Cracking a skill-specific interview, like one for Underwater Welding, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Underwater Welding Interview

Q 1. What are the primary differences between wet and dry underwater welding?

The core difference between wet and dry underwater welding lies in the environment the welding takes place in. Wet welding occurs directly in the underwater environment, with the arc submerged in water. This creates unique challenges due to the water’s impact on the welding process and the need for specialized equipment. Think of it like trying to weld while holding your equipment underwater – it’s significantly more difficult. Dry welding, on the other hand, involves creating a dry, pressurized environment around the weld area, usually through a cofferdam or a hyperbaric chamber. This mimics topside welding conditions, making the process more similar to what welders are accustomed to. Imagine working inside a bubble underwater, a protective environment that shields the welding process.

Q 2. Explain the safety procedures involved in underwater welding.

Safety is paramount in underwater welding. Procedures involve rigorous pre-dive checks of equipment, including thorough inspections of welding machines, power cables, and life support systems. Divers undergo comprehensive medical examinations to ensure their fitness. A detailed dive plan, including emergency procedures, is essential. Communication is key; divers rely on underwater communication systems to coordinate actions and report any issues. Dedicated standby divers are always present for immediate assistance. Following strict decompression protocols after the dive is crucial to prevent decompression sickness (‘the bends’). Regular safety briefings and training maintain awareness of potential hazards like electric shock, gas poisoning, and equipment malfunctions. This is not just a job; it’s a delicate operation where meticulous planning and safety measures are the difference between success and disaster. For example, during an offshore platform repair, multiple safety divers might surround a single welding diver, ready to intervene should anything go wrong.

Q 3. Describe the various types of underwater welding processes.

Several processes exist for underwater welding, each with its strengths and limitations. Electrode welding (SMAW) is the most common, using a covered electrode to shield the arc. Gas metal arc welding (GMAW), or MIG welding, uses a continuous wire feed for increased deposition rate. Gas tungsten arc welding (GTAW), or TIG welding, offers superior quality but is slower. Flux-cored arc welding (FCAW) is a self-shielded process used in certain conditions. Finally, Plasma arc welding (PAW) is characterized by high current density, leading to increased welding speed. The choice of process often depends on factors such as water depth, current availability, and the required weld quality. Imagine using SMAW for simple repairs in shallower waters, while for critical repairs on a deep-sea pipeline, GTAW or PAW might be preferred due to the higher quality and control.

Q 4. What are the limitations of each underwater welding process?

Each underwater welding process faces unique limitations. SMAW struggles with high deposition rates. GMAW can be affected by water currents and the need for careful shielding gas management. GTAW is highly sensitive to water currents and less suitable for rapid repairs. FCAW produces welds of lower quality compared to GTAW, while PAW requires specialized, sophisticated equipment, leading to higher costs. The choice of method must therefore consider the required weld quality, project timeline, depth limitations, and budgetary considerations. The environment plays a crucial role – a fast-flowing current might make GTAW practically impossible.

Q 5. How do you select the appropriate welding process for a given underwater application?

Selecting the right welding process involves a thorough assessment of several factors. The water depth heavily influences the choice; shallower depths allow for more options, while deeper dives necessitate processes better suited to handling pressure. The required weld quality is paramount – high-quality welds for critical structures demand processes like GTAW or PAW. The welding current availability at the site is another constraint. Project timeline impacts the choice; faster processes are preferred for time-sensitive repairs. The accessibility of the welding site and the structural geometry influence the feasibility of certain processes. Finally, budgetary considerations weigh heavily in the decision-making process. A cost-benefit analysis helps to strike a balance between weld quality and project budget. For example, a simple patch on a submerged pipeline at shallow depth could warrant SMAW, whereas a complex repair on a deep-sea oil rig might require the more precise (and expensive) GTAW or PAW.

Q 6. Explain the role of hyperbaric chambers in underwater welding operations.

Hyperbaric chambers play a vital role in underwater welding, particularly in dry welding. They provide a safe and controlled environment for divers during and after their work. They are essentially pressurized chambers that simulate the ambient water pressure, allowing divers to work in a dry atmosphere. This dramatically reduces the challenges of wet welding and allows for more controlled weld quality. After a dive, divers use hyperbaric chambers for decompression to prevent decompression sickness. They allow gradual pressure reduction, allowing the body to safely release dissolved gases accumulated during the dive. The chamber’s pressure control is critical for preventing divers from suffering from any pressure-related illness. Without hyperbaric chambers, many deep-sea underwater welding projects would be extremely hazardous, if not impossible.

Q 7. What are the challenges posed by underwater welding compared to topside welding?

Underwater welding presents unique challenges compared to topside welding. The most significant difference is the immersive environment. Water’s properties, such as pressure, buoyancy, currents, and visibility, severely impact the welder’s control and the weld quality. The pressure at depth complicates things – high pressure changes material properties and requires specialized equipment. The limited visibility increases the risk of errors. Water currents can disrupt the welding arc and affect the weld pool. Dealing with corrosion and the accumulation of marine growth adds further difficulty. Finally, underwater welding necessitates additional safety precautions and specialized equipment, adding to the complexities of the procedure. It’s like comparing welding in a comfortable, well-lit workshop to welding in a stormy ocean – the differences are stark and demand significantly more skill and expertise.

Q 8. How do you mitigate the effects of water pressure on welds?

Mitigating the effects of water pressure on underwater welds is paramount for ensuring structural integrity. The immense pressure at depth significantly impacts the welding process and the weld’s properties. We primarily address this through two key strategies: proper equipment selection and meticulous weld procedure design.

First, specialized equipment is crucial. Hyperbaric chambers, designed to withstand the external water pressure, protect the welder and the welding process. These chambers maintain a near-atmospheric pressure environment inside, significantly reducing the impact of water pressure on the weld pool and the metal being joined. The equipment itself, like welding torches and power sources, is also designed to operate under pressure, often using high-pressure gas systems to counteract the surrounding water.

Second, the weld procedure must account for the unique conditions. We utilize specialized welding techniques such as the use of specialized filler metals, often with higher yield strength to compensate for the increased pressure, and modified welding parameters like current and voltage to accommodate the pressure and the different heat transfer characteristics underwater. Preheating the base metal can also be beneficial, mitigating potential cracking issues due to rapid cooling in the water.

For instance, during a recent offshore pipeline repair, we utilized a hyperbaric welding chamber and specialized flux-cored wire to successfully weld a section at 50 meters depth, successfully resisting the substantial pressure without compromising the weld integrity. The rigorous planning, including the choice of equipment and weld parameters based on depth and material, was key to its success.

Q 9. Describe the different types of underwater welding equipment.

Underwater welding employs various equipment tailored to the specific environment and welding process. The primary types include:

- Hyperbaric Welding Chambers: These sealed chambers, submerged with the welder inside, maintain a near-atmospheric pressure environment during welding. This is the safest method for deeper and more complex operations.

- Atmospheric Diving Suits (ADS): AD suits allow welders to perform operations at considerable depths while maintaining a normal atmospheric pressure inside the suit. The welder’s movements, though restricted, allow greater maneuverability than hyperbaric chambers. They require specialized welding equipment designed to operate with the suit’s manipulator arms.

- Wet Welding (Manual Metal Arc Welding): This involves welding directly in the water, using a specialized welding process and electrodes with water-resistant coatings. While versatile, this method is typically limited to shallower depths and simpler welds.

- Remotely Operated Vehicles (ROVs): For very deep or hazardous environments, ROVs with robotic manipulators are used to perform welds under precise control, eliminating the need for human divers.

Each equipment type has its own advantages and limitations regarding depth capability, cost, safety, and application suitability. The choice of equipment is always carefully considered based on the specific project requirements and risk assessment.

Q 10. How do you ensure the quality of underwater welds?

Ensuring the quality of underwater welds requires a multi-faceted approach, encompassing careful planning, execution, and rigorous inspection. We emphasize several key aspects:

- Qualified Personnel: Highly trained and experienced divers and welders are essential for underwater welding. Regular training and certification ensure they possess the skills to handle the demanding environment and produce high-quality welds.

- Stringent Procedure Qualification Records (PQRs): Detailed PQRs ensure consistent weld quality by documenting the precise welding parameters, including current, voltage, and travel speed, for each welding scenario. This creates a reference point for repeatability.

- Proper Pre-Welding Preparation: Thorough surface preparation of the base metals is critical to ensuring a sound weld. This includes cleaning, degreasing, and removing any contaminants that could compromise the weld integrity. Specialized underwater cleaning techniques may be necessary.

- Real-Time Monitoring: During the welding process, parameters are continuously monitored to ensure they remain within the established PQR limits. Any deviations are immediately addressed.

- Post-Weld Inspection: A combination of visual inspection and non-destructive testing is crucial to detecting any flaws in the completed weld. This verification step is crucial to confirming that the weld meets the required standards.

For example, during a recent offshore platform repair, meticulous surface preparation, continuous weld parameter monitoring, and thorough post-weld inspection via underwater ultrasonic testing (UT) ensured the integrity and structural safety of the repairs.

Q 11. What are the common defects found in underwater welds and how are they detected?

Common defects found in underwater welds are similar to those in topside welds, but the unique underwater environment introduces additional challenges. These defects include:

- Porosity: Small gas pockets in the weld metal, often caused by moisture or contamination.

- Lack of Fusion: The weld metal does not properly fuse with the base material, leading to weaknesses.

- Undercutting: A groove melted into the base metal alongside the weld bead, weakening the weld.

- Cracks: Fractures in the weld metal due to residual stresses or hydrogen embrittlement.

- Incomplete Penetration: The weld does not penetrate the entire thickness of the base material.

Detection methods involve a combination of visual inspection, often conducted underwater by remotely operated vehicles (ROVs) equipped with high-resolution cameras or diver inspection, followed by more sophisticated non-destructive testing (NDT) methods, like magnetic particle testing (MPT) or ultrasonic testing (UT), once the weld is accessible.

Q 12. Explain the importance of non-destructive testing (NDT) in underwater welding.

Non-destructive testing (NDT) plays a vital role in ensuring the quality and safety of underwater welds. Because access to underwater structures is often limited and repairs can be expensive and difficult, verifying weld integrity without damaging the structure is critical. NDT methods allow for the detection of internal flaws that visual inspection might miss, preventing catastrophic failures. This is particularly important in high-risk environments such as offshore oil and gas platforms, pipelines and subsea infrastructure.

NDT provides the necessary confidence in the structural integrity of the weld, which is crucial for ensuring the safety of personnel and the overall operational integrity of the underwater structure.

Q 13. What are the different NDT methods used for underwater welds?

Several NDT methods are suitable for underwater welds, each with strengths and limitations depending on the weld type, material, and access:

- Ultrasonic Testing (UT): High-frequency sound waves are used to detect internal flaws like porosity, cracks, and lack of fusion. Underwater UT is adaptable to different geometries and can be employed remotely using specialized probes.

- Magnetic Particle Testing (MPT): This method is used to detect surface and near-surface flaws in ferromagnetic materials. Specialized underwater systems apply magnetic fields and ferromagnetic particles to reveal defects.

- Radiographic Testing (RT): X-rays or gamma rays are used to create images revealing internal flaws. Underwater RT, however, has limited use and is only feasible in certain scenarios due to logistical complexity and the challenges of shielding radiation in a marine environment.

- Visual Inspection: While not technically NDT, visual inspection by divers or ROVs equipped with high-resolution cameras is crucial for initial assessments of surface defects.

The choice of method depends on factors like the weld material, accessibility, depth, and the type of defects anticipated. Often, a combination of methods is employed to ensure a comprehensive assessment.

Q 14. Describe your experience with underwater welding codes and standards.

My experience encompasses a broad range of underwater welding codes and standards, including those established by organizations such as AWS (American Welding Society), ASME (American Society of Mechanical Engineers), and ISO (International Organization for Standardization). I’m familiar with codes relevant to various applications, such as those governing the construction and repair of offshore structures, pipelines, and subsea equipment.

I have consistently adhered to the strictest safety protocols and quality control measures outlined in these codes, incorporating the principles of risk assessment and mitigation into every project. Understanding the specific requirements, limitations, and implications of different codes is a crucial aspect of ensuring the safe and reliable delivery of any underwater welding project. For example, in recent projects, we complied with DNV GL standards for subsea pipeline repair to ensure compliance with strict international regulations and best practices.

This familiarity with industry codes is essential to ensure the long-term safety and structural integrity of the completed projects. My experience with these standards informs every aspect of our work, from selecting the appropriate equipment and materials to ensuring the precise execution of the welding process itself.

Q 15. How do you handle emergencies during underwater welding operations?

Emergency response in underwater welding is paramount. Our procedures are meticulously planned and rehearsed, mirroring those of above-water high-risk operations but with added considerations for the aquatic environment. A dedicated emergency team is always on standby, equipped with readily available emergency oxygen supplies, recompression chambers (in case of decompression sickness), and rescue equipment. Communication is critical; we use underwater communication systems for real-time updates and instructions. We have established clear protocols for various emergency scenarios, including equipment malfunctions, diver distress, fire, and entanglement. For instance, if a welder experiences a sudden equipment failure, the pre-arranged signal triggers immediate ascent to the surface, followed by a thorough equipment inspection and repair. Following a significant incident, a post-incident review analyzes the situation to identify areas for improvement and prevent recurrence.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the environmental concerns related to underwater welding?

Underwater welding poses several environmental concerns. The most significant is potential water pollution from the welding process itself. Welding fumes, electrode coatings, and slag can contain harmful substances. Strict adherence to regulations and the use of environmentally friendly electrodes and techniques are crucial to minimizing this impact. We also need to consider the impact on marine life. The heat, noise, and light generated during welding can disturb or harm aquatic organisms. Moreover, any accidental release of welding materials or damage to the underwater structure can negatively impact the ecosystem. To mitigate these risks, we employ strategies such as careful placement of containment barriers to collect any debris or runoff and environmentally sensitive site selection to minimize disruption to marine habitats. Pre-dive environmental impact assessments are conducted to ensure minimal harm to the area.

Q 17. What are the health risks associated with underwater welding?

Underwater welding presents substantial health risks to divers. The primary risk is decompression sickness (‘the bends’), caused by dissolved gases forming bubbles in the bloodstream due to rapid ascents or prolonged exposure to high pressure. Other hazards include oxygen toxicity from high partial pressures of oxygen in breathing mixtures, carbon monoxide poisoning from incomplete combustion of the welding arc, and exposure to hazardous fumes and particulates from electrode coatings. The confined environment within the diving helmet and suit can lead to hypercapnia (excess carbon dioxide). We mitigate these risks through strict adherence to decompression tables, regular health checks of welders, meticulous pre-dive checks to maintain the integrity of diving and welding equipment, and mandatory use of appropriate breathing mixtures and safety equipment. For instance, frequent breaks and controlled ascents are crucial in managing decompression-related risks.

Q 18. How do you manage the risks associated with decompression sickness in underwater welding?

Managing decompression sickness (DCS) risk involves a multi-pronged approach. First, we adhere strictly to established decompression schedules, tailored to the depth and duration of the dive. This often involves using specialized dive computers and decompression tables. Divers undergo thorough pre-dive medical screenings to identify any pre-existing conditions that could exacerbate DCS risk. We also emphasize the importance of slow, controlled ascents to allow the body to gradually release dissolved gases. Emergency recompression chambers are always available on-site, ready to treat any divers who experience symptoms of DCS. Finally, post-dive monitoring is crucial, including follow-up medical checks, even if no immediate symptoms are evident. Regular training and awareness sessions keep our team up-to-date with the latest advancements in DCS prevention and treatment.

Q 19. Describe your experience with different types of underwater cutting equipment and techniques.

My experience encompasses various underwater cutting equipment and techniques. I’m proficient with both oxy-fuel cutting and electric arc cutting methods. Oxy-fuel cutting, using oxygen and acetylene, is effective for various materials but is limited in deep water due to the pressure affecting gas mixture and flame stability. I’ve utilized plasma arc cutting systems for their precision and suitability for thicker materials. I am also experienced with underwater abrasive water jet cutting for its versatility in cutting different materials with minimal heat and environmental impact. Each technique has its advantages and disadvantages, which I carefully consider based on the specific job requirements, depth, and material being cut. For example, on a recent offshore platform repair project, we used plasma arc cutting for its speed and precision in cutting through heavily corroded steel plates at a moderate depth.

Q 20. How do you prepare underwater welding joints for welding?

Preparing underwater welding joints is crucial for a strong and durable weld. First, the joint surfaces must be thoroughly cleaned to remove any corrosion, marine growth, or other contaminants. This often involves using specialized underwater cleaning tools like wire brushes, chisels, and scrapers. Once clean, the surfaces are carefully aligned and secured in place using clamping devices or temporary welds. Gaps must be consistent and controlled for effective penetration. Preheating the joint may be necessary depending on the material and water temperature to ensure proper fusion. Finally, the prepared joint is inspected for any defects before welding commences. The entire process demands precision and attention to detail, as any imperfections in preparation can compromise the weld quality and the structural integrity of the underwater structure.

Q 21. What are the different types of underwater welding electrodes?

Several types of electrodes are used in underwater welding, each with unique properties. The most common are flux-cored electrodes, which contain a flux material that shields the weld from water and provides additional metallurgical benefits. These are often chosen for their ability to produce good quality welds in various underwater conditions. Solid electrodes, similar to those used in conventional welding, can also be employed but are more challenging to use underwater due to the greater risk of porosity from the presence of moisture. Electrode selection depends on several factors: the base metal being welded, the depth of the operation, and the desired weld properties. For example, in deep-water operations, specialized electrodes designed for high-pressure environments are often used to ensure weld quality and prevent porosity. Each electrode type requires specific welding parameters and techniques for optimal performance.

Q 22. How do you maintain underwater welding equipment?

Maintaining underwater welding equipment is crucial for safety and efficient operation. It’s a multi-faceted process focusing on both the equipment itself and the support systems.

- Regular Inspection: Before, during, and after each dive, a thorough visual inspection is mandatory. This checks for any damage, leaks, corrosion, or wear and tear on hoses, cables, electrodes, and the welding unit itself.

- Cleaning: After each use, equipment must be meticulously cleaned to remove salt, marine growth, and welding spatter. This prevents corrosion and ensures proper functionality. Freshwater rinsing is crucial, followed by drying.

- Testing: Regular testing of pressure gauges, regulators, and safety mechanisms is vital. This often involves leak checks and functional tests to ensure that safety systems are fully operational. Calibration schedules are strictly adhered to.

- Storage: When not in use, equipment should be stored in a dry, clean, and climate-controlled environment. This minimizes corrosion and extends the lifespan of the equipment. Proper lubrication of moving parts is also critical.

- Maintenance Log: A detailed log should be maintained, recording all inspections, maintenance procedures, repairs, and any issues encountered. This ensures traceability and helps prevent future problems.

For example, I once discovered a small crack in a high-pressure hose during a pre-dive inspection. This prevented a potentially catastrophic failure during the operation. Early detection and prompt replacement of this critical component saved time and prevented a significant safety risk.

Q 23. Explain the procedure for pre- and post-weld inspections.

Pre- and post-weld inspections are critical for ensuring the quality and safety of underwater welds. These inspections follow a rigorous protocol to identify defects and verify weld integrity.

Pre-weld Inspection: This involves assessing the base metal for surface imperfections (e.g., cracks, pitting, corrosion), verifying the dimensional accuracy of the joint, and checking the cleanliness of the weld area. This phase also includes confirming that the welding parameters (e.g., current, voltage, electrode type) are correctly set based on the material being welded. Non-destructive testing (NDT) methods, such as visual inspection and ultrasonic testing, might be used.

Post-weld Inspection: After welding, a thorough visual inspection is performed to check for surface defects such as cracks, porosity, undercuts, and excessive spatter. More advanced NDT methods, like radiographic testing (RT) or magnetic particle inspection (MPI), may be employed to detect internal flaws that are invisible to the naked eye. This phase will also involve checking the weld dimensions (e.g., penetration, reinforcement) against the specified requirements. Detailed records, including photographs and NDT reports, are maintained for future reference.

Imagine welding a critical joint on an offshore platform leg. A pre-weld inspection might reveal corrosion that needs to be addressed before welding. Post-weld inspection ensures the completed weld meets strict quality standards and is sound enough to withstand the immense pressure of the deep sea. Failure to perform these inspections could have disastrous consequences.

Q 24. Describe your experience with underwater welding in different environments (e.g., deep sea, shallow water).

My experience encompasses a wide range of underwater welding environments, from shallow coastal waters to deep-sea operations. Each environment presents unique challenges.

- Shallow Water: Work in shallow waters is often more accessible, with simpler logistics and less extreme pressure. Visibility tends to be better, making inspection easier. However, currents and wave action can still create difficulties.

- Deep Sea: Deep-sea welding is significantly more complex due to the high pressure, reduced visibility, and longer dive times. Specialized equipment, including remotely operated vehicles (ROVs) and saturation diving techniques, is often employed. The increased pressure necessitates the use of specific welding procedures and equipment capable of withstanding extreme conditions.

For example, I’ve worked on pipeline repairs in relatively shallow waters off the coast of [Location], where visibility and manageable currents made the work feasible with standard diving equipment. In contrast, my participation in a deep-sea repair of a subsea oil well head involved saturation diving and the use of an ROV for inspection and support, highlighting the different levels of complexity.

Q 25. What safety precautions must be taken before starting an underwater welding operation?

Safety is paramount in underwater welding. Numerous precautions must be taken before even starting the operation.

- Pre-dive Briefing: A thorough briefing outlining the job, procedures, potential hazards, emergency procedures, and communication protocols must be conducted.

- Equipment Check: A complete and rigorous inspection of all diving and welding equipment is mandatory. This involves verifying the functionality of safety equipment, such as emergency oxygen supplies, communication systems, and buoyancy control devices.

- Environmental Assessment: Factors like water currents, visibility, depth, and potential marine life must be carefully assessed to develop a safe work plan. Weather conditions also play a crucial role.

- Standby Diver: A standby diver is always present to assist the welder in case of any emergency. They’re equipped to handle any unforeseen circumstances, including equipment failure or diver distress.

- Surface Support: A dedicated surface support team is essential to monitor the operation, maintain communication, and provide timely assistance if needed.

- Emergency Procedures: A detailed emergency plan, including procedures for decompression sickness, equipment failure, and other potential incidents, must be established and clearly communicated.

For instance, during a recent project, we had to postpone the dive due to unexpected strong currents. The safety of the divers was prioritized over the project timeline. Adherence to strict safety procedures prevents accidents and ensures a successful outcome.

Q 26. How do you assess the structural integrity of an underwater structure before undertaking welding repairs?

Assessing the structural integrity of an underwater structure before welding repairs requires a systematic approach that combines visual inspection with advanced non-destructive testing (NDT) methods.

- Visual Inspection: A thorough visual inspection is conducted using underwater cameras, ROVs, or divers to identify obvious signs of damage, such as corrosion, cracks, pitting, or deformation. The extent and location of the damage are carefully documented.

- Non-Destructive Testing (NDT): Advanced NDT techniques are employed to evaluate the structural integrity beneath the surface. Common methods include ultrasonic testing (UT), which measures the thickness of the structure and detects internal flaws; magnetic particle inspection (MPI) for detecting surface and near-surface cracks in ferromagnetic materials; and radiographic testing (RT) to produce images of internal structures and defects. The choice of NDT method depends on the material and the type of defect suspected.

- Structural Analysis: Based on the inspection findings, a structural analysis is often performed to determine the load-bearing capacity of the structure and assess the potential impact of the damage. This may involve finite element analysis (FEA) or other computational methods.

For instance, before welding repairs on a damaged offshore platform leg, we conducted UT to measure the remaining thickness of the leg, identify any internal flaws, and assess its remaining strength. This helped us determine the extent of the repairs needed and allowed us to plan the welding procedure accordingly.

Q 27. Describe your experience working with different types of subsea structures (e.g., pipelines, platforms).

My experience encompasses working with various subsea structures, each requiring specialized techniques and considerations.

- Pipelines: Pipeline welding often involves working in confined spaces, requiring expertise in handling the pipeline’s geometry and ensuring complete penetration. The welding process must be carefully controlled to prevent damage to the pipeline’s internal coating.

- Platforms: Platform welding involves working on large structures with complex geometries, often in challenging environments. Welding repairs may require significant logistical planning and coordination with other trades.

- Subsea Equipment: Welding repairs on subsea equipment like manifolds and wellheads requires meticulous work given the high pressure and the critical nature of these components. Specialized equipment and techniques might be necessary.

For example, I’ve welded sections of pipelines in various locations, and the challenges varied based on the pipeline’s diameter, location, and the specific defect being repaired. Welding on a subsea manifold necessitated using advanced NDT techniques to ensure the repair met rigorous standards before putting it back into operation.

Q 28. What are your strengths and weaknesses as an underwater welder?

My strengths as an underwater welder lie in my experience, problem-solving abilities, and commitment to safety.

- Experience: Years of experience in diverse underwater welding environments have provided me with a robust skillset and the ability to adapt to various challenges.

- Problem-Solving: Underwater welding often involves unexpected issues, and my ability to quickly assess the situation, identify solutions, and implement them effectively is a key strength.

- Safety: I prioritize safety above all else and strictly adhere to all safety regulations and protocols.

A weakness I’m actively working on is delegation. While I excel at hands-on work, I’m learning to more effectively delegate tasks to enhance team efficiency. This involves carefully assessing team member skills, distributing tasks appropriately, and providing clear directions.

Key Topics to Learn for Underwater Welding Interview

- Welding Processes: Understanding different underwater welding techniques (e.g., wet welding, dry welding, hyperbaric welding) and their applications in various environments. This includes knowledge of equipment specifics and limitations.

- Materials and Metallurgy: Familiarity with the properties of different metals commonly used in underwater structures and their behavior under pressure and in marine environments. Consider the impact of corrosion and how to mitigate it.

- Safety Procedures and Regulations: Deep understanding of diving safety protocols, emergency procedures, and relevant industry regulations (e.g., OSHA, ASME). This includes risk assessment and mitigation strategies.

- Equipment and Technology: Knowledge of the tools, equipment, and technology used in underwater welding, including welding machines, underwater cutting tools, and life support systems. Be prepared to discuss maintenance and troubleshooting.

- Non-Destructive Testing (NDT): Understanding various NDT methods used to ensure weld quality and structural integrity, such as visual inspection, radiography, and ultrasonic testing.

- Environmental Considerations: Awareness of environmental regulations and best practices for minimizing the impact of underwater welding on marine ecosystems.

- Project Management & Problem Solving: Describe your experience in planning and executing underwater welding projects, including dealing with unexpected challenges and adapting to changing conditions.

Next Steps

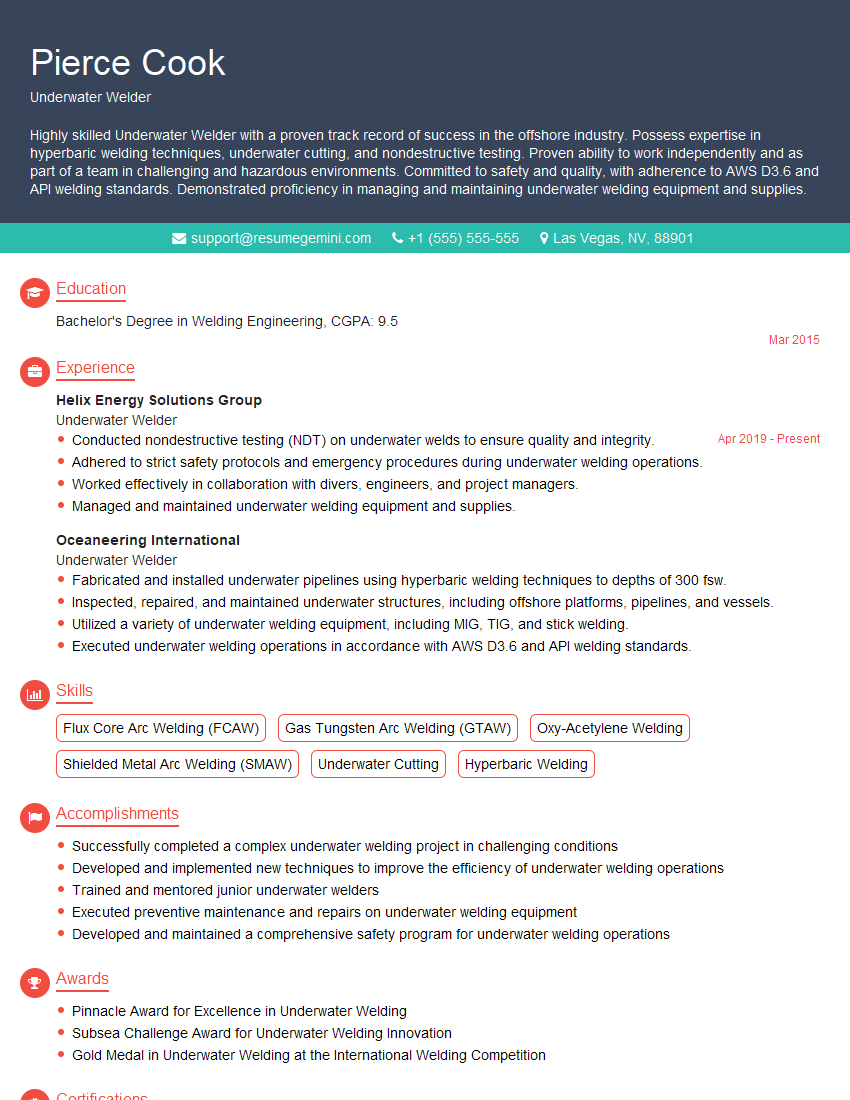

Mastering underwater welding opens doors to a specialized and highly rewarding career, offering unique challenges and opportunities for professional growth within the offshore energy, marine construction, and salvage industries. To maximize your job prospects, it’s crucial to present your skills and experience effectively. Creating an Applicant Tracking System (ATS)-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, ensuring your qualifications shine through. Examples of resumes tailored to the underwater welding field are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO