The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Engine Diagnosis and Repair interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Engine Diagnosis and Repair Interview

Q 1. Explain the process of diagnosing a misfire in an internal combustion engine.

Diagnosing a misfire involves systematically identifying which cylinder(s) are misfiring and then pinpointing the cause. A misfire occurs when a cylinder fails to ignite the air-fuel mixture properly, leading to rough running, reduced power, and potentially damage to the catalytic converter.

The process typically begins with a visual inspection, looking for any obvious issues like loose spark plug wires or damaged ignition components. Then, we move to diagnostic tools. A scan tool can read diagnostic trouble codes (DTCs) which might indicate a specific cylinder misfire. However, DTCs alone don’t tell the whole story.

Next, we use a data-driven approach. We’ll use a digital multimeter to check the voltage at the spark plugs, testing the ignition system. We might then check for proper fuel delivery using a fuel pressure gauge. Finally, and often most important, we’ll use a cylinder balance test or a misfire detection tool. This allows precise identification of which cylinder(s) are misfiring, even if the code doesn’t specify it. From there, we investigate further, checking for issues like faulty spark plugs, worn ignition coils, clogged injectors, vacuum leaks, or even compression issues in the identified cylinder(s).

For example, I once worked on a vehicle with a random misfire code. The scan tool showed a misfire across multiple cylinders, but the cylinder balance test pinpointed one specific cylinder as the culprit. Further inspection revealed a severely worn spark plug in that cylinder, solving the problem.

Q 2. Describe different types of engine sensors and their functions.

Engine sensors are the eyes and ears of the engine control unit (ECU), providing crucial data for proper operation. Think of them as the nervous system of the engine. A variety of sensors exist, each with a specific role:

- Mass Airflow Sensor (MAF): Measures the amount of air entering the engine, crucial for calculating the correct fuel injection.

- Throttle Position Sensor (TPS): Monitors the throttle plate’s position, informing the ECU about the driver’s requested engine power.

- Crankshaft Position Sensor (CKP): Detects the crankshaft’s rotation, essential for precise ignition timing and fuel injection.

- Cam Position Sensor (CMP): Monitors the camshaft’s position, vital for valve timing and fuel injection synchronization.

- Oxygen Sensor (O2): Measures the oxygen content in the exhaust gases, helping the ECU adjust the air-fuel mixture for optimal combustion and emissions.

- Engine Coolant Temperature Sensor (ECT): Measures the engine coolant’s temperature, used to regulate engine parameters and warn of overheating.

- Manifold Absolute Pressure (MAP) Sensor: Measures the pressure in the intake manifold, another key component for accurate fuel mixture calculations.

These sensors work together to provide real-time data that the ECU uses to make adjustments, ensuring optimal engine performance, fuel efficiency, and emission control. A faulty sensor can lead to poor performance, rough running, or even engine failure.

Q 3. How do you troubleshoot a no-start condition in a vehicle?

Troubleshooting a no-start condition requires a systematic approach, starting with the basics and progressing to more complex issues. It’s like solving a puzzle, systematically eliminating possibilities.

Step 1: The Basics

- Battery: Check battery voltage and cranking amperage. A weak battery is a common cause.

- Starter Motor: Listen for the starter engaging. A clicking sound could indicate a low battery or a faulty starter solenoid.

- Fuel Supply: Check for fuel delivery at the fuel rail by carefully depressing the pressure release valve on the rail to see if there’s fuel pressure. Check fuel pump operation. If the pump doesn’t run, suspect a faulty pump, relay or fuse

Step 2: Ignition System

- Ignition Switch: Verify that the ignition system is receiving power. Check the ignition switch and fuses for any issues.

- Spark Plugs and Wires: Visually check the spark plugs and wires for damage and test for spark using an inductive clamp-on spark tester.

- Ignition Coil: Check the coil for proper resistance using a multimeter, replace if faulty.

Step 3: Sensors and ECU

- Crankshaft and Cam Sensors: Check sensors for proper operation and voltage using a multimeter.

- ECU: Although less common, a faulty ECU can prevent a car from starting. This usually requires professional-grade diagnostic tools.

Step 4: Security and Immobilizer systems

- Key Fobs Check the vehicle’s immobilizer system, ensuring the correct key fob is being used. If a second key fob is available for testing, this will help confirm a key fob problem.

By following this structured approach, you can efficiently isolate the problem and repair it, saving time and effort. Remember safety first, always disconnect the negative battery terminal before working on the electrical system.

Q 4. What are the common causes of excessive engine oil consumption?

Excessive oil consumption can stem from several sources, often indicating wear or damage within the engine. It’s crucial to identify the root cause to prevent further damage.

- Worn Piston Rings: These rings seal the combustion chamber, and wear can allow oil to seep past into the combustion chamber, burning it off.

- Valve Stem Seals: These seals prevent oil from leaking down the valve stems; damage or hardening can lead to increased consumption.

- Worn Cylinder Walls: Scratches or excessive wear on the cylinder walls can allow oil to pass by the pistons.

- Breather System Issues: A clogged or faulty positive crankcase ventilation (PCV) system can cause excessive oil pressure, leading to leaks or oil consumption.

- Leaking Oil Seals: Various seals throughout the engine can fail, leading to oil leaks which eventually burn off.

Diagnosing the specific cause often requires a combination of visual inspection (checking for leaks), compression testing (to assess piston ring condition), and potentially a leak-down test (to check for leaks past the piston rings and valves). Each potential problem needs to be investigated individually to find the actual cause.

For instance, a vehicle with blue smoke from the exhaust (a sign of burning oil) may have worn piston rings, and compression testing might reveal low compression in one or more cylinders, confirming the diagnosis. In another case, obvious oil leaks might suggest a faulty valve cover gasket or oil pan gasket.

Q 5. Explain the principles of engine compression testing and its significance.

Engine compression testing measures the pressure inside each cylinder when the piston is at top dead center (TDC). It’s a critical test to evaluate the health of the engine’s internal components.

The process involves removing the spark plugs, inserting a compression gauge into the spark plug hole, and cranking the engine. The gauge measures the pressure, with lower-than-specified readings indicating a potential problem. The readings are compared between cylinders to identify inconsistencies. Low compression in one cylinder might suggest a problem with the piston rings, valves, or head gasket in that specific cylinder.

The significance lies in its ability to quickly detect problems like worn piston rings, burned or warped valves, head gasket leaks, or cracked cylinder heads which can reduce engine power, lead to misfires, and even cause engine failure. A compression test provides a detailed picture of how well the engine is sealing, making it a cornerstone of accurate diagnosis for many engine issues. A leak down test can supplement this process to reveal where the leakage is occurring.

For example, if one cylinder shows significantly lower compression than the others, it pinpoints the source of the problem, directing the mechanic towards more specific investigations, like a leak-down test or an inspection of the valves and rings.

Q 6. How do you diagnose a problem with engine cooling system?

Diagnosing cooling system problems requires a methodical approach, checking various components for malfunctions.

Step 1: Visual Inspection

- Leaks: Look for external leaks around the radiator, hoses, water pump, thermostat housing, and engine block.

- Fluid Level: Check the coolant level in the expansion tank (overflow reservoir); low levels indicate a leak.

- Hoses: Inspect for cracks, bulges, or kinks in the radiator hoses and other cooling system hoses.

Step 2: Functional Tests

- Temperature Gauge: Observe the engine temperature gauge for erratic behavior or overheating.

- Thermostat: Verify that the thermostat opens and closes correctly. A stuck thermostat can cause overheating or poor engine warm-up.

- Radiator Fan: Check if the radiator fan operates when the engine reaches a certain temperature. A faulty fan can cause overheating.

- Water Pump: Inspect the water pump for leaks or evidence of improper operation. A failed water pump can stop coolant circulation.

Step 3: Pressure Testing

- Pressure Test: A pressure test of the cooling system helps identify leaks that are not readily visible. Leaks will cause the pressure to drop.

Step 4: Further Diagnosis

- Head Gasket: If there’s coolant in the engine oil or exhaust, suspect a blown head gasket.

- Radiator Cap: Check the radiator cap for proper pressure relief. A faulty cap can lead to an inability to maintain pressure.

By systematically checking these components, the cause of the cooling system malfunction can be effectively identified and addressed.

Q 7. What are the signs of a failing catalytic converter?

A failing catalytic converter often exhibits several telltale signs.

- Check Engine Light (CEL): The most common indication is a illuminated check engine light, often accompanied by diagnostic trouble codes (DTCs) related to the catalytic converter or oxygen sensors.

- Reduced Engine Performance: The engine may run poorly, with reduced power or hesitation, especially at higher speeds. The catalytic converter’s restrictions cause pressure buildup in the exhaust.

- Exhaust Noise: A rattling or growling sound from the exhaust system is another possible symptom indicating internal damage or blockage.

- Poor Fuel Economy: A clogged catalytic converter increases back pressure, leading to reduced fuel efficiency.

- Exhaust Smell: A strong smell of rotten eggs (sulfur) indicates that the converter is not properly converting harmful gases and is failing.

Diagnosing a failing catalytic converter often requires a combination of a scan tool to check for DTCs, a visual inspection for physical damage, and potentially backpressure measurements. A faulty catalytic converter is usually confirmed with a combination of tests and observation of the described symptoms.

Q 8. How do you interpret diagnostic trouble codes (DTCs)?

Diagnostic Trouble Codes, or DTCs, are numerical codes stored by a vehicle’s onboard diagnostic (OBD) system. They indicate a malfunction within the engine or other vehicle systems. Interpreting them involves several steps. First, retrieve the code using an OBD-II scanner. The code itself provides a clue; for example, a P0171 code typically points to a lean condition in the engine’s air-fuel mixture. Next, consult a DTC lookup table or a repair manual specific to the vehicle’s make, model, and year. These resources will provide a detailed description of the code’s meaning and potential causes. Finally, perform additional diagnostic tests, such as checking sensor readings, inspecting wiring harnesses, and performing pressure tests, to pinpoint the root cause. It’s not simply about reading the code; it’s about understanding the underlying system failure and then systematically checking to confirm the issue. Remember, one code can sometimes be a symptom of a larger problem, so thorough investigation is key. For instance, a P0171 might be caused by a faulty oxygen sensor, a vacuum leak, or even a failing mass airflow sensor. The diagnostic process requires systematically eliminating potential causes.

Q 9. Explain the function of the oxygen sensor and its role in emissions control.

The oxygen sensor is a crucial component in modern engine management systems, primarily responsible for monitoring the exhaust gas’s oxygen content. This information is fed back to the engine control unit (ECU), which then adjusts the air-fuel mixture to optimize combustion and minimize emissions. Think of it as the engine’s ‘taste bud’ for oxygen. A properly functioning oxygen sensor ensures a stoichiometric air-fuel ratio (approximately 14.7:1 for gasoline engines), reducing harmful emissions like carbon monoxide (CO), hydrocarbons (HC), and nitrogen oxides (NOx). The sensor itself uses a zirconia ceramic element that generates a voltage proportional to the oxygen concentration difference between the exhaust gas and the surrounding air. This voltage signal is interpreted by the ECU, allowing precise control of fuel delivery. A faulty oxygen sensor can lead to increased emissions, reduced fuel economy, and even a check engine light due to incorrect air/fuel mixture calculations by the ECU. A rich or lean condition can also damage the catalytic converter over time.

Q 10. Describe the different types of fuel injection systems.

Fuel injection systems deliver fuel to the engine’s cylinders, replacing older carburetor systems for better control and efficiency. There are two main types:

- Port Fuel Injection (PFI): In this system, fuel injectors are located in the intake manifold, spraying fuel into the intake ports just before the cylinders. This is a relatively simpler and cost-effective design, common in many vehicles.

- Direct Fuel Injection (DFI): With DFI, fuel injectors are positioned directly within the combustion chamber. This allows for more precise fuel delivery and better control over the air-fuel mixture. DFI engines often exhibit improved fuel economy and power compared to PFI.

Q 11. How do you diagnose a problem with the ignition system?

Diagnosing ignition system problems involves a systematic approach, starting with visual inspection of components like spark plug wires, distributor cap (if applicable), and ignition coil. Look for cracks, corrosion, or loose connections. Next, use a spark tester to check for spark at each spark plug. A weak or missing spark indicates a problem within the ignition system. A multimeter can be used to measure the primary and secondary coil voltages, and a dwell meter can check the dwell time (the amount of time the ignition coil is energized). If there is no spark, the issue may be a faulty ignition coil, a bad crankshaft position sensor (CKP), or a problem within the engine control module (ECM). Checking for proper voltage at the coil is important to identify whether the problem is with the coil itself or with the control circuitry. A faulty CKP sensor will prevent the ECM from sending the signal to fire the coil, preventing a spark from occurring. Furthermore, a faulty camshaft position sensor (CMP) can result in an improper ignition timing sequence. Each component’s function and associated diagnostic procedure must be considered within the larger ignition system to effectively diagnose the cause of ignition issues.

Q 12. What are the common causes of engine overheating?

Engine overheating is a serious issue that can lead to significant engine damage. Several factors can contribute to this problem:

- Low Coolant Level: Insufficient coolant prevents efficient heat transfer from the engine block to the radiator.

- Faulty Thermostat: A malfunctioning thermostat, either stuck open or closed, can disrupt the proper coolant flow.

- Radiator Problems: A clogged radiator or a leaking radiator prevents efficient heat dissipation.

- Water Pump Failure: A failed water pump prevents the coolant from circulating through the engine.

- Faulty Cooling Fan: If the cooling fan isn’t working, the radiator won’t cool the coolant effectively, particularly during idling or low-speed driving.

- Head Gasket Failure: A blown head gasket can allow coolant to leak into the combustion chamber or oil, causing overheating and other significant problems.

Q 13. Explain the function of the timing belt/chain and its importance.

The timing belt or chain synchronizes the rotation of the crankshaft and camshaft(s), ensuring the valves open and close at the precise moments relative to the piston movement. This is critical for proper engine operation and power production. The timing belt is usually a rubber belt with teeth that mesh with sprockets on the crankshaft and camshaft. It needs periodic replacement as it wears out over time. A timing chain, typically made of metal, is more durable but can still stretch or break. If the timing belt or chain breaks, the valves and pistons can collide, resulting in catastrophic engine damage. This is often referred to as a ‘valve-to-piston’ event and can be very costly to repair. The importance of regular maintenance, including timing belt replacement at the recommended intervals, cannot be overstated. Ignoring this can lead to a costly engine overhaul or replacement. Regular inspection for wear and tear, as well as listening for unusual noises coming from the timing belt area, are preventative measures that can be taken.

Q 14. How do you diagnose a problem with the vehicle’s exhaust system?

Diagnosing exhaust system problems starts with a visual inspection, checking for leaks, rust, holes, or damage to the exhaust pipes, muffler, catalytic converter, and other components. Listen for unusual noises like rattling, rumbling, or excessive exhaust sounds which often point to a leak. A visual inspection usually reveals major structural issues, but exhaust leaks in hard-to-reach areas can be harder to find. Exhaust gas analyzers can be used to measure the levels of carbon monoxide, hydrocarbons, and oxygen in the exhaust gas, which can help identify problems with the catalytic converter or other emission control devices. Using a smoke machine to check for leaks in the exhaust system is another diagnostic tool. You introduce smoke into the exhaust system and look for the leak points. A leak in the exhaust system can lead to reduced engine performance, louder exhaust noise, and increased emissions. A faulty catalytic converter reduces engine power and causes poor fuel economy. Addressing these problems promptly prevents further damage and ensures safety and emission compliance.

Q 15. What are the safety precautions when working on an engine?

Safety is paramount when working on an engine. Think of it like performing surgery – precision and caution are critical. Before you even touch the engine, you need to disconnect the battery’s negative terminal to prevent accidental shorts and electrical shocks. This is your first line of defense against injury. Next, ensure the vehicle is securely parked on a level surface, preferably with the parking brake engaged. Always wear appropriate personal protective equipment (PPE), including safety glasses to protect your eyes from flying debris, gloves to prevent cuts and chemical exposure, and hearing protection to reduce the noise from power tools. Never work under a vehicle supported only by a jack; always use jack stands for stability. Furthermore, be mindful of hot surfaces – engines can retain significant heat even after being turned off. Finally, if you’re working with fluids like oil or coolant, ensure proper disposal methods to protect the environment and your health. Always refer to the vehicle’s service manual for specific safety precautions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain how to perform a cylinder leak down test.

A cylinder leak-down test helps identify problems with cylinder sealing, like worn piston rings or blown head gaskets. Imagine it as a pressure test for your engine’s cylinders. You need a leak-down tester, which is essentially a compressed air source with a gauge and a fitting that connects to a spark plug hole. Here’s how it works:

- Prepare: Disconnect the spark plugs from the cylinder you’re testing, and crank the engine to top dead center (TDC) on the compression stroke of that cylinder. You’ll need a compression gauge or a degree wheel to accurately find TDC.

- Connect: Attach the leak-down tester to the spark plug hole.

- Pressurize: Introduce compressed air into the cylinder. The gauge will show you the pressure.

- Listen & Observe: Listen for escaping air. Escaping air from the intake indicates intake valve problems; from the exhaust, it suggests exhaust valve problems; from the crankcase, it implies piston ring or head gasket issues.

- Record: Note the percentage of air lost and where it’s escaping from. A higher percentage indicates a more significant problem.

- Repeat: Repeat the test for each cylinder to compare results.

Interpreting the results requires experience. A small amount of leakage is normal, but a significant loss of pressure points to the need for repair.

Q 17. How do you diagnose a problem with the vehicle’s transmission?

Diagnosing transmission problems requires a systematic approach. It’s like detective work, looking for clues. Start with the basics: Listen for unusual noises – grinding, whining, or clunking during shifting. Feel for any vibrations or rough shifts. Check the transmission fluid – is it the correct type and level? Low fluid is a major red flag. Then, observe the vehicle’s performance – are shifts delayed or harsh? Does the vehicle slip or not shift at all? Next, consider advanced diagnostics: A scan tool can sometimes retrieve trouble codes from the transmission control module (TCM), which may pinpoint the issue. You might also test for correct fluid pressure using a specialized gauge, or you could even conduct a road test observing how the transmission performs under various conditions. If you’re dealing with a complex automatic transmission issue, consulting a transmission specialist is prudent.

Q 18. Describe different types of engine oils and their applications.

Engine oils are categorized by their viscosity (thickness) and additives. Think of viscosity as the oil’s resistance to flow – thinner oils flow easier in cold temperatures, while thicker oils provide better protection at high temperatures. Common viscosity grades are SAE 5W-30, 10W-30, and 15W-40. The ‘W’ stands for ‘winter’. The number before ‘W’ indicates cold-temperature viscosity, while the number after indicates hot-temperature viscosity. Additives enhance performance. For example, some oils include detergents to keep the engine clean, anti-wear agents to reduce friction, and viscosity modifiers to maintain consistent thickness. Different types include:

- Conventional Oil: The basic, refined crude oil. More affordable but requires more frequent changes.

- Synthetic Oil: Manufactured oil with superior performance in extreme temperatures and longer drain intervals.

- Synthetic Blend: A mixture of conventional and synthetic oils; a good compromise between price and performance.

Choosing the right oil depends on the vehicle’s manufacturer’s recommendations, operating conditions, and climate. Always refer to your owner’s manual.

Q 19. Explain the difference between a fuel injector and a carburetor.

Fuel injectors and carburetors both deliver fuel to the engine, but they do it very differently. Think of a carburetor as a simple mechanical device, and a fuel injector as a precise electronic system. A carburetor uses airflow to draw fuel into a mixture that’s then sent to the cylinders. It’s a relatively simple system but less precise in fuel delivery. A fuel injector, on the other hand, is electronically controlled and precisely meters fuel into each cylinder. This results in improved fuel efficiency, lower emissions, and better engine performance. Carburetors are mostly found in older vehicles, while fuel injection is standard in modern engines.

Q 20. How do you perform a vacuum test on an engine?

A vacuum test assesses the engine’s intake manifold vacuum. A strong vacuum indicates a healthy engine; weak vacuum suggests problems. You’ll need a vacuum gauge and a length of hose to connect it to a vacuum port on the intake manifold. With the engine running at idle, connect the gauge. The reading should be within the manufacturer’s specifications. A low reading could indicate a vacuum leak, restricted air filter, faulty PCV valve, or even a problem with the engine itself. To find the leak, carefully spray a mixture of carb cleaner around potential leak points and observe the gauge; a sudden drop in vacuum indicates a leak.

Q 21. What are the common causes of rough idling?

Rough idling, that shaky engine at idle, can have several causes. Think of it like a poorly coordinated team – various engine components aren’t working in sync. Common causes include:

- Vacuum Leaks: Small cracks or holes in the intake system can disrupt airflow.

- Dirty or Faulty Mass Airflow Sensor (MAF): This sensor measures airflow; a dirty or faulty sensor leads to inaccurate fuel delivery.

- Faulty Throttle Position Sensor (TPS): This sensor monitors throttle position; a malfunctioning sensor can cause erratic fuel delivery.

- Spark Plug Issues: Worn, fouled, or improperly gapped spark plugs can cause misfires, leading to rough idling.

- Ignition System Problems: Issues with the ignition coil, wires, or distributor (in older vehicles) can cause misfires.

- Dirty Fuel Injectors: Clogged fuel injectors can deliver an inconsistent fuel spray.

- Low Compression: Worn piston rings or valves can reduce compression, leading to rough running.

Diagnosing the specific cause may involve a combination of visual inspections, diagnostic scans, and testing individual components.

Q 22. Explain the function of the PCV system.

The Positive Crankcase Ventilation (PCV) system is crucial for preventing the buildup of harmful pressure and crankcase blow-by gases in your engine. Think of it as the engine’s breath-control system. Blow-by gases are a mixture of unburned fuel, oil vapors, and combustion byproducts that escape past the piston rings during the combustion process. These gases are harmful to the environment and can damage the engine if allowed to accumulate.

The PCV system works by drawing these blow-by gases from the crankcase and routing them back into the intake manifold to be re-burned during the next combustion cycle. This reduces emissions and prevents pressure buildup in the crankcase, which could lead to oil leaks and sludge formation. A common component is the PCV valve, a one-way valve that controls the flow of these gases. A malfunctioning PCV valve can lead to increased crankcase pressure, oil leaks, and reduced engine performance.

For example, a clogged PCV valve will restrict the flow of blow-by gases, leading to excessive crankcase pressure. This could cause your oil dipstick to be blown out, or the valve cover gasket to leak. Conversely, a faulty valve that doesn’t close properly might allow excessive amounts of oil vapors into the intake manifold, leading to excessive oil consumption and potentially fouling spark plugs.

Q 23. How do you diagnose a problem with the engine’s electrical system?

Diagnosing electrical system problems requires a systematic approach, starting with a visual inspection for obvious issues like loose connections, damaged wiring, or corrosion. I usually begin by checking the battery’s voltage and ensuring the charging system (alternator and voltage regulator) is functioning correctly using a multimeter. A low voltage reading can indicate a weak battery or charging system failure.

Next, I would use a scan tool to retrieve any diagnostic trouble codes (DTCs) stored in the engine control module (ECM) or other related control units. These codes can pinpoint specific electrical faults. For example, a code related to a specific sensor indicates that the sensor may be faulty or its wiring harness is damaged.

Further diagnostics might involve using a wiring diagram to trace circuits, checking for continuity and resistance in wiring harnesses with a multimeter, and testing the operation of individual components like sensors, actuators, and relays. I often use a circuit testing tool to carefully isolate the faulty component or wire, preventing damage to other parts during testing.

Imagine a scenario where the engine is cranking but not starting. I might initially check the battery voltage. If it’s low, I’d check the charging system. If the voltage is good, I might then check for spark at the spark plugs or verify fuel injector operation. Using a scan tool can quickly identify if there are any communication issues between the ECM and other modules. A systematic approach, combined with the right tools, allows for a precise diagnosis.

Q 24. Describe the different types of engine management systems.

Engine management systems have evolved significantly over time. Early systems were primarily mechanical, relying on carburetors and distributors for fuel and ignition timing control. Modern vehicles utilize sophisticated electronic engine control units (ECUs) or Engine Control Modules (ECMs). These ECUs manage various engine parameters electronically, resulting in better fuel efficiency and reduced emissions.

There are several types, including:

- Carburetor Systems (Older Technology): These systems use a carburetor to mix air and fuel mechanically. They are simple but less precise and efficient than modern systems.

- Electronic Fuel Injection (EFI): EFI systems use sensors and an ECU to precisely control the amount of fuel injected into the engine. Various EFI strategies exist, such as multi-point fuel injection (each cylinder has its own injector) and throttle body injection (single injector before the throttle).

- Electronic Ignition Systems: These use an ECU to precisely control the ignition timing based on various engine parameters like engine speed and load.

- OBD-I, OBD-II, and OBD-II Enhanced Systems: On-board diagnostics (OBD) systems are designed to monitor and diagnose engine performance and emissions. OBD-II is a standardized system that allows mechanics to retrieve diagnostic trouble codes (DTCs) using scan tools. Enhanced systems include more sophisticated sensors and greater diagnostic capability.

The choice of system depends on the vehicle’s age and technological specifications. Understanding the specific system is crucial for accurate diagnosis and repair.

Q 25. Explain how to use a scan tool to diagnose engine problems.

A scan tool is an indispensable tool for diagnosing modern engine problems. It connects to the vehicle’s diagnostic port (usually located under the dashboard) and retrieves diagnostic trouble codes (DTCs) stored in the vehicle’s computer (ECU/ECM). These codes indicate specific faults within the engine management system.

Here’s how I use a scan tool:

- Connect the Scan Tool: Connect the scan tool to the vehicle’s diagnostic port and power on the tool.

- Retrieve DTCs: The scan tool will read the codes from the ECU. These codes are usually alphanumeric (e.g., P0171, P0300) and refer to specific problems. For example, P0171 often indicates a lean condition in one of the engine banks. P0300 points to a random misfire.

- Analyze Freeze Frame Data: The scan tool can provide freeze frame data, which is a snapshot of the engine’s operating conditions at the moment the DTC was set. This data helps pinpoint the cause of the problem.

- View Live Data: Many scan tools display live data, allowing me to monitor various engine parameters like engine speed, fuel trim, oxygen sensor readings, and coolant temperature. This is useful for identifying intermittent problems or problems that don’t set a DTC.

- Clear DTCs (After Repair): Once the problem is fixed, I will clear the codes from the ECU and verify that the issue is resolved.

It’s important to understand that DTCs provide clues, not definitive diagnoses. I often use the DTCs in conjunction with other diagnostic techniques such as visual inspection, testing with multimeters, and pressure tests to reach a conclusive diagnosis.

Q 26. How do you diagnose a problem with the vehicle’s braking system related to engine function?

Braking system problems rarely directly relate to engine function, except in specific cases involving engine-driven vacuum assist for the brake booster. In older vehicles, or those with vacuum-assist braking systems, insufficient vacuum from the engine can lead to soft or unresponsive brakes. This indicates a problem with the engine’s vacuum pump or a leak in the vacuum lines.

Diagnosing this requires verifying that the engine is producing sufficient vacuum. I’d use a vacuum gauge to measure the vacuum at the brake booster input. Low vacuum readings point towards either an engine problem affecting vacuum production (e.g., vacuum leak, faulty PCV valve) or a leak in the vacuum lines to the booster. Identifying the leak requires a careful visual inspection of all vacuum hoses. Sometimes a smoke test can be helpful to pinpoint leaks.

Modern vehicles generally use electronically assisted braking systems that don’t rely on engine vacuum. However, issues like low battery voltage, as discussed earlier, can still affect the operation of the electronic brake control systems resulting in brake failure or malfunction. Again a systematic approach, checking battery voltage and electrical connections, is crucial. A scan tool can identify codes related to the brake control system’s electronic components.

Q 27. What are some common causes of low engine power?

Low engine power is a common complaint, and many factors can contribute. It’s crucial to adopt a systematic approach for diagnosis.

Some common causes include:

- Restricted Airflow: A clogged air filter, dirty mass airflow sensor (MAF), or issues in the intake system can restrict airflow to the engine, reducing power. A visual inspection of the air filter and testing the MAF sensor are crucial steps.

- Fuel Delivery Problems: A clogged fuel filter, malfunctioning fuel pump, or faulty fuel injectors can restrict the flow of fuel to the engine, leading to low power. A fuel pressure test can help determine if the fuel pressure is adequate.

- Ignition System Issues: Worn spark plugs, faulty ignition coils, or problems with the ignition timing can lead to misfires, resulting in loss of power. Checking spark and ignition timing is important.

- Exhaust System Restrictions: A clogged catalytic converter or exhaust muffler can restrict exhaust flow, reducing engine power. A visual inspection of the exhaust system can help identify blockages.

- Vacuum Leaks: Leaks in the engine’s vacuum system can cause erratic engine operation and reduced power. A smoke test is very effective for detecting vacuum leaks.

- Mechanical Issues: Worn piston rings, low compression, or issues with the valve train can significantly reduce engine power. A compression test is necessary to assess the health of the engine’s cylinders.

The diagnostic process involves a combination of visual inspection, testing with specialized tools (e.g., vacuum gauge, fuel pressure gauge, compression tester), and the use of a scan tool to retrieve diagnostic trouble codes.

Q 28. Describe your experience with diagnosing and repairing diesel engines.

I have extensive experience diagnosing and repairing diesel engines, both light-duty and heavy-duty. Diesel engines, while robust, present unique challenges due to their high compression ratios and reliance on precise fuel injection. My experience covers a wide range of issues.

I’m proficient in diagnosing problems related to:

- Fuel System Issues: This includes diagnosing problems with fuel injectors (testing their spray pattern, flow rate, and atomization), fuel pumps (checking pressure and flow), and fuel lines (checking for leaks and restrictions). I frequently use specialized diesel fuel injector test equipment.

- Turbocharger and Supercharger Problems: Testing turbocharger boost pressure, checking for leaks in the intake system, and assessing turbine shaft play is routine for me. I can also diagnose issues with supercharger clutches and bearings.

- Engine Management System Diagnostics: Diesel engine management systems, though complex, are similar in concept to gasoline engines. Using scan tools and understanding the specific parameters of the diesel ECU is crucial for diagnosing DTCs and resolving software-related problems.

- Emission Control System Diagnostics: Diesel particulate filters (DPFs), selective catalytic reduction (SCR) systems, and exhaust gas recirculation (EGR) systems are crucial for emission control. Understanding their function and the common faults they experience is essential. I am familiar with the various diagnostic and regeneration procedures involved.

- Mechanical Issues: Diagnosing problems like low compression, worn piston rings, and issues with the cylinder head gasket are part of my regular practice. I frequently conduct compression tests, cylinder leak-down tests, and other assessments for mechanical issues.

I have experience working on a variety of diesel engine brands, from light-duty vehicles to heavy-duty trucks and agricultural machinery. My approach always involves a systematic process that combines visual inspection, diagnostic tests, and the use of specialized tools.

Key Topics to Learn for Engine Diagnosis and Repair Interview

- Internal Combustion Engine Fundamentals: Understanding the four-stroke cycle, engine components (intake, compression, combustion, exhaust), and their functions. Practical application: Diagnosing misfires based on understanding combustion.

- Engine Diagnostic Systems: Familiarization with OBD-II systems, sensor operation (e.g., MAF, MAP, O2 sensors), and interpreting diagnostic trouble codes (DTCs). Practical application: Troubleshooting a vehicle’s check engine light using diagnostic tools.

- Fuel Systems: Knowledge of fuel injection systems (port, direct injection), fuel pressure regulation, and fuel delivery problems. Practical application: Identifying and repairing fuel leaks or diagnosing low fuel pressure issues.

- Ignition Systems: Understanding spark plug function, ignition coils, and distributor systems (where applicable). Practical application: Diagnosing misfires caused by faulty ignition components.

- Emission Control Systems: Knowledge of catalytic converters, oxygen sensors, and evaporative emission control systems. Practical application: Understanding emissions testing procedures and diagnosing emission-related problems.

- Cooling and Lubrication Systems: Understanding the function of cooling systems (radiators, water pumps, thermostats) and lubrication systems (oil pumps, oil filters). Practical application: Diagnosing overheating or low oil pressure issues.

- Electrical Systems: Understanding basic automotive electrical circuits, wiring diagrams, and troubleshooting electrical problems. Practical application: Identifying and repairing faulty electrical components related to engine operation.

- Engine Performance Troubleshooting: Developing systematic approaches to diagnose performance issues (rough running, stalling, lack of power). Practical application: Utilizing diagnostic tools and procedures to effectively isolate and repair performance problems.

- Engine Repair Techniques: Understanding procedures for engine component replacement, gasket replacement, and other common engine repair tasks. Practical application: Demonstrating knowledge of safe and efficient repair techniques.

Next Steps

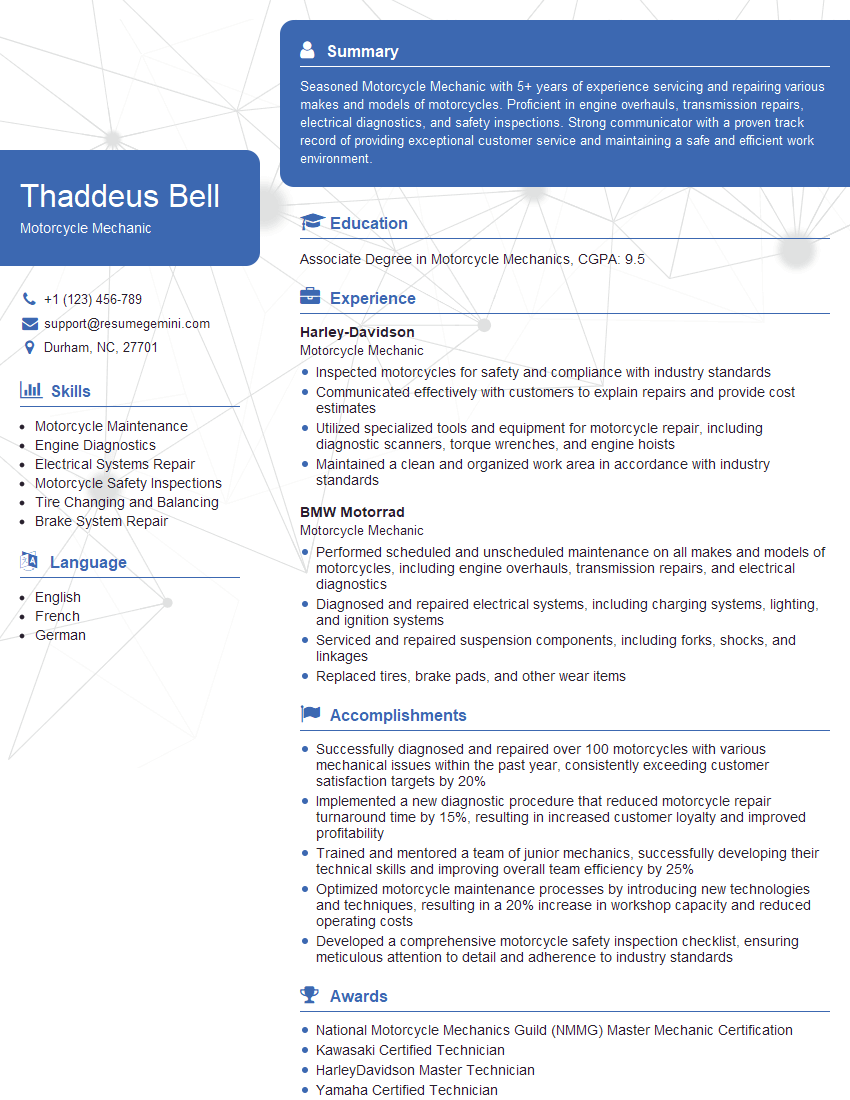

Mastering Engine Diagnosis and Repair opens doors to rewarding careers with excellent growth potential. A strong understanding of these critical skills is highly sought after by employers. To maximize your job prospects, it’s crucial to create an ATS-friendly resume that effectively highlights your qualifications. ResumeGemini is a trusted resource to help you build a professional and impactful resume. They provide examples of resumes tailored to Engine Diagnosis and Repair to help you showcase your skills effectively. Invest in creating a strong resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO