The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Wheel Inspection and Repair interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Wheel Inspection and Repair Interview

Q 1. Explain the process of visually inspecting a wheel for damage.

Visually inspecting a wheel for damage is the first and often most crucial step in ensuring its safety and performance. It’s a systematic process that requires attention to detail and a trained eye. Think of it like a thorough medical check-up for your vehicle’s wheels.

- Start with a clean wheel: Dirt and grime can obscure damage. Clean the wheel thoroughly before inspection.

- Examine the wheel’s surface: Look for cracks, bends, dents, or gouges. Pay close attention to the areas around the lug holes, spokes, and the rim itself. Even a small crack can compromise structural integrity.

- Check the tire bead area: Ensure the tire sits properly on the wheel, examining for any signs of damage or wear that could indicate a prior impact.

- Inspect the valve stem: Make sure it’s securely in place and not damaged. A leaking valve can lead to a flat tire.

- Look for curb rash: This is common damage to the outer rim. While cosmetic, significant curb rash can weaken the wheel structure.

- Check for corrosion: Rust or pitting can weaken the metal. Pay particular attention to areas where water can collect.

- Rotate the wheel: Inspect all sides of the wheel, turning it slowly to catch any damage that might be hidden from a single viewpoint.

Document any damage with photos and detailed notes. This is crucial for insurance claims or for tracking damage progression.

Q 2. Describe the different types of wheel damage you’ve encountered.

Over the years, I’ve seen a wide range of wheel damage. Some of the most common include:

- Bends and Cracks: These often result from hitting potholes or curbs. They can be subtle or quite obvious, compromising the wheel’s structural integrity. I’ve seen wheels with hairline cracks that were initially missed, leading to a catastrophic failure later on.

- Curb Rash: Cosmetic damage to the outer edge of the rim. While not always structural, severe curb rash can weaken the wheel.

- Dents: These can be anywhere on the wheel and can range in severity. Small dents might be purely cosmetic, while larger ones affect structural integrity.

- Corrosion and Rust: Especially prevalent in areas with harsh winters. Corrosion weakens the metal, making it more susceptible to damage.

- Impact Damage: This can range from small chips to large gouges, usually indicating a significant impact event. These are serious and often require wheel replacement.

- Stress Cracks: These are often difficult to spot, appearing as hairline cracks around the lug holes or near bends. They indicate serious underlying fatigue and require immediate attention.

Remember, even seemingly minor damage can lead to serious consequences. A small crack, for instance, can propagate under stress, eventually leading to a catastrophic failure at high speeds.

Q 3. How do you determine if a wheel needs to be replaced or repaired?

The decision to repair or replace a wheel depends on several factors: the severity and type of damage, the wheel’s material (aluminum or steel), and the cost of repair versus replacement.

- Minor cosmetic damage (e.g., small scratches, minor curb rash): These often don’t affect structural integrity and can be left alone or repaired cosmetically (e.g., repainting, polishing).

- Structural damage (e.g., bends, cracks, significant dents): These necessitate repair or replacement. Minor bends in steel wheels can sometimes be repaired, but aluminum wheels are less forgiving and often require replacement.

- Repair cost vs. replacement cost: A repair might seem cheaper initially, but if a repair is not done properly it can lead to more problems later. A wheel repair shop’s expertise and reputation should be considered.

- Safety concerns: If there’s any doubt about the wheel’s structural integrity, replacement is always the safest option.

I always prioritize safety. A compromised wheel puts the driver, passengers, and other road users at risk. When in doubt, replace it.

Q 4. What are the safety hazards associated with damaged wheels?

Damaged wheels pose significant safety hazards. A failure can lead to:

- Loss of control: A sudden tire deflation or wheel collapse can cause the vehicle to veer off course, leading to an accident.

- Tire separation: A damaged wheel can cause the tire to separate from the rim, resulting in a sudden loss of air pressure and loss of control.

- Wheel detachment: In extreme cases, the wheel can detach completely from the vehicle, posing a significant risk to the vehicle and other road users.

- Damage to other vehicle components: A damaged wheel can affect the suspension, brakes, and other parts of the vehicle.

- Injury or death: The consequences of a wheel failure can be catastrophic, leading to serious injury or even death.

Regular wheel inspections and prompt attention to any damage are crucial for preventing these hazards. Think of it this way: your wheels are the only point of contact between your vehicle and the road. They have to be reliable.

Q 5. Explain the procedure for balancing a wheel.

Wheel balancing is the process of distributing the weight of a wheel and tire assembly evenly to minimize vibrations during rotation. Imagine spinning a slightly lopsided coin – it wobbles. Wheel balancing aims to prevent that wobble in your vehicle’s wheels.

The procedure typically involves these steps:

- Mounting the wheel and tire assembly on the balancing machine: The machine measures the imbalance.

- Determining the imbalance: The machine indicates the amount and location of the imbalance.

- Adding weights: Small weights are added to the wheel’s inner or outer edge (or both) to counteract the imbalance. These weights are precisely placed according to the machine’s readings.

- Re-checking the balance: The wheel is re-checked on the machine to ensure that the imbalance has been corrected.

Accurate wheel balancing is vital for smooth driving, tire longevity, and overall vehicle safety. An unbalanced wheel puts increased stress on your suspension, steering components, and tires.

Q 6. What tools and equipment are necessary for wheel balancing?

Proper wheel balancing requires specialized tools and equipment:

- Wheel balancer: This electronic machine precisely measures the imbalance in a wheel and tire assembly.

- Balancing weights: These come in various sizes and types (clip-on, stick-on) to correct the imbalance.

- Wheel mounting tools: These tools securely mount the wheel and tire onto the balancer. They include wheel chocks to securely hold the wheel during mounting.

- Torque wrench: A torque wrench is crucial for tightening lug nuts to the manufacturer’s specified torque. Over-tightening can damage the wheel studs, while under-tightening can lead to loose wheels.

- Air compressor: To inflate the tire to the correct pressure, and a gauge to confirm the proper pressure.

Maintaining these tools and ensuring they’re calibrated correctly is essential for accurate balancing. A poorly maintained machine can lead to inaccurate readings and an improperly balanced wheel.

Q 7. How do you diagnose and correct wheel alignment issues?

Diagnosing and correcting wheel alignment issues involves checking the angles of the wheels relative to the vehicle’s frame and each other. Think of it like ensuring your vehicle’s wheels are pointing in the right direction and tracking straight.

The process usually involves:

- Visual inspection: Checking for signs of misalignment like uneven tire wear, pulling to one side during driving, or a vibrating steering wheel.

- Using a wheel alignment machine: This machine precisely measures the various alignment angles (toe, camber, caster).

- Adjusting the alignment: Adjusting the suspension components to correct the measured angles. This involves adjusting tie rod ends, control arms, or other suspension components.

- Post-alignment check: Re-checking the alignment angles to ensure the corrections have been made accurately.

Incorrect wheel alignment leads to uneven tire wear, reduced fuel efficiency, poor handling, and increased risk of accidents. Proper wheel alignment ensures optimal handling and extends the lifespan of your tires.

Q 8. Describe the different types of wheel alignment adjustments.

Wheel alignment adjustments focus on correcting the angles of the wheels relative to each other and the vehicle’s frame. This ensures the wheels track straight and smoothly, minimizing tire wear and improving handling. There are four primary adjustments:

- Camber: This refers to the inward (negative camber) or outward (positive camber) tilt of the wheel when viewed from the front or rear. Think of it like leaning a bicycle; too much lean in either direction is detrimental.

- Caster: This is the angle of the steering axis, viewed from the side. It influences steering return and stability; a steeper caster angle generally leads to better high-speed stability.

- Toe: This is the angle between the wheels, as viewed from above. Toe-in means the front of the wheels points slightly inwards, and toe-out is the opposite. Proper toe setting is crucial for straight-line tracking.

- Thrust Angle: This refers to the alignment of the rear axle with the front wheels. If misaligned, it can cause vehicle pull and uneven tire wear.

These adjustments are made by altering the suspension components, such as tie rods, control arms, and strut mounts. Specialized equipment, like a wheel alignment machine, is used to precisely measure and adjust these angles.

Q 9. What are the consequences of improper wheel alignment?

Improper wheel alignment leads to a cascade of negative consequences, significantly impacting safety, vehicle performance, and cost. The most common include:

- Uneven Tire Wear: This is perhaps the most noticeable effect, leading to premature tire wear on one side or the other. This translates directly to increased costs for tire replacements.

- Vehicle Pull or Wander: The vehicle may pull to one side, requiring constant steering corrections, making driving stressful and potentially dangerous, especially at higher speeds.

- Reduced Fuel Efficiency: The extra effort required to counteract misalignment increases fuel consumption.

- Increased Steering Effort: Driving becomes more difficult and tiring.

- Reduced Handling and Stability: The car’s response to steering inputs becomes unpredictable, leading to a loss of control, especially during emergency maneuvers.

- Premature Suspension Wear: The extra stress placed on suspension components due to misalignment accelerates their deterioration.

Imagine trying to push a shopping cart with one wheel slightly askew – it would be difficult to control and tiring. Improper alignment is analogous to this, only with potentially serious consequences.

Q 10. What are the common causes of wheel damage?

Wheel damage can stem from various sources, often a combination of factors. The most common causes are:

- Potholes and Road Debris: Impact with potholes or striking curbs or road debris like rocks can severely bend or crack rims.

- Curb Rash: Careless parking or maneuvering, resulting in scraping the wheel against a curb, causing scratches and dents.

- Improper Tire Inflation: Under-inflation weakens the wheel structure and increases the chance of damage from impact.

- Excessive Load: Exceeding the vehicle’s weight capacity can strain the wheels beyond their limits.

- Corrosion: Rust and corrosion, especially in areas with harsh climates, weakens the wheel structure, increasing susceptibility to damage.

- Accidents: Collisions, even minor ones, can significantly damage wheels.

Regular inspection and preventative measures, like avoiding potholes where possible and maintaining proper tire inflation, can minimize the risk of damage.

Q 11. How do you repair a bent or damaged wheel rim?

Repairing a bent or damaged wheel rim depends on the severity of the damage. Minor bends might be correctable through hammering or specialized wheel straightening machines, which use hydraulic pressure to gently coax the rim back into shape. However, this process requires precision and expertise to avoid further damage. For more significant bends or cracks, repair might not be feasible, and replacement is often the safer and more cost-effective option.

The process typically involves:

- Assessment: Carefully examining the wheel to determine the extent of the damage.

- Straightening (if possible): Using specialized equipment and techniques to straighten the bent areas. This often includes using a heat source to make metal more malleable.

- Balancing: After straightening, the wheel must be dynamically balanced to ensure even rotation.

- Inspection: Thorough visual and sometimes X-ray inspection to confirm no structural damage remains.

If the wheel is beyond repair, a replacement is necessary, ensuring it’s the correct size and specification for your vehicle.

Q 12. Describe the process of repairing a cracked wheel.

Repairing a cracked wheel is generally more complex and often less effective than repairing a bent wheel. The success of the repair greatly depends on the location and size of the crack. Minor cracks might be welded, but this process requires significant expertise to avoid weakening the wheel structure. Often, the welded area needs additional reinforcement. However, this repair is only a viable option if the structural integrity of the wheel is not compromised.

If the crack is significant, it’s often safer and more advisable to replace the damaged wheel entirely. The risk of sudden failure, leading to accidents, outweighs the cost of a replacement.

Q 13. What are the different methods used to repair alloy wheels?

Alloy wheels can be repaired using several methods, depending on the type and extent of the damage:

- Straightening: As discussed before, minor bends can often be straightened using specialized equipment.

- Welding: Small cracks or breaks can be repaired through welding, but it’s crucial to use the correct filler material and ensure proper post-weld heat treatment to avoid further issues.

- Patching: For larger cracks or holes, patching may be an option but is often less structurally sound than other methods.

- Refurbishment: This involves repairing surface damage like curb rash and scratches, and refinishing the wheel, such as repainting, powder coating or diamond cutting.

The choice of repair method depends on several factors, including the severity of the damage, the wheel material, and the available resources. In many cases, especially with significant damage, replacement will be more suitable.

Q 14. What safety precautions should be taken during wheel repair?

Safety is paramount during any wheel repair. Precautions include:

- Protective Equipment: Always wear safety glasses, gloves, and appropriate clothing to prevent injury from flying debris, sharp edges, or chemical exposure (during paint or refinishing processes).

- Proper Ventilation: When using chemicals or welding, ensure adequate ventilation to prevent inhalation of harmful fumes.

- Wheel Mounting and Removal: Use the proper tools and procedures to mount and dismount the wheels to prevent damage to the wheel or the vehicle.

- Handling of Heavy Objects: Wheels can be heavy; use lifting equipment and proper lifting techniques to avoid injury.

- Proper Disposal of Hazardous Materials: Dispose of hazardous materials such as solvents and paints in accordance with environmental regulations.

- Work Area Safety: Maintain a clean and organized workspace to reduce the risk of accidents.

Ignoring safety protocols could lead to injuries or further damage to the wheel or surrounding equipment.

Q 15. How do you ensure the proper torque when installing a wheel?

Ensuring proper torque when installing a wheel is paramount for safety and vehicle handling. Improper torque can lead to wheel detachment, which is incredibly dangerous. We achieve the correct torque using a torque wrench, a specialized tool that measures the amount of rotational force applied. This wrench is calibrated to the manufacturer’s specified torque value for the specific vehicle and wheel lug nuts. For instance, a torque wrench might be set to 80 ft-lbs (foot-pounds) for a particular vehicle. I always double-check the manufacturer’s specifications in the owner’s manual or a reputable repair manual before beginning the process. After tightening all the lug nuts in a star pattern (opposite nuts tightened in sequence) to the specified torque, I always recheck the torque after driving a short distance. This ensures the nuts have properly seated and prevents any loosening.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper wheel lug nut tightening.

Proper wheel lug nut tightening is critical for road safety. Under-tightening can lead to the wheel coming loose, resulting in loss of control, accidents, and potential injury. Over-tightening, on the other hand, can strip the threads of the lug nuts or studs, damage the wheel, and even cause the wheel studs to break. Think of it like this: the lug nuts are the only thing holding your wheel securely to your vehicle at high speeds. The proper torque ensures the right amount of clamping force. Incorrect tightening also impacts the wheel’s alignment, leading to uneven tire wear, vibrations, and handling issues. Consistent, proper tightening prevents all these problems and contributes to a safer, smoother driving experience.

Q 17. What are the signs of a worn or damaged wheel bearing?

Worn or damaged wheel bearings present several noticeable signs. One common indicator is a grinding, humming, or rumbling noise, especially noticeable at higher speeds or when turning. This is often described as a low-frequency growl that increases with vehicle speed. Another symptom is excessive play or looseness in the wheel. If you can noticeably move the wheel up and down or side to side, it indicates a severely worn bearing. A vibration felt in the steering wheel or through the vehicle’s chassis, particularly at certain speeds, can also be a sign of a failing bearing. Sometimes, there’s also a slight pulling or drifting to one side. Finally, if you notice increased heat in the affected wheel (caution: check carefully!), it’s often a strong indicator of bearing failure due to friction. In some cases, there might be signs of grease leaking around the bearing.

Q 18. How do you inspect wheel bearings?

Inspecting wheel bearings requires a methodical approach. First, I visually inspect the hub assembly for any signs of damage, leaks, or unusual wear. Then, with the vehicle safely supported, I jack up the affected wheel and carefully spin it. I listen for any unusual noises and check for any play or looseness by trying to move the wheel up and down, and side to side. Excessive play is a clear indication of wear. Further inspection might involve using a dial indicator to accurately measure bearing end play. For a more thorough assessment, the wheel and hub assembly may need to be removed, allowing for a direct examination of the bearing itself. This involves carefully removing the wheel, brake components, and then the hub assembly to get access to the bearing. Then, the bearing is carefully checked for any signs of damage. Sometimes, specialized bearing inspection tools are used to check for play, roughness or defects.

Q 19. Describe your experience with different types of wheel materials (steel, aluminum, etc.).

I have extensive experience with various wheel materials, including steel, aluminum, and even some composite materials. Steel wheels are durable, strong, and cost-effective. However, they are heavier than aluminum wheels, potentially impacting fuel efficiency. Aluminum wheels, on the other hand, are lighter, improving handling and fuel economy. They are also more aesthetically pleasing, coming in a wide variety of designs. However, they’re more susceptible to damage from impacts and corrosion. Composite wheels are used in certain high-performance applications and offer a combination of strength and lightness, but they’re much more expensive. When dealing with these materials, I pay close attention to the material-specific repair techniques and appropriate tools. For example, repairing a crack in an aluminum wheel is different from repairing a steel wheel. The repair methods, like welding or patching, need to be adapted to the wheel material to guarantee safety and durability.

Q 20. What is the difference between static and dynamic wheel balancing?

Static and dynamic wheel balancing address different aspects of wheel imbalance. Static balance focuses on the imbalance caused by the weight distribution around the wheel’s center of rotation. Imagine a wheel with extra weight on one side. That weight makes the wheel want to stop in that position. Static balancing involves adding weights to the wheel’s outer edge to compensate for this imbalance, ensuring it spins smoothly while stationary. Dynamic balance, on the other hand, addresses the imbalance created by the wheel’s rotation. Even if a wheel is statically balanced, it might still have an uneven distribution of mass along its rotating axis, causing vibrations during movement. Dynamic balancing accounts for this, using weights to counteract both static and dynamic imbalances, resulting in smoother rotation at all speeds.

Q 21. How do you identify a damaged tire related to wheel issues?

Identifying tire damage related to wheel issues often involves a careful visual inspection. Look for uneven tire wear, which could be caused by incorrect wheel alignment or a damaged wheel. Bulges or lumps in the tire can indicate a damaged sidewall, sometimes caused by impacting a curb or pothole. Also, inspect the tire tread for embedded debris or damage that might have been caused by rubbing against parts of the wheel or suspension system. Pay close attention to the area where the tire meets the wheel rim. If you see any cuts, scrapes, or uneven wear along the edge of the tire, this suggests the wheel or tire installation might be incorrect, causing rubbing or misalignment. Sometimes, a tire may have bead damage, where the tire is not properly seated on the rim. Always thoroughly inspect both the tire and wheel to ensure they are both undamaged.

Q 22. How do you handle a situation where a wheel cannot be repaired?

If a wheel is beyond repair, the first step is to thoroughly document its condition, including photographs and detailed notes of the damage. This is crucial for insurance claims or warranty purposes. Then, I would recommend the wheel to the customer for replacement. The choice of replacement depends on factors like the vehicle type, budget, and availability. Sometimes, a direct OEM (Original Equipment Manufacturer) replacement is best; other times, a high-quality aftermarket option will suffice. It’s crucial to clearly explain the reasons why the wheel was deemed unrepairable and the implications of using a replacement versus trying to repair a compromised wheel which could ultimately compromise safety. We always put safety first.

For example, if a wheel has suffered significant structural damage like cracking near the mounting holes, repairing it would be unsafe and irresponsible. Replacing it is the only viable option.

Q 23. What are the legal and safety regulations related to wheel inspection and repair?

Legal and safety regulations surrounding wheel inspection and repair vary by location but generally focus on ensuring roadworthiness. Key aspects include adhering to manufacturer specifications, using approved repair techniques, and ensuring that repaired wheels meet or exceed original strength and safety standards. Inspectors and repair technicians should possess the necessary certifications and training to validate their competency. Failing to adhere to these regulations can lead to serious legal repercussions, including fines and potential liability in case of accidents.

For instance, many jurisdictions require regular vehicle inspections, which invariably include a wheel assessment. Using substandard repair techniques or neglecting to properly document repairs can lead to failure to pass these inspections. Furthermore, if a repaired wheel fails, causing an accident, severe legal ramifications could result.

Q 24. How do you document your inspection and repair work?

Documentation is paramount. My process involves a detailed written report, supplemented by photographic evidence. The report includes the vehicle identification number (VIN), wheel identification details (manufacturer, size, part number, etc.), a description of the damage, the repair techniques employed, and a final assessment of the wheel’s condition post-repair. Photos are taken at each stage: before repair, during the process, and after completion. The report is signed and dated by both the technician and the customer (or their representative) and a copy is kept on file for at least several years.

For example, for a minor curb rash repair, the report might simply note the location and extent of the damage, the application of filler and paint, and the final inspection confirming structural integrity. However, for more significant repairs, like crack repair, the report would detail the steps involved in the repair process, including the materials used and the testing procedures carried out to ensure safety.

Q 25. Describe your experience with different wheel repair techniques.

My experience encompasses a wide range of wheel repair techniques. These include:

- Curb rash repair: This involves repairing cosmetic damage to the wheel’s outer edge, often using filler, sanding, and repainting.

- Crack repair: This is a more complex procedure requiring specialized tools and materials to restore the structural integrity of a cracked wheel. It may involve welding, bonding, or a combination of both, depending on the crack’s severity and location.

- Bent wheel repair: This involves carefully straightening a bent wheel using specialized equipment like a wheel straightening machine. The process ensures the wheel’s geometry is restored to its original specifications.

- Corrosion repair: This focuses on addressing rust and corrosion, often involving cleaning, sanding, applying rust inhibitors, and repainting.

- Wheel refinishing: This involves stripping the existing finish, repairing any damage, and applying a new finish (e.g., powder coating or painting).

The choice of technique depends on the type and severity of the damage.

Q 26. Explain your troubleshooting process when encountering a wheel-related problem.

My troubleshooting process follows a systematic approach. First, I visually inspect the wheel, carefully noting the type and extent of the damage. Then, I perform a more thorough inspection, checking for cracks, bends, or other structural issues. I might use specialized tools like a wheel balancer to assess the wheel’s dynamic balance. If the problem isn’t immediately apparent, I might conduct further tests to pinpoint the cause. The goal is to thoroughly diagnose the root cause before deciding on the most effective repair strategy.

For example, if a vehicle exhibits vibration, it could be due to a bent wheel, an imbalance, or other issues. I would systematically check each possibility, starting with a visual inspection, followed by balancing and, if necessary, a more in-depth analysis.

Q 27. How do you stay updated on the latest wheel repair technologies and techniques?

Staying current in this field requires continuous learning. I regularly attend industry conferences, workshops, and training courses offered by wheel repair equipment manufacturers and professional organizations. I also actively participate in online forums and professional networks to stay abreast of new techniques and technologies. Reading trade journals and accessing manufacturer information keeps me informed about advancements in materials and equipment. This commitment to ongoing professional development ensures I’m employing the safest and most efficient methods available.

For example, new advancements in welding techniques or the introduction of new materials for crack repair are constantly emerging, requiring continuous learning to implement these best practices.

Q 28. Describe a challenging wheel repair you successfully completed and the steps involved.

One challenging repair involved a severely cracked aluminum wheel on a high-performance vehicle. The crack was located near one of the mounting lug holes, creating significant structural compromise. A simple weld wasn’t feasible due to the risk of distortion and weakening the aluminum.

Steps Involved:

- Detailed Assessment: I carefully documented the damage with photos and measurements, determining the crack’s depth and extent.

- Preparation: The area surrounding the crack was cleaned meticulously to remove any debris or contaminants.

- Specialized Repair: I used a combination of techniques: first, I employed a specialized epoxy designed for aluminum crack repair to stabilize the crack and bridge the gap. Then, I used a precisely controlled low-heat welding process to reinforce the repair, ensuring minimal heat distortion.

- Machining and Finishing: After the repair had fully cured, I carefully machined the repair area to achieve a smooth, even surface. This was followed by a meticulous polishing and repainting process.

- Testing: I then conducted a rigorous inspection including a dynamic balance test to ensure the wheel’s structural integrity and stability.

The final result was a wheel that was aesthetically pleasing and structurally sound, meeting the rigorous safety standards of the high-performance vehicle. It was a testament to the importance of thorough assessment, specialized tools, and precise repair techniques.

Key Topics to Learn for Wheel Inspection and Repair Interview

- Wheel Component Knowledge: Understanding the construction, materials, and function of various wheel components (rims, tires, hubs, bearings).

- Inspection Techniques: Mastering visual inspection methods for detecting cracks, corrosion, damage, and wear, including the use of specialized tools.

- Repair Methods: Familiarizing yourself with common wheel repair techniques such as welding, straightening, and refinishing. Understanding the limitations of each method.

- Safety Procedures: Demonstrating knowledge of safe handling practices for damaged wheels and the use of appropriate safety equipment.

- Diagnostic Skills: Explaining how to identify the root cause of wheel damage or failure based on observable symptoms.

- Quality Control: Understanding the importance of adhering to industry standards and ensuring the repaired wheel meets safety and performance requirements.

- Industry Regulations and Standards: Familiarity with relevant safety standards and regulations governing wheel repair and maintenance.

- Practical Application: Describing your experience in diagnosing wheel issues, performing repairs, and ensuring quality control in a real-world setting.

- Problem-Solving: Demonstrating your ability to troubleshoot complex wheel issues, analyze the problem, and implement effective solutions.

Next Steps

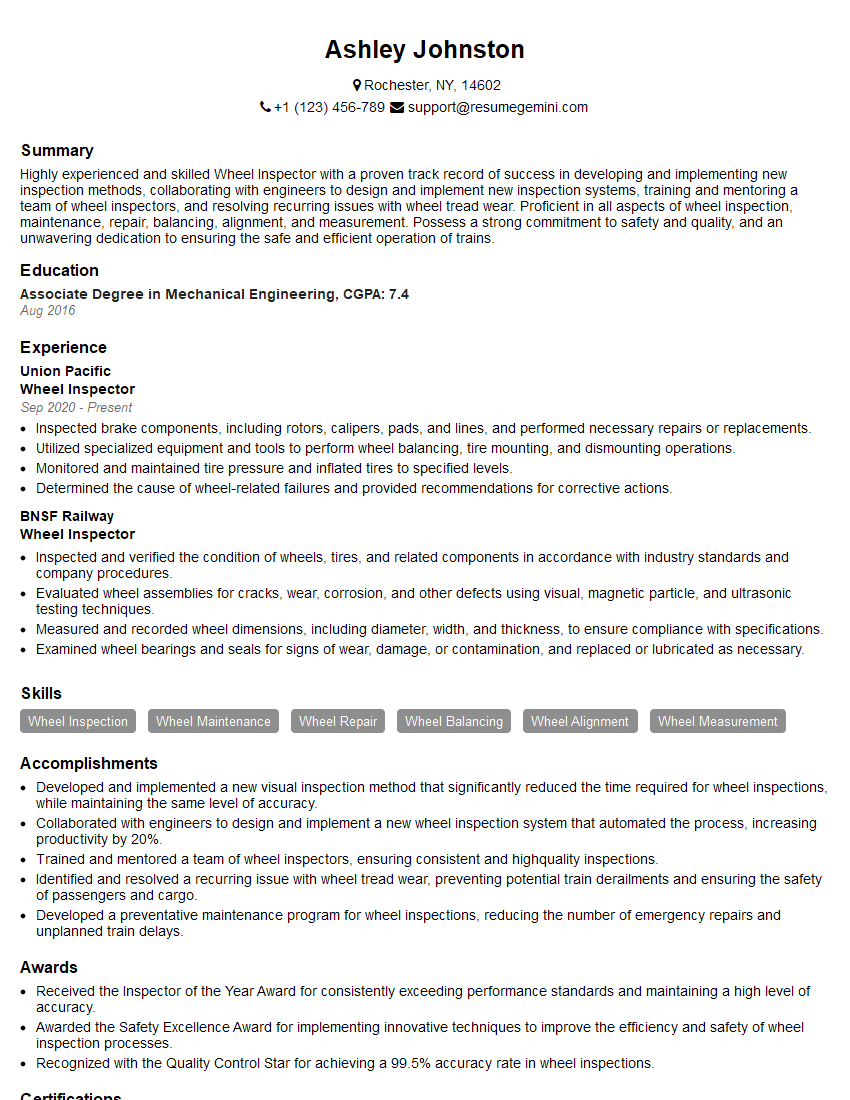

Mastering Wheel Inspection and Repair opens doors to a rewarding career with excellent growth potential in the automotive and transportation industries. A strong understanding of these skills positions you for advancement and higher earning potential. To maximize your job prospects, focus on creating an ATS-friendly resume that showcases your expertise effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to your skills and experience. Examples of resumes tailored to Wheel Inspection and Repair are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO