The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Understanding of Crude Oil and Refined Products interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Understanding of Crude Oil and Refined Products Interview

Q 1. Explain the difference between sweet and sour crude oil.

The terms “sweet” and “sour” crude oil refer to the sulfur content. Sweet crude oil has a low sulfur content (generally less than 0.5% by weight), while sour crude oil has a high sulfur content (generally greater than 0.5% by weight). This seemingly small difference significantly impacts processing and pricing.

Sweet crude is easier and cheaper to refine because less processing is needed to remove sulfur compounds, which are harmful to the environment and refinery equipment. They also produce cleaner-burning fuels. Think of it like this: sweet crude is the easier-to-prepare ingredient; it’s ready to be used with minimal effort.

Sour crude requires more extensive and costly processing to remove the sulfur, often involving complex hydrodesulfurization units. The sulfur needs to be removed to meet environmental regulations and prevent corrosion in engines. Think of it like a tougher ingredient that requires more steps in preparation before it’s usable.

Q 2. Describe the process of fractional distillation in a refinery.

Fractional distillation is the cornerstone of crude oil refining. It’s a physical separation process that leverages the different boiling points of various hydrocarbons present in crude oil. Imagine boiling a pot of mixed vegetables – each vegetable will boil at a slightly different temperature.

The process begins with heating the crude oil to a very high temperature in a furnace. This vaporizes the oil. The resulting vapor then enters a tall distillation column (fractionating tower), which is progressively cooler at higher levels. As the vapor rises, different hydrocarbon fractions condense at different heights, depending on their boiling points.

- Heavier fractions, with higher boiling points (like bitumen and fuel oil), condense lower down in the column.

- Lighter fractions, with lower boiling points (like gasoline and naphtha), condense higher up.

Each fraction is then collected separately. These fractions are then further processed into various refined products such as gasoline, diesel, jet fuel, and others through processes like cracking, alkylation, and isomerization.

Q 3. What are the key properties of gasoline, diesel, and jet fuel?

Gasoline, diesel, and jet fuel, while all derived from crude oil, possess distinct properties that cater to their respective applications.

- Gasoline: High volatility (it evaporates easily) is essential for starting a car engine. It also needs a specific octane rating (a measure of its resistance to knocking or pinging during combustion) to prevent engine damage. A higher octane number is better.

- Diesel: Higher density and viscosity (thickness) compared to gasoline. It’s designed for compression ignition engines, which ignite fuel by compression rather than a spark. Cetane number, analogous to octane in gasoline, measures its ignition quality.

- Jet fuel: Needs a narrow boiling point range for smooth combustion at high altitudes. It requires excellent thermal stability to withstand high temperatures in jet engines and low freezing points to operate in extremely cold conditions.

These differences are crucial for safety and optimal performance in their respective applications. For instance, using diesel in a gasoline car would lead to engine failure.

Q 4. How does API gravity affect crude oil pricing?

API gravity is a measure of how heavy or light a crude oil is compared to water. A higher API gravity indicates lighter crude oil, and a lower API gravity indicates heavier crude oil. API gravity directly impacts crude oil pricing because lighter crudes are generally more valuable.

Lighter crude oils are easier to refine and yield a higher proportion of valuable light products like gasoline. Heavier crudes require more processing and yield more heavy products like fuel oil, which are less profitable. Therefore, crudes with a higher API gravity typically fetch a higher price in the market.

For example, a West Texas Intermediate (WTI) crude with an API gravity of 39° would command a higher price than a similar volume of crude oil from another region with an API gravity of 25°.

Q 5. What are the different types of crude oil benchmarks (e.g., Brent, WTI)?

Crude oil benchmarks serve as reference prices for different types of crude oil traded globally. They provide a standard against which other crudes are priced. Some key benchmarks include:

- Brent Crude: A blend of several crudes produced in the North Sea. It’s considered a global benchmark and significantly influences global oil prices.

- West Texas Intermediate (WTI): A light, sweet crude oil primarily produced in the United States. It’s a key benchmark for North American crude oil.

- Dubai Crude: A medium-sour crude oil produced in the Middle East. It’s a major benchmark for Asian markets.

- Oman Crude: Another Middle Eastern benchmark, often used as a reference price in Asian trading.

These benchmarks differ in their quality (API gravity, sulfur content), location, and trading volumes, which affect their pricing. For instance, Brent Crude’s price often differs from WTI’s, reflecting regional supply and demand.

Q 6. Explain the concept of crude oil refining margins.

Crude oil refining margins represent the difference between the price of crude oil and the value of the refined products derived from it. In simpler terms, it’s the profit a refinery makes after processing crude oil into usable products like gasoline and diesel.

These margins fluctuate constantly based on several factors, including crude oil prices, the prices of refined products (gasoline, diesel, etc.), and operating costs of the refinery. A high refining margin indicates strong profitability for refineries. Conversely, low or negative margins suggest that refineries are losing money on their operations.

For example, if the cost of crude oil is $70 per barrel, and the value of the refined products derived from that barrel is $85, then the refining margin is $15 per barrel. This is a simplified example, as actual margin calculations are more complex and take into account various byproducts and operating costs.

Q 7. What factors influence the price of crude oil?

Crude oil prices are influenced by a complex interplay of several factors, making them highly volatile. Some key drivers are:

- Geopolitical events: Political instability, wars, and sanctions in major oil-producing regions can significantly disrupt supply and boost prices.

- Supply and demand dynamics: Global supply shortages, driven by factors like production cuts by OPEC or natural disasters, push prices upwards. Increased global demand, often linked to economic growth, also boosts prices.

- OPEC decisions: The Organization of the Petroleum Exporting Countries (OPEC) significantly influences global oil supply through coordinated production decisions. OPEC’s decisions can significantly affect prices.

- Economic growth: Strong economic growth globally leads to increased energy consumption and thus higher oil demand, influencing prices.

- Currency fluctuations: Oil is priced in US dollars. Changes in the dollar’s value against other currencies influence the price of oil for buyers in different countries.

- Technological advancements: Technological breakthroughs in exploration and production can impact the cost of extraction and affect supply, thus influencing prices.

- Seasonal variations: Demand for heating oil in winter months tends to increase prices.

These factors are interconnected and influence each other, making it challenging to predict oil prices with complete accuracy. Analyzing these factors is crucial for oil traders, investors, and energy companies.

Q 8. Describe the process of cracking in petroleum refining.

Cracking is a crucial process in petroleum refining where large, complex hydrocarbon molecules in crude oil are broken down into smaller, more valuable molecules like gasoline and other lighter products. Imagine it like breaking a giant LEGO castle into smaller, more useful bricks. There are two main types: thermal cracking and catalytic cracking.

Thermal Cracking: This older method relies on high temperatures (around 450-550°C) and pressure to break the bonds in the larger hydrocarbon chains. While simpler, it produces a lower yield of desirable products and more undesirable byproducts.

Catalytic Cracking: This modern method uses catalysts (typically zeolites) to facilitate the breaking of bonds at lower temperatures and pressures. This leads to a higher yield of gasoline and other valuable products, such as LPG (Liquefied Petroleum Gas), and fewer undesirable byproducts. Catalysts act like tiny helpers, speeding up the reaction and making it more efficient. Think of them as specialized tools that make the LEGO castle demolition much more precise and productive.

The cracked products are then separated through fractional distillation based on their boiling points, yielding various refined products tailored for different applications.

Q 9. What are the environmental concerns associated with crude oil extraction and refining?

Crude oil extraction and refining present significant environmental challenges. Extraction processes can lead to habitat destruction, water pollution (from produced water and oil spills), and greenhouse gas emissions (methane, for example). Refining activities, while essential, generate air pollution from burning fossil fuels and releasing various pollutants such as sulfur oxides (SOx) and nitrogen oxides (NOx), contributing to acid rain and smog. The refining process also generates wastewater containing various hydrocarbons and other pollutants that need careful treatment to prevent water contamination.

Furthermore, the transportation of crude oil and refined products, whether by pipeline, tanker, or truck, poses risks of spills and accidents leading to substantial environmental damage. The long-term effects of climate change, exacerbated by the combustion of petroleum products, pose the most significant concern, impacting weather patterns, sea levels, and ecosystems worldwide.

Mitigating these concerns requires employing environmentally friendly extraction techniques, implementing stringent emission control measures in refineries, investing in renewable energy sources, and developing efficient and safe transportation systems. Improved waste management and responsible disposal of refinery byproducts are equally important.

Q 10. Explain the role of sulfur content in crude oil and refined products.

Sulfur content in crude oil and refined products is a critical factor influencing both environmental impact and product quality. Crude oil can contain varying levels of sulfur compounds, ranging from negligible amounts to several percent by weight. These sulfur compounds are undesirable for several reasons:

- Environmental Impact: When petroleum products containing sulfur are burned, they release sulfur oxides (SOx) into the atmosphere. SOx contribute to acid rain, air pollution, and respiratory problems.

- Product Quality: Sulfur compounds can corrode engines and reduce the performance and lifespan of catalysts in vehicles. They can also produce unpleasant odors.

Therefore, refineries employ various processes, such as hydrodesulfurization (HDS), to remove sulfur from crude oil and refined products. HDS involves reacting sulfur compounds with hydrogen at high pressure and temperature in the presence of a catalyst to convert them into hydrogen sulfide (H2S), which is then captured and treated or converted into elemental sulfur. The resulting refined products have much lower sulfur content, meeting stricter environmental regulations and improving product quality.

Q 11. What are the different types of petroleum products and their applications?

Petroleum refining yields a vast array of products with diverse applications. Some key examples include:

- Gasoline: The primary fuel for automobiles and other internal combustion engines.

- Diesel Fuel: Used in heavy-duty vehicles, trains, and ships.

- Jet Fuel: Powers aircraft.

- LPG (Liquefied Petroleum Gas): Used for cooking, heating, and as a vehicle fuel.

- Kerosene: Used as a fuel for lighting and heating, and as a jet fuel component.

- Fuel Oil: Used for heating and power generation.

- Lubricating Oils: Used to reduce friction in engines and machinery.

- Asphalt: Used in road construction.

- Petrochemicals: Used as building blocks for plastics, synthetic fibers, fertilizers, and many other products.

The specific properties of each product, such as boiling point, viscosity, and sulfur content, are carefully controlled during refining to meet the demands of various applications.

Q 12. What are the key components of a refinery?

A modern petroleum refinery is a complex network of interconnected processing units. Key components include:

- Distillation Units (Fractionators): Separate crude oil into fractions based on boiling point ranges.

- Conversion Units (Cracking, Hydrocracking, Coking): Convert heavier fractions into lighter, more valuable products.

- Treatment Units (Hydrodesulfurization, Alkylation, Isomerization): Improve the quality of refined products by removing impurities and enhancing their properties.

- Blending Units: Combine different refined products to create specific blends for different applications.

- Storage Tanks: Store crude oil, intermediate products, and finished products.

- Utilities and Support Systems: Provide necessary services such as power, steam, water, and waste treatment.

The layout and configuration of these units can vary depending on the refinery’s size, design, and the types of products it produces.

Q 13. How is crude oil transported?

Crude oil transportation is a multifaceted operation involving various modes of transport, each with its own advantages and disadvantages:

- Pipelines: The most efficient and cost-effective method for long-distance transportation, minimizing environmental risks compared to other modes. Pipelines, however, require significant upfront investment and are not always geographically feasible.

- Tankers (Sea): Essential for transporting crude oil across vast oceans, connecting producing countries to refineries worldwide. However, maritime transport poses risks of spills and accidents, along with security concerns.

- Tanker Trucks and Rail Cars: Primarily used for shorter distances, connecting refineries to distribution centers and consumers. These are less efficient than pipelines for large volumes but offer greater flexibility.

The choice of transportation method depends on factors like distance, volume, cost, and environmental considerations. Often, a combination of methods is used to move crude oil from wellhead to refinery.

Q 14. Explain the concept of octane rating in gasoline.

The octane rating of gasoline measures its resistance to knocking or pinging during combustion in an engine. Knocking occurs when the air-fuel mixture ignites prematurely, creating a sharp metallic sound and potentially damaging the engine. A higher octane rating indicates greater resistance to knocking.

The octane rating is determined by comparing the fuel’s anti-knock characteristics to those of a mixture of isooctane (2,2,4-trimethylpentane), which has an octane rating of 100, and n-heptane, which has an octane rating of 0. For example, a gasoline with an octane rating of 92 means it has the same anti-knock properties as a mixture of 92% isooctane and 8% n-heptane.

Engine design and operating conditions affect the required octane rating. High-performance engines often require higher octane fuel to prevent knocking under high compression ratios and demanding operating conditions. Lower octane fuel can be used in engines with lower compression ratios, but using higher octane fuel than necessary doesn’t significantly improve performance or fuel efficiency.

Q 15. What is the significance of viscosity in petroleum products?

Viscosity is a crucial property of petroleum products, essentially measuring a fluid’s resistance to flow. Think of it like this: honey is highly viscous, flowing slowly, while water is less viscous and flows easily. In petroleum, viscosity directly impacts how easily the product can be transported through pipelines, processed in refineries, and ultimately used in applications such as lubrication or fuel combustion.

Higher viscosity fuels, for example, might be suitable for heavy-duty machinery requiring thicker lubrication, while lower viscosity fuels are preferred for efficient combustion in vehicles and power generation. The viscosity of a product is heavily influenced by its chemical composition and temperature. Measuring and controlling viscosity is critical throughout the petroleum industry, from extraction to end-use. For instance, refiners use various techniques, such as blending and cracking, to adjust the viscosity of crude oil into various products meeting specific specifications. Incorrect viscosity can lead to operational issues such as pipeline blockages or inefficient engine performance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe different methods for crude oil exploration.

Crude oil exploration involves a multi-stage process using a combination of geological studies, geophysical surveys, and drilling. It begins with geological studies that analyze surface rock formations, seismic data, and other indicators to identify potential subsurface hydrocarbon traps.

- Seismic surveys use sound waves to map subsurface structures. Imagine sending sound waves into the earth; the reflections tell us about different rock layers and potential oil reservoirs. This is like using ultrasound to image a baby in the womb, but on a much larger scale.

- Gravity and magnetic surveys measure variations in the Earth’s gravitational and magnetic fields, helping to identify subsurface density and magnetic anomalies associated with hydrocarbon accumulations. These methods are similar to detecting a hidden object by its subtle influence on its surroundings.

- Exploratory drilling is the final step, involving drilling a well to directly sample and test the presence of hydrocarbons. This is the most expensive and high-risk step, but crucial to confirm the presence and quality of oil.

After drilling, the collected samples are analyzed to determine the type and quantity of hydrocarbons present. These explorations require substantial investment and advanced technology to optimize the chances of successful discovery. The whole process is a carefully orchestrated endeavor that blends scientific knowledge and risk management.

Q 17. What are the challenges in managing crude oil storage?

Managing crude oil storage presents several significant challenges. The primary concern is safety. Crude oil is highly flammable and can pose environmental risks if there is a spill. Therefore, storage facilities require robust safety measures including fire suppression systems, leak detection systems, and emergency response plans. Moreover, theft is another significant threat. Crude oil is a valuable commodity, and storage facilities are potential targets for theft. Hence, tight security measures, such as surveillance systems, access controls, and armed guards, are necessary.

Further, environmental protection is crucial. Storage tanks need to be properly maintained to prevent leaks, and measures need to be taken to address potential environmental damage, including spill response and remediation plans. Finally, storage capacity and logistics are also challenging. Efficient storage management requires careful planning and coordination to ensure adequate capacity to meet demand while minimizing storage costs and optimizing logistics for transportation.

Q 18. How does geopolitical instability affect crude oil prices?

Geopolitical instability significantly impacts crude oil prices due to its influence on supply and demand. Instability can disrupt oil production and transportation, leading to supply shortages and price spikes. For instance, wars, political unrest, or sanctions against major oil-producing nations can restrict oil exports, causing prices to rise. Conversely, political stability in oil-producing regions can lead to increased supply and lower prices.

Consider the impact of the 2022 Russia-Ukraine conflict: sanctions imposed on Russia (a major oil exporter) caused global energy markets to become volatile, resulting in significantly increased oil and gas prices worldwide. The perception of risk in certain regions also plays a role. If investors believe there’s a high chance of disruption in a major oil-producing area, they might push up prices proactively. Therefore, global events directly influence the perception of oil supply security and consequently its price.

Q 19. Explain the concept of oil reserves and their classification.

Oil reserves refer to the estimated quantity of crude oil that can be economically extracted from known reservoirs. They are classified based on the level of certainty regarding their extraction. This classification is essential for policymakers and investors in assessing the future availability of oil resources. Think of it like this: you have a bank account. ‘Proven reserves’ are like the money you have readily available in your checking account – you know you can access it immediately. The other categories represent increasingly less certain future resources.

- Proven Reserves (P1): A high degree of certainty of recovery at current prices and technology.

- Probable Reserves (P2): A moderate degree of certainty of recovery at current prices and technology.

- Possible Reserves (P3): A low degree of certainty of recovery at current prices and technology.

The classification of oil reserves helps in making informed decisions about investments, production planning, and energy policies. It helps countries and companies understand the lifespan of their oil resources and plan for the future.

Q 20. What are the different types of oil and gas contracts?

Oil and gas contracts define the terms and conditions under which oil and gas are explored, produced, and sold. They vary significantly based on the legal and regulatory frameworks of different countries and the specific circumstances of each project. There is no one-size-fits-all contract.

- Production Sharing Contracts (PSCs): These contracts involve a government granting a company the right to explore and produce oil and gas in exchange for a share of the production. The government retains ownership of the resources, while the company bears the exploration and production costs.

- Concessions: Under this model, the government grants a company exclusive rights to explore and produce oil and gas within a specific area for a specified period. The company retains ownership of the produced hydrocarbons, usually paying royalties and taxes to the government.

- Joint Venture Agreements: This involves the sharing of exploration and production costs and risks among multiple companies, often with varying equity stakes.

- Service Contracts: The government retains ownership of the resources and contracts with a company to provide services for exploration and production. The company is paid for its services, rather than taking a share of the production.

The choice of contract depends on various factors, including the level of risk involved, the size of the project, and the government’s regulatory framework. Each contract type has its own advantages and disadvantages for both the government and the operating companies. Careful negotiation and understanding of the legal and commercial implications are crucial in drafting and executing these contracts.

Q 21. Explain the process of oil and gas well completion.

Oil and gas well completion is the process of preparing a newly drilled well for production. It involves a series of operations after drilling that make the well capable of efficiently producing hydrocarbons. Think of it as preparing a house after the foundation has been laid: you need to install plumbing, wiring, and other essential systems before you can move in. Similarly, well completion prepares a well for production.

The process typically involves:

- Running casing and cementing: Steel pipes (casing) are inserted into the wellbore and cemented in place to stabilize the well and prevent the collapse of the formation.

- Perfoming the wellbore: Creating pathways (perforations) in the casing and cement to allow hydrocarbons to flow from the reservoir into the wellbore. This is like creating openings to allow water to flow into a pipe.

- Installing completion equipment: Installing valves, packers, and other equipment to control the flow of hydrocarbons, manage pressure, and prevent leaks. This is akin to installing valves and controls for a water distribution system.

- Testing the well: Performing tests to evaluate the well’s productivity and ensure everything functions correctly.

The specific well completion techniques employed depend on various factors, including reservoir pressure, the type of hydrocarbons being produced, and the well’s geological characteristics. Proper completion is critical for maximizing production and ensuring the well’s safety and longevity.

Q 22. Discuss the role of catalysts in refining processes.

Catalysts are essential in oil refining, acting as crucial components in many processes. They significantly speed up chemical reactions without being consumed themselves, allowing for more efficient and cost-effective production of refined products. Think of them as matchmakers, bringing together molecules to react at a much faster rate than would occur naturally. This is particularly important in processes like cracking and reforming, where large hydrocarbon molecules are broken down into smaller, more valuable ones, or rearranged to improve their properties.

- Fluid Catalytic Cracking (FCC): This is a prime example. In FCC, a powdered catalyst (typically zeolite) is mixed with hot, heavy oil fractions. The catalyst facilitates the breaking of large molecules into smaller, more desirable gasoline and diesel components. Without the catalyst, the reaction would be far too slow and inefficient.

- Hydrocracking: This process uses a catalyst under high pressure with hydrogen to convert heavy oil into lighter products like diesel and kerosene. The catalyst here assists in breaking carbon-carbon bonds and adding hydrogen, enhancing the quality and yield of the desired products.

- Reforming: This process uses a catalyst (often platinum or other metals) to rearrange the molecules in naphtha to produce higher-octane gasoline components. The catalyst facilitates the isomerization and dehydrogenation reactions needed to improve the gasoline’s anti-knock properties.

The choice of catalyst is critical, as different catalysts are optimized for different reactions and feedstocks. Catalyst deactivation is also a significant concern, requiring regular regeneration or replacement to maintain optimal refinery performance.

Q 23. What is the impact of biofuels on the petroleum industry?

Biofuels are increasingly impacting the petroleum industry, presenting both opportunities and challenges. They offer a renewable alternative to fossil fuels, driving a shift toward a more sustainable energy mix. However, their integration into existing petroleum refining infrastructure requires significant adjustments.

- Increased Competition: Biofuels, such as biodiesel and bioethanol, are competing with petroleum-based fuels, potentially reducing the demand for traditional refined products. This necessitates strategic adaptation by petroleum companies.

- Blending and Infrastructure Changes: Many countries mandate the blending of biofuels with gasoline and diesel. This requires modifications to refineries to accommodate the blending process and potentially changes to the distribution networks.

- New Refining Technologies: The production of advanced biofuels may necessitate investments in new refining technologies, which can be capital-intensive. This includes processes for converting biomass to fuels such as renewable diesel.

- Sustainability Concerns: The environmental impact of biofuel production must be carefully assessed. Concerns about deforestation, water usage, and fertilizer runoff necessitate sustainable practices to ensure true environmental benefits.

In summary, biofuels are forcing the petroleum industry to evolve, fostering innovation in renewable energy and demanding a shift towards a more diversified and sustainable approach to fuel production and consumption. The long-term success will depend on balancing the economic viability of biofuels with their environmental sustainability.

Q 24. Explain the concept of crude oil assay.

Crude oil assay is a comprehensive analysis of a crude oil sample to determine its physical and chemical properties. This information is vital for determining the suitability of the crude for refining and for optimizing the refining process to maximize the yield of valuable products.

The assay typically includes:

- Density and Gravity (API Gravity): Indicates the heaviness or lightness of the crude. Lighter crudes (higher API gravity) are generally easier and more profitable to refine.

- Sulfur Content: High sulfur content can lead to environmental problems and requires additional processing to remove it (hydrodesulfurization).

- Distillation Curve: Shows the boiling point distribution of the hydrocarbon components in the crude, helping to predict the yields of various refined products like gasoline, kerosene, and diesel.

- Compositional Analysis (Gas Chromatography): A detailed analysis of the different hydrocarbon types (paraffins, naphthenes, aromatics) in the crude. This provides insight into the suitability of the crude for specific refining processes.

- Metals Content (Vanadium, Nickel): These metals can foul catalysts during refining, so their levels are important for process optimization and catalyst selection.

The assay results form the basis for selecting appropriate refining processes and predicting the yields of different products. It’s essentially the blueprint that guides the refinery’s operations for a particular crude oil.

Q 25. How does the composition of crude oil affect refining processes?

The composition of crude oil significantly influences the refining process and the types of products that can be economically produced. Different crude oils have varying ratios of hydrocarbons, sulfur content, and other impurities, each impacting refinery operations.

- API Gravity: Lighter crudes (high API gravity) typically yield more gasoline and other light products. Heavier crudes (low API gravity) need more extensive processing (e.g., cracking) to produce lighter fractions, leading to different refinery configurations and potentially lower yields of high-value products.

- Sulfur Content: High-sulfur crudes require more extensive hydrodesulfurization, adding to refining costs and complexity. This process reduces sulfur emissions, complying with environmental regulations but increasing the overall refining cost.

- Asphaltenes and Resins: High concentrations of these components can lead to fouling and operational problems in the refinery, requiring special processing techniques to handle them.

- Metals Content: As mentioned, high metal content (vanadium, nickel) can deactivate catalysts, necessitating frequent catalyst regeneration or replacement and impacting operational efficiency.

Therefore, refineries are designed to handle specific crude oil types or blends of crudes. The crude oil’s properties dictate the refining strategy, the choice of processing units, and ultimately, the economic viability of the refining operation. Imagine trying to bake a cake with the wrong ingredients—the result won’t be optimal, and similarly, refining the wrong crude in the wrong way leads to inefficiency and lower profitability.

Q 26. Describe the various methods for improving the quality of refined products.

Improving the quality of refined products involves a range of techniques focusing on enhancing properties like octane rating (for gasoline), cetane number (for diesel), and sulfur content. These improvements are crucial for meeting environmental regulations and consumer demands.

- Alkylation: Combines smaller molecules (olefins and isoparaffins) to produce high-octane gasoline components. This boosts the gasoline’s anti-knock properties.

- Isomerization: Rearranges the molecular structure of hydrocarbons to improve their octane or cetane ratings. This increases the efficiency and performance of the fuel.

- Hydrodesulfurization (HDS): Removes sulfur compounds from refined products, reducing sulfur emissions and improving the environmental performance of the fuels. This is critical for meeting stringent environmental regulations.

- Treatment Processes: Several processes like solvent extraction, adsorption, and filtration are used to remove impurities like waxes, aromatics, and other undesirable components from fuels to improve their quality and stability. For instance, treating diesel to remove wax improves its low-temperature properties.

- Blending: Combining different refined products or adding additives to optimize their properties for specific applications. For example, blending different gasoline components to achieve the desired octane rating.

The specific methods used depend on the desired product quality, the feedstock properties, and the economic constraints. The goal is always to create high-quality, environmentally friendly products that meet consumer demand and satisfy regulatory requirements.

Q 27. What are the regulations and safety measures involved in handling crude oil and refined products?

Handling crude oil and refined products involves stringent regulations and safety measures due to their flammability, toxicity, and potential environmental impact. These regulations are designed to prevent accidents, protect workers, and minimize environmental damage.

- Occupational Safety and Health Administration (OSHA) Regulations: These regulations cover worker safety, including personal protective equipment (PPE), emergency response procedures, and hazardous waste management.

- Environmental Protection Agency (EPA) Regulations: These address air and water emissions, waste disposal, and spill prevention and response. They set limits on the amount of pollutants that can be released into the environment.

- Transportation Regulations: Strict regulations govern the transportation of crude oil and refined products by pipelines, tankers, and trucks. These include safety standards for vehicles and infrastructure to prevent leaks and spills.

- Storage Regulations: Regulations control the design, construction, and operation of storage tanks to prevent leaks, spills, and fires. This involves regular inspections, maintenance, and safety systems.

- Emergency Response Plans: Refineries and other facilities handling crude oil and refined products must have comprehensive emergency response plans to deal with spills, fires, or other emergencies. This includes training personnel, equipment, and procedures for containment and cleanup.

Failure to comply with these regulations can result in significant fines, legal action, and reputational damage. A strong safety culture and adherence to best practices are critical for responsible handling of these materials.

Q 28. Discuss the future trends and challenges facing the oil and gas industry.

The oil and gas industry faces numerous challenges and trends that will shape its future. These include the transition to renewable energy, technological advancements, geopolitical factors, and environmental concerns.

- Energy Transition: The global shift towards renewable energy sources (solar, wind, etc.) is a major challenge, potentially reducing the long-term demand for fossil fuels. The industry must adapt by diversifying into renewable energy or developing carbon capture and storage technologies.

- Technological Advancements: Advancements in areas such as artificial intelligence, machine learning, and robotics are transforming operations, improving efficiency and safety, and enabling the development of new resources.

- Geopolitical Instability: Global political events and conflicts significantly influence oil and gas prices and supply chains, demanding strategic planning and risk management.

- Environmental Regulations: Increasingly stringent environmental regulations are driving the need for cleaner production processes, emissions reduction, and responsible environmental stewardship. This includes reducing methane emissions and developing carbon-neutral operations.

- Resource Depletion: The finite nature of fossil fuel resources necessitates exploring new reserves and investing in enhanced oil recovery techniques. This requires balancing cost-effectiveness with sustainability.

The future of the oil and gas industry will depend on its ability to adapt to these challenges, embrace technological innovation, and contribute to a more sustainable energy future. This requires strategic investment in renewable energy sources, carbon reduction technologies, and operational improvements, ensuring a responsible transition to a lower-carbon world.

Key Topics to Learn for Understanding of Crude Oil and Refined Products Interview

- Crude Oil Composition and Properties: Understanding API gravity, sulfur content, viscosity, and other key properties and their impact on refining processes.

- Refining Processes: Familiarize yourself with fractional distillation, cracking (catalytic and thermal), reforming, alkylation, and isomerization. Understand the purpose and output of each process.

- Refined Product Specifications: Learn about the properties and specifications of gasoline, diesel, jet fuel, and other refined products. Understand how these specifications relate to performance and environmental regulations.

- Petrochemical Feedstocks: Explore the role of crude oil in producing petrochemicals such as ethylene, propylene, and benzene. Understand the connection between refining and the petrochemical industry.

- Crude Oil Trading and Pricing: Gain an understanding of crude oil benchmarks (Brent, WTI), pricing mechanisms, and market dynamics. Be prepared to discuss factors affecting price fluctuations.

- Environmental Considerations: Understand environmental regulations related to crude oil production, refining, and the use of refined products. Discuss emissions reduction strategies and sustainable practices within the industry.

- Safety and Operational Procedures: Demonstrate knowledge of safety protocols and best practices in handling crude oil and refined products, including risk management and emergency response procedures.

- Problem-solving Approaches: Practice analyzing hypothetical scenarios related to refinery operations, product quality issues, and market challenges. Develop your ability to propose practical solutions.

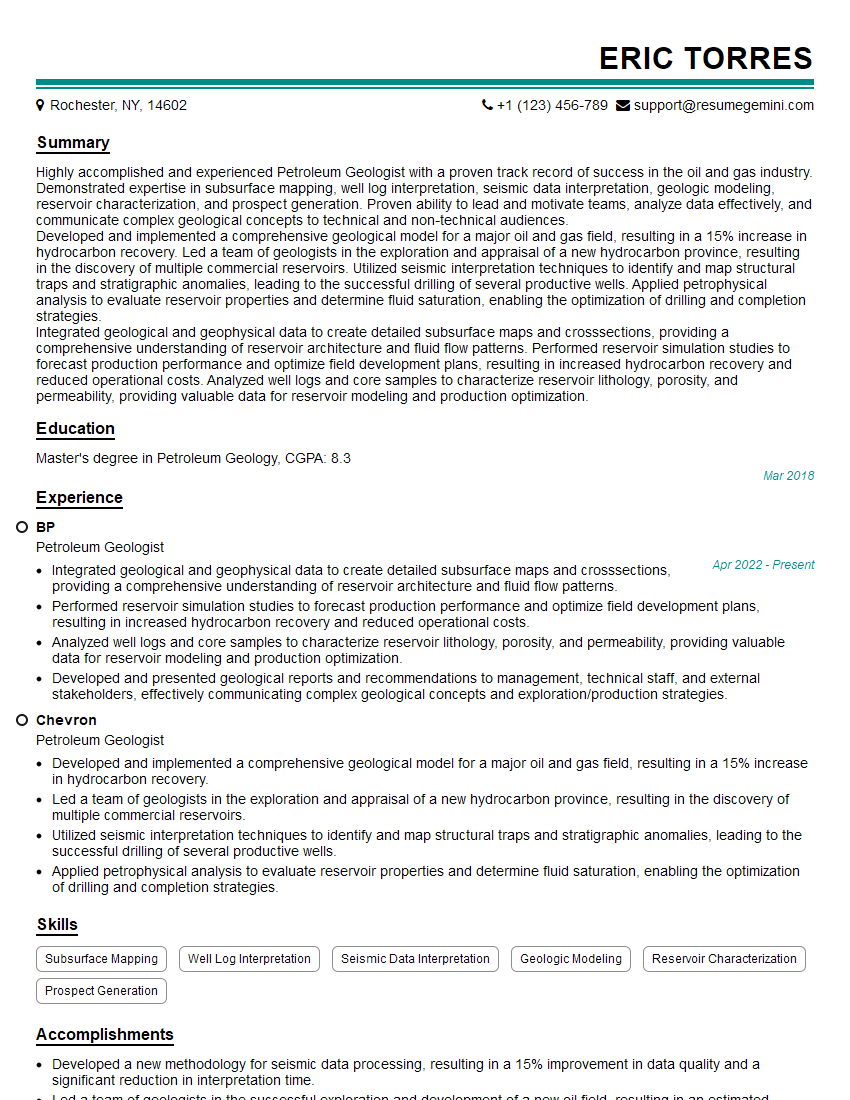

Next Steps

Mastering the understanding of crude oil and refined products is crucial for career advancement in the energy sector, opening doors to exciting opportunities and higher earning potential. To significantly improve your job prospects, it’s vital to create a strong, ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the energy industry. Examples of resumes specifically designed for candidates with expertise in Understanding of Crude Oil and Refined Products are available to help you get started. Invest in your future – build a resume that gets noticed!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO