The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Experience in high-volume manufacturing environments interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Experience in high-volume manufacturing environments Interview

Q 1. Describe your experience with high-volume production processes.

My experience in high-volume manufacturing spans over ten years, encompassing various roles from production supervisor to operations manager. I’ve worked in environments producing everything from consumer electronics to automotive components, always focused on optimizing processes to meet demanding production targets while maintaining quality. This has involved managing large teams, overseeing complex assembly lines, and ensuring seamless integration between different production stages. For example, in my previous role at Techtronics, we manufactured over 500,000 units per month of a specific smartphone model. This required meticulous planning, precise execution, and constant monitoring of key performance indicators (KPIs) to identify and rectify bottlenecks.

Q 2. Explain your understanding of Lean Manufacturing principles.

Lean Manufacturing is a philosophy focused on eliminating waste and maximizing value for the customer. It’s based on several core principles, including:

- Value Stream Mapping: Identifying all steps in a production process and eliminating non-value-added activities.

- Just-in-Time (JIT) Inventory: Minimizing inventory levels by receiving materials only when needed, reducing storage costs and minimizing waste from obsolete stock.

- Kaizen (Continuous Improvement): A culture of continuous improvement through small, incremental changes implemented by employees at all levels.

- 5S Methodology: Organizing the workplace to improve efficiency and reduce errors (Sort, Set in Order, Shine, Standardize, Sustain).

- Poka-Yoke (Error-Proofing): Designing processes to prevent mistakes from occurring.

In practice, I’ve used Lean principles to streamline production lines, reducing lead times and improving overall efficiency. For instance, by implementing a 5S program in our warehouse, we reduced search times for parts by 30% and improved overall workplace safety.

Q 3. How have you improved efficiency in a high-volume manufacturing setting?

Improving efficiency in high-volume manufacturing often requires a multi-pronged approach. In one instance, we were facing significant delays in the assembly of a crucial component. My team and I used a combination of methods to address the issue:

- Value Stream Mapping: We mapped out the entire assembly process, identifying bottlenecks and non-value-added steps.

- Process Optimization: We redesigned the assembly process to streamline workflows and reduce unnecessary movements.

- Operator Training: We implemented a comprehensive training program to improve operator skills and reduce errors.

- Automation: We explored opportunities to automate repetitive tasks, ultimately investing in robotic assistance for certain stages.

These efforts resulted in a 25% increase in assembly throughput within three months.

Q 4. What metrics do you use to track production performance?

Tracking production performance requires a comprehensive set of metrics. Key metrics I regularly use include:

- Overall Equipment Effectiveness (OEE): Measures the effectiveness of equipment utilization.

- Throughput: The rate at which products are produced.

- Cycle Time: The time it takes to complete one production cycle.

- Defect Rate: The percentage of defective products produced.

- Lead Time: The time it takes to produce a product from order to delivery.

- Inventory Turnover Rate: How efficiently inventory is managed.

I typically use dashboards and reporting tools to monitor these metrics in real-time, enabling proactive intervention and continuous improvement.

Q 5. Describe your experience with Six Sigma methodologies.

Six Sigma is a data-driven methodology aimed at reducing process variation and defects. My experience with Six Sigma includes applying DMAIC (Define, Measure, Analyze, Improve, Control) methodology to solve complex process issues. For example, we used Six Sigma to address a high defect rate in a specific sub-assembly. By following the DMAIC steps, we identified the root cause of the defect, implemented corrective actions, and reduced the defect rate by 90%. This involved using statistical tools such as control charts and process capability analysis to identify and track improvements.

Q 6. How do you manage inventory in a high-volume environment?

Managing inventory in a high-volume environment is crucial for maintaining production flow and minimizing costs. I utilize a combination of techniques, including:

- Just-in-Time (JIT) Inventory: Minimizing inventory levels by receiving materials only when needed.

- Kanban Systems: Using visual signals to manage the flow of materials between production stages.

- Demand Forecasting: Accurately predicting future demand to optimize inventory levels.

- Inventory Management Software: Utilizing software to track inventory levels and manage orders.

Effective inventory management ensures we have the necessary materials on hand without tying up excessive capital in storage.

Q 7. Explain your experience with different production scheduling techniques.

My experience encompasses various production scheduling techniques, including:

- MRP (Material Requirements Planning): Planning the procurement of materials based on production schedules.

- Kanban Scheduling: Using visual signals to manage the flow of work.

- Level Scheduling: Producing a consistent output over time.

- Mixed-Model Scheduling: Scheduling the production of different product variations in a single line.

The choice of scheduling technique depends on factors such as product complexity, demand variability, and production capacity. I’ve successfully implemented and managed each of these techniques in various high-volume manufacturing settings, adapting them to the specific needs of each project.

Q 8. How do you handle production bottlenecks?

Production bottlenecks are points in the manufacturing process where workflow slows down, impacting overall output. Identifying and resolving these bottlenecks is crucial for maintaining efficiency and meeting production targets. My approach involves a systematic process:

- Identify the Bottleneck: This often involves analyzing production data, observing the workflow firsthand, and collaborating with team members on the production floor. For example, I once identified a bottleneck at a packaging station due to an inefficient labeling machine.

- Analyze the Root Cause: Once identified, we investigate the underlying reason for the bottleneck. Is it due to equipment malfunction, insufficient workforce, material shortages, or process inefficiencies? Root cause analysis techniques like the ‘5 Whys’ method are invaluable here.

- Implement Solutions: Solutions vary depending on the root cause. In the labeling machine case, we explored options including repairing the machine, temporarily replacing it with a more efficient model, or adjusting the packaging process to mitigate the issue. We also examined the possibility of optimizing the number of personnel staffing the line during peak demand periods.

- Monitor and Improve: After implementing a solution, continuous monitoring is essential. We track key performance indicators (KPIs) like cycle time, throughput, and defect rates to ensure the solution is effective and to identify any new bottlenecks that may emerge.

Ultimately, proactive identification and strategic resolution are key to minimizing disruptions and maintaining a smooth production flow.

Q 9. Describe your experience with implementing or improving quality control systems.

In high-volume manufacturing, robust quality control systems are non-negotiable. My experience involves implementing and improving these systems, emphasizing a multi-pronged approach:

- Statistical Process Control (SPC): I’ve extensively used SPC charts (e.g., control charts) to monitor process variability and identify potential quality issues before they escalate. For example, I implemented an SPC system to track the dimensions of a critical component, enabling early detection and correction of deviations from specifications.

- Quality Audits: Regular audits, both internal and external, are vital. These audits assess compliance with standards, identify weaknesses, and ensure continuous improvement. I led audits that resulted in the identification and rectification of inconsistencies in our assembly process, resulting in a significant reduction in defects.

- Preventive Measures: Implementing preventive measures is far more cost-effective than addressing problems reactively. This includes rigorous incoming material inspection, employee training, regular equipment calibration, and the use of quality control checklists throughout the manufacturing process.

- Corrective Actions: When quality issues occur, establishing a clear process for corrective and preventive actions (CAPA) is crucial. This involves documenting the issue, identifying the root cause, implementing corrective actions, and preventing recurrence. I’ve implemented several CAPA systems, improving our response time to quality problems and preventing recurring issues.

By combining these approaches, I’ve contributed to achieving consistent high-quality products and minimizing waste.

Q 10. How do you ensure worker safety in a high-volume manufacturing environment?

Worker safety is paramount in any high-volume manufacturing setting. My approach focuses on a proactive, multi-layered strategy:

- Hazard Identification and Risk Assessment: Regularly identifying and assessing potential hazards through safety audits and worker input is essential. This includes identifying ergonomic risks, machine hazards, chemical hazards, and other potential dangers.

- Safety Training and Education: Comprehensive training programs, tailored to specific job roles and hazards, are critical. This includes both initial training and regular refresher courses to ensure workers remain up-to-date on safety protocols.

- Implementation of Safety Measures: Implementing engineering controls (e.g., machine guards, emergency shut-off buttons), administrative controls (e.g., work rotation, job safety analysis), and personal protective equipment (PPE) is key to mitigating risks. I’ve been involved in the implementation of several safety improvements, including the installation of improved lighting, implementation of safety harnesses for workers at height, and the development of comprehensive PPE inventory management.

- Incident Reporting and Investigation: Establishing a clear process for reporting and investigating workplace accidents is critical for identifying root causes, preventing recurrence, and improving safety measures. I’ve developed and implemented safety investigation processes involving accident reconstruction and root cause analysis.

- Safety Culture: Fostering a strong safety culture where safety is everyone’s responsibility is paramount. This includes open communication, employee involvement in safety initiatives, and regular safety meetings.

A safe work environment isn’t just a requirement; it’s a reflection of a company’s values and a key factor in productivity and employee morale.

Q 11. What is your experience with Kaizen events or continuous improvement initiatives?

Kaizen, meaning ‘continuous improvement’ in Japanese, is a core principle in my approach to manufacturing. I have extensive experience leading and participating in Kaizen events:

- Event Planning and Facilitation: I’ve led numerous Kaizen events, focusing on specific areas needing improvement. This involves defining the scope, assembling a cross-functional team, and establishing clear goals and timelines.

- Value Stream Mapping: We use value stream mapping to visually represent the current state and identify waste (muda) in the process. This allows us to pinpoint areas for improvement and optimize the flow.

- Implementation and Measurement: After identifying improvement opportunities, we implement changes, often in small, incremental steps. We then rigorously measure the impact of those changes, tracking KPIs to ensure effectiveness. For example, in one Kaizen event, we redesigned a workstation layout, which resulted in a 15% reduction in cycle time.

- Standardization: Once improvements are proven effective, we standardize the new processes to ensure consistency and prevent backsliding.

Kaizen isn’t a one-time event but an ongoing commitment to continuous improvement, and it’s fundamentally about empowering workers to identify and solve problems on the front line.

Q 12. How do you manage production costs in a high-volume setting?

Managing production costs in a high-volume setting requires a holistic approach focusing on efficiency and waste reduction:

- Lean Manufacturing Principles: Implementing lean manufacturing principles, such as eliminating waste (muda), optimizing workflow, and improving process efficiency, is crucial. This includes techniques like 5S (sort, set in order, shine, standardize, sustain) and Kanban.

- Material Cost Control: Effective procurement strategies, including negotiating favorable pricing with suppliers, optimizing inventory levels to minimize storage costs, and exploring alternative materials are vital. I’ve successfully negotiated contracts leading to substantial savings on raw materials.

- Labor Cost Management: Optimizing workforce allocation, improving worker productivity through training and process improvements, and leveraging automation where appropriate help control labor costs. We implemented a cross-training program to increase workforce flexibility and reduce overtime costs.

- Energy and Utility Cost Reduction: Implementing energy-efficient equipment and processes, and optimizing facility energy consumption, can yield significant savings. I’ve successfully implemented energy-saving measures leading to a noticeable decrease in operating costs.

- Process Optimization: Continuously monitoring and improving production processes, identifying and eliminating bottlenecks, and implementing automation can significantly reduce costs. For example, we automated a previously manual process, leading to a substantial decrease in production time and cost.

Cost management is not about cutting corners; it’s about making smart decisions to maximize efficiency and minimize waste.

Q 13. Describe your experience with preventative maintenance strategies.

Preventative maintenance (PM) is essential for minimizing downtime and maximizing equipment lifespan in high-volume manufacturing. My approach to PM involves:

- Developing a PM Schedule: Creating a detailed PM schedule based on equipment specifications, manufacturer recommendations, and historical maintenance data. This schedule outlines regular inspections, lubrication, cleaning, and component replacements.

- Implementing a CMMS (Computerized Maintenance Management System): Using a CMMS to track maintenance activities, schedule tasks, manage inventory, and generate reports is invaluable. This enables better planning and resource allocation. I’ve implemented and managed several CMMS systems in my previous roles.

- Training Maintenance Personnel: Providing comprehensive training to maintenance personnel on proper procedures, safety protocols, and troubleshooting techniques is crucial. Regular training ensures personnel are well-equipped to handle maintenance tasks effectively and safely.

- Data Analysis and Optimization: Analyzing maintenance data to identify patterns, predict potential failures, and optimize the PM schedule is critical. This data-driven approach allows for proactive maintenance and reduces unexpected downtime.

- Continuous Improvement: Regularly reviewing and improving the PM program based on performance data and feedback is vital. This ensures the program remains effective and adaptable to changing needs.

By proactively addressing potential equipment issues, a robust PM program contributes significantly to maintaining production efficiency and minimizing costly downtime.

Q 14. How do you handle unexpected equipment failures?

Unexpected equipment failures are inevitable in high-volume manufacturing. My approach to handling these situations is:

- Immediate Response: The first step involves immediately securing the affected equipment, ensuring worker safety, and assessing the extent of the damage. This often involves activating emergency procedures and isolating the affected equipment to prevent further damage or injury.

- Troubleshooting and Diagnosis: Using diagnostic tools and the expertise of maintenance personnel, we diagnose the cause of the failure. This may involve inspecting components, reviewing maintenance logs, and contacting equipment manufacturers for support.

- Repair or Replacement: Depending on the nature of the failure and the availability of spare parts, we either repair the equipment or replace faulty components. This often involves prioritizing repairs based on impact on production and utilizing efficient repair techniques.

- Root Cause Analysis: After the repair, we conduct a thorough root cause analysis to understand why the failure occurred. This helps prevent future occurrences through corrective actions. For example, if a motor burned out, we might investigate whether it was due to overheating, insufficient lubrication, or a voltage surge.

- Production Rescheduling: In some cases, production schedules need to be adjusted to account for the downtime. We explore alternative production arrangements or expedite repairs to minimize production losses.

Effective response to unexpected failures requires a combination of preparedness, skilled personnel, and a well-defined process to minimize disruption and ensure quick recovery.

Q 15. What is your experience with supply chain management in a high-volume environment?

In high-volume manufacturing, supply chain management is the lifeblood of the operation. It’s about strategically managing the flow of goods and services, from raw materials to finished products, to meet customer demand efficiently and profitably. My experience encompasses overseeing all aspects, from sourcing and procurement to inventory management and logistics. For example, at my previous role at Acme Manufacturing, we implemented a Vendor Managed Inventory (VMI) system for critical components. This allowed our key suppliers to manage their own inventory levels based on our forecasted demand, reducing our warehousing costs and improving responsiveness to market fluctuations. We also utilized sophisticated forecasting models, incorporating historical data, seasonal trends, and market intelligence to optimize purchasing decisions and avoid stockouts or overstocking.

Furthermore, I’ve been involved in negotiating contracts with suppliers, ensuring competitive pricing and reliable delivery schedules. This includes developing strong relationships with key suppliers and implementing rigorous quality control measures throughout the supply chain to prevent defects and minimize disruptions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure on-time delivery in high-volume manufacturing?

On-time delivery in high-volume manufacturing requires meticulous planning, execution, and constant monitoring. It’s not just about meeting deadlines; it’s about building trust with customers and maintaining a competitive edge. My approach centers around a robust production schedule, incorporating capacity planning, material availability, and potential bottlenecks. We leverage tools like Material Requirements Planning (MRP) systems to forecast demand, allocate resources, and manage inventory effectively. Imagine it like orchestrating a complex symphony – each instrument (machine, team, resource) must play its part precisely and in sync.

Beyond planning, real-time monitoring is crucial. I regularly review key performance indicators (KPIs) such as production output, lead times, and defect rates, using dashboards to identify and address deviations promptly. This proactive approach allows for immediate corrective actions – be it adjusting production schedules, re-allocating resources, or addressing equipment malfunctions – minimizing delays. For instance, at Beta Manufacturing, we implemented a Kanban system on the assembly line which dramatically improved workflow and reduced lead times by 20%.

Q 17. Describe your experience with different types of manufacturing processes (e.g., assembly, machining).

My experience spans a variety of manufacturing processes, including assembly, machining, and injection molding. In assembly, I’ve overseen the production of complex electronic devices, focusing on optimizing assembly lines for speed and efficiency. This includes experience with both manual and automated assembly processes. For machining, I’ve worked with CNC (Computer Numerical Control) machines, ensuring precision and minimizing waste. I understand the importance of proper tooling, programming, and maintenance to maintain high quality and output. In injection molding, I’ve been involved in optimizing mold designs, material selection, and process parameters to produce high-quality plastic components efficiently.

I also possess knowledge of lean manufacturing principles, which I apply across all processes to eliminate waste and improve overall efficiency. This includes value stream mapping to identify bottlenecks, implementing 5S methodology to improve workplace organization, and continuously striving for process improvement through Kaizen events.

Q 18. How do you motivate and manage a large team in a production setting?

Managing a large team in a production setting requires a blend of leadership, communication, and motivational skills. I believe in fostering a collaborative and empowering environment where each team member feels valued and respected. My approach focuses on clear communication of goals, expectations, and performance standards. This includes regular team meetings, one-on-one check-ins, and providing constructive feedback. I also empower my team by delegating tasks appropriately, providing them with the necessary resources and training, and allowing them autonomy within their roles.

Motivation is key. I recognize and reward outstanding performance, celebrate successes, and actively address any concerns or challenges. I believe in fostering a culture of continuous improvement where team members are encouraged to contribute ideas and participate in problem-solving. For instance, I implemented a suggestion box system at Gamma Manufacturing, resulting in several process improvements that significantly boosted productivity.

Q 19. Explain your experience with using ERP or MRP systems.

I have extensive experience using Enterprise Resource Planning (ERP) and Manufacturing Resource Planning (MRP) systems. These systems are essential for managing all aspects of a manufacturing operation, from planning and scheduling to inventory control and financial management. I am proficient in using various ERP and MRP software packages, including SAP and Oracle. My experience includes implementing, configuring, and maintaining these systems, ensuring they are integrated with other business systems and processes.

For example, at Delta Manufacturing, I led the implementation of a new ERP system, which streamlined our production planning and inventory management processes. This resulted in reduced lead times, improved inventory accuracy, and significant cost savings. I am also adept at extracting data from these systems to generate reports and analyze performance, enabling data-driven decision making.

Q 20. How do you ensure compliance with safety regulations and industry standards?

Ensuring compliance with safety regulations and industry standards is paramount in high-volume manufacturing. It’s not just a legal requirement; it’s a moral obligation to protect our employees and maintain a safe working environment. My approach involves developing and implementing comprehensive safety programs that align with all relevant regulations, including OSHA (Occupational Safety and Health Administration) guidelines and industry-specific standards. This includes conducting regular safety inspections, providing training to employees on safety procedures, and ensuring that all equipment is properly maintained and operated.

We utilize various safety measures, including personal protective equipment (PPE), machine guarding, and emergency response plans. I also foster a strong safety culture within the organization, promoting open communication about safety concerns and encouraging employees to report any hazards. Regular safety audits and continuous improvement initiatives are also key to maintaining a safe and compliant workplace.

Q 21. Describe a time you had to solve a complex production problem.

At Epsilon Manufacturing, we faced a critical production bottleneck due to a faulty component supplier. The supplier experienced a significant delay in delivering a crucial part, threatening to disrupt our entire production schedule and jeopardizing major customer orders. This was a complex problem because finding a suitable replacement supplier with the required quality and lead time was extremely challenging.

My solution involved a multi-pronged approach. First, I worked closely with the supplier to understand the root cause of the delay and develop a recovery plan. Simultaneously, I initiated a search for alternative suppliers, carefully evaluating their capabilities and reliability. We also implemented a temporary workaround by modifying the assembly process to utilize a slightly different component, minimizing the impact on production. Finally, we implemented a new supplier relationship management process to mitigate the risk of future disruptions. This involved diversifying our supplier base and establishing stronger communication and contingency plans.

Q 22. How do you handle conflict resolution within a production team?

Conflict resolution in a high-volume manufacturing environment requires a proactive and structured approach. It’s rarely about assigning blame but about identifying the root cause and finding a solution that keeps production flowing. My approach involves several key steps:

- Active Listening: I begin by actively listening to all parties involved, ensuring everyone feels heard and understood. This often involves asking clarifying questions to uncover the underlying issues.

- Identifying the Root Cause: Once I have a clear understanding of the situation, I focus on identifying the root cause of the conflict. Is it a communication breakdown? A scheduling issue? A lack of resources? Pinpointing the root cause is crucial for effective resolution.

- Collaborative Problem-Solving: I then facilitate a collaborative problem-solving session, bringing together all stakeholders to brainstorm solutions. This collaborative approach fosters a sense of ownership and commitment to the chosen solution.

- Implementing and Monitoring: Once a solution is agreed upon, I ensure its implementation and monitor its effectiveness. Regular follow-up helps identify any unforeseen challenges and allows for necessary adjustments.

- Documentation: Finally, I document the entire process, including the conflict, the root cause, the solution, and the outcome. This documentation serves as a valuable learning tool for future situations.

For example, I once resolved a conflict between two teams over the allocation of a critical piece of equipment. By carefully listening to both teams, I discovered that their different perspectives stemmed from a lack of clear communication regarding scheduling. Implementing a shared online calendar and clearer communication protocols quickly resolved the issue and prevented future conflicts.

Q 23. What is your experience with data analysis in a manufacturing setting?

Data analysis is integral to optimizing efficiency and reducing waste in high-volume manufacturing. My experience involves leveraging data from various sources, including MES (Manufacturing Execution System), SCADA (Supervisory Control and Data Acquisition) systems, and quality control databases. I’m proficient in using statistical process control (SPC) techniques to monitor key performance indicators (KPIs) such as production rates, defect rates, and downtime.

For instance, in a previous role, we used data analysis to identify a bottleneck in our assembly line. By analyzing production data, we discovered that a specific component was causing frequent stoppages due to quality issues. This led to a process improvement initiative that resulted in a 15% increase in production efficiency. Tools like R and Python, combined with visualization tools like Tableau, are invaluable in this process. We used these tools to create dashboards to monitor KPIs in real-time, allowing for timely interventions and proactive problem-solving.

I also have experience in predictive maintenance using data analytics. By analyzing machine sensor data, we could predict potential equipment failures and schedule maintenance proactively, minimizing unplanned downtime and reducing maintenance costs.

Q 24. How do you stay up-to-date with new technologies and industry trends in manufacturing?

Staying current in the rapidly evolving manufacturing landscape requires a multi-faceted approach. I actively participate in industry conferences and webinars, subscribe to relevant journals and online publications (like industry-specific news sites and blogs), and engage with online communities and professional networks. I also actively seek out training opportunities on emerging technologies.

Specifically, I’ve recently completed certifications in AI-powered quality control systems and Industry 4.0 technologies. I believe continuous learning is critical for maintaining a competitive edge and ensuring that my skills remain relevant. Reading case studies of successful implementations of new technologies in similar manufacturing settings also provides valuable insights.

Q 25. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, and aligned with the market rate for similar positions. After reviewing the job description and considering my qualifications, I am targeting a salary range of [Insert Salary Range]. I am open to discussing this further and am confident we can reach a mutually agreeable compensation package.

Q 26. What are your long-term career goals?

My long-term career goals involve progressing into a leadership role within a high-volume manufacturing organization. I aspire to lead and mentor teams, optimize production processes at scale, and drive continuous improvement initiatives. Ultimately, I aim to contribute significantly to the strategic growth and success of a manufacturing company.

Q 27. Why are you interested in this position?

I am highly interested in this position due to [Company Name]’s reputation for innovation and its commitment to [Mention specific company values or initiatives that resonate with you]. The opportunity to contribute my expertise in high-volume manufacturing to a company with such a strong track record is extremely exciting. The challenges presented by this role align perfectly with my skills and ambitions, and I believe I can make a significant contribution to your team.

Q 28. What are your strengths and weaknesses?

My strengths include strong analytical skills, a proven ability to solve complex problems, and excellent leadership and communication capabilities. I am adept at managing multiple priorities in a fast-paced environment and thrive in collaborative settings.

One area I am actively working on is delegation. While I am capable of handling a significant workload independently, I recognize the importance of effectively delegating tasks to build team capacity and foster growth within the team. I’m actively implementing strategies to improve my delegation skills, including clearer task assignments and regular check-ins with team members.

Key Topics to Learn for High-Volume Manufacturing Environments Interviews

- Lean Manufacturing Principles: Understand concepts like Kaizen, 5S, Kanban, and their practical application in optimizing production flow and minimizing waste. Consider examples from your experience where you implemented or witnessed these principles in action.

- Production Scheduling & Optimization: Discuss your experience with production scheduling software and techniques. Be prepared to explain how you’ve dealt with unexpected delays, prioritized tasks, and ensured on-time delivery in high-pressure situations. Consider the impact of different scheduling methodologies.

- Quality Control & Assurance: Detail your experience with quality control processes, including inspection procedures, defect tracking, and root cause analysis. Be ready to describe instances where you identified and resolved quality issues, contributing to improved product consistency.

- Safety Regulations & Procedures: Highlight your understanding and adherence to safety protocols within a manufacturing environment. Describe how you ensured a safe working environment for yourself and your colleagues, emphasizing your commitment to preventing accidents and injuries.

- Teamwork & Communication: Discuss your collaboration with different teams (production, engineering, maintenance) within a high-volume manufacturing setting. Explain how effective communication and teamwork were crucial to achieving production goals.

- Troubleshooting & Problem-Solving: Describe instances where you identified and resolved production bottlenecks or equipment malfunctions. Showcase your analytical skills and ability to implement effective solutions under pressure.

- Process Improvement Initiatives: Share examples of projects where you contributed to process improvements, leading to increased efficiency, reduced costs, or enhanced product quality. Quantify your accomplishments whenever possible.

Next Steps

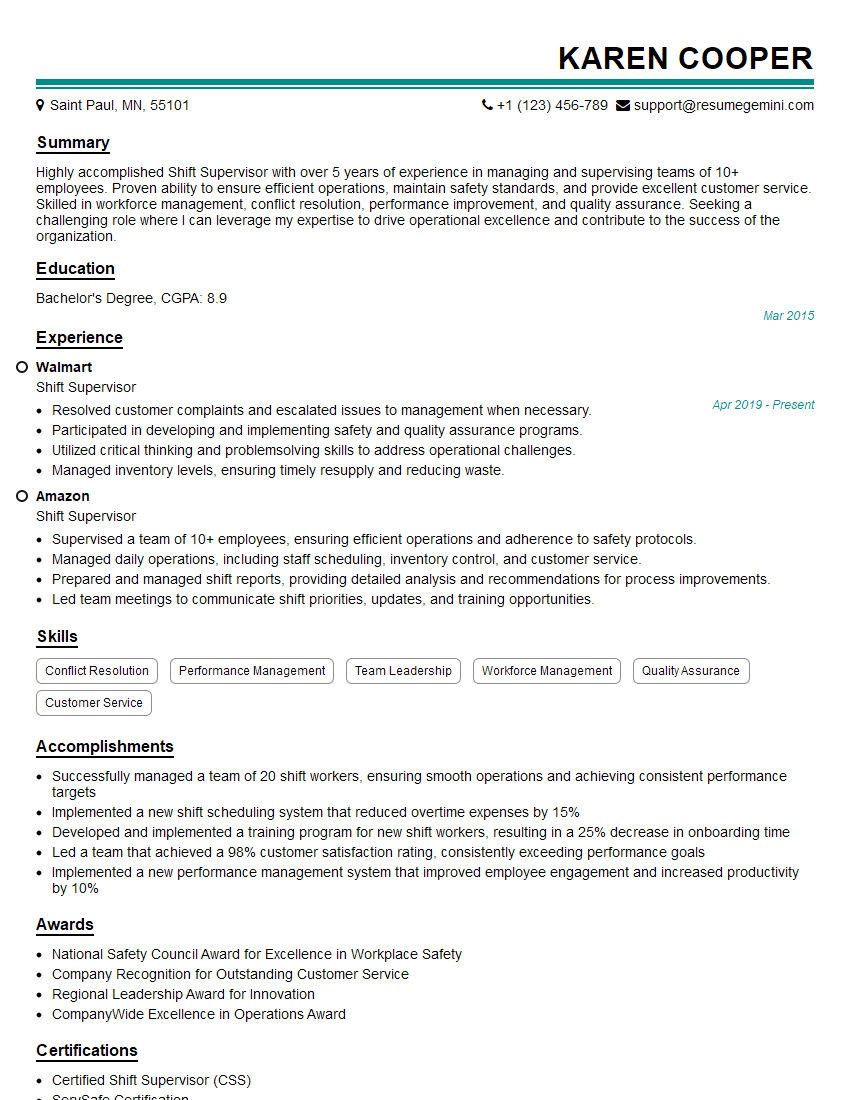

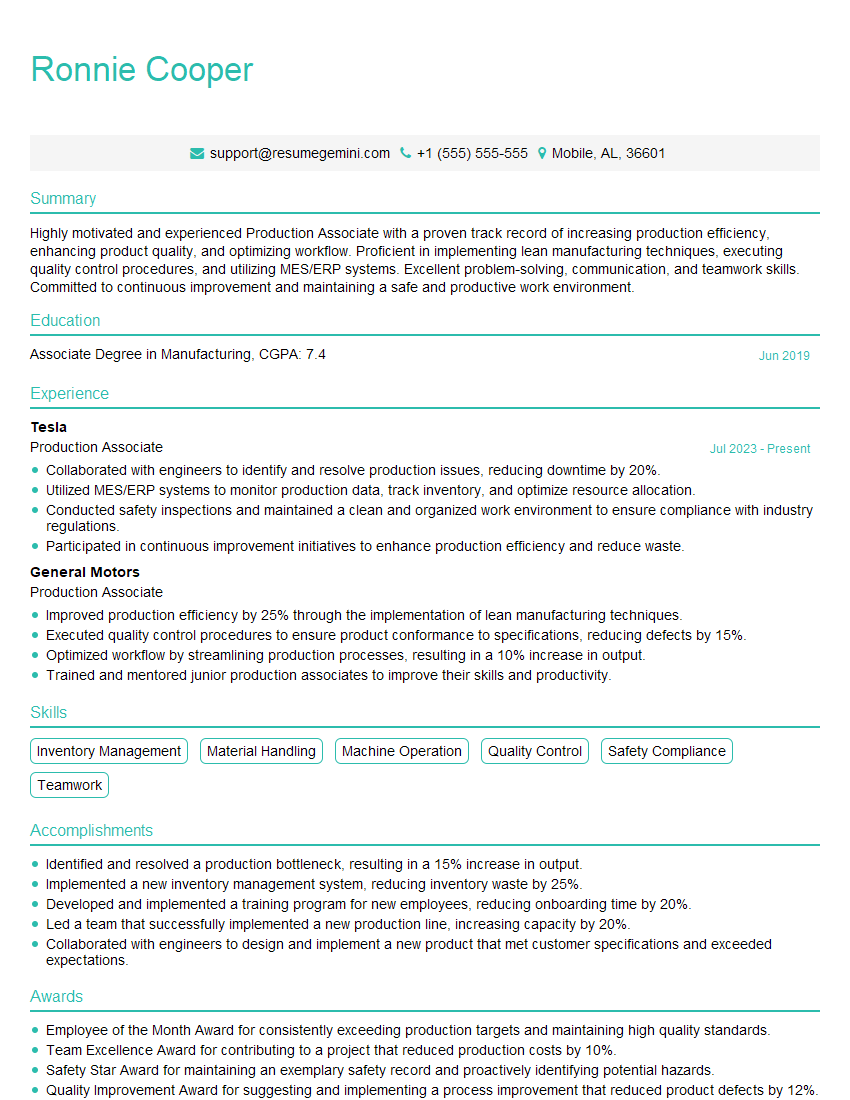

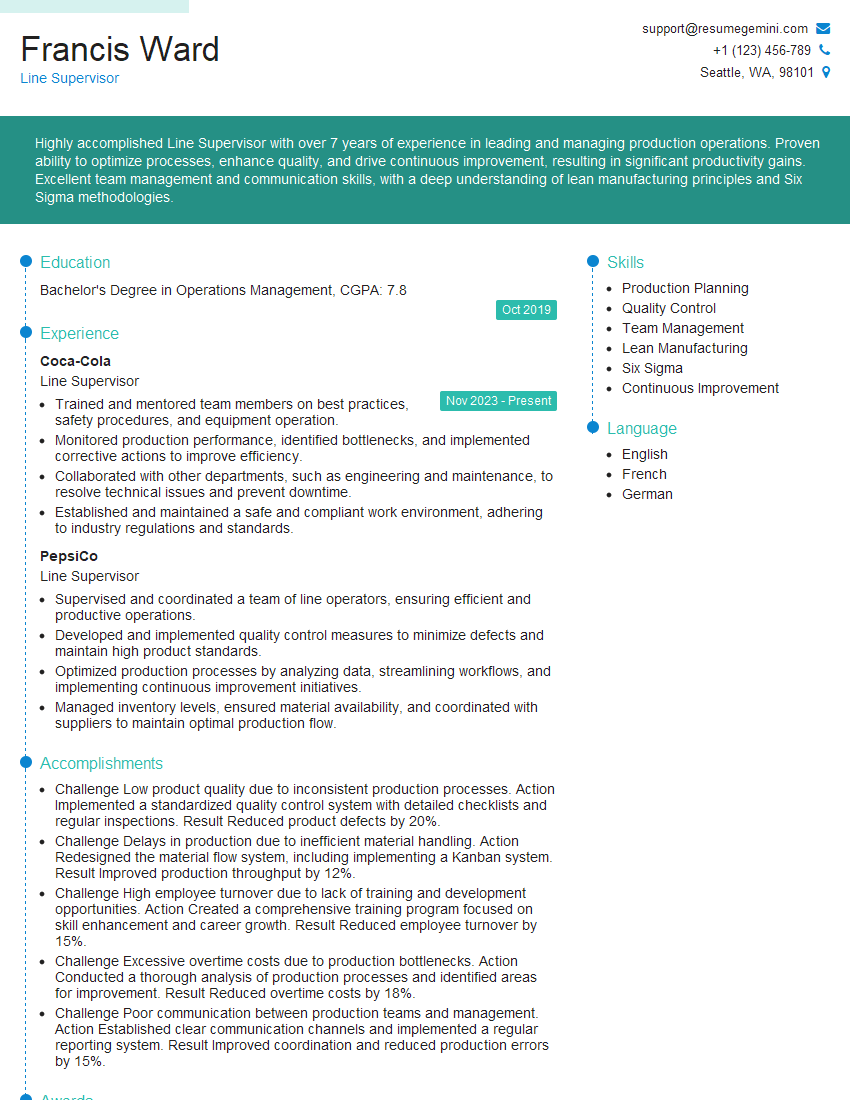

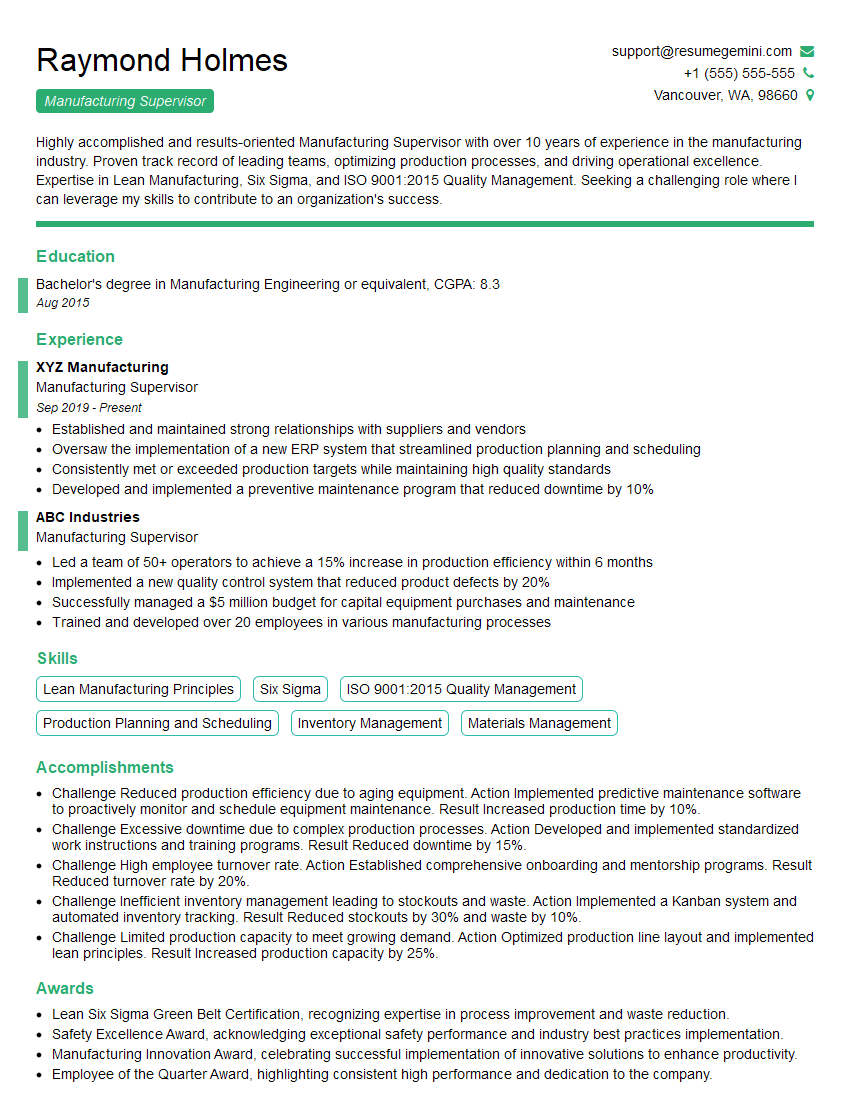

Mastering these key areas significantly enhances your prospects in high-volume manufacturing roles, opening doors to exciting career advancements and higher earning potential. An ATS-friendly resume is crucial for getting your application noticed by recruiters. ResumeGemini can help you craft a compelling resume that highlights your skills and experience effectively, significantly increasing your chances of landing your dream job. Examples of resumes tailored to high-volume manufacturing environments are available to help guide your resume creation. Start building your success story today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO