The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Final Finishing interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Final Finishing Interview

Q 1. Explain the different types of surface finishing processes.

Surface finishing processes encompass a wide range of techniques aimed at enhancing the appearance, durability, and functionality of a product’s surface. These processes can be broadly categorized into several types:

- Electroplating: This involves depositing a thin layer of metal onto a substrate using an electric current. This is commonly used for corrosion resistance, improved conductivity, or aesthetic appeal. For example, chrome plating on car bumpers or gold plating on jewelry.

- Painting: Applying liquid coatings (paints) to protect, decorate, or improve the surface properties. Different paint types exist, like acrylics, lacquers, and epoxies, each offering unique properties in terms of durability, gloss, and flexibility. Imagine painting a house or a car.

- Powder Coating: Applying a dry powder coating which is then cured using heat. This method is known for its durability and even coating thickness. Commonly used on appliances and outdoor furniture.

- Anodizing: An electrochemical process used to increase the thickness of the natural oxide layer on certain metals (like aluminum), enhancing corrosion resistance and providing attractive colors. This is frequently seen on architectural aluminum components.

- Sandblasting/Abrasive Blasting: Using compressed air to propel abrasive particles onto the surface, creating a textured finish or cleaning the surface before further processing. Commonly used in preparation for other finishing techniques.

- Chemical Conversion Coatings: These involve chemical reactions to form a protective layer on the surface of a metal, improving corrosion resistance. Phosphating and chromating are common examples.

The choice of process often depends on the material being finished, the desired properties, and cost considerations.

Q 2. Describe your experience with quality control in a final finishing environment.

My experience in quality control for final finishing spans over ten years, including roles in both small and large manufacturing environments. I’ve implemented and maintained rigorous quality control systems, focusing on statistical process control (SPC) methods to monitor and prevent defects. This includes regularly inspecting finished goods against pre-defined standards using tools like microscopes and thickness gauges.

A crucial aspect of my role has been root cause analysis of defects. For example, pinholing in a powder coating might indicate insufficient pre-treatment of the substrate, while inconsistent color could point to issues with the powder dispensing system or curing oven temperature. I’ve used data analysis techniques to track defect rates, identify trends, and implement corrective actions. I’ve also been instrumental in developing and delivering training to improve the finishing process and minimize errors, resulting in a significant reduction of rework and scrap.

Implementing and maintaining ISO 9001 standards and using documented procedures are critical elements of my approach. This ensures consistency and traceability throughout the finishing process.

Q 3. What are the key factors influencing the selection of a specific finishing process?

Selecting the appropriate finishing process involves considering several key factors:

- Substrate Material: Different materials require different finishing methods. For example, electroplating is suitable for metals, while powder coating can be used for various materials including metals and plastics.

- Desired Properties: The intended application dictates the required properties. Durability, corrosion resistance, aesthetic appeal, and conductivity are all potential factors.

- Cost: Different finishing processes have varying costs associated with materials, equipment, and labor.

- Environmental Considerations: The environmental impact of different finishing processes, including waste generation and emissions, is increasingly important. Some processes are more environmentally friendly than others.

- Production Volume: The production volume will influence the selection of equipment and process. High-volume production might favor automated systems, whereas lower volumes may be suited to manual processes.

For instance, choosing between powder coating and painting for a large batch of metal outdoor furniture would involve assessing the cost of each process, its durability under outdoor conditions, and the environmental implications of the chosen coating materials. A balance between these aspects is essential.

Q 4. How do you troubleshoot common finishing defects?

Troubleshooting finishing defects requires a systematic approach. I typically follow these steps:

- Visual Inspection: Carefully examine the defect to understand its nature and location.

- Data Analysis: Review production records, including material usage, process parameters (temperature, pressure, time), and environmental conditions.

- Root Cause Analysis: Use tools like the 5 Whys or fishbone diagrams to identify the underlying cause of the defect. For example, orange peel in a paint finish might be traced back to inadequate spraying techniques, improper air pressure, or wrong viscosity.

- Corrective Actions: Implement corrective actions based on the identified root cause. This might involve adjusting process parameters, replacing faulty equipment, or retraining personnel.

- Verification: After implementing corrective actions, verify that the defect has been resolved and the quality has improved.

For instance, if I encounter excessive surface roughness after electroplating, I would investigate factors such as surface preparation (cleaning, degreasing), plating solution concentration, current density, and plating time to pinpoint the issue and make the necessary adjustments. Documentation of the entire process and corrective actions is crucial.

Q 5. Describe your experience with different types of coating materials (e.g., paints, powders, etc.).

My experience encompasses a broad range of coating materials including:

- Paints (Solvent-based, Water-based, UV-curable): I have extensive experience with various paint types and their application methods, understanding their differing properties such as drying time, adhesion, flexibility, and durability. For example, solvent-based paints offer excellent durability but involve VOC emissions, while water-based paints are more environmentally friendly.

- Powder Coatings (Epoxy, Polyester, Hybrid): I’m proficient in powder coating application and curing processes. I understand the importance of powder selection based on factors such as desired properties and substrate compatibility. Epoxy powder coatings are commonly used for their chemical resistance, while polyester powder coatings offer excellent color and gloss retention.

- Electroplating Solutions (Nickel, Chrome, Gold, Silver): I have experience with the preparation, application, and control of electroplating solutions. This involves a deep understanding of electrochemistry and the factors influencing plating thickness and quality.

- Chemical Conversion Coatings (Phosphating, Chromating): I’m familiar with the chemistry of these coatings and their impact on corrosion resistance and paint adhesion.

I am adept at selecting the appropriate coating based on a product’s specific needs and performance criteria. My work always adheres to relevant safety and environmental regulations.

Q 6. Explain the importance of surface preparation in the finishing process.

Surface preparation is absolutely critical for successful finishing. It’s the foundation upon which a high-quality, durable finish is built. Inadequate preparation almost guarantees failure down the line. Think of it like trying to paint a house with peeling paint – you need to remove the old paint first! The same principle applies to any finishing process.

Surface preparation steps typically involve:

- Cleaning: Removing dirt, grease, oils, and other contaminants. This often involves solvent cleaning, alkaline cleaning, or ultrasonic cleaning.

- Degreasing: Removing any remaining oils or grease that could hinder adhesion.

- Abrasive Blasting/Polishing: Creating a uniform surface profile to improve adhesion. This is crucial for achieving a strong bond between the substrate and the coating.

- Priming (in some cases): Applying a primer to enhance adhesion and provide a uniform base for the topcoat. Primers can also provide corrosion protection.

If the surface isn’t adequately prepared, the coating may peel, blister, or fail prematurely. The cost of rework or complete failure far outweighs the investment in thorough surface preparation.

Q 7. What safety precautions are essential when working with finishing chemicals?

Working with finishing chemicals demands strict adherence to safety precautions. This includes:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves, eye protection, respirators, and protective clothing, as determined by the specific chemical being used and the relevant safety data sheets (SDS).

- Proper Ventilation: Ensure adequate ventilation to prevent the inhalation of hazardous fumes and vapors. This might involve using respirators or working in a well-ventilated area, or utilizing enclosed spray booths.

- Waste Disposal: Dispose of chemical waste according to regulations. This is vital to protect the environment and comply with safety guidelines.

- Emergency Procedures: Know and understand emergency procedures, including spill response and first aid, for each chemical used. This includes having eyewash stations and emergency showers readily accessible.

- SDS Review: Thoroughly review the SDS for each chemical before handling it. The SDS provides critical information about hazards, handling, storage, and emergency response.

- Training: Employees must receive proper training on the safe handling, use, and disposal of finishing chemicals. Regular refresher training is essential.

Neglecting safety precautions can result in serious health consequences, environmental damage, and legal liabilities. Safety should always be the top priority when working with finishing chemicals.

Q 8. How do you ensure consistency in the finishing process across different batches?

Maintaining consistency in finishing across batches is paramount for quality control. It’s like baking a cake – you want every cake to taste the same, right? We achieve this through meticulous process control and documentation.

- Standardized Procedures: We use detailed Standard Operating Procedures (SOPs) for every step, from pre-treatment to final coating application. This ensures every operator follows the same precise methods.

- Batch Tracking: Each batch receives a unique identifier, allowing us to track materials, process parameters (temperature, pressure, curing time), and quality inspection results. This data provides valuable insights for continuous improvement.

- Regular Calibration: All finishing equipment, including spray guns, ovens, and measuring devices, is calibrated regularly according to manufacturer’s specifications. This ensures accuracy and prevents deviations.

- Material Control: Strict adherence to material specifications, including batch numbers and supplier verification, is crucial. Consistent materials are the foundation for consistent results. This also includes regular checks for material degradation.

- Statistical Process Control (SPC): We use SPC charts to monitor key process parameters and identify potential variations early. This allows for proactive adjustments to maintain consistency.

For example, if we notice a trend of increasing thickness variations in our coating, we can investigate the cause – maybe the spray gun needs cleaning, the air pressure needs adjustment, or the material needs to be refreshed. By identifying and correcting these deviations early, we ensure consistency across all batches.

Q 9. Describe your experience with different finishing equipment (e.g., spray booths, ovens, etc.).

My experience encompasses a wide range of finishing equipment, from basic to highly sophisticated systems. I’m proficient in operating and maintaining various spray booths (both airless and conventional), convection and infrared ovens, and automated finishing lines.

- Spray Booths: I’ve worked with both downdraft and side-draft spray booths, understanding the importance of proper ventilation and filtration to maintain a safe and clean working environment, minimizing overspray and ensuring worker safety. I’m familiar with different types of spray guns and their applications, including airless, HVLP, and electrostatic spray systems.

- Ovens: I’ve experience with both convection and infrared curing ovens, each with its unique advantages and disadvantages. Convection ovens offer uniform heating, while infrared ovens are faster for certain applications. I understand the critical role temperature control and monitoring plays in achieving the desired cure and film properties.

- Automated Systems: I’ve also worked with automated finishing lines that integrate robotic spray systems, conveyor systems, and automated process control. These systems enhance efficiency and precision, significantly improving consistency and reducing human error.

I’ve been involved in the installation, commissioning, and troubleshooting of various pieces of equipment. My knowledge extends to the maintenance and safety protocols required for each system. For example, I know how to identify and fix common problems like nozzle clogging in spray guns, uneven temperature distribution in ovens, or malfunctions in automated systems.

Q 10. How do you manage waste and disposal of finishing materials?

Responsible waste management is essential in surface finishing. We adhere strictly to all environmental regulations and employ various strategies to minimize waste and ensure safe disposal.

- Waste Minimization: We focus on minimizing waste through process optimization, precise material application techniques, and regular equipment maintenance. This includes using the right amount of material, proper cleaning procedures, and efficient use of solvents.

- Waste Segregation: Different types of waste (e.g., solvents, solid waste, hazardous materials) are segregated according to local regulations. Clear labeling and proper storage are critical to prevent accidental mixing and contamination.

- Recycling and Recovery: Wherever feasible, we recycle or recover materials, such as used solvents, through distillation or other appropriate methods. This reduces the environmental impact and lowers disposal costs.

- Disposal Procedures: Hazardous waste is disposed of through licensed waste contractors, in compliance with all applicable environmental regulations. We maintain detailed records of all waste generated, disposed, and recycled.

We regularly conduct training for our personnel on proper waste handling and disposal procedures. Our commitment to environmental responsibility is reflected in our comprehensive waste management program.

Q 11. How do you maintain and troubleshoot finishing equipment?

Maintaining and troubleshooting finishing equipment is a crucial part of my role. Preventive maintenance is key to minimizing downtime and ensuring consistent performance.

- Preventive Maintenance Schedules: We follow strict preventive maintenance schedules for all equipment, including regular cleaning, lubrication, and inspections. This includes detailed checklists and documentation.

- Troubleshooting: When problems occur, I use a systematic approach to identify and resolve them. This often involves checking the operating parameters, inspecting components, and testing the system. I rely on both my experience and equipment manuals for diagnostics.

- Record Keeping: Detailed records of all maintenance activities, including repairs, replacements, and calibration, are meticulously maintained. This history helps to identify patterns, predict future issues, and optimize maintenance strategies.

- Training and Expertise: Our team is trained to perform basic maintenance tasks, while more complex repairs are handled by qualified technicians or service providers. I possess advanced knowledge to handle complex repairs and oversee maintenance activities.

For example, if an oven isn’t reaching the desired temperature, I’d first check the heating elements, then the thermostat, and finally the control system. If a spray gun clogs repeatedly, I would check the fluid delivery system for any blockages or leaks. Our approach is systematic and thorough to ensure quick resolution and minimal downtime.

Q 12. Explain your understanding of environmental regulations related to surface finishing.

Understanding and adhering to environmental regulations related to surface finishing is paramount. These regulations vary by location but typically cover aspects such as air emissions, wastewater discharge, and hazardous waste management.

- Air Emissions: We must ensure that volatile organic compounds (VOCs) emissions from our finishing processes are controlled to meet regulatory limits. This is achieved through the use of appropriate ventilation systems, low-VOC coatings, and regular monitoring.

- Wastewater Discharge: Wastewater from cleaning and rinsing operations must be treated to remove contaminants before discharge. We comply with all local wastewater discharge permits and regularly monitor the discharge quality.

- Hazardous Waste Management: All hazardous wastes, including solvents, cleaning agents, and paint sludge, must be managed in accordance with all federal, state, and local regulations. We work with licensed waste contractors to ensure proper disposal and maintain detailed records of all waste generated and disposed.

- Regulatory Compliance: We stay updated on all relevant environmental regulations and ensure our practices remain compliant. This involves attending training sessions, reviewing updated regulations, and conducting regular internal audits.

Non-compliance can lead to significant penalties, so staying informed and proactive is critical. We consider environmental compliance not just as a regulatory requirement but as a commitment to sustainability.

Q 13. How do you interpret and follow technical specifications and drawings related to finishing requirements?

Interpreting technical specifications and drawings is essential for ensuring the final finish meets the client’s requirements. It’s like following a recipe – you need to understand all the ingredients and instructions to produce the desired outcome.

- Drawing Review: I meticulously review all technical drawings and specifications to understand the required surface finish, including material type, thickness, color, and texture. I look for any special requirements, such as corrosion resistance or specific surface treatment.

- Material Selection: Based on the specifications, I select the appropriate coatings, primers, and other materials. I verify that the chosen materials meet the specified properties and performance standards.

- Process Parameter Determination: The specifications also determine the process parameters, including curing temperature, application methods, and drying times. I ensure that our finishing process is configured to meet these specifications precisely.

- Quality Control: Throughout the finishing process, I monitor the parameters and perform quality checks to ensure compliance with the specifications. This includes regular inspections and testing to verify the finish meets the requirements.

For example, if the drawings specify a specific gloss level, I’ll use a gloss meter to measure the finish and ensure it’s within the acceptable range. If the specifications call for a specific color match, I’ll use a spectrophotometer to verify the color accuracy.

Q 14. Describe your experience with different types of surface testing methods.

My experience includes various surface testing methods to ensure the final finish meets quality and performance requirements. These tests provide crucial feedback and ensure the finished product aligns with expectations.

- Thickness Measurement: We use methods such as wet film thickness and dry film thickness measurement to ensure the coating thickness meets the specifications. This is critical for achieving the desired properties, such as corrosion protection or wear resistance.

- Gloss Measurement: Gloss meters measure the surface reflectivity, which is crucial for aesthetic appearance and performance in certain applications. Different gloss levels are required for various applications.

- Color Measurement: Spectrophotometers measure the color precisely and ensure consistency across batches. This is particularly important for applications where color accuracy is paramount.

- Adhesion Testing: Several methods, including tape tests and cross-cut tests, evaluate the adhesion of the coating to the substrate. Good adhesion is essential for preventing premature coating failure.

- Corrosion Resistance Testing: Salt spray tests and other corrosion tests assess the coating’s ability to protect the substrate from corrosion. This is critical for applications exposed to harsh environments.

- Hardness Testing: Hardness tests, such as pencil hardness or Knoop hardness, evaluate the coating’s resistance to scratching and abrasion. This is relevant for applications requiring high durability.

The specific tests used depend on the application and the requirements of the specifications. We use these tests not only for quality control but also for continuous improvement, helping to optimize our finishing processes and improve overall product quality.

Q 15. How do you ensure the final finish meets the specified quality standards?

Ensuring final finish meets quality standards is a multi-step process that begins even before the finishing stage. It starts with a thorough understanding of the specifications, whether they’re detailed engineering drawings or client-provided samples. I meticulously review these documents to identify critical dimensions, surface tolerances, and finish requirements like color, gloss, and texture. Throughout the process, I use various quality control tools, such as:

- Regular inspections: Visual checks, using calibrated instruments like gloss meters and microscopes, are performed at each stage to ensure consistent quality. This allows us to catch potential issues early, saving time and resources.

- Sampling and testing: Representative samples are tested for durability, corrosion resistance, and other relevant properties to validate that the finish meets the required specifications. For example, in powder coating, we might test for adhesion and impact resistance.

- Statistical Process Control (SPC): Data from inspections is tracked and analyzed to monitor process stability and identify trends. This proactive approach helps prevent defects before they become significant problems.

- Calibration and maintenance of equipment: Regular calibration and preventive maintenance are critical to ensure that our finishing equipment consistently delivers precise results, leading to a predictable and high-quality finish.

Finally, comprehensive documentation of each step, including inspection results and any deviations, provides a clear audit trail and facilitates continuous improvement.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle discrepancies or non-conformances in the finishing process?

Handling discrepancies or non-conformances requires a systematic approach. The first step is to identify the root cause of the problem. This often involves carefully examining the defective parts, reviewing process logs, and potentially analyzing samples under a microscope. For example, if a batch of parts exhibits inconsistent plating thickness, we’d investigate factors such as the plating solution’s concentration, current density, and the cleanliness of the parts before plating.

Once the root cause is identified, corrective actions are implemented. This could range from adjusting process parameters (like temperature or time) to rectifying equipment malfunctions or retraining operators. A key part of this process is implementing preventative measures to stop the issue from recurring. This might involve changes to the workflow, improving operator training, or upgrading equipment.

Finally, non-conforming items are carefully managed; they may be reworked, scrapped, or sorted into a separate category for future consideration depending on the severity of the defect and cost-effectiveness of rework.

Q 17. Describe your experience with process improvement initiatives in final finishing.

I’ve been actively involved in several process improvement initiatives. In one instance, we implemented a Lean Manufacturing approach in our powder coating line. This involved optimizing the workflow, reducing waste (material and time), and improving the overall efficiency. We used techniques like Value Stream Mapping to identify bottlenecks and unnecessary steps. The result was a significant reduction in lead times and improved throughput.

Another example involves introducing automated inspection systems. By automating certain inspection tasks, we significantly improved accuracy and reduced human error. This led to a decrease in rejects and improved overall product quality. These improvements were tracked and measured with Key Performance Indicators (KPIs), such as defect rate and production efficiency.

Q 18. How do you manage your workload and prioritize tasks in a fast-paced finishing environment?

Managing workload in a fast-paced finishing environment requires effective prioritization and planning. I use several strategies:

- Prioritization matrix: I categorize tasks based on urgency and importance, focusing on high-priority items first. This ensures that critical projects are completed on time.

- Detailed scheduling: I create a detailed schedule with realistic deadlines, considering factors like equipment availability and lead times. This helps keep the entire process organized and on track.

- Effective communication: Clear and consistent communication with the team and other stakeholders ensures everyone is aware of deadlines and potential bottlenecks. This allows for proactive problem-solving and prevents delays.

- Time management techniques: Techniques like time blocking and the Pomodoro Technique help me focus on individual tasks and improve my overall efficiency.

Finally, regular review and adjustment of my schedule ensures I can adapt to changing priorities and maintain a manageable workload.

Q 19. What are your strengths and weaknesses in relation to final finishing?

My strengths in final finishing include a strong understanding of various surface treatment processes, meticulous attention to detail, and a proven ability to troubleshoot and solve complex problems. I’m also highly proficient in using various quality control instruments and interpreting their data. For instance, I’m experienced with using gloss meters, surface profilometers, and spectrophotometers to ensure the finished product meets the required specifications.

One area I’m constantly working on is staying ahead of the curve on the newest technologies and techniques. While I’m very knowledgeable about current processes, the field is constantly evolving, so I’m focused on enhancing my understanding of the latest automation and material science advancements.

Q 20. How do you stay updated with the latest advancements in finishing technologies?

Staying updated in this rapidly evolving field requires a multi-pronged approach. I regularly attend industry conferences and trade shows to learn about the latest advancements in finishing technologies and best practices. This provides opportunities to network with other professionals and learn about new techniques firsthand.

I also subscribe to relevant industry publications and journals, and I actively participate in online forums and communities to stay informed about emerging trends and research. Furthermore, I actively seek out training opportunities, such as webinars and workshops, to expand my knowledge and skills. This proactive approach keeps me abreast of innovations and ensures I can leverage the latest technologies to enhance efficiency and quality in my work.

Q 21. Describe your experience with different types of surface treatments (e.g., anodizing, electroplating).

My experience encompasses a range of surface treatments. I’ve worked extensively with anodizing, a process used to enhance the corrosion resistance and durability of aluminum and its alloys. I understand the importance of factors such as electrolyte concentration, current density, and temperature in achieving a consistent and high-quality anodize finish. I’ve also worked extensively with various electroplating processes, such as nickel plating, chrome plating, and zinc plating. In electroplating, precise control over parameters like current density, bath composition, and temperature is crucial for obtaining the desired thickness and properties of the plating.

Beyond these, I’m familiar with powder coating, painting, and other finishing techniques. My understanding of these processes extends beyond the basic application; I also have experience troubleshooting issues related to adhesion, coating uniformity, and the overall quality of the final surface.

Q 22. How do you handle difficult or challenging finishing projects?

Handling challenging finishing projects involves a systematic approach. First, I thoroughly analyze the project’s specifications, identifying potential obstacles. This might include unusual substrate materials, complex geometries, or stringent performance requirements. Then, I consult relevant datasheets and industry best practices to select the appropriate coatings and application techniques. For instance, if dealing with a porous substrate, I might need to incorporate a primer to ensure proper adhesion and prevent uneven absorption. If the project requires a specific gloss level or color match, I’ll use precise colorimeters and adjust application methods to achieve the desired result. Throughout the process, meticulous record-keeping is crucial, allowing me to track materials used, application parameters, and any deviations from the plan. Finally, thorough quality control checks, including visual inspection and testing for adhesion and durability, ensure the final product meets the specifications and the client’s expectations. A recent project involved finishing a set of intricately carved wooden furniture pieces requiring a high-gloss, durable finish. By carefully selecting a high-quality polyurethane and using a combination of spraying and hand-brushing techniques, I successfully achieved the desired result while preventing runs and sags in the intricate details.

Q 23. What are the key differences between different types of coatings (e.g., epoxy, polyurethane)?

Epoxy and polyurethane coatings, while both offering protective and decorative finishes, differ significantly in their properties and applications. Epoxy coatings are known for their exceptional hardness, chemical resistance, and adhesion. They’re often used in industrial settings for applications like flooring, tank linings, and protective coatings where durability and chemical resistance are paramount. Think of epoxy as the tough, protective shell. Polyurethane coatings, conversely, are more versatile. They offer a wider range of gloss levels, excellent flexibility, and good UV resistance, making them ideal for furniture, automotive finishes, and other applications where aesthetics and weatherability are important. Polyurethane is like the more adaptable, aesthetically pleasing finish. For example, a factory floor might benefit from an epoxy coating for its chemical resistance to spills, whereas a wooden dining table might require a polyurethane finish for its durability and elegant appearance.

Q 24. Explain the importance of proper cleaning and preparation before applying a finish.

Proper cleaning and preparation are paramount to achieving a high-quality, durable finish. Think of it as laying a strong foundation for a house – if the foundation is weak, the entire structure suffers. A clean surface ensures optimal adhesion, preventing peeling, chipping, or blistering. The process typically involves several steps: Firstly, removing any loose debris, dirt, or previous coatings with appropriate tools like scrapers, sanding, or chemical strippers. Secondly, any defects on the surface like scratches and cracks, should be filled. Then, thorough cleaning with appropriate solvents removes any grease, oil, or contaminants. Finally, the surface is often sanded to achieve a uniform texture and improve adhesion. Ignoring this crucial step can lead to premature coating failure. For instance, if you apply a coating to a greasy surface, the coating won’t properly adhere, leading to early failure. A well-prepared surface leads to a longer lasting and more aesthetically pleasing finish.

Q 25. Describe your experience with different finishing techniques (e.g., brushing, spraying, dipping).

My experience encompasses various finishing techniques, each with its advantages and disadvantages. Brushing is ideal for small, intricate projects or areas where precise control is necessary, allowing for careful application and minimizing waste. Spraying offers efficiency for large surfaces and achieves a more uniform finish, particularly for high-volume projects. However, it requires specialized equipment and expertise to avoid overspray and ensure even coating. Dipping is a cost-effective method for mass production, creating a consistent coating thickness. However, it is not suitable for all projects and might result in coating buildup in certain areas. I am proficient in all three, selecting the best technique based on the specific project requirements, material properties, and desired finish quality. For example, I would choose brushing for detailed woodwork, spraying for large metal structures, and dipping for uniform coating of small, identical parts.

Q 26. What is your experience with using different types of personal protective equipment (PPE) in final finishing?

Safety is paramount in final finishing. My experience includes the consistent and proper use of various PPE, including respirators to prevent inhalation of hazardous fumes, safety glasses to protect eyes from splashes or debris, gloves to shield hands from chemical irritants, and protective clothing to minimize skin exposure to coatings and solvents. The type of PPE used depends on the specific materials and techniques involved. For instance, when working with isocyanate-based coatings, I would always use a full-face respirator with appropriate cartridges. Regular inspection and maintenance of PPE are essential to ensure its effectiveness. I always prioritize safety and ensure I’m following all relevant safety protocols and regulations, which significantly minimizes the risk of workplace accidents and ensures my long-term health.

Q 27. How do you measure and document the thickness of coatings?

Measuring and documenting coating thickness is critical for ensuring quality and meeting project specifications. We use several methods, including wet film thickness gauges for measuring the thickness of the coating before curing and dry film thickness gauges for measuring the cured coating. These gauges provide precise measurements in mils or micrometers. Another technique is the use of destructive methods, such as cross-sectional analysis with microscopy, to verify the coating thickness and its uniformity, particularly when dealing with multi-layer coatings or specific performance requirements. Detailed records of these measurements are maintained, including the location, date, and thickness measured. Accurate documentation is vital for quality control, troubleshooting, and compliance with industry standards. These records also help in improving future processes and ensuring repeatability of results.

Q 28. Describe a situation where you had to adapt your finishing process to meet a specific customer requirement.

In a recent project, a client requested a unique textured finish on a series of metal panels for a high-end architectural application. The standard smooth finish was not suitable. The challenge lay in achieving the desired texture without compromising the durability or corrosion resistance of the final product. I investigated various techniques, including specialized texturing rollers, spray techniques with specific nozzle configurations, and even the application of textured powder coatings. After experimenting, I determined that a multi-stage process involving a base coat, a textured intermediate coat applied with a specific roller, and a final clear coat provided the best balance of texture, durability, and corrosion resistance. The client was highly satisfied with the outcome. This experience highlighted the importance of adaptability and problem-solving in final finishing, requiring creative solutions to meet specific customer demands. The success was a result of careful testing and iterative adjustments to the finishing process.

Key Topics to Learn for a Final Finishing Interview

- Surface Preparation: Understanding different surface treatments, their applications, and choosing the appropriate method for various materials. This includes practical knowledge of cleaning, sanding, priming, and filling techniques.

- Coating Application Techniques: Mastering various application methods such as spraying, brushing, rolling, and dipping. This involves understanding the properties of different coatings and their application requirements for optimal results.

- Quality Control and Inspection: Developing a keen eye for detail to identify imperfections and ensure consistent high-quality finishes. This includes understanding industry standards and quality control procedures.

- Health and Safety Regulations: Familiarity with relevant health and safety regulations concerning materials handling, personal protective equipment (PPE), and waste disposal in a final finishing environment.

- Troubleshooting and Problem-Solving: Diagnosing and resolving common issues encountered during the final finishing process, such as uneven coating, surface defects, and curing problems. This includes understanding the root causes of such problems and implementing corrective actions.

- Material Knowledge: A comprehensive understanding of different coating types (e.g., paints, varnishes, lacquers), their properties, and their suitability for various substrates. This includes understanding the chemical and physical properties of coatings and their interaction with different materials.

- Equipment Operation and Maintenance: Safe and efficient operation and basic maintenance of relevant equipment, including spray guns, mixing equipment, and other finishing tools.

Next Steps

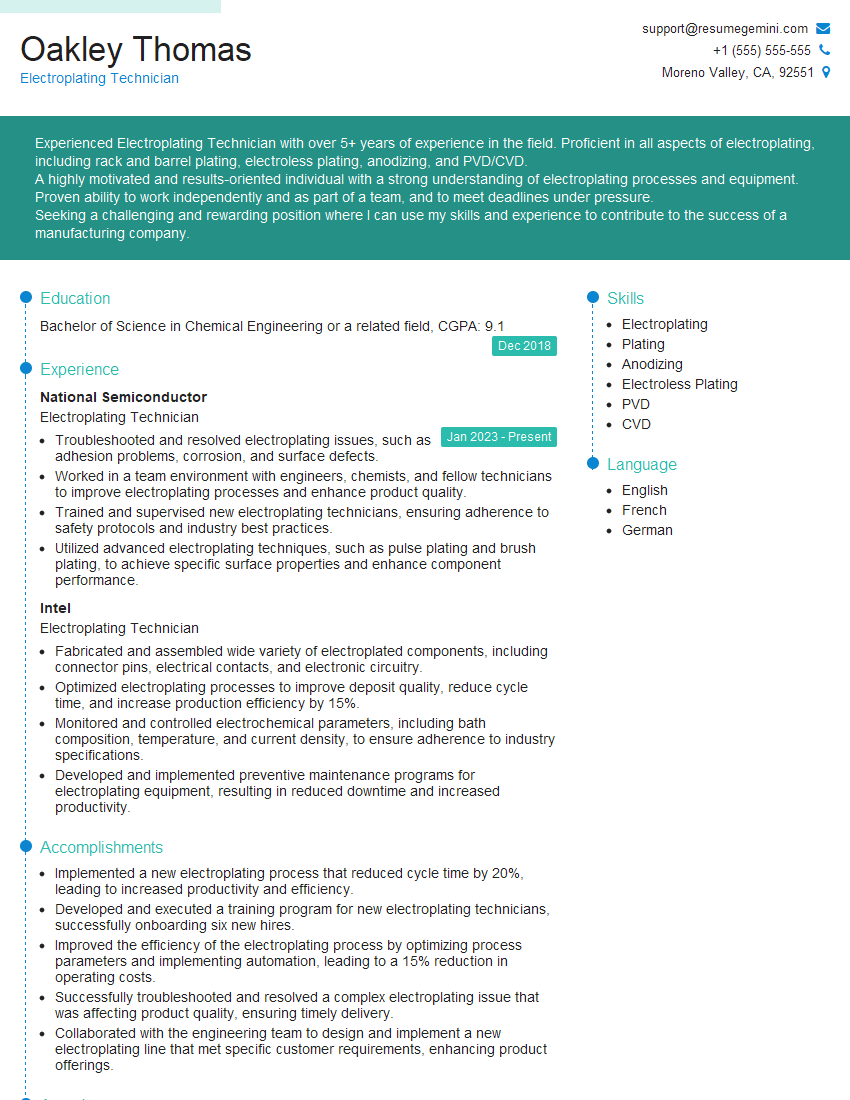

Mastering final finishing techniques significantly enhances your career prospects in manufacturing, construction, and various other industries demanding high-quality surface treatments. A strong understanding of these principles will set you apart from other candidates. To maximize your chances, creating a compelling and ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume showcasing your skills and experience effectively. Examples of resumes tailored to final finishing positions are available to help guide your creation process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO