Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Generator and Alternator Repair interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Generator and Alternator Repair Interview

Q 1. Explain the difference between a generator and an alternator.

While both generators and alternators produce alternating current (AC) electricity, the key difference lies in their method of excitation. Generators typically use a permanent magnet or separately excited DC field to induce current in the stator windings. Alternators, on the other hand, use rotor windings excited by a DC current to generate a rotating magnetic field, inducing AC in the stator. Think of it like this: a generator is like a hand crank powering a lightbulb – simpler, often used for smaller applications. An alternator is like a car’s charging system – more complex, capable of higher power output, and self-exciting in many cases.

In simpler terms: Generators are often simpler, smaller, and use external excitation, while alternators are commonly larger, more efficient, and self-exciting, meaning they use part of their own output to power their field windings.

Q 2. Describe the function of a voltage regulator in an alternator.

The voltage regulator is crucial in maintaining a consistent output voltage from the alternator. It controls the excitation current flowing to the rotor windings. If the voltage rises too high, the regulator reduces the excitation current. Conversely, if the voltage drops, it increases the current. This ensures that the battery is charged correctly without overcharging or undercharging. Imagine it like a thermostat for the alternator; it keeps the electrical output at the optimal level.

A faulty voltage regulator can lead to a variety of problems, including overcharging (damaging the battery), undercharging (leaving the battery weak), and even alternator damage due to excessive current or voltage. Modern alternators often use sophisticated electronic regulators for precise control.

Q 3. How do you diagnose a faulty alternator?

Diagnosing a faulty alternator involves a multi-step approach. Firstly, check the battery voltage – a consistently low voltage even after engine running suggests a problem. Then, measure the alternator’s output voltage using a multimeter while the engine is running. A voltage significantly lower or higher than the vehicle’s specification indicates a fault. Another critical test involves checking the alternator’s output current with the engine running; a significantly low current points towards issues. Furthermore, visually inspect the alternator for any physical damage, loose connections, or belt issues. Finally, more advanced diagnostic tools can be used to evaluate the regulator, diodes, and stator windings for precise identification.

For instance, if you’re getting a low battery charge, and your multimeter shows a consistently low alternator output voltage under load, the problem points towards a faulty alternator, possibly due to issues within the rotor, stator, or diodes.

Q 4. What are the common causes of generator failure?

Generator failures are often caused by several factors. Worn-out bearings are a common culprit, leading to increased friction and eventual failure. Damaged stator windings, resulting from overheating or short circuits, are another frequent cause. Problems with the excitation system (in separately excited generators) can also lead to failure. Furthermore, environmental factors like moisture ingress leading to insulation breakdown or excessive vibration causing component stress can contribute significantly. Finally, ignoring regular maintenance schedules like lubrication of bearings will accelerate the degradation process.

A good example: I once had a generator fail due to a bearing seizing. The generator overheated, causing damage to the stator windings, resulting in a complete failure. Regular inspections could have detected the bearing wear earlier, avoiding expensive repairs.

Q 5. Explain the principle of operation of a three-phase alternator.

A three-phase alternator generates three separate AC voltages, each 120 degrees out of phase with each other. This is achieved using three sets of stator windings, physically spaced 120 degrees apart around the rotor. As the rotor (with its DC excited field windings) rotates, it induces AC voltage in each of these stator windings. The resulting three voltages are used to power three-phase motors or can be converted to single-phase power for common household use. This configuration provides higher power output, smoother operation, and improved efficiency compared to single-phase alternators.

Imagine three separate generators working together, slightly offset in time, creating a smoother and more powerful supply. That’s the basic principle of a three-phase system.

Q 6. How do you test the stator windings of a generator?

Testing stator windings involves using a multimeter to check for continuity, insulation resistance, and short circuits. First, disconnect the stator windings from the rest of the generator. Then, measure the resistance between each pair of winding leads. A low resistance indicates continuity; a high resistance or an open circuit suggests a broken winding. Next, measure the insulation resistance between each winding and the generator’s frame. A low insulation resistance indicates a short circuit. Finally, perform a winding-to-winding insulation resistance test using a megger. This will provide a more accurate measure of the insulation’s condition. Any significant deviation from the manufacturer’s specifications indicates a fault requiring repair or replacement.

Remember, safety is crucial: Always disconnect the generator from the power source before performing any tests.

Q 7. How do you test the rotor windings of an alternator?

Testing rotor windings in an alternator is similar to testing stator windings but requires careful attention due to the rotating nature of the component. First, the rotor needs to be removed from the alternator and isolated. Then, measure the resistance between each winding lead using a multimeter. As with the stator, low resistance indicates good continuity; high resistance or open circuit signifies a problem. Next, measure the insulation resistance between each winding and the rotor shaft, as well as between windings. A low reading in either case indicates a short circuit to ground or between windings. A megger test can also be applied for a more comprehensive assessment of the insulation condition.

It’s essential to remember that working with a rotor involves dealing with a rotating part with potentially high voltages. Take all necessary precautions before testing.

Q 8. Describe the process of troubleshooting a generator that won’t start.

Troubleshooting a generator that won’t start is a systematic process of elimination. Think of it like diagnosing a car that won’t start – you need to check the basics first before moving to more complex issues.

- Fuel System: Begin by ensuring there’s sufficient fuel and that the fuel is reaching the engine. Check the fuel tank level, fuel lines for blockages, and fuel filter for contamination. A clogged filter is a common culprit.

- Battery and Starting System: Test the battery voltage using a multimeter. A low voltage indicates a weak or dead battery. Check the battery connections for corrosion or looseness. If the battery is good, inspect the starter motor for proper engagement and listen for any unusual sounds.

- Engine Controls: Make sure the engine’s control system is properly engaged. This includes checking switches, relays, and the ignition system for proper functionality. A faulty governor, for example, might prevent the engine from starting.

- Prime Mover Issues: If the engine is not turning over, the problem might lie within the prime mover itself (diesel, gas, etc.). This could involve issues with the spark plugs (gas engines), glow plugs (diesel engines), or even compression issues requiring a compression test.

- Other Factors: Don’t overlook simple things like a tripped circuit breaker or a faulty switch.

Remember to always consult the generator’s specific operation and maintenance manual for detailed troubleshooting steps.

Q 9. What safety precautions should be taken when working on generators and alternators?

Safety is paramount when working with generators and alternators, as these machines handle high voltages and currents. Always follow these precautions:

- Lockout/Tagout (LOTO): Before any work begins, always use a lockout/tagout procedure to isolate the power source, preventing accidental energization. This is crucial to prevent electrical shock.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, insulated gloves, and sturdy work boots. A hard hat is also recommended, especially in industrial environments.

- Proper Grounding: Ensure the generator is properly grounded to prevent electrical shock and surges. A grounding rod is usually required, and connections must be clean and secure.

- Ventilation: Generators produce carbon monoxide, a deadly gas. Work in a well-ventilated area, away from enclosed spaces or confined areas.

- Fire Safety: Be aware of potential fire hazards, especially around fuel sources. Keep a fire extinguisher readily available.

- Trained Personnel: Only qualified and trained personnel should work on generators and alternators. Improper handling can lead to serious injury or death.

Always consult the relevant safety regulations and guidelines for your specific location and industry.

Q 10. Explain the importance of proper grounding in generator systems.

Proper grounding in generator systems is essential for both safety and performance. Imagine it as a safety net for your electrical system.

- Safety: Grounding provides a path for fault currents to flow to earth, preventing dangerous voltage buildup on the generator’s metal casing. This significantly reduces the risk of electrical shock.

- Performance: Proper grounding helps to minimize electrical noise and interference, leading to more stable and reliable generator operation. It also protects sensitive electronic equipment connected to the generator.

- Surge Protection: A good ground helps to dissipate surges and transient voltages that can damage the generator and connected equipment. Lightning strikes, for instance, can cause significant damage if the system isn’t properly grounded.

Grounding typically involves connecting a low-resistance wire from the generator’s frame to a dedicated grounding rod or system. Regular inspection of grounding connections is crucial to ensure system integrity.

Q 11. How do you perform a load test on a generator?

A load test verifies the generator’s ability to deliver its rated power under various load conditions. It’s like a stress test for the generator.

The process typically involves:

- Safe Setup: Ensure proper grounding and ventilation, and have appropriate safety equipment.

- Load Bank Connection: A resistive load bank, a device that simulates the load the generator will supply, is connected to the generator’s output terminals. The size of the load bank should match the generator’s capacity.

- Load Application: Gradually increase the load on the load bank to simulate real-world operating conditions. The generator’s voltage, current, frequency, and power factor should be monitored during the test.

- Monitoring and Data Recording: Use a multimeter or a dedicated generator testing device to monitor the generator’s performance parameters under load. Record these parameters at different load levels.

- Analysis: Compare the recorded data with the generator’s nameplate specifications. Any significant deviations could indicate problems like insufficient output power, voltage regulation issues, or overheating.

Load tests must be performed by skilled technicians to ensure safety and obtain accurate results. Never exceed the generator’s rated load capacity.

Q 12. What are the different types of generator prime movers?

The prime mover is the engine that drives the generator’s alternator. Different types exist depending on the application’s needs and fuel availability.

- Internal Combustion Engines (ICE): These are the most common type, including gasoline engines, diesel engines, and natural gas engines. Diesel engines are preferred for larger generators due to their higher efficiency and torque.

- Gas Turbines: These are used in larger power generation applications where high power output and fast response times are needed, such as in emergency power systems.

- Steam Turbines: These are typically found in larger power plants using steam generated from various sources, such as fossil fuels, nuclear reactors, or geothermal energy.

- Water Turbines: These are used in hydroelectric power plants, harnessing the power of moving water to drive the generator.

The choice of prime mover depends on factors like required power output, fuel cost, environmental considerations, and maintenance requirements.

Q 13. Explain the concept of power factor and its importance in generator systems.

Power factor represents the efficiency of electrical power usage. Imagine it as how effectively you utilize the energy supplied by the generator.

It’s the ratio of real power (used for actual work) to apparent power (total power supplied). A power factor of 1 indicates perfect efficiency, while a lower power factor (e.g., 0.8) means a portion of the supplied power is not utilized effectively, leading to wasted energy and increased operating costs.

In generator systems, a low power factor can result in:

- Overloading: The generator appears to be overloaded even if the real power demand is within its capacity. This is because the apparent power is higher than the real power.

- Increased Current: Higher currents flow through the generator windings and wiring, increasing the risk of overheating and equipment damage.

- Higher Fuel Consumption: The generator needs to produce more apparent power to deliver the required real power, resulting in increased fuel consumption.

Power factor correction methods are often employed to improve efficiency, which usually involves adding capacitive components to the system.

Q 14. How do you diagnose a short circuit in a generator winding?

Diagnosing a short circuit in a generator winding requires careful and systematic testing. It’s like finding a hidden electrical fault.

Methods include:

- Insulation Resistance Test (Megger Test): A megger test measures the insulation resistance between the windings and ground, and between different windings. A low resistance indicates a short circuit.

- High-Pot Test: This test applies a high voltage to the windings to check for insulation breakdown. A noticeable spark or current flow might indicate a short circuit.

- Phase-to-Phase and Phase-to-Ground Continuity Test: Using a multimeter set to continuity mode, check for unintended connections between different phases or between a phase and the ground. A continuous beep suggests a short circuit.

- Visual Inspection: Carefully examine the windings for any visible damage like burn marks or loose connections. This can often help pinpoint the location of the short circuit.

Once the location of the short circuit is identified, repair or replacement of the affected winding might be necessary. This work requires specialized knowledge and tools and should only be done by experienced technicians.

Q 15. What are the common types of alternator rectifiers?

Alternator rectifiers convert the AC output of the alternator into DC power for the vehicle’s electrical system. The most common type is the three-phase bridge rectifier, a configuration using six diodes arranged in a bridge circuit. Each diode allows current flow in only one direction, effectively converting the three-phase AC waveform into a pulsating DC waveform. Another, less common type, is a single-phase rectifier, which uses fewer diodes and is simpler but less efficient. In some older designs, you might find selenium rectifiers, but these are largely obsolete due to their lower efficiency and shorter lifespan compared to diode-based rectifiers.

Think of it like this: imagine a water pump (alternator) producing water that flows back and forth (AC). The rectifier is like a one-way valve system that only allows the water to flow in one direction (DC), delivering a steady stream to your car’s battery.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you interpret alternator output waveforms?

Interpreting alternator output waveforms involves using an oscilloscope to analyze the voltage and current signals. A healthy alternator should produce a relatively smooth, pulsating DC waveform with minimal ripple. The amplitude should be consistent and stable at the alternator’s rated voltage. Significant deviations indicate problems.

- High ripple: Suggests rectifier issues, such as faulty diodes or insufficient filtering.

- Low output voltage: Could be due to worn brushes, stator winding problems, or a faulty voltage regulator.

- Intermittent output: Points to issues with the rotor, stator, or wiring connections. A complete loss of output indicates a major fault.

- Distorted waveform: Usually points to a problem within the stator windings, possibly a short or an open circuit.

By comparing the observed waveform to the expected waveform for the alternator’s design, a skilled technician can pinpoint the specific component causing the issue. This requires a strong understanding of electrical theory and the alternator’s operating principles.

Q 17. Explain the different types of generator voltage regulators.

Generator voltage regulators maintain a stable output voltage despite varying loads and engine speeds. There are several types:

- Carbon Pile Regulators: Older technology using stacks of carbon discs to vary resistance and control voltage. They are simple but less precise and prone to wear.

- Transistorized Regulators: More modern regulators using transistors for precise voltage control. They offer better efficiency and accuracy than carbon pile regulators.

- Electronic Regulators (AVR – Automatic Voltage Regulators): These are the most advanced type, employing integrated circuits and feedback mechanisms for highly accurate and stable voltage regulation. They are common in modern generators and offer features like over-voltage and under-voltage protection.

The choice of regulator depends on the generator’s size, application, and required precision. For instance, a small portable generator might use a simpler transistorized regulator, while a large industrial generator would likely use a sophisticated AVR for maintaining a consistent voltage supply to critical equipment.

Q 18. How do you maintain a generator’s cooling system?

Maintaining a generator’s cooling system is crucial for preventing overheating and extending its lifespan. This involves regularly checking and cleaning the following:

- Radiator: Inspect for debris buildup, corrosion, and leaks. Clean the fins with compressed air or a brush to ensure proper airflow. A clogged radiator severely restricts cooling.

- Cooling Fan: Check the fan for proper operation and alignment. Ensure that it spins freely and doesn’t make unusual noises. A faulty fan can dramatically reduce cooling capacity.

- Coolant Level: Maintain the correct coolant level according to the manufacturer’s recommendations. Use the proper type of coolant for the generator’s engine.

- Coolant Condition: Periodically check the coolant for contamination or degradation. Replace the coolant at recommended intervals to prevent corrosion and maintain optimal heat transfer.

- Airflow: Ensure adequate airflow around the generator to prevent overheating. Keep the area around the generator free of obstructions.

Ignoring cooling system maintenance can lead to catastrophic engine damage, costly repairs, and potential safety hazards.

Q 19. Describe the process of replacing brushes in an alternator.

Replacing alternator brushes is a relatively straightforward procedure but requires care and attention to detail. Here’s a step-by-step guide:

- Disconnect the battery: This is essential for safety to prevent electrical shocks.

- Remove the alternator: This may vary depending on the vehicle and alternator design. Consult a repair manual for specific instructions.

- Remove the brush holder assembly: Usually, this involves removing screws or clips securing the assembly.

- Inspect the commutator: Check for excessive wear, grooves, or damage. If necessary, carefully clean the commutator using fine sandpaper.

- Install the new brushes: Ensure the brushes are properly seated in their holders and make good contact with the commutator.

- Reassemble the alternator: Follow the disassembly steps in reverse order.

- Test the alternator: After reinstallation, test the alternator’s output using a multimeter to verify its proper functioning.

It’s important to use brushes of the correct specification for the alternator. Using incorrect brushes can damage the commutator and lead to premature alternator failure. Always consult a repair manual for specific instructions for your model of alternator.

Q 20. What are the common causes of overheating in a generator?

Overheating in a generator can stem from several causes:

- Cooling System Problems: A clogged radiator, faulty cooling fan, low coolant level, or contaminated coolant can all restrict heat dissipation, leading to overheating.

- Excessive Load: Demanding too much power from the generator exceeds its capacity, causing it to overheat.

- Worn Bearings: Worn bearings generate increased friction, producing excessive heat.

- Electrical Problems: Short circuits or high resistance in the wiring or windings can cause significant heat generation.

- Lack of Ventilation: Inadequate airflow around the generator prevents heat dissipation.

- Blocked Air Intake: Debris or obstructions blocking the air intake can restrict airflow to the engine.

Regular maintenance, including checking coolant levels, cleaning the radiator, and inspecting the cooling fan, is crucial to prevent overheating and ensure safe operation.

Q 21. How do you diagnose a faulty AVR (Automatic Voltage Regulator)?

Diagnosing a faulty AVR (Automatic Voltage Regulator) requires a systematic approach:

- Check the Generator’s Output Voltage: Use a multimeter to measure the generator’s output voltage under different loads. An unstable or incorrect voltage strongly suggests an AVR problem.

- Inspect the AVR for Physical Damage: Examine the AVR for any signs of damage, such as burn marks, loose connections, or physical damage.

- Test the AVR’s Input and Output Signals: Use an oscilloscope to analyze the AVR’s input (from the generator) and output (to the generator’s field windings) signals. Deviations from the expected waveforms indicate a problem.

- Check for Loose Connections: Loose connections within the AVR or its wiring can cause malfunctions.

- Load Testing: Perform a load test to check the voltage stability under different loads. A large voltage drop under load points to a faulty AVR.

- Compare Measurements to Specifications: Compare measured values to the AVR’s specifications to identify any anomalies.

If the AVR is suspected to be faulty, it’s usually best to replace it with a new unit rather than attempting repairs, as internal components can be difficult to diagnose and replace.

Q 22. Explain the function of a generator’s circuit breaker.

A generator’s circuit breaker is essentially a safety switch that protects the generator and the connected electrical system from damage caused by overcurrents, short circuits, or ground faults. Think of it as a sophisticated fuse, but much faster and more precise. When a fault occurs, causing excessive current flow, the circuit breaker instantly interrupts the current, preventing damage to the generator windings, wiring, and connected equipment. This prevents fires, equipment failure, and potential injury.

For example, imagine a short circuit in a building powered by a generator. The massive surge in current would melt wires and potentially start a fire. The circuit breaker detects this surge and quickly disconnects the generator from the load, preventing catastrophic damage. Different types of circuit breakers exist, such as thermal-magnetic breakers which react to both heat buildup and rapid current changes.

Q 23. How do you troubleshoot a generator that is producing low voltage?

Troubleshooting low voltage from a generator involves a systematic approach. First, check the generator’s output voltage using a multimeter, ensuring it’s within the acceptable range specified by the manufacturer. Low voltage can stem from several issues:

- Engine Problems: A poorly running engine (due to low fuel, clogged air filter, or mechanical issues) will reduce the speed of the alternator, resulting in lower voltage output.

- Alternator Issues: Problems within the alternator itself, such as worn brushes, damaged rotor windings, or rectifier problems, are common culprits. A visual inspection for loose connections or burnt components is crucial. Load testing the alternator on a bench can pinpoint internal issues.

- Wiring and Connections: Loose connections, corroded terminals, or damaged wiring in the generator’s output circuit can significantly reduce voltage. Check all connections carefully.

- Excessive Load: The generator may be overloaded, meaning it’s trying to supply more power than it’s capable of. Reducing the load will improve the voltage.

- Voltage Regulator Issues: The voltage regulator controls the output voltage. A malfunctioning regulator can fail to maintain the correct voltage.

Troubleshooting involves checking each of these areas methodically. Often, a simple visual inspection and tightening of connections can solve the problem. If not, more advanced testing equipment may be needed to diagnose issues with the alternator or voltage regulator.

Q 24. What are the common types of generator synchronizing methods?

Synchronizing generators, the process of connecting two or more generators to a common busbar, ensuring they operate in unison, primarily uses two methods:

- Dark Light Method: This is a less precise manual method relying on visual observation of synchroscope indicators (lamps or meters) to match the voltage and frequency of both generators. It requires experienced operators and is less accurate than other methods.

- Automatic Synchronizer: Modern generators utilize automatic synchronizers, which use sophisticated electronic circuitry to compare the voltage, frequency, and phase angles of the incoming generator with the running system. The synchronizer automatically closes the breaker once the parameters match, providing a safer and more accurate synchronization.

The choice of method depends on the size and complexity of the generator system and the skill level of the operators. Larger power plants invariably employ automatic synchronizers, while smaller standalone generators might use the dark light method if appropriately skilled personnel are available.

Q 25. Describe the process of paralleling two generators.

Paralleling two generators involves carefully connecting them to operate in parallel, sharing the electrical load. The process requires a meticulous approach to prevent damage to the generators and the electrical system. This is done in several steps:

- Preparation: Ensure both generators are running smoothly, at the same frequency and voltage. The voltage and phase angle should also match.

- Synchronization: Use a synchronoscope (either manual or automatic) to check that the voltage, frequency, and phase angles of both generators are matched. Close synchronizing switches only when all three match.

- Breaker Closure: Once synchronized, close the breaker connecting the second generator to the busbar (the common point where multiple generators connect).

- Load Sharing: Gradually increase the load on both generators, adjusting their governors (controls that regulate the speed) to ensure they share the load equally. Unequal load sharing puts additional stress on the generators.

- Monitoring: Continuously monitor the generators’ performance – voltage, frequency, and current – to maintain synchronization and equal load sharing.

Improper paralleling can lead to large current surges, damaging the generators. It’s crucial to follow the specific procedures outlined in the generator’s manual and ensure that qualified personnel perform this operation.

Q 26. How do you interpret a generator’s performance data?

Generator performance data, usually displayed on a control panel or logged electronically, provides critical insights into the generator’s health and efficiency. Key parameters include:

- Voltage: Should remain within the specified range; deviations indicate issues with the alternator or voltage regulator.

- Frequency: Should be stable and within the acceptable range (typically 50Hz or 60Hz). Fluctuations indicate engine speed variations.

- Current: Indicates the electrical load; high current may indicate an overload.

- Power Factor: Represents the efficiency of the electrical load; a low power factor indicates a reactive load that requires correction.

- Engine Parameters: These include engine speed, oil pressure, coolant temperature, and fuel consumption – all vital for engine health assessment.

Analyzing this data helps identify potential problems early on. For instance, a consistently low power factor could suggest a need for power factor correction capacitors, while gradual increases in fuel consumption could highlight a developing engine problem. Regular analysis of these parameters helps in preventative maintenance and maximizing the lifespan of the generator.

Q 27. What are the different types of generator protection systems?

Generator protection systems are critical for safeguarding generators from various fault conditions. These systems act as safety nets, preventing damage and ensuring reliable operation. Common types include:

- Overcurrent Protection: Circuit breakers and fuses protect against excessive current flow, which can damage windings.

- Overvoltage and Undervoltage Protection: Relays detect voltage outside the acceptable range, preventing damage from overvoltages or insufficient voltage.

- Reverse Power Protection: Prevents backfeeding into the grid when the generator is being synchronized or shut down.

- Frequency Protection: Detects and protects the generator from operating at frequencies outside of its designed range.

- Ground Fault Protection: Detects ground faults, isolating the fault to prevent shock and fire hazards.

- Over Temperature Protection: Sensors monitor the temperature of the engine and generator windings, shutting down the system if temperatures become dangerous.

- Loss of Excitation Protection: Protects the generator from damage caused by the loss of field excitation.

These systems work independently and in conjunction to provide comprehensive protection. Choosing appropriate protection relays for a given generator requires careful analysis of the application and potential fault conditions.

Q 28. Explain the importance of regular maintenance for generators and alternators.

Regular maintenance for generators and alternators is crucial for ensuring reliable operation, safety, and longevity. Preventive maintenance extends the life of these expensive assets and prevents costly downtime. A well-maintained system is less likely to experience sudden failures. Neglecting this can lead to unforeseen breakdowns, potentially causing substantial financial losses and safety risks.

Regular maintenance involves:

- Visual Inspections: Checking for loose connections, corrosion, damage to wiring, and leaks.

- Engine Oil and Filter Changes: Essential for engine lubrication and preventing wear.

- Fuel System Cleaning: Keeping the fuel system clean prevents contamination and fuel issues.

- Cooling System Maintenance: Checking coolant levels and ensuring proper cooling prevents overheating.

- Alternator Component Checks: Inspecting brushes, slip rings, and voltage regulators, and load testing when needed.

- Battery Maintenance: Regularly testing and charging batteries ensures they remain ready for starting.

The specific maintenance schedule depends on the generator’s size, type, and operating conditions, usually outlined in the manufacturer’s recommendations. It’s best practice to follow these recommendations closely and document all maintenance activities. Think of it like servicing your car – regular checkups and maintenance prevent major breakdowns later on.

Key Topics to Learn for Generator and Alternator Repair Interview

- Fundamental Electrical Principles: Understanding Ohm’s Law, Kirchhoff’s Laws, and AC/DC theory is crucial for diagnosing electrical faults in generators and alternators.

- Generator Systems: Learn about different types of generators (e.g., synchronous, asynchronous), their operating principles, and common components (stators, rotors, voltage regulators).

- Alternator Systems: Master the function of alternators in vehicles and power systems, including their excitation systems, rectifiers, and voltage regulation mechanisms.

- Troubleshooting Techniques: Develop proficiency in using diagnostic tools (multimeters, oscilloscopes) to identify and isolate faults in generator and alternator circuits.

- Practical Repairs: Gain hands-on experience in repairing common alternator and generator issues, such as replacing brushes, rectifiers, stator windings, and voltage regulators.

- Safety Procedures: Familiarize yourself with all relevant safety protocols for working with high-voltage electrical systems.

- Preventive Maintenance: Understand the importance of regular maintenance schedules and procedures to prevent failures and extend the lifespan of generators and alternators.

- Testing and Measurement: Develop expertise in performing various tests (e.g., load testing, diode testing) to assess the performance and condition of generators and alternators.

- Component Identification: Become familiar with identifying and understanding the function of various components within a generator and alternator system.

- Interpreting Wiring Diagrams: Develop the skill to read and interpret complex wiring diagrams to troubleshoot electrical issues effectively.

Next Steps

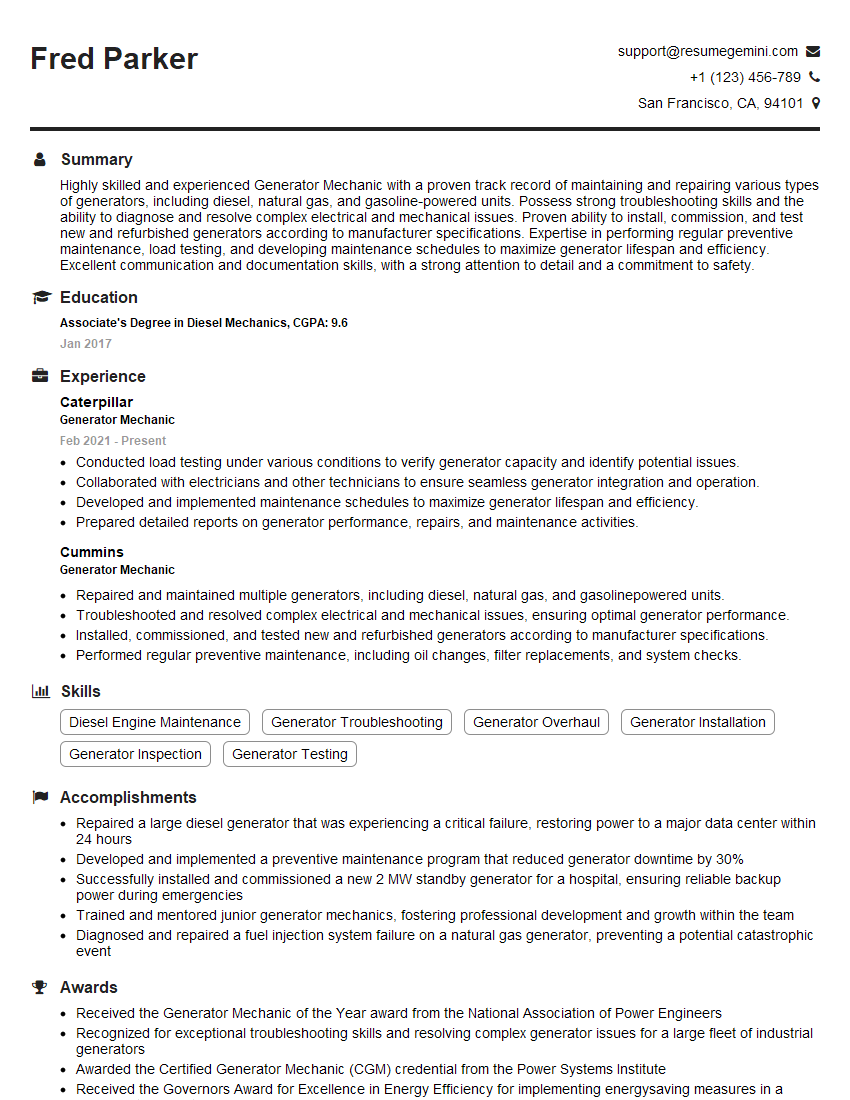

Mastering Generator and Alternator Repair opens doors to rewarding and stable careers in automotive, industrial, and power generation sectors. A strong understanding of these systems is highly valued by employers. To maximize your job prospects, crafting a compelling and ATS-friendly resume is crucial. ResumeGemini can help you build a professional resume that showcases your skills and experience effectively. ResumeGemini provides examples of resumes tailored to the Generator and Alternator Repair field to guide you through the process. Invest time in creating a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO