Cracking a skill-specific interview, like one for Rigging and Mast Maintenance, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Rigging and Mast Maintenance Interview

Q 1. Explain the different types of rigging hardware and their applications.

Rigging hardware encompasses a wide array of components crucial for safely and effectively suspending or securing loads. The choice of hardware depends heavily on the specific application, load weight, environmental conditions, and the overall rigging system design.

- Shackles: These are U-shaped metal components with a pin or screw to connect two parts of a rigging system. Bow shackles are common for connecting to an eye-shaped component, while Dee shackles provide more flexibility in connection points. They are rated for specific working loads and should always be inspected for damage before use.

- Hooks: Used for attaching to a lifting point. Different types exist, including safety hooks (with latches to prevent accidental disengagement) and various sizes and strengths depending on the load. Proper hook selection is vital for safe lifting, considering the load’s weight, angle, and potential for slippage.

- Swivels: Prevent twisting and kinking of ropes or chains, reducing wear and tear. They allow for free rotation of one component relative to another, which is particularly useful in applications where the load might rotate.

- Wire Rope Clips (Clamps): These secure wire rope to other components, preventing slippage. They are used in sets of at least three, correctly spaced, to effectively distribute clamping pressure and prevent damaging the rope. Incorrect installation can lead to catastrophic failure.

- Turnbuckles: Adjustable devices used to fine-tune the tension in a rigging system. They allow precise adjustments for alignment and proper load distribution. However, over-tightening can damage the components.

- Eye Bolts: Bolts with a looped end, providing a secure attachment point for a shackle or other rigging hardware. They are crucial for creating fixed points on structural members.

For example, in a crane lift, shackles connect the crane hook to the main lifting sling, while swivels prevent twisting of the sling. On a sailboat mast, shackles and turnbuckles are used for adjusting the standing rigging.

Q 2. Describe the process of inspecting a mast for damage.

Inspecting a mast for damage is a crucial safety procedure that should be performed regularly, especially before use. A thorough inspection involves a visual examination from all angles, coupled with hands-on checks where appropriate.

- Visual Inspection: Start by observing the mast from the base to the top, looking for any signs of bending, cracks, corrosion (especially at the metal-to-metal joints), dents, or any other surface irregularities. Pay close attention to areas subject to high stress, such as attachment points for rigging and spreaders.

- Hands-on Inspection: Use your hands to gently feel the mast’s surface for any inconsistencies. Look for swelling, soft spots, or areas where the material feels unusually thin or compromised. Check the integrity of all bolted connections and fasteners, ensuring they are tight and free from corrosion.

- Check for Corrosion: Look closely for signs of rust or other corrosion, especially in areas where water can accumulate. Significant corrosion can significantly weaken the mast’s structure.

- Examine Rigging Connections: Inspect all rigging attachment points for signs of wear or damage. Check the condition of the hardware (shackles, bolts, etc.), making sure they’re free from corrosion, cracks, or deformation.

- Look for evidence of impact: Check for any signs of previous impact such as dents or scratches.

If any damage is found, no matter how small, the mast should be removed from service until it can be properly inspected and repaired by a qualified professional.

Q 3. What are the safety precautions for working at heights on a mast?

Working at heights on a mast presents significant risks. Adhering to strict safety protocols is paramount.

- Fall Protection: A full body harness connected to a secure anchor point (independent of the mast) is mandatory. The harness must be properly fitted and regularly inspected. A fall arrest system should be in place to prevent serious injury in the event of a fall.

- Access Equipment: Use appropriate access equipment, such as climbing systems, scaffolds, or properly inspected and maintained mobile elevating work platforms (MEWPs), to access the mast safely. Never climb the mast without proper safety equipment and training.

- Communication: Maintain clear communication with ground personnel at all times. Have a designated person to observe and assist during the work. Use a two-way radio or other communication system to coordinate actions.

- Weather Conditions: Never work on a mast during inclement weather, such as high winds, rain, or ice. Weather conditions can drastically increase the risk of falls and accidents.

- Training and Competence: All personnel involved must receive appropriate training and demonstrate competency in working at heights and handling mast-related tasks. This includes safe harness usage, rescue techniques, and awareness of potential hazards.

- Permit-to-Work System: A permit-to-work system, outlining the tasks, hazards, and safety precautions, should be in place and fully understood by all involved before work commences.

For example, during a mast inspection, a qualified rigger would wear a full body harness attached to a secure anchor point, use appropriate climbing equipment, and maintain communication with ground crew.

Q 4. How do you calculate the safe working load for a rigging system?

Calculating the safe working load (SWL) of a rigging system is critical for preventing accidents. It’s not simply the strength of the single strongest component; it’s a calculation involving several factors.

The SWL is typically determined by the manufacturer for individual components (ropes, chains, shackles, etc.). However, the overall SWL of the rigging system is the lowest SWL of any component within the system. For instance, If one component has a SWL of 5000 kg and another has 3000 kg, the system’s SWL is 3000 kg.

The calculation also needs to account for several factors:

- Angle of the load: Lifting a load at an angle reduces the effective SWL. Angle multipliers are used to account for this reduction. For example, lifting at a 30-degree angle might reduce the effective SWL by 87%.

- Type of load: The nature of the load (e.g., sharp edges, unpredictable movement) can influence the SWL.

- Environmental factors: Temperature, humidity, and corrosion can all impact the strength of rigging components, reducing the SWL.

- Safety factors: A safety factor, typically between 5 and 10, is applied to account for unforeseen circumstances and ensure a wide margin of safety. This means the SWL is significantly lower than the ultimate breaking strength of the component.

In practice, specialized software or engineering calculations are often used to determine the correct SWL for complex rigging systems. This ensures the system remains well within its safe operating limits and avoids potential failures.

Q 5. What are the common causes of mast failure?

Mast failure can have devastating consequences. Understanding the common causes is crucial for prevention.

- Material Fatigue: Repeated stress over time can weaken the material, leading to cracks and eventual failure. This is especially relevant for masts exposed to cyclical loading (like bending in the wind).

- Corrosion: Exposure to the elements, particularly salt water, can cause corrosion, reducing the mast’s structural integrity. This is a particularly significant problem for metal masts.

- Impact Damage: Collisions with objects or even strong impacts from wind or waves can cause dents, cracks, or other forms of damage that compromise the mast’s strength.

- Improper Installation or Maintenance: Faulty installation, inadequate maintenance, or the use of incorrect or damaged hardware can all lead to mast failure.

- Overloading: Exceeding the mast’s designed load capacity puts it under excessive stress, greatly increasing the risk of failure.

- Design Flaws: Rarely, a mast might fail due to flaws in the original design.

- Improper Rigging: Incorrect rigging techniques or the use of inappropriate rigging hardware can concentrate stress in specific areas, leading to premature failure.

Regular inspection and maintenance are paramount in mitigating the risk of mast failure. A qualified professional should regularly assess the mast’s condition and address any potential issues proactively.

Q 6. Explain the different types of knots used in rigging.

Various knots are used in rigging, each serving a specific purpose. The choice of knot depends heavily on the application and the type of rope being used.

- Bowline: Forms a fixed loop that will not slip or tighten under load. It’s a fundamental knot used in many applications, ideal for attaching a rope to a ring or eye.

- Clove Hitch: A simple and quick knot used for attaching a rope to a post or ring. It’s not suitable for heavy loads or dynamic situations.

- Figure Eight Knot: A stopper knot used to prevent a rope from running through a system. It’s often used as a safety knot on the end of a climbing rope.

- Reef Knot (Square Knot): Used to join two ropes of similar diameter. It’s relatively easy to tie but can come undone under load, so it’s generally not suitable for critical applications. A more secure alternative is the double sheet bend.

- Sheet Bend: Used to join two ropes of different diameters. It is a more secure knot than a reef knot for joining ropes of different sizes.

- Prusik Knot: A friction knot used for climbing and rescue operations, allowing a climber to ascend or descend a rope.

It’s crucial to be able to tie these knots securely and correctly. Improper knot tying can lead to serious accidents. Riggers undergo extensive training on appropriate knot selection and tying techniques to ensure safety.

Q 7. Describe your experience with different types of lifting equipment.

Throughout my career, I’ve gained extensive experience with various types of lifting equipment, ensuring safe and efficient operations in diverse rigging scenarios.

- Mobile Cranes: I’m proficient in operating and inspecting various types of mobile cranes, including crawler cranes, rough-terrain cranes, and all-terrain cranes. This includes understanding load charts, safe operating procedures, and pre-operational checks.

- Tower Cranes: I have experience working with tower cranes, understanding their setup, operation, and limitations. I’m familiar with the safety protocols specific to tower crane operation.

- Forklifts: I’m experienced with using forklifts for lifting and transporting materials in a construction setting, adhering to all safety regulations and site-specific requirements.

- Hoists and Winches: I’m skilled in the operation and maintenance of various hoists and winches, ensuring safe lifting procedures and regular inspection of all safety mechanisms.

- Lifting slings (chain, wire rope, webbing): I can select, inspect, and utilize different types of lifting slings, understanding the load limitations and the correct usage to prevent damage or accidents.

My experience also includes hands-on work with specialized lifting equipment used in challenging environments, such as those encountered in offshore operations or high-altitude construction projects.

Q 8. How do you ensure the stability of a mast during maintenance?

Ensuring mast stability during maintenance is paramount for safety. It involves a multi-faceted approach focusing on proper support, bracing, and securing the mast against external forces like wind.

- Temporary Guying: Before commencing any work, we use temporary guy wires – strong ropes or cables attached to secure anchor points – to stabilize the mast. This prevents swaying and accidental movement. The tension in these guys is carefully adjusted based on wind conditions and the mast’s height. We always ensure these guy wires are properly anchored to prevent slippage.

- Lifting Equipment: If the maintenance involves lifting components, we use appropriate lifting gear, such as cranes or hoists, with the mast properly supported and secured during the lift. A critical aspect here is the use of spreader bars to distribute the load evenly, minimizing stress on any single point on the mast.

- Work Platforms: Working at height demands safe access. We utilize properly inspected and secured work platforms, such as scaffolding or elevating work platforms, that are positioned to provide stable and safe access to the areas requiring maintenance. The platforms should be secured to prevent movement, especially in windy conditions.

- Environmental Conditions: Weather plays a major role. High winds, heavy rain, or even extreme heat can compromise stability. Work is often halted during periods of inclement weather until conditions improve.

For instance, during a recent maintenance project on a 100-foot communication mast, we utilized three sets of guy wires anchored to concrete weights, ensuring a stable working environment even with moderate wind gusts.

Q 9. What are the regulations and standards you follow in rigging and mast maintenance?

Rigging and mast maintenance are governed by stringent regulations and standards to ensure safety. These vary by location but often include guidelines from organizations like OSHA (Occupational Safety and Health Administration) in the US or similar national or international standards bodies.

- OSHA Regulations: In the US, OSHA’s regulations regarding fall protection, crane operation, and working at heights are paramount. We meticulously follow these standards, including ensuring proper training and certifications for personnel.

- Manufacturer’s Specifications: Every mast and its components come with manufacturer’s specifications outlining maintenance schedules, load limits, and safety procedures. We always adhere to these guidelines to ensure the equipment’s longevity and safety.

- Industry Best Practices: Beyond formal regulations, we stay updated with industry best practices. This involves continuous professional development, attending workshops, and studying technical literature to refine our techniques and adopt the latest safety protocols.

- Local Regulations: Depending on the location, there may be specific local regulations or permits required for working on masts, especially in areas with restricted airspace or proximity to power lines. We diligently obtain all necessary permits and comply with all local safety requirements.

For example, our team is certified in the proper use of all our equipment, and we maintain detailed logs of all inspections and maintenance activities, ensuring full compliance with the regulations.

Q 10. How do you handle unexpected problems during a rigging operation?

Unexpected problems during rigging operations require a calm and methodical approach. Our priority is always safety.

- Risk Assessment: We conduct an immediate risk assessment to understand the nature of the problem and identify potential hazards. This often involves halting the operation and reassessing the situation.

- Communication: Clear and concise communication is critical, both within the team and with any relevant stakeholders. This helps prevent misunderstandings and ensures everyone is aware of the situation and the planned course of action.

- Problem Solving: We systematically analyze the problem, exploring potential solutions and evaluating their feasibility and safety. This might involve consulting with engineers, referring to technical manuals, or seeking advice from experienced colleagues.

- Contingency Plans: We always have contingency plans in place. This means having backup equipment, alternative procedures, and emergency contact information readily available. Knowing what to do if things go wrong minimizes downtime and enhances safety.

- Documentation: Thorough documentation is critical for future reference and for learning from mistakes. We detail the problem, the actions taken, and the outcome to prevent similar incidents in the future.

For example, once a rigging sling unexpectedly failed during a lift. We immediately halted the operation, reassessed the situation, and used a backup sling. A full investigation was undertaken to determine the cause of the failure. This prevented a potentially serious accident.

Q 11. Explain your experience with fall protection systems.

Fall protection is an absolute necessity in mast maintenance. Our experience encompasses a range of systems designed to prevent falls from heights.

- Full Body Harnesses: All personnel working at heights use properly fitted and inspected full body harnesses. These harnesses are critical for distributing the force of a fall and preventing serious injury.

- Anchor Points: We use robust anchor points that are independently inspected and certified to meet the required load capacity. These anchor points are essential for connecting the fall protection system.

- Lanyards and Self-Retracting Lifelines (SRLs): We use both lanyards and SRLs depending on the work configuration. Lanyards provide a certain degree of freedom, while SRLs automatically retract and arrest a fall, minimizing the impact distance.

- Fall Arrest Systems: Our fall arrest systems are regularly inspected and tested, ensuring they meet safety standards and are in optimal working condition. We conduct routine inspections and maintain detailed records of all inspections.

- Rescue Plans: We have detailed rescue plans in place for any fall-related incidents. These plans involve emergency contacts, procedures for rescue, and equipment for safe retrieval.

I’ve personally been involved in implementing and overseeing fall protection systems on numerous projects, ensuring compliance with all safety regulations and best practices. Regular training on proper use and inspection of this equipment is a key component of our safety program.

Q 12. Describe your experience with different types of rigging slings.

My experience with rigging slings covers a wide range of types, each suited to different applications and load capacities.

- Polyester Web Slings: These are commonly used for their high strength-to-weight ratio, flexibility, and relatively low cost. We use them frequently for lifting lighter loads.

- Nylon Web Slings: Similar to polyester, but with a slightly different strength and elongation characteristics. We choose these based on the specific load and environmental conditions.

- Chain Slings: These are used for heavy-duty lifting, providing exceptional strength and durability, particularly when handling abrasive or sharp materials. However, they are heavier and can be more challenging to handle.

- Wire Rope Slings: Used for extremely heavy lifts and in demanding environments. They are very strong but require careful inspection for signs of wear, especially fraying or kinking.

- Round Slings: Often made of synthetic materials such as nylon or polyester, these slings offer excellent flexibility and are suitable for a variety of lifting applications.

Choosing the correct sling type is critical. For example, using a polyester web sling for a heavy load would be unsafe. We always conduct a thorough pre-lift inspection to ensure the sling is appropriate for the load and conditions.

Q 13. How do you perform a pre-lift inspection?

A pre-lift inspection is a crucial step to prevent accidents and ensure a safe lift. It’s a systematic examination of all components before any lifting begins.

- Equipment Inspection: This includes checking the crane or hoist for any visible damage, ensuring proper functioning of all mechanisms, and verifying the load capacity. All certifications and maintenance records are also reviewed.

- Rigging Hardware Inspection: Each component of the rigging system, including slings, shackles, hooks, and wire ropes, is thoroughly inspected for signs of wear, damage, or corrosion. This includes checking for fraying, kinking, distortion, or any other defects.

- Load Inspection: The load itself is examined to determine its weight, center of gravity, and any potential hazards. We also confirm that the load is properly secured and prepared for lifting.

- Work Area Inspection: The surrounding area is assessed for any obstacles, overhead obstructions, or other hazards that could affect the lift. The area should be clear and safe for the planned lifting operation.

- Weather Conditions: Environmental factors such as wind speed, rain, or extreme temperatures are evaluated. Lifting operations may be postponed if conditions are unsuitable.

I always use a standardized checklist during the pre-lift inspection to ensure thoroughness and prevent overlooking critical details. This systematic approach minimizes risks and prevents potentially disastrous outcomes.

Q 14. What are the signs of a worn or damaged rigging component?

Identifying worn or damaged rigging components is crucial for safety. Ignoring these signs can lead to catastrophic failures.

- Slings: Look for fraying, cuts, burns, excessive wear, distortion, or any signs of chemical damage. Any significant weakening or reduction in strength requires immediate replacement.

- Shackles: Check for cracks, bends, or deformation in the pins or body of the shackle. Excessive wear on the pins or threads indicates damage.

- Hooks: Examine for cracks, bends, distortion, or straightening of the hook. Wear at the throat or tip also indicates weakening and requires replacement.

- Wire Rope: Look for broken wires, kinks, excessive wear, corrosion, or any visible damage to the outer strands. Significant damage necessitates replacement.

- Chain: Inspect for broken links, elongation, deformation, or excessive wear on the links. Any signs of damage or weakening should lead to immediate removal from service.

We use a visual inspection method supplemented by regular load testing for critical components. Any component showing signs of wear beyond acceptable limits is immediately removed from service and replaced, ensuring that our equipment remains safe and reliable.

Q 15. Explain the importance of communication during a rigging operation.

Effective communication is the cornerstone of safe and efficient rigging operations. It’s not just about talking; it’s about ensuring everyone on the team understands the plan, their roles, and potential hazards. Miscommunication can lead to accidents, delays, and costly mistakes.

- Pre-Job Briefing: Before any rigging activity, a thorough briefing is crucial. This includes reviewing the rigging plan, identifying potential hazards, assigning roles and responsibilities, and establishing clear communication channels (e.g., hand signals, radios). For example, we always use a standardized checklist to ensure every member is briefed on the weight and dimensions of the load, the lifting path, and the emergency procedures.

- Clear and Concise Language: Using precise terminology and avoiding jargon is essential. Everyone needs to understand the instructions immediately and without ambiguity. Think of it like a well-rehearsed play – each actor needs to know their lines and cues perfectly.

- Non-Verbal Communication: Hand signals and visual cues play a vital role, particularly in noisy environments. We always utilize a standard set of hand signals to ensure everyone understands instructions clearly, especially when verbal communication might be difficult.

- Post-Job Debrief: After completing the operation, a debriefing helps identify areas for improvement and reinforce lessons learned. This collaborative process fosters a culture of safety and continuous improvement. We document these debriefings to track trends and address any recurring issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with rigging software or planning tools.

I’ve extensively used rigging software like CAD (Computer-Aided Design) programs to create detailed rigging plans and simulations. These programs allow me to model the load, the lifting equipment, and the entire work environment. This helps in predicting potential problems, calculating stresses on equipment, and optimizing lifting procedures. For example, I used CAD software to simulate the lifting of a large transformer, and through the simulation, identified that a slight modification in the rigging configuration would significantly reduce stress on the crane’s boom.

I’m also proficient in utilizing specialized rigging software that calculates the forces acting on different components of the rigging system. These calculations are essential to ensure that the system’s components are adequately sized to safely handle the loads. We also use project management tools for planning and tracking progress, ensuring tasks are completed on schedule and within budget.

Q 17. How do you maintain accurate records of rigging and mast maintenance activities?

Maintaining accurate records is paramount for safety, compliance, and efficient maintenance. We use a combination of digital and physical records. This includes:

- Digital Database: We maintain a comprehensive digital database that stores inspection reports, maintenance logs, certificates of compliance for all rigging equipment and components. This database allows for easy access to historical data, which helps in predicting future maintenance needs and ensuring all equipment is compliant with safety standards.

- Physical Logs: Physical logs are maintained on site, recording daily inspections, repairs, and any anomalies observed during operations. These logs are then transferred to our digital database, ensuring redundancy and allowing for immediate access to critical information in the field.

- Photographs and Videos: We utilize photographs and videos to document the condition of the rigging equipment, as well as the steps of installation, disassembly, and maintenance procedures. This visual record provides a comprehensive overview of the activity and can be incredibly useful for troubleshooting or training purposes.

This multi-layered approach ensures that records are always accessible, consistently updated, and comprehensive.

Q 18. What are your troubleshooting skills regarding rigging equipment malfunctions?

Troubleshooting rigging equipment malfunctions requires a systematic approach. I begin by assessing the situation, identifying the problem, and then implementing the appropriate solution. My approach involves:

- Safety First: Secure the area and ensure the safety of personnel before attempting any repairs.

- Visual Inspection: Conduct a thorough visual inspection of the malfunctioning equipment to identify the source of the problem. This often involves looking for signs of wear and tear, damage, or incorrect assembly.

- Functional Testing: Perform functional tests to confirm the nature of the malfunction. This may involve simple checks like load testing individual components.

- Component Replacement: If a component is damaged or worn beyond acceptable limits, it needs to be replaced. We always use certified replacement parts to ensure quality and safety.

- Documentation: Meticulously document all troubleshooting steps, repairs, and component replacements. This information is critical for future maintenance and record-keeping.

For instance, if a hoist malfunctions, I’d first check the power supply, then examine the motor and braking system, and finally inspect the cables and sheaves for any damage. My experience allows me to quickly pinpoint the likely cause and implement a solution efficiently and safely.

Q 19. How do you identify and mitigate risks associated with mast climbing?

Mast climbing presents inherent risks, but these can be effectively mitigated through careful planning and adherence to safety protocols. My approach focuses on:

- Pre-Climb Inspection: Thoroughly inspect the mast, ropes, and climbing equipment before each climb to identify any defects or potential hazards. This includes checking for wear and tear, corrosion, and proper functioning of safety equipment.

- Proper Fall Protection: Implementing robust fall protection systems is non-negotiable. This includes using harnesses, lanyards, and appropriate anchorage points on the mast. Regular checks ensure these systems remain functional and correctly attached.

- Weather Conditions: Never climb in adverse weather conditions such as high winds, rain, or ice. These conditions significantly increase the risk of falls or accidents.

- Communication: Maintaining clear communication with ground personnel is crucial. We use two-way radios to maintain constant contact and report any issues or unusual circumstances.

- Training and Competence: Only trained and competent personnel should perform mast climbing activities. Regular training and refresher courses ensure everyone remains proficient in safe climbing techniques and emergency procedures.

A good analogy is mountaineering – meticulous preparation and adherence to safety protocols are paramount to prevent accidents. In mast climbing, this means planning each step carefully and implementing the necessary safeguards.

Q 20. Describe your experience with different types of mast materials.

I have experience with various mast materials, each with its own advantages and disadvantages:

- Steel Masts: Strong, durable, and relatively inexpensive, steel masts are commonly used in many applications. However, they are susceptible to corrosion, requiring regular maintenance and protective coatings.

- Aluminum Masts: Lighter than steel masts, aluminum is a good choice where weight is a concern. However, it’s less strong than steel and can be more expensive.

- Fiberglass Masts: Fiberglass masts offer excellent corrosion resistance and are lightweight. They are ideal for applications where corrosion resistance is critical but might be more susceptible to damage from impacts.

- Carbon Fiber Masts: These masts offer exceptional strength-to-weight ratios, making them ideal for applications requiring high strength and minimal weight. However, they are the most expensive option.

The choice of mast material depends on several factors, including the intended application, budget constraints, and environmental conditions. I always ensure that the chosen material is suitable for the intended use and meets all safety standards.

Q 21. Explain the process of assembling and disassembling a mast.

The process of assembling and disassembling a mast is highly dependent on the mast’s design and the specific components involved. However, the general process involves these steps:

- Planning and Preparation: Carefully review the mast’s assembly instructions and gather all necessary tools and components. Prepare a safe work area, clear of obstructions.

- Base Assembly: Begin by assembling the mast’s base section, ensuring that it is securely and properly aligned.

- Section-by-Section Assembly: Add mast sections one at a time, ensuring each section is properly aligned and securely fastened. Use appropriate tools and follow the manufacturer’s recommendations.

- Guying and Stabilizing: If necessary, install guy wires or other stabilizing systems to prevent the mast from swaying or collapsing.

- Final Inspection: Once assembled, conduct a thorough inspection of the entire mast to ensure all connections are secure, and the mast is stable and plumb.

- Disassembly: Disassembly follows the reverse process, starting with removing the guy wires and stabilizing components, then carefully removing each section. Pay close attention to the safety procedures throughout this process.

Safety is the utmost priority throughout the entire process. We always adhere to strict safety protocols and utilize appropriate lifting equipment, as necessary, to prevent accidents and damage.

Q 22. How do you ensure the proper tensioning of rigging components?

Proper tensioning of rigging components is crucial for safety and the structural integrity of the entire system. It’s not about simply pulling tight; it’s about achieving the precise tension specified in the engineering plans and load calculations. This often involves using specialized tensioning tools like dynamometers (load cells) to measure the actual tension in each component.

The process typically involves several steps:

- Initial Setting: We use winches or other mechanisms to apply a preliminary tension. This step is often guided by pre-determined values or visual estimations based on experience.

- Measurement: A dynamometer is attached to the component to accurately measure the existing tension. This data is compared to the required tension.

- Adjustment: Based on the measurement, we carefully adjust the tension using the winch or other tensioning devices. Small, incremental adjustments are key to avoid over-tensioning or sudden slack.

- Verification: We repeat the measurement process until the desired tension is achieved within an acceptable tolerance. This ensures accuracy and consistency across all components.

For example, when rigging a heavy piece of equipment, we might use a dynamometer to ensure each wire rope is loaded to its specified tension, ensuring that the load is distributed evenly and prevents uneven wear or breakage.

Q 23. What are the different types of anchors used in rigging?

The type of anchor used in rigging depends heavily on the specific application, ground conditions, and load requirements. There’s no one-size-fits-all solution. Here are some common types:

- Deadmen Anchors: These are buried anchors, often large timber logs or steel plates, that resist pull forces by friction and embedment in the ground. They’re ideal for temporary anchoring in suitable soil conditions.

- Screw Anchors: These are helical anchors driven into the ground using specialized equipment. They are excellent for various soil types, providing strong and reliable anchorage.

- Plate Anchors: Heavy steel plates are bolted to a solid base, such as concrete. These are suited for high load applications and situations where a firm, fixed base is available.

- Rock Anchors: These specialized anchors are drilled and cemented into solid rock, providing exceptional holding power. They are often used in challenging terrain or for extremely heavy loads.

- Foundation Anchors: When rigging is attached to permanent structures, building foundations often serve as the anchor points. This requires careful assessment of the foundation’s capacity.

Selecting the appropriate anchor involves detailed site assessment and load calculations. For instance, during a bridge construction project, rock anchors would be crucial for supporting the temporary rigging structures given the heavy loads involved and the need for reliable, stable anchoring.

Q 24. Describe your experience with working in confined spaces.

I have extensive experience working in confined spaces, adhering strictly to safety protocols. This includes regular training in confined space entry procedures, which covers hazard identification, atmospheric monitoring, rescue techniques, and communication strategies. My experience encompasses work on various projects, from inspecting and maintaining mast sections on tall ships to conducting internal inspections of industrial equipment.

Before entering a confined space, a thorough risk assessment is conducted. This involves identifying potential hazards such as oxygen deficiency, toxic gases, and limited visibility. We use appropriate personal protective equipment (PPE), including respirators, safety harnesses, and communication devices. The work is carefully planned and executed, often with a standby team monitoring atmospheric conditions and overall safety.

One memorable instance involved inspecting the interior of a large industrial tank. We followed a rigorous entry permit system, thoroughly purged the tank of any hazardous gases, and utilized continuous atmospheric monitoring equipment throughout the operation. This careful planning and meticulous attention to safety allowed the inspection to proceed smoothly and without incident.

Q 25. How do you manage a team during a rigging operation?

Managing a team during a rigging operation requires strong leadership, clear communication, and a commitment to safety. My approach centers on several key principles:

- Pre-Job Briefing: A thorough briefing before every operation is essential. This covers the task specifics, safety procedures, risk assessment, communication protocols, and individual responsibilities.

- Clear Communication: Using a combination of verbal instructions, hand signals, and radio communication ensures everyone is aware of actions and potential hazards. Maintaining clear communication channels is paramount, especially in complex or dynamic environments.

- Delegation and Supervision: Assigning tasks based on individuals’ skills and experience, while maintaining close supervision, ensures efficiency and safety. Regular check-ins confirm the task progression and address any concerns promptly.

- Safety Emphasis: Safety is paramount. I emphasize adherence to all safety regulations and procedures. Every team member is empowered to stop work if an unsafe condition arises.

- Post-Job Debrief: After the operation, conducting a debrief allows the team to reflect on what went well, identify areas for improvement, and share lessons learned.

For example, during the rigging of a large crane, I ensured my team understood their roles clearly, emphasizing the importance of communication during lifting and positioning. This proactive approach allowed the operation to complete safely and efficiently.

Q 26. Explain your understanding of load distribution in rigging.

Load distribution in rigging is crucial for ensuring safety and preventing structural failure. The goal is to distribute the weight evenly across all components to avoid overloading any single element. This involves understanding the load’s center of gravity, choosing appropriate rigging hardware, and selecting the correct attachment points.

Understanding the load’s center of gravity allows for efficient weight distribution. If the load is not balanced, it can cause uneven stress on the rigging system. This understanding guides the placement of slings and shackles, ensuring even load distribution. For example, using multiple slings properly spaced minimizes stress on any one sling.

We use engineering calculations and specialized software to determine the safe working load (SWL) for each component and to design the rigging configuration. This ensures that the combined SWL of all components exceeds the actual load to provide a safety margin.

Improper load distribution can lead to catastrophic failures. For instance, using a single point of lift for a heavy, unbalanced load can cause structural failure of the rigging and potentially lead to injuries or damage. Using multiple slings and ensuring the correct angle of each sling are crucial for effective load distribution and safety.

Q 27. Describe your experience with emergency procedures during a rigging operation.

Emergency procedures are integral to any rigging operation. We have established protocols for various scenarios, including equipment malfunctions, unforeseen weather changes, and injuries. Regular drills and training ensure that the team is prepared to respond effectively.

Our emergency procedures include:

- Emergency Shutdown: We have clear procedures for immediately halting the operation if any unsafe condition or malfunction occurs.

- Communication: Effective communication is essential. We utilize radios and visual signals to alert the team and coordinate actions during an emergency.

- Rescue Procedures: We have detailed plans for rescuing injured personnel, including the use of specialized equipment and trained personnel.

- Evacuation Plans: We have pre-determined evacuation routes and procedures in case of an emergency requiring immediate site evacuation.

- Post-Incident Analysis: After an incident, a thorough analysis is conducted to understand the root cause, identify areas for improvement in the procedures, and implement preventative measures.

During one operation, a sudden gust of wind caused a significant shift in the load. Following our emergency procedures, we immediately halted the operation, reassessed the situation, adjusted the rigging, and successfully completed the lift after the wind had subsided. The swift and organized response prevented any injury or damage.

Q 28. What is your experience with different types of climbing techniques?

My experience with climbing techniques is extensive, focusing primarily on safe and efficient ascent and descent methods relevant to mast and rigging maintenance. I’m proficient in various techniques:

- Rope Access Techniques: This is my primary climbing method for mast and rigging work. I use various rope access techniques including ascenders, descenders, and a variety of safety systems to access and work at heights.

- Ladder Climbing: Although less common for significant heights, proper ladder climbing techniques are essential for shorter sections of masts and structures, and proper safety procedures are followed.

- Scaffolding: For some tasks, scaffolding provides a stable and safe working platform. Proper assembly, inspection and use of scaffolding is mandatory.

Each technique requires specialized training and certification. Safety is always the primary concern, and I always adhere to stringent safety protocols, which include proper harness usage, regular equipment inspections, and detailed risk assessments.

For instance, during a mast maintenance project on a tall sailing vessel, I employed advanced rope access techniques to reach different sections of the mast, ensuring efficient and safe inspection and repair work.

Key Topics to Learn for Rigging and Mast Maintenance Interview

- Rigging Fundamentals: Understanding different types of rigging systems, components, and their applications in mast maintenance.

- Mast Structure and Materials: Knowledge of various mast materials (e.g., aluminum, steel, fiberglass), their strengths, weaknesses, and maintenance requirements.

- Inspection and Maintenance Procedures: Detailed understanding of routine inspection protocols, identifying potential hazards, and performing preventative maintenance.

- Safety Regulations and Procedures: Thorough knowledge of relevant safety standards, regulations, and best practices for working at heights and with rigging equipment.

- Troubleshooting and Repair Techniques: Ability to diagnose and solve common rigging and mast problems, including damage assessment and repair strategies.

- Specialized Tools and Equipment: Familiarity with the operation and maintenance of specialized tools used in rigging and mast maintenance.

- Load Calculations and Stress Analysis: Understanding how to calculate loads and assess the structural integrity of masts and rigging systems.

- Emergency Procedures: Knowledge of emergency response plans in case of rigging or mast failure.

- Communication and Teamwork: Understanding the importance of effective communication and teamwork in a rigging and mast maintenance environment.

- Practical Application: Be prepared to discuss real-world scenarios and how you would apply your knowledge to solve practical problems.

Next Steps

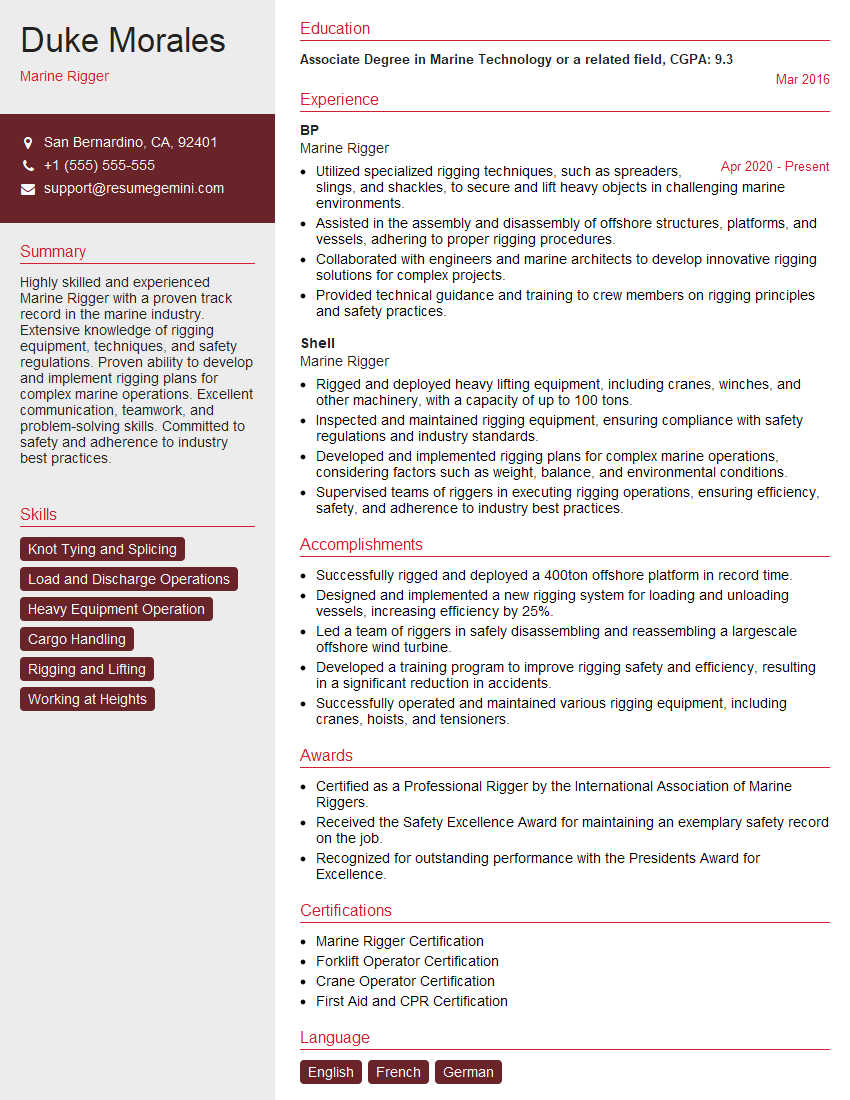

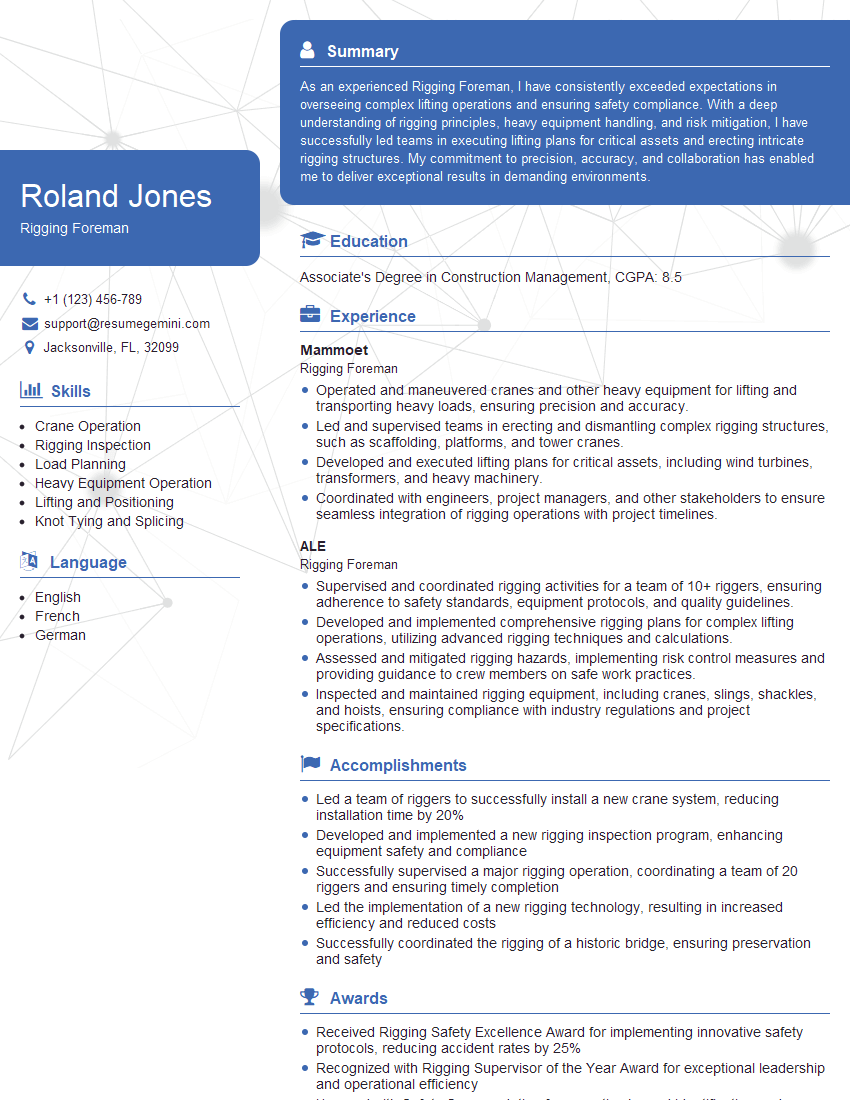

Mastering Rigging and Mast Maintenance opens doors to exciting career opportunities with significant growth potential in various industries. A strong resume is crucial for showcasing your skills and experience to potential employers. Crafting an ATS-friendly resume that highlights your expertise is key to getting your application noticed. To help you build a compelling and effective resume, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform to create professional resumes, and we offer examples of resumes tailored specifically to the Rigging and Mast Maintenance field to help guide you. Invest the time to build a strong resume – it’s an investment in your future.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO