Unlock your full potential by mastering the most common Dredging and Reclamation interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Dredging and Reclamation Interview

Q 1. Explain the different types of dredging methods.

Dredging methods are categorized based on how they excavate and transport sediment. The primary types are:

- Trailing Suction Hopper Dredgers (TSHD): These are like giant vacuum cleaners of the sea. A trailing suction pipe, dragged along the seabed, sucks up sediment and pumps it into a hopper located within the vessel. Once the hopper is full, the dredge travels to a disposal site and releases the sediment. They’re ideal for large-scale projects in relatively flat areas.

- Cutter Suction Dredgers (CSD): These are powerful machines with rotating cutters that break up compacted sediment, making it easier to suck up. They are excellent for digging in denser materials and deeper water. CSDs often use pipelines to transport sediment to a considerable distance.

- Bucket Dredgers: These employ a series of buckets on a rotating wheel to dig and lift sediment. Bucket dredgers are highly versatile and capable of handling a wide range of soil types, including hard clay and rock. They are particularly useful in confined spaces and for precise excavation.

- Grab Dredgers: These use a clamshell-like bucket to grab and lift sediment. They’re often used for smaller projects or for areas where precise excavation is needed. They’re not as efficient as CSDs or TSHDs for large volumes.

- Dipper Dredgers: These resemble large excavators on barges. A dipper bucket is used to excavate and deposit material onto barges or a nearby location. They’re suitable for digging in relatively shallow water and hard soil types.

The choice of dredging method depends heavily on factors such as the type of sediment, water depth, project scale, and environmental considerations.

Q 2. Describe your experience with cutter suction dredgers.

I have extensive experience with cutter suction dredgers (CSDs), having overseen projects ranging from channel deepening in busy ports to land reclamation initiatives. My work includes designing optimal dredging strategies, selecting appropriate CSD specifications based on soil conditions and project requirements, and managing the overall operation, including monitoring efficiency and addressing any unforeseen challenges. For example, on a recent project to expand a port in Southeast Asia, we used a CSD with a powerful cutter head to excavate through dense clay and silty sand. We utilized sophisticated pipeline systems to transport the dredged material several kilometers to a designated disposal area, carefully managing the slurry density to minimize environmental impact. During this project, I focused on optimizing the cutter head speed and pump pressure to maximize excavation rate while maintaining the pipeline’s operational efficiency, reducing both time and cost.

Q 3. What are the environmental considerations in dredging projects?

Environmental considerations are paramount in dredging. The key concerns are:

- Water Quality: Dredging can disturb sediment containing pollutants, leading to turbidity (cloudiness) and the release of contaminants into the water column. This can harm aquatic life and ecosystems. Mitigation strategies include careful sediment management, turbidity curtains, and water quality monitoring.

- Habitat Disturbance: Dredging directly impacts benthic habitats (the seafloor), destroying ecosystems and displacing organisms. Careful planning, including habitat mapping and avoidance strategies, is crucial.

- Sediment Disposal: The disposal of dredged material must be managed responsibly. Uncontrolled disposal can lead to pollution and habitat damage. Options include confined disposal facilities, beneficial use (e.g., beach nourishment), and deep-sea disposal (with stringent regulations).

- Noise Pollution: Dredging equipment generates significant noise pollution, which can affect marine mammals and other aquatic species. Minimizing noise through operational adjustments and implementing mitigation measures is important.

Environmental impact assessments (EIAs) are mandatory for most dredging projects to identify potential impacts and define appropriate mitigation measures.

Q 4. How do you manage dredging project risks and safety?

Risk management and safety are critical in dredging. My approach involves:

- Hazard Identification and Risk Assessment: A thorough assessment identifies potential hazards such as equipment malfunction, environmental incidents, and human error. This informs the development of risk mitigation strategies.

- Safety Procedures and Training: Strict safety protocols are implemented, including pre-job briefings, regular inspections, and comprehensive training for all personnel. Emergency response plans are crucial.

- Equipment Maintenance: Regular maintenance and inspection of dredging equipment minimize the risk of malfunctions and accidents.

- Environmental Monitoring: Continuous monitoring of water quality and sediment parameters allows for early detection of potential problems and timely corrective action.

- Communication and Coordination: Effective communication and coordination among all project stakeholders (including contractors, regulatory agencies, and the local community) are vital for success.

A proactive approach to risk management significantly reduces the likelihood of accidents and ensures project success while protecting the environment and personnel.

Q 5. Explain your experience with sediment transport modeling.

I have extensive experience using sediment transport models, such as Delft3D and MIKE 21, to predict the movement of sediment during dredging operations and to assess the potential impacts of dredging on the surrounding environment. These models use complex algorithms to simulate hydrodynamic processes and sediment transport, allowing us to predict changes in water depth, flow patterns, and sediment concentration. In one project, we used Delft3D to simulate the impact of channel deepening on nearby shorelines. The model helped us predict potential erosion and deposition patterns, allowing us to optimize the dredging plan and minimize negative environmental effects. The results were crucial in obtaining the necessary permits and ensuring the long-term stability of the project.

Q 6. Describe your experience with different types of reclamation projects.

My reclamation experience encompasses various project types:

- Land Creation from Dredged Material: This involves using dredged material to create new land areas, typically for development purposes. This requires careful consideration of soil compaction, drainage, and environmental impacts.

- Coastal Protection: Reclamation can create new coastal landforms to protect existing shorelines from erosion. This might involve creating artificial reefs or beach nourishment using dredged sand.

- Habitat Restoration: Reclamation can be used to restore degraded habitats by creating new wetlands or intertidal areas using dredged material and careful ecological engineering.

Each project requires a unique approach, considering the local environmental conditions, engineering requirements, and regulatory guidelines. For example, in one project involving creating a new industrial area, we utilized dredged material with appropriate soil amendment to ensure sufficient strength and stability for infrastructure development while mitigating environmental concerns by carefully managing water quality during the process.

Q 7. How do you ensure compliance with environmental regulations during dredging?

Ensuring regulatory compliance is crucial. This involves:

- Obtaining Necessary Permits: Securing all required permits from relevant environmental and regulatory agencies prior to commencing dredging activities. This includes submitting detailed environmental impact assessments and project plans.

- Adhering to Permit Conditions: Strictly adhering to all conditions stipulated in the issued permits. This might include limitations on dredging depths, sediment disposal locations, and water quality monitoring protocols.

- Regular Monitoring and Reporting: Regularly monitoring environmental parameters (e.g., turbidity, water quality, noise levels) and submitting accurate reports to the regulatory agencies.

- Emergency Response Planning: Having a comprehensive emergency response plan to handle any unforeseen environmental incidents.

- Collaboration with Regulatory Agencies: Maintaining open communication and collaboration with regulatory agencies throughout the project lifecycle.

Proactive compliance not only minimizes the risk of penalties but also demonstrates environmental responsibility and strengthens the project’s sustainability.

Q 8. Explain your experience with dredge spoil disposal methods.

Dredge spoil disposal is a critical aspect of dredging projects, encompassing the safe and environmentally responsible management of excavated material. The method chosen depends heavily on the spoil’s characteristics (e.g., toxicity, grain size) and the surrounding environment. My experience includes a wide range of disposal techniques.

- Confined Disposal Facilities (CDFs): These engineered landfills are designed to contain dredged material securely, minimizing environmental impact. I’ve overseen the construction and operation of several CDFs, ensuring compliance with stringent regulatory requirements regarding liner integrity, leachate collection, and gas monitoring. For example, on a recent project involving contaminated sediments, we implemented a multi-layered geomembrane system within the CDF to prevent contaminant migration into groundwater.

- Open Water Disposal (OWD): While less common due to stricter environmental regulations, I have experience with OWD in situations where rigorous testing confirmed the material’s inertness and minimal environmental impact. This always involved thorough pre- and post-disposal environmental monitoring to evaluate the effects on water quality and benthic communities.

- Beneficial Use: This environmentally sound approach involves repurposing dredge spoil for constructive purposes. I’ve been involved in projects where dredged material was used for land reclamation, creating new habitats or expanding existing ones. One notable project involved using dredged sand to create a beach nourishment area, restoring a critically eroded coastline. This required careful analysis of the material’s suitability and extensive permitting processes.

- Dike Construction: Creating containment areas using dredged material itself. I have worked on projects where the dredged material was suitable for forming dikes around the disposal area, reducing the overall footprint and associated costs.

Selecting the appropriate disposal method involves rigorous environmental impact assessments, cost-benefit analyses, and stakeholder consultations to ensure compliance and minimize negative impacts on the environment and surrounding communities.

Q 9. Describe your experience with project planning and scheduling in dredging projects.

Project planning and scheduling in dredging are crucial for success, requiring meticulous attention to detail and coordination. My approach involves a phased methodology, starting with a comprehensive feasibility study.

- Feasibility Study: This includes site surveys, environmental impact assessments, geotechnical investigations, and preliminary cost estimations. This stage informs the scope of the project and guides subsequent planning.

- Detailed Design: Following the feasibility study, a detailed engineering design is developed, specifying dredging techniques, equipment selection, and disposal plans. This is where I use software like AutoCAD Civil 3D and other specialized dredging design tools.

- Scheduling and Sequencing: A detailed project schedule is created using tools like Primavera P6, outlining all tasks, dependencies, and resource allocation. Critical path analysis is crucial to identify potential bottlenecks and develop mitigation strategies. For instance, coordinating barge movements, dredge mobilization, and disposal site availability requires careful scheduling.

- Risk Management: Identifying potential risks (e.g., weather delays, equipment malfunction, regulatory changes) and developing contingency plans is crucial. This involves regular monitoring and proactive risk mitigation measures.

Effective communication and collaboration among all project stakeholders are paramount throughout the planning and scheduling phases. This includes regular meetings, progress reports, and open communication channels to maintain alignment and address any issues promptly.

Q 10. How do you manage budgets and resources in dredging projects?

Budget and resource management in dredging projects demands a combination of meticulous planning and proactive monitoring. My approach emphasizes creating a realistic budget that incorporates all anticipated costs.

- Detailed Cost Breakdown: The budget is meticulously broken down into different categories, including dredging operations, disposal, equipment rental, labor, permits, environmental monitoring, and contingency funds. This requires thorough cost estimation based on historical data and market analysis.

- Resource Allocation: Resources (personnel, equipment, materials) are carefully allocated based on the project schedule and work breakdown structure. This is often done using specialized project management software.

- Cost Control: Regular cost tracking and variance analysis are crucial for identifying cost overruns early on and implementing corrective actions. I use earned value management techniques to track project performance against the baseline budget.

- Value Engineering: I actively seek opportunities for value engineering to reduce costs without compromising project quality or safety. This might involve optimizing dredging techniques, negotiating better rates with suppliers, or exploring alternative disposal options.

Effective communication with the client and project team is essential to maintain budget transparency and ensure that any cost variations are understood and approved.

Q 11. What are the key performance indicators (KPIs) you track in dredging projects?

Key Performance Indicators (KPIs) are crucial for monitoring the progress and performance of dredging projects. The specific KPIs tracked depend on the project’s goals and characteristics, but some key examples include:

- Cubic Meters Dredged per Day/Hour: Measures the efficiency of the dredging operation and the productivity of the equipment.

- Cost per Cubic Meter Dredged: Tracks the cost-effectiveness of the project.

- Percentage of Project Completion: Provides an overall view of progress against the planned schedule.

- Environmental Compliance Rate: Measures adherence to environmental regulations and permits.

- Safety Incident Rate: Tracks safety performance and identifies areas for improvement.

- Disposal Site Capacity Utilization: Monitors the usage of the disposal site and ensures sufficient capacity.

- Timely Completion of Milestones: Tracks if crucial project milestones are met on schedule.

Regular monitoring and reporting of these KPIs are essential for identifying issues, making data-driven decisions, and ensuring the project is progressing according to plan. Dashboards and reporting tools are used to visualize these KPIs and facilitate decision-making.

Q 12. Describe your experience with stakeholder management in dredging projects.

Stakeholder management is paramount in dredging projects, as these projects often involve diverse interests and potentially conflicting priorities. My approach involves proactive engagement and open communication.

- Stakeholder Identification and Analysis: Identifying all stakeholders (e.g., regulatory agencies, local communities, environmental groups, port authorities, contractors) and understanding their interests and concerns is a critical first step. This includes mapping out stakeholder influence and relationships.

- Communication Plan: Developing a clear communication plan that outlines methods, frequency, and channels for communication with each stakeholder group is important. This could involve public forums, regular meetings, newsletters, or online portals.

- Engagement and Consultation: Proactively engaging stakeholders through consultations, public hearings, and feedback sessions demonstrates transparency and builds trust. Addressing concerns and incorporating feedback into the project plans is crucial.

- Conflict Resolution: Developing strategies for resolving conflicts among stakeholders and mediating disagreements in a fair and efficient manner is essential. This often involves negotiation and compromise.

By prioritizing proactive communication, transparency, and inclusivity, I strive to build strong relationships with all stakeholders and ensure the project progresses smoothly while addressing everyone’s concerns. Successful stakeholder management is crucial for securing necessary permits and ensuring public support for the project.

Q 13. How do you address unexpected challenges or delays in dredging projects?

Unexpected challenges and delays are inevitable in dredging projects. My approach involves a proactive risk management strategy combined with a robust problem-solving framework.

- Proactive Risk Assessment: Identifying potential risks (e.g., unforeseen ground conditions, equipment failure, adverse weather) during the planning phase is crucial. This informs the development of contingency plans and mitigation strategies.

- Problem Identification and Analysis: When challenges arise, the first step is to identify the root cause and analyze its impact on the project schedule, budget, and environmental goals.

- Solution Development and Implementation: Developing and implementing solutions requires creativity, technical expertise, and collaborative decision-making. This might involve adapting the dredging method, procuring replacement equipment, or adjusting the project schedule.

- Communication and Reporting: Keeping stakeholders informed about the challenges and the actions taken is essential. Transparent and timely communication maintains trust and facilitates collaboration.

- Lessons Learned: After each challenge, a thorough review of the situation is undertaken to identify lessons learned and improve future project planning and execution. This fosters continuous improvement and risk mitigation.

A flexible approach and a willingness to adapt to changing circumstances are vital for successfully navigating unexpected challenges in dredging projects. My experience has shown that early problem identification and proactive communication are key to minimizing the impact of delays.

Q 14. What software or tools are you proficient in for dredging project management?

Proficiency in various software and tools is essential for effective dredging project management. My expertise includes:

- Primavera P6: For project scheduling, critical path analysis, and resource allocation.

- AutoCAD Civil 3D: For design and modeling of dredging projects, including bathymetry and earthworks.

- Microsoft Project: For task management and progress tracking.

- GIS Software (e.g., ArcGIS): For spatial data analysis, site surveys, and environmental impact assessment.

- Specialized Dredging Simulation Software: For optimizing dredging strategies and predicting project performance.

- Microsoft Office Suite (Excel, Word, PowerPoint): For report writing, data analysis, and presentations.

Beyond software, I am also proficient in using various data analysis techniques, including earned value management (EVM) and statistical process control (SPC), to monitor project performance and identify areas for improvement. I believe that leveraging technology and data analysis is key to enhancing efficiency and optimizing dredging project outcomes.

Q 15. Explain your understanding of the different types of dredge equipment.

Dredge equipment varies widely depending on the project’s scale, location, and material type. Think of it like choosing the right tool for a job – a small shovel for a flowerbed, a backhoe for a foundation, and a massive excavator for a large construction site. Similarly, dredging uses diverse machinery.

Bucket Dredges: These are like giant shovels, using clamshell or backhoe buckets to excavate material. They’re effective for various materials and depths, but slower than other methods. I’ve used them extensively in smaller harbor maintenance projects where precision was crucial.

Trailing Suction Hopper Dredges (TSHDs): These are essentially giant vacuum cleaners for the seabed. They use a submerged pump to suck up material and store it in an onboard hopper for later disposal. TSHDs are highly efficient for large-scale projects, especially sand and silt removal in deeper waters. I was involved in a major channel deepening project using a TSHD that dramatically improved navigation.

Cutter Suction Dredges (CSD): These are powerful machines, equipped with rotating cutters to break up denser materials before suctioning them. They’re ideal for hard clay, rock, and other consolidated sediments. I remember one project where a CSD was essential to remove compacted material obstructing a vital waterway.

Grab Dredges: Similar to bucket dredges, grab dredges use a grab bucket to lift and transport dredged material. They are often used in confined spaces or for selective removal of materials.

Selecting the right dredge depends on factors like the type of soil, water depth, and project objectives. A thorough site assessment is always the first step.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the quality of dredged material?

Ensuring dredged material quality involves rigorous testing and monitoring throughout the process. It’s not just about digging up material; it’s about ensuring it’s suitable for its intended use, whether that’s land reclamation, beach nourishment, or disposal.

Sampling and Analysis: Before dredging begins, we conduct extensive sampling to determine the material’s composition, including grain size distribution, organic content, contaminants (heavy metals, pollutants), and geotechnical properties. We use various methods, from grab samplers to core borings, depending on the sediment type and depth.

Contaminant Assessment: This is critically important. If the dredged material is contaminated, it might require special handling and treatment to meet environmental regulations. We work closely with environmental agencies to ensure compliance and mitigate any potential risks.

Quality Control during Dredging: Regular monitoring during the dredging process is crucial to confirm that the material meets the specified quality standards. This might involve real-time analysis of the dredged material or frequent laboratory testing.

Disposal and Reuse: The quality of dredged material dictates how it’s disposed of or reused. Clean material might be used for land reclamation or beach nourishment, whereas contaminated material might need to be confined in a designated disposal site.

Maintaining quality control is paramount for environmental protection and project success. Neglecting this can lead to costly remediation or environmental damage.

Q 17. Describe your experience with land reclamation techniques.

Land reclamation involves creating new land from water bodies using dredged material. It’s a complex process demanding careful planning and execution. I’ve been involved in numerous reclamation projects, each with its unique challenges.

Site Selection and Preparation: This initial phase is crucial and involves detailed surveys to assess the suitability of the site, considering factors like water depth, soil conditions, wave action, and environmental impact.

Dredging and Placement: The dredged material is transported to the reclamation site and placed in layers, often compacted to ensure stability. The technique used depends on the material and the desired land elevation.

Consolidation and Stabilization: Once the material is placed, it’s often necessary to consolidate and stabilize it to prevent settlement and erosion. This can involve techniques like preloading, wick drains, or the use of geotextiles.

Environmental Considerations: Environmental impact assessments are vital throughout the process. This includes minimizing disturbance to marine life, preventing water pollution, and ensuring the long-term stability of the reclaimed land.

Post-Reclamation Development: The final phase involves preparing the reclaimed land for its intended use, which might include infrastructure development, landscaping, or other site improvements. I’ve worked on projects that have created new industrial areas, residential zones, and even airport extensions.

Successful land reclamation relies on integrating engineering, environmental science, and meticulous project management.

Q 18. How do you assess the geotechnical properties of dredged material?

Assessing the geotechnical properties of dredged material is fundamental to ensuring the stability and safety of any dredging or reclamation project. This involves a series of laboratory and field tests.

Laboratory Testing: Samples are subjected to various tests to determine their grain size distribution, Atterberg limits (liquid limit, plastic limit), shear strength, consolidation characteristics, and permeability. These tests give us insights into the material’s behavior under different conditions.

In-situ Testing: Field tests like cone penetration tests (CPT) or Standard Penetration Tests (SPT) provide data on the material’s strength and density in its natural state. This helps validate the laboratory findings and account for field conditions.

Data Analysis and Interpretation: The collected data is analyzed to determine the material’s suitability for specific applications. For example, its strength and compressibility will determine whether it’s appropriate for land reclamation or if additional stabilization is required.

Geotechnical assessment ensures we choose the right dredging method, predict the material’s behavior during placement, and design appropriate structures for the reclaimed land.

Q 19. Explain your experience with coastal protection projects.

Coastal protection projects often integrate dredging and reclamation to address erosion, storm surge, and sea-level rise. I have extensive experience in this area, working on projects that ranged from small-scale beach nourishment to large-scale barrier island restoration.

Beach Nourishment: This involves dredging sand from offshore sources and placing it on eroding beaches to widen them and protect coastal infrastructure. I’ve overseen several projects where this was vital in mitigating coastal erosion and protecting valuable property.

Barrier Island Restoration: These projects often involve dredging to restore eroded barrier islands, which provide crucial protection to mainland coastlines. This requires careful consideration of sediment transport patterns and the potential impact on adjacent ecosystems.

Breakwater Construction: Dredged material can be used to create breakwaters, which are submerged structures that dissipate wave energy and protect coastlines from erosion. I’ve been involved in projects where this was a key component of the overall coastal protection strategy.

Coastal protection projects require a holistic approach, integrating engineering principles with ecological considerations to create sustainable and effective solutions.

Q 20. Describe your understanding of hydrographic surveying in dredging.

Hydrographic surveying is the backbone of any successful dredging project. It’s essentially mapping the underwater terrain to provide detailed information about water depth, seabed topography, and the location of underwater obstacles. Think of it as creating a detailed blueprint of the underwater world.

Survey Techniques: Various techniques are employed, including echo sounding, multibeam sonar, and side-scan sonar. Echo sounding provides a single-beam depth measurement, while multibeam sonar provides a wider swath of data, giving a more comprehensive picture of the seabed. Side-scan sonar helps identify underwater objects and features.

Data Processing and Analysis: The raw data collected needs to be processed and analyzed to create accurate bathymetric charts and three-dimensional models of the seabed. This involves specialized software and expertise.

Pre-Dredging and Post-Dredging Surveys: Surveys are conducted before and after dredging to determine the volume of material removed and to verify that the dredging operation has achieved its objectives.

Accurate hydrographic surveying is crucial for efficient dredging operations, ensuring the removal of the correct amount of material and avoiding potential damage to underwater infrastructure or ecosystems.

Q 21. How do you manage the environmental impact of dredging on marine life?

Managing the environmental impact of dredging requires a proactive and integrated approach. It’s not just about complying with regulations; it’s about minimizing disruption to marine ecosystems and ensuring the long-term health of the environment.

Environmental Impact Assessment (EIA): This is a crucial first step, evaluating the potential impacts on water quality, marine life, and other environmental parameters. We must consider the potential for sediment plumes, habitat loss, and noise pollution.

Mitigation Measures: Based on the EIA, we implement various mitigation measures. This might include using specific dredging techniques to minimize turbidity, implementing sediment curtains to contain sediment plumes, or establishing temporary exclusion zones to protect sensitive habitats. I’ve worked on projects where we implemented innovative techniques, like using bubble curtains to reduce sediment dispersal.

Monitoring and Reporting: Ongoing monitoring is essential to track the environmental impact of the dredging operation. This includes water quality sampling, benthic surveys to assess the impact on bottom-dwelling organisms, and noise monitoring. Regular reports are submitted to regulatory agencies.

Restoration and Compensation: In some cases, habitat restoration or compensation measures are required to offset any negative environmental impacts. This might involve creating artificial reefs or restoring damaged habitats. I’ve personally overseen projects where we implemented such restoration efforts to achieve a net positive environmental outcome.

Environmental stewardship is paramount in dredging. A responsible approach ensures that we balance the needs of development with the protection of the marine environment.

Q 22. What are your experience with pipeline dredging?

Pipeline dredging is a highly efficient method for transporting dredged material over long distances. It involves using a dredge to excavate material, which is then pumped through a pipeline to a designated disposal site. My experience encompasses various aspects, from project planning and pipeline design to operational management and environmental monitoring. For instance, I was involved in a project where we used a trailing suction hopper dredge to excavate sand from a riverbed, pumping it via a submerged pipeline over 5km to a land reclamation site. This required careful consideration of pipeline diameter, slope, and the use of booster pumps to maintain consistent flow and prevent blockages. We also implemented regular monitoring of pipeline pressure and flow rates to ensure optimal performance and prevent spills.

Another key aspect is understanding the material properties. Different materials require different pipeline designs and pumping strategies. Fine sediments, for example, require careful velocity control to prevent settling within the pipeline. While coarser materials might necessitate higher pressure and potentially different pipeline materials to withstand abrasion.

Q 23. How do you estimate the cost of a dredging project?

Estimating the cost of a dredging project is a complex process involving a detailed breakdown of various components. It’s not a simple calculation but rather a comprehensive assessment. It begins with a thorough site investigation, including bathymetric surveys to determine the volume of material to be dredged, geotechnical testing to characterize the soil properties, and environmental impact assessments. The cost estimate then includes:

- Mobilization and Demobilization: Costs associated with transporting equipment to and from the site.

- Dredging Operations: This is usually the largest cost component, factoring in the type of dredge, operational hours, and fuel costs.

- Disposal Costs: This includes transportation and disposal of dredged material, which can vary significantly depending on the chosen method and location.

- Environmental Monitoring and Mitigation: Costs associated with environmental impact studies, permits, and monitoring during and after the project.

- Contingency: A percentage added to cover unforeseen costs or delays.

- Engineering and Project Management: Salaries and expenses for project engineers and managers.

I typically use a bottom-up estimating approach, breaking down the project into smaller, manageable tasks and assigning costs to each. This allows for better accuracy and easier identification of potential cost overruns. Software tools such as specialized dredging cost estimation software are also employed for more complex projects.

Q 24. What are the challenges of dredging in different soil conditions?

Dredging in different soil conditions presents unique challenges. The ease or difficulty of dredging depends heavily on the soil’s consistency and composition. For example:

- Clay: Very cohesive and sticky, requiring specialized equipment like cutter suction dredges to break up the material. Clay can also be difficult to pump efficiently through pipelines due to its high viscosity. We might need to add flocculants to improve pumpability.

- Sand: Relatively easy to dredge, typically using trailing suction hopper dredges or clamshell dredges. However, the size and density of sand particles will influence the choice of equipment and operational parameters. Very fine sands can become easily suspended and cause turbidity issues.

- Rock: Requires specialized equipment like rock-breaking tools or even blasting techniques. These methods increase the project’s complexity and cost.

- Organic Soils (peat): These are often soft and unstable, requiring careful planning to prevent environmental damage and ensure stability of the dredged area. They can also create operational difficulties due to their low bearing capacity.

Each condition necessitates a tailored approach. Thorough geotechnical investigation is crucial to select the appropriate dredging method and equipment, minimizing environmental impact and optimizing efficiency.

Q 25. Describe your experience with the permitting process for dredging projects.

The permitting process for dredging projects is complex and varies considerably depending on location and the project’s scale and environmental impact. It typically involves multiple government agencies and requires extensive documentation. My experience includes navigating the regulatory landscape for various projects, preparing and submitting detailed permit applications, and engaging with regulatory bodies to address their concerns. The process commonly includes:

- Environmental Impact Assessment (EIA): A comprehensive assessment of the potential environmental impacts, including water quality, benthic habitats, and noise pollution.

- Public Consultation: Engaging with stakeholders and the public to address their concerns and incorporate their feedback.

- Permit Applications: Submitting detailed applications to relevant agencies, including information on the dredging method, disposal plan, and mitigation measures.

- Permitting Review and Approval: The agencies review the applications, conduct their own assessments, and issue permits once satisfied.

- Compliance Monitoring: Ongoing monitoring to ensure compliance with the permit conditions throughout the project duration.

Successfully navigating this process demands meticulous planning, robust documentation, and proactive engagement with regulatory agencies. Proactive communication and collaboration are crucial for a smooth permitting process.

Q 26. How do you ensure the sustainability of dredging and reclamation projects?

Sustainability is paramount in dredging and reclamation projects. My approach involves integrating environmental considerations at every stage, from planning to post-project monitoring. Key elements include:

- Minimizing Environmental Impact: Employing environmentally friendly dredging techniques, such as reduced turbidity dredging methods, to minimize disruption to aquatic life and water quality.

- Sustainable Disposal of Dredged Material: Utilizing beneficial reuse options, such as using dredged material for land reclamation, beach nourishment, or habitat restoration, instead of simply disposing of it in landfills.

- Monitoring and Mitigation: Implementing rigorous monitoring programs to track the environmental impacts and take corrective actions as needed.

- Stakeholder Engagement: Involving local communities and other stakeholders in the decision-making process to ensure their concerns are addressed and their support is secured.

- Life-Cycle Assessment (LCA): Conducting an LCA to evaluate the environmental impacts of the project throughout its entire life cycle.

By embracing these principles, we can ensure that dredging and reclamation projects deliver economic benefits while minimizing their environmental footprint and promoting long-term ecological health. For example, in one project, we successfully utilized dredged sand to create a new coastal habitat, providing a valuable nesting ground for endangered sea turtles.

Q 27. Explain your understanding of different types of reclamation fills.

Reclamation fill refers to the material used to create new land from water bodies. Several types exist, each with its own properties and suitability for different projects. The selection depends on factors like project requirements, material availability, and environmental considerations:

- Sand Fill: Commonly used for its stability and drainage properties. Ideal for projects requiring structural strength and good compaction characteristics.

- Clay Fill: Used to improve water retention and reduce permeability. However, clay fill can be prone to shrinking and swelling, requiring careful compaction and management.

- Rock Fill: Used in applications requiring high stability and resistance to erosion. Common in coastal protection works or areas requiring slope stabilization.

- Dredged Material Fill: Material dredged from waterways or other water bodies. The properties vary depending on the source and need proper processing and treatment to ensure suitability.

- Mixed Fill: A combination of different materials to optimize the fill’s properties. Often used to achieve desired engineering characteristics like permeability, compressibility, and stability.

The choice of fill material is critical to the success of a reclamation project. Poor fill selection can lead to instability, settlement, and environmental problems. Proper geotechnical investigation and design are paramount.

Q 28. How do you monitor the performance of dredging equipment?

Monitoring dredging equipment performance is crucial for ensuring efficiency, productivity, and safety. This involves a multi-faceted approach involving both real-time and historical data analysis. Real-time monitoring might involve:

- Monitoring of key parameters: This includes measuring parameters like engine RPM, fuel consumption, pump pressure, dredging depth, and material throughput. Sensors and data loggers are employed to capture this data.

- Visual inspections: Regular visual checks of the equipment’s components and operation for signs of wear and tear, leaks, or other anomalies.

- Operational data logging: Recording operational data allows for trend analysis, identifying potential issues before they escalate, and optimizing operational parameters.

Historical data analysis helps in identifying trends and patterns that might not be apparent through real-time monitoring alone. This might involve analyzing fuel consumption data over time to identify maintenance needs or evaluating material throughput against predicted rates to optimize dredging parameters. This approach helps us ensure the efficient operation and longevity of the equipment.

Key Topics to Learn for Dredging and Reclamation Interview

- Dredging Methods: Understanding various dredging techniques (e.g., bucket dredging, hydraulic dredging, cutter suction dredging) and their suitability for different projects and soil types. Consider the advantages and disadvantages of each method.

- Environmental Impact Assessment: Knowledge of environmental regulations and best practices related to dredging and reclamation projects. This includes understanding the impact on marine life, water quality, and coastal ecosystems, and mitigation strategies.

- Site Surveys and Data Analysis: Expertise in conducting thorough site surveys, analyzing bathymetric data, and interpreting soil reports to inform project planning and execution. This involves understanding sediment characteristics and their impact on dredging operations.

- Project Management and Cost Estimation: Familiarity with project lifecycle management, including planning, scheduling, budgeting, and risk assessment for dredging and reclamation projects. Ability to accurately estimate project costs and timelines.

- Reclamation Techniques: Understanding different land reclamation methods, including fill placement, land consolidation, and shoreline protection techniques. This includes considerations for structural integrity and long-term stability.

- Equipment and Technology: Familiarity with the types of equipment used in dredging and reclamation, including dredgers, barges, pipelines, and positioning systems. Understanding the operational principles and maintenance requirements of this equipment.

- Safety and Regulations: Thorough understanding of all relevant safety regulations and procedures pertaining to dredging and reclamation operations. This includes risk management and incident prevention.

- Material Handling and Disposal: Knowledge of efficient and environmentally sound methods for handling and disposing of dredged material, including beneficial reuse options.

- Problem Solving and Troubleshooting: Ability to identify and resolve challenges that may arise during dredging and reclamation projects, such as equipment malfunctions, unexpected soil conditions, and environmental issues.

Next Steps

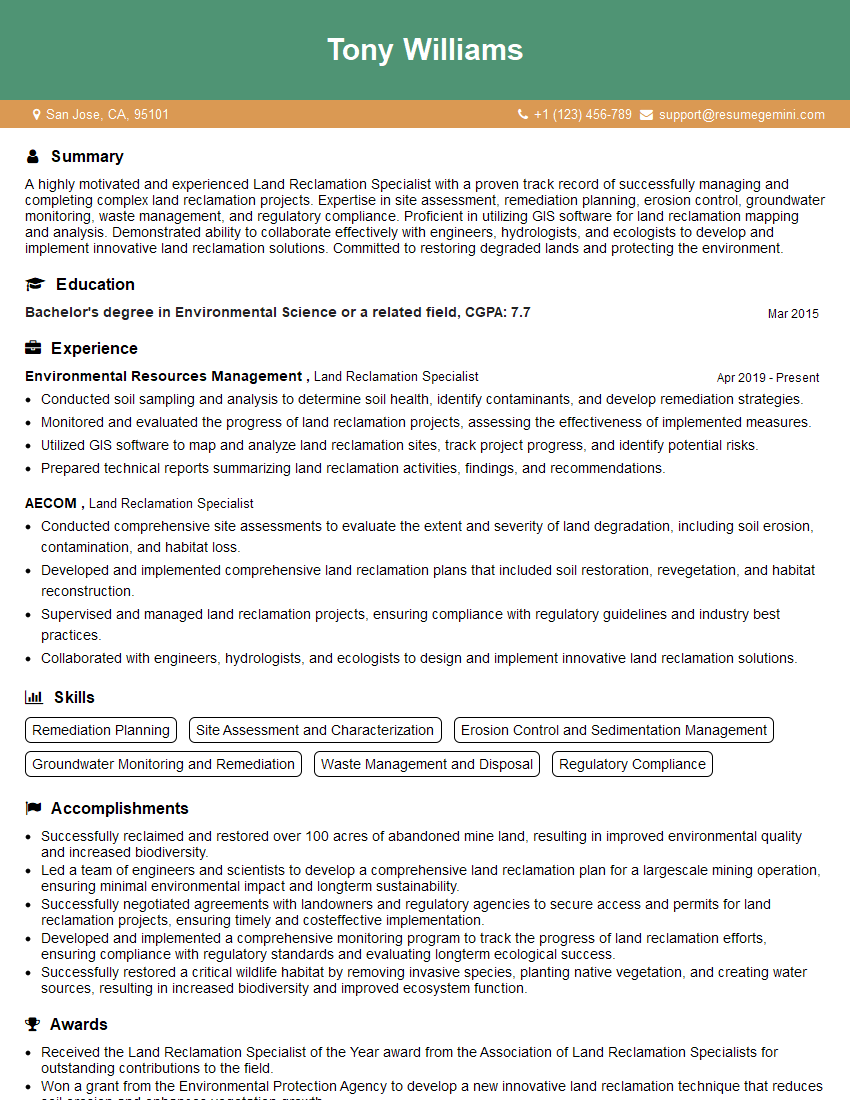

Mastering the principles of dredging and reclamation opens doors to exciting career opportunities in a vital industry. Building a strong foundation in these areas is crucial for career advancement and securing your dream role. To enhance your job prospects, it’s vital to create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the dredging and reclamation industry. Examples of resumes specifically designed for this field are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO