Cracking a skill-specific interview, like one for Barcoding and RFID Technologies, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Barcoding and RFID Technologies Interview

Q 1. Explain the difference between 1D and 2D barcodes.

The core difference between 1D and 2D barcodes lies in their data storage capacity and the type of information they can encode. 1D barcodes, like the ubiquitous UPC codes on grocery products, store data linearly – as a sequence of bars and spaces representing digits or characters. They’re simple, efficient for identifying single items, and readily scanned by common barcode scanners.

2D barcodes, however, such as QR codes and Data Matrix codes, store data in two dimensions, using a complex pattern of squares or dots. This allows them to encode significantly more information, including text, URLs, images, and even complex product specifications. Think about a QR code on a product packaging – it can link to detailed product information, instructions, or even a video. This increased capacity is a key advantage in environments requiring more detailed tracking or data accessibility.

- 1D Barcode Example:

0 70000 12345 6(a simplified UPC code) - 2D Barcode Example: A QR code encoding a website address, contact details, and product serial number.

In short, choose 1D for simple identification and tracking, while 2D excels where detailed information needs to be easily accessible and encoded.

Q 2. Describe the various types of RFID tags and their applications.

RFID tags come in a variety of forms, each suited for different applications based on their read range, durability, cost, and memory capacity.

- Passive Tags: These tags don’t have their own power source; they derive energy from the RFID reader’s signal. They’re cost-effective and ideal for applications where power is limited, like tracking inventory in a warehouse. Their read range is typically shorter than active tags.

- Active Tags: These tags have their own battery, enabling longer read ranges and the ability to transmit more data. They’re suitable for tracking assets over longer distances, such as livestock tracking or vehicle location monitoring. The longer lifespan and greater power consumption comes at a higher cost.

- Battery-Assisted Passive Tags (BAP): These tags are a hybrid approach, combining elements of both passive and active tags. They have a small battery to supplement the energy received from the reader, allowing for a longer read range and more data transmission compared to passive tags, but are less expensive and less power-hungry than active tags.

- Read-Only Tags: These tags can only be read; their data cannot be altered. They’re often used for product identification or security applications.

- Read-Write Tags: These tags allow data to be written and updated. They are excellent for tracking assets whose status might change over time, like inventory levels in a distribution center.

Applications: Passive tags are widely used in retail inventory management, while active tags are prevalent in supply chain management, asset tracking, and animal identification. Read-write tags find use in library management systems or access control.

Q 3. What are the advantages and disadvantages of RFID compared to barcoding?

RFID and barcoding both serve the purpose of identifying and tracking items, but they have distinct advantages and disadvantages.

| Feature | RFID | Barcoding |

|---|---|---|

| Read Range | Longer; can read multiple tags simultaneously | Short; requires line-of-sight |

| Data Capacity | Higher; can store more information | Lower; limited to alphanumeric data |

| Read Speed | Faster; can read many items quickly | Slower; reads one item at a time |

| Durability | Can withstand harsh conditions (depending on tag type) | Susceptible to damage, smudging, or wear |

| Cost | Generally higher, especially for active tags | Lower |

| Environmental Conditions | Can be affected by metal or liquids but advanced technologies have greatly minimized this effect. | Easily obscured by dirt or labels. |

In essence, RFID excels in applications requiring high-throughput, long-range identification, and data-rich tracking, whereas barcoding is well-suited for simple identification and situations where cost is a primary concern.

Q 4. How does RFID work?

RFID systems rely on the interaction between three core components: the RFID tag, the RFID reader, and the RFID antenna.

- RFID Tag: Contains a microchip and an antenna. The microchip stores the unique identification number (UID) and other data. The antenna transmits and receives radio waves.

- RFID Reader: Houses a transceiver which both transmits radio waves to activate the tags and receives the data sent back from the tags. The reader interprets the data, then transmits it usually to a host computer via a network connection (WiFi, Ethernet, etc.).

- RFID Antenna: The antenna transmits the radio waves from the reader to the tags, and receives signals in return. The antenna’s design influences the reader’s range, orientation and performance.

The process begins when the reader’s antenna emits radio waves. A passive tag’s antenna absorbs this energy to power its microchip. The microchip then sends back its unique identifier and any stored data. Active tags transmit their data continuously or when triggered. The reader receives and decodes this data, which is then sent to a computer system for processing. Think of it like a silent conversation between the reader and the tags, using radio waves as the language.

Q 5. Explain the concept of RFID middleware.

RFID middleware acts as a bridge between the RFID reader and the enterprise’s back-end systems. It’s a software layer responsible for translating the raw data received from the RFID readers into a format understandable by the enterprise resource planning (ERP) system, warehouse management system (WMS), or other relevant databases. It’s critical for managing the flow of data and integrating it into existing business processes.

Key functionalities of RFID middleware include:

- Data filtering and transformation: Removing redundant data and formatting it for compatibility with other systems.

- Data aggregation: Combining data from multiple readers into a unified view.

- Event management: Tracking and managing events, such as the movement of items within a warehouse.

- Data security and access control: Securing sensitive RFID data.

- Integration with other systems: Connecting the RFID system with enterprise databases and business applications.

Without middleware, integrating RFID data into the enterprise workflows would be considerably challenging, requiring significant custom programming and impacting workflow efficiency.

Q 6. What are some common RFID deployment challenges?

Deploying an RFID system can present several challenges:

- Cost: RFID tags, readers, antennas, and middleware can be expensive, particularly for large-scale deployments.

- Environmental interference: Metal objects, liquids, and other environmental factors can interfere with signal transmission, affecting read rates.

- Data security: Protecting sensitive data stored on RFID tags from unauthorized access is paramount.

- Integration complexity: Integrating RFID systems with existing IT infrastructure can be complex and require specialized expertise.

- Tag management: Accurately tracking and managing a large number of RFID tags can be difficult.

- Read rate inconsistencies: Achieving consistent read rates and minimizing read errors can be challenging, often requiring careful system design and tuning.

Addressing these challenges often involves careful planning, selecting the appropriate RFID technology, thorough testing, and robust security measures. Proper site surveys and the implementation of mitigation strategies (like strategic antenna placement) significantly improve the success of a deployment.

Q 7. Describe your experience with RFID reader technologies.

My experience with RFID reader technologies spans several years and encompasses a wide range of reader types and applications. I’ve worked extensively with both fixed and handheld readers, from simple low-frequency readers for close-range applications to high-frequency, long-range readers for warehouse and supply chain management.

I’m proficient in configuring and troubleshooting various reader technologies, including those using UHF, HF, and LF frequencies. My experience extends to reader networking and integration with different middleware and back-end systems. I’ve been involved in projects involving the selection and deployment of reader systems optimized for specific environments and application needs, paying close attention to factors such as read range, read rate requirements, and environmental conditions. This includes specifying appropriate antenna types, locations and settings based on the project requirements and site survey data. I’m also familiar with a range of reader manufacturers and their specific technologies and capabilities.

Furthermore, I have hands-on experience with analyzing read data, identifying and resolving performance bottlenecks, and optimizing reader configurations to ensure maximum efficiency and accuracy. This includes using performance monitoring software and conducting read rate testing under different conditions.

Q 8. How do you ensure data accuracy in a barcoding or RFID system?

Data accuracy in barcoding and RFID systems is paramount. It relies on a multi-pronged approach encompassing hardware, software, and processes. For barcodes, this starts with high-quality printers and well-maintained scanners to ensure clear, legible codes. Regular calibration and testing of scanning equipment are crucial. Data validation checks within the software, such as checksum verification for barcodes, help detect errors during data entry and processing. For RFID, the accuracy hinges on signal strength, tag quality, and reader sensitivity. Regular antenna and reader maintenance is essential. Error correction codes built into RFID tags help mitigate data corruption during transmission. Employing robust data validation techniques, including data redundancy and cross-checking with other systems, further enhances accuracy. Think of it like a triple-check system: good hardware, robust software, and verification processes working together. In one project involving inventory management, we implemented a system where each barcode scan was cross-referenced against the database entry; if a mismatch occurred, an alert was generated, preventing inaccurate data from entering the system.

Q 9. Explain the process of implementing an RFID system.

Implementing an RFID system involves several key stages. First is the needs assessment: defining the application (inventory tracking, access control, etc.) and understanding the environment (metal interference, distance requirements). Next is system design: selecting appropriate RFID tags (passive, active, frequency), readers, antennas, and the middleware that connects the system. This is followed by the procurement and installation of the hardware. Next comes the software development or integration. This includes configuring the readers, developing database schemas to store the data, and creating the user interface. Then comes system testing, both individually and integrally, to ensure data integrity and read rates meet the requirements. Finally, implementation and training are vital for the successful adoption of the system by users. Consider a recent project where we implemented an RFID system for a large warehouse. The design phase involved selecting UHF passive tags for pallets, strategically positioning antennas to cover all aisles, and designing a custom database to track the location and movement of inventory in real-time.

Q 10. How do you troubleshoot RFID read errors?

Troubleshooting RFID read errors requires a systematic approach. Begin with checking the basics: antenna placement and orientation, reader power and signal strength, tag integrity (check for damage or deactivation), and environmental factors (metal, liquids). Test the read range – it might need adjustment. Examine the data logs to identify patterns or error codes. Are errors consistent with a specific location or tag type? This indicates a problem with the antenna placement, specific tags, or environmental interference. Testing different antennas or frequencies can also pinpoint potential issues. Inspect the cabling and connections for any damage or loose connections. For example, if you consistently have read errors in a particular aisle of a warehouse, you may need to reposition the antenna or add another antenna for better coverage. It is a methodical process of elimination.

Q 11. What are the key performance indicators (KPIs) for an RFID system?

Key Performance Indicators (KPIs) for an RFID system vary depending on the application, but common ones include read rate (percentage of tags successfully read), accuracy (percentage of correctly identified tags), tag retention rate (percentage of tags still active over time), system uptime (percentage of time the system is operational), and cost per read (cost of the system divided by the number of successful reads). Other crucial metrics may include data latency (time for data to be processed and become available) and throughput (number of tags read per unit of time). For a retail application, read rate and accuracy are paramount; for asset tracking, tag retention rate and system uptime become equally critical. Monitoring these KPIs is vital for optimizing the system’s performance and identifying areas for improvement.

Q 12. What are the different antenna types used in RFID systems and their characteristics?

RFID systems use various antenna types, each with distinct characteristics. Linear antennas provide a narrow, focused read zone, ideal for narrow aisles or conveyor belts. Circular polarized antennas offer wider coverage and better performance in environments with metallic objects. The choice of antenna depends on the specific application. For instance, linear antennas are suitable for applications needing precise targeting, such as identifying individual items on a conveyor, while circular polarized antennas are better for environments where tag orientation may vary, like a large warehouse. Other types include panel antennas for wider coverage, and specialized antennas for specific applications (e.g., underground applications). The frequency of the antenna, its gain, and its polarization pattern all impact performance.

Q 13. How do you address RFID tag interference?

RFID tag interference can stem from multiple sources, including metallic objects, liquids, and other RFID tags operating on the same frequency. Mitigation strategies include careful antenna placement to minimize interference, employing appropriate frequency hopping spread spectrum (FHSS) technology, using different frequencies for different areas or applications, and implementing tag anti-collision algorithms. Proper shielding and grounding techniques can help minimize metallic interference. In one project, we resolved tag interference in a metal-intensive environment by strategically repositioning antennas and implementing a frequency hopping algorithm, dramatically improving the read rates. Careful planning and testing during the system design phase are crucial to prevent these issues.

Q 14. Explain your experience with RFID data management and analysis.

My experience with RFID data management and analysis involves designing and implementing databases to store and manage large volumes of RFID data, using SQL and NoSQL databases. I’ve worked with data visualization tools to create dashboards showing key performance indicators. This includes performing data cleansing, handling missing data and outliers, and identifying anomalies using statistical methods. I leverage data mining techniques to extract valuable insights from the data, such as identifying trends in asset movement, predicting maintenance needs, or optimizing warehouse layouts. For example, in a supply chain optimization project, we analyzed RFID data to identify bottlenecks and inefficiencies in the material flow, resulting in significant cost savings and improved on-time delivery rates. Data analytics plays a central role in ensuring the system delivers maximum value.

Q 15. What are the security considerations for RFID systems?

RFID security is paramount, as unauthorized access or modification of data can have significant consequences. Think of it like a high-security building – you need multiple layers of protection.

- Data Encryption: Protecting data transmitted between tags and readers is crucial. We use strong encryption algorithms like AES to scramble the data, making it unreadable without the correct decryption key. This is like using a coded message only those with the key can decipher.

- Authentication and Access Control: This involves verifying the authenticity of both the RFID tag and the reader. We can implement various methods, including password protection, digital signatures, and unique identifiers, to prevent unauthorized access. This is like a security guard checking IDs before letting someone enter.

- Physical Security: Protecting the readers and tags themselves from physical tampering is vital. This involves securing the infrastructure, using tamper-evident seals, and implementing physical access controls. This is like securing the building itself with locks, alarms, and surveillance.

- Data Integrity Checks: Implementing mechanisms to detect and prevent data corruption or manipulation is essential. Hashing algorithms and checksums can be used to verify the integrity of the data. Think of it like a checksum verifying a file download to ensure no data got lost during the process.

- Regular Security Audits and Updates: Keeping software and firmware updated and performing regular security audits are crucial to identify and address vulnerabilities. Regular maintenance is as important as initial security implementation.

For example, in a pharmaceutical supply chain, we’d implement robust encryption and authentication to prevent counterfeiting and track medication throughout its journey, ensuring patient safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle data integration between RFID systems and other enterprise systems?

Integrating RFID systems with enterprise systems requires careful planning and the right technology. It’s like connecting different parts of a complex machine to work seamlessly.

Typically, we utilize middleware solutions, APIs (Application Programming Interfaces), or Enterprise Service Buses (ESBs) to facilitate this integration. These act as translators, allowing RFID data to be seamlessly integrated into existing databases, ERP systems, or other enterprise applications.

For example, imagine a retail inventory management system. RFID data from tags on products is read by readers. The middleware then takes this data – product ID, location, quantity – and updates the inventory database in real time. This allows for immediate inventory visibility and helps optimize stock replenishment.

Specific methods include:

- Database Integration: Directly connecting the RFID system’s database to the enterprise system’s database using ETL (Extract, Transform, Load) processes.

- API Integration: Using APIs to send and receive data between the RFID system and other systems. This is a more flexible approach, allowing for easier updates and changes.

- Message Queues: Using message queues like RabbitMQ or Kafka to asynchronously transfer data, improving system resilience and scalability.

The choice of integration method depends on factors like the existing IT infrastructure, data volume, real-time requirements, and security considerations.

Q 17. What is the role of EPCglobal standards in RFID?

EPCglobal standards are like the common language for RFID systems. They define the data structure and communication protocols used in RFID, ensuring interoperability between different RFID systems from various vendors. This is critical for seamless data exchange and avoids the chaos of having incompatible systems.

Key EPCglobal standards include:

- EPC (Electronic Product Code): A unique identifier for each tagged item, enabling global tracking.

- EPCIS (EPC Information Service): A standardized way of capturing, reporting, and querying RFID event data (e.g., when and where a tag was read).

- RFID data encoding schemes: Standardized ways to represent data on RFID tags.

Imagine a global supply chain. EPCglobal standards ensure that RFID data from a tag in China can be seamlessly integrated with systems in Europe and the United States, providing end-to-end visibility.

Without these standards, each RFID system would use its own proprietary protocols, making interoperability and data exchange extremely difficult and costly.

Q 18. Describe your experience with different RFID frequencies (e.g., UHF, HF, LF).

Different RFID frequencies cater to various needs, much like choosing the right tool for a specific job.

- UHF (Ultra-High Frequency): Typically operates at 860-960 MHz. It offers a longer read range (several meters) and is ideal for tracking pallets, cases, and large items in warehouses or logistics applications. Think of it as the long-range scanner for large-scale operations.

- HF (High Frequency): Operating at 13.56 MHz, it provides shorter read ranges (a few centimeters to a meter), but offers higher data capacity and better accuracy. It’s suitable for applications like access control, payment systems, and tracking individual items in close proximity. This is like a more precise, shorter-range scanner for detailed information.

- LF (Low Frequency): Operating at 125-134 kHz, it offers the shortest read range (a few centimeters), but is more robust against environmental interference. It’s ideal for applications like animal tagging or harsh industrial settings. Think of it as the robust, short-range scanner that’s less susceptible to interference.

My experience spans all three frequencies. I’ve designed UHF systems for large-scale inventory management in distribution centers, HF systems for contactless payment terminals, and LF systems for tracking assets in a manufacturing environment with metallic interference.

Q 19. What are the different types of RFID readers (e.g., handheld, fixed, mobile)?

RFID readers come in various forms, each suited for different applications.

- Handheld Readers: Portable devices used for manual data capture. They are ideal for inventory taking, asset tracking, or point-of-sale applications. Think of them as the mobile workforce’s data collection tool.

- Fixed Readers: Permanently installed readers that monitor tags passing through a specific location. They are commonly used in access control systems, conveyor belts, or automated warehousing systems. This is like a stationary security guard at a checkpoint.

- Mobile Readers: Integrated into mobile devices (smartphones or tablets) or mounted on vehicles, enabling data capture on the move. These are used for field service, fleet management, or delivery tracking. This is like a mobile security team responding to incidents.

- Portal Readers: These are large readers, sometimes spanning an entire doorway or gate, designed to read numerous tags simultaneously as items pass through. Common in warehousing and logistics. These are like large-scale security scanners.

The choice of reader depends on the application requirements. For example, a large warehouse might use a combination of fixed and portal readers for high-throughput inventory management, whereas a field service technician might use a handheld reader for on-site asset tagging.

Q 20. Explain your experience with RFID software solutions.

My experience with RFID software encompasses a range of solutions, from basic tag reading and data logging to complex enterprise systems.

I’ve worked with software solutions that:

- Manage tag inventories and configurations: Software allows for creating, managing and updating tag information within a central database.

- Process and analyze RFID data: This includes real-time data visualization, reporting, and alerts for inventory tracking, asset management, and location-based services.

- Integrate with other enterprise systems: Connecting RFID systems to ERP, WMS, or other systems for complete visibility and process automation.

- Provide dashboards and reporting tools: Customizable dashboards offer insights into key performance indicators (KPIs) and provide visual representations of data to improve decision-making.

I’ve used several commercial software packages, as well as developed custom solutions using programming languages such as Java, C#, and Python, along with database technologies such as SQL and NoSQL databases. For instance, I once customized an open-source RFID middleware to integrate with a legacy ERP system in a manufacturing plant, resulting in significant improvements to their inventory accuracy.

Q 21. How do you optimize RFID tag placement for optimal performance?

Optimizing RFID tag placement is critical for reliable performance; it’s like placing sensors strategically to get the best readings. Several factors influence optimal placement:

- Tag Orientation: The orientation of the tag relative to the reader’s antenna is crucial. Many tags have a preferred orientation for optimal signal strength. Experimentation and testing are key.

- Metal Interference: Metal objects can significantly attenuate RFID signals. Tags should be placed away from metal surfaces or use specialized tags designed for metal environments. This is analogous to avoiding obstructions for a Wi-Fi signal.

- Read Range: The read range depends on the frequency and environment. The tags need to be positioned within the reader’s effective range. Simulations and testing are frequently used to ensure adequate coverage.

- Tag Density: In high-density applications, careful planning is needed to avoid tag collisions (when multiple tags interfere with each other). This might involve adjusting read power or using specialized tag anti-collision algorithms.

- Environmental Factors: Moisture, temperature, and other environmental factors can affect signal strength. Tags and readers should be chosen and placed accordingly.

In practice, we use simulation tools and field testing to find the ideal tag placement. We might conduct site surveys, analyze potential interference sources, and perform various tests to determine the optimal configuration. For example, in a clothing retail store, we might strategically position tags on garments and place readers near the exits to maximize read accuracy.

Q 22. How do you manage and maintain an RFID infrastructure?

Managing and maintaining an RFID infrastructure is a multifaceted process requiring a proactive approach. It’s similar to managing a complex network, but with a focus on radio frequency technology. This involves several key aspects:

- Regular Tag and Reader Inventory: Periodically checking the status of all RFID tags and readers to ensure they are functioning correctly and identifying any that need replacing or repair. This prevents data loss and system failures. Think of it like regularly checking your network devices for errors.

- Signal Strength Monitoring: Constantly monitoring the signal strength of the RFID readers to optimize their placement and performance. Weak signals lead to read errors. Visualizing this is like monitoring the strength of a Wi-Fi signal – you need a strong signal for reliable connections.

- Software Updates and Maintenance: Keeping the RFID system software up-to-date with the latest patches and security updates is crucial to prevent vulnerabilities and improve performance. This is analogous to installing operating system updates on your computer.

- Data Backup and Recovery: Regularly backing up the RFID data to prevent data loss in case of system failure or disaster. This is the equivalent of backing up your computer files to an external hard drive.

- Preventive Maintenance: Regular cleaning and inspection of RFID readers and antennas to prevent dust and debris buildup, which can affect signal strength and reading accuracy. This is akin to regularly cleaning your computer’s components to prevent overheating.

- Documentation and Reporting: Maintaining detailed records of the system configuration, maintenance activities, and performance metrics is crucial for troubleshooting and future upgrades. This helps you trace any problems and improve your system over time.

By implementing these procedures, you ensure the long-term reliability and efficiency of your RFID system.

Q 23. What are the environmental factors affecting RFID performance?

Environmental factors significantly impact RFID performance. Different RFID frequencies are affected differently, so understanding the operating frequency is critical. These factors include:

- Metal and Liquids: Metal objects and liquids can significantly attenuate (weaken) RFID signals, leading to read errors or complete signal blockage. Think about how a metal cabinet can block your Wi-Fi signal.

- Temperature and Humidity: Extreme temperatures and humidity can affect the performance of both RFID tags and readers. High temperatures can damage components, while humidity can cause corrosion.

- Electromagnetic Interference (EMI): Other electronic devices emitting electromagnetic waves can interfere with RFID signals, causing read errors or system instability. This is like two radio stations interfering with each other.

- Dust and Debris: Dust and debris can accumulate on RFID antennas, reducing signal strength and causing read errors. Similar to dust accumulating on a computer fan and hindering its performance.

- Distance and Orientation: The distance between the reader and the tag and their relative orientation significantly impact read success. The farther away or the more the tag is angled, the weaker the signal becomes. Imagine trying to use a Bluetooth device from far away – the signal weakens.

Careful consideration of these factors during system design and deployment is crucial for optimal RFID performance. For example, choosing appropriate RFID frequencies and tag types for a specific environment is essential. Metal detectors and similar technologies could be placed at a safe distance.

Q 24. What is your experience with RFID system lifecycle management?

My experience with RFID system lifecycle management encompasses all stages, from initial planning and design to decommissioning. I’ve been involved in projects using various RFID technologies like UHF, HF, and LF. This involves:

- Needs Assessment and System Design: Defining the requirements of the RFID system, choosing the appropriate hardware and software, and designing the system architecture. This includes considerations like the number of tags, readers, and antennas, and their placement.

- Implementation and Deployment: Installing and configuring the RFID hardware and software, and testing the system to ensure it meets the requirements. Thorough testing is crucial to identify and address any potential issues early.

- Maintenance and Support: Providing ongoing maintenance and support for the RFID system, including regular inspections, repairs, and software updates. This is the phase where proactive management is key.

- System Upgrades and Enhancements: Planning and implementing upgrades and enhancements to the RFID system to improve its performance and functionality, such as adding new readers or implementing new software features. This involves staying up-to-date with the latest technology advancements.

- Decommissioning: Planning and executing the decommissioning of the RFID system, including removing the hardware and disposing of it properly. This includes data archival and appropriate security measures.

Throughout this lifecycle, I emphasize data security and compliance with relevant regulations. This systematic approach ensures a smooth and efficient RFID system operation, maximizing return on investment and minimizing disruptions.

Q 25. Describe a situation where you had to solve a complex RFID problem.

In a recent project for a large warehouse, we were experiencing extremely high read error rates with our UHF RFID system. The initial investigation pointed to signal interference, but the source remained elusive. We systematically eliminated possibilities:

- Signal Strength Analysis: We used a signal strength meter to map the signal across the warehouse, identifying areas with weak signals. This pinpointed several problem zones.

- EMI Investigation: We examined potential sources of EMI, including nearby electrical equipment, metal structures, and other electronic devices. This revealed significant interference from a newly installed high-frequency welding machine.

- Reader Optimization: We adjusted the reader settings and antenna positioning to minimize the interference from the welding machine. We also considered using specialized antennas designed to mitigate the EMI.

- Tag Optimization: We evaluated the tags’ performance in the warehouse’s unique environment and considered using tags with higher sensitivity or different materials.

- Shielding Solutions: As a final solution, we implemented targeted shielding around the welding machine to reduce its interference. We carefully selected materials to minimize disruption to the warehouse workflow.

By using a methodical approach combining problem analysis, testing, and targeted solutions, we reduced read error rates to acceptable levels, delivering a functional and reliable RFID system.

Q 26. How do you ensure data integrity and security within an RFID system?

Ensuring data integrity and security in an RFID system requires a multi-layered approach:

- Data Encryption: Encrypting RFID data both in transit and at rest to protect it from unauthorized access. Think of it like using a strong password to protect sensitive files on your computer.

- Access Control: Implementing robust access control mechanisms to restrict access to the RFID system and its data to authorized personnel only. This is like using user permissions to control who can access files on a shared network drive.

- Authentication and Authorization: Implementing authentication and authorization protocols to verify the identity of users and devices attempting to access the system. Similar to login credentials on a website or application.

- Data Validation and Error Checking: Implementing mechanisms for data validation and error checking to ensure that the data is accurate and reliable. This could involve checksums or other redundancy methods.

- Regular Security Audits: Conducting regular security audits to identify and address any vulnerabilities in the RFID system. This is like regularly scanning your computer for viruses and malware.

- Physical Security: Implementing physical security measures to protect RFID readers, antennas, and tags from theft or tampering. This includes securing the equipment in a locked room or using security cameras.

A well-designed security strategy considers both technical and physical aspects, mirroring best practices for securing any sensitive data system.

Q 27. What are some emerging trends in Barcoding and RFID technologies?

Several emerging trends are shaping the future of barcoding and RFID technologies:

- Internet of Things (IoT) Integration: RFID is increasingly integrated with IoT platforms, enabling real-time data collection and analysis across diverse applications. This connects physical assets to digital systems for improved tracking and management.

- Artificial Intelligence (AI) and Machine Learning (ML): AI and ML algorithms are being used to analyze RFID data, enabling predictive maintenance, optimized inventory management, and improved decision-making. AI can identify patterns and predict potential issues.

- Blockchain Technology: Blockchain’s immutability and security features are being explored for improving RFID data integrity and traceability in supply chain and authentication applications. This creates tamper-proof records.

- Passive Ultra-High Frequency (UHF) Tags with Enhanced Read Ranges: Advancements in passive UHF tag technology are leading to longer read ranges, further improving efficiency and reducing the need for many readers.

- Near-Field Communication (NFC) and Bluetooth Low Energy (BLE) Integration: Combining RFID with NFC and BLE technologies allows for greater interaction and data exchange with mobile devices and other systems.

- Improved Tag Durability and Longevity: Tags are becoming more durable and capable of withstanding harsher environmental conditions, extending their lifespan and minimizing replacement costs.

These trends are transforming how barcoding and RFID technologies are used, making them more efficient, reliable, and secure.

Q 28. How do you balance cost and performance when selecting RFID technology?

Balancing cost and performance in RFID technology selection requires a thorough understanding of the application’s needs and available options. There’s no one-size-fits-all answer; it’s a trade-off:

- Identify Your Needs: Clearly define the specific requirements of your application, including the number of tags, read range, environmental conditions, data capacity, and required read rate.

- Technology Selection: Evaluate different RFID technologies (UHF, HF, LF) based on their capabilities and costs. UHF offers longer read ranges but higher costs, while LF offers shorter ranges and lower costs. HF sits in between.

- Tag Selection: Choose tags that meet your needs in terms of durability, read range, memory capacity, and cost. Passive tags are cheaper than active tags, but active tags offer better read ranges.

- Reader and Antenna Selection: Select readers and antennas that are compatible with your chosen tags and offer the required performance at an acceptable cost. Multiple smaller readers might be cheaper than a few larger ones.

- Software and Integration Costs: Consider the costs associated with software development, integration, and ongoing maintenance. This can sometimes overshadow hardware costs.

- Return on Investment (ROI): Analyze the potential return on investment based on the cost of the RFID system and the benefits it will provide. The cost savings from improved efficiency, reduced errors, and better inventory control must be weighed against the initial investment.

A well-defined cost-benefit analysis will guide you towards the most cost-effective and performant RFID solution. You might need to prioritize certain aspects based on the application’s critical needs. For example, in a high-security setting, sacrificing some cost for enhanced security features may be justifiable.

Key Topics to Learn for Barcoding and RFID Technologies Interview

- Barcode Symbologies: Understand the different types of barcodes (e.g., EAN, UPC, QR Code, Data Matrix), their applications, and their respective advantages and limitations. Consider the decoding process and error correction mechanisms.

- RFID Technologies: Familiarize yourself with various RFID frequency bands (HF, UHF, LF), tag types (passive, active), and reader technologies. Explore the concepts of tag encoding, data transmission, and antenna design.

- Data Capture and Integration: Learn about the methods of capturing data from barcodes and RFID tags, including hardware and software solutions. Understand how this data is integrated into existing systems (e.g., ERP, WMS).

- Practical Applications: Explore real-world applications in various industries such as supply chain management, inventory control, asset tracking, access control, and healthcare. Be prepared to discuss specific use cases and benefits.

- System Design and Implementation: Understand the considerations involved in designing and implementing barcoding and RFID systems, including network architecture, data security, and system scalability.

- Troubleshooting and Problem Solving: Develop your ability to diagnose and troubleshoot common issues related to barcode and RFID systems, such as read errors, data corruption, and system malfunctions. Consider different approaches to problem-solving in these technical domains.

- Data Analysis and Reporting: Understand how to analyze data collected from barcode and RFID systems to gain insights and improve operational efficiency. Consider the importance of data visualization and reporting tools.

Next Steps

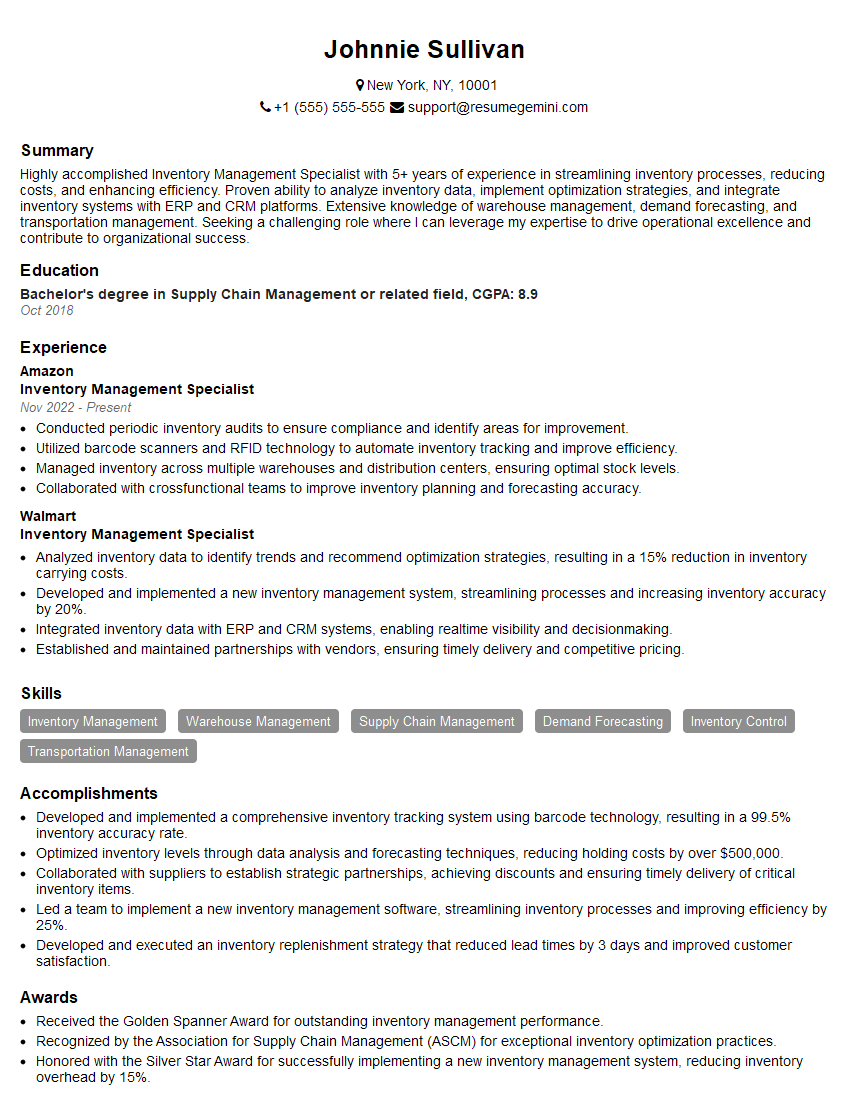

Mastering Barcoding and RFID Technologies opens doors to exciting career opportunities in diverse and rapidly growing industries. A strong understanding of these technologies significantly enhances your value to prospective employers. To maximize your job prospects, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience effectively. Examples of resumes tailored to Barcoding and RFID Technologies are available to further guide your resume creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO