Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Radial Drilling Machine Operation interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Radial Drilling Machine Operation Interview

Q 1. Explain the principle of operation of a radial drilling machine.

A radial drilling machine’s primary function is to create precisely located holes in workpieces of varying sizes and shapes. Its key principle lies in its unique design: a drill head that can be moved radially (along a horizontally rotating arm) and vertically (along a column). This allows for precise positioning over a large work area without repositioning the workpiece. Imagine it like a giant, adjustable arm with a drill at the end. You can swing the arm to position the drill over any point within its reach and then adjust the height to match the workpiece.

The operation begins by clamping the workpiece securely to the machine’s table. The operator then adjusts the arm to position the drill bit directly over the desired drilling location. Once positioned, the feed mechanism is engaged, slowly lowering the drill bit into the workpiece to create the hole. The radial movement allows access to various points on large pieces, eliminating the need to move the workpiece itself, improving efficiency and precision.

Q 2. Describe the different types of radial drilling machines.

Radial drilling machines come in various types, primarily categorized by their size and features. The most common differentiation is based on the arm’s capacity and the motor’s power.

- Floor-type Radial Drills: These are large, heavy-duty machines typically found in large workshops or factories. They offer a wide range of drilling capabilities and are robust enough for handling significant workpieces and demanding drilling operations.

- Column-type Radial Drills: These offer a smaller footprint than floor-type drills, making them suitable for smaller spaces. They’re still powerful enough for many applications but are generally smaller and less powerful.

- Portable Radial Drills: While less common, portable models exist, often smaller and lighter, designed for specific tasks or situations where moving a larger machine is impractical.

- CNC Radial Drills: These machines incorporate Computer Numerical Control (CNC) technology, allowing for automated drilling operations based on programmed instructions. This drastically increases precision, consistency and efficiency, particularly in high-volume production.

The choice depends heavily on the type and volume of work. A small workshop might opt for a column-type machine, while a large manufacturing plant will likely use floor-type or CNC radial drills for higher precision and capacity.

Q 3. What are the safety precautions to be followed while operating a radial drilling machine?

Safety is paramount when operating any radial drilling machine. Failure to adhere to safety protocols can lead to serious injury. Here’s a list of crucial precautions:

- Proper Training: Operators must receive thorough training before using the machine.

- Personal Protective Equipment (PPE): Always wear safety glasses, hearing protection, and appropriate clothing. Gloves may also be necessary.

- Machine Inspection: Before commencing work, inspect the machine for any damage, loose parts, or malfunctioning components. Report any issues immediately.

- Workpiece Securement: Ensure the workpiece is securely clamped to the table to prevent movement during drilling.

- Clearance: Maintain sufficient clearance around the machine to prevent accidental collisions or injuries.

- Emergency Stop: Familiarize yourself with the location and operation of the emergency stop button.

- Lockout/Tagout: Follow proper lockout/tagout procedures during maintenance or repairs.

- Avoid Loose Clothing or Jewelry: These can get caught in moving parts.

- Never Reach into Moving Parts: Always wait for all movement to cease before making adjustments or cleaning.

Following these guidelines minimizes the risk of accidents, protecting both the operator and the equipment.

Q 4. How do you select the correct drill bit for a specific job?

Selecting the correct drill bit is crucial for achieving accurate and efficient drilling. The selection process involves considering several factors:

- Material of the workpiece: Different materials require different drill bit materials and designs. For example, a high-speed steel (HSS) bit is suitable for most metals, while carbide bits are necessary for harder materials like hardened steel.

- Diameter of the hole: Select a drill bit with the desired hole diameter.

- Drill bit point angle: The point angle affects the cutting action and the type of hole created. A 118° angle is standard for general-purpose drilling in metals.

- Drill bit length: Choose a drill bit long enough to drill through the workpiece, accounting for the depth of the hole.

- Drill bit shank type: Ensure the shank type (e.g., straight shank, Morse taper shank) matches the machine’s spindle.

For example, drilling a hole in aluminum might use an HSS bit, while drilling into titanium alloy would require a carbide-tipped drill bit due to titanium’s hardness. Incorrect bit selection can lead to broken bits, inaccurate holes, or damage to the machine.

Q 5. Explain the process of setting up a radial drilling machine for a specific operation.

Setting up a radial drilling machine involves several steps to ensure accurate and safe operation:

- Secure the Workpiece: Clamp the workpiece firmly to the table, ensuring stability and preventing movement during drilling.

- Position the Drill Head: Swing the radial arm and adjust the drill head vertically to position the drill bit directly above the desired drilling location. Accurate positioning is critical to prevent inaccurate holes.

- Select the Drill Bit: Choose the correct drill bit based on the material, hole size, and depth.

- Check for Clearance: Ensure sufficient clearance exists between the workpiece, the drill head, and other machine components.

- Set the Feed Rate: Adjust the feed rate (speed at which the drill bit advances into the workpiece) according to the material and drill bit. Too fast a feed can break the bit, while too slow can be inefficient.

- Set the Spindle Speed: Select the appropriate spindle speed based on the drill bit diameter and the material being drilled. A chart or guide provided by the manufacturer should be consulted.

- Engage the Drill: Carefully engage the feed mechanism, gradually lowering the drill bit into the workpiece.

Careful and accurate setup is essential for producing precise, high-quality holes.

Q 6. How do you ensure the accuracy of drilling operations?

Ensuring the accuracy of drilling operations requires attention to several details throughout the process:

- Accurate Workpiece Positioning: Use precise measuring tools to ensure the workpiece is positioned correctly on the machine table.

- Proper Drill Bit Alignment: Align the drill bit perfectly with the marked drilling location to prevent misaligned or inaccurate holes. Use alignment tools if necessary.

- Consistent Feed Rate: Maintaining a consistent feed rate prevents uneven hole diameters or surfaces.

- Regular Machine Maintenance: Regular maintenance keeps the machine in optimal working condition, promoting accuracy.

- Use of Fixtures or Jigs: For repetitive or complex drilling operations, using fixtures or jigs increases precision and consistency, preventing human error.

- Calibration: Regularly calibrate the machine to ensure accuracy. This may involve checking the alignment of the drill head, the accuracy of the depth stop, and the spindle speed.

By adhering to these practices, one can greatly minimize deviations from the planned hole dimensions and locations, guaranteeing precision.

Q 7. How do you troubleshoot common problems encountered while operating a radial drilling machine?

Troubleshooting common problems in radial drilling involves systematic investigation and problem-solving:

- Drill Bit Breaking: This usually indicates incorrect speed, feed rate, dull drill bit, or improper workpiece clamping. Check these factors and replace the bit if necessary.

- Inaccurate Hole Location: This might stem from improper workpiece positioning, incorrect drill head alignment, or a worn machine. Re-check the setup, potentially using a dial indicator for precise alignment, and verify machine calibration.

- Excessive Vibration: This suggests issues like worn bearings, unbalanced drill bit, or an improperly clamped workpiece. Inspect the machine for loose or damaged parts, ensure the drill bit is properly balanced, and re-secure the workpiece.

- Overheating: Overheating indicates issues like incorrect speed selection, inadequate lubrication, or a dull drill bit. Adjust the speed, ensure proper lubrication, and replace the bit as needed.

- Chattering (vibrating cut): This might be caused by a dull drill bit, improper clamping of the workpiece, or feed rates that are too high. Replace the bit, check the workpiece security, and reduce the feed rate.

A methodical approach, carefully checking each potential cause, is essential for effective troubleshooting. Referencing the machine’s manual can be invaluable in isolating problems.

Q 8. What are the different types of drilling operations performed on a radial drilling machine?

Radial drilling machines are incredibly versatile, allowing for a range of drilling operations. These aren’t limited to just creating simple holes; the precise control offered allows for complex tasks.

- Drilling: This is the most fundamental operation – creating holes of various diameters and depths.

- Reaming: Enlarging existing holes to precise dimensions for a smoother finish or better fit. Think of it like gently smoothing out a rough-hewn hole.

- Boring: Similar to reaming, but typically used for creating larger, more precise holes, often with specialized tools.

- Counterboring: Creating a larger diameter hole at the end of an existing hole, commonly used for recessing screw heads.

- Countersinking: Creating a cone-shaped recess at the end of a hole, often to accommodate countersunk screws.

- Tapping: Cutting internal threads in a hole to accommodate bolts or screws. This requires a special tap drill bit.

For instance, in manufacturing a large metal component, we might use a radial drill to first drill pilot holes, then ream them to a precise size, and finally tap threads for fastening.

Q 9. Explain the importance of regular maintenance of a radial drilling machine.

Regular maintenance is crucial for the safe and efficient operation of a radial drilling machine. Neglecting maintenance can lead to inaccurate drilling, damage to the machine, increased downtime, and even workplace accidents. Imagine trying to drive a car without regular oil changes – eventually, it would break down.

Proper maintenance ensures:

- Accuracy: A well-maintained machine drills more accurately and consistently.

- Longevity: Regular servicing extends the machine’s lifespan, saving you significant costs in the long run.

- Safety: Proper lubrication and inspection prevent unexpected failures that could cause injuries.

- Productivity: Minimizing downtime due to breakdowns means more efficient production.

Q 10. What are the common maintenance tasks performed on a radial drilling machine?

Common maintenance tasks include:

- Regular Lubrication: Applying lubrication to all moving parts as per the manufacturer’s recommendations. This reduces friction and wear.

- Inspection of Belts and Pulleys: Checking for wear, fraying, or misalignment. Worn belts can slip and cause inaccurate drilling.

- Cleaning: Removing chips and debris from the machine bed, table, and other components. Accumulated debris can interfere with smooth operation and even damage parts.

- Checking for Loose Fasteners: Ensuring all bolts and nuts are tight to prevent vibrations and movement during operation.

- Spindle and Arm Inspection: Checking for any play or looseness in the spindle and arm assembly. Play can lead to inaccurate drilling.

- Coolant System Check: Inspecting coolant levels, filter conditions, and ensuring proper flow. Coolant is essential for preventing overheating and extending drill bit life.

- Electrical System Inspection: Checking for any damage to wiring or electrical components. Electrical issues can be dangerous and lead to machine failure.

A scheduled maintenance program, often documented and tracked, is vital for ensuring the machine is always in optimal condition.

Q 11. How do you interpret engineering drawings for radial drilling operations?

Interpreting engineering drawings is fundamental to successful radial drilling. These drawings provide all the necessary information for accurate hole placement, dimensions, and tolerances.

I typically follow these steps:

- Identify the relevant views: The drawing will usually show multiple views (top, front, side) to clearly illustrate hole locations and dimensions.

- Locate the hole specifications: The drawing will indicate the diameter, depth, and position of each hole using various notations, such as diameter symbols (Ø) and coordinate systems.

- Understand tolerances: The drawing will specify tolerances indicating the acceptable range of deviation from the ideal dimensions. This is crucial for ensuring the drilled holes meet the required specifications.

- Determine the drilling sequence: For complex parts with multiple holes, the drawing might indicate a preferred drilling sequence to prevent damage or interference.

- Check for any special instructions or notes: Pay close attention to any additional notes or specifications regarding surface finish, hole type (counterbored, countersunk etc.), or special tooling requirements.

Imagine working on a large aircraft component. The engineering drawings are your roadmap for accurately drilling the numerous precisely placed holes required for proper functionality. A misinterpretation could have significant consequences.

Q 12. How do you calculate the feed rate and speed for drilling operations?

Calculating the correct feed rate and speed is vital for efficient and accurate drilling. Incorrect settings can lead to broken drill bits, damaged workpieces, or poor surface finishes. Think of it like choosing the right gear for climbing a hill in a car – too slow and it’s inefficient, too fast and you might stall.

The calculation depends on several factors:

- Material being drilled: Harder materials require slower speeds and feeds.

- Drill bit diameter: Larger bits generally require slower speeds and heavier feeds.

- Drill bit material: Different drill bit materials (high-speed steel, carbide) have different optimal cutting speeds.

While specific formulas exist (often found in machining handbooks and the machine’s manual), many modern radial drills have automated feed and speed control based on the selected drill bit and material settings. However, understanding the principles allows for manual adjustment and troubleshooting. For example, if the drill bit is overheating, the feed rate needs to be reduced.

Q 13. Describe the process of changing drill bits on a radial drilling machine.

Changing drill bits on a radial drilling machine involves several steps to ensure safety and accuracy.

- Secure the machine: Ensure the machine is switched off and locked out to prevent accidental movement.

- Release the chuck: Loosen the chuck jaws using the appropriate wrench. This process is crucial and must be done cautiously.

- Remove the old drill bit: Carefully remove the old bit, making sure to avoid injury from sharp edges. Dispose of it properly.

- Insert the new drill bit: Insert the new drill bit into the chuck, ensuring it is aligned correctly and firmly seated.

- Tighten the chuck: Tighten the chuck jaws securely using the wrench, applying sufficient pressure to prevent slippage during operation. Again, caution is essential here to avoid damaging the bit or chuck.

- Test the bit: Before commencing drilling, perform a test run at a low speed to ensure the bit is securely held and spinning correctly. This prevents accidental damage in the process.

Remember, always follow the manufacturer’s instructions and safety guidelines when working with a radial drilling machine and changing drill bits. This process becomes almost second nature with experience, but safety must always be the priority.

Q 14. What are the different types of coolants used in radial drilling operations?

Coolants are essential in radial drilling to dissipate heat generated during the cutting process, preventing damage to the drill bit and the workpiece. The choice of coolant depends on the material being drilled and the specific application.

- Water-based coolants: These are commonly used and relatively inexpensive. They provide good cooling and lubrication.

- Oil-based coolants: These offer better lubrication and are often used for drilling tougher materials. However, they can be more expensive and present disposal challenges.

- Synthetic coolants: These are designed for specific applications and often provide superior performance in terms of cooling, lubrication, and corrosion prevention. They are generally more expensive.

- Air coolants: While not a liquid, compressed air can be used for cooling in some applications, although it generally provides less effective cooling than liquid coolants.

The selection of coolant is critical to the longevity of the drill bit and the quality of the drilled hole. For instance, drilling aluminum might require a water-soluble coolant, while steel might benefit from an oil-based coolant with extreme pressure additives. The wrong choice can lead to broken drill bits, poor surface finishes, and even unsafe working conditions due to excessive heat.

Q 15. Explain the importance of using the correct coolant for a specific material.

Selecting the right coolant is crucial for efficient and safe radial drilling. Coolant’s role goes beyond simple cooling; it influences the machining process significantly. The choice depends heavily on the material being drilled. For instance, using a coolant inappropriate for aluminum can lead to built-up edge formation on the drill bit, resulting in poor surface finish and potentially damaging the workpiece. Conversely, a coolant designed for steel might be too aggressive for a softer material like brass, causing excessive material removal and a rough surface.

Different materials have varying thermal properties and chemical reactivities. A suitable coolant must effectively manage heat generation during drilling, preventing workpiece distortion and drill bit damage. It also helps in lubricating the cutting zone, reducing friction and wear. For example, water-soluble coolants are generally suitable for ferrous metals, offering good cooling and lubrication. However, for aluminum, a coolant with lower lubricity and higher cooling capacity might be preferred to avoid smearing.

- Steel: Water-based coolants with added lubricants are effective.

- Aluminum: Synthetic coolants with high cooling capacity are often used.

- Cast Iron: Similar to steel, but potentially requiring a coolant with better chip evacuation properties due to the brittle nature of cast iron.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle different types of materials during drilling operations?

Handling diverse materials during drilling requires adapting the machine settings and selecting appropriate tooling and coolants. Each material presents unique challenges. For instance, drilling brittle materials like cast iron requires lower speeds and feeds to prevent chipping or cracking. Tougher materials like hardened steel demand robust drill bits with appropriate coatings to withstand high cutting forces. Softer materials like aluminum can be more prone to work hardening, requiring sharper bits and potentially different drilling techniques to minimize this effect.

The process also necessitates careful consideration of clamping techniques. Soft materials may require gentler clamping to avoid deformation. In contrast, materials with a tendency to vibrate during drilling need secure clamping to maintain accuracy and prevent damage to the workpiece and the machine. For example, a vise might be suitable for small, regular shaped workpieces, whereas a fixture might be necessary for larger and more complex shapes to ensure proper alignment and support during the drilling process.

Q 17. What are the common problems associated with improper coolant usage?

Improper coolant usage can result in several issues, impacting both the quality of the work and the longevity of the equipment. The most common problems include:

- Excessive heat build-up: Leading to workpiece distortion, tool wear, and potential fire hazards.

- Poor surface finish: Due to inadequate lubrication, causing friction and smearing.

- Tool breakage: Excessive heat and friction can lead to premature failure of the drill bit.

- Rust and corrosion: If an unsuitable coolant is used, corrosion can damage the workpiece and machine components. For instance, not using a rust preventative in a humid environment could corrode the workpiece during processing and after.

- Built-up edge formation: Especially problematic when drilling aluminum, leading to poor surface finish and inaccurate hole dimensions.

- Inefficient chip removal: An improper coolant might not effectively flush chips away, resulting in clogging and damage.

Q 18. How do you identify and rectify misalignment issues in a radial drilling machine?

Misalignment in a radial drilling machine is a serious issue, leading to inaccurate holes and potential damage to the machine and workpiece. Identifying misalignment requires careful inspection and testing. We can start by visually inspecting the drill head and workpiece for any obvious misalignments. Then, we can use a dial indicator to accurately measure the alignment of the drill bit with the workpiece. For the arm and spindle, we often rely on a combination of visual inspection and measurements using precision tools like machinist squares.

Rectification involves making adjustments to the machine’s components. This might involve tightening or loosening various clamping mechanisms or even requiring more complex adjustments to the machine’s geometry. Always refer to the machine’s manual for the proper adjustment procedures. Minor adjustments can be made directly on the machine. More substantial misalignments might require more extensive calibration or professional intervention.

Example: If the dial indicator shows an offset when the drill bit is rotating, the spindle might be misaligned and might require adjustment of the spindle gibs or the entire spindle assembly. Improper alignment of the arm can cause the drill bit to not align properly with the workpiece, necessitating checking and adjusting the arm’s mounting and pivot mechanisms.

Q 19. Describe the process of checking for and adjusting the alignment of the radial arm.

Radial arm alignment is critical for precise drilling. Checking and adjusting it involves several steps:

- Visual Inspection: Begin by visually inspecting the arm for any obvious signs of misalignment or damage. Look for any looseness or irregularities in the mounting.

- Leveling: Use a precision level to ensure the radial arm is perfectly level in both the horizontal and vertical planes. Adjust the leveling screws as needed.

- Alignment Check: Use a machinist’s square or a dial indicator to check the alignment of the radial arm with respect to the column. This involves checking for perpendicularity.

- Fine Adjustment: If minor misalignment is found, use the adjustment mechanisms on the arm’s mounting to correct the position. These mechanisms usually involve fine-tuning screws or clamps.

- Re-check: After making adjustments, repeat steps 3 and 4 until the alignment is accurate.

Important Note: Always refer to the machine’s manual for specific procedures and torque specifications for adjusting screws. Attempting adjustments without proper knowledge can damage the machine.

Q 20. What are the different types of jigs and fixtures used in radial drilling operations?

Various jigs and fixtures are employed in radial drilling to ensure accurate hole placement and efficient operation. These aids significantly improve repeatability and reduce operator skill dependence. Common types include:

- Drill Jigs: Simple jigs guide the drill bit, ensuring the hole is drilled in the correct location. They typically have bushings to guide the drill bit. These are often used for simple repetitive drilling tasks.

- Drill Bushings: These are simple, cylindrical inserts that guide the drill bit. They’re often incorporated into jigs or directly mounted to the workpiece.

- Clamping Fixtures: These secure the workpiece firmly in place during drilling. They provide stability and prevent movement during operation. The design depends on the workpiece’s shape and material.

- Angle Plates: Used to hold the workpiece at specific angles during drilling, allowing for angled holes.

- V-blocks and Parallel Blocks: These are simple support fixtures that help to accurately position cylindrical or rectangular workpieces.

Q 21. How do you select the appropriate jig or fixture for a specific operation?

Selecting the appropriate jig or fixture involves considering various factors related to the specific drilling operation:

- Workpiece Geometry: The shape and size of the workpiece dictate the type of fixture needed to securely hold it during drilling. Complex shapes often necessitate custom-designed fixtures.

- Number and Location of Holes: The number of holes and their positions determine the complexity of the jig or fixture. Simple jigs are suitable for fewer holes in predictable locations.

- Hole Tolerance: Tight tolerance requirements necessitate more precise jigs and fixtures to guarantee accurate hole location. A simple jig might suffice for less demanding applications.

- Material Properties: The material’s hardness and brittleness influence the clamping pressure and the design of the fixture. Brittle materials might require softer clamping to prevent damage.

- Production Volume: High-volume production justifies investment in more elaborate, reusable fixtures that improve efficiency. For low-volume applications, simpler, less expensive jigs might be sufficient.

Example: For drilling multiple identical holes in a flat plate, a simple drill jig with bushings would be ideal. However, for drilling angled holes in a complex component, a custom-designed fixture with multiple clamping points might be necessary.

Q 22. Explain the process of setting up and using a jig or fixture.

Setting up and using a jig or fixture in radial drilling is crucial for ensuring accuracy and repeatability. A jig is a device that guides the drill bit, while a fixture holds the workpiece securely in place. Think of it like this: the jig is the ‘directions’ for the drill, and the fixture is the ‘stable platform’ for the work.

Setup Process:

- Select the appropriate jig or fixture: This depends on the workpiece’s geometry and the drilling requirements. For instance, a simple drilling operation on a flat plate might only need a simple clamp, whereas a complex part may require a custom-designed jig with multiple bushings.

- Secure the fixture to the radial arm’s table: Ensure a solid and stable base using appropriate bolts and clamps. Vibrations can cause inaccuracies, so a firm attachment is vital.

- Position the workpiece within the fixture: Accurately place the workpiece according to the jig’s design, referencing any alignment pins or locating surfaces. Double-check this step – any error here will propagate through the entire process.

- Align the drill bit with the jig’s bushing: Carefully align the drill bit with the correct bushing in the jig. This ensures that the hole is drilled in the precise location and angle.

- Lock the radial arm and drill head: Secure the radial arm and drill head in the desired position before starting the drilling operation. This prevents accidental movement and ensures accurate drilling.

Example: In one project, we used a custom-designed jig with multiple drill bushings to create precisely spaced holes in a large aluminum plate used for a specialized machine. The jig ensured consistent hole placement, significantly improving the final product’s quality and saving time.

Q 23. How do you ensure the safety of jigs and fixtures during operation?

Safety is paramount when using jigs and fixtures. Here’s how we ensure their safe operation:

- Regular Inspection: We perform regular inspections for wear and tear, cracks, or any damage that could compromise the fixture’s integrity. A damaged fixture can lead to accidents.

- Secure Mounting: Always ensure the fixture is securely mounted to the machine table. Loose fixtures can shift during drilling, potentially causing damage or injury.

- Proper Clamping: Use appropriate clamping mechanisms and ensure the workpiece is firmly clamped in place to prevent movement during the drilling operation. Insufficient clamping can lead to workpiece slippage, a major safety hazard.

- Sharp Tools: Using dull tools requires more force, increasing the risk of the workpiece moving unexpectedly. Always maintain sharp drill bits.

- Safety Guards: Employ appropriate safety guards, especially if the operation creates chips or debris. These guards protect operators from flying debris.

- Lockout/Tagout: Before any maintenance or adjustment, we always implement lockout/tagout procedures to prevent accidental start-up.

Example: In one instance, a minor crack was detected during a routine inspection of a fixture. This prevented a potential catastrophic failure during operation, avoiding a serious workplace accident.

Q 24. Describe the importance of work holding devices in radial drilling.

Work-holding devices are absolutely essential in radial drilling. They ensure the workpiece is securely held in place, preventing movement during the drilling process. This is crucial for several reasons:

- Accuracy: Without proper work holding, the workpiece might shift, resulting in inaccurate hole placement. This is especially critical for precise applications like machining molds or aircraft components.

- Safety: A moving workpiece during drilling is a significant safety hazard, potentially causing injury to the operator or damage to the machine.

- Efficiency: Secure work holding allows for faster and more efficient drilling, as the operator doesn’t need to constantly adjust the workpiece.

- Repeatability: Proper work-holding allows for consistent and repeatable drilling operations, vital for mass production environments.

Example: In high-volume manufacturing, the use of specialized vises and fixtures allows for precise and consistent drilling of hundreds of identical parts, without the need for constant operator intervention. Without these devices, the production process would be significantly slower and prone to errors.

Q 25. How do you ensure the accurate positioning of workpieces during drilling operations?

Accurate positioning of workpieces is achieved through a combination of techniques:

- Measuring Tools: Precise measurements using calipers, micrometers, and dial indicators are used to ensure accurate workpiece placement relative to the drill bit.

- Jigs and Fixtures: As discussed, jigs and fixtures provide pre-determined locations for drilling, eliminating reliance on manual measurement for each hole.

- Alignment Pins and Bushings: These features on jigs and fixtures help to guide and align the workpiece, ensuring repeatable accuracy.

- Machine Alignment: The radial drilling machine itself needs to be properly aligned and calibrated to ensure accurate drilling. This includes checking the alignment of the drill spindle and the table.

- Visual Inspection: Always visually inspect the workpiece’s position before starting the drilling operation. A final check is crucial to avoid costly mistakes.

Example: When drilling a series of holes in a complex part, using a custom jig with precision alignment pins allows for repeated drilling to within tolerances of 0.001 inches, critical for many engineering applications.

Q 26. What are the different types of clamping mechanisms used in radial drilling?

Various clamping mechanisms are used in radial drilling, each suited to specific needs:

- Vise Clamps: These are versatile and widely used for holding workpieces of various sizes and shapes. They provide strong clamping force and are simple to operate.

- Magnetic Chucks: Ideal for ferrous materials, these provide a quick and secure way to hold workpieces. They’re particularly useful for thin or delicate parts.

- Clamp Blocks and Straps: These offer flexibility in clamping odd-shaped workpieces, particularly useful for larger and irregularly shaped parts that don’t fit neatly into a vise.

- Hydraulic Clamps: These provide high clamping forces and are often used for heavier workpieces that require strong holding power.

- Pneumatic Clamps: These use compressed air to provide clamping force, enabling quick clamping and release cycles.

Example: For a large and oddly shaped casting, we used a combination of clamp blocks and straps to secure the workpiece during drilling, ensuring stability and preventing any movement during the operation. The flexibility of this method is crucial for handling diverse parts.

Q 27. How do you handle emergency situations during radial drilling operations?

Emergency situations require immediate and decisive action. Our procedures emphasize safety first:

- Stop the machine immediately: This is the priority. Use the emergency stop button without delay.

- Assess the situation: Determine the nature of the emergency. Is it a machine malfunction, a workpiece-related issue, or an injury?

- Secure the area: If necessary, evacuate the immediate area to prevent further accidents.

- First aid: If an injury has occurred, administer first aid and contact emergency medical services immediately.

- Report the incident: Thoroughly document the incident, including its cause, actions taken, and any injuries or damages.

- Repair or maintenance: After securing the area, initiate repair or maintenance of the machine as needed. Only qualified personnel should perform this task.

Example: During one operation, a drill bit broke, sending debris flying. We immediately stopped the machine, secured the area, collected the debris, and then thoroughly inspected the machine for further damage before resuming work.

Q 28. Describe your experience with troubleshooting and repairing radial drilling machines.

Troubleshooting and repairing radial drilling machines requires a good understanding of mechanical systems. My experience encompasses:

- Identifying Malfunctions: I’m adept at diagnosing problems through systematic checks, including inspecting belts, checking electrical connections, and listening for unusual sounds.

- Component Replacement: I’ve replaced various components like drill chucks, feed mechanisms, and electrical components. This requires knowledge of machine specifications and proper safety procedures.

- Lubrication and Maintenance: Regular lubrication and preventive maintenance are crucial. I’m experienced in performing these tasks to extend the machine’s lifespan and prevent breakdowns.

- Calibration and Alignment: I have experience calibrating and aligning the machine’s components to ensure accurate drilling. This often involves precision measurements and adjustments.

- Hydraulic and Pneumatic Systems: I’m familiar with the hydraulic and pneumatic systems of these machines and can troubleshoot issues related to these systems.

Example: I once diagnosed a recurring problem of inaccurate drilling by carefully inspecting the machine’s alignment. A slight misalignment of the drill spindle was identified and corrected, restoring the machine’s accuracy and eliminating the need for costly rework.

Key Topics to Learn for Radial Drilling Machine Operation Interview

- Machine Setup and Operation: Understanding the various components, their functions, and the correct procedures for setting up the machine for different drilling tasks. This includes spindle speed selection, feed rate adjustments, and proper tool clamping.

- Safety Procedures and Regulations: Thorough knowledge of all safety protocols associated with operating a radial drilling machine, including lockout/tagout procedures, personal protective equipment (PPE) requirements, and emergency shutdown procedures. Practical application involves demonstrating a commitment to safe work practices.

- Drilling Techniques and Applications: Mastering various drilling techniques, such as spot facing, countersinking, and reaming. Understanding the applications of these techniques in different manufacturing processes and materials is crucial.

- Tool Selection and Maintenance: Knowing how to select the appropriate drill bits, tooling, and cutting fluids for different materials and drilling operations. Understanding preventative maintenance procedures to ensure optimal machine performance and longevity.

- Troubleshooting and Problem-Solving: Developing the ability to diagnose and resolve common issues encountered during operation, such as tool breakage, inaccurate drilling, or machine malfunctions. This includes understanding the cause-and-effect relationships in the machining process.

- Blueprint Reading and Interpretation: Ability to accurately interpret engineering drawings and specifications to determine the required drilling parameters and tolerances.

- Measurement and Quality Control: Utilizing various measuring instruments to ensure the accuracy and precision of drilled holes, adhering to specified tolerances and quality standards.

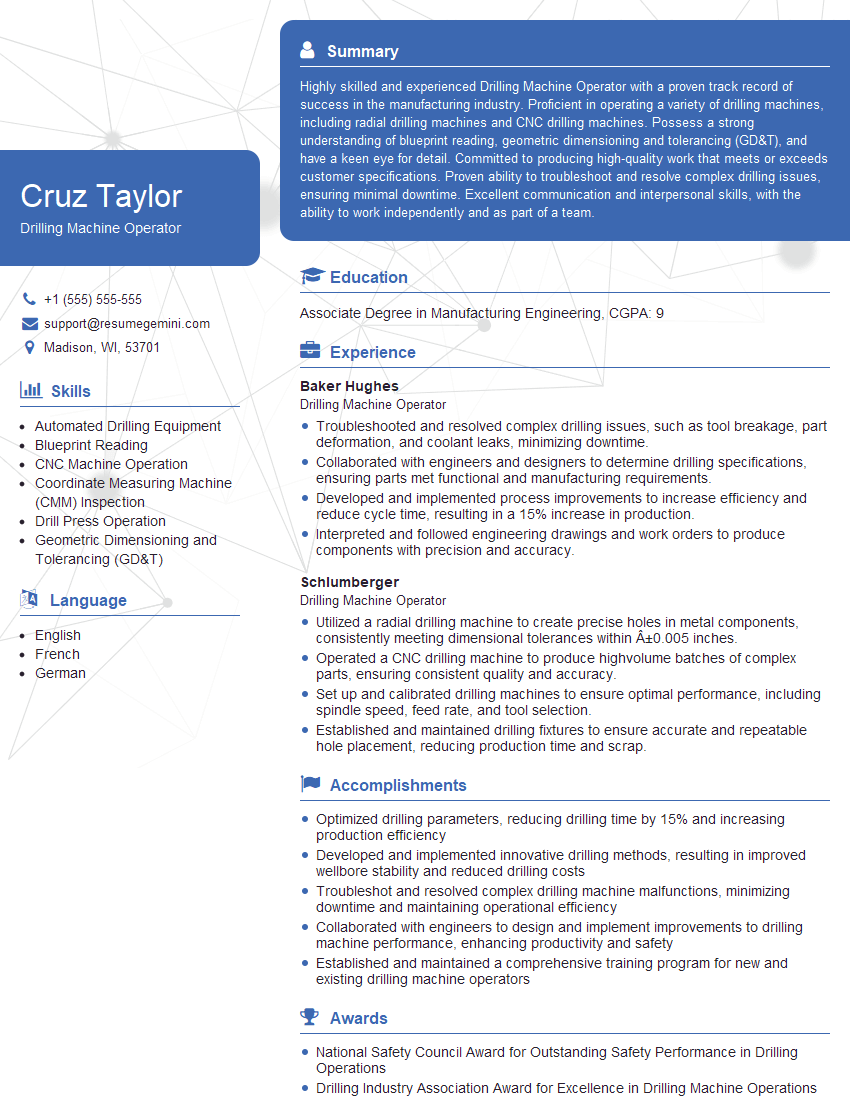

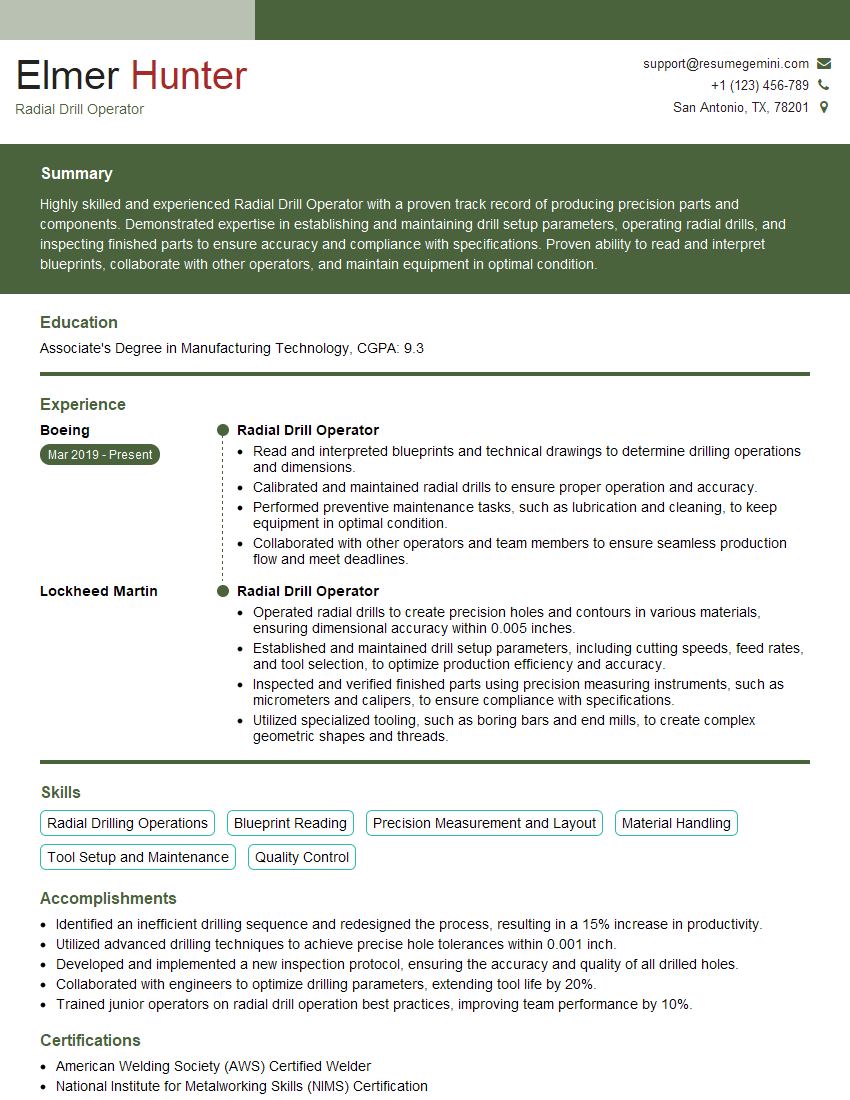

Next Steps

Mastering Radial Drilling Machine Operation opens doors to exciting career opportunities in manufacturing and engineering, offering excellent potential for growth and advancement. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your skills and experience effectively. Examples of resumes tailored to Radial Drilling Machine Operation are available to help guide your resume creation. Investing time in crafting a compelling resume will significantly increase your chances of landing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO