Unlock your full potential by mastering the most common Understanding of marine propulsion systems interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Understanding of marine propulsion systems Interview

Q 1. Explain the difference between a geared and a direct drive propulsion system.

The core difference between geared and direct drive propulsion systems lies in how the engine’s power is transmitted to the propeller. In a direct drive system, the propeller shaft is directly connected to the engine’s output shaft. Think of it like a bicycle – you pedal directly to turn the wheels. This is simple and reliable but limits engine speed and propeller diameter. Large, slow-running engines are typically needed.

A geared propulsion system, on the other hand, uses a gearbox to reduce the engine’s high speed to a lower, more suitable speed for the propeller. This is analogous to a car’s transmission – it allows the engine to operate at its optimal speed while the wheels (propeller) turn at a more efficient speed. This setup enables the use of smaller, higher-speed engines, leading to better fuel efficiency and space savings. Most modern ships use geared systems.

Example: A large container ship might use a slow-speed, direct drive system due to its immense size and power requirements. A smaller tugboat or fast ferry would likely use a geared system for improved maneuverability and efficiency.

Q 2. Describe the operation of a marine diesel engine.

A marine diesel engine, much like a car’s diesel engine, operates on the Diesel cycle. It’s a four-stroke internal combustion engine that burns fuel oil. The four strokes are:

- Intake: The piston moves down, drawing in air into the cylinder.

- Compression: The piston moves up, compressing the air to a high temperature and pressure.

- Power: Fuel is injected into the hot, compressed air, causing it to ignite spontaneously (auto-ignition). The expanding gases push the piston down, generating power.

- Exhaust: The piston moves up, expelling the burnt gases from the cylinder.

These four strokes are repeated continuously for each cylinder. Marine diesel engines are typically larger and more robust than their automotive counterparts, designed to handle the harsh conditions at sea and operate reliably for extended periods with minimal maintenance.

Practical Application: The size and type of marine diesel engine chosen are dependent on the vessel’s size, speed, and power requirements. Larger vessels often have multiple diesel engines operating in tandem.

Q 3. What are the common types of marine propellers and their applications?

Several types of marine propellers exist, each suited for different applications:

- Fixed-pitch propellers: The simplest type, with a constant blade angle. These are cost-effective but less efficient than controllable pitch propellers. Common on smaller vessels and those operating at consistent speeds.

- Controllable-pitch propellers (CPP): The blade angle can be adjusted while the propeller is rotating, allowing for optimal performance across a wide range of speeds and conditions. Highly efficient and versatile, typically used on larger vessels.

- Ducted propellers: The propeller is enclosed within a duct, improving efficiency and thrust, especially at lower speeds. Often found on tugs and vessels requiring high maneuverability in confined spaces.

- Supercavitating propellers: Designed to operate at high speeds, creating a vapor cavity around the blades to reduce drag. Used on high-speed vessels like torpedoes and hydrofoils.

Example: A cruise ship would likely use controllable-pitch propellers for efficient cruising at various speeds. A tugboat might use a ducted propeller for superior thrust in maneuvering large vessels.

Q 4. How does a controllable pitch propeller work?

A controllable-pitch propeller (CPP) adjusts its blade angle while rotating, allowing for precise control over thrust and speed. This is achieved by a hydraulic or electro-hydraulic system that changes the pitch of each blade individually. The system consists of a pitch-changing mechanism connected to the propeller hub and controlled from the bridge.

By changing the blade angle, the CPP can achieve:

- Forward thrust: The blades are pitched to create a forward force.

- Reverse thrust: The blades are pitched to reverse the propeller’s thrust.

- Variable thrust: The blade angle adjusts to provide varying amounts of thrust without changing engine speed.

This allows for better fuel efficiency and maneuverability compared to fixed-pitch propellers.

Q 5. Explain the function of a thrust bearing in a marine propulsion system.

The thrust bearing in a marine propulsion system is crucial for supporting the axial load (thrust) generated by the propeller. Imagine the propeller pushing against the water – this force needs to be transferred back to the engine without damaging the shaft or its bearings. The thrust bearing absorbs this substantial axial load, preventing the propeller shaft from moving fore and aft.

Typically, thrust bearings are either of the collar-type (using multiple collars and thrust faces) or Kingsbury-type (using tilting shoes). These bearings are designed to handle high loads and operate reliably in a marine environment.

Failure of the thrust bearing can lead to significant damage to the propulsion system and even endanger the vessel.

Q 6. Describe the process of shaft alignment in a marine propulsion system.

Shaft alignment in a marine propulsion system is critical for optimal performance and longevity. Misalignment can cause vibrations, excessive wear on bearings, and even shaft failure. The process involves precise alignment of the engine’s output shaft, intermediate shafts (if any), and the propeller shaft.

The process generally involves:

- Preparation: Ensuring the shafts are clean and free of obstructions.

- Measurement: Using specialized alignment tools (e.g., dial indicators, laser alignment systems) to measure the shaft alignment precisely.

- Adjustment: Carefully adjusting the coupling alignment using shims or other methods to achieve the desired alignment tolerances.

- Verification: Re-measuring and verifying the alignment after adjustments are made.

Modern alignment systems utilize laser technology for greater accuracy and efficiency. Proper shaft alignment significantly reduces wear and tear and ensures efficient power transmission.

Q 7. What are the different types of marine gears and their characteristics?

Marine gears are crucial for reducing the engine’s high rotational speed to a more appropriate speed for the propeller. Several types exist:

- Reduction gears: The most common type, using gears to decrease the engine’s speed. These can be single-reduction (one gear reduction stage) or double-reduction (two stages) depending on the speed reduction required.

- Reverse-reduction gears: These include a mechanism for reversing the propeller’s direction, allowing the vessel to go astern.

- Cycloidal gears: A more complex type offering high efficiency and a compact design, often used in specialized applications.

The characteristics of each gear type vary depending on factors such as efficiency, noise levels, size, weight, and cost. The choice of gear type depends on the specific propulsion system design and operational requirements of the vessel.

Example: Large container ships commonly use double-reduction gears due to the significant speed reduction required. Smaller vessels might opt for single-reduction gears for simpler design and lower cost.

Q 8. Explain the principles of cavitation and its effect on propeller performance.

Cavitation is the formation of vapor bubbles in a liquid due to a decrease in pressure. In marine propellers, this happens when the propeller blades move so fast that the pressure of the water around them drops below the vapor pressure of the water. These vapor bubbles then collapse violently as they move into areas of higher pressure, causing damage and reduced efficiency.

The effects on propeller performance are significant: reduced thrust, increased vibrations, noise, erosion of the propeller blades, and ultimately, a reduction in the vessel’s speed and fuel efficiency. Imagine trying to swim in a pool filled with popping bubbles – you’d struggle to move forward and your movements would be inefficient. Similarly, cavitation disrupts the smooth flow of water around the propeller, hindering its ability to generate thrust.

Several factors influence cavitation, including propeller design, speed of the vessel, water temperature, and the presence of air bubbles in the water. Proper propeller design, such as selecting the right pitch and diameter, is crucial to minimize cavitation. Maintaining a vessel’s hull clean and free from fouling also assists, ensuring a smoother flow of water around the propeller.

Q 9. How does a marine propulsion system contribute to the overall fuel efficiency of a vessel?

A well-designed and maintained marine propulsion system is paramount to a vessel’s fuel efficiency. It’s all about optimizing the energy transfer from the engine to the water. Several key aspects play a role:

- Engine efficiency: A modern, well-maintained engine with optimal fuel injection and combustion processes contributes directly to reducing fuel consumption.

- Propeller design: As mentioned earlier, a correctly designed propeller that minimizes cavitation and maximizes thrust for a given power input is crucial. This includes selecting the appropriate propeller pitch, diameter and shape for the specific vessel and operating conditions.

- Hull design: The hull’s shape significantly impacts water resistance. A hydrodynamically efficient hull minimizes drag, reducing the power required from the propulsion system. Fouling on the hull increases drag, thereby increasing fuel consumption.

- Transmission efficiency: The gearbox or other transmission components should be in good condition and properly lubricated to minimize energy loss during power transfer.

- Shaft alignment: Misalignment within the propulsion shafting system will lead to increased vibrations, power losses and premature wear, indirectly increasing fuel use.

Think of it as a chain: each link (engine, propeller, hull, transmission) must be strong and efficient for the entire system to work optimally. A weak link will compromise the overall efficiency, leading to higher fuel costs and reduced performance.

Q 10. Describe different types of marine engine monitoring systems.

Marine engine monitoring systems vary in complexity depending on the vessel’s size and type. They typically include:

- Basic monitoring systems: These often consist of gauges displaying engine speed (RPM), oil pressure, water temperature, and fuel level. They provide a basic overview of engine health.

- Electronic monitoring systems: More advanced systems use sensors and electronic displays to monitor a broader range of parameters, including exhaust gas temperature, fuel consumption rates, vibration levels, and even engine component temperatures. These often provide real-time data and allow for remote monitoring and diagnosis.

- Integrated monitoring systems: These integrate data from multiple systems aboard the vessel, including the engine, propulsion system, navigation, and auxiliary systems, providing a comprehensive overview of the vessel’s operation and condition. These may include sophisticated alarm systems and data logging capabilities.

- Data acquisition systems (DAS): DAS systems are capable of recording vast amounts of data from different sources providing critical insights into engine performance trends, allowing for predictive maintenance. The data is often analyzed to identify potential problems before they become major issues.

For example, a large container ship will utilize a highly sophisticated integrated system, whereas a smaller recreational boat might have a simpler, gauge-based monitoring system.

Q 11. What are the common causes of engine vibrations in a marine vessel?

Engine vibrations in marine vessels are a common issue, often stemming from several sources:

- Propeller imbalance: An unbalanced propeller is a major contributor to vibrations. This can be due to manufacturing defects, damage to a blade, or uneven fouling.

- Engine misalignment: Improper alignment of the engine, transmission, and propeller shafting causes significant vibrations. Even slight misalignment can induce substantial forces leading to increased wear and tear.

- Engine problems: Internal engine problems such as worn bearings, unbalanced rotating parts, or issues within the combustion cycle can generate vibrations.

- Hull resonance: The natural frequencies of the vessel’s hull may resonate with the frequency of the engine or propeller, amplifying vibrations. This is a design consideration and can be accounted for during the vessel construction process.

- Loose components: Loose parts in the engine or its mounting structure can cause vibrations, especially at certain engine speeds.

Identifying the root cause requires careful investigation, often involving vibration analysis using specialized equipment to pinpoint the source and frequency of the vibrations. This can often involve performing a shaft alignment check, a propeller balancing check and careful inspection of engine components.

Q 12. Explain the importance of regular maintenance for a marine propulsion system.

Regular maintenance is critical for ensuring the longevity, reliability, and efficiency of a marine propulsion system. Neglecting maintenance can lead to costly repairs, downtime, and even safety hazards.

Regular maintenance includes:

- Regular oil changes: Using the correct grade and type of lubricating oil is paramount for engine health. Following the manufacturer’s recommended oil change intervals is essential.

- Cooling system checks: Regular inspection of the cooling system (both fresh water and seawater) to identify leaks, corrosion and ensure proper functionality is crucial for preventing overheating.

- Fuel system maintenance: Regular cleaning of fuel filters and tanks prevents contamination and ensures smooth fuel delivery to the engine.

- Propeller inspections: Regular inspections of the propeller for damage, fouling, and corrosion are necessary to maintain its efficiency and prevent cavitation.

- Shaft alignment checks: As mentioned before, periodic shaft alignment checks are important to identify and correct misalignment before it causes significant damage or vibration issues.

- Exhaust system inspection: Leaks and obstructions in the exhaust system should be identified and resolved promptly for optimal performance.

Think of it like maintaining a car: regular servicing prevents major problems and keeps it running efficiently. Ignoring maintenance in a marine propulsion system carries far greater consequences due to the harsh marine environment and the greater potential for damage.

Q 13. How do you troubleshoot a propulsion system malfunction?

Troubleshooting a propulsion system malfunction requires a systematic approach:

- Safety First: Ensure the engine is shut down and all safety precautions are in place before commencing any troubleshooting.

- Gather Information: Collect information about the nature of the malfunction, when it occurred, and any preceding events. This includes reviewing any warning lights or error messages from monitoring systems.

- Visual Inspection: Conduct a thorough visual inspection of the engine, transmission, propeller, and associated systems looking for any obvious signs of damage, leaks, or loose components.

- System Checks: Check fuel supply, cooling system operation, lubrication systems, and electrical connections.

- Diagnostic Tools: Use diagnostic tools such as engine diagnostic software or multimeters to check key parameters and identify faults within the engine’s control systems.

- Component Testing: If necessary, individual components may need to be tested, potentially requiring removal and bench testing.

- Professional Assistance: For complex issues, seeking assistance from qualified marine engineers is advisable.

For instance, if the engine fails to start, the troubleshooting could involve checking the battery, fuel supply, starter motor, and ignition system. A systematic approach ensures the problem is addressed efficiently and effectively, avoiding unnecessary work and potential further damage.

Q 14. Describe the safety procedures related to working on a marine propulsion system.

Safety is paramount when working on a marine propulsion system. Procedures must adhere to strict safety guidelines:

- Lockout/Tagout Procedures: Before working on any part of the propulsion system, implement lockout/tagout procedures to prevent accidental startup. This is critical for preventing injury or death.

- Personal Protective Equipment (PPE): Use appropriate PPE, including safety glasses, gloves, hearing protection, and potentially respirators, depending on the task.

- Emergency Shutdown Procedures: Be familiar with the vessel’s emergency shutdown procedures and ensure they are readily accessible.

- Fire Prevention Measures: Take precautions to prevent fires, including keeping the work area clean and free of flammable materials. Have fire extinguishers readily available.

- Working at Heights: If working at heights, use appropriate safety harnesses and fall protection equipment.

- Confined Space Entry: If working in confined spaces (such as engine rooms), follow proper confined space entry procedures including atmospheric monitoring and standby personnel.

- Hot Surfaces: Be mindful of hot surfaces and take necessary precautions to prevent burns.

- Hazardous Materials: Handle hazardous materials (such as engine oil, fuel, or coolants) with care, following appropriate safety protocols.

Failure to follow safety procedures can result in serious injury or death. A thorough risk assessment prior to any work is essential, tailoring safety precautions to the specific tasks involved.

Q 15. What are the environmental regulations related to marine propulsion systems?

Environmental regulations for marine propulsion systems are increasingly stringent, aiming to reduce the impact of shipping on the marine environment. These regulations primarily focus on minimizing emissions of air pollutants and preventing water pollution.

- Air Pollution: The International Maritime Organization (IMO) has implemented the MARPOL Annex VI, which sets limits on sulfur oxides (SOx), nitrogen oxides (NOx), and particulate matter (PM) emissions from ships. This has led to the widespread adoption of Exhaust Gas Cleaning Systems (scrubbers) and the use of low-sulfur fuels. Future regulations are likely to focus on reducing greenhouse gas (GHG) emissions, possibly through carbon intensity targets or carbon trading schemes.

- Water Pollution: Regulations prohibit the discharge of oily bilge water, sewage, and garbage into the sea. Ballast water management is another crucial aspect, aimed at preventing the spread of invasive species through the discharge of ballast water. Regulations also govern the prevention of noise pollution from ships.

Compliance with these regulations is crucial for ship operators, impacting vessel design, fuel selection, and operational practices. Non-compliance can result in hefty fines and port state control detentions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the role of the propulsion control system?

The propulsion control system is the brain of a ship’s propulsion system. It manages the power delivered to the propeller(s), ensuring safe and efficient operation. Think of it as the driver of a car, responsible for speed control, maneuvering, and preventing damage.

Its functions include:

- Speed control: Precisely controlling the rotational speed of the propeller to maintain desired ship speed.

- Direction control: Controlling the direction of thrust for maneuvering, including reversing and turning.

- Power management: Optimizing fuel consumption by managing engine power according to operational needs.

- Protection: Implementing safety features to prevent engine damage, such as overload protection and low-lubrication oil alerts.

- Monitoring: Providing real-time feedback on system performance through data logging and displays, aiding in predictive maintenance.

Modern propulsion control systems often incorporate automation and advanced control algorithms for enhanced efficiency and safety. For example, they may use dynamic positioning systems to maintain a vessel’s position without anchors in challenging environments.

Q 17. Explain the working principle of a water jet propulsion system.

A water jet propulsion system uses a pump to draw water from the sea, accelerate it through a nozzle, and then discharge it at high velocity to generate thrust. Imagine a powerful vacuum cleaner, but instead of sucking up dirt, it sucks in water and shoots it out the back to propel the vessel forward.

Here’s a breakdown of the process:

- Intake: Water is drawn into the pump through an intake grate.

- Pumping: A high-speed pump increases the water’s velocity.

- Nozzle: The high-velocity water is directed through a nozzle, creating a high-pressure jet.

- Thrust Generation: The reaction force from the expelled water propels the vessel forward.

- Steering: The direction of the jet can be changed using a swiveling nozzle or multiple nozzles, allowing for steering and maneuvering.

Water jet propulsion is particularly suitable for shallow-draft vessels, as it eliminates the need for a deep propeller shaft. This makes it ideal for applications in shallow waters, such as in harbors or rivers.

Q 18. Describe the advantages and disadvantages of different types of propulsion systems.

Various propulsion systems cater to different vessel types and operational requirements. Each has its own set of advantages and disadvantages:

- Propellers:

- Advantages: High efficiency, relatively simple design, well-established technology.

- Disadvantages: Vulnerable to damage from debris, limited maneuverability in confined spaces, requires sufficient water depth.

- Water Jets:

- Advantages: Excellent maneuverability, suitable for shallow waters, less vulnerable to damage from debris.

- Disadvantages: Lower efficiency compared to propellers, more complex and costly than propellers.

- Podded Drives:

- Advantages: Enhanced maneuverability, increased efficiency due to azimuth thrusters, reduced vibrations.

- Disadvantages: High initial cost, complex design, potentially higher maintenance costs.

- Azimuth Thrusters:

- Advantages: 360-degree maneuverability, enhanced dynamic positioning capabilities.

- Disadvantages: Complex design, high cost, potentially lower efficiency compared to propellers.

The optimal choice depends on factors such as vessel size, operational profile, cost considerations, and environmental conditions.

Q 19. What are the key performance indicators (KPIs) for a marine propulsion system?

Key Performance Indicators (KPIs) for marine propulsion systems are crucial for assessing efficiency, reliability, and overall performance. These KPIs are essential for optimizing operational costs and preventing costly breakdowns.

- Fuel Consumption: Measured in grams of fuel per kilowatt-hour (g/kWh) or liters per nautical mile (l/nm). Lower fuel consumption indicates better efficiency.

- Propulsion Efficiency: The ratio of thrust power to brake power, indicating how effectively the engine power is converted into thrust. A higher efficiency percentage is desirable.

- Shaft Power: The power delivered to the propeller shaft. It’s crucial to monitor shaft power to ensure it aligns with engine power and prevents overloading.

- Reliability: Measured by the Mean Time Between Failures (MTBF). A higher MTBF suggests better system reliability and reduced downtime.

- Maintenance Costs: Tracking maintenance costs helps in identifying areas for improvement and optimizing maintenance strategies.

- Emissions: Monitoring SOx, NOx, PM, and GHG emissions helps assess compliance with environmental regulations.

Regular monitoring of these KPIs allows for proactive maintenance, identification of potential issues, and optimization of operational practices for enhanced efficiency and sustainability.

Q 20. How do you calculate the propeller efficiency?

Propeller efficiency is a crucial metric indicating how effectively the propeller converts the power it receives into thrust. It’s not a simple calculation, as it involves several factors, but a simplified representation can be given using the following formula:

ηp = ηh * ηo

Where:

ηpis the propeller efficiency.ηhis the hydrodynamic efficiency, representing how efficiently the propeller converts power into thrust considering factors like blade shape and water flow.ηois the open-water efficiency, accounting for the propeller’s performance in open water, separate from the hull’s influence.

Accurate calculation requires detailed hydrodynamic analysis using computational fluid dynamics (CFD) or empirical data from propeller open water tests. This data is often incorporated into design software, enabling engineers to optimize propeller design for maximum efficiency. Factors like propeller diameter, pitch, and blade shape significantly influence the efficiency.

Q 21. Explain the concept of shaft horsepower and brake horsepower.

Shaft horsepower (SHP) and brake horsepower (BHP) are both measures of power, but they represent different stages in the power transmission chain of a marine propulsion system. Think of it like this: BHP is the power produced by the engine, while SHP is the power actually delivered to the propeller.

- Brake Horsepower (BHP): This is the power measured at the engine’s output shaft, before any losses due to transmission occur. It represents the engine’s raw power output.

- Shaft Horsepower (SHP): This is the power transmitted to the propeller shaft. It’s lower than BHP because some power is lost due to friction in gears, bearings, and other components within the transmission system.

The difference between BHP and SHP represents the transmission losses. Understanding this difference is vital for assessing the efficiency of the power transmission system and identifying potential areas for improvement. For example, a significant discrepancy suggests potential issues with the transmission system, like worn bearings or misalignment.

Q 22. Describe the components of a marine propulsion system.

A marine propulsion system is the complex network of components responsible for moving a vessel through water. Think of it like a car’s engine, transmission, and wheels, but adapted for a maritime environment. Key components include:

- Prime Mover: This is the power source, typically a diesel engine, gas turbine, or electric motor. It generates the power needed to propel the ship.

- Transmission System: This transfers power from the prime mover to the propeller. This could be a gearbox (reducing engine speed for optimal propeller performance), a reduction gear, or a direct-drive system (common in electric propulsion).

- Propeller(s): These rotating blades convert rotational power into thrust, pushing the vessel through the water. Different propeller designs are optimized for varying vessel types and operational requirements. Some vessels utilize multiple propellers for enhanced maneuverability.

- Shafting: Connects the prime mover to the propeller(s), transferring the torque and rotational energy. This system includes bearings and seals to minimize friction and prevent leaks.

- Control System: This manages the speed and direction of the prime mover and propeller(s), enabling the vessel to maneuver effectively. Modern systems often incorporate sophisticated automation and remote control capabilities.

- Auxiliary Systems: These support the main propulsion system and include cooling systems, lubrication systems, and fuel systems. Their proper functioning is crucial for the reliability and safety of the whole propulsion system.

For example, a large container ship might use a massive diesel engine connected to a gearbox and a large diameter propeller, while a smaller fishing boat could use a smaller diesel engine with a direct drive to a smaller propeller.

Q 23. What are the different types of marine fuels and their impact on propulsion systems?

Marine fuels significantly impact propulsion system performance, efficiency, and environmental impact. The choice of fuel depends on factors like vessel size, operational profile, and environmental regulations. Common types include:

- Heavy Fuel Oil (HFO): A high-energy-density fuel, cost-effective but high in sulfur and particulate emissions. Its use is increasingly restricted in emission control areas (ECAs).

- Marine Gas Oil (MGO): A cleaner-burning alternative to HFO, with lower sulfur content. It’s widely used in ECAs but more expensive than HFO.

- Liquefied Natural Gas (LNG): A low-emission fuel, significantly reducing greenhouse gas and sulfur oxide emissions. Its infrastructure and storage require specialized equipment.

- Liquefied Petroleum Gas (LPG): Another low-emission option, but its energy density is lower than LNG.

- Biofuels: Derived from renewable sources, offering a potential pathway toward reducing carbon emissions. They’re currently under development and deployment at a smaller scale.

The impact on the propulsion system lies primarily in fuel compatibility. Engines are designed for specific fuel types, and using the wrong fuel can lead to damage, inefficiency, and increased emissions. The choice also influences the design of fuel storage and handling systems. For example, LNG requires cryogenic storage tanks, impacting vessel design and cost.

Q 24. What are the potential risks associated with different types of marine propulsion systems?

Different marine propulsion systems carry distinct risks. These risks often relate to safety, environmental impact, and operational efficiency. Examples include:

- Engine Failure: Any prime mover can fail, leading to loss of propulsion and potential hazards, especially in harsh weather conditions. Regular maintenance and redundancy systems (e.g., having multiple engines) mitigate this.

- Propeller Damage: Striking submerged objects or experiencing cavitation (formation of vapor bubbles around the propeller) can damage propellers, reducing efficiency or causing complete failure.

- Shaft Failure: Wear, corrosion, or fatigue can lead to shaft breakage, resulting in loss of propulsion and potential damage to the vessel.

- Fire and Explosion: Fuel systems pose fire and explosion risks, especially when dealing with flammable fuels like HFO, MGO, or LNG. Proper safety procedures and equipment are crucial.

- Environmental Pollution: Spills or leaks of fuel or lubricating oil can cause significant environmental damage. Prevention measures, such as double-hull designs and spill response plans, are vital.

- System Complexity: Modern propulsion systems are sophisticated, increasing the potential for system failures due to complex interactions. Proper training and diagnostics are essential.

Risk mitigation strategies include rigorous maintenance schedules, redundant systems, safety training for crew, and adherence to strict safety regulations and environmental standards.

Q 25. Explain the concept of dynamic positioning (DP) system in relation to propulsion.

Dynamic Positioning (DP) is a computer-controlled system that maintains a vessel’s position and heading without the use of anchors or mooring lines. It achieves this by using a combination of thrusters (azimuth thrusters, tunnel thrusters, etc.) and sophisticated control algorithms. The propulsion system plays a crucial role in DP because the thrusters are directly driven by the propulsion system’s power.

Imagine a ship needing to remain stationary above an underwater pipeline for maintenance. Without DP, the ship would drift due to wind, waves, and currents. DP continuously monitors the ship’s position and heading using GPS, motion sensors, and other data, and adjusts the thrusters’ power and direction to maintain the desired position and heading. This involves precise control of the propulsion system’s power output, ensuring efficient and stable vessel positioning.

DP systems are widely used in offshore operations, such as drilling, pipelaying, and subsea construction, where precise positioning is critical.

Q 26. How does the hull form influence the performance of the propulsion system?

The hull form, or the shape of the vessel’s underwater body, significantly influences the propulsion system’s performance. A well-designed hull minimizes resistance to movement through the water, thus improving efficiency and reducing the power required for propulsion. Key aspects include:

- Hull Shape and Length: A longer, slender hull generally creates less resistance, especially at higher speeds. The shape (e.g., bulbous bow) can reduce wave making resistance.

- Wetted Surface Area: A smaller wetted surface area means less frictional resistance, impacting the overall propulsive efficiency.

- Propeller-Hull Interaction: The hull’s shape around the propeller can impact propeller efficiency. A poorly designed hull can generate turbulence and vortices that negatively affect thrust and increase propeller shaft vibrations.

For example, a high-speed vessel may have a sleek, slender hull to minimize resistance, requiring a powerful but efficient propulsion system. In contrast, a bulk carrier might have a fuller hull form optimized for cargo capacity, potentially needing a less powerful propulsion system, but its fuel efficiency might be slightly lower.

Computational Fluid Dynamics (CFD) is now widely used to optimize hull designs for reduced resistance and improved propeller-hull interaction, leading to more efficient propulsion systems.

Q 27. What are the latest advancements in marine propulsion technology?

Marine propulsion technology is constantly evolving, driven by the need for increased efficiency, reduced emissions, and improved maneuverability. Recent advancements include:

- Electric Propulsion: Increasingly popular, particularly for larger vessels. This offers improved efficiency, greater flexibility in power distribution, and reduced noise and vibration. It often utilizes electric motors directly driving the propeller or podded propulsion units, where the motor and propeller are integrated into a single unit.

- Hybrid Propulsion Systems: Combine traditional prime movers (e.g., diesel engines) with electric motors, allowing the vessel to switch between different power sources for optimal efficiency. This allows for efficient operation at various speeds and loads.

- Advanced Propeller Designs: Innovations like ducted propellers, contra-rotating propellers, and optimized blade profiles enhance propeller efficiency and reduce cavitation.

- Fuel Cell Technology: Offers potential for zero-emission propulsion using hydrogen or other fuels. This is still under development for larger maritime applications but is showing promising results for smaller vessels.

- Automation and Control Systems: Advanced control systems enable optimized power management, predictive maintenance, and automated navigation, leading to improved efficiency and reduced operational costs.

These advancements not only improve the economic and operational aspects of vessel operation but also contribute to a more environmentally sustainable maritime industry.

Q 28. Describe your experience with troubleshooting and maintaining marine propulsion systems.

Throughout my career, I’ve extensively worked with various marine propulsion systems, ranging from small outboard engines to large diesel-electric systems on commercial vessels. My troubleshooting experience frequently involves systematically investigating performance issues or breakdowns. My approach typically follows these steps:

- Data Gathering: First, I collect all relevant data, including engine performance parameters (e.g., fuel consumption, exhaust temperatures, RPM), propeller performance, and any error codes. Visual inspections are also crucial, looking for any obvious signs of leaks, damage, or unusual vibrations.

- Diagnosis: Based on the collected data, I proceed with a diagnostic analysis, pinpointing the likely source of the problem. This might involve checking fuel quality, analyzing lubrication oil, inspecting the shaft alignment, or using specialized diagnostic tools.

- Repair or Replacement: Once the problem is identified, I either carry out the necessary repairs or recommend replacement of faulty components. This requires a deep understanding of engine and system mechanics.

- Testing and Verification: After repairs, thorough testing is crucial to verify the system’s proper operation and to ensure the problem has been resolved effectively.

For example, I once worked on a case where a vessel experienced a significant loss of propulsion. After investigating, I discovered that a faulty bearing in the reduction gear was causing excessive friction, leading to a reduction in power transmission. Replacing the bearing restored the propulsion system to its optimal performance. My experience covers routine maintenance tasks such as oil changes, filter replacements, and inspections, as well as complex repairs requiring specialized knowledge and tools.

Key Topics to Learn for Understanding of Marine Propulsion Systems Interview

- Types of Marine Propulsion Systems: Understand the differences and applications of various propulsion systems, including propeller-driven systems, water jets, and azipods. Consider their relative advantages and disadvantages in different operational contexts.

- Propeller Theory and Design: Grasp the fundamental principles of propeller thrust generation, efficiency, and cavitation. Be prepared to discuss propeller selection criteria based on vessel type and operational requirements.

- Engine Room Systems Integration: Demonstrate understanding of how propulsion systems interact with other engine room components, such as main engines, gearboxes, shafting, and control systems. Be ready to discuss troubleshooting scenarios involving multiple system failures.

- Maintenance and Troubleshooting: Familiarize yourself with common maintenance procedures, fault diagnosis techniques, and preventative measures related to marine propulsion systems. Practice explaining your problem-solving approach.

- Performance Monitoring and Optimization: Understand the importance of monitoring key performance indicators (KPIs) related to propulsion efficiency and fuel consumption. Be able to discuss strategies for optimizing performance and minimizing operational costs.

- Regulations and Safety: Demonstrate knowledge of relevant international maritime regulations and safety standards related to marine propulsion systems and their operation. This includes aspects of pollution prevention and environmental protection.

- Emerging Technologies: Stay updated on advancements in marine propulsion technologies, such as hybrid and electric propulsion systems, and their potential impact on the industry.

Next Steps

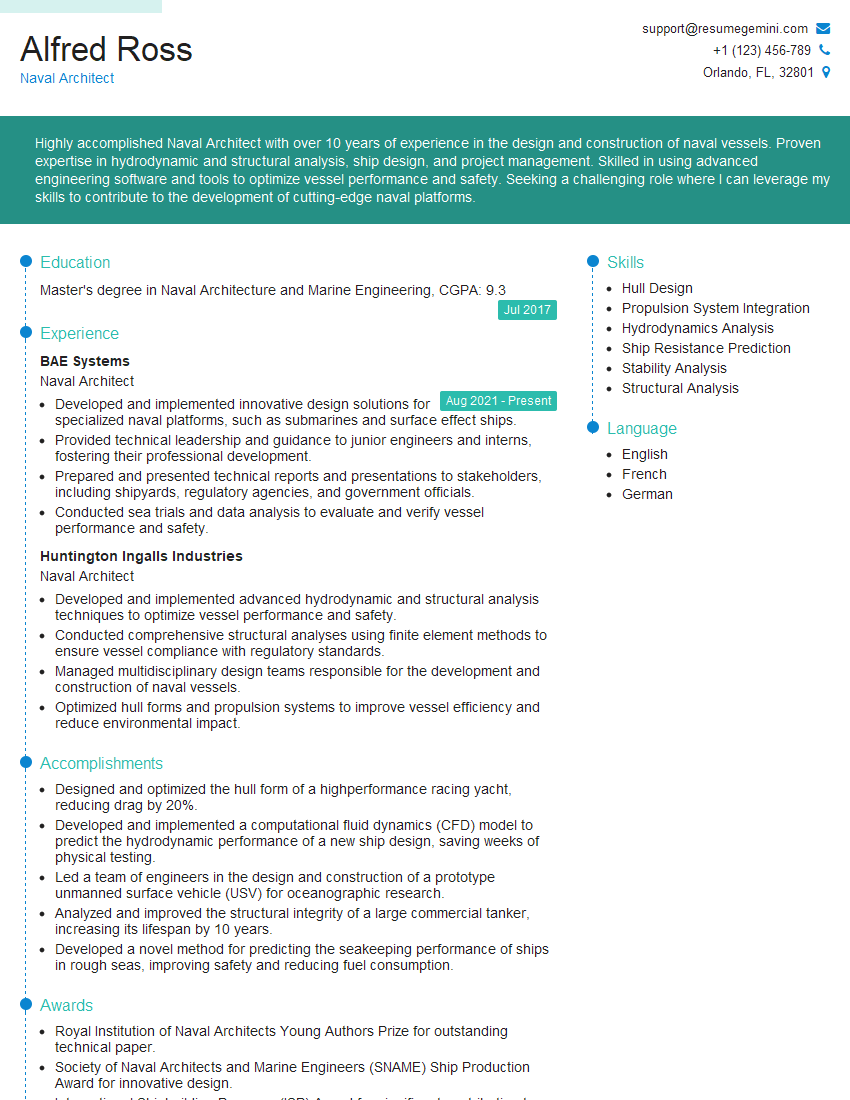

Mastering marine propulsion systems is crucial for career advancement in the maritime industry, opening doors to specialized roles and higher earning potential. A strong understanding of these systems showcases your technical expertise and problem-solving abilities, making you a highly valuable asset to any employer. To maximize your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your application stands out. We provide examples of resumes tailored to marine propulsion systems expertise to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO