The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Supplier Quality Control interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Supplier Quality Control Interview

Q 1. Describe your experience in implementing supplier quality management systems.

Implementing a supplier quality management system (SQMS) involves a structured approach to ensuring consistent quality from your suppliers. It’s not just about reacting to problems; it’s about proactively preventing them. My experience includes designing and deploying SQMS across various industries, from automotive to medical devices. This involves several key stages:

- Supplier Selection and Qualification: This begins with rigorous pre-qualification questionnaires, site visits, and assessments of their quality management systems (often referencing ISO 9001 or similar standards). We analyze their capabilities, capacity, and past performance data to ensure they meet our requirements. For instance, in one project, we developed a weighted scoring system for evaluating potential suppliers based on factors like certifications, experience, and financial stability.

- Performance Monitoring and Measurement: Once a supplier is onboarded, we establish key performance indicators (KPIs) and regularly monitor their performance against those metrics. This might involve reviewing incoming inspection reports, analyzing defect rates, and tracking on-time delivery performance. We use dashboards and reporting tools to visualize this data and identify trends.

- Continuous Improvement: SQMS is a continuous cycle. Regular reviews, supplier performance meetings, and collaborative problem-solving sessions are crucial. We actively engage suppliers in identifying areas for improvement and work together to implement corrective and preventative actions. For example, we once helped a supplier implement a new statistical process control (SPC) system to reduce variation in their manufacturing process.

Throughout this process, effective communication and collaboration are paramount. Building strong relationships with suppliers fosters trust and a shared commitment to quality.

Q 2. Explain your understanding of ISO 9001 and its relevance to supplier quality.

ISO 9001 is a globally recognized standard for quality management systems. It provides a framework for organizations to demonstrate their ability to consistently provide products and services that meet customer and regulatory requirements. Its relevance to supplier quality is significant because it provides a common language and benchmark for evaluating supplier capabilities.

By requiring suppliers to be ISO 9001 certified (or to demonstrate equivalent capabilities), we ensure a baseline level of quality management practices. This includes aspects like:

- Documented Procedures: ISO 9001 requires suppliers to document their processes, ensuring consistency and traceability.

- Internal Audits: Regular internal audits help suppliers identify and correct weaknesses in their systems.

- Management Review: Top management’s commitment to quality is crucial, and the management review process ensures continuous improvement efforts.

- Corrective Actions: A robust system for addressing non-conformances and preventing recurrence is essential.

While certification alone isn’t a guarantee of perfect performance, it significantly reduces the risk of dealing with suppliers lacking a fundamental understanding of quality management.

Q 3. How do you assess and mitigate risks associated with supplier performance?

Assessing and mitigating supplier risks involves a proactive and multi-faceted approach. We employ a risk assessment matrix that considers various factors, including:

- Financial Stability: A supplier’s financial health directly impacts their ability to meet commitments.

- Capacity and Capability: Can the supplier consistently meet our volume and quality requirements?

- Geographical Location: Political instability, natural disasters, or logistical challenges in a supplier’s region can disrupt supply chains.

- Technological Dependence: Over-reliance on a single supplier or technology increases vulnerability.

- Quality History: Past performance data, including defect rates and on-time delivery, offers valuable insights.

Mitigation strategies depend on the identified risks. For example:

- Diversification: Using multiple suppliers for critical components reduces reliance on a single source.

- Contingency Planning: Developing backup plans in case of disruptions, such as having alternative suppliers or stockpiles of critical materials.

- Supplier Development: Investing in supplier improvement initiatives to enhance their capabilities and reduce risks.

- Contractual Agreements: Clearly defining responsibilities, performance expectations, and consequences for non-compliance in contracts.

Regularly reviewing and updating the risk assessment ensures we remain prepared for potential challenges.

Q 4. What are the key performance indicators (KPIs) you use to monitor supplier quality?

We utilize a range of KPIs to monitor supplier quality, categorized for clarity:

- Quality KPIs:

- Defect Rate: The percentage of non-conforming parts or services.

- PPM (Parts Per Million): A more precise measure of defects.

- Return Rate: The percentage of products returned due to quality issues.

- Customer Complaints Related to Supplier Parts: Direct feedback on the impact of supplier quality on our customers.

- Delivery KPIs:

- On-Time Delivery Rate: The percentage of orders delivered on schedule.

- Lead Time: The time it takes for a supplier to deliver an order.

- Cost KPIs:

- Cost of Poor Quality (COPQ): The total cost associated with quality defects and non-compliance.

These KPIs are tracked through a combination of supplier-provided data, our own inspection reports, and customer feedback. We use data visualization tools to identify trends and highlight areas needing attention.

Q 5. Explain your approach to conducting supplier audits.

Our supplier audit approach is systematic and thorough. It’s not simply a ‘check-the-box’ exercise; it’s an opportunity to understand the supplier’s processes, identify risks, and build a collaborative relationship. The process typically involves:

- Planning: Defining the scope of the audit, identifying key areas to be assessed, and developing a checklist based on our requirements and industry best practices.

- On-site Assessment: Conducting a thorough on-site review of the supplier’s facilities, processes, documentation, and quality management system. This includes document reviews, interviews with personnel, and observation of processes in action.

- Data Collection and Analysis: Gathering evidence through observation, interviews, and document review. We analyze this data to identify strengths, weaknesses, and potential risks.

- Reporting: Issuing a comprehensive audit report that summarizes our findings, including observations, non-conformances, and recommendations for improvement. This report is shared with the supplier and relevant stakeholders.

- Follow-up: Monitoring the supplier’s implementation of corrective actions to address any identified non-conformances.

We employ a combination of planned audits and announced audits to ensure a holistic picture of the supplier’s performance.

Q 6. How do you handle supplier non-conformances and corrective actions?

Handling supplier non-conformances requires a structured approach focusing on timely resolution and prevention. Our process involves:

- Identification and Reporting: Non-conformances are identified through incoming inspection, customer complaints, or supplier audits. A formal non-conformity report is created, documenting the issue and its impact.

- Root Cause Analysis: We use various techniques (e.g., 5 Whys, Fishbone diagrams) to identify the underlying causes of the non-conformance. This is crucial for preventing recurrence.

- Corrective Actions: The supplier proposes and implements corrective actions to address the root cause of the non-conformance. We review and approve these actions.

- Preventive Actions: Measures are put in place to prevent similar non-conformances from happening again. This may involve process improvements, training, or equipment upgrades.

- Verification: We verify that the corrective and preventative actions are effective through follow-up audits or monitoring of supplier performance.

- Documentation: All aspects of the non-conformance handling process are meticulously documented for traceability and future reference.

Effective communication with the supplier throughout this process is vital. We work collaboratively to find solutions and build a stronger, more reliable relationship.

Q 7. Describe your experience with root cause analysis techniques.

Root cause analysis (RCA) is essential for effectively addressing supplier non-conformances and preventing their recurrence. I’m proficient in several techniques, including:

- 5 Whys: A simple yet powerful technique where you repeatedly ask ‘Why?’ to uncover the underlying causes of a problem. For example, if a batch of parts is rejected: Why were the parts rejected? (Because they were out of spec). Why were they out of spec? (Because the machine was miscalibrated). Why was the machine miscalibrated? (Because the operator didn’t perform the required calibration checks). Why weren’t the checks performed? (Because the training was inadequate).

- Fishbone Diagram (Ishikawa Diagram): A visual tool that helps brainstorm potential causes categorized by factors like materials, methods, manpower, machinery, measurement, and environment. This is particularly useful for complex problems with multiple contributing factors.

- Pareto Analysis: Identifying the vital few causes that contribute to the majority of problems. This allows us to prioritize our efforts on the most impactful areas.

- Fault Tree Analysis (FTA): A top-down, deductive approach that systematically breaks down a problem into its contributing factors. This is useful for analyzing complex systems and identifying potential failure points.

The choice of technique depends on the complexity of the problem and the available data. Often, a combination of techniques is used for a more comprehensive analysis.

Q 8. How do you collaborate with suppliers to improve quality and efficiency?

Collaboration with suppliers is crucial for improving both quality and efficiency. It’s not just about receiving parts; it’s about building a partnership. My approach involves several key steps:

- Open Communication: Regular meetings, both planned and impromptu, are essential. We use a combination of video conferencing, email, and in-person visits to ensure clear communication and prompt issue resolution.

- Shared Goals & Metrics: We collaboratively define clear quality objectives and key performance indicators (KPIs) that both parties understand and track. This creates a shared sense of ownership and accountability.

- Data Sharing & Transparency: We employ data-driven approaches, sharing relevant quality data such as defect rates, process capability indices (Cpk), and customer feedback. This helps identify areas for improvement and track progress.

- Root Cause Analysis (RCA): When issues arise, we use collaborative RCA methods like the 5 Whys or fishbone diagrams to pinpoint the root cause and implement effective corrective actions. For example, if a batch of components fails a strength test, we work together to determine whether the issue stems from material defects, a flawed process at the supplier, or inadequate testing on our end.

- Continuous Improvement Initiatives: We actively encourage and support the implementation of lean manufacturing principles, such as Kaizen events, to streamline processes and reduce waste at the supplier’s facility. This could involve optimizing their production flow, reducing lead times, or improving material handling.

For example, in a past project with a supplier of electronic components, we implemented a collaborative quality improvement project that reduced their defect rate by 40% within six months, resulting in significant cost savings and improved on-time delivery.

Q 9. What are your preferred methods for supplier performance evaluation?

Supplier performance evaluation is a critical component of effective supplier management. My preferred methods incorporate a balanced scorecard approach, looking at both quantitative and qualitative aspects of performance. This includes:

- On-Time Delivery Performance (OTDP): Measured by tracking the percentage of orders delivered on or before the agreed-upon schedule. Significant deviations trigger investigation and corrective action.

- Quality Metrics: This includes defect rates, returns, and customer complaints directly attributable to the supplier’s components. We use statistical process control (SPC) charts to monitor trends and identify potential problems proactively.

- Cost Analysis: Evaluating the supplier’s price competitiveness, considering total cost of ownership, and investigating opportunities for cost reduction without sacrificing quality.

- Capability Audits: Regular on-site audits to assess the supplier’s quality management system (QMS), manufacturing processes, and adherence to specifications. We use checklists and documented procedures to ensure consistency and objectivity.

- Supplier Surveys & Feedback: Gathering qualitative data through surveys and regular feedback sessions to understand the supplier’s perspectives, challenges, and areas for improvement. This often reveals issues not apparent through quantitative data alone.

This comprehensive approach allows for a nuanced understanding of supplier performance, going beyond simply looking at defect rates and considering the broader context of their operations and contribution to our overall supply chain.

Q 10. How do you manage supplier relationships to ensure long-term quality?

Managing supplier relationships for long-term quality requires nurturing trust and collaboration. My approach focuses on:

- Long-Term Contracts: Establishing long-term contracts with key suppliers fosters stability and encourages investment in quality improvement initiatives. It signals commitment and reduces uncertainty for both parties.

- Performance Recognition: Recognizing and rewarding suppliers who consistently meet or exceed expectations fosters loyalty and motivation to maintain high quality standards. This might include awards, preferential treatment in future contracts, or publicly acknowledging their achievements.

- Open Communication Channels: Maintaining clear and open lines of communication is essential for resolving issues promptly and preventing misunderstandings. Regular meetings, shared dashboards, and readily available contact points ensure this.

- Collaborative Problem-Solving: Adopting a proactive approach to address challenges collaboratively, rather than reactively, strengthens the relationship and promotes mutual respect. This ensures we work together to find solutions rather than assigning blame.

- Relationship Management: Building strong personal relationships with key personnel at the supplier’s organization fosters trust and mutual understanding, facilitating effective collaboration and conflict resolution.

For instance, maintaining a strong relationship with a key supplier of critical components resulted in them proactively alerting us to a potential issue with a new material batch, allowing us to intervene early and prevent significant quality problems downstream.

Q 11. Explain your experience with supplier selection and qualification processes.

Supplier selection and qualification are critical for ensuring consistent product quality. My process involves a multi-stage approach:

- Initial Screening: Identifying potential suppliers based on factors like capacity, technical capabilities, financial stability, and geographic location. We often use pre-qualification questionnaires to narrow the field.

- Capability Assessment: Thoroughly evaluating the supplier’s quality management system (QMS) through detailed audits, review of quality documentation, and site visits. This confirms their adherence to relevant standards, such as ISO 9001.

- Sample Evaluation: Testing samples of the supplier’s products to verify their compliance with our specifications and performance requirements. We often employ destructive testing methods to ensure that parts meet the necessary quality standards.

- Trial Run/Pilot Production: Conducting a pilot run or small-scale production to assess the supplier’s ability to meet our volume and delivery requirements while maintaining quality. This allows us to test the entire supply chain before committing to larger volumes.

- Performance Monitoring: Continuously monitoring the supplier’s performance using key metrics and regular communication. Ongoing evaluation ensures they continue to meet expectations after qualification.

For example, when selecting a new supplier for a crucial engine component, we conducted rigorous testing and a pilot production run, including both destructive and non-destructive testing, to ensure they met the stringent specifications required for this application. This ensured a quality part was supplied, even under high stress conditions.

Q 12. How do you balance cost and quality considerations when working with suppliers?

Balancing cost and quality is a constant challenge in supplier management. It’s not about choosing one over the other; it’s about finding the optimal balance that delivers the best value. My approach involves:

- Total Cost of Ownership (TCO): Analyzing the total cost of ownership, which includes not only the initial purchase price but also factors such as transportation, inspection, warranty claims, and potential downtime due to defects. A slightly higher upfront cost might be justified if it significantly reduces downstream costs.

- Value Engineering: Collaborating with suppliers to identify opportunities for cost reduction without compromising quality. This could involve simplifying designs, using alternative materials, or improving manufacturing processes.

- Negotiation & Collaboration: Negotiating prices with suppliers while maintaining clear quality expectations. Building strong relationships often leads to more favorable pricing and flexibility.

- Risk Assessment: Identifying and mitigating risks associated with cost-cutting measures. For instance, sourcing cheaper materials might require additional testing and inspection to ensure quality is not compromised.

- Continuous Improvement: Focusing on continuous improvement efforts to reduce costs over time while maintaining or enhancing quality. This might involve Kaizen events or implementing lean manufacturing techniques.

For example, by working with a supplier to implement lean manufacturing techniques, we were able to reduce their production costs by 15% without affecting the quality of their parts. This highlights that cost reduction and quality improvement are not mutually exclusive.

Q 13. Describe your experience with different quality tools (e.g., SPC, FMEA, Pareto charts).

I have extensive experience using various quality tools to improve supplier performance and manage quality risks. Here are some examples:

- Statistical Process Control (SPC): SPC charts (e.g., control charts) are used to monitor process variability and identify trends indicative of potential quality issues. This allows for proactive intervention before defects become widespread.

Example: Using a control chart to monitor the diameter of a critical component, identifying a shift in the mean that suggests a process drift. - Failure Mode and Effects Analysis (FMEA): FMEA is used to systematically identify potential failure modes in the supplier’s processes, assess their severity, occurrence, and detectability, and implement preventive actions. This is crucial for proactively mitigating potential risks.

Example: Conducting an FMEA on the supplier’s welding process to identify potential failure modes and develop preventive measures. - Pareto Charts: Pareto charts help identify the most significant contributors to quality problems, allowing for prioritization of improvement efforts. By focusing on the vital few, rather than the trivial many, resources are used more effectively.

Example: Using a Pareto chart to identify the top three defects in a supplier's product line and prioritize corrective actions. - Root Cause Analysis (RCA): Techniques like the 5 Whys or fishbone diagrams are used to systematically investigate the root causes of quality problems, leading to effective corrective actions. Addressing root causes prevents recurrence.

These tools allow for a data-driven approach to supplier quality management, facilitating proactive problem-solving and continuous improvement.

Q 14. How do you ensure supplier compliance with regulatory requirements?

Ensuring supplier compliance with regulatory requirements is paramount. My approach involves:

- Regular Audits: Conducting regular audits to verify the supplier’s compliance with relevant regulations and standards (e.g., ISO 14001 for environmental management, RoHS for hazardous substances). This might include both on-site and document-based audits.

- Documentation Review: Thoroughly reviewing the supplier’s documentation, including certificates of compliance, test reports, and quality management system documentation, to ensure they adhere to all relevant legal and regulatory requirements.

- Supplier Training: Providing training to suppliers on relevant regulatory requirements to ensure they understand their obligations and responsibilities. This helps create awareness and reduce compliance-related issues.

- Compliance Monitoring: Continuously monitoring the supplier’s compliance through regular communication, performance reviews, and review of regulatory updates. We maintain a process to remain updated on changes in relevant regulations.

- Legal and Regulatory Expertise: Leveraging internal legal and compliance expertise or external consultants to ensure our audits and compliance monitoring process addresses all relevant regulatory and legal frameworks.

Non-compliance can result in significant risks, including legal liabilities, product recalls, and reputational damage. Therefore, a proactive and rigorous approach to ensuring supplier compliance is essential.

Q 15. How do you manage supplier change control processes?

Managing supplier change control is crucial for maintaining consistent product quality. It’s essentially a process to systematically evaluate and approve any proposed changes from a supplier that could impact the product or service we receive. This includes changes to materials, manufacturing processes, equipment, personnel, or even the supplier’s location.

- Formal Change Request Process: We implement a formal process where the supplier submits a detailed change request, outlining the proposed change, its rationale, and its potential impact. This request undergoes a thorough review by our team, considering aspects like quality, cost, delivery, and regulatory compliance.

- Impact Assessment: A critical step involves assessing the impact of the proposed change. We may conduct simulations, trials, or even pilot runs to evaluate the impact on the end product’s performance and quality. For example, a change in raw material might require extensive testing to ensure it meets our specifications and doesn’t compromise product durability.

- Risk Mitigation: Any identified risks associated with the change are meticulously addressed through mitigation plans. These plans could involve additional quality checks, tighter monitoring, or even training for our teams to handle the change effectively.

- Documentation & Approval: The entire change control process is meticulously documented. This documentation includes the change request, the impact assessment, the risk mitigation plan, and the final approval or rejection of the change. Clear approvals are crucial, typically requiring signatures from relevant stakeholders.

For instance, if a supplier wants to switch to a new manufacturing process, we’d require them to provide complete documentation, including validation data, process flow diagrams, and risk assessments. Only after a thorough review and approval would the change be implemented.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is your experience with supplier scorecards and performance dashboards?

Supplier scorecards and performance dashboards are invaluable tools for monitoring and improving supplier performance. They provide a clear, concise view of a supplier’s strengths and weaknesses across various key performance indicators (KPIs).

My experience encompasses developing and utilizing scorecards that track KPIs such as on-time delivery, defect rates, lead times, and responsiveness. These dashboards visually represent supplier performance, allowing for quick identification of trends and areas needing improvement. We typically use a weighted scoring system, prioritizing KPIs based on their criticality to our business. For example, on-time delivery might carry a higher weight than packaging aesthetics.

We also incorporate feedback from internal teams and customer satisfaction data into the scorecards to provide a holistic view of supplier performance. The data is used not only for performance evaluation but also for continuous improvement initiatives. We use this data to identify top-performing suppliers and those requiring additional support or corrective action. For instance, if a supplier consistently misses delivery deadlines, we’ll work with them collaboratively to identify the root cause and implement corrective actions, possibly through process improvement training or additional capacity investments.

Q 17. How do you handle supplier capacity issues that impact quality?

Supplier capacity issues directly impact quality because they can lead to rushed production, increased defects, and compromised quality control measures. Addressing these issues requires a proactive and collaborative approach.

- Capacity Assessment: We regularly assess supplier capacity to ensure it aligns with our projected demand. This involves analyzing their production capacity, lead times, and potential bottlenecks. This might involve reviewing their manufacturing equipment, workforce, and material availability.

- Collaborative Problem Solving: When capacity issues arise, we work closely with the supplier to identify the root causes and develop solutions. This could involve discussions about process improvements, technology upgrades, or potential outsourcing options.

- Demand Forecasting: Accurate demand forecasting is essential to avoid capacity constraints. By providing suppliers with accurate forecasts, they can better plan their resources and avoid sudden shortages that compromise quality.

- Risk Mitigation Strategies: We employ strategies such as diversifying our supply base, building safety stock, or implementing flexible manufacturing agreements to mitigate the risks associated with capacity issues. For example, having multiple suppliers for a critical component ensures that if one experiences capacity issues, the others can compensate.

For instance, if a supplier experiences a sudden surge in demand from other clients, impacting our orders, we would work with them to explore options like overtime production, or explore a temporary allocation of production capacity from a backup supplier.

Q 18. Describe your experience with different types of supplier contracts.

My experience encompasses various supplier contract types, each tailored to specific circumstances and risk profiles. The most common types include:

- Fixed-Price Contracts: These contracts define a fixed price for goods or services, regardless of cost fluctuations. They offer price certainty but require meticulous upfront planning and specification.

- Cost-Plus Contracts: In these contracts, the supplier is reimbursed for their actual costs plus a predetermined markup. They offer flexibility but require rigorous cost tracking and transparency.

- Time and Materials Contracts: These contracts are based on the time spent and materials used. They are suitable for projects with evolving scopes but require meticulous tracking of time and materials.

- Performance-Based Contracts: These contracts link payment to the supplier’s performance on pre-defined KPIs. They incentivize high performance but require robust monitoring and measurement systems.

The choice of contract depends on factors such as the complexity of the goods or services, the supplier’s risk tolerance, and the level of certainty required for costs and timelines. For example, a complex engineering project might benefit from a cost-plus contract, while a standardized component might be best suited for a fixed-price contract.

Q 19. How do you address communication barriers with international suppliers?

Communication barriers with international suppliers are a common challenge in global supply chains. Overcoming these barriers requires a multi-faceted approach:

- Clear Communication Protocols: Establishing clear communication protocols, including preferred methods of communication (email, video conferencing, etc.), response times, and documentation requirements, is crucial. This ensures everyone is on the same page.

- Language Support: Providing language support through translation services or employing bilingual staff facilitates clear communication and avoids misunderstandings. This is crucial for technical documents and discussions.

- Regular Communication: Regular communication, even for seemingly minor updates, minimizes the risk of misinterpretations and facilitates proactive problem-solving. Scheduling regular virtual meetings can build trust and relationship.

- Cultural Sensitivity: Understanding and respecting cultural differences is essential for building strong relationships and ensuring effective communication. Consider cultural norms when scheduling meetings and communicating information.

- Technology Leverage: Utilizing project management software, translation tools, and secure communication platforms enhances communication efficiency and transparency.

For instance, when working with a supplier in a country with a different time zone, we schedule meetings at times convenient for both parties and ensure all important documents are translated into both languages.

Q 20. What strategies do you use to prevent supplier quality issues from occurring?

Preventing supplier quality issues requires a proactive, multi-layered approach that focuses on building strong relationships, establishing clear expectations, and implementing robust quality management systems.

- Supplier Selection: Rigorous supplier selection processes, including thorough audits and assessments, are crucial for identifying reliable and capable suppliers. This includes evaluating their quality management systems, facilities, and personnel.

- Early Supplier Involvement: Involving suppliers early in the product development process facilitates collaboration and allows for early identification and resolution of potential quality issues. This proactive approach avoids costly fixes down the line.

- Continuous Improvement Programs: Encouraging and supporting continuous improvement initiatives at the supplier level ensures ongoing efforts to enhance quality and efficiency. This could involve training, process optimization and technology implementation.

- Regular Audits and Inspections: Regular on-site audits and inspections help maintain consistent quality standards. This ensures that the supplier is adhering to our requirements and industry best practices.

- Training and Development: Providing training and development opportunities to the supplier’s staff enhances their quality awareness and skills. This ensures consistent application of our standards.

For example, we might conduct regular audits at our supplier’s facilities, focusing on aspects like their quality management system, employee training and adherence to safety standards. We would also involve them in design reviews and provide training on using our quality management tools.

Q 21. How do you leverage data analytics to improve supplier quality performance?

Data analytics is a powerful tool for improving supplier quality performance. By leveraging data, we can identify trends, pinpoint root causes of quality issues, and implement data-driven improvements.

- Data Collection: We collect data from various sources, including supplier scorecards, quality inspection reports, and customer feedback. This data provides a comprehensive view of supplier performance.

- Data Analysis: Using statistical tools and techniques, we analyze the collected data to identify patterns, correlations, and outliers. This helps us identify the root cause of defects and other quality issues.

- Predictive Analytics: We leverage predictive analytics to anticipate potential quality issues before they occur. This allows for proactive intervention and prevents significant disruptions.

- Data Visualization: We use dashboards and other visualization tools to present the data in a clear and accessible manner. This facilitates data-driven decision-making and promotes better communication among stakeholders.

For example, using data analytics, we identified a correlation between specific weather conditions at a supplier’s location and the defect rate of a particular component. This enabled us to implement proactive measures to mitigate the impact of these weather conditions on quality.

Q 22. Describe your experience with continuous improvement initiatives in supplier quality.

Continuous improvement in supplier quality is a journey, not a destination. It involves systematically identifying areas for enhancement within the supplier network and implementing strategies to achieve better performance. My experience centers around leveraging methodologies like Lean and Six Sigma.

For instance, at a previous role, we tackled consistently late deliveries from a key electronics supplier. We employed a Kaizen event (a focused improvement workshop) with the supplier’s team. Through collaborative root cause analysis, we uncovered issues with their internal scheduling and material handling. By implementing visual management techniques and streamlining their process flow, we reduced lead times by 25%, significantly improving on-time delivery rates.

Another example involved reducing the defect rate of a critical component. We implemented a Statistical Process Control (SPC) system with the supplier, enabling them to monitor their process in real-time and identify deviations early. This proactive approach, coupled with training on root cause analysis tools like the 5 Whys, led to a 40% decrease in defects within six months.

- Data-driven decision making: Using metrics to track progress and identify areas for improvement.

- Collaborative problem-solving: Working closely with suppliers to find solutions.

- Process optimization: Streamlining processes to improve efficiency and reduce waste.

- Training and development: Upskilling suppliers to enhance their capabilities.

Q 23. How do you measure the effectiveness of your supplier quality management system?

Measuring the effectiveness of a supplier quality management system (SQMS) requires a multi-faceted approach, combining qualitative and quantitative data. Key performance indicators (KPIs) are crucial.

- Supplier performance metrics: This includes on-time delivery, defect rate, adherence to specifications, and response time to corrective actions. We often utilize a weighted scoring system to reflect the criticality of each metric.

- Customer satisfaction: Gathering feedback on the quality of materials or services received from our suppliers is essential. We regularly conduct customer surveys and analyze warranty claims.

- Process efficiency metrics: These could include cycle times for quality audits, turnaround time for corrective actions, and effectiveness of preventative measures.

- Cost of quality (COQ): Tracking the cost of prevention, appraisal, internal and external failures provides a holistic view of quality performance. A reduction in COQ demonstrates a successful SQMS.

For example, using a dashboard that displays these KPIs in real-time allows for quick identification of trends and potential problems. Regular management reviews of this data ensures proactive intervention and continuous improvement.

Q 24. What is your approach to developing supplier quality improvement plans?

Developing supplier quality improvement plans requires a systematic approach. It starts with a thorough understanding of the root cause of any quality issue, often using tools like Fishbone diagrams and Pareto analysis.

- Identify the problem: Clearly define the quality issue, including its impact on the business.

- Root cause analysis: Utilize appropriate tools to identify the underlying causes.

- Develop corrective actions: Create specific, measurable, achievable, relevant, and time-bound (SMART) actions to address the root causes.

- Implement corrective actions: Work with the supplier to implement the agreed-upon actions.

- Verify effectiveness: Monitor the implementation and effectiveness of corrective actions using appropriate metrics.

- Preventative actions: Implement measures to prevent similar issues from occurring in the future. This could involve process improvements, training, or updated procedures.

Imagine a scenario where a supplier consistently delivers components with surface imperfections. The improvement plan would involve identifying the cause (e.g., faulty equipment, inadequate training), collaborating with the supplier on corrective actions (e.g., equipment calibration, operator retraining), and monitoring the defect rate to ensure effectiveness. Regular follow-up meetings are essential to ensure accountability and track progress.

Q 25. How do you identify and mitigate potential supply chain disruptions?

Identifying and mitigating potential supply chain disruptions requires a proactive and comprehensive approach. It’s about building resilience into the supply chain.

- Supplier risk assessment: Regularly assess suppliers based on factors such as geographic location, financial stability, political and environmental risks. This might involve assigning risk scores to each supplier and developing contingency plans.

- Diversification of suppliers: Reducing reliance on a single supplier for critical components minimizes the impact of potential disruptions from any one source.

- Inventory management: Maintaining sufficient safety stock for critical items can cushion against delays or shortages. This must be balanced with inventory holding costs.

- Early warning systems: Establishing systems for monitoring potential disruptions (e.g., natural disasters, political instability, pandemics) through news feeds, industry reports, and supplier communication.

- Contingency planning: Developing alternative sourcing options, backup suppliers, or flexible manufacturing processes to respond to disruptions.

For example, during the pandemic, we proactively identified suppliers vulnerable to lockdowns and explored alternative sources. This involved a thorough reassessment of our supplier risk profiles and negotiations with potential backup suppliers, ensuring uninterrupted supply of critical components.

Q 26. Describe your experience with supplier relationship management (SRM) tools.

My experience with Supplier Relationship Management (SRM) tools encompasses both cloud-based platforms and internal systems. These tools are invaluable for managing the entire supplier lifecycle, from selection and onboarding to performance monitoring and improvement.

I’ve worked with systems that provide features such as:

- Supplier performance dashboards: Real-time visibility into key metrics.

- Document management: Centralized storage and management of contracts, specifications, and quality records.

- Communication tools: Facilitating collaboration and communication with suppliers.

- Risk management modules: Tools for identifying and assessing supplier risks.

- Auditing and compliance management: Streamlining the audit process and ensuring adherence to regulations.

One specific example involved implementing a cloud-based SRM system that integrated with our ERP system. This provided seamless data flow, enhancing efficiency and data accuracy. The system significantly improved our ability to track supplier performance, identify trends, and proactively address potential issues.

Q 27. How do you stay current with industry best practices in supplier quality control?

Staying current with industry best practices in supplier quality control is an ongoing process. It involves continuous learning and engagement with industry resources.

- Professional organizations: Active membership in organizations like ASQ (American Society for Quality) provides access to resources, publications, and networking opportunities.

- Industry conferences and webinars: Attending conferences and webinars keeps me updated on the latest trends, technologies, and best practices.

- Publications and journals: Regularly reading industry publications and journals helps me stay abreast of new developments and research findings.

- Online courses and certifications: Pursuing online courses and certifications demonstrates a commitment to continuous professional development.

- Networking: Building relationships with other professionals in the field allows for the exchange of ideas and best practices.

For example, I recently completed a certification in ISO 9001:2015, which has significantly enhanced my understanding of quality management systems and their application in supplier relationships. I also regularly participate in industry webinars on topics such as supply chain risk management and advanced quality planning.

Key Topics to Learn for Supplier Quality Control Interview

- Supplier Selection & Evaluation: Understanding criteria for selecting reliable suppliers, including audits and performance evaluations. Practical application: Developing a supplier scorecard based on quality metrics.

- Incoming Inspection & Quality Assurance: Methods for inspecting incoming materials and components to ensure they meet specifications. Practical application: Implementing a robust sampling plan and managing non-conforming materials.

- Corrective and Preventive Actions (CAPA): Processes for identifying, investigating, and resolving quality issues with suppliers. Practical application: Leading root cause analysis investigations and implementing effective corrective actions.

- Statistical Process Control (SPC): Applying statistical methods to monitor and control supplier processes. Practical application: Interpreting control charts and identifying process trends.

- Quality Management Systems (QMS): Understanding and applying relevant quality standards (e.g., ISO 9001). Practical application: Auditing suppliers’ QMS compliance and identifying areas for improvement.

- Supplier Relationship Management (SRM): Building and maintaining strong relationships with key suppliers to drive continuous improvement. Practical application: Collaborating with suppliers to implement process improvements and reduce defects.

- Risk Management: Identifying and mitigating potential quality risks associated with suppliers. Practical application: Conducting supplier risk assessments and implementing mitigation strategies.

- Problem-Solving Techniques: Utilizing tools like 5 Whys, Fishbone diagrams, and Pareto charts to effectively address quality issues. Practical application: Applying these tools to analyze supplier-related problems and find effective solutions.

- Data Analysis & Reporting: Interpreting quality data to identify trends and inform decision-making. Practical application: Creating dashboards and reports to track supplier performance and communicate key quality metrics.

Next Steps

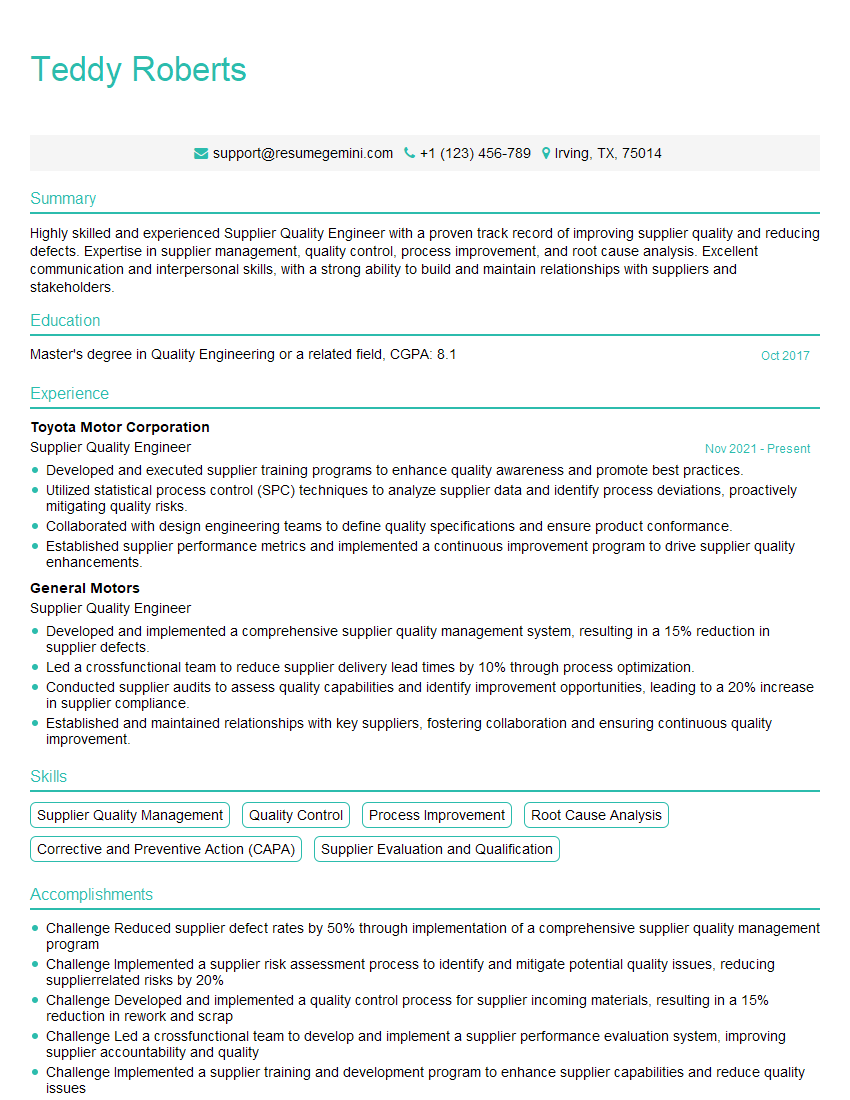

Mastering Supplier Quality Control opens doors to exciting career advancements, offering opportunities for leadership roles and increased responsibility within the supply chain. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to Supplier Quality Control are available to guide your creation process, ensuring your application stands out.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

There are no reviews yet. Be the first one to write one.