Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Slickline Operations interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Slickline Operations Interview

Q 1. Describe the different types of slickline tools used in well intervention.

Slickline tools are specialized instruments deployed downhole using a thin, flexible wireline (the slickline) for various well intervention tasks. The type of tool depends on the operation required. Here are some examples:

- Retrievable Packers: These tools seal off sections of the wellbore, often used for zonal isolation during testing or stimulation.

- Fishing Tools: Used to retrieve dropped objects or damaged equipment from the wellbore. Types include overshots, jars, and various grabs.

- Downhole Gauges: These measure various parameters like pressure, temperature, or fluid levels. They are often retrievable after data acquisition.

- Perforating Guns: Although typically deployed with larger wireline, smaller-scale perforating guns exist and can be run on slickline in certain circumstances for limited perforations.

- Valve Operators: These manipulate valves within the well, for example, opening or closing subsurface safety valves (SSVs).

- Mechanical Conveyors: Small conveyors which can be used to bring samples up or to place small components or tools downhole

The choice of slickline tool hinges on the specific well intervention operation needed and the well’s unique conditions.

Q 2. Explain the process of running a slickline tool into a well.

Running a slickline tool involves a careful, step-by-step process emphasizing safety and precision:

- Pre-job Planning: This includes verifying the tool’s integrity, planning the operation sequence, and ensuring all necessary equipment is available and in good working order.

- Rig-up: Setting up the slickline unit, ensuring proper tension on the wireline and that the drum is correctly mounted on the unit.

- Tool Assembly: Attaching the chosen tool to the end of the slickline, ensuring a secure connection. This often involves visual inspection and sometimes specialized testing to guarantee a secure connection.

- Lowering the Tool: Carefully lowering the slickline into the well, maintaining constant tension and monitoring the depth. We use depth indicators and often utilize a pressure gauge or other tools that show movement in the wellbore to ensure the tool is in the correct location.

- Performing the Operation: Once the tool reaches its target depth, the operation (e.g., retrieving a sample, closing a valve) is performed. This step is very specific to the tool employed.

- Retrieving the Tool: After the operation, the tool is carefully retrieved from the well, maintaining constant control of the slickline to prevent damage or accidents. Again, we closely monitor depth indicators and pressure gauges.

- Rig-down: Disassembling the equipment, cleaning, and storing tools after the operation is complete.

Throughout the process, constant monitoring of the slickline tension and depth is crucial to prevent accidents and ensure operational efficiency.

Q 3. How do you ensure the safe handling and operation of slickline equipment?

Safe handling and operation of slickline equipment are paramount. We achieve this through:

- Regular Inspections: Thorough inspections of the slickline, winch, and all associated equipment are conducted before and after each operation. This identifies worn or damaged components, which we replace immediately.

- Proper Training: All personnel involved in slickline operations receive comprehensive training, including safety procedures, emergency response protocols, and equipment operation. Training incorporates a strong emphasis on hazard identification and risk assessment.

- Standard Operating Procedures (SOPs): We strictly adhere to detailed SOPs to ensure consistency and minimize the risk of error. These cover every aspect of the operation, from setup to post-job cleanup.

- Maintenance Schedules: Regular maintenance schedules for the slickline winch and other equipment help to avoid malfunctions and keep the equipment in good working order. We follow manufacturer’s recommendations for lubrication, component replacement, etc.

- Competency Assessments: We regularly assess the competency of personnel involved in slickline operations through practical demonstrations and theoretical knowledge tests. This ensures that our crew continues to work safely and effectively.

A proactive approach to safety is critical in slickline operations, and it forms the foundation of our approach.

Q 4. What are the common challenges faced during slickline operations?

Slickline operations can present various challenges, including:

- Stuck Tools: Tools can become stuck in the wellbore due to various reasons, such as differential sticking, bridging, or debris.

- Slickline Breakage: The slickline can break due to excessive tension, corrosion, or damage. This necessitates a complex and time-consuming fishing operation.

- Wellbore Conditions: Deviated wells, narrow wellbores, or the presence of high-pressure zones can complicate operations and increase the risk of accidents.

- Equipment Malfunctions: Mechanical failures of the slickline winch or other equipment can halt operations and lead to delays or safety concerns. Regularly scheduled maintenance reduces this risk.

- Environmental Factors: Weather conditions, such as high winds or rain, can affect operations and create safety hazards.

Effective risk management and well-planned contingency measures are critical to mitigating these challenges.

Q 5. Describe your experience with different types of well completions.

My experience encompasses various well completions, including:

- Cased and Cemented Completions: I’ve worked extensively with wells that have been cased and cemented, requiring careful navigation of the casing and cement to reach the target zone. This usually involves ensuring the tool does not catch on imperfections in the wellbore.

- Openhole Completions: I have experience with openhole completions where the tools interact directly with the formation. This demands extra care to prevent damage to the tools and formation.

- Gravel-Packed Completions: I’m familiar with operating in gravel-packed completions, understanding how the gravel pack can impact tool operation and necessitating specific strategies to avoid tool hang-ups.

- Coiled Tubing Completions: While not directly slickline, understanding coiled tubing completions enhances the overall picture of well intervention techniques and the tools we might encounter.

Understanding the specific completion type is crucial in selecting the appropriate slickline tools and planning the operation. Each type presents its unique challenges and opportunities.

Q 6. How do you troubleshoot problems encountered during slickline operations?

Troubleshooting in slickline operations requires a systematic approach:

- Identify the Problem: Carefully assess the nature of the problem. Is the tool stuck? Is there a slickline malfunction? Are we not getting the results we expected?

- Gather Information: Collect all available data, including depth readings, pressure gauges, and any relevant observations from the crew.

- Analyze the Situation: Based on the gathered information, hypothesize the root cause of the problem. What factors could have contributed to this event?

- Develop a Solution: Devise a plan of action to address the problem. This might involve using specialized fishing tools, adjusting slickline tension, or altering the operation sequence.

- Implement and Monitor: Execute the chosen solution carefully, closely monitoring the results to ensure its effectiveness. Is it solving the problem, or are we getting unexpected results?

- Document the Outcome: Thoroughly document the problem, the solution, and the outcome. This informs future operations and helps to improve troubleshooting efficiency.

A methodical approach coupled with experience allows for efficient problem solving and minimizing downtime.

Q 7. What safety precautions do you follow while operating slickline equipment?

Safety is paramount in slickline operations. Our safety procedures include:

- Pre-Job Safety Meetings: Detailed safety meetings are held before every operation, reviewing potential hazards and outlining safety protocols.

- Personal Protective Equipment (PPE): All personnel wear appropriate PPE, including safety glasses, gloves, and hard hats. This may extend to specialized equipment depending on the specific job.

- Emergency Response Plan: A well-defined emergency response plan is in place to handle unexpected events, such as slickline breakage or personnel injury.

- Lockout/Tagout Procedures: Strict lockout/tagout procedures are followed when working on equipment to prevent accidental energization.

- Environmental Considerations: We implement measures to minimize environmental impact, such as proper waste disposal and spill prevention.

- Regular Communication: Constant communication between crew members ensures that everyone is aware of the situation and potential hazards.

A strong safety culture where everyone takes responsibility for their actions and those of their teammates is the cornerstone of our work.

Q 8. Explain the importance of proper logging and documentation in slickline operations.

Proper logging and documentation are paramount in slickline operations for several critical reasons. Think of it like a meticulous medical chart – it’s essential for tracking progress, identifying potential issues, and ensuring accountability. Without detailed records, troubleshooting becomes a nightmare, and the potential for costly mistakes or even accidents significantly increases.

- Safety: Detailed records of operations, including equipment used, personnel involved, and any anomalies encountered, are crucial for accident investigation and prevention. This allows us to identify trends and implement safety improvements.

- Troubleshooting: If a problem arises during or after the operation (e.g., a tool getting stuck), comprehensive logs provide invaluable information for determining the cause and finding a solution. For instance, knowing the exact depth at which a snag occurred guides the selection of appropriate fishing tools.

- Regulatory Compliance: Many jurisdictions mandate precise logging for slickline operations, and accurate records are essential to demonstrate compliance. This can save your company from hefty fines and legal repercussions.

- Efficiency and Optimization: Analyzing past operations using well-maintained logs allows us to identify inefficiencies and optimize future work. We can determine the best practices for specific well conditions and reduce operational time and costs.

In my experience, I’ve found that using a standardized logging format, coupled with digital tools and databases, greatly enhances efficiency and accuracy. We document everything from the initial pre-job planning to the post-job analysis, including equipment parameters, operational procedures, and observed results. This ensures a comprehensive and auditable record for each operation.

Q 9. How do you manage risks associated with slickline operations?

Risk management in slickline operations is a proactive process, not a reactive one. It involves identifying potential hazards, assessing their likelihood and severity, and implementing controls to mitigate them. It’s like being a detective, anticipating problems before they occur.

- Pre-Job Planning: This is crucial. We thoroughly review well information, including wellbore conditions, previous operations, and potential hazards (e.g., high pressure, H2S). This allows for choosing appropriate equipment and procedures.

- Equipment Inspection: Rigorous pre-operational inspection of slickline, tools, and equipment is non-negotiable. We follow strict checklists to ensure everything is in top condition. A faulty tool can lead to catastrophic consequences.

- Personnel Training: Highly skilled and trained personnel are vital. Continuous training and competency assessments ensure everyone understands safe operating procedures and emergency response protocols.

- Emergency Response Plan: We must have a detailed plan for handling emergencies, including equipment failures, well control issues, or medical emergencies. This plan is rehearsed regularly to ensure efficiency and effectiveness in times of crisis.

- Communication: Clear and consistent communication between the slickline crew and the rig crew is paramount. Miscommunication can quickly lead to errors.

For instance, in one operation, we identified a high risk of wireline breakage due to a suspected change in wellbore geometry. To mitigate this, we reduced the operating tension and used a larger diameter slickline. This prevented a potential costly fishing job.

Q 10. Describe your experience with different types of fishing tools.

My experience encompasses a wide array of fishing tools, each designed for specific scenarios. Think of it as a specialized toolbox for well intervention.

- Jarring Tools: Used to free stuck tools or equipment by creating impact. Different types are available, varying in size and impact force. I’ve extensively used hydraulic jars and mechanical jars.

- Over-shot Tools: Designed to capture and retrieve broken components or tools from the wellbore. They come in various sizes and designs to accommodate different types of debris.

- Retrieving Tools: These tools are used for removing various types of debris and include grapples, spears, and magnetic tools. The choice depends heavily on the nature of what’s stuck.

- Swabbing Tools: Primarily used for cleaning the wellbore or removing debris. They use a combination of pressure and mechanical action for this process.

- Specialized Tools: There are many specialty tools, such as cutters, mills, and shaped retrieval tools for more complex situations. Selecting the right tool demands a thorough understanding of the situation and the stuck object.

I recall an instance where a downhole tool became stuck due to a sudden collapse of the wellbore. Using a combination of jarring tools and a shaped overshot, we successfully retrieved the entire assembly, minimizing downtime and avoiding a more complex and costly fishing operation.

Q 11. Explain the concept of wireline tension and its importance.

Wireline tension is the force applied to the slickline during operations. It’s like the ‘muscle’ of the operation. Controlling this force is crucial for several reasons.

- Tool Control: Maintaining adequate tension ensures the tools operate as intended. Insufficient tension can lead to tool slippage or ineffective operation. Too much tension can cause equipment damage or even a wireline break.

- Safety: Proper tension control minimizes the risk of equipment failure and prevents accidents. Sudden tension changes can be particularly dangerous.

- Data Accuracy: In logging operations, maintaining a constant tension is vital to obtaining accurate measurements. Variations in tension can skew the data.

- Wellbore Protection: Excessive tension can damage the wellbore. This can lead to costly repairs or even the complete abandonment of the well.

Imagine trying to use a fishing rod with no tension on the line – you wouldn’t have any control over your hook! Similarly, in slickline operations, controlling wireline tension is crucial for success and safety.

Q 12. How do you calculate the required weight and tension for slickline operations?

Calculating the required weight and tension for slickline operations is a complex process that depends on many factors. There isn’t a single formula, but rather a process involving multiple considerations.

- Weight of the Tool String: This includes the weight of all tools and equipment being lowered.

- Friction in the Wellbore: The wellbore’s geometry and condition (e.g., inclination, roughness) heavily influence friction, necessitating added tension.

- Fluid Density: The buoyancy of the drilling fluid affects the effective weight of the tools.

- Desired Tension: This varies based on the operation. We always use a safety factor.

- Slickline Strength: The maximum allowable tension is determined by the slickline’s specifications.

The calculation usually involves using engineering software and empirical data. It often follows iterative processes to optimize tension and minimize risk. We often use tension indicators and sensors to monitor and adjust tension in real-time during the operation. Experienced judgment and adherence to safety standards are key here. It’s a combination of calculations and practical experience.

Q 13. What are the limitations of slickline technology?

Slickline technology, while versatile, does have limitations:

- Weight Capacity: Slickline can only support a limited weight, restricting the size and type of tools that can be used. Heavier tools often require wireline instead.

- Depth Limitations: Although advancements extend operational depths, extreme depths may still exceed the capabilities of slickline. High tensile strength wireline becomes necessary for deep wells.

- Environmental Factors: Highly deviated wells, complex wellbore geometries, and corrosive environments can challenge slickline operations. Specialized equipment may be required.

- Accessibility: Slickline is less adaptable to complex interventions than some other well intervention techniques (such as coiled tubing). In certain scenarios, slickline might not be the most effective choice.

For instance, in a highly deviated well with a complex geology, using slickline to run a large milling tool might be impossible due to the weight limitations. In such cases, coiled tubing or other methods would be more suitable.

Q 14. How do you determine the appropriate slickline size for a specific operation?

Selecting the appropriate slickline size is based on several critical factors that need careful consideration. You want to choose a size that’s strong enough for the job but not excessively large and unwieldy.

- Operating Depth: Deeper wells require a stronger slickline with a larger diameter to withstand the increased weight and tension.

- Weight of Tool String: Heavier tools require a slickline with a higher tensile strength and potentially a larger diameter.

- Wellbore Conditions: Rough wellbores or those with unexpected restrictions may require a slightly larger diameter slickline for better durability.

- Environmental Considerations: Corrosive environments necessitate slickline with specific materials for resistance to chemicals.

- Manufacturer Recommendations: Following the manufacturer’s guidelines and recommendations on slickline selection is essential for safety and operational success.

It’s a balance. Too small, and you risk breakage; too large, and it becomes difficult to handle. We often consult tables and charts provided by slickline manufacturers, combining those figures with our operational experience and well-specific considerations to reach a safe and effective decision.

Q 15. Describe your experience with different types of downhole tools and their applications.

My experience encompasses a wide range of downhole tools used in slickline operations. These tools are essentially small, specialized instruments deployed on a thin wireline (the slickline) into a wellbore to perform various tasks. The specific tool used depends entirely on the operation’s objective.

- Pumps: These deliver fluids or chemicals into the well for things like cementing, acidizing, or fracturing. I’ve worked with both positive displacement and jet pumps, each suited for different viscosities and flow rates. For example, a positive displacement pump might be used for precise chemical injection, while a jet pump is ideal for higher volume applications.

- Retrievable Packers: These devices isolate sections of the wellbore, allowing for selective operations. I’ve experienced setting and retrieving different types, including inflatable and mechanical packers, and troubleshooting issues like leaks or improper seating.

- Flow Control Devices: These regulate fluid flow in the well, often used during testing or production optimization. This includes tools like bridge plugs and restrictors. Proper selection is crucial, for example, selecting a bridge plug with a suitable pressure rating to handle the well’s conditions.

- Measurement Tools: These gather data within the well. I have extensive experience with temperature and pressure gauges, as well as specialized tools for measuring fluid levels or assessing the condition of the well’s casing or tubing. For instance, casing inspection tools may use magnetic flux leakage or ultrasonic techniques to detect corrosion.

- Fishing Tools: These are critical for retrieving dropped or stuck objects in the wellbore. I’m proficient in using various overshot, jars, and other specialized fishing tools, understanding the selection criteria and techniques for successful retrieval based on the nature of the stuck object.

The selection and application of these tools require a detailed understanding of well conditions, operational objectives, and safety procedures. Each deployment involves careful planning and execution to ensure the operation is successful and safe.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret slickline logs and data?

Slickline logs and data are interpreted through a combination of experience, knowledge of well conditions, and careful analysis of the recorded information. The data itself might be pressure readings, temperature profiles, or even simply the presence/absence of a specific signal, depending on the tool used. The interpretation process involves several steps:

- Data Validation: First, the data is checked for inconsistencies or anomalies that might indicate equipment malfunction or signal interference. This includes checking against other data sources like pressure gauges on the surface.

- Correlation with Well History: The data is compared to previous logs and well history to identify trends and patterns. For instance, a sudden drop in temperature might indicate a change in fluid flow, while a pressure increase could suggest a zone of high permeability.

- Tool Response Interpretation: Each tool has a specific response to various well conditions. Understanding this response is crucial for accurately interpreting the data. For example, a certain level reading of a depth gauge needs to be adjusted for cable stretch.

- Geological Context: Interpreting the data requires knowledge of the geological formations in the well. This information can help to explain observed patterns and anomalies.

For example, a temperature log showing a sharp increase at a specific depth might indicate a gas inflow or the presence of a geothermal anomaly. Combining this information with pressure data and well history can then inform decisions about production optimization or well intervention.

Q 17. Explain the process of retrieving a stuck slickline tool.

Retrieving a stuck slickline tool is a complex process requiring careful planning and execution, and often involves a series of steps:

- Assessment: First, a thorough assessment of the situation is conducted. This involves determining the depth and nature of the stuck tool, as well as the reasons for the sticking. Is it mechanical, due to pressure changes, or something else?

- Strategy Development: Based on the assessment, a retrieval strategy is developed. This might involve using specialized fishing tools such as overshots, jars, or wash-overs to free the tool.

- Tool Selection: Appropriate fishing tools are selected based on the nature of the stuck object and the well’s conditions. The size and type of tool are critical for success; an incorrect choice can exacerbate the situation.

- Gradual Pulling and Release Techniques: The stuck tool is then carefully pulled using the winch, often with breaks and pauses to avoid damaging the tool or the wellbore. Techniques like using jars to create shock impulses can help to free the stuck tool.

- Alternative Techniques: If the standard techniques fail, alternative methods such as milling or drilling may be employed. These are more invasive and usually more expensive options.

- Documentation: Throughout the entire retrieval process, detailed records are kept. This documentation includes decisions, actions taken, equipment used and the outcome.

A successful retrieval minimizes downtime and prevents potential damage to the well. Experience plays a vital role in effectively assessing the situation and selecting the optimal retrieval technique.

Q 18. What are the environmental considerations during slickline operations?

Environmental considerations are paramount in slickline operations. Minimizing the environmental impact is achieved through several key practices:

- Waste Management: Proper handling and disposal of drilling fluids, produced water, and other waste materials are crucial. This often involves using specialized containment systems and following strict environmental regulations.

- Spill Prevention: Preventive measures, including regular inspections of equipment and the implementation of emergency response plans, minimize the risk of spills.

- Air Emissions: Control of air emissions from the equipment, especially those involving combustion engines, is important. This might involve the use of emission control equipment or minimizing operation times.

- Noise Reduction: Slickline operations can be noisy. Using noise reduction equipment or implementing procedures to minimize noise pollution near sensitive areas, such as wildlife habitats, is crucial.

- Water Management: Managing the usage and disposal of water used in operations must consider the local water resources and regulations. Careful planning ensures minimum water use and efficient disposal.

Compliance with all applicable environmental regulations and the implementation of best practices is essential. Environmental audits and reporting are integral components of responsible slickline operations.

Q 19. Describe your experience working with different types of wellheads and tubing heads.

My experience includes working with a variety of wellheads and tubing heads, each with unique designs and operating procedures. The type of wellhead and tubing head used depends heavily on the well’s pressure and temperature conditions, as well as the type of well (e.g., oil, gas, or injection well).

- Wellhead Types: I’ve worked with various wellhead designs, including those with bolted, flanged, or threaded connections. Each design presents its own challenges and requires specific handling techniques. For example, a high-pressure well might necessitate a wellhead with specialized pressure ratings and safety features.

- Tubing Head Types: Similarly, I’m familiar with different tubing head configurations, including those with various types of seals and connections. Understanding the design features is critical for safe and efficient slickline operations. For instance, a damaged seal could lead to leaks and potentially jeopardize an operation.

- Safety Procedures: Regardless of the type of wellhead or tubing head, safety procedures are paramount. This includes proper lockout/tagout procedures before any work is performed, ensuring that pressure is relieved and the well is secured. Before working on any head, an appropriate risk assessment needs to be done.

Understanding the unique characteristics of each wellhead and tubing head design allows for the safe and efficient execution of slickline operations. Careful planning and meticulous adherence to safety protocols are non-negotiable.

Q 20. How do you maintain and inspect slickline equipment?

Maintaining and inspecting slickline equipment is critical for ensuring safe and efficient operations. This involves a multi-faceted approach:

- Regular Inspections: All equipment undergoes regular visual inspections, checking for wear and tear, damage, or corrosion. This includes the slickline itself, the winch, the tools, and all associated components. Any defects are immediately addressed to prevent failures.

- Functional Tests: Regular functional tests are performed to ensure the proper operation of all components. This might involve testing the winch’s braking system, the cable’s strength, and the functionality of the various tools.

- Lubrication: Regular lubrication is crucial to ensure the smooth operation of moving parts and to prevent wear and tear. Appropriate lubricants are used for all components.

- Calibration: Measurement tools are regularly calibrated to maintain accuracy. This ensures that the data collected is reliable and can be used for informed decision-making.

- Record Keeping: Detailed records are kept of all inspections, maintenance, and repairs. This includes the date, the type of work performed, and the condition of the equipment. This information is essential for tracking the equipment’s history and identifying potential maintenance issues.

A robust maintenance program is essential for minimizing downtime and preventing accidents. Proper upkeep ensures that equipment remains reliable and safe for operation.

Q 21. What are the different types of slickline winches and their capabilities?

Slickline winches are the heart of slickline operations, providing the controlled power needed to deploy and retrieve tools. Different winches cater to different needs and well conditions.

- Manual Winches: These are simpler, smaller winches that are often used for lighter applications or in locations with limited power access. They are manually operated, requiring significant human effort and expertise.

- Electric Winches: These are more powerful and efficient, offering more precise control over the slickline’s movement. They are commonly used in modern slickline operations because of their capabilities.

- Hydraulic Winches: These provide even greater control and power, especially useful in challenging well conditions or for heavier tools. Hydraulic winches often feature sophisticated control systems and safety features.

The choice of winch depends on various factors including the depth of the well, the weight of the tools, the type of operation, and the available power source. Each type of winch needs appropriate training to operate safely and efficiently, and regular maintenance is necessary to ensure reliability.

Q 22. How do you address wellbore instability during slickline operations?

Wellbore instability during slickline operations is a serious concern, potentially leading to stuck tools and costly remedial work. Addressing it requires a multi-pronged approach focusing on proactive measures and reactive solutions.

- Pre-job planning: Thorough review of well logs (e.g., gamma ray, caliper, density logs) to identify potential instability zones – such as shale formations, fractured intervals, or high-pressure zones. This helps in selecting appropriate tools and fluids.

- Mud engineering: Utilizing drilling mud with optimized properties – including density, viscosity, and filtration control – to stabilize the wellbore and prevent formation collapse or swelling. This might include adding weighting agents or specialized mud additives. For example, a high-viscosity mud might be selected for a highly fractured formation.

- Tool selection: Choosing slickline tools designed to minimize stress on the wellbore. For example, using smaller diameter tools and employing specialized centralizers to prevent the tool from contacting the wellbore wall reduces the risk of damage and sticking.

- Slow and controlled operations: Performing slickline operations slowly and deliberately minimizes the risk of damaging the wellbore. This reduces shock loads and prevents sudden tool movement that could cause problems.

- Real-time monitoring: Close monitoring of weight-on-bit (if applicable), torque, and other relevant parameters can indicate potential problems early on, allowing for timely intervention. Unusual increases in torque might signal impending tool sticking.

- Reactive measures: If a tool does get stuck, a well-planned retrieval strategy is crucial. This might involve attempts to free the tool using various techniques, such as using overpull, back-reaming, or specialized fishing tools. The severity of the situation dictates the approach. Sometimes, abandoning the tool may be the only safe option.

In essence, anticipating potential issues and responding effectively through careful planning and execution is key to mitigating wellbore instability during slickline operations.

Q 23. What is your experience with hydraulic fracturing operations using slickline tools?

My experience with hydraulic fracturing operations using slickline tools encompasses a variety of tasks, predominantly focusing on stimulation diagnostics and post-frac evaluations. I’ve been involved in deploying slickline-conveyed tools to measure downhole pressure and temperature, assess fracture conductivity, and inspect the condition of deployed equipment post-fracturing.

Specifically, I have experience with:

- Deploying pressure gauges and temperature sensors to monitor the pressure profile during fracturing and assess the effectiveness of the stimulation process.

- Retrieving samples from the fracture using specialized slickline-deployed tools.

- Inspecting perforations and evaluating the integrity of the casing post-fracturing to identify any issues resulting from the treatment.

This experience has provided me with a thorough understanding of the challenges and nuances of integrating slickline technology into hydraulic fracturing operations, allowing me to effectively troubleshoot issues and ensure the efficient completion of the job.

Q 24. Explain your understanding of relevant safety regulations and procedures.

My understanding of relevant safety regulations and procedures is comprehensive, incorporating both company-specific guidelines and industry best practices. This includes adherence to:

- OSHA regulations: I am intimately familiar with relevant OSHA standards for well operations, including those pertaining to hazardous energy control (lockout/tagout procedures), confined space entry, and personal protective equipment (PPE) use.

- API standards: I’m well-versed in the relevant API standards concerning well control, drilling operations, and slickline procedures. Understanding these standards is crucial for safe and efficient operation.

- Company-specific safety protocols: I always strictly adhere to the specific safety regulations and operating procedures established by my employer, including daily safety briefings, permit-to-work systems, and emergency response protocols.

- Incident reporting and investigation: I am trained in the proper procedures for reporting and investigating incidents, near misses, and potential hazards. Thorough documentation is vital for preventing recurrence.

Safety is my top priority. I believe a proactive approach – where safety is paramount and everyone is aware of the risks and mitigation plans – is crucial to the successful completion of every slickline operation.

Q 25. How do you handle emergency situations during slickline operations?

Handling emergency situations during slickline operations requires swift, decisive action and a calm, methodical approach. My training emphasizes immediate response and efficient communication.

- Assessment: The first step is to quickly assess the situation to determine the nature and severity of the emergency (e.g., stuck tool, well control issue, equipment malfunction).

- Communication: Immediately communicate the emergency to the supervisor and other relevant personnel, providing a clear and concise description of the situation.

- Well control: If a well control incident is suspected, immediately activate the well control procedures, prioritizing safety. This might involve shutting in the well and taking steps to stabilize the situation.

- Tool retrieval: If the emergency involves a stuck tool, try to free the tool using standard procedures. If this is unsuccessful, escalate to more complex retrieval methods.

- Emergency shutdown: If necessary, immediately shut down all operations and evacuate the area. Safety is paramount in all circumstances.

- Post-incident analysis: After the emergency has passed, a thorough investigation is performed to identify the root cause and implement corrective measures to prevent future recurrence.

Regular drills and training are crucial for effective response in emergency situations.

Q 26. Describe your experience with performing pre-job risk assessments.

Pre-job risk assessments are an integral part of my workflow. I always conduct a thorough risk assessment before any slickline operation, following a structured approach such as a Job Safety Analysis (JSA).

- Identifying hazards: The first step involves identifying all potential hazards related to the specific operation, including those associated with the wellbore, equipment, and environmental conditions. This includes considering potential wellbore instability, equipment failure, and environmental factors like weather.

- Assessing risks: Once hazards are identified, I assess the likelihood and severity of each hazard occurring. This step often involves using a matrix to rank each hazard.

- Developing controls: Based on the risk assessment, I develop appropriate controls to mitigate the identified hazards. These controls might include using specific equipment, modifying procedures, or implementing additional safety precautions.

- Documentation: The entire risk assessment process, including identified hazards, risk levels, and implemented controls, is thoroughly documented and shared with the team.

- Review and update: The risk assessment is regularly reviewed and updated as needed, particularly if changes occur in the planned operation or environmental conditions.

A comprehensive pre-job risk assessment is not just a checklist; it’s a proactive measure that helps identify and address potential risks before they cause incidents.

Q 27. What are your strengths and weaknesses as a slickline operator?

Strengths: My strengths as a slickline operator include my strong problem-solving skills, attention to detail, methodical approach, and commitment to safety. I am adept at troubleshooting complex situations and have a proven track record of successfully completing challenging operations under pressure. My experience with a wide range of slickline tools and techniques is another valuable asset. I am also a highly effective communicator and team player, capable of working well under pressure and coordinating with different teams seamlessly.

Weaknesses: While I possess a broad range of skills, I could benefit from further developing my expertise in advanced well intervention techniques, specifically those involving complex fishing operations. I also aim to enhance my proficiency in using cutting-edge data acquisition and analysis software for optimizing slickline operations.

Q 28. Describe a time you successfully solved a challenging problem during slickline operations.

During a slickline operation to retrieve a stuck downhole tool, we encountered an unusual challenge: the tool was severely stuck, and conventional methods such as overpull were proving ineffective. Initial attempts resulted in higher torque, suggesting the tool might be stuck due to a combination of mechanical binding and differential sticking (tool becoming stuck against the wellbore wall).

After analyzing the situation and reviewing the well logs, I proposed a different approach. Instead of relying solely on brute force, we utilized a combination of techniques. We carefully applied a controlled, oscillating pressure to the tool, combined with slow, measured overpull. This combination of pressure and controlled movement managed to break free the stuck tool. The controlled pressure helped to overcome the differential sticking while the oscillating motion helped alleviate the mechanical binding.

This solution highlighted the importance of a thorough understanding of the well conditions and the ability to adapt strategies based on real-time observations. The successful retrieval of the tool saved significant time and cost, showcasing the benefits of thoughtful problem-solving and a proactive approach to unexpected issues in slickline operations.

Key Topics to Learn for Slickline Operations Interview

- Slickline Tool Running Procedures: Understanding the complete cycle, from pre-job planning and tool assembly to running, retrieving, and post-job analysis. This includes safety protocols and emergency procedures.

- Slickline Equipment Knowledge: Familiarity with various slickline tools, their applications, limitations, and maintenance requirements. Be prepared to discuss different types of wireline, reels, and associated equipment.

- Wellbore Conditions and Their Impact: Knowing how factors like pressure, temperature, and wellbore geometry affect slickline operations and the selection of appropriate tools and techniques.

- Troubleshooting and Problem Solving: Ability to diagnose and resolve common issues encountered during slickline operations, including wireline breaks, tool malfunctions, and unexpected wellbore conditions. Describe your problem-solving methodology.

- Safety Regulations and Best Practices: Demonstrate a thorough understanding of relevant safety regulations and best practices within the oil and gas industry, particularly regarding slickline operations. Highlight your commitment to a safe working environment.

- Data Interpretation and Reporting: Explain your experience collecting, analyzing, and reporting data obtained during slickline operations. This includes interpreting pressure and temperature readings and identifying anomalies.

- Hydraulics and Fluid Dynamics: Understanding the principles of hydraulics and fluid dynamics as they relate to slickline operations, including pressure calculations and fluid flow management.

Next Steps

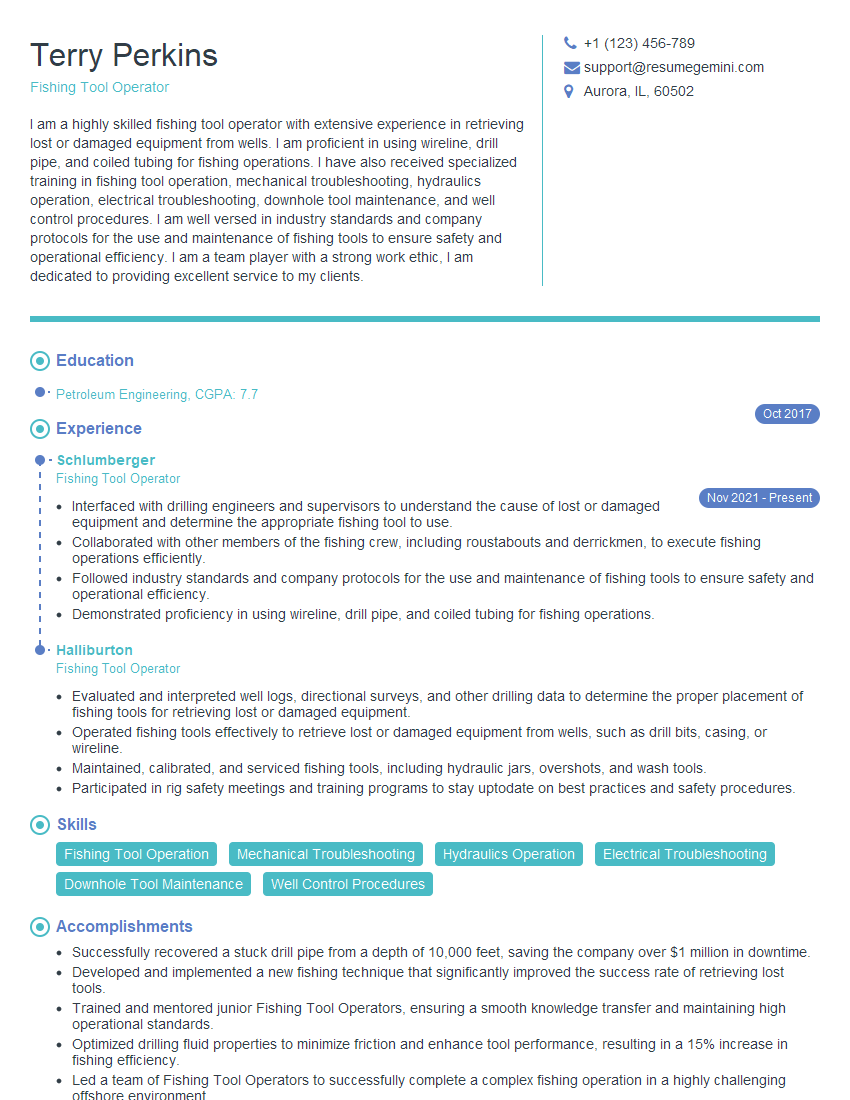

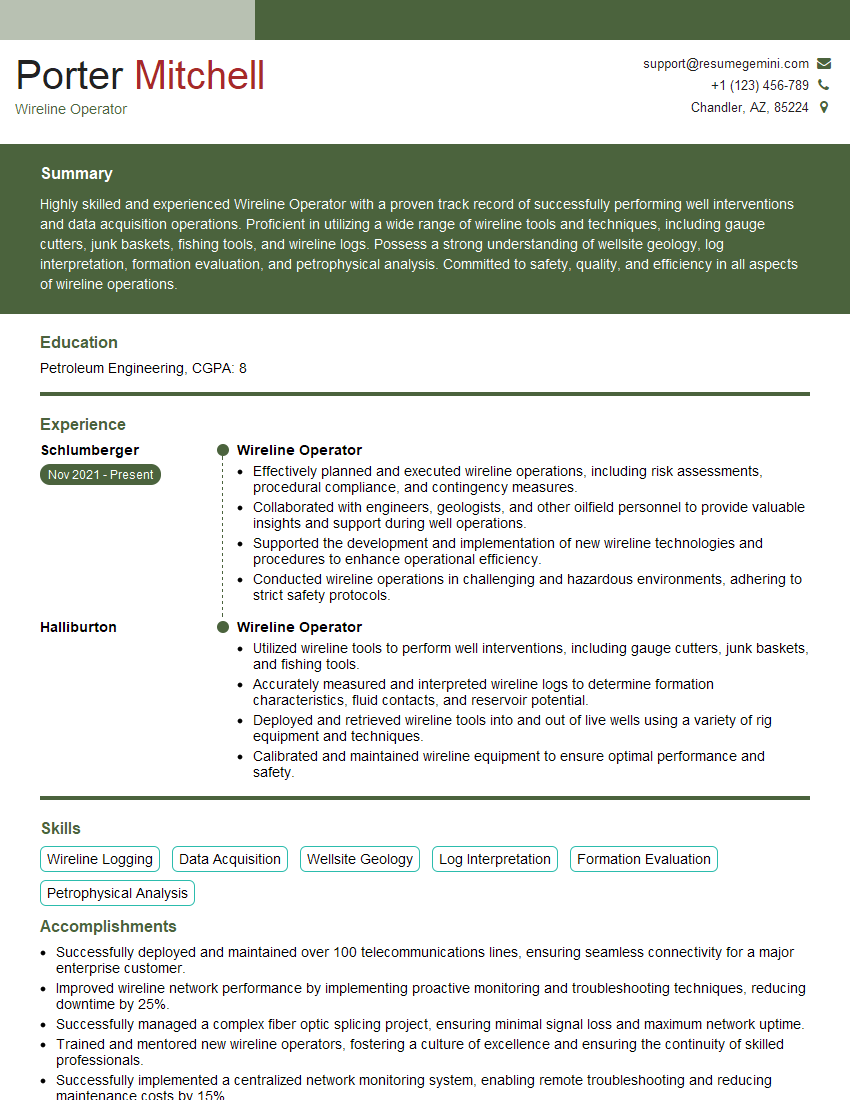

Mastering Slickline Operations opens doors to exciting career advancements within the energy sector, offering opportunities for increased responsibility and higher earning potential. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Slickline Operations are available to guide you, ensuring your application stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO