Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important ISO Standards Knowledge interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in ISO Standards Knowledge Interview

Q 1. Explain the PDCA cycle in the context of ISO 9001.

The PDCA cycle, or Plan-Do-Check-Act cycle, is a fundamental process improvement methodology integral to ISO 9001’s Quality Management System (QMS). It’s a continuous improvement loop designed to identify problems, implement solutions, and monitor their effectiveness.

- Plan: This stage involves defining objectives, processes, and resources required to achieve those objectives. For example, if a company wants to reduce production errors, the plan might involve implementing new training for staff and purchasing upgraded equipment.

- Do: This is the implementation phase. The planned actions are executed, and data is collected on the process. Continuing the example, staff would undergo the new training and the new equipment would be used in production.

- Check: This stage focuses on monitoring and measuring the results of the implemented actions. Data analysis is crucial here to determine if the plan is effective. The company would analyze error rates after the training and equipment upgrade to see if there’s improvement.

- Act: Based on the findings from the ‘Check’ phase, decisions are made. If the plan was successful, it is standardized. If not, the plan is revised and the cycle begins again. If error rates decreased significantly, the new training and equipment would be adopted permanently. If not, further adjustments to training, equipment, or both would be necessary, restarting the cycle.

Think of it like baking a cake: You plan the recipe (Plan), bake the cake (Do), taste-test it (Check), and adjust the recipe for the next time based on the taste (Act).

Q 2. Describe the key differences between ISO 9001 and ISO 14001.

While both ISO 9001 and ISO 14001 are internationally recognized standards focused on management systems, they address different aspects of an organization.

- ISO 9001: Focuses on establishing, implementing, maintaining, and continually improving a Quality Management System (QMS) to meet customer requirements and enhance customer satisfaction. It centers around product and service quality.

- ISO 14001: Focuses on establishing, implementing, maintaining, and continually improving an Environmental Management System (EMS) to minimize environmental impact. It deals with environmental aspects, legal compliance, and pollution prevention.

Key Differences:

- Scope: ISO 9001 is about product quality, while ISO 14001 is about environmental performance.

- Focus: ISO 9001 emphasizes customer satisfaction and consistent product quality. ISO 14001 prioritizes environmental protection and legal compliance.

- Metrics: ISO 9001 uses metrics related to product defects, customer feedback, and process efficiency. ISO 14001 utilizes metrics like waste reduction, emissions, and energy consumption.

Imagine a manufacturing company: ISO 9001 ensures their products are consistently high-quality, meeting customer expectations. ISO 14001 ensures their production process minimizes environmental damage, adheres to environmental regulations, and reduces waste.

Q 3. What are the core principles of ISO 14001?

The core principles of ISO 14001 are built around a proactive approach to environmental management. These principles guide organizations in building and maintaining effective Environmental Management Systems (EMS).

- Plan: Establish an environmental policy, identify environmental aspects, set environmental objectives, and develop programs to achieve those objectives. This involves a thorough assessment of the environmental impact of all activities.

- Do: Implement the planned EMS, including training personnel, providing resources, and establishing operational controls.

- Check: Monitor and measure environmental performance, evaluate compliance with legal requirements and the organization’s own objectives. Internal audits are a key component of this stage.

- Act: Take corrective actions to address any non-conformances identified during the monitoring and review process. Continuously improve the EMS based on performance data and stakeholder feedback.

- Leadership & Commitment: Top management must actively support and be committed to the EMS’s success.

- Preventative Action: Focus on preventing pollution and minimizing environmental risks before they occur, rather than reacting to problems.

- Continual Improvement: Regularly review and improve the EMS to enhance its effectiveness and environmental performance.

A practical example: A company might plan to reduce water consumption (Plan), implement water-saving technologies (Do), monitor water usage regularly (Check), and adjust practices if consumption remains high (Act). All this under the guidance of committed leadership.

Q 4. How does an organization demonstrate compliance with ISO 27001?

Demonstrating compliance with ISO 27001, the standard for Information Security Management Systems (ISMS), requires a multi-faceted approach.

- Implement an ISMS: Develop and implement a comprehensive ISMS that addresses all the requirements of the standard. This includes establishing an information security policy, conducting risk assessments, developing and implementing security controls, and establishing incident response procedures.

- Documentation: Maintain detailed documentation of all aspects of the ISMS. This includes policies, procedures, risk assessments, and audit findings.

- Internal Audits: Conduct regular internal audits to assess the effectiveness of the ISMS and identify areas for improvement.

- Management Review: Regularly review the ISMS performance to ensure its continued suitability, adequacy, and effectiveness.

- Certification (Optional but recommended): While not mandatory, certification by a third-party auditor provides independent verification of compliance with ISO 27001. This can enhance credibility with customers and stakeholders.

A company demonstrates compliance by showing that they have a robust system in place for managing and mitigating information security risks, backed by solid documentation and a proactive approach to continuous improvement.

Q 5. What are the key elements of a documented management system?

A documented management system comprises all the documented information needed to establish, implement, maintain, and improve a management system (like a QMS, EMS, or ISMS).

- Documented Information: This includes policies, procedures, work instructions, forms, and records that describe how the organization operates and how it achieves its objectives.

- Policy Manual: The top-level document outlining the organization’s overall intentions and direction regarding its management system. This sets the tone for the entire operation.

- Procedures: Step-by-step instructions for performing specific tasks or processes. For example, a procedure for handling customer complaints or conducting internal audits.

- Work Instructions: Detailed instructions for performing individual tasks within a process.

- Records: Evidence of conformity with requirements. Examples include meeting minutes, audit reports, and calibration records.

- Control of Documented Information: A system to ensure documented information is current, accurate, readily available, and protected from unauthorized changes.

Imagine a recipe book: The policy manual is the introduction, procedures are the recipes, work instructions are the detailed steps for each step of the recipe, and records are the notes you take about what worked well and what didn’t. This entire book ensures consistency and repeatability.

Q 6. Explain the concept of internal audits and their importance.

Internal audits are systematic, independent, and documented examinations performed to determine whether a management system conforms to planned arrangements and whether these arrangements are implemented and maintained effectively.

- Purpose: To identify any non-conformances or areas for improvement within the management system before an external audit.

- Process: Internal audits typically involve reviewing documents, interviewing personnel, and observing processes. A formal audit report is issued.

- Importance: Internal audits provide an organization with a proactive way to identify weaknesses and implement corrective actions. They improve the management system, enhance compliance, and reduce the risk of non-conformances during external audits.

- Frequency: The frequency of internal audits depends on the complexity and risk profile of the management system. They could be conducted annually, semi-annually, or even more frequently.

Think of it as a self-checkup for your management system. Regular internal audits help you stay healthy and prevent serious issues from developing.

Q 7. What are the common non-conformances found during ISO audits?

Common non-conformances found during ISO audits vary depending on the standard, but some recurring issues include:

- Lack of documented information or outdated documentation: Procedures that are not up-to-date, missing records, or inadequate descriptions of processes.

- Inadequate training of personnel: Employees not adequately trained on their responsibilities within the management system.

- Ineffective corrective and preventive actions: Failing to properly investigate and address root causes of problems.

- Lack of management review: Insufficient review of the management system’s performance.

- Lack of evidence of continual improvement: The absence of a demonstrable commitment to continuous improvement.

- Insufficient control over processes: Processes not adequately defined, controlled, and monitored.

- Incomplete or ineffective risk assessments: Failure to properly identify and address risks relevant to the management system.

These issues often stem from a lack of proper planning, implementation, or follow-up. Addressing these issues proactively is key to successfully achieving and maintaining ISO certification.

Q 8. Describe your experience with corrective and preventive actions (CAPA).

Corrective and Preventive Actions (CAPA) is a systematic process for identifying, analyzing, and addressing quality issues to prevent recurrence. It’s a crucial element of any effective ISO management system, ensuring continuous improvement and preventing future problems.

In my experience, implementing CAPA involves a structured approach. First, we meticulously document any nonconformity or near miss. This includes a thorough description of the issue, its potential impact, and any immediate actions taken to mitigate the effect. Then, we conduct a root cause analysis, employing tools like the 5 Whys or fishbone diagrams to delve deeper than the surface symptoms. Identifying the root cause is critical; simply addressing the immediate problem without understanding the underlying issue will likely lead to recurrence. Following this, we develop effective corrective actions to address the immediate problem and preventive actions to avoid similar situations in the future. These actions are documented, assigned responsibilities, timelines and verified for effectiveness. Finally, we monitor the effectiveness of the implemented CAPA. This is often done by reviewing data relevant to the issue, conducting audits, or re-evaluating the process affected.

For example, in a previous role, we experienced a recurring issue with a specific component failing during assembly. Through a thorough CAPA process, we discovered the root cause was a faulty supplier providing components outside of the specified tolerances. The corrective action involved sourcing from an alternative supplier, while the preventive action included implementing more stringent incoming inspection procedures and closer monitoring of supplier performance.

Q 9. How do you manage risks and opportunities within an ISO framework?

Risk and opportunity management is vital within any ISO framework. It’s about proactively identifying potential issues that could negatively impact objectives (risks) and potential situations that could lead to positive improvements (opportunities). ISO standards, such as ISO 31000, provide a structured approach to risk management.

My approach typically involves a risk assessment process. This involves identifying risks and opportunities, analyzing their likelihood and impact, and evaluating the existing controls. We use a risk matrix to visualize and prioritize risks, focusing on those with a high likelihood and high impact. For each identified risk, we develop control measures to mitigate potential negative consequences. For opportunities, we determine how to capitalize on them. This often includes incorporating them into our objectives and processes. Regular monitoring and review are crucial to ensure the effectiveness of the implemented controls and to identify any emerging risks or opportunities.

Think of it like sailing a ship. Risks are potential storms, and opportunities are favorable winds. We need to constantly scan the horizon (assess risks), adjust the sails (implement controls), and navigate towards our destination (achieve objectives), proactively adapting to the changing conditions (monitoring and review).

Q 10. What is the role of top management in achieving ISO certification?

Top management plays a pivotal role in achieving ISO certification and maintaining its effectiveness. Their commitment, visible leadership, and active involvement are essential. They must demonstrate a clear understanding of the management system and its importance to the organization’s strategic direction.

Specifically, top management’s responsibilities include establishing the quality policy, ensuring the necessary resources are available, communicating the importance of the management system, promoting a culture of continual improvement, and reviewing the management system’s performance regularly. Their commitment sets the tone for the entire organization, influencing the attitudes and behaviors of all employees. Without top management’s full engagement, the management system is likely to lack the necessary support and resources for successful implementation and maintenance.

Imagine building a house. Top management is like the architect— setting the overall design and vision, securing the necessary funding and materials, and ensuring that the construction team (employees) are well-equipped and motivated to build a strong and stable structure (ISO compliant management system).

Q 11. Explain the concept of continual improvement within ISO standards.

Continual improvement is the foundation of all ISO standards. It’s a mindset and a process of constantly seeking ways to enhance the effectiveness of the management system. It’s not a one-time event; rather, it’s an ongoing journey of improvement.

The Plan-Do-Check-Act (PDCA) cycle is often used to guide the process. We plan improvements based on data analysis, internal audits, and management reviews. We then do implement the planned changes. Next, we check the effectiveness of the changes through monitoring and measurement. Finally, we act by standardizing successful changes and addressing any shortcomings. This iterative cycle ensures that improvements are continuously made and sustained.

For instance, tracking key performance indicators (KPIs) helps identify areas for improvement. If customer satisfaction scores drop, this signals a need for action. By analyzing the root cause and implementing improvements (PDCA cycle), we aim to elevate customer satisfaction back to its desired level and maintain that improvement. Continual improvement is not about fixing isolated problems, but enhancing the entire system’s efficiency and effectiveness.

Q 12. How do you ensure the effectiveness of your management system?

Ensuring the effectiveness of a management system relies on several key factors. Regular monitoring and measurement are paramount. This involves establishing key performance indicators (KPIs) to track the performance of various processes and the overall management system. Internal audits provide an objective assessment of the system’s compliance and effectiveness, identifying areas for improvement. Management reviews, conducted by top management, provide a high-level overview of the system’s performance, allowing for strategic decision-making.

The effectiveness is also linked to the commitment of all employees. Proper training, communication, and engagement are crucial for ensuring that everyone understands their roles and responsibilities within the system. A well-documented system, clear procedures, and readily available resources also contribute significantly to the system’s effectiveness. Finally, proactive risk management and continuous improvement efforts are essential to ensure that the system remains relevant and effective over time. This holistic approach guarantees that the management system serves its intended purpose and helps the organization achieve its objectives.

Think of it as maintaining a car. Regular check-ups (internal audits), oil changes (process improvements), and overall attention to its functioning (management reviews) are all required to ensure smooth and effective performance.

Q 13. Describe your experience with ISO implementation projects.

I have extensive experience in ISO implementation projects across diverse industries. My approach always begins with a thorough gap analysis to determine the current state of the organization’s processes and identify areas that require improvement to align with the chosen ISO standard (e.g., ISO 9001, ISO 14001). This involves document review, interviews with staff, and observations of existing processes.

Next, I develop a customized implementation plan, setting clear objectives, timelines, and responsibilities. This plan typically includes training for employees, the development of new procedures and documentation, and the establishment of a monitoring and measurement system. Throughout the implementation process, I facilitate workshops and meetings to engage employees and build consensus. Internal audits are conducted at various stages to assess progress and identify any issues. Finally, I support the organization in preparing for and successfully completing the certification audit.

In one project, we implemented ISO 9001 in a small manufacturing company. The initial gap analysis revealed inconsistencies in documentation and a lack of formal process descriptions. Through collaborative workshops, we developed clear procedures, trained employees on the new system, and implemented a document control system. The company successfully achieved certification and saw improvements in efficiency and customer satisfaction as a direct result of the implementation.

Q 14. What are the key clauses in ISO 9001:2015?

ISO 9001:2015, the internationally recognized standard for quality management systems, is structured around a series of interconnected clauses. While all are important, some key clauses include:

- Clause 4: Context of the organization: This clause emphasizes understanding the organization’s internal and external context, including its needs and expectations of interested parties.

- Clause 5: Leadership: This highlights the importance of leadership commitment, ensuring that top management actively engages with the quality management system.

- Clause 6: Planning: This section focuses on establishing quality objectives, determining the necessary resources, and establishing processes to achieve the planned results.

- Clause 7: Support: This addresses the resources needed for the quality management system to function effectively, including infrastructure, competence, awareness, and communication.

- Clause 8: Operation: This covers operational planning and control, including aspects like procurement, production, and service provision.

- Clause 9: Performance evaluation: This clause covers monitoring, measurement, analysis, and evaluation of the management system’s performance.

- Clause 10: Improvement: This emphasizes the importance of continual improvement, addressing nonconformities, and implementing corrective and preventive actions.

These clauses are not independent but interconnected, forming a robust framework for establishing, implementing, maintaining, and continually improving a quality management system.

Q 15. What is the significance of context of the organization in ISO standards?

The context of the organization is absolutely crucial in ISO standards implementation. It’s not a one-size-fits-all approach. Think of it like this: a tailor doesn’t make the same suit for everyone; they take measurements and understand the individual’s needs. Similarly, ISO standards require organizations to understand their unique circumstances – their size, the industry they operate in, their resources, their risks, and their goals. This understanding forms the basis for tailoring the management system to their specific needs.

For example, a small startup will have different needs than a multinational corporation. A food processing company will face different challenges than a software development firm. The context includes understanding these differences and adapting the requirements accordingly. Ignoring the context leads to an ineffective and potentially unsustainable management system.

- External Context: This encompasses factors outside the organization that impact its operations, such as market conditions, legal requirements, and stakeholder expectations.

- Internal Context: This includes factors within the organization such as its structure, culture, resources, and capabilities.

A thorough analysis of both internal and external context is the foundation for a successful ISO implementation. This analysis informs the identification of interested parties, risks, and opportunities, making the entire process more relevant and impactful.

Career Expert Tips:

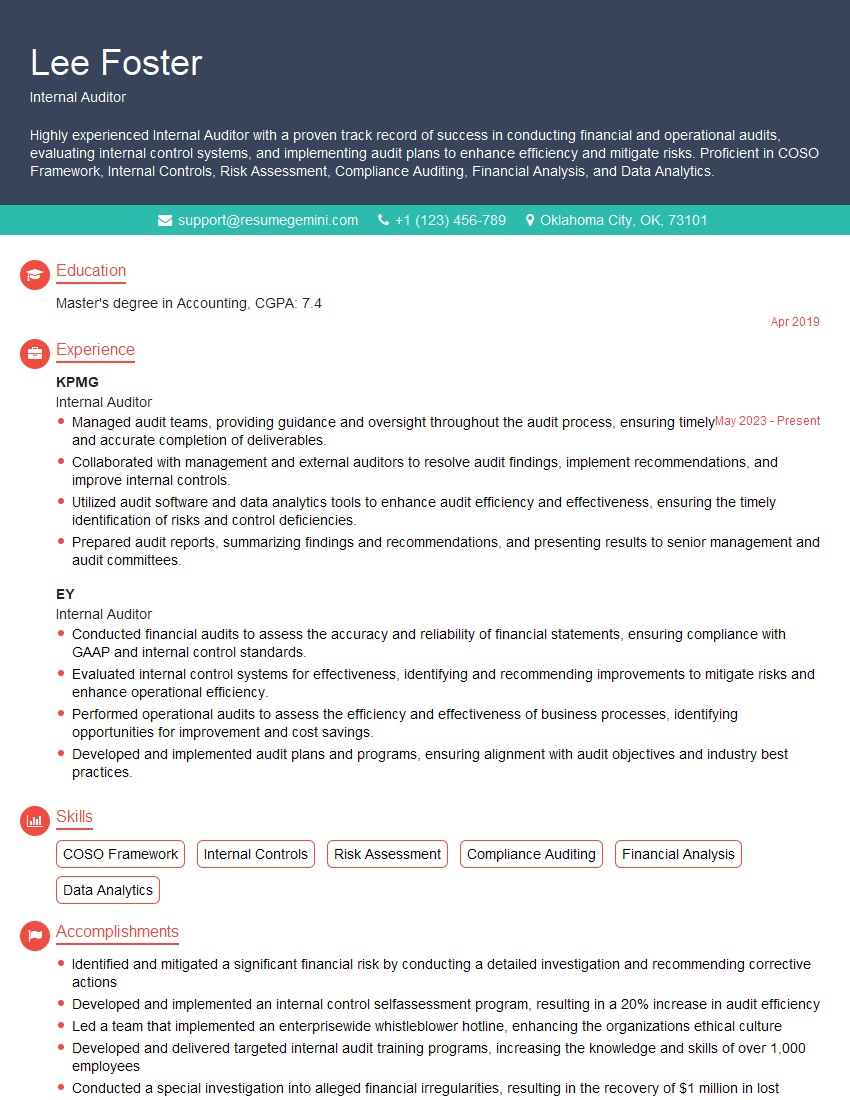

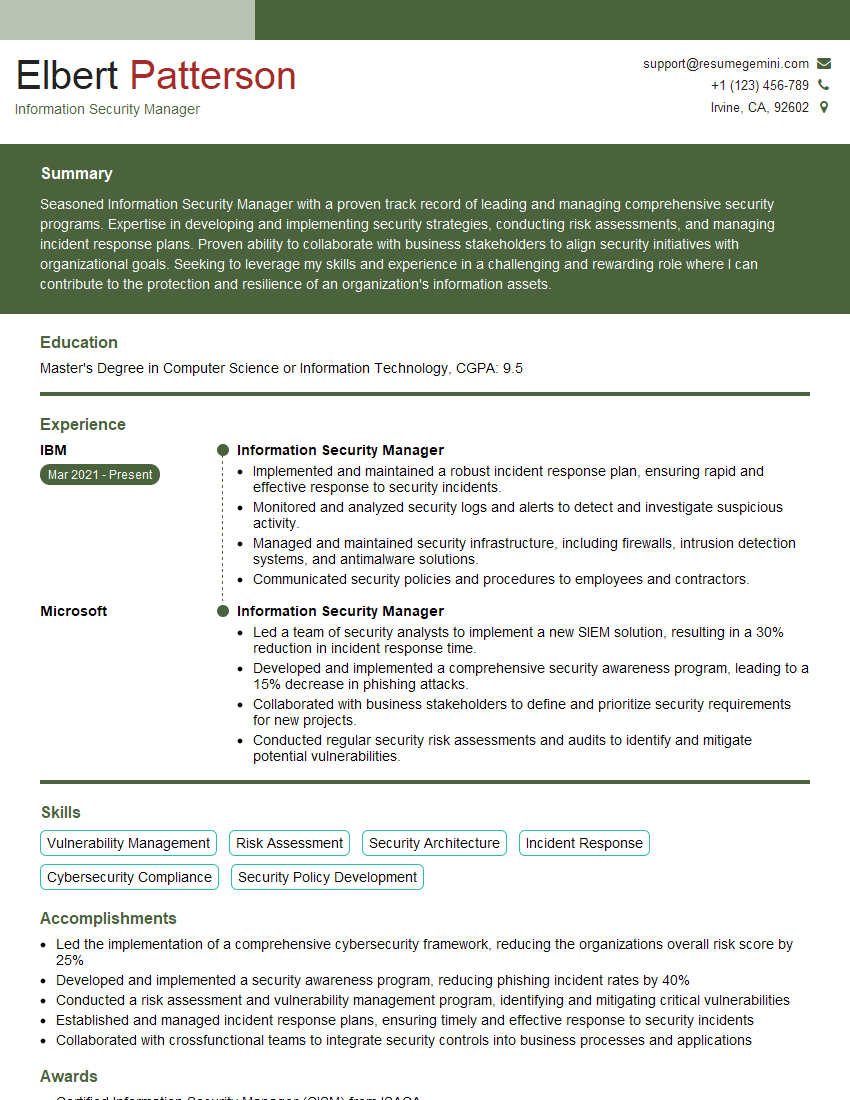

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle conflicting requirements from different ISO standards?

Conflicting requirements between different ISO standards are a common challenge. It’s important to remember that these standards are designed to be complementary, not contradictory. However, conflicts can arise. The best approach is a systematic and documented one.

- Prioritization: Determine which standard is more critical to your organization’s context and objectives. For example, if you’re in the medical device industry, the requirements of ISO 13485 (medical devices) would likely override a less specific standard in terms of conflict resolution.

- Integration: Look for ways to integrate the requirements of both standards. This often means combining processes or creating a system that addresses the needs of both standards efficiently.

- Documentation: Clearly document the conflicting requirements, how they were resolved, and the rationale behind your decision. This is essential for demonstrating compliance and traceability.

- Management Review: Regularly review your management system to ensure that the resolution remains effective and addresses any new conflicts.

For example, if ISO 9001 (quality management) and ISO 14001 (environmental management) both require record-keeping, you might integrate them into a single, comprehensive system rather than having two separate ones. The key is to be transparent and well-documented in your approach.

Q 17. Explain the difference between a documented procedure and a work instruction.

While both documented procedures and work instructions are part of a management system’s documentation, they serve different purposes and have distinct characteristics.

- Documented Procedure: This outlines how a specific process is to be executed. It’s a high-level overview of the steps, responsibilities, and expected outcomes. Think of it as a recipe – it gives you the general steps, but not all the minute details.

- Work Instruction: This provides very detailed, step-by-step guidance for performing a specific task within a process. It’s more prescriptive and leaves little room for interpretation. Think of it as the detailed instruction manual that comes with an appliance – it guides you through each specific step.

For example, a documented procedure might describe the overall process of ‘handling customer complaints’. A work instruction, on the other hand, might detail the specific steps for ‘logging a customer complaint in the CRM system’. The documented procedure sets the general framework, while the work instructions provide the detailed instructions for specific tasks within that framework.

Q 18. What is your understanding of the ‘Plan-Do-Check-Act’ (PDCA) cycle?

The Plan-Do-Check-Act (PDCA) cycle is a cornerstone of continuous improvement. It’s a cyclical process that helps organizations systematically improve their processes and performance. Imagine it as a never-ending loop for refinement.

- Plan: Define objectives, identify necessary resources, and develop a plan for achieving the desired outcome.

- Do: Implement the plan, collect data, and monitor results.

- Check: Evaluate the results against the planned objectives and identify any deviations or areas for improvement.

- Act: Take corrective and preventative actions based on the findings of the check phase, and update processes and documentation accordingly.

For example, if a company wants to reduce customer wait times, they might use PDCA. They’d plan strategies (Plan), implement them (Do), track the wait times (Check), and adjust their approach based on the data (Act). Then, the cycle repeats to further refine the process.

Q 19. Describe your experience with gap analysis for ISO compliance.

Gap analysis is a crucial step in achieving ISO compliance. It involves comparing the organization’s current practices against the requirements of the chosen ISO standard to identify areas where improvements are needed. It’s like comparing a blueprint (the ISO standard) to the existing structure of a building (your organization’s current practices) to see what needs to be built or modified.

My experience involves conducting comprehensive gap analyses using various methods such as document review, interviews with staff at all levels, observation of processes, and internal audits. I then create a documented report detailing the gaps and proposing practical steps for closing them. This often includes prioritizing gaps based on criticality and feasibility. For example, some gaps might require immediate attention (like a critical safety risk), while others can be tackled later (like improving documentation).

The output of the gap analysis usually informs the development of an implementation plan with timelines, responsibilities, and resource allocation. This plan guides the organization through the necessary changes to achieve compliance.

Q 20. How do you maintain the integrity of the management system documentation?

Maintaining the integrity of management system documentation is paramount. This ensures that the system remains accurate, current, and reliable. It’s like maintaining a well-organized and up-to-date library – you wouldn’t want outdated or incorrect information being accessed.

- Version Control: Use a version control system to manage document revisions. This allows traceability and prevents confusion caused by outdated documents. This can involve simple numbering systems or more sophisticated software solutions.

- Access Control: Restrict access to documents based on the roles and responsibilities of individuals. Not everyone needs access to every document.

- Regular Review: Regularly review and update documents to ensure accuracy and relevance. This should be scheduled and documented.

- Document Control Procedure: Establish a clear documented procedure that defines how documents are created, reviewed, approved, distributed, and archived. This procedure should be followed consistently.

- Training: Ensure that all personnel involved are trained on the document control procedure and understand their responsibilities.

By implementing these measures, you ensure that your documentation accurately reflects your management system and supports its continued effectiveness and compliance.

Q 21. Explain the role of stakeholders in ISO compliance.

Stakeholders play a vital role in ISO compliance. They are any individuals or groups who are impacted by or can impact the organization’s management system. It’s important to understand their expectations and concerns, as they are critical to successful implementation and maintenance.

- Identifying Stakeholders: The first step is to identify all relevant stakeholders, including employees, customers, suppliers, regulators, and the local community. This should be documented.

- Communication: Establish effective communication channels to keep stakeholders informed about the implementation and ongoing status of the management system.

- Engagement: Actively engage stakeholders in the process, seeking their input and addressing their concerns. This helps build buy-in and support.

- Addressing Concerns: Address stakeholder concerns promptly and transparently, providing justification for decisions and actions.

For example, customers are stakeholders who expect quality products and services. Suppliers are stakeholders who need clear requirements and communication. Regulators are stakeholders who ensure compliance with legal and regulatory frameworks. Engaging these diverse stakeholders throughout the process is critical for successful ISO implementation and demonstrating ongoing compliance.

Q 22. How do you ensure effective communication during an ISO implementation?

Effective communication is the backbone of any successful ISO implementation. Think of it as the lifeblood – without it, the entire system falters. It’s not just about informing people; it’s about engaging them, fostering buy-in, and ensuring everyone understands their role and responsibilities.

- Establish Clear Communication Channels: We utilize various methods, including regular meetings, email updates, intranet portals, and even dedicated communication champions within each team to ensure information reaches everyone efficiently. For instance, a weekly newsletter highlighting key updates on the ISO project proved highly effective in one implementation.

- Targeted Communication Strategies: We tailor our communication to the audience. Management receives high-level strategic updates, while employees on the shop floor receive more practical, task-oriented information. Using simple language and avoiding jargon is key.

- Feedback Mechanisms: We actively solicit feedback through surveys, suggestion boxes, and informal discussions to gauge understanding and address any concerns proactively. This two-way communication is crucial for identifying and resolving issues early.

- Training and Education: Comprehensive training is essential. We provide training sessions specifically designed to educate employees about the ISO standard’s requirements and how their roles contribute to overall compliance. Interactive sessions with practical exercises ensure knowledge retention.

By implementing these strategies, we create a culture of open communication, ensuring everyone is informed, involved, and committed to the ISO implementation process.

Q 23. What are some common challenges in ISO implementation and how do you address them?

Implementing ISO standards presents several challenges. Resistance to change is a common hurdle, as is the initial time and resource investment required. Lack of top management commitment can also derail the process.

- Resistance to Change: We address this by involving employees early in the process, actively listening to their concerns, and highlighting the benefits of ISO certification – such as improved efficiency and reduced risks. We also celebrate early successes to build momentum and demonstrate tangible value.

- Resource Constraints: Careful planning and prioritization are critical. We define clear objectives, allocate resources strategically, and track progress against a defined timeline. Outsourcing specific tasks, where cost-effective, can also help manage resources effectively.

- Lack of Management Commitment: Without buy-in from the top, the implementation stalls. We demonstrate the strategic value of ISO certification, highlighting its positive impact on the business’s reputation, competitiveness, and profitability. Securing management sponsorship and clear responsibility assignment are crucial.

- Maintaining Momentum: Implementation can be lengthy, so sustaining motivation is vital. Regular progress reviews, celebrating milestones, and acknowledging individual contributions help keep the team engaged and focused.

Overcoming these challenges requires proactive planning, effective communication, and a strong commitment from all stakeholders. Treating ISO implementation as a continuous improvement journey, rather than a one-time project, helps foster a sustainable approach.

Q 24. How familiar are you with ISO 45001 (Occupational Health and Safety)?

I’m very familiar with ISO 45001, the international standard for occupational health and safety management systems (OHSMS). I understand its requirements thoroughly, including its focus on risk assessment, hazard control, legal compliance, and the active participation of workers in the OHSMS. I’ve been involved in several successful implementations and audits of this standard.

My experience includes assisting organizations in developing and implementing their OHSMS, conducting internal audits to ensure conformity, and preparing for and supporting external certification audits. I’m also well-versed in the various clauses of ISO 45001, understanding the interconnectedness of different elements and how they contribute to a safe and healthy workplace.

I’ve worked with organizations across various sectors, from manufacturing to healthcare, adapting the OHSMS implementation strategy to their specific needs and risk profiles. For example, I helped a manufacturing company implement robust procedures for managing hazardous substances, drastically reducing workplace accidents.

Q 25. Describe your experience with conducting management reviews.

Management reviews are critical for evaluating the effectiveness of the management system and ensuring continuous improvement. They aren’t just routine meetings; they’re strategic sessions designed to assess performance, identify areas for improvement, and make necessary changes.

My experience includes facilitating management reviews for various organizations. I prepare comprehensive reports that analyze key performance indicators (KPIs), nonconformities, audit findings, and customer feedback. The reviews are structured, covering all aspects of the management system, from strategic alignment to operational effectiveness. We use a data-driven approach, relying on objective evidence to inform decisions.

For instance, in one management review, we identified a significant increase in customer complaints related to a specific product. This led to a thorough investigation, resulting in improved production processes and a reduction in complaints. The review also allowed us to proactively address potential risks and ensure the system’s ongoing effectiveness.

I ensure that management reviews are both thorough and efficient, focusing on meaningful discussions and actionable outcomes. They’re not just about identifying problems; they’re about implementing solutions and driving continuous improvement.

Q 26. How do you ensure the objectivity and impartiality of internal audits?

Objectivity and impartiality are crucial during internal audits to ensure that the audit process is credible and the findings are reliable. To maintain objectivity and impartiality, I employ several key strategies.

- Auditor Selection: Auditors are selected based on their competence, experience, and independence from the areas they are auditing. We avoid assigning auditors who have a direct interest or involvement in the processes they are reviewing. For example, an auditor responsible for a specific process would not be assigned to audit that process.

- Audit Planning: A well-defined audit plan helps maintain objectivity. The plan should outline the scope, objectives, and methodology of the audit, ensuring consistency and fairness.

- Documented Evidence: All findings are based on documented evidence. This evidence serves as an objective basis for evaluating compliance and identifying areas for improvement.

- Training: Auditors receive thorough training on auditing principles and techniques, including how to avoid bias and ensure impartiality. They are also trained to properly document their findings and follow established audit procedures.

- Verification of Findings: Where possible, a second auditor may verify critical findings to ensure the accuracy and objectivity of the assessment. This also reduces the potential for errors or biases.

By adhering to these principles, we ensure that our internal audits are unbiased, credible, and contribute to the continuous improvement of our management system. This approach strengthens the organization’s confidence in its system and facilitates more effective corrective actions.

Q 27. What metrics do you use to track the performance of a management system?

Tracking the performance of a management system requires a well-defined set of metrics. The specific metrics will depend on the context and the management system in question (e.g., ISO 9001, ISO 14001, ISO 45001). However, some common and widely applicable metrics include:

- Number and type of nonconformities: This helps track the effectiveness of the system in preventing and detecting nonconformities. A trend analysis can reveal areas needing improvement.

- Effectiveness of corrective and preventive actions: This monitors how well the system addresses identified problems and prevents recurrence.

- Customer satisfaction: For many organizations, customer feedback is a crucial indicator of the effectiveness of their management system.

- Employee engagement and satisfaction: Engaged employees contribute to a more effective management system. This metric might involve employee surveys or feedback mechanisms.

- Process efficiency and effectiveness: This could include metrics like cycle times, defect rates, and resource utilization.

- Environmental performance (if applicable): This might include energy consumption, waste generation, and emissions.

- Occupational health and safety performance (if applicable): This might include incident rates, lost-time injuries, and near misses.

These metrics should be regularly monitored and reviewed, and data should be analyzed to identify trends and areas for improvement. The selection of appropriate metrics is crucial in order to accurately assess the effectiveness of the management system.

Q 28. How do you ensure ongoing compliance after achieving ISO certification?

Achieving ISO certification is not the end goal; it’s the beginning of a continuous improvement journey. Maintaining compliance requires ongoing effort and a commitment to the management system.

- Internal Audits: Regular internal audits are essential for identifying areas of nonconformity and ensuring ongoing compliance with the standard’s requirements. These audits should be conducted according to a defined schedule and should be thorough and objective.

- Management Reviews: Regular management reviews help assess the effectiveness of the management system and identify areas for improvement. These reviews should involve top management and should be data-driven.

- Corrective and Preventive Actions: An effective system for managing corrective and preventive actions (CAPA) is vital for addressing identified nonconformities and preventing their recurrence.

- Training and Awareness: Ongoing training and awareness programs are needed to keep employees up-to-date on the standard’s requirements and their roles and responsibilities within the management system. This helps maintain a culture of continuous improvement.

- Documentation Control: Maintaining up-to-date and accurate documentation is critical for demonstrating compliance. Document control procedures must be effective and regularly reviewed.

- Surveillance Audits: Certification bodies conduct surveillance audits to verify that the organization continues to meet the requirements of the standard after initial certification. These are planned, scheduled audits.

By focusing on these key areas, organizations can ensure their management system remains effective and that they maintain their ISO certification. It’s crucial to view compliance as a dynamic process rather than a static state.

Key Topics to Learn for ISO Standards Knowledge Interview

- ISO 9001:2015 (Quality Management Systems): Understanding the core principles, requirements, and implementation strategies. Focus on practical application in various industries and the benefits of certification.

- ISO 14001:2015 (Environmental Management Systems): Learn about environmental impact assessment, compliance, and continuous improvement methodologies. Explore real-world examples of successful EMS implementation and the associated benefits.

- ISO 45001:2018 (Occupational Health and Safety Management Systems): Master the key requirements and practical application of this standard, including risk assessment, hazard control, and incident investigation. Understand its role in creating a safe and healthy workplace.

- Internal Audits & Management Reviews: Develop a strong understanding of conducting effective internal audits and participating in management reviews. This includes understanding nonconformances, corrective actions, and preventive actions.

- Documentation & Record Keeping: Learn the importance of maintaining accurate and comprehensive documentation within an ISO-compliant system. Understand how proper record keeping supports continuous improvement and demonstrates compliance.

- Understanding of the PDCA Cycle (Plan-Do-Check-Act): This is a fundamental framework used in many ISO standards. Be prepared to discuss its application in various contexts and its role in driving continuous improvement.

- Gap Analysis & Implementation Strategies: Understand how to assess the current state of an organization’s management system against ISO requirements and develop effective implementation strategies to bridge the gap.

Next Steps

Mastering ISO Standards Knowledge is crucial for career advancement in numerous fields, opening doors to exciting opportunities and higher earning potential. A strong understanding of these standards demonstrates your commitment to quality, efficiency, and ethical practices. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. Examples of resumes tailored to ISO Standards Knowledge are available to help guide you through the process. Invest in your future – build a winning resume today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO