulations or company policies. I’d approach the situation with a focus on education and a collaborative effort towards safe work practices.

However, if the behavior continues or poses an immediate safety risk, I would immediately report the issue to my supervisor. Documentation is key. I’d clearly outline the incident, including dates, times, and the individuals involved. This ensures a record is maintained for future reference and investigation if required. Safety is a shared responsibility, and addressing these issues effectively is crucial for creating a safer working environment.

Q 26. Describe your process for escalating safety concerns to management.

My process for escalating safety concerns follows a clear hierarchy. First, I would report the concern to my immediate supervisor. If the issue isn’t resolved or addressed appropriately, I would escalate it to the next level of management, possibly a safety manager or operations manager. Maintaining thorough documentation at each stage, including dates, times, actions taken, and individuals involved, is critical.

If the safety concern remains unresolved after going through the internal channels, depending on the severity and nature of the issue, I may consider reporting it to relevant regulatory bodies, such as the [Mention relevant regulatory body, e.g., Federal Railroad Administration (FRA) in the US]. This is a last resort, but it’s important to understand and exercise the appropriate channels to ensure worker safety.

Q 27. What safety measures do you take when performing a railcar inspection?

Safety is my top priority during railcar inspections. My standard procedures include:

- Personal Protective Equipment (PPE): Always wearing appropriate PPE, including high-visibility clothing, safety glasses, gloves, and steel-toe boots.

- Awareness of Surroundings: Maintaining constant awareness of my surroundings, including moving trains, other personnel, and potential hazards within the inspection area.

- Following established Procedures: Adhering strictly to established inspection procedures and checklists, ensuring thoroughness and consistency.

- Proper Tools and Equipment: Using appropriate tools and equipment for the inspection, ensuring they are in good working condition.

- Communication: Maintaining clear communication with other personnel in the area, especially when working near active tracks or moving equipment.

- Reporting: Promptly reporting any unsafe conditions or potential hazards identified during the inspection.

Safety is not just a set of rules, it’s a mindset. A proactive approach to safety ensures that every inspection is completed safely and efficiently, without incident. I have personally prevented several potential accidents by carefully following safety procedures and reporting unsafe conditions immediately.

Key Topics to Learn for Conduct Inspections of Rail Cars and Couplers Interview

- Rail Car Components and Functionality: Understanding the various parts of a rail car (wheels, axles, brakes, couplers, etc.) and how they function together is crucial. This includes knowledge of different rail car types and their specific features.

- Coupler Inspection Procedures: Mastering the practical steps involved in a thorough coupler inspection, including visual checks for damage, wear, and proper alignment. This also includes understanding the different types of couplers and their respective safety mechanisms.

- Brake System Inspection: Learn about the different types of braking systems used on rail cars and how to effectively inspect their components for proper function and safety. This involves understanding air pressure systems and related safety regulations.

- Wheel and Axle Inspection: Know how to identify signs of wear, damage, or defects in wheels and axles, including understanding the implications of such issues for safety and operational efficiency. This will include familiarity with gauging techniques and acceptable tolerances.

- Documentation and Reporting: Understanding the importance of accurate and detailed documentation of inspection findings, including the use of appropriate forms and reporting procedures. This also involves knowing how to communicate findings effectively.

- Safety Regulations and Compliance: Familiarize yourself with relevant safety regulations and compliance standards related to rail car inspections, including understanding the consequences of non-compliance.

- Problem-Solving and Troubleshooting: Develop your ability to identify and troubleshoot potential issues identified during inspections, including understanding the potential consequences of identified problems and how to escalate them appropriately.

Next Steps

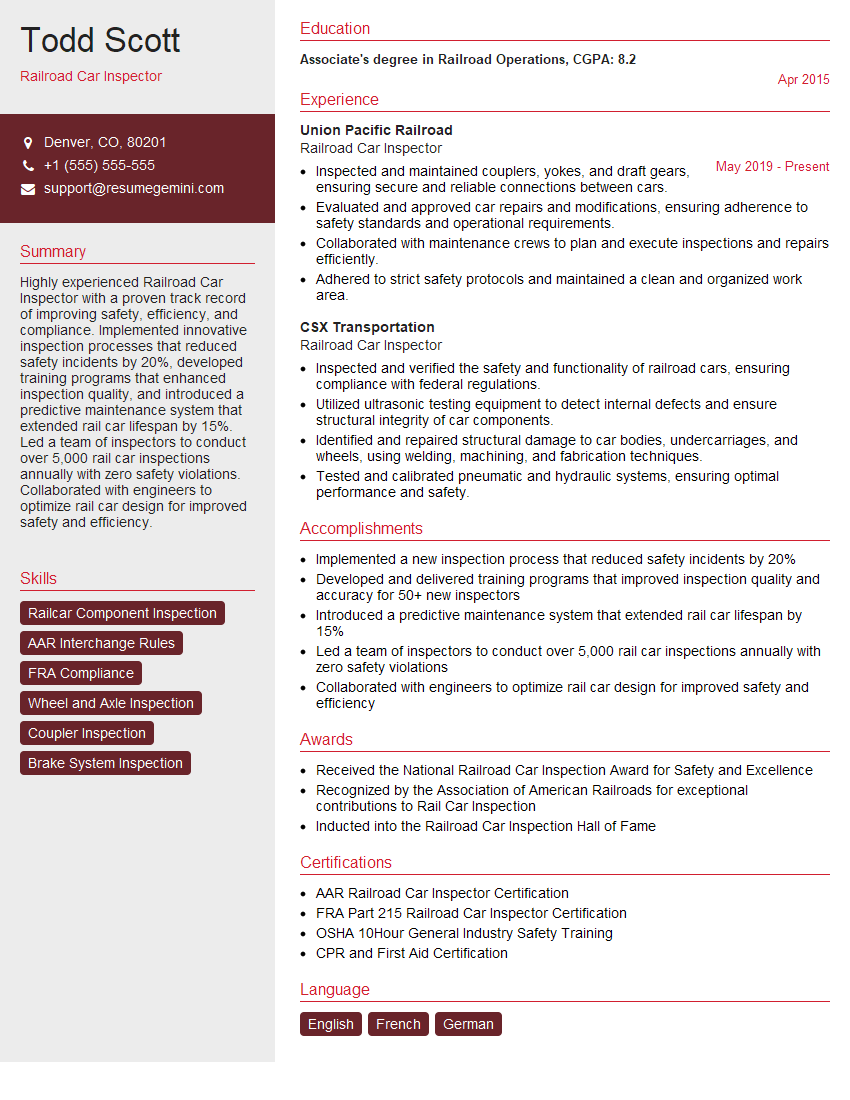

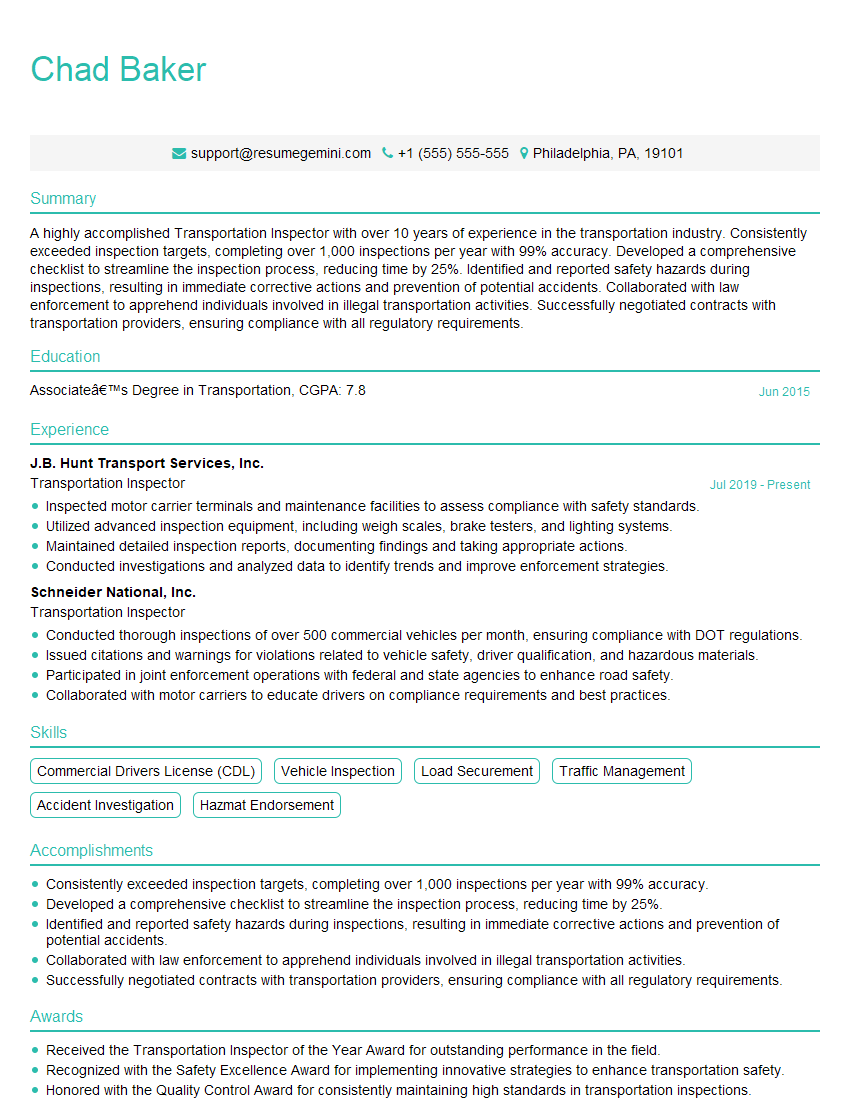

Mastering the art of conducting rail car and coupler inspections is a critical step towards a successful and rewarding career in the rail industry. It demonstrates a commitment to safety and operational efficiency, opening doors to greater responsibility and advancement opportunities. To maximize your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Conduct Inspections of Rail Cars and Couplers are available to help guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO