Unlock your full potential by mastering the most common Operate coupling and uncoupling equipment interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Operate coupling and uncoupling equipment Interview

Q 1. Describe the different types of coupling mechanisms you are familiar with.

Coupling mechanisms connect different pieces of equipment, allowing for power transfer, data transmission, or fluid flow. The type of coupling used depends on the application and the characteristics of the connected equipment. Here are some common types:

- Rigid Couplings: These offer direct, rigid connections, transmitting torque with minimal misalignment. They are suitable for applications requiring precise alignment and minimal flexibility, like connecting a motor directly to a pump shaft. However, they are susceptible to damage from misalignment.

- Flexible Couplings: These tolerate some misalignment between connected shafts, absorbing vibrations and shock loads. Common types include elastomeric couplings (using rubber or similar materials), gear couplings (using interlocking gears), and jaw couplings (using interlocking jaws). They are ideal for applications with slight misalignment or fluctuating loads, such as a motor driving a conveyor belt.

- Fluid Couplings: These use fluid (typically oil) to transmit torque. They provide smooth starts, overload protection, and act as shock absorbers. They are used in applications demanding smooth operation and protection from sudden torque surges, for example, in marine propulsion systems.

- Magnetic Couplings: These use magnetic fields to transmit torque without physical contact between the shafts. This is useful for applications requiring isolation, such as transferring motion through a sealed barrier to prevent contamination or leakage, like in some chemical processing equipment.

The choice of coupling depends on factors like torque requirements, speed, misalignment tolerance, and the operating environment.

Q 2. Explain the safety procedures for coupling and uncoupling equipment.

Safety is paramount when coupling and uncoupling equipment. The procedures vary based on the type of coupling and the equipment involved, but general principles include:

- Lockout/Tagout (LOTO): Always de-energize the equipment completely using LOTO procedures before attempting any coupling or uncoupling operations. This prevents accidental startup during maintenance or connection.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, and possibly hearing protection, depending on the equipment and the environment.

- Proper Lifting Techniques: If the equipment is heavy, use appropriate lifting devices and follow safe lifting practices to avoid injury.

- Visual Inspection: Before connecting components, visually inspect both coupling halves and the shafts to ensure they are free of damage, debris, and correct alignment.

- Step-by-Step Approach: Follow the manufacturer’s instructions meticulously, ensuring each step is completed correctly before proceeding to the next. Do not rush.

- Clear Communication: If working as a team, establish clear communication to avoid accidents.

- Emergency Procedures: Be aware of emergency procedures and know how to react in case of an accident.

Always consult the equipment’s operating and safety manuals before performing any coupling or uncoupling operations.

Q 3. How do you identify potential hazards before coupling or uncoupling equipment?

Identifying potential hazards before coupling or uncoupling equipment is crucial for preventing accidents. A thorough risk assessment should be performed, including:

- Visual Inspection: Look for obvious hazards like damaged components, loose parts, leaks, or obstructions.

- Environmental Hazards: Consider the surrounding environment. Are there potential tripping hazards, confined spaces, or exposure to hazardous materials?

- Equipment Condition: Check the equipment’s operational status. Is the equipment properly grounded? Are there any warning lights or alarms?

- Alignment: Ensure proper shaft alignment to prevent stress and damage to the coupling and connected equipment.

- Torque Capacity: Verify that the coupling is rated for the torque of the equipment being connected.

- Material Compatibility: Check if materials are compatible. For example, ensure proper sealing materials are used for fluid couplings to prevent leakage.

A pre-job safety briefing involving all personnel involved is recommended to address potential hazards and mitigation strategies.

Q 4. What are the common causes of coupling and uncoupling failures?

Coupling and uncoupling failures can stem from various causes:

- Misalignment: Improper alignment between shafts is a major cause of coupling failure, leading to excessive wear, vibration, and eventual breakage.

- Overload: Exceeding the coupling’s torque capacity can result in damage or failure.

- Corrosion: Corrosion of coupling components weakens them and can lead to failure.

- Fatigue: Repeated cyclic loading can cause fatigue failure in the coupling material.

- Improper Installation: Incorrect installation procedures can result in weakened connections and premature failure.

- Wear and Tear: Normal wear and tear from long-term operation eventually leads to component degradation and failure.

- Improper Lubrication: Lack of lubrication, or the use of inappropriate lubricants, can lead to excessive wear and tear.

Regular inspection and maintenance are vital to prevent these failures.

Q 5. How do you troubleshoot coupling and uncoupling problems?

Troubleshooting coupling and uncoupling problems requires a systematic approach:

- Safety First: De-energize the equipment and follow proper LOTO procedures.

- Visual Inspection: Carefully inspect the coupling and connected equipment for visible damage, misalignment, or leaks.

- Check for Obstructions: Ensure there are no obstructions preventing proper connection.

- Verify Alignment: Use appropriate tools to check for shaft misalignment.

- Check Lubrication: Examine lubrication levels and the condition of the lubricant.

- Inspect Components: Carefully examine individual coupling components for wear, damage, or corrosion.

- Consult Manuals: Refer to the equipment and coupling manuals for troubleshooting guidance.

- Consult Experts: If the problem persists, consult experienced technicians or engineers.

Proper documentation of the troubleshooting process is essential for future reference.

Q 6. Describe your experience with different types of coupling equipment.

Throughout my career, I’ve worked extensively with various types of coupling equipment, including:

- Elastomeric Couplings: These were used in a conveyor system to dampen vibrations and accommodate minor misalignment between the motor and the conveyor drive shaft. Regular inspections ensured the elastomer remained intact and was not showing signs of wear.

- Gear Couplings: I’ve experienced using gear couplings in high-torque applications, such as large industrial pumps. The precise engagement of the gears ensured efficient power transmission, but careful alignment was crucial during installation.

- Fluid Couplings: In a marine application, fluid couplings provided a smooth start for the propulsion system and protection from shock loads. Regular oil checks and maintenance were essential to keep the system running reliably.

- Rigid Couplings: I’ve encountered rigid couplings in applications where precise alignment was critical, such as connecting a high-speed spindle to a precision machining tool. These required very careful installation and alignment.

My experience encompasses both installation, maintenance, and troubleshooting of these diverse coupling types in various industrial settings.

Q 7. What are the limitations of different coupling mechanisms?

Every coupling mechanism has limitations. Understanding these limitations is critical for selecting the right coupling for a given application.

- Rigid Couplings: Their inability to tolerate misalignment limits their applicability to precisely aligned systems. Any misalignment can lead to rapid wear and failure.

- Flexible Couplings: While they tolerate misalignment, they may have limitations on the amount of misalignment they can handle. Excessive misalignment can still lead to premature wear and failure. They can also introduce some torsional flexibility, which may be undesirable in certain high-precision applications.

- Fluid Couplings: They introduce slip, reducing efficiency compared to direct mechanical couplings. They also require regular maintenance and fluid changes.

- Magnetic Couplings: They are typically less efficient than direct mechanical couplings due to energy losses in the magnetic field. They may also have limitations on torque capacity and the distance they can effectively transmit torque.

Careful consideration of these limitations is crucial for selecting and using couplings effectively and safely.

Q 8. How do you ensure the proper alignment of equipment before coupling?

Proper alignment before coupling is crucial to prevent damage and ensure efficient operation. Think of it like connecting two pieces of a perfectly crafted puzzle – they need to fit together seamlessly. We use various tools and techniques to achieve this. For example, laser alignment systems provide precise measurements of shaft misalignment, allowing for minute adjustments. Mechanical alignment tools like dial indicators help measure parallelism and concentricity. Before engaging the coupling, we visually inspect for any obstructions or damage, ensuring both shafts are clean and free of debris. A slight misalignment can lead to excessive vibration, premature wear, and even catastrophic failure. In a refinery setting, for instance, improper alignment of pump shafts could lead to seal failure and costly leaks.

- Laser Alignment: Offers the highest accuracy for critical applications.

- Dial Indicators: A more traditional method, suitable for many applications.

- Visual Inspection: A critical first step to identify obvious problems.

Q 9. What safety precautions do you take when working with high-pressure couplings?

Safety is paramount when handling high-pressure couplings. We treat every coupling operation as a potentially hazardous activity. Before beginning any work, we ensure the system is depressurized completely. We use pressure gauges and bleed valves to verify zero pressure. Appropriate Personal Protective Equipment (PPE) is mandatory, including safety glasses, gloves, and potentially hearing protection depending on the equipment’s noise level. We follow strict lockout/tagout procedures to prevent accidental activation of the system during coupling/uncoupling. Furthermore, we carefully inspect the couplings for any visible damage or signs of wear before connecting them, ensuring the correct coupling type is used for the specific pressure and application. One crucial aspect is to always approach the task methodically, double-checking each step, and never rushing the process. In an industrial pipeline, a single lapse in safety can result in a serious accident with significant environmental and financial implications.

Q 10. How do you handle emergency situations during coupling or uncoupling?

Emergency situations during coupling or uncoupling require immediate and decisive action. If a leak occurs, we immediately isolate the section by closing appropriate valves, preventing further pressure buildup and potential escalation. If a coupling fails, we will secure the area and implement the emergency shutdown protocols specific to the plant or facility. This may include activating emergency alarms, notifying relevant personnel, and initiating the emergency response team. If a personal injury occurs, first aid is administered immediately, followed by contacting emergency medical services. The immediate priority is always to ensure the safety of personnel, followed by containing the incident and preventing further damage. We meticulously document the event and conduct a thorough root cause analysis to prevent future occurrences. For example, during a chemical transfer operation, a sudden failure could result in a chemical spill. Swift action to isolate the system and prevent further spread is paramount.

Q 11. What are the maintenance procedures for coupling and uncoupling equipment?

Regular maintenance of coupling and uncoupling equipment is key to preventing failures and ensuring operational reliability. This involves visual inspections for wear, corrosion, or damage. We check for proper lubrication, ensuring the correct lubricant type and sufficient quantity are applied. We also check for any signs of leakage or looseness. Depending on the type of coupling and the operating conditions, more specific procedures might apply. For example, flexible couplings might require periodic alignment checks, while rigid couplings will focus on bolt tightness and surface wear. We maintain detailed records of all maintenance activities to track the equipment’s history and ensure compliance with safety and operational standards. A well-maintained coupling system will reduce downtime and improve safety. Think of it as regular car maintenance – preventative checks prevent major breakdowns down the road.

Q 12. How do you inspect coupling and uncoupling equipment for damage?

Inspecting coupling and uncoupling equipment for damage is a crucial part of preventative maintenance. We visually examine the couplings for any signs of wear, cracks, corrosion, or deformation. We check for proper seating of the coupling components and ensure there’s no excessive play or looseness. We look for any signs of leakage at the connection points. For specific coupling types, detailed inspection procedures might be necessary. For example, we might use specialized tools to check the integrity of seals or the alignment of shafts. Any significant damage detected requires immediate action, which could range from repairing or replacing the damaged component to completely shutting down the system if the damage is extensive. In a power generation plant, for instance, a damaged coupling could lead to significant downtime and loss of revenue.

Q 13. Explain the importance of proper lubrication in coupling mechanisms.

Proper lubrication is critical in coupling mechanisms, reducing friction and wear, and extending the lifespan of the components. Lubrication creates a protective film between moving parts, preventing metal-to-metal contact and reducing the risk of seizing or galling. It also dissipates heat generated during operation, preventing overheating and potential damage. The type and viscosity of lubricant must be carefully selected based on the operating conditions, temperature, and the materials of the coupling components. Insufficient or incorrect lubrication can lead to increased wear, friction, vibrations, and ultimately, premature failure. In a high-speed rotating machinery, proper lubrication is essential to avoid catastrophic failure.

Q 14. How do you select the appropriate coupling for a specific application?

Selecting the appropriate coupling for a specific application involves considering several factors. The primary considerations include the type of machinery being coupled, the operating speed, torque requirements, misalignment capabilities, and the operating environment. Different coupling types are designed for different needs. For example, rigid couplings are suitable for applications requiring precise alignment, while flexible couplings can accommodate misalignment. Fluid couplings offer smooth starting and overload protection. The operating environment (temperature, chemicals, etc.) should also be considered when selecting a coupling material. Thorough consideration of these factors will ensure the selected coupling meets the specific needs of the application and helps avoid costly mistakes. In a manufacturing environment, choosing the wrong coupling could lead to frequent downtime and reduced productivity.

Q 15. What are the different types of connectors used in coupling and uncoupling?

Coupling and uncoupling equipment relies on various connectors, chosen based on the application’s specific needs regarding fluid type, pressure, flow rate, and safety requirements. The selection process is crucial for preventing leaks and ensuring operational efficiency.

- Flanged Connections: These are robust and widely used, particularly for high-pressure applications. They rely on a bolted connection between two flanges, often incorporating gaskets for sealing. Think of the large pipes you see in industrial plants – many use flanged connections.

- Cam and Groove Couplings: Quick-connect systems, excellent for rapid connection and disconnection, often used with hoses for transferring fluids. These are common in fire fighting equipment and some industrial applications.

- Threaded Connections: Simple and effective, but they might require more time for connection and can be susceptible to leaks if not tightened correctly. You’ll frequently see this type of connector in plumbing and smaller diameter piping.

- Quick Disconnect Couplings: Designed for ease and speed, these utilize various mechanisms like push-pull or bayonet-style locking. They are a staple in many hydraulic and pneumatic systems.

- Hydraulic Hose Assemblies: These involve specialized crimped or clamped connections between hoses and fittings, crucial for maintaining system integrity under pressure.

The choice depends on factors like the application’s pressure and flow rate, the type of fluid, the frequency of coupling/uncoupling, and the required safety level. Selecting the right connector is a key step in ensuring operational safety and efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with hydraulic coupling systems.

My experience with hydraulic coupling systems spans over ten years, encompassing design, installation, maintenance, and troubleshooting. I’ve worked extensively with diverse systems, from small-scale agricultural machinery to large-scale industrial presses. This experience has exposed me to various types of hydraulic couplings – including quick disconnects, flanged couplings, and specialized high-pressure couplings.

One memorable project involved troubleshooting a complex hydraulic system on a large industrial stamping machine. A recurring leak in a high-pressure coupling led to significant downtime. By systematically inspecting each component, including the coupling itself, the lines, and the related components, I identified a microscopic crack in the coupling body. Replacement solved the issue, highlighting the criticality of regular inspection and the need for high-quality components.

I’m proficient in interpreting hydraulic schematics, diagnosing pressure drops and leaks, selecting appropriate couplings based on pressure and flow requirements, and performing routine maintenance such as lubricating and inspecting coupling components. I’m also experienced in working with different types of hydraulic fluids and understanding their compatibility with various coupling materials.

Q 17. How do you handle leaks in coupling systems?

Leaks in coupling systems represent a serious safety hazard and operational inefficiency. My approach to handling leaks is systematic and thorough. It begins with the identification of the leak source. This often involves visual inspection, pressure testing, and possibly using leak detection fluid.

Once located, the repair strategy depends on the nature of the leak. Minor leaks from threaded connections might be resolved by tightening the connections or applying sealant. Leaks in the coupling body itself usually necessitate replacing the coupling. For hose leaks, replacing the damaged section of the hose is necessary.

If a leak persists, the problem could extend beyond the coupling itself, so a thorough investigation of the entire system is often needed. This could include checks for damaged hoses, faulty valves, or other system components. Safety is paramount; if the leak poses an immediate risk, the system should be shut down and depressurized immediately before any repair attempts.

Q 18. What is the significance of torque settings in coupling procedures?

Torque settings are crucial in coupling procedures, as they directly impact the seal integrity and operational safety of the system. Incorrect torque can lead to leaks, premature component failure, or even catastrophic system failure. The proper torque ensures that the connection is sufficiently tight to prevent leaks but not over-tightened, which could damage the components.

Manufacturers often provide specific torque recommendations for each coupling type and size. These values should be strictly adhered to. Using a calibrated torque wrench is essential to ensure accuracy. Over-torquing can damage threads or gaskets, while under-torquing can lead to leaks. Think of it like building with LEGOs – you need just the right amount of pressure to connect the bricks securely, neither too loose nor too tight.

Q 19. What are the consequences of improper coupling and uncoupling?

Improper coupling and uncoupling can result in a range of negative consequences, some with serious safety implications.

- Leaks: This leads to fluid loss, environmental hazards, and potential damage to equipment.

- Equipment Damage: Incorrect coupling can cause misalignment or excessive stress on machinery components, leading to premature wear or catastrophic failure.

- Safety Hazards: Leaks can create slippery surfaces, and high-pressure fluid jets can cause serious injury. Improperly coupled equipment might malfunction, posing risks to personnel.

- Downtime and Reduced Efficiency: Leaks and equipment failures result in costly downtime and reduced productivity.

- Environmental Concerns: Leaks involving hazardous fluids can cause environmental contamination.

These consequences highlight the importance of proper training, adherence to procedures, and regular equipment maintenance to minimize risks.

Q 20. How do you ensure the safe disconnection of equipment?

Ensuring safe disconnection involves a methodical approach focused on safety and minimizing risks. The first step is to depressurize the system fully. This prevents accidental release of fluids under pressure, which can cause serious injury. After depressurization, visual inspection ensures no residual pressure remains. Next, use the correct tools and procedures to disconnect the equipment – adhering strictly to manufacturer’s guidelines. Ensure that all fasteners are properly loosened before separating the components. Finally, inspect the coupling components for wear or damage; replace or repair any worn or damaged parts before reconnection. Proper handling and storage of disconnected parts are vital to prevent further damage or injury.

Q 21. How do you communicate effectively with team members during coupling operations?

Effective communication is crucial during coupling operations to ensure safety and efficiency. I employ several strategies:

- Clear and Concise Instructions: Before beginning any operation, I ensure everyone understands the steps involved, utilizing clear and unambiguous language, avoiding jargon unless all team members understand the terms.

- Visual Aids: When necessary, I use diagrams or checklists to clarify procedures and prevent misunderstandings.

- Regular Check-ins: During operations, I maintain consistent communication, verifying that each step is completed correctly and safely. I actively listen for concerns or observations from team members.

- Non-Verbal Communication: Clear hand signals and visual cues ensure everyone is aware of the ongoing procedures and any potential hazards.

- Post-Operation Debrief: Following completion, a brief debrief reviews any issues encountered or lessons learned for future tasks.

Maintaining a respectful, collaborative environment fosters clear communication and prevents accidents or mishaps during coupling operations.

Q 22. What are the environmental considerations related to coupling and uncoupling?

Environmental considerations in coupling and uncoupling operations are crucial for safety and regulatory compliance. They primarily focus on preventing spills, leaks, and emissions of hazardous materials. For instance, coupling and uncoupling liquid chemicals requires careful consideration to avoid spills that could contaminate soil or water sources. Similarly, connecting gas lines needs stringent safety protocols to prevent leaks and the potential for explosions or asphyxiation. The specific considerations depend on the materials being handled. Working with flammable materials requires explosion-proof equipment and a controlled environment. Operations near bodies of water need additional measures to prevent environmental damage. Proper containment systems and emergency response plans are essential components of environmental safety during coupling and uncoupling. Finally, noise pollution from the coupling process itself should also be considered, especially in sensitive environments.

Q 23. Describe your experience with pneumatic coupling systems.

My experience with pneumatic coupling systems spans over ten years, encompassing design, installation, maintenance, and troubleshooting across various industrial applications. I’ve worked extensively with quick-disconnect couplings, multi-port manifolds, and pressure-regulating systems. One memorable project involved integrating a new pneumatic system into a high-speed bottling plant. The challenge was minimizing downtime during the switchover. We implemented a phased approach, carefully documenting each step, and conducting rigorous testing to ensure seamless functionality before fully integrating the new system. This involved carefully calibrating air pressure, verifying the integrity of each connection, and troubleshooting minor leaks using specialized pneumatic tools and leak detection techniques. Through this experience, I honed my skills in system design, fault diagnosis, and predictive maintenance for pneumatic coupling systems. I’m proficient in identifying potential pressure drop issues, diagnosing faulty actuators, and implementing preventive maintenance schedules to reduce system failures. This approach minimizes downtime and ensures optimal production efficiency.

Q 24. What are the different types of coupling failures?

Coupling failures can stem from various sources, broadly categorized as mechanical, material, and operational failures. Mechanical failures can include:

- Wear and tear: Repeated use can cause wear on coupling components, leading to loose connections or complete failure.

- Misalignment: Improper alignment of coupling components creates stress points and premature wear.

- Corrosion: Exposure to harsh environments can corrode components, weakening them and leading to failure.

- Material degradation: Using inappropriate materials for the application or exposure to incompatible chemicals can cause material degradation and weaken the coupling.

- Fatigue: Cyclic loading or vibrations can lead to material fatigue and fracture.

- Improper coupling techniques: Incorrect handling or forceful engagement can damage components.

- Overpressure: Exceeding the design pressure limits of the coupling.

- Lack of maintenance: Neglecting regular inspection and maintenance can lead to unnoticed wear or damage.

Q 25. How do you prevent coupling and uncoupling accidents?

Preventing coupling and uncoupling accidents requires a multi-pronged approach incorporating engineering controls, administrative controls, and personal protective equipment (PPE). Engineering controls focus on designing safer systems: using robust, well-maintained equipment, implementing interlocks to prevent accidental disconnections, and designing systems that minimize the risk of spills or leaks. Administrative controls involve establishing robust Standard Operating Procedures (SOPs), providing comprehensive training to personnel, and implementing regular inspections and maintenance schedules. PPE is crucial for protecting workers, including safety glasses, gloves, and protective clothing appropriate to the materials being handled. Furthermore, a strong safety culture that prioritizes safe work practices and encourages reporting of near misses is vital. Regular safety audits and risk assessments also help identify and mitigate potential hazards. Think of it like a layered defense system – multiple safeguards working together to eliminate or mitigate risks.

Q 26. What are the regulatory requirements for coupling and uncoupling operations?

Regulatory requirements for coupling and uncoupling operations vary depending on the industry and the materials being handled. However, common regulations often involve compliance with OSHA (Occupational Safety and Health Administration) guidelines, which emphasize safety training, use of proper equipment, and adherence to safety protocols. Regulations concerning hazardous materials will require compliance with the relevant hazardous materials transportation regulations (e.g., DOT in the US). Environmental regulations also play a significant role, demanding proper containment systems and spill prevention measures. Specific industry standards, like those set by ASME (American Society of Mechanical Engineers) for pressure vessels and piping systems, also guide safe coupling and uncoupling practices. Compliance with these regulations often involves thorough documentation of procedures and training records.

Q 27. Explain the use of specialized tools in coupling and uncoupling procedures.

Specialized tools are often essential for safe and efficient coupling and uncoupling, especially in complex or high-pressure systems. These include torque wrenches for ensuring proper tightening of couplings, preventing leaks, and avoiding damage to components. For example, in high-pressure hydraulic systems, special wrenches and adapters are needed to handle the high forces involved, preventing injury to personnel and damage to equipment. Other specialized tools include leak detection equipment, alignment tools for ensuring correct positioning of coupling components, and specialized handling equipment for large or heavy couplings. The use of appropriate tools not only enhances safety and efficiency but also extends the lifespan of the coupling system by reducing wear and tear.

Q 28. How do you document coupling and uncoupling activities?

Documentation of coupling and uncoupling activities is critical for safety, maintenance, and regulatory compliance. This typically involves maintaining detailed logs of all coupling and uncoupling events, including date, time, personnel involved, equipment used, and any observations or anomalies. Pre- and post-coupling checklists help ensure that all procedures are followed meticulously. Photographs or videos can also serve as visual documentation, particularly in complex systems. Maintenance logs track inspections, repairs, and replacements, providing a record of the coupling system’s history and helping to predict potential failures. Accurate documentation is essential for identifying trends, preventing recurring issues, and meeting regulatory compliance requirements. In the case of an incident, these records can prove invaluable in investigations, helping to determine the root cause and preventing similar occurrences in the future.

Key Topics to Learn for Operate Coupling and Uncoupling Equipment Interview

- Safety Procedures: Understanding and adhering to all relevant safety protocols for operating and maintaining coupling and uncoupling equipment. This includes lockout/tagout procedures, personal protective equipment (PPE) requirements, and hazard identification.

- Types of Couplings: Familiarity with various coupling types (e.g., quick-connect couplings, threaded couplings, flange couplings) and their applications in different industrial settings. Understanding the strengths and weaknesses of each type is crucial.

- Operational Procedures: Mastering the correct procedures for coupling and uncoupling equipment, including pre-operation checks, proper connection techniques, and post-operation inspection.

- Troubleshooting Common Issues: Developing the ability to diagnose and resolve common problems, such as leaks, misalignments, and damaged components. This includes understanding preventative maintenance schedules.

- Hydraulic and Pneumatic Systems: For systems utilizing these, understanding the principles of hydraulic and pneumatic pressure, flow control, and their role in coupling/uncoupling operations.

- Material Compatibility: Knowledge of material compatibility within the coupling system to avoid corrosion, degradation, or leaks. Understanding the impact of different fluids and environments.

- Maintenance and Inspection: Understanding routine maintenance tasks, inspection schedules, and the importance of record-keeping for preventative maintenance. Knowing how to identify wear and tear and when to replace components.

Next Steps

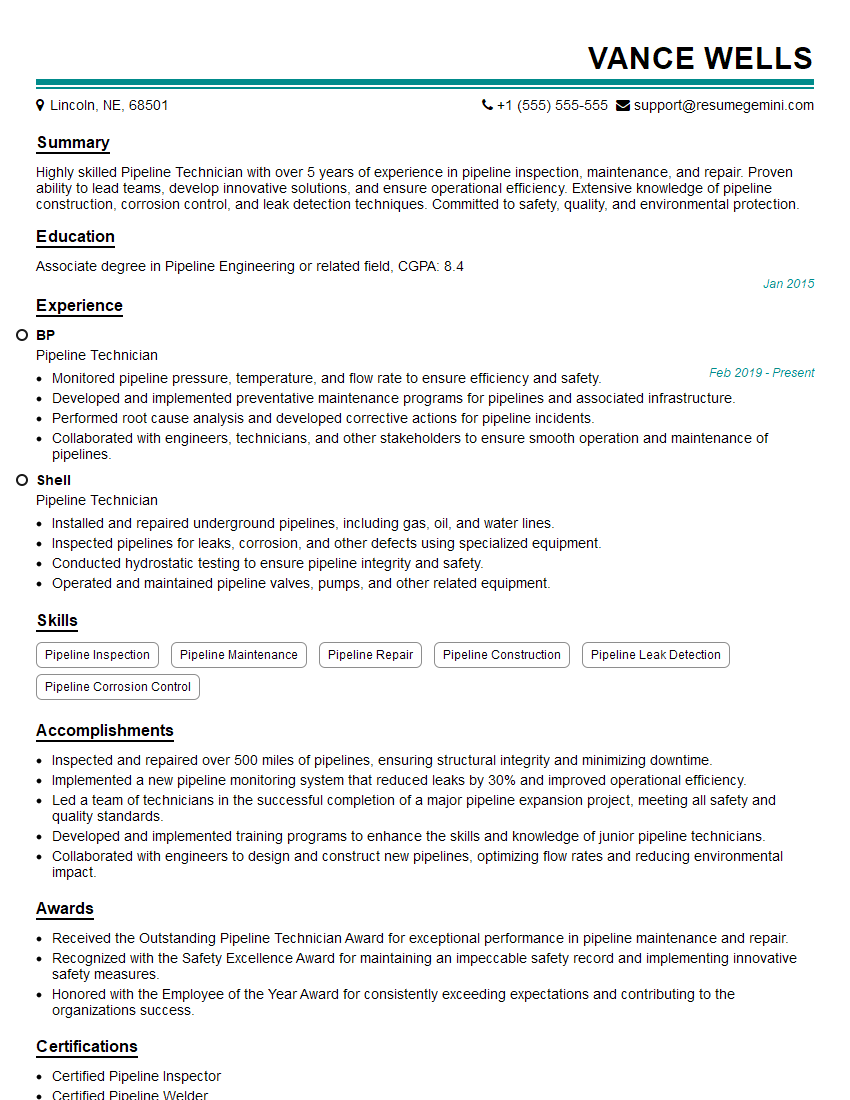

Mastering the operation and maintenance of coupling and uncoupling equipment is highly valuable in many industrial sectors, opening doors to diverse and rewarding career opportunities. A strong understanding of these systems demonstrates technical proficiency and commitment to safety, making you a highly desirable candidate. To enhance your job prospects, focus on creating a professional and ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a compelling resume tailored to the specific demands of this field. Examples of resumes tailored to Operate coupling and uncoupling equipment positions are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO