Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Cable Laying and Repair interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Cable Laying and Repair Interview

Q 1. Explain the process of cable laying in shallow water.

Shallow water cable laying, typically in depths up to 20 meters, involves a more direct approach than deep-sea operations. It often utilizes specialized vessels equipped with cable-laying equipment, but the process is less complex in terms of dynamic positioning and environmental considerations.

The process generally begins with careful survey of the seabed to identify obstacles and determine the optimal route. Then, the cable is carefully paid out from the vessel, often assisted by a remotely operated vehicle (ROV) or divers for monitoring and guiding the cable onto the seabed.

We use various methods depending on the seabed conditions. For example, in relatively flat and stable seabed areas, the cable can be directly laid onto the seafloor. However, rocky or uneven terrain may require the use of trenching equipment towed behind the vessel to create a protective furrow for the cable.

The entire operation is monitored closely using sonar and other underwater imaging systems to ensure the cable is laid correctly and avoids potential hazards. Accurate tracking and documentation are critical for future maintenance and repair activities. On one project, we utilized a specially designed plough to bury the cable several meters beneath the seabed in an area notorious for fishing activity, minimizing risk of damage.

Q 2. Describe the different types of cable faults you have encountered.

Over my career, I’ve encountered a wide range of cable faults, broadly categorized as mechanical and electrical. Mechanical faults include things like cable breaks (often caused by anchor damage or fishing gear), abrasion from seabed movement, or crushing damage from external pressure. Electrical faults are typically more subtle and include issues like water ingress, causing shorts or high attenuation, or even simple connector problems.

I’ve also seen instances of faulty splices, where the connection between two cable sections isn’t properly made, leading to signal loss or intermittent connectivity. One memorable case involved a severe kink in a fiber optic cable caused by an improperly secured buoy during a storm. This kink resulted in significant signal degradation across multiple channels, requiring a complex repair procedure.

- Mechanical Faults: Breaks, kinks, abrasions, crushing.

- Electrical Faults: Water ingress, shorts, high attenuation, connector issues, faulty splices.

Q 3. How do you identify and troubleshoot a fault in a fiber optic cable?

Troubleshooting a fiber optic cable fault is a systematic process. It starts with identifying the location of the fault, usually using an Optical Time-Domain Reflectometer (OTDR), which I’ll explain further in a later answer. Once the location is pinpointed, the next step is to access the affected section of the cable.

This might involve mobilizing a repair vessel, deploying an ROV, or even using divers for shallow-water repairs. After accessing the fault, we visually inspect the cable for signs of damage. If the damage is localized, we’ll usually repair the cable by splicing in a new section. For more extensive damage, a replacement section might be necessary.

After the repair, the quality of the connection is rigorously tested using an OTDR and other optical testing equipment to ensure signal integrity and attenuation levels are within acceptable limits. A simple example: a dropped signal on a specific wavelength can often be traced to a microscopic crack in the fiber, requiring precise splicing and testing to restore full functionality.

Q 4. What safety procedures are crucial during cable laying operations?

Safety is paramount in cable laying and repair operations. We adhere to strict safety protocols throughout the entire process. This includes comprehensive risk assessments before any work commences. We use detailed method statements and permit-to-work systems to manage potential hazards.

Onboard safety training for all personnel is mandatory, covering aspects such as working at heights, handling heavy equipment, working near water, and emergency procedures. Personal protective equipment (PPE) is mandatory and includes life vests, hard hats, safety glasses, and appropriate clothing. We also maintain constant communication among the crew, using radios and other communication tools, to ensure awareness of ongoing activities and to promptly address any safety concerns.

Regular safety inspections and audits are carried out to ensure compliance with regulations and best practices. For example, when working near high voltage power cables, dedicated safety zones and trained personnel are employed to ensure no accidents occur.

Q 5. Explain the use of an OTDR in cable fault location.

An Optical Time-Domain Reflectometer (OTDR) is an indispensable tool for locating faults in fiber optic cables. It works by sending pulses of light down the fiber and analyzing the reflections that return. These reflections are caused by changes in the refractive index of the fiber, such as those caused by a break, bend, or splice.

The OTDR measures the time it takes for the light pulses to travel down the fiber and back, allowing us to determine the distance to the fault. The strength of the reflected signal also provides information about the severity of the fault.

Think of it like an echo-sounding device, but for light. The OTDR’s graphical output shows the fiber’s characteristics along its length, with any faults appearing as distinct events on the trace. This allows for very precise location of the fault, enabling efficient and targeted repair efforts. We routinely use OTDR data to plan repairs and verify the success of our work.

Q 6. How do you handle cable damage during a repair operation?

Handling cable damage during repair requires a careful and systematic approach. First, we fully assess the extent of the damage, taking into account the type of cable, the nature of the damage, and the environmental conditions. This assessment informs the chosen repair strategy.

For minor damage, like small abrasions, we may be able to apply protective sleeving or coatings to reinforce the cable. More severe damage usually necessitates a section of cable replacement. The damaged section is carefully removed, and a new section is spliced in, paying close attention to proper fusion splicing techniques and ensuring the integrity of the splice.

In cases of underwater damage, we might employ ROVs or divers to handle the repair. After the repair, thorough testing, using OTDR and other optical testing equipment, is essential to verify the success of the repair and ensure signal quality has been restored. One specific example I encountered was the repair of a cable damaged by a ship’s anchor. We used an ROV to carefully remove the damaged section and replace it with a new fiber using an underwater splicing kit.

Q 7. Describe your experience with different cable jointing techniques.

My experience encompasses a variety of cable jointing techniques, tailored to different cable types and environments. For fiber optic cables, fusion splicing is the preferred method for its superior performance and reliability. This involves precisely aligning the fiber ends using a fusion splicer, then fusing them together with an electric arc. This creates a seamless connection with minimal signal loss.

Mechanical splicing methods are also used, particularly for older cables or in situations where fusion splicing isn’t feasible. These involve mechanically clamping the fibers together. However, these methods often lead to higher signal loss compared to fusion splicing.

For power cables, jointing methods vary greatly depending on the cable’s voltage and insulation type. Specialized tools and techniques are used to ensure electrical safety and insulation integrity. I’ve worked extensively with various termination techniques, including heat-shrink tubing, epoxy resin filling, and specialized cable glands. Each technique requires precision and attention to detail to meet stringent industry standards. We document all aspects of every joint, including type of connector, splice details, and test results, for future reference and maintenance purposes.

Q 8. What are the challenges of cable laying in deep sea environments?

Deep-sea cable laying presents unique and significant challenges. The immense pressure at depth requires specialized, robust cables and equipment. Imagine trying to lay a garden hose in the Mariana Trench – the pressure alone would crush it. Furthermore, the unpredictable seabed terrain, including underwater mountains, canyons, and even potential landslides, necessitates precise route planning and careful cable handling to prevent damage. Strong currents can also make positioning and laying the cable incredibly difficult, potentially leading to cable snags or even breakage. Finally, visibility is severely limited, relying heavily on sonar and remotely operated vehicles (ROVs) for guidance and inspection, increasing the complexity and cost of the operation.

For example, during a recent project in the Atlantic, we had to navigate a complex underwater canyon system. Using advanced sonar mapping and a dynamic positioning vessel, we were able to successfully lay the cable, mitigating the risk of snagging. This highlights the importance of sophisticated technology and detailed planning in deep-sea cable laying.

Q 9. How do you ensure the integrity of a cable splice?

Ensuring the integrity of a cable splice is crucial for maintaining a reliable communication link. Think of it like seamlessly joining two pieces of a vital artery – any imperfection could lead to catastrophic failure. The process begins with meticulous preparation. The cables are carefully cleaned and prepared, removing any damaged or compromised outer sheath material. Then, the inner conductors are carefully stripped and joined using specialized connectors. The splice is then encapsulated using a waterproof, pressure-resistant material to protect it from the harsh marine environment. Testing is crucial. We use specialized equipment to ensure the electrical and mechanical properties of the splice meet stringent standards. Finally, the entire splice is thoroughly documented and inspected to guarantee long-term reliability. This usually involves high-voltage testing to ensure the insulation is robust and also optical testing if fibre-optic cables are involved.

Q 10. What are the different types of cable used in telecommunications?

Telecommunication cables come in various types, each designed for specific applications and environments. The most common are coaxial cables, fiber-optic cables, and hybrid cables. Coaxial cables, familiar from older cable TV systems, use a central conductor surrounded by an insulator and a shield, carrying signals effectively over short to medium distances. However, they become less efficient over long distances and are less bandwidth-capable than fiber optic cables. Fiber-optic cables use light pulses to transmit data, offering exceptionally high bandwidth and long-distance transmission capabilities. These are the backbone of modern undersea telecommunication networks. Hybrid cables combine both coaxial and fiber-optic components, offering a balance of legacy and cutting-edge transmission capabilities. The choice of cable depends heavily on factors like distance, bandwidth requirements, and budget. Selecting the right cable is key to the system’s overall performance and longevity.

Q 11. Explain the process of cable termination.

Cable termination is the process of preparing the end of a cable for connection to other equipment. It’s like preparing the end of an electrical wire before you connect it to a socket. The process involves carefully stripping away the outer layers of the cable, exposing the internal conductors. These conductors are then connected to appropriate connectors, which are designed to match the specific equipment. For example, a fiber-optic cable requires a precise mechanical splice or connector, maintaining the proper alignment of the fibers. After the connection, the termination point is carefully sealed and protected to prevent damage from moisture and environmental factors. This is crucial to maintain the integrity and safety of the cable system. Proper termination ensures signal quality and prevents corrosion or water ingress, maintaining the reliability of the overall network.

Q 12. How do you perform cable testing and what equipment do you use?

Cable testing is vital for ensuring the functionality and integrity of a cable system. Think of it like a thorough health check for the cable. We use various sophisticated instruments, such as Time Domain Reflectometers (TDRs) to locate faults or breaks, Optical Time Domain Reflectometers (OTDRs) for fiber optic cables, and cable testers that can check the electrical continuity and resistance. TDRs send pulses down the cable and measure the time it takes for the reflections to return, pinpointing any discontinuities along the cable’s length. OTDRs perform a similar function but for the optical signals in fiber optic cables. We also perform high-voltage tests to assess insulation integrity. The results of these tests are meticulously documented to provide a complete assessment of the cable’s health and operational capability. This data guides repair efforts and helps predict potential future problems.

Q 13. What are the environmental considerations in cable laying?

Environmental considerations are paramount in cable laying. We need to be mindful of the impact on marine ecosystems, minimizing disruption to sea life and habitats. This includes careful route planning to avoid sensitive areas like coral reefs or breeding grounds. Furthermore, the cable’s design must withstand the harsh marine environment, including corrosion, extreme pressure, and biofouling (organisms attaching to the cable). We must also comply with strict environmental regulations and obtain necessary permits before commencing any work. Sustainability is becoming an increasingly important aspect, encouraging the use of environmentally friendly materials and minimizing waste during the cable laying process. For instance, using environmentally friendly coatings and minimizing seabed disturbance during the laying process are critical considerations.

Q 14. Describe your experience working with ROVs (Remotely Operated Vehicles) in cable repair.

ROVs are indispensable tools in cable repair, especially in deep-sea environments. Imagine a surgeon using a robotic arm to perform delicate surgery – that’s the role of an ROV in undersea cable repair. My experience involves using ROVs to inspect damaged cables, identify the precise location of faults, and assist in repair operations. We use high-resolution cameras and manipulators controlled from a surface vessel to locate and repair damaged sections, even in difficult-to-reach areas. The ROV’s maneuverability allows for precise operations in challenging currents or uneven seabed terrain. For example, during a cable repair operation in the Pacific, an ROV successfully located and assessed the damage caused by a fishing trawler, providing critical information for the repair team. The use of ROVs drastically reduces the risks involved in human deep-sea interventions, while significantly increasing the efficiency and precision of the repair process.

Q 15. Explain the role of a cable landing station.

A Cable Landing Station (CLS) is the crucial onshore facility where submarine cables come ashore. Think of it as the ‘gateway’ to the underwater world of telecommunications. It’s not just a point of connection; it’s a complex hub managing the transition from the underwater cable to the terrestrial network. The CLS houses vital equipment, including repeaters (amplifiers for the signal), branching units (allowing connections to multiple destinations), and sophisticated monitoring systems that continuously track cable health. It also features robust power supplies, backup generators, and security measures to ensure network uptime. For instance, a CLS might house a sophisticated fiber optic splicing facility allowing for seamless integration with the land-based infrastructure, or a repair bay equipped to handle minor cable damages without interrupting service.

Without a well-equipped and strategically placed CLS, maintaining the integrity of submarine cable networks and ensuring reliable global communications would be impossible. Its importance is underscored by the fact that many CLS’s include redundant systems and are designed to withstand extreme events like earthquakes or floods.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage cable slack during installation?

Managing cable slack during installation is paramount to prevent damage and ensure longevity. Too little slack can lead to cable breakage from stress, while excessive slack creates potential hazards like snagging on seabed obstructions or damage during currents. The amount of slack needed varies based on factors like water depth, seabed topography, and the cable’s characteristics. We use sophisticated modeling software to calculate the precise amount of slack necessary. In practice, this involves a combination of techniques including:

- Dynamic Positioning (DP) vessels: These ships use GPS and advanced systems to maintain precise position during cable laying, minimizing the introduction of unnecessary stress and allowing for precise slack management.

- Cable tension monitoring: Real-time monitoring of cable tension using specialized sensors provides feedback to control the payout rate and maintain optimal tension.

- Burial techniques: Once laid, the cable is often buried using specialized equipment to protect it from external damage. The burial process itself also considers slack to avoid strain on the cable.

- Slack calculations incorporating environmental conditions: Calculations take into account the anticipated seabed currents, tides, and potential temperature fluctuations, as these factors can all impact cable tension and the necessary slack over time. This ensures sufficient slack to accommodate these movements and protect the cable’s integrity.

Imagine laying a garden hose; you wouldn’t pull it taut, but leave some slack to accommodate movements. Similarly, we need to account for environmental fluctuations that the cable will experience in the long term.

Q 17. Describe your experience with different types of cable protection systems.

My experience encompasses a range of cable protection systems, chosen based on specific environmental factors and project requirements. These include:

- Armored cables: These cables incorporate metallic layers providing protection against abrasion and physical damage from fishing gear or anchors. The armor type and thickness vary based on the severity of the risk. For example, in areas with heavy fishing traffic, a stronger armor would be used.

- Burial: Burying the cable beneath the seabed is one of the most effective ways of protection from external damage. This is often done using water jets, ploughs, or trenching systems. The burial depth depends on the anticipated threats, cable type and site-specific soil conditions.

- Rock protection: In areas with rocky seabeds, rock protection systems may be necessary. This often involves deploying concrete mattresses or other protective materials around the cable to prevent rock abrasion.

- Concrete coating: A concrete coating can offer additional protection against abrasion and physical damage, particularly in shallow water environments where the cable may be subject to more intense forces.

The selection process is based on risk assessment, and we often utilize a combination of techniques to ensure optimum protection in high-risk environments. For instance, a cable laid in a high-traffic shipping area may require a combination of armoring, burial, and potentially additional rock protection.

Q 18. What are the limitations of different cable testing methods?

Different cable testing methods have limitations. For example:

- Time Domain Reflectometry (TDR): While excellent for locating faults, TDR struggles to pinpoint precise fault locations in long cables, and the resolution can be affected by cable type and environmental conditions.

- Optical Time Domain Reflectometry (OTDR): OTDR is widely used for fiber optic cables and is very precise in fault location, but can be expensive and complex to operate. Also, the interpretation can be affected by variations in light loss due to environmental conditions.

- Electrical testing: Testing for insulation resistance and capacitance helps identify potential weaknesses, but may not detect subtle faults or those that only manifest under operational conditions. Furthermore, these tests can be time consuming.

Choosing the right method requires careful consideration of the specific cable type, the suspected nature of the fault, and the available resources. Often, a combination of methods is employed for comprehensive diagnosis.

Q 19. How do you interpret cable test results?

Interpreting cable test results requires expertise. For example, in OTDR results, high attenuation values point to possible fiber damage, while back reflections indicate potential connector problems or breaks. In TDR testing, a sudden change in impedance suggests a fault location. Similarly, low insulation resistance suggests a potential short circuit. We use specialized software to analyze these results and often corroborate the findings with additional tests. The interpretation considers various factors, including the cable’s specifications, environmental conditions at the time of testing, and past maintenance history.

I always cross-reference test results from different methods before reaching conclusions, as this provides a more holistic understanding and enhances the accuracy of fault diagnosis. It’s like solving a puzzle; each piece of data contributes to the overall picture. This multi-faceted approach minimizes errors and increases the likelihood of identifying the problem quickly and effectively.

Q 20. What are the key performance indicators (KPIs) for cable laying projects?

Key Performance Indicators (KPIs) for cable laying projects include:

- On-time completion: Meeting scheduled milestones is critical for minimizing project costs and disruptions. Delays can lead to significant financial penalties.

- Within-budget completion: Efficient management of resources and materials is crucial to staying within the allocated budget.

- Cable fault rate: A low fault rate during and after installation indicates a successful project, demonstrating efficient planning and execution.

- Safety record: Maintaining a strong safety record is paramount. Injuries or accidents can lead to delays and increased costs. This necessitates strict adherence to safety protocols and procedures.

- Environmental impact: Minimizing the environmental impact of the project, including avoiding damage to marine ecosystems, is crucial and often a contractual requirement.

Regular monitoring of these KPIs ensures the project stays on track and meets all the desired outcomes. We use project management software to track progress and identify potential issues early on, allowing for proactive measures to mitigate any risks.

Q 21. How do you manage risk during a cable repair operation?

Risk management during cable repair is crucial, as downtime can have significant consequences. My approach involves:

- Thorough risk assessment: Identifying potential hazards, like weather conditions, seabed obstructions, and equipment failure, is the first step. This often involves reviewing historical data and environmental predictions.

- Contingency planning: Developing detailed plans for handling various scenarios is essential. This might include alternative repair strategies, backup equipment, or emergency procedures.

- Safety procedures: Adhering to strict safety protocols, including proper use of safety gear and emergency response plans, protects the crew and minimizes risks.

- Communication protocols: Maintaining clear communication channels between the onshore team, the repair vessel, and other stakeholders is essential. This ensures efficient coordination and timely decision-making.

- Environmental protection: Repair operations must minimize their environmental impact. This includes careful handling of waste materials and minimizing any damage to marine life or habitats.

For example, if we anticipate challenging weather conditions, we’ll ensure the repair vessel has the necessary equipment and staffing to handle potential delays or disruptions. We also ensure that all personnel are trained in emergency procedures and familiar with the specific risks associated with the repair site.

Q 22. Describe your experience with cable burial techniques.

Cable burial techniques are crucial for protecting underground cables from damage. My experience encompasses various methods, tailored to the specific terrain and cable type. These include trenching, plowing, and directional drilling.

- Trenching: This traditional method involves digging a trench, laying the cable, and backfilling. It’s suitable for accessible areas but can be time-consuming and disruptive. I’ve overseen numerous trenching projects, ensuring proper depth and backfill compaction to prevent cable damage.

- Plowing: This method uses a specialized plow to create a furrow, minimizing ground disruption. It’s faster than trenching and ideal for longer stretches, but it’s less suitable for rocky or densely populated areas. I’ve successfully managed projects using plowing techniques, carefully monitoring cable tension and soil conditions.

- Directional Drilling: This is used for difficult terrains or where surface disruption needs to be minimized. A drilling rig bores a path underground, pulling the cable through the created channel. I have extensive experience with directional drilling, including navigating obstacles and ensuring precise cable placement, particularly vital in urban environments.

My experience covers diverse cable types, including high-voltage power cables and fiber optic cables, each requiring specific burial depths and protective measures.

Q 23. How do you maintain accurate records during cable installation and repair?

Maintaining accurate records is paramount for cable infrastructure management and future maintenance. We employ a rigorous system encompassing several key components.

- Digital Mapping: Using GIS software, we create detailed maps of cable routes, including depths, cable types, and splice locations. This provides a centralized, accessible record of the entire network.

- As-Built Drawings: Following installation, we produce detailed as-built drawings reflecting the actual cable layout, which might differ slightly from initial plans due to unforeseen ground conditions. This is essential for future repairs or upgrades.

- Database Management: We use a relational database to log all aspects of the installation, including dates, crew details, equipment used, and any encountered issues. This ensures traceability and allows for efficient reporting and analysis.

- Physical Documentation: Each cable section is labeled and marked with unique identifiers. This physical labeling, along with detailed documentation at each splice point, ensures quick identification during repairs.

Regular audits ensure the accuracy and completeness of these records, which is crucial for minimizing downtime and improving overall efficiency.

Q 24. What is your experience with different cable materials (e.g., copper, fiber optic)?

My experience spans various cable materials, each with unique characteristics requiring specific handling and installation procedures.

- Copper Cables: I’m well-versed in working with various gauges of copper cables, from power distribution to telecommunications applications. Understanding the effects of corrosion and the need for proper grounding is critical.

- Fiber Optic Cables: Working with fiber optics requires specialized knowledge, including handling techniques to avoid damage to the delicate fibers. I understand the importance of proper splicing and testing to ensure signal integrity. I’ve worked with various types of fiber, including single-mode and multi-mode, and have experience with fusion splicing and mechanical splicing techniques.

Beyond the material itself, understanding the cable’s construction, including sheathing, armoring, and the impact of environmental factors (e.g., water ingress, temperature fluctuations), is key to ensuring long-term performance and avoiding premature failure.

Q 25. Explain your experience with cable route planning and surveying.

Cable route planning and surveying are critical for efficient and safe installations. It involves a detailed assessment of the terrain and infrastructure to identify the optimal path.

- Site Surveys: We conduct thorough site surveys, utilizing tools such as GPS, ground-penetrating radar (GPR), and aerial imagery to identify potential obstacles like underground utilities, rocky areas, or environmentally sensitive zones.

- Route Optimization: Using specialized software, we analyze survey data to design the most efficient and cost-effective cable route, minimizing environmental impact and avoiding conflict with existing infrastructure. This frequently involves considering factors like minimizing bends to reduce signal loss in fiber optics.

- Stakeout and Marking: Once the route is finalized, we clearly mark the path on the ground to guide the installation crews. This ensures accurate cable placement and minimizes excavation in unintended areas.

In my experience, meticulous planning and surveying are fundamental to preventing delays, reducing costs, and avoiding costly rework later in the project.

Q 26. How do you ensure compliance with industry regulations and standards?

Compliance with industry regulations and standards is a non-negotiable aspect of cable laying and repair. We adhere strictly to all relevant local, national, and international standards.

- Safety Regulations: We rigorously follow safety protocols, including OSHA regulations (or equivalent) for excavation, trenching, and working with high-voltage cables. This includes regular safety training and risk assessments.

- Environmental Regulations: We are acutely aware of environmental regulations and strive to minimize the environmental impact of our operations, adhering to regulations on ground disturbance, waste disposal, and habitat protection.

- Industry Standards: We follow standards set by organizations like TIA (Telecommunications Industry Association), IEC (International Electrotechnical Commission), and others relevant to the specific cable type and application. This ensures interoperability and quality.

- Permitting and Approvals: We diligently obtain all necessary permits and approvals from relevant authorities before commencing any work.

Maintaining comprehensive documentation of compliance is essential, allowing for efficient audits and demonstration of adherence to all applicable regulations.

Q 27. Describe a challenging cable repair situation you faced and how you resolved it.

During a recent project, a major fiber optic cable suffered significant damage due to a third-party excavation. The cable was severed in multiple locations, leading to a widespread service outage. The challenge was to restore service quickly and efficiently while minimizing further disruption.

My approach involved a structured, multi-step process:

- Immediate Assessment: I first conducted a thorough assessment of the damage, precisely locating all breaks and evaluating the extent of the damage.

- Emergency Repair: We deployed a specialized team with fusion splicing equipment to repair the severed fibers. Temporary repairs were implemented to restore partial service while permanent repairs were in progress.

- Coordination: Close coordination with the third-party responsible for the damage was essential to determine liability and initiate compensation procedures.

- Long-Term Solution: To prevent future damage, we collaborated with local utility companies to update underground utility maps and implement proactive measures to protect the repaired cable section.

Through careful planning, efficient coordination, and the application of our expertise, we successfully restored full service within a significantly shorter timeframe than originally anticipated, minimizing customer disruption and ensuring long-term cable integrity.

Q 28. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and qualifications in this specialized field. Considering my extensive background in cable laying and repair, my proven ability to manage complex projects, and my commitment to adhering to the highest safety and regulatory standards, I am seeking a competitive salary range of [Insert Salary Range Here]. I am confident that my contributions will significantly benefit your organization.

Key Topics to Learn for Cable Laying and Repair Interview

- Cable Types and Properties: Understanding different cable types (coaxial, fiber optic, etc.), their characteristics, and applications in various networks.

- Installation Techniques: Mastering trenching methods, aerial cable placement, underground conduit installation, and splicing techniques.

- Fault Location and Repair: Developing proficiency in using testing equipment (OTDR, TDR) to pinpoint cable faults and applying effective repair strategies.

- Safety Regulations and Procedures: Demonstrating a thorough understanding of safety protocols, including working at heights, trench safety, and handling hazardous materials.

- Network Topology and Design: Familiarity with different network architectures and understanding how cable layout contributes to overall network performance.

- Preventive Maintenance and Troubleshooting: Explaining strategies for proactive cable maintenance and troubleshooting common issues to minimize downtime.

- Documentation and Reporting: Understanding the importance of accurate record-keeping, including as-built drawings and repair reports.

- Teamwork and Communication: Highlighting your ability to collaborate effectively within a team and communicate technical information clearly.

- Problem-solving and Critical Thinking: Showcasing your ability to analyze complex situations, identify root causes of problems, and develop effective solutions under pressure.

Next Steps

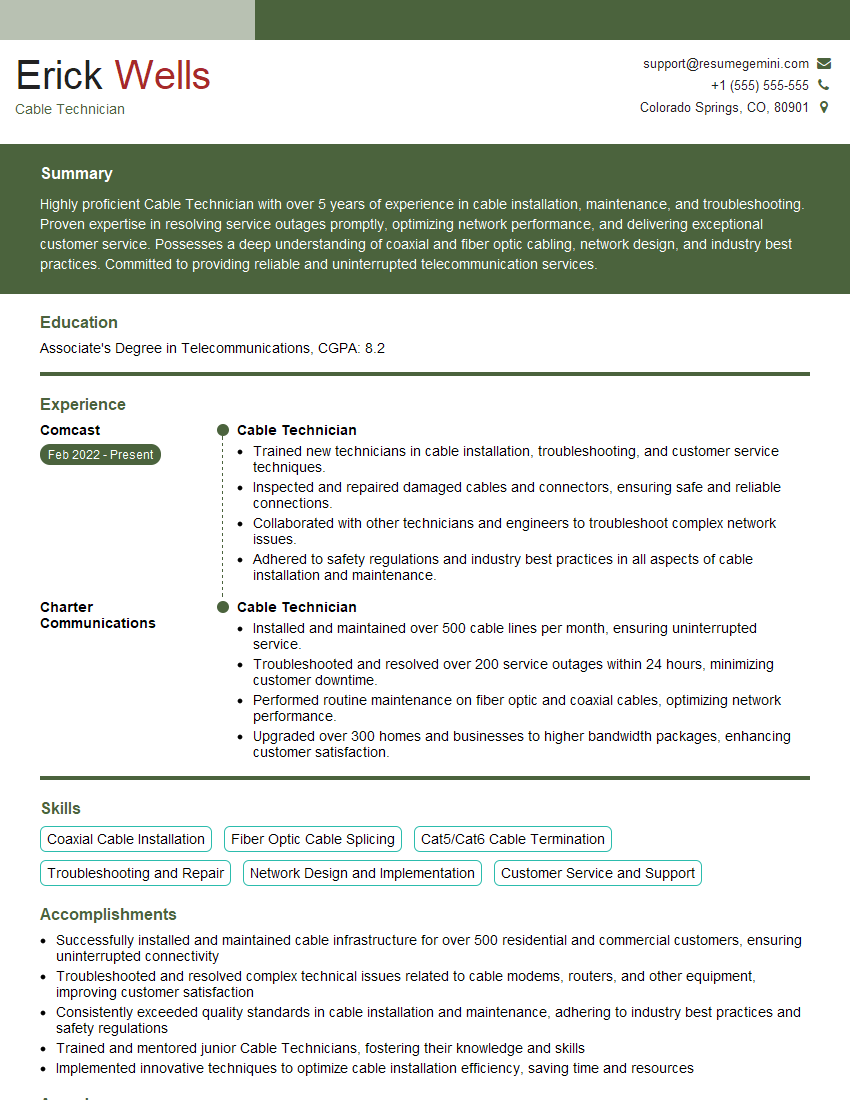

Mastering Cable Laying and Repair opens doors to a rewarding career with excellent growth potential in the telecommunications industry. To maximize your job prospects, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of Cable Laying and Repair roles. We provide examples of resumes specifically designed for this field to help you showcase your skills and experience effectively. Invest time in crafting a compelling resume—it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO