Unlock your full potential by mastering the most common Supplier Qualification and Evaluation interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Supplier Qualification and Evaluation Interview

Q 1. Describe your experience in developing and implementing supplier qualification processes.

Developing and implementing supplier qualification processes is crucial for ensuring consistent product quality, mitigating risks, and optimizing supply chain efficiency. My approach involves a multi-stage process, starting with defining clear requirements and criteria based on the specific needs of our organization. This includes aspects such as quality management systems, capacity, financial stability, and ethical practices.

Next, I develop a structured questionnaire and checklist to evaluate potential suppliers against these pre-defined criteria. This is followed by site visits and thorough audits to verify the information provided and assess their operational capabilities firsthand. For example, in a previous role, we implemented a new supplier qualification process for a critical component in our medical device manufacturing. This involved developing a detailed scoring system weighted on factors like quality certifications, production capacity, and delivery performance. The system allowed us to objectively compare potential suppliers and select the best fit.

Finally, the process includes regular monitoring and performance reviews using key performance indicators (KPIs) to ensure continuous compliance and improvement. This ensures that the selected suppliers consistently meet our expectations and maintain the high standards necessary for our products and services.

Q 2. How do you assess supplier financial stability and risk?

Assessing supplier financial stability and risk is vital to prevent disruptions in the supply chain. I utilize a combination of methods to gauge this, including reviewing financial statements (balance sheets, income statements, cash flow statements) to identify trends and potential red flags like high debt levels or declining profitability. Credit reports from reputable agencies provide additional insights into a supplier’s creditworthiness and payment history.

Beyond financial statements, I also consider factors such as the supplier’s market position, customer concentration, and diversification of revenue streams. A supplier heavily reliant on a single customer is more vulnerable to financial instability. For instance, a supplier who primarily works with a single automotive manufacturer faces greater risk if that manufacturer experiences a downturn. I also look for indicators of operational efficiency, as a supplier with high operating costs might be less resilient to economic shocks.

Finally, qualitative assessments involve discussions with the supplier’s management team to gain insights into their strategic planning and risk management capabilities. A holistic approach combining quantitative and qualitative data provides a more comprehensive and reliable assessment of financial stability and risk.

Q 3. Explain your approach to conducting supplier audits.

My approach to conducting supplier audits is systematic and comprehensive, adhering to industry best practices and relevant standards (e.g., ISO 9001, IATF 16949). It begins with defining the audit scope and objectives, clearly specifying the areas to be audited based on the supplier’s role in our supply chain and the associated risks. This includes documentation review, process walkthroughs, and on-site inspections to evaluate compliance with relevant regulations and internal requirements.

During the audit, I employ a combination of techniques including interviews with personnel at all relevant levels, observation of work processes, and examination of records. A key aspect is the use of checklists and standardized audit protocols to ensure consistency and objectivity. For example, if auditing a supplier for a food product, a critical area would be their adherence to food safety regulations and hygiene standards. If auditing a supplier of automotive parts, the focus will likely be on quality control processes and adherence to IATF 16949.

After the audit, I prepare a detailed report summarizing the findings, including any non-conformances identified. The report includes recommendations for corrective actions and a plan for follow-up audits to verify the effectiveness of these actions. Collaboration and open communication with the supplier throughout the process are critical for successful outcomes.

Q 4. What key performance indicators (KPIs) do you use to monitor supplier performance?

Monitoring supplier performance requires a set of relevant Key Performance Indicators (KPIs) tailored to the specific requirements of each supplier and product. The KPIs should align with the critical aspects of the supplier’s performance, such as quality, delivery, cost, and service. Common KPIs I use include:

- On-Time Delivery (OTD): Percentage of orders delivered on or before the agreed-upon date.

- Quality Rate: Percentage of defect-free products or services received.

- Lead Time: Time taken from order placement to delivery.

- Cost per Unit: The cost of goods or services received.

- Customer Satisfaction: Feedback from the customer on the supplier’s performance.

- Defect Rate: Number of defective items per unit of production.

These KPIs are tracked regularly, and any deviations from the targets trigger a review process to identify the root causes and implement corrective actions. Regular performance reviews with suppliers are essential to discuss these metrics, understand potential challenges, and develop improvement plans collaboratively. Data visualization tools are used to track progress and identify trends over time, providing a clear picture of supplier performance and allowing for proactive interventions when needed.

Q 5. How do you manage supplier relationships and resolve conflicts?

Managing supplier relationships and resolving conflicts requires a proactive and collaborative approach. Building strong relationships is key to effective collaboration and conflict resolution. This starts with clear communication, mutual respect, and a shared understanding of goals and expectations. Regular communication, including both formal and informal meetings, keeps the lines of communication open and allows for early identification and resolution of potential issues.

When conflicts arise, a structured approach is necessary. This involves clearly defining the problem, identifying the root causes, and collaboratively developing solutions. Mediation or negotiation can often be successful in resolving disputes. For example, if there’s a conflict concerning late deliveries, we might work together to identify bottlenecks in their production process and find ways to improve efficiency, possibly involving investment or technical support on our end. However, in cases of significant or persistent issues, we may need to reassess the supplier’s suitability and consider alternative options.

Transparency and fairness are crucial in maintaining positive relationships. Open communication about challenges and performance issues, coupled with a willingness to work together toward solutions, is essential for a successful partnership. It’s important to remember that successful supplier relationships are based on trust, mutual benefit, and a long-term perspective.

Q 6. What is your experience with different supplier qualification methodologies (e.g., ISO 9001, IATF 16949)?

My experience encompasses various supplier qualification methodologies, including ISO 9001 and IATF 16949. ISO 9001 is a widely recognized quality management system standard applicable across many industries. It focuses on establishing and maintaining a robust quality management system to consistently meet customer requirements. During supplier qualification, I assess their adherence to ISO 9001 principles, including documentation control, internal audits, and corrective action procedures.

IATF 16949, specific to the automotive industry, builds upon ISO 9001 with additional requirements tailored to the automotive sector’s unique demands. This includes specific guidelines for process control, risk management, and continuous improvement. In automotive supplier qualification, I verify their compliance with IATF 16949, paying close attention to aspects such as production part approval process (PPAP) and control plans.

Beyond these specific standards, my experience includes working with suppliers following other industry-specific standards and regulations. The approach always involves thoroughly understanding the relevant standards and requirements and adapting the qualification process accordingly to ensure the chosen methodologies align with the specific needs of our products and supply chains.

Q 7. How do you ensure supplier compliance with regulatory requirements?

Ensuring supplier compliance with regulatory requirements is a critical aspect of effective supplier management. This starts with identifying all applicable regulations relevant to the products and services provided by the supplier. This might include environmental regulations, safety standards, or industry-specific rules. The supplier qualification process incorporates assessments of the supplier’s understanding and compliance with these regulations.

This includes reviewing relevant documentation, such as permits, licenses, and compliance reports, and conducting on-site audits to verify compliance with regulations. For example, if a supplier manufactures electronic components, compliance with RoHS (Restriction of Hazardous Substances) would be a crucial aspect of the evaluation. Similar checks apply to other relevant regulations like REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) or any industry-specific safety regulations.

Regular monitoring and updates are essential to address changes in legislation. We maintain a system for tracking regulatory changes and ensure that our suppliers remain updated on relevant legal obligations. Non-compliance with regulatory requirements can have severe consequences, ranging from fines to product recalls, therefore proactive management and strict enforcement of compliance standards are critical.

Q 8. Describe your experience in negotiating contracts with suppliers.

Negotiating supplier contracts requires a strategic approach balancing value, risk, and long-term relationships. My experience encompasses all stages, from initial RFP (Request for Proposal) development to final contract execution and ongoing performance monitoring. I start by clearly defining our needs and desired outcomes, including specifications, timelines, and key performance indicators (KPIs). This forms the foundation for robust negotiations.

For example, in a recent negotiation with a packaging supplier, I successfully leveraged market analysis to secure a 15% reduction in unit cost while maintaining quality standards. This involved a thorough understanding of their production costs and exploring alternative materials. I also focus on building rapport with the supplier’s team, fostering a collaborative environment where mutual understanding and trust enable win-win outcomes. I incorporate clauses addressing risk mitigation, such as intellectual property protection, liability limitations, and termination provisions, tailored to the specific context of the agreement. Finally, I meticulously review the final contract, ensuring clarity and compliance with relevant regulations.

Q 9. How do you identify and mitigate supply chain risks?

Identifying and mitigating supply chain risks is crucial for business continuity and resilience. My approach involves a multi-faceted risk assessment incorporating various methods. First, I conduct a thorough supplier analysis, considering factors like their financial stability, geographic location, production capacity, and compliance history. Second, I evaluate potential disruptions such as natural disasters, political instability, or pandemics. I regularly monitor geopolitical events and leverage industry intelligence to anticipate emerging risks.

For example, the recent global chip shortage highlighted the risk of single-sourcing. To mitigate such risks, we diversify our supplier base and establish strategic partnerships with multiple suppliers capable of providing the same components, thereby reducing dependency on any single entity. Additionally, we implement contingency planning strategies, which include maintaining safety stock levels, exploring alternative sourcing options, and maintaining open communication channels to proactively address any emerging issues. We also use a risk matrix to prioritize and assign resources to the most critical risks.

Q 10. Explain your process for selecting and onboarding new suppliers.

My process for selecting and onboarding new suppliers is a structured, multi-stage approach designed to ensure due diligence and a smooth transition. The process begins with identifying potential suppliers through market research, industry directories, and networking. We then pre-qualify suppliers based on criteria such as financial stability, technical capabilities, and quality certifications (e.g., ISO 9001).

Qualified suppliers undergo a rigorous evaluation process which may include site visits, audits (including financial and operational audits), and review of quality management systems. We assess their capacity to meet our specific requirements, focusing on factors such as production capacity, delivery timelines, and compliance with relevant regulations (e.g., environmental and labor laws). Once a supplier is selected, a detailed onboarding plan is developed. This includes establishing clear communication channels, defining performance expectations, and providing necessary training and documentation. Throughout the process, comprehensive documentation is maintained to ensure traceability and compliance.

Q 11. How do you measure the effectiveness of your supplier qualification program?

Measuring the effectiveness of a supplier qualification program involves using both quantitative and qualitative metrics. Key Performance Indicators (KPIs) such as supplier defect rates, on-time delivery performance, and lead times provide quantitative data. These KPIs are tracked regularly and compared against established targets. For instance, a reduction in the average defect rate from 3% to 1% demonstrates the program’s effectiveness in improving supplier quality.

Qualitative metrics include supplier satisfaction surveys, feedback from internal stakeholders, and the overall effectiveness of risk mitigation strategies. Regular reviews of the supplier qualification process itself are also necessary to identify areas for improvement and ensure its continued effectiveness. We use a balanced scorecard approach that integrates both quantitative and qualitative measures to get a holistic view of the program’s impact.

Q 12. How do you handle supplier non-conformances?

Handling supplier non-conformances requires a structured approach that balances corrective action with maintaining a positive supplier relationship. Upon identifying a non-conformance, a thorough investigation is conducted to determine the root cause. This may involve analyzing data, conducting interviews, and reviewing production processes. Based on this investigation, a Corrective Action Preventative Action (CAPA) plan is developed collaboratively with the supplier.

The plan outlines specific actions to rectify the immediate issue and prevent recurrence. We monitor the implementation of the CAPA plan closely and track its effectiveness. This process is documented thoroughly and reviewed regularly. While holding suppliers accountable for their performance, we also strive to foster collaboration and support them in improving their processes. The approach taken depends on the severity of the non-conformance; minor issues are often addressed through informal communication, while more serious breaches may lead to formal warnings or contract termination.

Q 13. What is your experience with supplier performance management systems?

My experience with supplier performance management systems (SPMS) involves designing, implementing, and managing systems that track and analyze supplier performance data. These systems typically leverage software to monitor KPIs, track corrective actions, and facilitate communication with suppliers. A well-designed SPMS allows for continuous monitoring of supplier performance, providing early warnings of potential problems and enabling proactive intervention.

For example, I have implemented an SPMS using a cloud-based platform that integrates with our enterprise resource planning (ERP) system. This allows for automated data collection and real-time performance monitoring. The system generates reports and dashboards providing insights into supplier performance, enabling us to identify top-performing and underperforming suppliers and take appropriate action. The system also includes features for conducting supplier assessments, managing contracts, and tracking supplier relationships. This holistic approach facilitates effective management of the entire supplier ecosystem.

Q 14. How do you ensure data accuracy and integrity in supplier qualification processes?

Ensuring data accuracy and integrity in supplier qualification processes is crucial for making informed decisions. We implement several measures to achieve this. First, we use standardized data collection methods and templates to minimize errors and inconsistencies. Second, we employ data validation techniques to ensure the data entered into the system is accurate and complete. For example, we use drop-down menus and pre-defined fields to prevent data entry errors.

Third, we regularly audit the data to identify and correct any inconsistencies. We also use a system of checks and balances, ensuring multiple individuals review the data before it is finalized. For example, supplier self-assessments are validated by our team through site visits and data verification. Finally, we maintain a robust data governance policy that outlines procedures for data collection, storage, and access. This comprehensive approach ensures high-quality data that supports effective decision-making and minimizes the risk of errors.

Q 15. Describe your experience with supplier diversity programs.

Supplier diversity programs aim to increase the participation of minority-owned, women-owned, veteran-owned, and disabled veteran-owned businesses in a company’s supply chain. My experience encompasses developing and implementing these programs, from initial assessment of the current supplier base to establishing goals and targets for diverse supplier engagement. This involves actively seeking out diverse suppliers through networking events, online databases, and partnerships with relevant organizations.

For example, in my previous role, we successfully increased our diverse supplier spend by 15% in two years by implementing a mentorship program that paired established suppliers with emerging diverse businesses. This provided invaluable support, including access to resources, networking opportunities, and guidance on navigating the procurement process. Furthermore, we established a dedicated team to focus exclusively on supplier diversity outreach and relationship management, resulting in a more robust and inclusive supply chain.

Beyond simply meeting quotas, the success of a supplier diversity program is measured by its long-term impact on the business and the community. This includes evaluating supplier performance, ensuring fair and equitable treatment, and fostering ongoing relationships. It’s about building a truly diverse and resilient supply chain that benefits all stakeholders.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you leverage technology to improve supplier qualification and evaluation?

Technology plays a crucial role in streamlining and improving the efficiency of supplier qualification and evaluation. We utilize a Supplier Relationship Management (SRM) system to centralize all supplier data, including performance metrics, financial information, and compliance records. This system allows for automated evaluation processes, reducing manual effort and improving accuracy.

For example, we use automated scoring systems to evaluate bids based on predefined criteria such as price, quality, and delivery performance. This not only reduces bias but also allows for a more objective comparison of suppliers. We also utilize data analytics to identify trends and potential risks within our supply chain. This might involve analyzing supplier performance data to pinpoint areas for improvement or identifying potential supply chain disruptions before they impact our operations.

Furthermore, technology aids in communication and collaboration. Secure online portals enable efficient communication and document sharing with suppliers, simplifying the onboarding and ongoing relationship management process. This enhances transparency and reduces reliance on time-consuming email exchanges and manual paperwork. Example: Our SRM system integrates with our ERP to automatically update supplier information and purchase orders.

Q 17. How do you ensure the confidentiality of sensitive supplier information?

Protecting the confidentiality of sensitive supplier information is paramount. We implement robust security measures, including data encryption both in transit and at rest, access control based on the principle of least privilege, and regular security audits. All sensitive data is stored on secure servers with strict access controls, and employees are trained on data security protocols.

We utilize Non-Disclosure Agreements (NDAs) with all suppliers to legally protect confidential information. These agreements outline the responsibilities of both parties regarding the handling and protection of sensitive data. Regular security awareness training is provided to all employees involved in supplier management to reinforce best practices and ensure they understand the potential consequences of data breaches. We also maintain detailed audit trails to track access to sensitive information and identify potential vulnerabilities.

Think of it like a bank vault – multiple layers of security are required to keep sensitive information safe. Our approach is multi-faceted and incorporates both technical and procedural controls to ensure the confidentiality and integrity of supplier data.

Q 18. What are the key elements of a strong supplier contract?

A strong supplier contract is the cornerstone of a successful supplier relationship. Key elements include clearly defined terms and conditions, including scope of work, payment terms, performance metrics, and intellectual property rights. Specific deliverables and timelines must be outlined, along with penalties for non-compliance.

Furthermore, the contract should address issues such as confidentiality, liability, termination clauses, and dispute resolution mechanisms. A well-structured contract protects both the buyer and the supplier, minimizing the risk of misunderstandings or disputes. It’s crucial to ensure the contract aligns with relevant laws and regulations.

For example, a robust contract would include specific details on quality control, inspection procedures, and acceptable levels of defects. It would also detail procedures for handling changes to the scope of work and addressing unexpected circumstances. A well-drafted contract is a proactive measure that prevents conflicts and facilitates a smooth and productive working relationship.

Q 19. Describe your experience with different supplier rating systems.

My experience encompasses various supplier rating systems, from simple weighted scoring models to more sophisticated systems that incorporate qualitative and quantitative data. Simple systems might use a weighted average of factors like price, quality, and on-time delivery. More complex systems may integrate feedback from various stakeholders, incorporate risk assessments, and even utilize machine learning algorithms to predict future supplier performance.

For instance, I’ve used systems that incorporate customer satisfaction data, financial stability analysis, and supplier sustainability initiatives into the rating. These more holistic approaches provide a more comprehensive view of supplier capabilities and risks. The choice of rating system depends on the complexity of the procurement process, the strategic importance of the supplier, and the resources available for evaluation. Regular review and updating of rating systems are essential to ensure their continued relevance and accuracy. The ultimate goal is to use the rating system to make informed decisions that optimize the supply chain and minimize risk.

Q 20. How do you handle supplier capacity constraints?

Handling supplier capacity constraints requires a proactive and multi-faceted approach. The first step is to identify the nature and extent of the constraint. This might involve communication with the supplier to understand the root cause of the capacity issue. Then we explore potential solutions, which could include negotiating alternative delivery schedules, seeking additional suppliers, or working with the existing supplier to improve their capacity.

For example, if a supplier is facing a temporary production bottleneck, we might negotiate a phased delivery schedule to manage the constraint over time. If the constraint is more significant, we might explore alternative sourcing strategies, such as finding a secondary supplier to share the workload. We also regularly monitor supplier capacity utilization to anticipate potential issues and proactively manage risks. Collaboration and open communication with the supplier are critical in resolving capacity constraints successfully.

In some cases, investing in the supplier’s capacity expansion might be a viable solution, particularly for strategic suppliers. This could involve financial assistance, technical support, or process improvements.

Q 21. How do you balance cost and quality when selecting suppliers?

Balancing cost and quality when selecting suppliers is a crucial aspect of effective procurement. It’s not about simply choosing the cheapest option, but rather finding the optimal balance between cost, quality, and other factors such as reliability, delivery performance, and ethical considerations.

We often use a weighted scoring system that assigns different weights to cost and quality, reflecting their relative importance to the overall project goals. For example, in a project where quality is paramount (like medical device manufacturing), quality might be weighted more heavily than cost. Conversely, for a commodity item, cost might be the primary factor. Furthermore, we consider the total cost of ownership (TCO), which includes not only the initial purchase price but also factors like maintenance, transportation, and potential warranty costs.

We also analyze supplier performance data to assess quality consistently. This helps us to understand the long-term cost implications of choosing different suppliers. Ultimately, the goal is to select a supplier that provides the desired quality at a competitive price while managing risk effectively.

Q 22. Describe your experience with different supplier types (e.g., manufacturing, service providers).

My experience encompasses a wide range of supplier types, from large multinational manufacturers providing complex components to smaller, specialized service providers offering critical logistical support. For example, I’ve worked extensively with manufacturers of automotive parts, where rigorous quality control and adherence to stringent specifications are paramount. This involved managing their performance metrics, conducting regular audits, and negotiating contracts. On the service provider side, I’ve collaborated with IT firms responsible for our cybersecurity and logistics companies handling our global supply chain. This required different evaluation criteria, focusing on service level agreements (SLAs), security protocols, and the reliability of delivery. The key difference in my approach lies in tailoring the qualification process to the specific needs and risks associated with each supplier type. For manufacturers, it’s heavily weighted towards quality and production capacity; for service providers, it emphasizes service level adherence, security, and responsiveness.

Q 23. How do you ensure supplier sustainability and ethical sourcing?

Ensuring supplier sustainability and ethical sourcing is integral to our procurement strategy. We achieve this through a multi-faceted approach. Firstly, we incorporate sustainability criteria into our supplier selection process, evaluating their environmental impact, labor practices, and commitment to ethical business conduct. This includes reviewing their environmental certifications (e.g., ISO 14001) and social compliance audits. Secondly, we engage in regular dialogues with our suppliers to understand their sustainability initiatives and encourage improvements. This can involve joint projects aimed at reducing carbon footprints or enhancing worker safety. Thirdly, we utilize third-party verification tools to independently assess supplier claims and ensure transparency. Finally, we reward suppliers who demonstrate strong sustainability performance through preferential treatment in contract renewals and new business opportunities. For instance, we prioritize suppliers who use recycled materials or implement initiatives to reduce waste. This holistic approach enables us to create a mutually beneficial relationship, driving both business success and positive environmental and social impact.

Q 24. What are your strategies for continuous improvement in supplier qualification?

Continuous improvement in supplier qualification is a dynamic process. We employ several strategies. Firstly, we regularly review and update our supplier qualification criteria and processes, reflecting changes in industry best practices, regulatory requirements, and our own business needs. Secondly, we actively seek feedback from our internal stakeholders and suppliers to identify areas for enhancement. Thirdly, we leverage data analytics to track supplier performance metrics and identify trends that indicate potential risks or opportunities for improvement. For example, a surge in defect rates from a specific supplier might prompt a deeper investigation into their manufacturing processes. Finally, we invest in training our procurement team to enhance their skills and knowledge in supplier qualification and management. This ensures that our processes remain efficient, effective, and aligned with best practices.

Q 25. Explain your approach to managing supplier relationships throughout the product lifecycle.

Managing supplier relationships throughout the product lifecycle is crucial. We establish a collaborative relationship from the initial selection process, involving them early in product development to leverage their expertise and ensure design for manufacturability (DFM). During the production phase, we maintain regular communication, monitoring performance against agreed-upon metrics and promptly addressing any issues. For example, we use scorecards to track key performance indicators (KPIs) and conduct regular performance reviews. In the post-production phase, we collaborate on continuous improvement initiatives, seeking feedback to enhance future products and services. We also work collaboratively on end-of-life management of products, ensuring responsible disposal and recycling. This lifecycle approach fosters long-term partnerships and enhances our ability to mitigate risks and capitalize on opportunities.

Q 26. How do you address supplier performance issues proactively?

Proactive management of supplier performance issues is paramount. We utilize a multi-layered approach. Firstly, we implement robust monitoring systems, tracking KPIs such as on-time delivery, quality, and cost. Any deviation from established targets triggers an immediate investigation. Secondly, we foster open communication channels with our suppliers, encouraging early reporting of potential issues. Thirdly, we utilize early warning indicators, such as changes in supplier financials or operational disruptions, to identify potential risks before they escalate into major problems. Finally, we have a structured escalation process to address critical issues promptly and effectively. This includes collaborating with the supplier to develop and implement corrective actions. This proactive strategy helps us avoid major disruptions and maintains supply chain stability.

Q 27. Describe your experience with supplier corrective action requests (SCARs).

My experience with Supplier Corrective Action Requests (SCARs) is extensive. I’ve managed numerous SCARs across various supplier categories. The process typically starts with identifying a non-conformance, which might be a quality defect, a delivery delay, or a breach of contract. Then a formal SCAR is issued to the supplier, clearly outlining the problem, the required corrective actions, and the deadline for completion. We maintain open communication throughout the process, providing support and guidance to the supplier to ensure timely resolution. We track the implementation of corrective actions and verify their effectiveness through follow-up audits. Once the issue is resolved, we close the SCAR, documenting the lessons learned to prevent recurrence. A key aspect is to focus not only on immediate remediation but also on root cause analysis to prevent similar issues from happening again. We often utilize tools like Pareto charts and fishbone diagrams to identify root causes and implement systemic improvements.

Q 28. How do you evaluate the effectiveness of your supplier onboarding process?

Evaluating the effectiveness of our supplier onboarding process is crucial. We employ several methods. Firstly, we conduct post-onboarding surveys with both the supplier and our internal teams to gather feedback on the clarity, efficiency, and completeness of the process. Secondly, we track key metrics such as time to onboard, the number of errors or delays during the process, and the supplier’s time to achieve full operational capability. Thirdly, we conduct regular audits of the newly onboarded suppliers to assess their compliance with our requirements and their performance against established KPIs. By analyzing this data, we can identify areas for improvement in our onboarding process, ensuring a smooth and efficient integration of new suppliers and reducing the risk of delays or quality issues.

Key Topics to Learn for Supplier Qualification and Evaluation Interview

- Supplier Selection Criteria: Defining and prioritizing key factors like cost, quality, reliability, and ethical considerations. Practical application: Developing a weighted scoring system to objectively compare potential suppliers.

- Risk Assessment and Mitigation: Identifying and evaluating potential risks associated with suppliers, including financial, operational, and reputational risks. Practical application: Creating a risk matrix and developing mitigation strategies for high-risk suppliers.

- Supplier Audits and Performance Monitoring: Conducting thorough audits to verify compliance with standards and expectations, and establishing key performance indicators (KPIs) to track supplier performance. Practical application: Designing an audit checklist and developing a performance monitoring dashboard.

- Contract Negotiation and Management: Understanding the legal and commercial aspects of supplier contracts, including terms and conditions, payment schedules, and dispute resolution mechanisms. Practical application: Negotiating favorable terms and conditions with suppliers and managing contract compliance.

- Continuous Improvement: Implementing processes for ongoing supplier performance improvement, including feedback mechanisms, corrective actions, and capacity planning. Practical application: Establishing a system for regular supplier performance reviews and implementing improvement plans.

- Supply Chain Sustainability: Integrating environmental, social, and governance (ESG) factors into supplier selection and evaluation processes. Practical application: Developing a sustainability scorecard for evaluating supplier environmental and social responsibility.

- Technology & Data Analytics in Supplier Management: Leveraging technology and data analytics to streamline supplier qualification and evaluation processes and gain actionable insights. Practical application: Using software to automate tasks, analyze supplier performance data and identify trends.

Next Steps

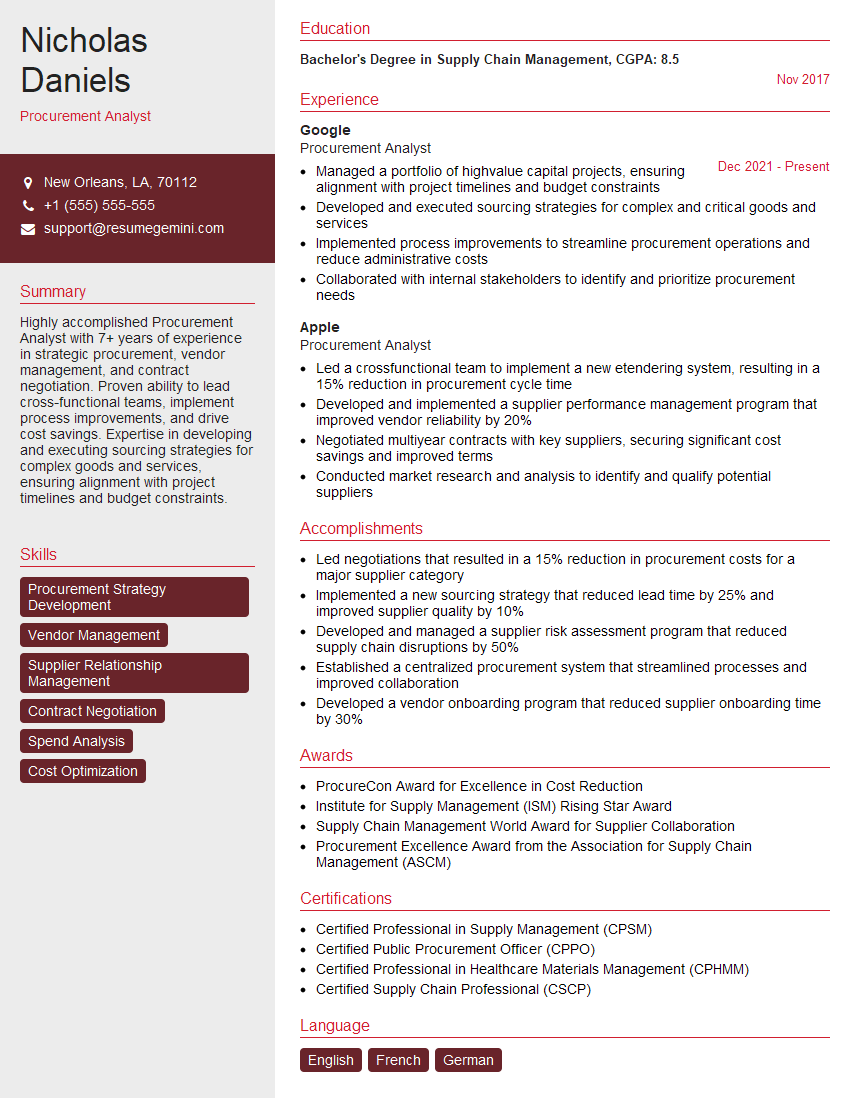

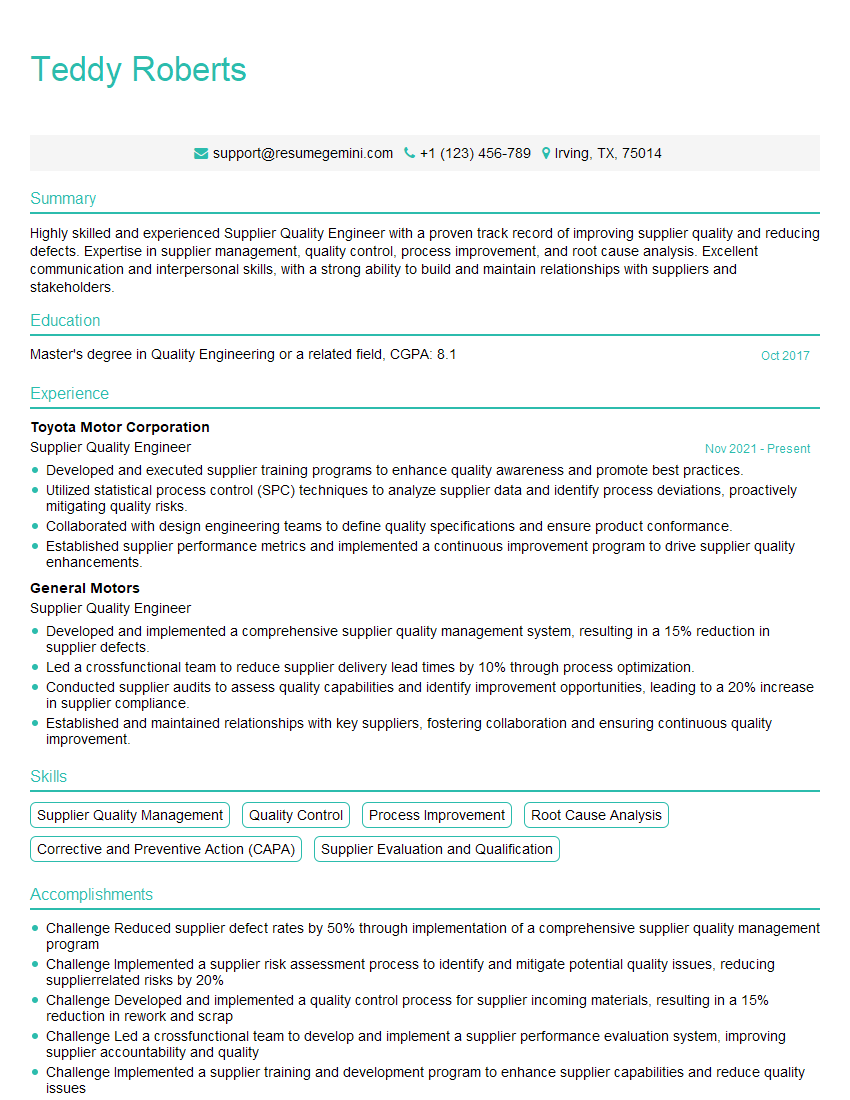

Mastering Supplier Qualification and Evaluation is crucial for career advancement in procurement, supply chain management, and related fields. It demonstrates your ability to manage risk, optimize costs, and ensure the consistent delivery of high-quality goods and services. To significantly increase your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and effective resume that highlights your skills and experience. Examples of resumes tailored to Supplier Qualification and Evaluation roles are provided to guide your resume building process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO