Preparation is the key to success in any interview. In this post, we’ll explore crucial Inspect and repair locomotives interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Inspect and repair locomotives Interview

Q 1. Describe the process of diagnosing a faulty locomotive engine.

Diagnosing a faulty locomotive engine involves a systematic approach combining observation, testing, and analysis. It starts with gathering information – what symptoms is the engine exhibiting? Is it lacking power, making unusual noises, emitting excessive smoke, or overheating? This initial assessment guides the next steps.

Next, I’d check the readily accessible components. This might include visually inspecting fuel lines for leaks, checking oil and coolant levels, and listening for unusual sounds like knocking or hissing. I’d use diagnostic tools like pressure gauges to measure fuel pressure and compression in the cylinders. For modern locomotives, onboard diagnostic systems (OBD) provide valuable data, often pinpointing specific faults. For example, a low fuel pressure reading might point to a faulty fuel pump, while low compression in a cylinder could indicate a problem with the piston rings or valves.

After preliminary checks, more in-depth diagnostics may be needed. This could involve using specialized tools to test injectors, sensors, and other engine components. Sometimes, it requires disassembling parts of the engine for a closer inspection. The ultimate goal is to identify the root cause, not just the symptoms. For instance, an overheating engine might be due to a faulty radiator, a clogged coolant system, or a problem with the cooling fan – all requiring different solutions.

Q 2. Explain the different types of locomotive brakes and their maintenance.

Locomotives typically employ multiple braking systems for safety and redundancy. The primary system is the air brake system, using compressed air to apply brakes to the wheels. There are two main types within this: dynamic brakes and straight air brakes. Dynamic brakes use the traction motors as generators to slow the locomotive, reducing wear on the friction brakes and extending their lifespan. Straight air brakes are simpler and are used on older models. They apply pressure directly to the brake shoes. Modern locomotives also utilize independent parking brakes, which are typically spring-applied, air-released, ensuring the locomotive remains stationary even if air pressure is lost.

Maintenance of these braking systems is crucial for safety. Regular inspections include checking air pressure, inspecting hoses and air lines for leaks and damage, lubricating moving parts, and testing the brake system’s effectiveness. This involves regularly testing the air pressure gauges, checking for leaks with soapy water, and performing brake tests under controlled conditions to ensure proper application and release. Component replacement, such as brake shoes and air lines, is done as needed, following strict manufacturer’s guidelines and safety protocols. Proper maintenance of the air compressor is also vital as it’s the heart of the air brake system.

Q 3. How do you troubleshoot electrical issues in a locomotive?

Troubleshooting electrical issues in a locomotive requires a methodical approach, starting with safety. Always disconnect the power supply before beginning any electrical work. The process begins with identifying the problem. Is it a complete power failure, intermittent issues, or a specific component malfunction? Knowing this helps narrow down the search area.

I would use a combination of visual inspection, testing with multimeters, and referring to wiring diagrams. Visual inspection helps to spot any obvious damage, such as frayed wires, loose connections, or burned components. A multimeter is indispensable for measuring voltage, current, and resistance, allowing me to identify faulty circuits or components. Wiring diagrams are crucial for understanding the locomotive’s electrical system and tracing circuits. For example, if the headlights aren’t working, I’d trace the circuit from the power source, checking voltage at each connection point, until I locate the fault – be it a blown fuse, a damaged wire, or a faulty switch. Modern locomotives often have sophisticated diagnostic systems that can help isolate problems, providing error codes pointing towards the faulty component.

It’s important to remember that working with high-voltage systems in locomotives requires specialized training and adherence to strict safety procedures. Never attempt repairs without the necessary expertise and equipment.

Q 4. What safety procedures do you follow when inspecting a locomotive?

Safety is paramount when inspecting a locomotive. Before approaching the locomotive, I always ensure that the brakes are set and the engine is shut down. I’d check for any visual signs of danger, like steam leaks, sparking wires, or spilled fluids. I would always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and steel-toed boots. When working around moving parts or high-voltage systems, additional safety measures like lockout/tagout procedures are essential to prevent accidental startup. This involves physically locking out the power supply, preventing any unexpected energizing. Before entering any confined space, I’d ensure proper ventilation and check for hazardous gases using appropriate detectors. Regular training and awareness are key to maintaining a safe working environment.

Q 5. Describe your experience with locomotive air brake systems.

My experience with locomotive air brake systems spans several years, encompassing both preventative maintenance and troubleshooting. I’ve worked on various types of air brake systems, from older straight air systems to more modern electronically controlled systems. This involves regularly inspecting and testing air compressors, pressure gauges, brake cylinders, and air lines. I’m proficient in identifying and resolving issues such as air leaks, malfunctioning valves, and brake cylinder problems. I’ve also participated in the installation and maintenance of automatic brake adjustment systems, which automatically maintain optimal brake shoe clearance. My experience also includes troubleshooting problems involving emergency brake applications and diagnosing the root cause of brake failures. I am familiar with various diagnostic techniques and tools used to assess the air brake system’s performance. For example, I have a thorough understanding of how to correctly interpret the readings from various air pressure gauges and how to troubleshoot problems using test gauges. This knowledge helps to ensure that the brake systems are always in optimal condition and reliable in operation.

Q 6. What are the common causes of locomotive engine overheating?

Locomotive engine overheating can stem from several causes. One common culprit is insufficient coolant flow, possibly due to a clogged radiator, a malfunctioning water pump, or a leak in the cooling system. Problems with the cooling fan, such as a broken fan belt or a malfunctioning fan motor, can also lead to overheating. Another factor is low coolant levels, caused by leaks or improper maintenance. Engine problems, such as low compression or a faulty injector, can also generate excess heat. Finally, environmental conditions, such as high ambient temperatures and extended periods of operation at high loads, can contribute to overheating. For instance, operating a locomotive in desert conditions with inadequate airflow, especially during prolonged uphill climbs, can quickly lead to overheating.

Q 7. How do you perform a pre-trip inspection on a locomotive?

A pre-trip inspection is a critical safety procedure. It involves a thorough visual examination of the locomotive’s exterior and interior components before starting operation. Externally, I check for any signs of damage, such as leaks, dents, or loose parts. I inspect the wheels and undercarriage for any obstructions or damage. I then inspect the brake system, checking for leaks and verifying that the brakes are functioning correctly. I also check the coupling system, ensuring that all components are securely connected. Internally, I check the oil, coolant, and fuel levels and look for any leaks. I also verify that the gauges and lights are working properly. A critical step is to check the air brake system pressure and confirm that the train air brake system is properly charged and functioning correctly. The final step involves ensuring that all safety devices are in place and functioning correctly. This methodical approach ensures that the locomotive is in safe operating condition before its commencement of service.

Q 8. Explain your experience with repairing locomotive fuel systems.

Locomotive fuel systems are complex, involving fuel tanks, pumps, filters, injectors, and control systems. My experience encompasses the entire lifecycle, from preventative maintenance to major overhauls. For example, I’ve diagnosed and repaired fuel leaks by meticulously tracing lines, identifying faulty seals, and replacing components. I’m proficient in troubleshooting issues like low fuel pressure, which can stem from clogged filters, worn pumps, or even faulty sensors. In one instance, a locomotive experienced intermittent power loss due to a partially clogged fuel filter. A simple filter replacement resolved the problem, highlighting the importance of regular preventative maintenance. I’m also adept at working with various fuel types and understanding the specific requirements for each, ensuring optimal performance and minimizing downtime.

My work also includes understanding and repairing fuel injection systems, which are crucial for efficient combustion. These systems often employ sophisticated electronic controls. I use diagnostic tools to identify problems in the injection system – for example, checking fuel injector spray patterns for proper atomization, verifying injector timing, and calibrating the fuel injection control module (FICM) to ensure accurate fuel delivery.

Q 9. Describe your knowledge of locomotive wheel and axle maintenance.

Locomotive wheel and axle maintenance is critical for safety and operational efficiency. It involves regular inspections for wear, cracks, and other defects. I’m experienced in various techniques, including visual inspections, ultrasonic testing (UT) to detect subsurface flaws, and magnetic particle inspection (MPI) to find surface cracks. Wheel sets are also regularly gauged to measure tread wear and ensure proper alignment. Axle journals require meticulous attention, ensuring proper lubrication and checking for overheating or bearing damage. I’ve handled situations requiring wheel truing, where worn wheels are machined to restore their proper profile. Furthermore, I’m familiar with the procedures for safe removal and installation of wheel sets, understanding the critical safety measures involved in handling heavy components and preventing damage to the locomotive undercarriage.

One specific example involved diagnosing a rhythmic clicking sound emanating from a locomotive. After careful inspection and UT testing, we identified a minute crack in one of the axles. The proactive identification and replacement of that axle prevented a potentially catastrophic failure.

Q 10. How do you diagnose and repair locomotive traction motor issues?

Diagnosing and repairing locomotive traction motor issues requires a systematic approach. I begin with a thorough visual inspection, checking for signs of overheating, damage to the windings, or loose connections. I then use specialized diagnostic tools to measure voltage, current, and resistance in different parts of the motor circuit. This allows me to isolate the problem, whether it’s a faulty armature, field winding, or a problem with the motor’s control system. For example, a sudden loss of power might indicate a shorted armature winding, while unusual sounds during operation could point to bearing wear. I’m experienced in performing winding repairs, replacing bearings, and troubleshooting the motor’s control circuitry. Often, specialized software and data analysis are needed to understand the motor’s operational parameters and pinpoint anomalies.

Troubleshooting often involves interpreting diagnostic codes and using schematic diagrams to trace signals and identify faulty components. This demands both a deep understanding of electrical engineering principles and the ability to utilize sophisticated diagnostic equipment. Working on traction motors involves safety precautions due to the high voltages and currents involved.

Q 11. What are the different types of locomotive couplers, and how are they maintained?

Locomotives utilize different types of couplers, primarily knuckle couplers and AAR (Association of American Railroads) couplers, each with specific maintenance requirements. Knuckle couplers are the most common type, designed to allow for automatic coupling and uncoupling. Their maintenance involves regular inspections for wear and tear, lubrication of moving parts, and ensuring the proper functioning of the locking mechanism. AAR couplers are more robust and are often used for heavy-haul applications. They require more rigorous maintenance due to the forces they endure, including thorough inspections for cracks, alignment checks, and pin and yoke lubrication. Regular lubrication and visual checks are essential. I am experienced in diagnosing and repairing issues such as coupler lock failures, which can severely hinder operational efficiency and safety.

Beyond regular maintenance, I understand the importance of safety procedures when working with couplers, especially during coupling and uncoupling operations, which is a high-risk activity. I follow industry best practices to minimize the risk of injury or damage to the equipment.

Q 12. Explain your experience with troubleshooting locomotive computer systems.

Modern locomotives rely heavily on sophisticated computer systems for control, monitoring, and diagnostics. My experience includes troubleshooting these systems using diagnostic software and hardware. This involves interpreting diagnostic trouble codes (DTCs) and using data logging to identify intermittent issues. I’m familiar with different communication protocols used in locomotive networks, including CAN bus systems and other proprietary protocols. I use specialized diagnostic tools to access and analyze data from various onboard control modules, such as the engine control module (ECM), the brake control system, and the traction control system. Problems may range from simple sensor faults to complex software glitches requiring advanced diagnostic procedures. For example, a seemingly minor software bug can lead to substantial performance issues or even safety hazards if not promptly identified and fixed.

Troubleshooting computer systems can also involve working with manufacturers’ technical documentation and online resources to resolve complex problems. My ability to effectively utilize these resources is an essential part of my diagnostic and repair process.

Q 13. How familiar are you with different types of locomotive engines (e.g., diesel-electric, steam)?

I’m familiar with various locomotive engine types, including diesel-electric, steam, and even some gas turbine locomotives. Diesel-electric locomotives, the most common type, are my area of expertise. I understand the intricate interactions between the diesel engine, the generator, and the traction motors. Steam locomotives, while less prevalent today, require a unique set of skills and knowledge regarding boiler maintenance, steam distribution, and valve gear adjustments. The fundamentals of engine operation, however, remain consistent across different types. I can readily adapt my knowledge to address different types of locomotives. While I haven’t worked extensively with gas turbines, my understanding of combustion and power generation systems makes it easier for me to learn new systems quickly.

My experience allows me to appreciate the historical significance of steam locomotives while focusing on the practical aspects of maintaining and repairing the modern diesel-electric fleet. The underlying principles of mechanical and electrical engineering remain essential regardless of the locomotive type.

Q 14. Describe your experience with performing routine locomotive maintenance.

Routine locomotive maintenance is crucial for safety, reliability, and longevity. My experience covers a wide range of tasks, including regular lubrication of moving parts, checking fluid levels (oil, coolant, fuel), inspecting brake systems, performing wheel and axle inspections, and testing safety devices. I’m also adept at conducting thorough visual inspections of the entire locomotive, identifying any potential issues before they become major problems. These procedures adhere to strict schedules outlined by the manufacturer and regulatory bodies. It also includes documenting all maintenance activities and adhering to strict safety protocols.

A significant part of routine maintenance involves the timely replacement of worn or damaged parts to prevent failures. This preventative approach minimizes unexpected downtime and ensures the continued operational efficiency of the locomotive. I always prioritize safety and efficiency in my work, which is why routine maintenance is so important to me.

Q 15. How do you handle emergency situations involving locomotive malfunctions?

Handling locomotive malfunctions requires a calm and systematic approach. My first priority is always safety – ensuring the immediate area is secure and no one is at risk. This includes isolating power sources and using appropriate safety equipment like high-visibility clothing and protective eyewear. Next, I assess the situation. Is the malfunction critical (e.g., complete engine failure, brake failure) or less severe (e.g., minor electrical fault, warning light)? For critical failures, immediate communication with the dispatcher and relevant teams is crucial. We’ll follow established emergency protocols, potentially involving towing the locomotive or implementing temporary repairs to ensure safe movement to a designated repair location. Less severe issues might involve troubleshooting using diagnostic tools to identify the source of the problem and performing on-site repairs if feasible and safe.

For example, during a recent incident involving a sudden loss of air pressure in the braking system, I immediately applied the emergency brake, secured the area, and contacted the dispatcher. While waiting for assistance, I initiated a preliminary investigation using the onboard diagnostic system to pinpoint the source of the leak. This allowed the repair crew to arrive prepared and fix the issue efficiently and safely.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of regular lubrication in locomotive maintenance.

Regular lubrication is paramount for locomotive maintenance because it reduces friction between moving parts. Think of it like oiling the hinges on a door – without lubrication, the parts wear down quickly, leading to increased friction, heat build-up, and ultimately, catastrophic failure. Locomotives have thousands of moving parts, from the massive wheels and axles to intricate internal engine components. Proper lubrication minimizes wear and tear, extending the lifespan of expensive components and reducing the risk of breakdowns. It also improves fuel efficiency by reducing the energy lost through friction. We use various lubricants, each suited for different applications and operating temperatures. Lubrication schedules are meticulously followed, often specified by the manufacturer, and involve tasks like greasing wheel bearings, lubricating connecting rods, and oiling gears.

Q 17. What are the common causes of locomotive wheel flats?

Locomotive wheel flats are a serious issue, potentially causing derailments and significant damage. They typically result from several factors:

- Sudden braking: Harsh braking, particularly at high speeds, can cause the wheels to skid and flatten.

- Wheel defects: Pre-existing cracks or flaws in the wheel can propagate under stress, leading to a flat spot.

- Overheated wheels: Extreme heat generated by prolonged slippage or braking can weaken the wheel’s material and cause flats.

- Impact damage: Striking an obstruction on the tracks can create instantaneous impact forces, resulting in flats.

Detecting wheel flats involves regular inspections using visual checks and specialized ultrasonic testing which helps to detect hidden subsurface flaws. Once detected, the damaged wheel needs replacement or repair, often requiring significant downtime for the locomotive.

Q 18. Describe your experience working with different types of locomotive diagnostic tools.

My experience spans a range of diagnostic tools, both onboard and external. Onboard diagnostic systems (OBD) provide real-time data on various locomotive parameters, allowing for quick identification of potential problems. These systems are becoming increasingly sophisticated, providing detailed information about the engine, braking system, electrical components, and more. I’m proficient in using external diagnostic tools as well, such as multi-meters for checking electrical circuits, pressure gauges for monitoring brake and air systems, and ultrasonic flaw detectors for wheel inspections. I’ve also worked with specialized software packages that allow detailed analysis of the data collected from these diagnostic tools. For instance, I recently used a sophisticated data logger to track performance data over an extended period, which pinpointed a subtle anomaly in the engine’s fuel injection system that could have led to major issues later on.

Q 19. How do you maintain accurate records of locomotive maintenance and repairs?

Maintaining accurate records is crucial for ensuring the safe and efficient operation of locomotives. We use a computerized maintenance management system (CMMS) to track all aspects of locomotive maintenance and repair. This system allows us to record every inspection, repair, and part replacement, including date, time, personnel involved, and the specific problems addressed. The CMMS generates reports that provide valuable insights into the locomotive’s performance and maintenance history. These reports help us identify trends, predict potential failures, and optimize maintenance schedules. All documentation is stored securely and accessible to authorized personnel. This detailed record keeping is vital for regulatory compliance and ensures accountability throughout the process.

Q 20. What safety regulations must be followed when working on locomotives?

Safety regulations are paramount when working on locomotives. These regulations cover various aspects, including:

- Lockout/Tagout procedures: This crucial safety measure ensures that power to the locomotive is completely isolated before any work begins.

- Personal Protective Equipment (PPE): Appropriate PPE, such as hard hats, safety glasses, gloves, and high-visibility clothing, must be worn at all times.

- Confined space entry procedures: Specific procedures must be followed when working in confined spaces like the engine compartment or under the locomotive.

- Hot work permits: Permits are required for any activities involving heat or sparks near flammable materials.

- Hazard communication: Workers must be fully informed about the potential hazards associated with the work and the necessary safety precautions.

Adherence to these regulations is non-negotiable and is essential for preventing accidents and injuries. Regular safety training and audits are conducted to reinforce these procedures and ensure compliance.

Q 21. Explain your experience with repairing locomotive suspension systems.

Locomotive suspension systems are critical for ensuring smooth operation and ride quality. My experience with these systems includes diagnosing and repairing various issues. This often involves inspecting components such as springs, dampers, and air bags for wear and tear, leaks, or damage. I’m proficient in replacing worn or damaged parts, adjusting suspension components to the manufacturer’s specifications, and performing load tests to ensure the system is functioning correctly. I also have experience working with different types of suspension systems, including those using coil springs, air springs, and bolster arrangements. For instance, I once had to repair a locomotive’s air suspension system that had developed a significant leak. I systematically checked each air bag and identified the faulty unit, replacing it and ensuring the system was properly pressurized before returning the locomotive to service.

Q 22. How familiar are you with different types of locomotive batteries and charging systems?

Locomotive batteries are crucial for starting the engine and powering auxiliary systems. I’m very familiar with various types, including lead-acid batteries (the most common, requiring regular maintenance like water level checks and terminal cleaning), nickel-cadmium batteries (known for longer lifespan but higher cost and potential for hazardous waste disposal), and more recently, lithium-ion batteries (offering higher energy density and lighter weight but demanding sophisticated Battery Management Systems (BMS) for safe operation).

Charging systems are equally vital, typically comprising a main alternator driven by the locomotive’s engine and a sophisticated charging regulator that controls the charging rate and prevents overcharging. I’ve worked extensively with both traditional and modern systems, including those with integrated monitoring and diagnostics capabilities. For example, I once diagnosed a faulty charging regulator on a diesel-electric locomotive by analyzing voltage and current readings, leading to its timely replacement and preventing potential battery damage.

- Lead-Acid: Common, require regular maintenance.

- Nickel-Cadmium: Longer lifespan, higher cost, environmental concerns.

- Lithium-Ion: High energy density, sophisticated BMS required.

Q 23. Describe your experience with hydraulic systems in locomotives.

Hydraulic systems in locomotives are essential for braking, suspension, and other crucial functions. My experience includes troubleshooting and repairing various components like hydraulic pumps, actuators, valves, and reservoirs. I understand the importance of maintaining proper fluid levels, filtering, and pressure regulation to prevent leaks and malfunctions. Think of it like the circulatory system of a locomotive; if there’s a blockage or leak, the entire system suffers. I’ve worked on numerous occasions repairing leaks in hydraulic lines, often requiring precise welding and pressure testing to ensure the system’s integrity. One specific incident involved tracing a persistent leak in a braking system; using specialized leak detection equipment, we identified a hairline crack in a high-pressure hydraulic line, necessitating its replacement and rigorous testing to ensure safe operation.

Q 24. How do you interpret locomotive diagnostic codes?

Locomotive diagnostic codes are like a car’s check engine light, but much more complex. Modern locomotives use sophisticated onboard computers that monitor various systems and generate codes indicating malfunctions. I’m proficient in interpreting these codes using specialized diagnostic tools and software. Each code points to a specific system and often a particular component. For instance, a code might indicate a problem with a specific sensor, a faulty actuator, or a communication error between different systems. My approach involves systematically checking the indicated system, using schematics, wiring diagrams, and testing equipment to pinpoint the root cause and implement the necessary repairs.

Think of it as detective work. You have clues (codes), and you use your knowledge and tools to solve the mystery and find the culprit.

Q 25. What is your experience with locomotive preventative maintenance programs?

Preventative maintenance is the cornerstone of reliable locomotive operation. My experience encompasses developing and implementing comprehensive maintenance schedules based on manufacturer recommendations and operational data. This includes regular inspections, lubrication, fluid changes, and component replacements to prevent unexpected failures. I’m also familiar with condition-based monitoring techniques, using data from onboard sensors to predict potential problems and schedule maintenance proactively. For example, I helped implement a predictive maintenance program for a fleet of locomotives that significantly reduced downtime and maintenance costs by anticipating and addressing potential issues before they led to major breakdowns.

Q 26. Describe your experience with welding and fabrication related to locomotive repairs.

Welding and fabrication skills are essential in locomotive repair. I’m proficient in various welding techniques, including MIG, TIG, and stick welding, to repair damaged components such as fuel tanks, body panels, and underframes. I also possess experience in metal fabrication, often creating custom parts to replace damaged or obsolete components. This requires precise measurements, careful cutting, and skillful welding to ensure the repaired or fabricated parts meet the required specifications and maintain the structural integrity of the locomotive. Recently, I fabricated and welded a replacement bracket for a damaged air compressor mount, ensuring the compressor was securely fixed and operated correctly.

Q 27. How do you ensure compliance with all relevant safety standards during locomotive repair?

Safety is paramount in locomotive repair. I strictly adhere to all relevant safety regulations, including those outlined by the Federal Railroad Administration (FRA) and other governing bodies. This involves using appropriate personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection. We also follow lockout/tagout procedures to prevent accidental energization of electrical systems during repairs. Before commencing any repair, a thorough risk assessment is conducted to identify potential hazards and develop mitigation strategies. Every step follows strict safety protocols, from proper handling of hazardous materials to ensuring the work area is properly secured and personnel are trained in safe practices. A safety-first mentality is not merely a policy, but a fundamental part of our work culture.

Q 28. Explain your experience with troubleshooting locomotive cooling systems.

Locomotive cooling systems are critical for preventing overheating of the engine and other components. My experience includes troubleshooting various cooling system issues, including radiator leaks, fan motor failures, clogged filters, and thermostat malfunctions. Diagnosing these problems often involves pressure testing, flow rate checks, and temperature measurements. For example, I once resolved a persistent overheating issue by identifying a restricted radiator core, necessitating its cleaning or replacement. Understanding the interplay between different components – the radiator, fans, water pump, thermostat, and coolant – is key to effectively troubleshooting these systems. It’s like understanding the human body’s cooling system; if one part malfunctions, the entire system is affected.

Key Topics to Learn for Inspect and Repair Locomotives Interview

- Locomotive Systems: Understanding the intricate workings of diesel-electric, electric, and other locomotive systems. This includes power generation, transmission, braking, and control systems. Practical application: Diagnosing issues based on system behavior and readings.

- Safety Regulations and Procedures: Deep knowledge of relevant safety standards, protocols, and regulations pertaining to locomotive inspection and repair. Practical application: Ensuring compliance during all inspection and repair processes, prioritizing safety in every decision.

- Troubleshooting and Diagnostics: Developing expertise in identifying and resolving mechanical, electrical, and pneumatic issues in locomotives. This includes using diagnostic tools and interpreting data. Practical application: Effectively isolating faults and implementing effective repair strategies.

- Preventive Maintenance: Understanding and executing scheduled maintenance procedures to prevent major breakdowns and ensure optimal locomotive performance. Practical application: Implementing effective lubrication schedules, component inspections, and early detection of potential failures.

- Welding and Fabrication: Proficiency in welding techniques relevant to locomotive repair and fabrication. Practical application: Repairing damaged components, creating custom parts, and maintaining structural integrity.

- Pneumatic and Hydraulic Systems: Understanding the principles and operation of pneumatic and hydraulic systems in locomotives. Practical application: Troubleshooting air brake systems, diagnosing hydraulic leaks and malfunctions.

- Electrical Wiring Diagrams and Schematics: Ability to read and interpret complex electrical schematics and wiring diagrams. Practical application: Tracing circuits, identifying faulty components, and performing accurate repairs.

- Record Keeping and Documentation: Maintaining accurate and detailed records of all inspections, repairs, and maintenance performed. Practical application: Ensuring clear and concise documentation for compliance and future reference.

Next Steps

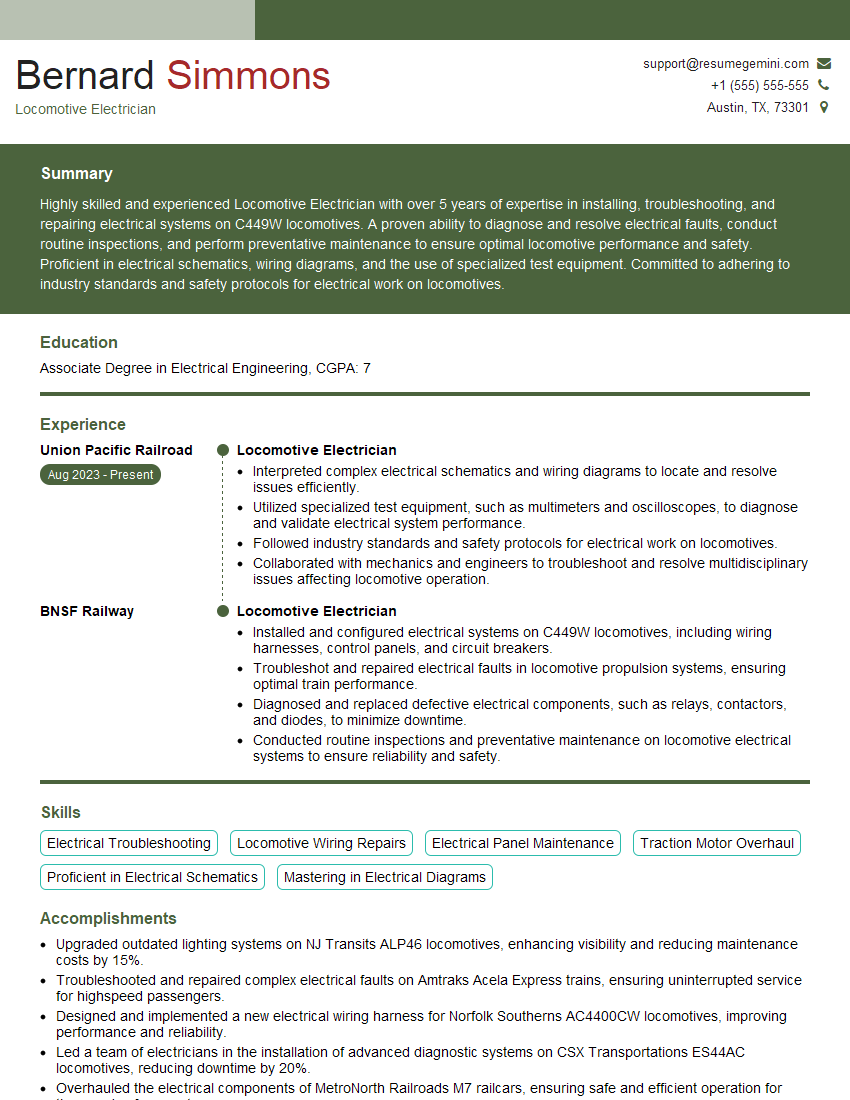

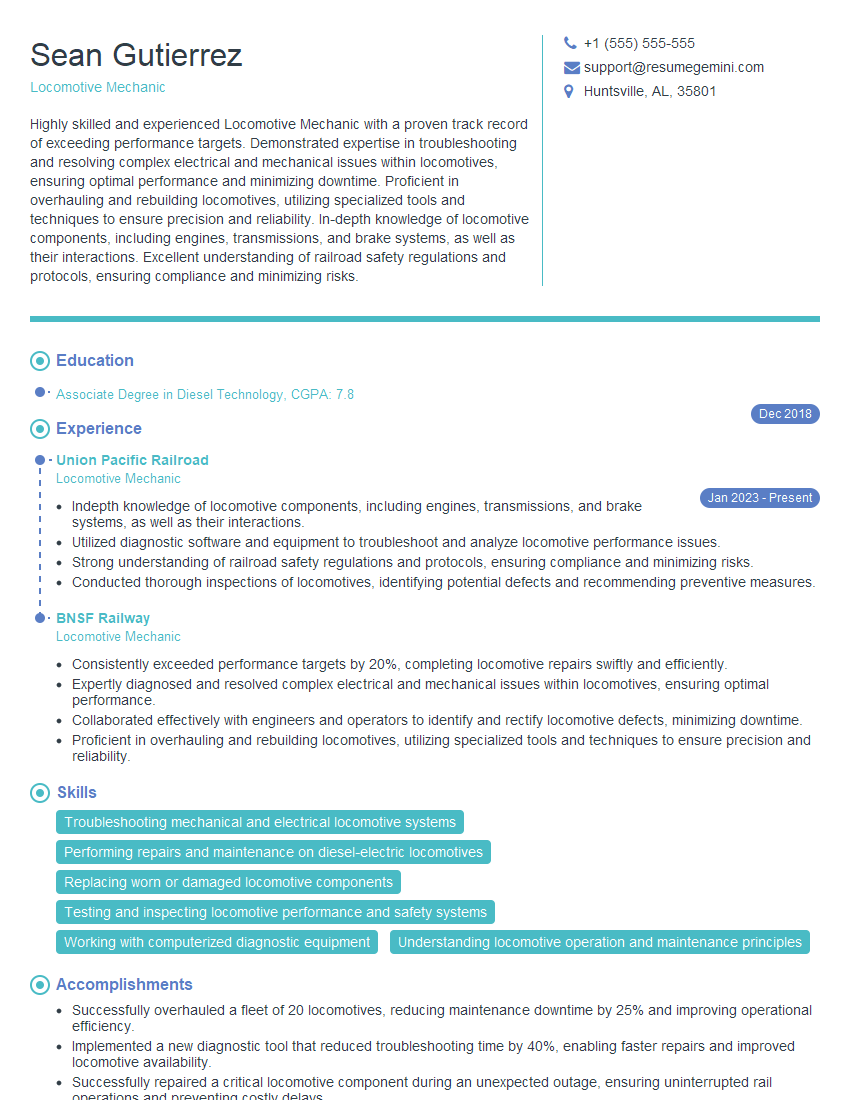

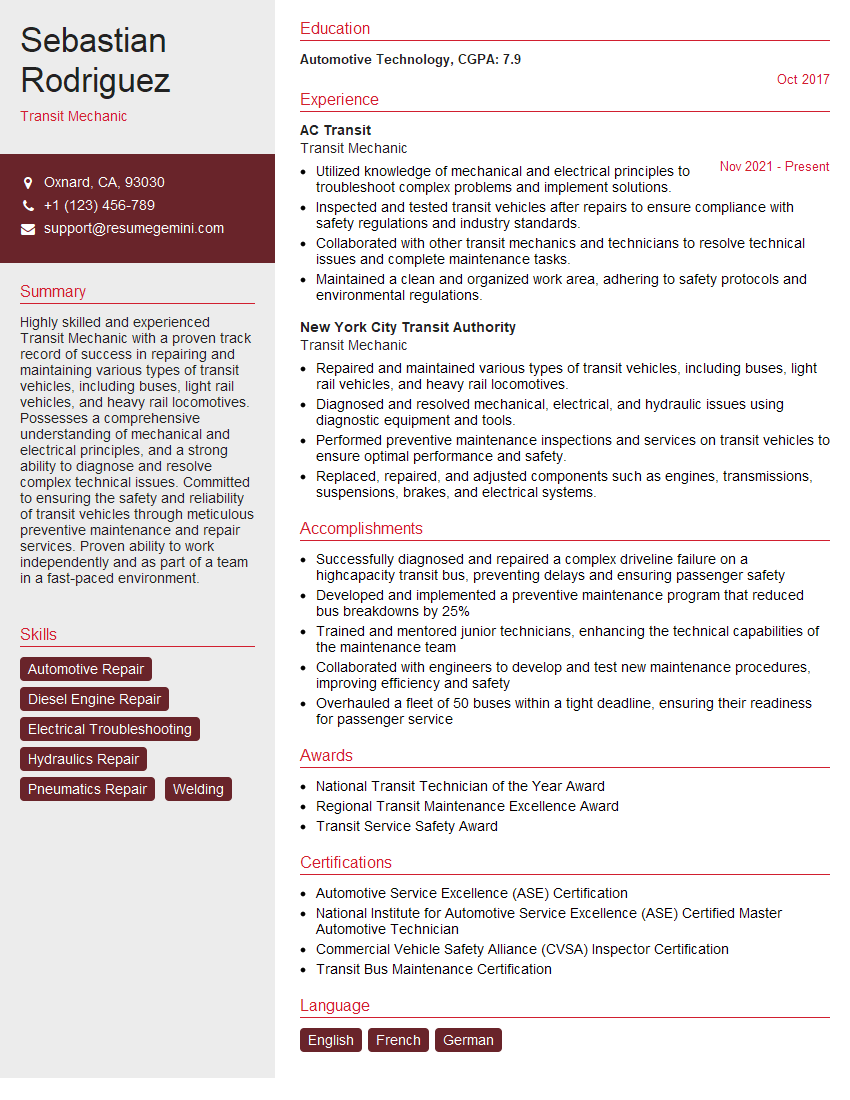

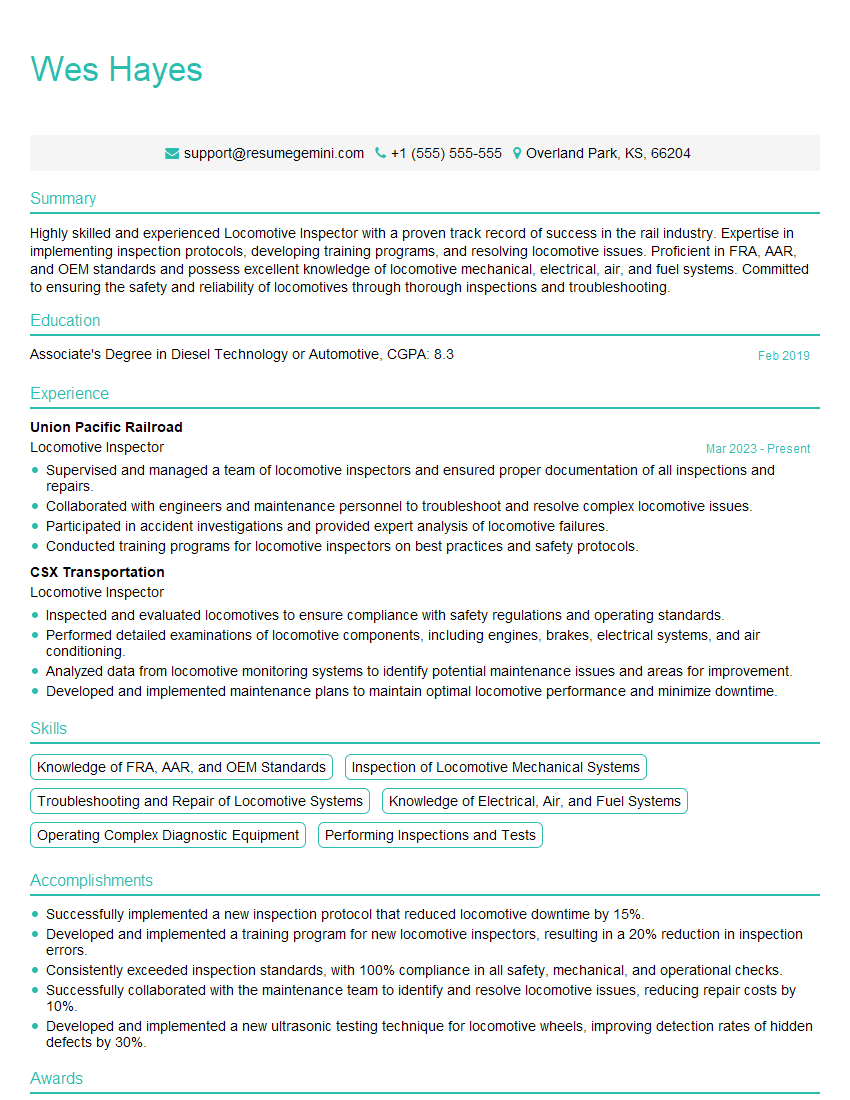

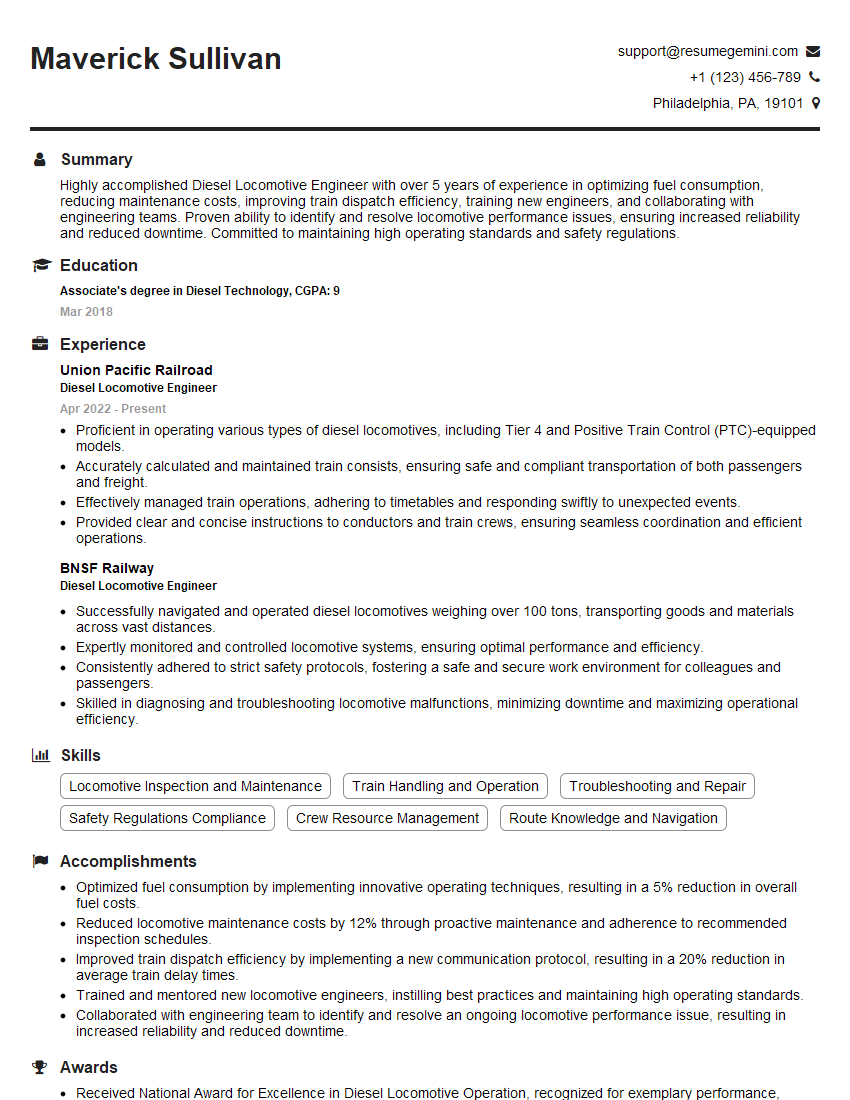

Mastering the intricacies of locomotive inspection and repair opens doors to a rewarding and stable career with excellent growth potential. This specialized skillset is highly valued in the transportation industry, offering opportunities for advancement and increased earning potential. To significantly boost your job prospects, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to the Inspect and Repair Locomotives field are available to guide you. Invest time in crafting a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO