Cracking a skill-specific interview, like one for Shop Organization, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Shop Organization Interview

Q 1. Describe your experience with implementing a new inventory management system.

Implementing a new inventory management system is a significant undertaking requiring careful planning and execution. My experience involves a phased approach, starting with a thorough needs assessment to identify the current system’s shortcomings and the desired improvements. This includes analyzing current processes, data flow, reporting requirements, and staff training needs. For example, in a previous role, we transitioned from a manual spreadsheet-based system to a cloud-based solution. The key was selecting a system that integrated seamlessly with our existing ERP and accounting software. The implementation involved data migration, user training, system testing, and a go-live plan with robust support to address any immediate issues. Post-implementation, we monitored key performance indicators (KPIs) such as order fulfillment time, inventory accuracy, and reporting efficiency to gauge the system’s impact and make any necessary adjustments. This iterative process ensured a smooth transition and the realization of the system’s full potential. We also established a system of ongoing user feedback to further optimize the solution over time.

Q 2. How do you optimize warehouse layout for maximum efficiency?

Optimizing warehouse layout for maximum efficiency is crucial for minimizing handling time and maximizing throughput. My approach involves applying lean principles and considering several key factors. First, I analyze product velocity – the frequency with which items are picked. Fast-moving items should be located closest to packing stations and shipping docks, minimizing travel time. This is often referred to as ‘A’ location (highest-velocity) with subsequent ‘B’ and ‘C’ locations. Second, I consider product size and weight to optimize storage space. Larger, heavier items are usually stored at ground level and closer to loading docks, while smaller, lighter items are stored at higher levels. Third, I ensure clear pathways and sufficient space for equipment movement to prevent congestion. Think of it like designing a well-oiled machine – every component needs space and freedom to move effectively. I utilize software tools to create visual representations of the layout, allowing for experimentation and simulation before implementation. This process often involves considering seasonal demands and potential future growth to create a scalable and flexible warehouse design.

Q 3. Explain your approach to cycle counting and inventory accuracy.

Cycle counting is a critical aspect of maintaining inventory accuracy. Instead of a complete physical count (which disrupts operations), cycle counting involves regularly counting smaller subsets of inventory. My approach is to develop a schedule that prioritizes high-value, high-velocity items, and those prone to discrepancies. We use barcode scanners or RF (radio frequency) technology for efficient data collection. Any discrepancies are immediately investigated, and the root cause is identified and corrected. This could involve anything from improving picking procedures to fixing data entry errors. The data from cycle counts is analyzed to identify patterns and improve the accuracy of the overall inventory management system. For example, we might discover a consistent problem with a particular picking location, prompting an adjustment in the warehouse layout. Regular reconciliation of the cycle count data with the inventory management system strengthens confidence in our inventory reports and optimizes inventory levels.

Q 4. What metrics do you use to measure warehouse performance?

Measuring warehouse performance requires a multi-faceted approach, utilizing key performance indicators (KPIs). These KPIs provide insights into different aspects of warehouse operation. I typically monitor metrics such as:

- Order fulfillment rate: The percentage of orders fulfilled accurately and on time.

- Inventory accuracy: The percentage of items whose actual count matches the recorded count.

- Order cycle time: The time elapsed between order placement and shipment.

- Storage capacity utilization: The percentage of available storage space utilized.

- Labor productivity: The number of units handled or orders processed per labor hour.

- Damage and loss rates: The percentage of damaged or lost inventory.

Q 5. How do you handle discrepancies in inventory records?

Handling inventory discrepancies requires a systematic approach. When a discrepancy is identified, the first step is to conduct a thorough investigation to determine the root cause. This might involve reviewing picking lists, checking for damaged goods, reviewing receiving documentation, and examining inventory management system logs. Depending on the magnitude of the discrepancy, a full recount of the affected inventory might be necessary. The investigation should not only find the discrepancy but also pinpoint the source of the error. For example, we might find a process flaw, such as inaccurate scanning, or a data entry error. Once the root cause is identified, corrective actions are implemented to prevent future occurrences. This might include retraining staff, adjusting inventory management processes, or upgrading equipment. Documentation of the discrepancy, investigation, and corrective actions is crucial for maintaining audit trails and continuous improvement.

Q 6. Describe your experience with different inventory control methods (FIFO, LIFO, etc.).

Different inventory control methods, such as FIFO (First-In, First-Out) and LIFO (Last-In, First-Out), have significant implications for inventory management and financial reporting. FIFO assumes that the oldest items are sold first, which is suitable for perishable goods or those susceptible to obsolescence. LIFO, on the other hand, assumes that the newest items are sold first; this method can be advantageous during periods of inflation because it lowers taxable income. My experience includes applying both methods based on the specific needs of the products. For instance, a grocery store would typically utilize FIFO for its produce to minimize spoilage, whereas a lumber yard might use LIFO to manage fluctuating wood prices. I also have experience with weighted average costing, a method where the cost of goods sold is based on the average cost of all available inventory. The choice of method depends on a number of factors including product type, industry regulations, and accounting practices. A proper understanding of these methods is vital for accurate cost accounting and effective inventory management.

Q 7. How do you manage and prioritize incoming and outgoing shipments?

Managing incoming and outgoing shipments requires careful coordination and planning. I utilize a system that prioritizes shipments based on several factors including urgency, delivery deadlines, and product value. For incoming shipments, we use advanced shipment notifications (ASNs) to anticipate arrivals and prepare receiving staff. This helps to minimize receiving time and reduce storage congestion. We also implement quality checks upon receipt to ensure that the correct quantities and quality of goods are received. For outgoing shipments, we use warehouse management system (WMS) software to optimize picking routes and loading sequences. We prioritize orders based on urgency and delivery deadlines, ensuring timely fulfillment. Real-time tracking of shipments allows us to monitor progress and proactively address any potential delays. Effective communication with carriers and customers is crucial to ensure smooth and efficient shipment processes. This can include using tracking numbers, providing timely updates, and handling inquiries effectively.

Q 8. Explain your experience with warehouse safety procedures and regulations.

Warehouse safety is paramount. My experience encompasses a comprehensive understanding and strict adherence to OSHA (Occupational Safety and Health Administration) regulations and best practices. This includes regular safety training for all personnel, focusing on topics like forklift operation, proper lifting techniques, hazard communication (SDS sheets), and emergency procedures. I’ve implemented and overseen programs such as lock-out/tag-out procedures for machinery maintenance and fire safety drills to ensure preparedness for various scenarios. In a previous role, I successfully reduced workplace incidents by 15% within a year by implementing a robust safety audit program and addressing identified hazards proactively. This involved regular inspections, clear communication of safety protocols, and prompt remediation of any potential safety violations. For example, we identified a blind corner in the warehouse that consistently resulted in near-misses. Implementing mirrors and improved lighting immediately mitigated this risk.

Q 9. How do you improve warehouse efficiency through technology?

Technology is key to boosting warehouse efficiency. I’ve leveraged Warehouse Management Systems (WMS) extensively to streamline operations. A WMS allows for real-time tracking of inventory, automated order fulfillment, and optimized routing for picking and packing. This minimizes travel time for workers and reduces errors. Furthermore, I’ve implemented Radio Frequency Identification (RFID) technology in several warehouses, which provides superior accuracy in inventory tracking compared to traditional barcode scanning. RFID allows for automatic identification and tracking of goods without the need for line-of-sight scanning, making processes like receiving and shipping much faster and more efficient. For example, in one project, implementing a WMS and RFID resulted in a 20% reduction in order fulfillment time and a 10% decrease in picking errors.

Beyond WMS and RFID, I’ve also explored the benefits of using robotics for tasks like automated guided vehicles (AGVs) for material handling and automated storage and retrieval systems (AS/RS) for maximizing vertical space utilization. Data analytics provided by the WMS also allows for continuous improvement by identifying bottlenecks and areas for optimization within the warehouse workflow. This data-driven approach ensures ongoing improvements to efficiency.

Q 10. Describe your experience with warehouse space optimization techniques.

Warehouse space optimization is crucial for cost reduction and operational efficiency. My approach begins with a thorough assessment of the existing layout, considering factors like product turnover rates, storage capacity, and workflow patterns. I employ various techniques including slotting optimization (strategically placing high-demand items closer to packing stations), implementing vertical storage solutions (e.g., high-bay racking), and optimizing aisle widths to maximize usable space. I’ve also successfully implemented cross-docking strategies in some warehouses to minimize storage time for goods that transit directly from receiving to shipping. For instance, in one project, implementing slotting optimization based on ABC analysis (classifying inventory based on demand) reduced picking time by 18% and freed up 15% of warehouse floor space.

Q 11. How do you handle peak seasons and increased order volumes?

Managing peak seasons requires proactive planning and flexible strategies. This starts with accurate demand forecasting to predict order volumes and anticipate potential bottlenecks. I typically implement strategies such as temporary staffing increases, extending operating hours, and optimizing warehouse layouts to accommodate higher throughput. Prior to the peak season, we review and adjust our WMS settings, ensuring that we have optimized pick paths, optimized our packing and shipping routines, and have sufficient supplies on hand to meet the increase in demand. Pre-planning, including securing sufficient labor and optimizing inventory levels, is key. In the past, I’ve successfully implemented a temporary, scalable workforce solution that allowed us to meet a 300% increase in order volume during the holiday season without compromising service levels. This included pre-training temporary workers and providing clear workflow instructions to facilitate a smooth operation.

Q 12. What are your strategies for preventing stockouts and overstocking?

Preventing stockouts and overstocking hinges on accurate inventory management and demand forecasting. I use a combination of methods including implementing robust inventory tracking systems (WMS and RFID), utilizing statistical forecasting models to predict future demand, and employing safety stock calculations to buffer against unexpected fluctuations. Regular inventory cycle counting helps identify discrepancies and prevent stockouts. Close collaboration with sales and procurement teams ensures that inventory levels are aligned with actual demand. For example, using a combination of WMS and forecasting techniques, we reduced stockout rates by 12% and minimized excess inventory by 8% over the course of a year. The key is to maintain a balance between meeting customer demand and minimizing storage costs.

Q 13. How do you manage damaged or obsolete inventory?

Damaged or obsolete inventory needs to be handled efficiently and cost-effectively. My approach involves regular inventory audits to identify damaged or obsolete items. Depending on the product, we may consider options such as repairs, returns to suppliers, donations to charity, or liquidation through salvage sales. A detailed tracking system is crucial to monitor and analyze the causes of damage and obsolescence, to help prevent future occurrences. Implementing proper storage techniques to prevent damage in the first place is also vital. For instance, we might implement better humidity control to prevent damage to sensitive goods or stricter rotation techniques (FIFO – First In, First Out) to minimize the risk of obsolescence. The overall goal is to minimize losses and maintain accurate inventory records.

Q 14. What is your experience with barcode scanning and RFID technology?

I have extensive experience with both barcode scanning and RFID technology. Barcode scanning is a cost-effective solution for basic inventory tracking, but its limitations become apparent in high-volume environments or when tracking items in transit. RFID, while more expensive initially, offers superior accuracy and efficiency, especially in situations requiring real-time tracking and automation. I’ve led projects implementing both technologies, integrating them with WMS to improve various aspects of warehouse operations. For example, RFID improved accuracy in our receiving process by 95%, reducing time spent on manual reconciliation. In another instance, integrating barcode scanners into our picking process streamlined the workflow and reduced picking errors. My selection of technology always depends on the specific needs and budget of the warehouse.

Q 15. How do you ensure accurate picking and packing processes?

Accurate picking and packing are the cornerstones of efficient order fulfillment. We achieve this through a multi-pronged approach focusing on systematization, training, and verification.

- Clear Labeling and Organization: Every shelf, bin, and location is clearly labeled with SKU numbers, location codes, and potentially even visual cues. This makes locating items quick and error-free. Think of it like a well-organized library – you can find any book quickly if the shelving system is logical and consistently applied.

- Barcode/RFID Scanning: We utilize barcode or RFID scanners at every stage – from receiving to picking to packing – to verify the items being picked and packed against the order. This eliminates manual data entry errors and provides a complete audit trail.

- Double-Checking and Quality Control: A secondary verification step is crucial. This could involve a second picker checking the order, or a dedicated quality control team inspecting the packed items before shipment. This is akin to proofreading a document before sending it – it catches any overlooked mistakes.

- Warehouse Management System (WMS): A robust WMS is essential for directing pickers to the most efficient picking paths and optimizing the overall picking process. The WMS will guide pickers through the warehouse, preventing them from going to the wrong locations. It’s like having a GPS for your warehouse.

- Regular Audits and Process Improvements: We regularly audit our picking and packing processes to identify areas for improvement. Any errors are investigated to determine root causes and implement corrective actions. This continuous improvement cycle helps maintain accuracy over time.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle returns and refunds?

Handling returns and refunds efficiently is vital for customer satisfaction and minimizing losses. Our process focuses on speed, accuracy, and data management.

- Clear Return Policy: We have a transparent and easily accessible return policy, clearly outlining the process and timeframes. This reduces misunderstandings and ensures smooth returns.

- Streamlined Return Process: We use a simple and intuitive online portal or a clear physical process for returns, minimizing customer effort. The easier it is for the customer to return an item, the happier they are.

- Inspection and Quality Check: Returned items are carefully inspected to determine their condition and eligibility for a refund or exchange. This is crucial to prevent fraudulent returns.

- Inventory Management: The returned items are immediately reintegrated into the inventory system, updating quantities and statuses. This ensures the item can be quickly resold or processed appropriately.

- Refund Processing: Refunds are processed quickly and accurately, with clear communication to the customer at each stage. We strive for fast and efficient payment processing to keep customers happy. We use automated systems wherever possible.

Q 17. How do you train and manage warehouse staff?

Training and managing warehouse staff is critical for maintaining operational efficiency and a positive work environment. We employ a layered approach.

- Comprehensive Onboarding: New employees receive thorough training on safety procedures, warehouse layout, operating procedures (picking, packing, etc.), and the WMS. We use a combination of classroom instruction, on-the-job training, and mentorship.

- Ongoing Training and Development: We provide ongoing training to keep staff updated on new processes, technologies, and best practices. This includes regular refresher courses on safety and efficiency.

- Performance Management: We use performance metrics to monitor individual and team productivity and identify areas for improvement. Regular feedback is provided, and opportunities for advancement are offered.

- Team Building and Communication: We foster a positive work environment through team-building activities and open communication channels. A happy and motivated team is a productive team.

- Safety First: Safety is paramount. We conduct regular safety training and maintain a safe work environment to prevent accidents and injuries. It is vital to create a safe environment for all employees.

Q 18. Describe your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) spans several years and various platforms. I’m proficient in implementing, configuring, and optimizing WMS functionalities.

- WMS Implementation: I’ve been involved in multiple WMS implementations, from requirements gathering and system selection to testing and go-live support. I understand the challenges of migrating data from legacy systems and ensuring a smooth transition.

- WMS Optimization: I have experience in identifying and resolving WMS inefficiencies through process analysis and system configuration adjustments. This includes optimizing picking routes, improving inventory accuracy, and streamlining reporting.

- WMS Integration: I’m familiar with integrating WMS with other systems like ERP (Enterprise Resource Planning) and TMS (Transportation Management Systems). This seamless data flow is essential for complete visibility across the supply chain.

- Specific WMS Experience: (Mention specific WMS systems you’ve worked with, e.g., Manhattan Associates, Blue Yonder, etc.).

I believe a well-implemented WMS is the backbone of a highly efficient warehouse operation.

Q 19. How do you manage supplier relationships to ensure timely delivery?

Managing supplier relationships is crucial for ensuring timely delivery and maintaining product quality. We focus on collaboration, communication, and performance monitoring.

- Strategic Partnerships: We develop strong relationships with key suppliers, fostering open communication and collaboration. This includes regular meetings and performance reviews.

- Performance Monitoring: We track supplier performance metrics, such as on-time delivery, order accuracy, and quality control. This data informs our decision-making and allows us to identify and address issues proactively.

- Clear Communication: We maintain clear and consistent communication with suppliers, sharing forecasts and providing timely feedback. We use various communication channels (emails, portals, etc.) to ensure all information is relayed effectively.

- Supplier Audits: We conduct regular audits of our suppliers to ensure they meet our quality standards and compliance requirements. This ensures they are fulfilling their contractual obligations and maintaining our standards of quality.

- Contingency Planning: We have contingency plans in place to mitigate the risks associated with supplier disruptions, such as sourcing alternative suppliers or maintaining safety stock.

Q 20. What is your experience with forecasting inventory needs?

Accurate inventory forecasting is essential for avoiding stockouts and minimizing excess inventory. We employ a multi-faceted approach.

- Historical Data Analysis: We analyze historical sales data to identify trends and seasonality patterns. This provides a foundation for our forecasts.

- Demand Forecasting Techniques: We use various forecasting techniques, such as moving averages, exponential smoothing, and time series analysis. The choice of technique depends on the specific product and its demand characteristics.

- Market Research and Trend Analysis: We monitor market trends, industry forecasts, and competitor activity to refine our demand projections. This ensures the accuracy of our forecasting.

- Sales and Marketing Input: We actively solicit input from our sales and marketing teams to incorporate promotional plans, new product launches, and other factors that may impact demand.

- Regular Review and Adjustment: Forecasts are not static. We regularly review and adjust them based on actual sales data and any changes in market conditions. This continuous refinement is key to accurate forecasting.

Q 21. How do you maintain a clean and organized warehouse environment?

Maintaining a clean and organized warehouse is crucial for safety, efficiency, and inventory accuracy. We adopt a proactive approach.

- 5S Methodology: We implement the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to create a structured and efficient work environment. This is a widely used approach for workplace organization.

- Regular Cleaning Schedule: We have a regular cleaning schedule that includes sweeping, mopping, and dusting. Designated areas for waste disposal are also implemented.

- Proper Storage and Handling: We use appropriate storage solutions to prevent damage and maintain order. Items are stored according to size, weight, and frequency of access.

- Designated Areas: We designate specific areas for different activities (receiving, picking, packing, shipping) to prevent congestion and maintain a clear workflow. This keeps the workspace flowing effectively.

- Employee Involvement: We encourage employee participation in maintaining cleanliness and organization. This fosters a sense of ownership and accountability.

Q 22. Describe your experience with implementing Lean principles in a warehouse setting.

Implementing Lean principles in a warehouse focuses on eliminating waste and maximizing efficiency. My experience involves applying the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to optimize workflow and reduce unnecessary movement. For example, in a previous role, we implemented a 5S program in our receiving department, resulting in a 15% reduction in processing time. We also utilized Kaizen events, which are focused improvement workshops, to address specific bottlenecks. One such event led to the redesign of our picking process, incorporating a more efficient route optimization system, reducing travel time by 20%. Lean thinking also guided our efforts in reducing inventory holding costs through techniques like Kanban systems, ensuring we only order materials as needed, which prevented overstocking and storage inefficiencies.

Q 23. How do you handle inventory shrinkage?

Inventory shrinkage is a significant concern. My approach involves a multi-pronged strategy. First, robust cycle counting is crucial. Instead of a single, large annual inventory count, we perform regular, smaller counts of specific sections. This allows for quicker identification of discrepancies. Second, I focus on improving inventory control systems through the use of barcode scanners and RFID technology to track items precisely. Third, we investigate potential causes for shrinkage, such as theft, damage, or errors in the receiving and shipping process. We analyze data to identify patterns and implement preventative measures accordingly. For example, if we noticed consistently high shrinkage in a particular area, we might review security footage or revise our internal handling procedures.

Q 24. What are your strategies for improving warehouse security?

Improving warehouse security is essential for protecting assets. My strategies include implementing a robust access control system with keycard entry and security cameras strategically placed throughout the facility. Regular security audits identify vulnerabilities and help us implement improvements. We also provide comprehensive training to warehouse staff on security protocols and the importance of reporting suspicious activity. Furthermore, I advocate for strong relationships with local law enforcement. We have implemented a security system that integrates with local authorities, enabling immediate response in case of an incident. This multi-layered approach is vital in preventing theft and ensuring the overall safety of the facility.

Q 25. Describe your experience with different types of warehouse equipment (forklifts, conveyor belts, etc.).

I have extensive experience with various warehouse equipment. My familiarity with forklifts includes different types such as sit-down, stand-up, and reach trucks, each suited to different tasks. I understand the importance of proper maintenance and operator training to ensure safe and efficient operation. I’ve also worked with conveyor systems, including roller conveyors, belt conveyors, and sortation systems. My expertise extends to utilizing Warehouse Management Systems (WMS) to optimize the routing and scheduling of equipment, minimizing idle time and improving overall throughput. For example, I once implemented a system that dynamically adjusted conveyor belt speed based on real-time order demand, significantly improving efficiency during peak periods.

Q 26. How do you ensure compliance with relevant industry regulations?

Compliance with industry regulations is paramount. This includes adhering to safety standards (OSHA in the US, or equivalent regulations in other countries), environmental regulations related to waste disposal and emissions, and data privacy regulations such as GDPR. My approach involves staying updated on all relevant regulations and implementing robust internal control systems to guarantee compliance. We conduct regular internal audits to assess our adherence to these standards and identify areas for improvement. We maintain meticulous records and documentation to demonstrate compliance to regulatory bodies during inspections. Training employees on relevant regulations ensures that everyone understands their responsibilities in maintaining compliance.

Q 27. How do you utilize data analytics to improve warehouse operations?

Data analytics plays a crucial role in optimizing warehouse operations. We leverage data from our WMS, inventory tracking systems, and other sources to identify trends, improve forecasting accuracy, and make data-driven decisions. For instance, we use data analytics to analyze picking patterns, identify slow-moving items, and optimize storage locations for faster order fulfillment. We also use predictive analytics to forecast demand and optimize inventory levels, minimizing stockouts and reducing holding costs. This includes the use of dashboards to visualize key performance indicators (KPIs) and identify areas for improvement in real-time.

Q 28. What is your experience with using KPIs to track and improve warehouse performance?

Key Performance Indicators (KPIs) are essential for tracking and improving warehouse performance. I use a range of KPIs, including order fulfillment rate, inventory turnover rate, picking accuracy, and storage utilization. Regularly monitoring these KPIs allows us to identify bottlenecks and areas needing attention. For example, a consistently low order fulfillment rate might indicate a need to improve our picking process or optimize our inventory management. Tracking these KPIs allows us to measure the impact of implemented changes and demonstrate the effectiveness of our improvement initiatives. We use data visualization tools to make KPI data easily accessible and understandable to all stakeholders.

Key Topics to Learn for Shop Organization Interview

- Inventory Management: Understanding inventory control systems, cycle counting, and optimizing stock levels. Practical application: Describe a time you improved inventory accuracy or reduced waste through efficient organization.

- Space Optimization: Efficient layout design, maximizing storage capacity, and implementing 5S methodologies (Sort, Set in Order, Shine, Standardize, Sustain). Practical application: Explain how you would reorganize a poorly laid-out shop floor to improve workflow and safety.

- Workflow and Process Improvement: Analyzing current processes, identifying bottlenecks, and implementing Lean principles to streamline operations. Practical application: Describe a situation where you improved a shop’s workflow leading to increased efficiency or reduced lead times.

- Safety and Compliance: Understanding and adhering to safety regulations, maintaining a clean and organized work environment, and implementing preventative measures to minimize accidents. Practical application: Explain your approach to maintaining a safe and compliant shop environment.

- Equipment Maintenance and Management: Scheduling preventative maintenance, tracking equipment performance, and ensuring proper upkeep of tools and machinery. Practical application: Describe your experience with maintaining and managing shop equipment to prevent downtime.

- Material Handling and Logistics: Understanding efficient material flow, optimizing transportation within the shop, and managing the movement of goods. Practical application: Explain how you would improve the material handling process in a specific scenario.

- Data Analysis and Reporting: Utilizing data to track key performance indicators (KPIs), identify areas for improvement, and make data-driven decisions. Practical application: Describe how you would use data to identify inefficiencies and propose solutions.

Next Steps

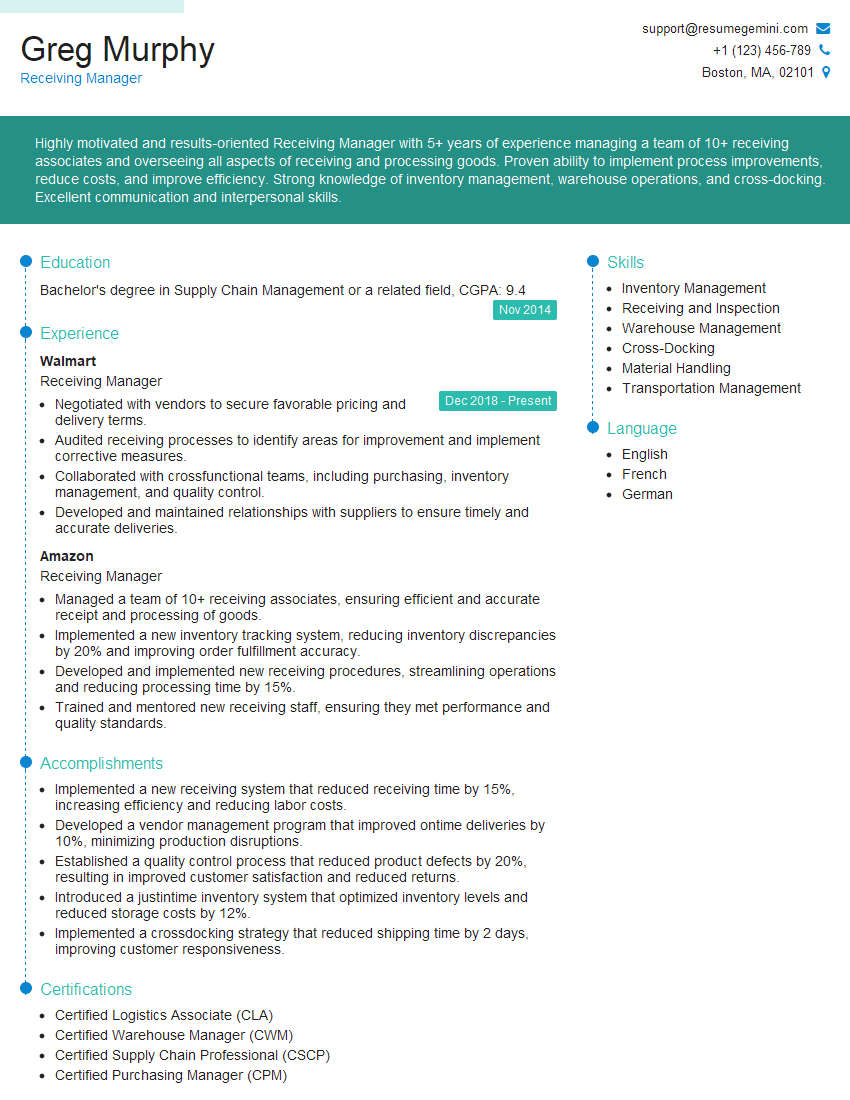

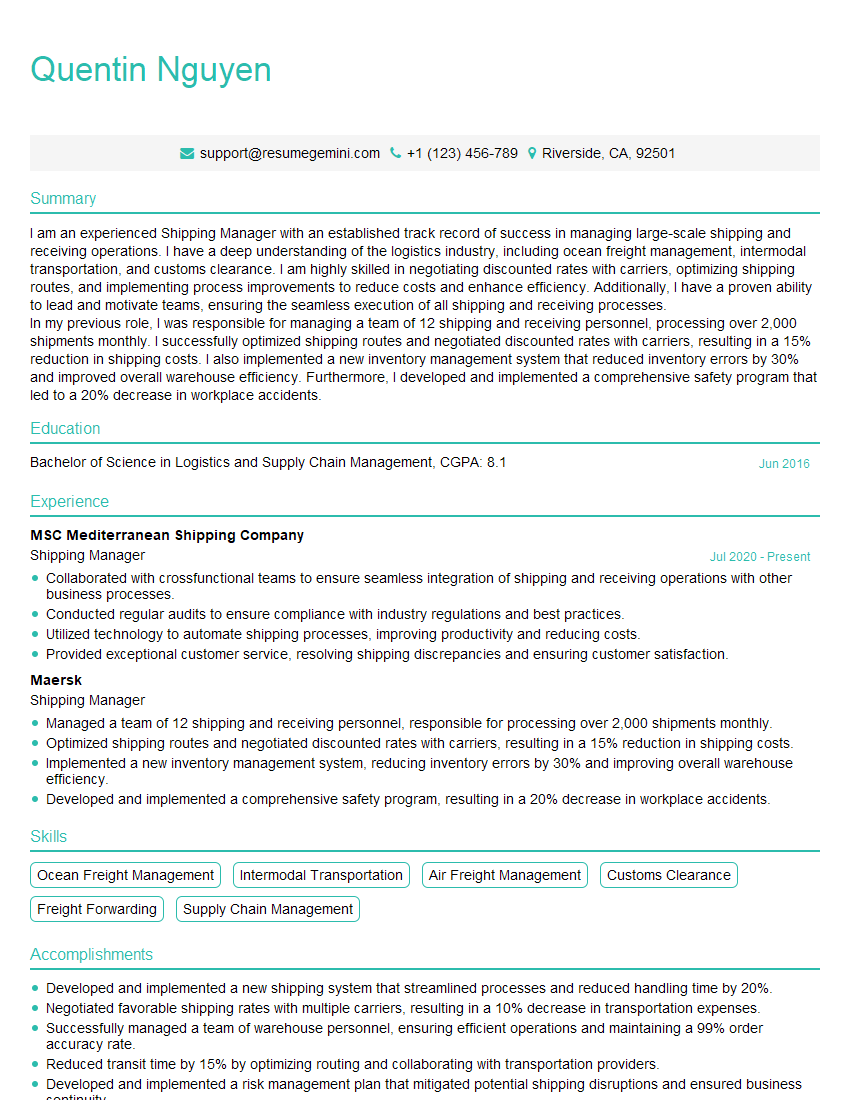

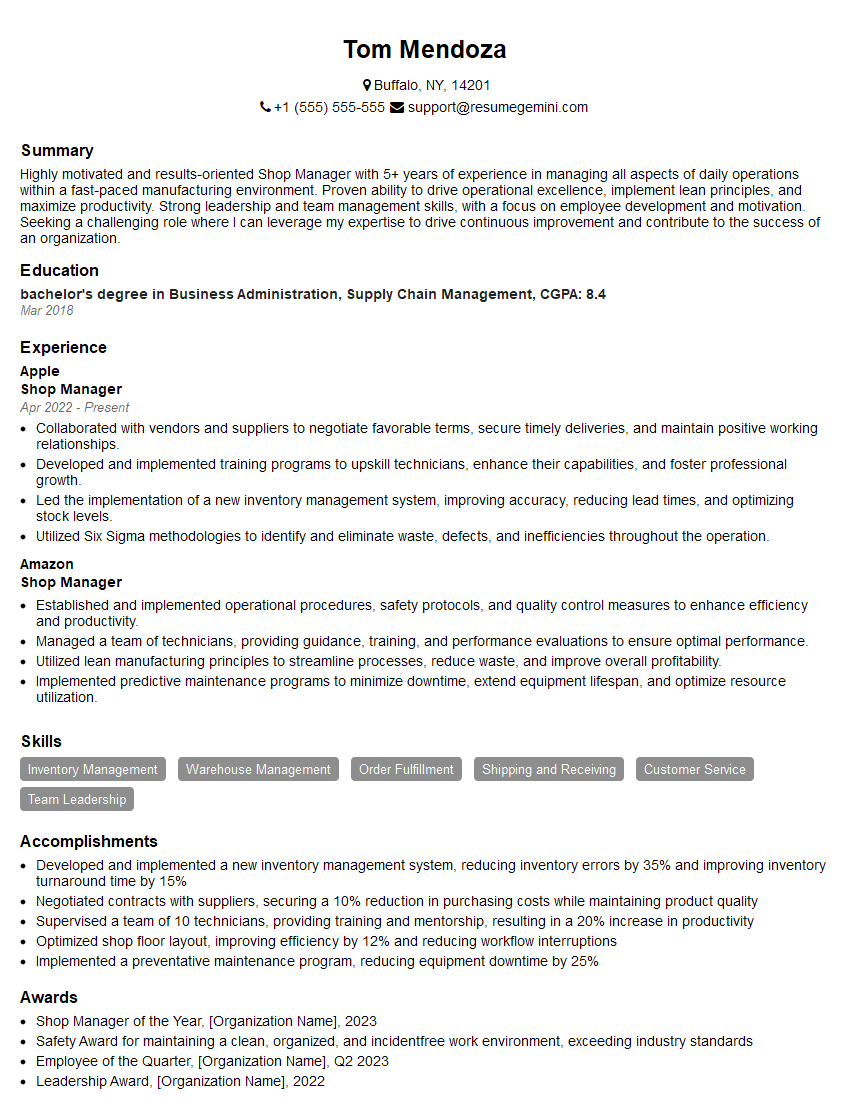

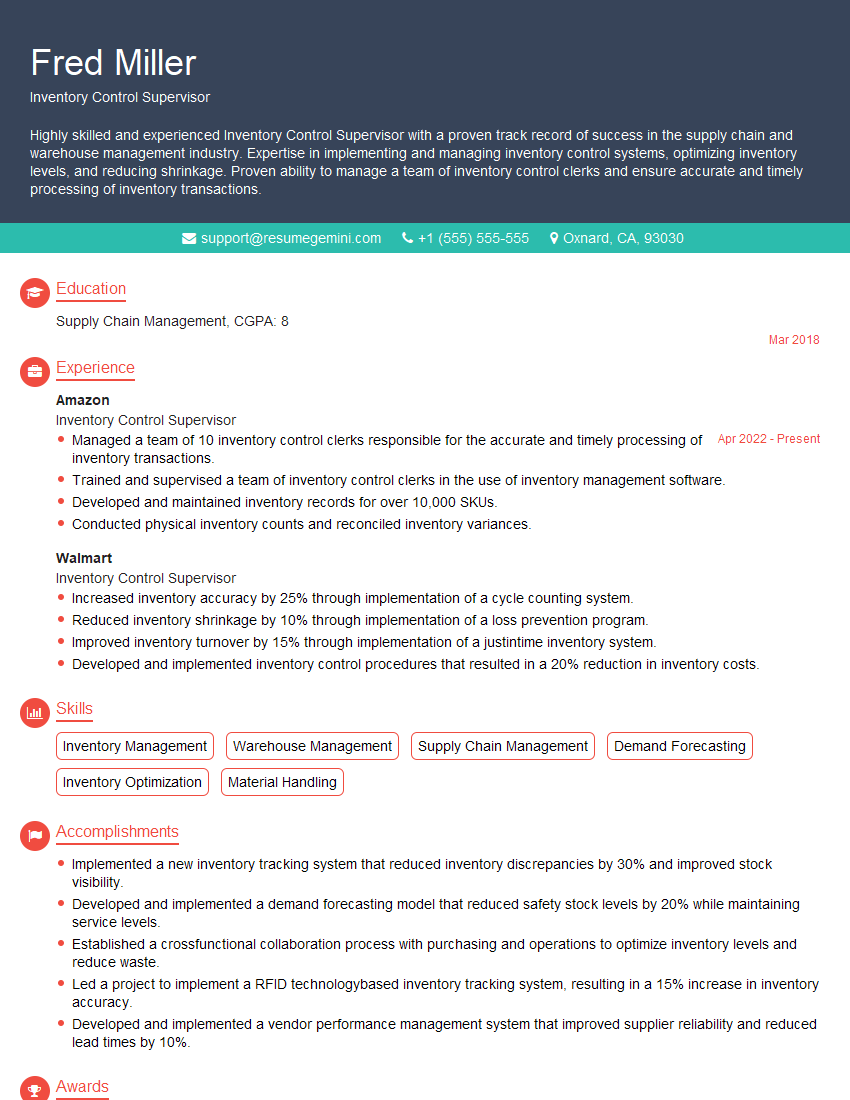

Mastering Shop Organization is crucial for career advancement, opening doors to leadership roles and higher earning potential. A strong understanding of these principles demonstrates your ability to optimize processes, improve efficiency, and create a safe and productive work environment. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to Shop Organization are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO