Preparation is the key to success in any interview. In this post, we’ll explore crucial Sanding Equipment Maintenance and Operation interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Sanding Equipment Maintenance and Operation Interview

Q 1. Explain the different types of sanding equipment and their applications.

Sanding equipment comes in various types, each suited for different applications. The choice depends on the material being sanded, the desired finish, and the scale of the project.

- Belt Sanders: These are powerful tools ideal for heavy-duty sanding of large, flat surfaces like wood flooring or countertops. Their wide belts cover significant areas quickly. Think of them as the ‘bulldozers’ of the sanding world.

- Disc Sanders: These use a rotating disc abrasive to sand curved or irregular surfaces. They are versatile and useful for shaping wood, metal, or even removing rust. They’re excellent for detail work where a belt sander would be too cumbersome.

- Orbital Sanders (Random Orbital Sanders): These are less aggressive than belt or disc sanders. Their random orbital motion creates a smoother, less scratch-prone finish, perfect for fine sanding and final polishing. Imagine them as the ‘finishing touch’ artists of sanding.

- Spindle Sanders: These utilize a small rotating spindle with different attachments for various tasks. They excel in intricate detailing and sanding hard-to-reach areas. They’re like the ‘detailers’ focusing on the smaller, more precise areas.

- Sheet Sanders: These use sheets of sandpaper attached to a backing pad, offering a level of control similar to hand sanding, but with the assistance of a powered machine. They are handy for smaller projects and areas that require more precise sanding.

For instance, I once used a belt sander to quickly level a warped wooden tabletop before switching to a random orbital sander for a smooth, even finish. The spindle sander came in handy for detailing the edges.

Q 2. Describe the process of maintaining sanding belts and discs.

Maintaining sanding belts and discs is crucial for both performance and safety. Neglecting maintenance leads to uneven sanding, premature wear, and potential accidents.

- Regular Inspection: Regularly check for tears, cracks, or excessive wear on belts and discs. Replace damaged components immediately.

- Cleaning: After each use, clean the belts and discs with a brush to remove accumulated dust and debris. This prevents clogging and ensures even sanding.

- Proper Storage: Store belts and discs in a dry, clean environment to prevent rust and damage.

- Tension Adjustment (Belts): Ensure the belt is properly tensioned. Too loose, and it will slip and produce uneven sanding. Too tight, and it will put unnecessary stress on the equipment and reduce lifespan.

- Disc Alignment (Discs): Make sure the disc is correctly aligned to avoid vibrations and uneven wear.

I always start my workday by visually inspecting the sanding belts and discs before any use. A quick brush-down after each use is essential, and I keep a detailed record of their use to estimate their remaining life and replace them before they become too worn.

Q 3. How do you identify and troubleshoot common problems with sanding equipment?

Troubleshooting sanding equipment involves a systematic approach. Start by identifying the problem, then work through possible causes.

- Lack of Power/No Start: Check the power cord, outlet, and motor. A blown fuse or tripped circuit breaker is common.

- Uneven Sanding: Examine the sanding belt or disc for wear, tears, or improper alignment. Check the tension of the belt. The problem might also be in the machine’s components.

- Excessive Vibration: Check for loose parts, worn bearings, or an unbalanced sanding disc.

- Overheating: Overuse or a clogged dust collection system can lead to overheating. Always allow for cooling breaks and ensure proper ventilation.

- Unusual Noises: Grinding, squealing, or humming sounds indicate potential problems with bearings, belts, or the motor. These require professional attention.

For instance, when a belt sander started vibrating excessively, I checked the belt tension and alignment first. Finding everything to be correct, I carefully checked the machine’s bearings, replacing a worn one that solved the issue.

Q 4. What safety precautions are essential when operating sanding equipment?

Safety is paramount when using sanding equipment. Sanding generates dust and moving parts pose risks of injury.

- Eye Protection: Always wear safety glasses or a face shield to protect your eyes from flying debris.

- Respiratory Protection: Use a dust mask or respirator to avoid inhaling sanding dust, especially with materials containing harmful substances.

- Hearing Protection: Sanding equipment can be loud, so hearing protection is necessary to prevent hearing damage.

- Gloves: Wear work gloves to protect your hands from cuts and splinters.

- Proper Clothing: Wear close-fitting clothing to prevent snagging on moving parts. Avoid loose sleeves or jewelry.

- Machine Guards: Always ensure all safety guards are in place and functioning correctly. Never operate a machine with missing or damaged guards.

- Grounding: Ensure the equipment is properly grounded to prevent electric shocks.

A colleague once suffered a minor eye injury from a flying wood chip. This incident reinforced the importance of always wearing safety glasses, a lesson I never forgot.

Q 5. Explain the importance of proper dust collection systems in sanding operations.

Effective dust collection is essential for health, safety, and maintaining equipment performance. Sanding produces fine particles that can be harmful if inhaled and also clog equipment.

- Health Hazards: Many sanding materials release dust that can cause respiratory problems, allergies, and even cancer.

- Equipment Maintenance: Dust buildup can clog sanding equipment, reducing its efficiency and lifespan. Regular cleaning becomes more frequent without a good dust collection system.

- Work Environment: A dusty work environment is not only unhealthy but also unsafe. It reduces visibility, creates a slip hazard (depending on the material), and can lead to accidents.

A well-maintained dust collection system, coupled with regular filter changes, is an investment in both worker health and equipment longevity. In my experience, a significant improvement in the quality of both work life and work product resulted from improving our dust collection system.

Q 6. How do you determine the appropriate grit size for a specific sanding task?

Choosing the right grit size is crucial for achieving the desired finish. Grit size refers to the coarseness of the abrasive; lower numbers indicate coarser grits.

- Coarse Grit (e.g., 24-60): Used for initial shaping, removing material quickly, and leveling uneven surfaces.

- Medium Grit (e.g., 80-120): Used for smoothing after initial shaping, removing scratches left by coarser grits.

- Fine Grit (e.g., 150-220): Used for refining the surface, achieving a smoother finish.

- Extra Fine Grit (e.g., 240+): Used for polishing, achieving a very smooth, almost glass-like surface.

Consider the material and the desired finish. For instance, removing deep scratches on a wooden surface requires coarser grits initially, followed by progressively finer grits for a smooth finish. Using too fine a grit at the start would be inefficient, while ending on a coarse grit would leave a rough surface.

Q 7. Describe your experience with different types of abrasives.

Abrasives are the heart of sanding. Different abrasives offer varying cutting performance, durability, and suitability for different materials.

- Aluminum Oxide: A common and versatile abrasive, suitable for most materials, including wood, metal, and plastics. It offers a good balance of cutting speed and longevity.

- Silicon Carbide: Known for its sharp cutting action, this abrasive is particularly well-suited for sanding hard materials like stone, ceramic, and glass.

- Ceramic Aluminum Oxide: A more recent development, this abrasive provides a longer lifespan and more aggressive cutting than standard aluminum oxide. Often used in high-performance applications.

- Cloth Backed Abrasives: Useful for sanding curved surfaces and contoured areas due to their flexibility. Generally used with finer grits for finishing.

I’ve worked extensively with all these types of abrasives. The choice depends on the job; for instance, while aluminum oxide is my go-to for most wood sanding projects, I rely on silicon carbide for sharpening ceramic tools.

Q 8. What are the signs of worn-out sanding belts or discs?

Worn-out sanding belts and discs show several telltale signs. Think of it like the tread on a tire; eventually, it wears down and loses effectiveness. The most obvious sign is a significant reduction in the abrasive material. You’ll notice the belt or disc becoming thinner, with exposed backing material. This reduces the effectiveness of the sanding process and can cause uneven results. Another sign is glazing or loading – the abrasive surface becomes clogged with material, making it dull and ineffective. You might see a shiny, almost glass-like appearance on the surface instead of the expected rough texture. Cracking or fraying on belts are also major red flags, indicating a weakened structure that’s prone to breakage and potential injury. Finally, inconsistent sanding performance—such as uneven finish or increased pressure required—indicates wear and tear, even if the physical signs aren’t yet as prominent.

- Reduced Abrasive Material: Thinning of the belt or disc, exposing backing.

- Glazing/Loading: Shiny, clogged surface losing its abrasive qualities.

- Cracking/Fraying (belts): Structural weakness leading to potential breakage.

- Inconsistent Performance: Uneven finishes or increased pressure needed.

Q 9. How do you perform preventative maintenance on sanding equipment?

Preventative maintenance is key to extending the lifespan of your sanding equipment and ensuring consistent performance. It’s like regular servicing for your car—far better than dealing with a breakdown. My routine includes regular cleaning; removing dust and debris after each use prevents clogging and premature wear. I also inspect belts and discs for wear and replace them proactively before they cause problems. Proper storage is crucial, particularly for belts, to prevent damage from moisture or impact. Lubrication of moving parts, according to the manufacturer’s instructions, ensures smooth operation and prevents friction wear. Checking for loose screws, belts, and other components prevents vibration damage. Finally, regular checks of the motor and power supply are crucial for safety. I even keep a detailed maintenance log to track all the inspections and replacements. That way, I can spot any patterns that might indicate issues before they become major problems.

Q 10. How do you handle a malfunctioning sanding machine?

If a sanding machine malfunctions, the first step is safety. Turn it off immediately and unplug it to prevent injury. Never attempt repairs while the machine is powered on. Once it’s safe, I systematically assess the problem. If it’s a simple issue like a jammed belt or clogged dust port, I’ll address that. However, if the problem seems more complex, such as unusual noises, overheating, or a failure to start, I avoid tinkering myself. Instead, I consult the machine’s manual and then contact the manufacturer or a qualified technician. Improper repairs can lead to further damage or even create a safety hazard. My priority is always safety and a proper repair. Downtime is costly, but safety and avoiding potential accidents are paramount.

Q 11. Explain the process of replacing sanding belts or discs.

Replacing sanding belts and discs is a straightforward but crucial process. Always ensure the machine is unplugged and turned off. For belts, I typically loosen the tensioning mechanism, remove the old belt, and carefully install the new one, ensuring it’s correctly aligned and snug. For discs, the process usually involves releasing a clamping mechanism, removing the old disc, and securely mounting the new one, paying close attention to any specific alignment instructions. It’s important to choose the correct grit and type of abrasive for the job. Always refer to the manufacturer’s instructions, as methods vary slightly depending on the specific machine model. A wrongly installed belt or disc can lead to uneven sanding, damage to the machine, or even accidents. After installation, I perform a test run at a low speed to ensure everything is correctly positioned and functions smoothly.

Q 12. What are the key performance indicators (KPIs) for sanding operations?

Key Performance Indicators (KPIs) for sanding operations focus on efficiency, quality, and safety. We track factors such as the rate of material removal (how quickly the work is completed), the consistency of the surface finish (measured by surface roughness or visual inspection), the number of defects (scratches, imperfections, etc.), and the downtime due to maintenance or repairs. Safety KPIs involve tracking near misses and accidents to identify potential hazards and implement improvements. We also monitor material usage and waste to minimize costs. By tracking these KPIs, we can identify areas for improvement and optimize the sanding process for better efficiency, higher-quality results, and a safer work environment. I find using data-driven approaches helps improve our overall performance.

Q 13. How do you ensure the quality and consistency of sanding results?

Ensuring consistent sanding quality involves several interconnected factors. First, maintaining the equipment is vital. Regular maintenance ensures the machine runs smoothly and the abrasive is sharp. Using the appropriate grit for the material and desired finish is crucial. Too coarse a grit leads to excessive material removal and potential damage, while too fine a grit results in slow progress. Consistent pressure and speed throughout the sanding process are also essential. Think of it like painting – if your pressure varies, the final coat won’t be even. Finally, paying close attention to the condition of the work surface, making sure it’s properly prepared and supported, helps prevent unevenness. Proper training of operators is also essential for achieving consistent results. Combining careful technique, well-maintained tools, and a clear understanding of the process produces consistently excellent work.

Q 14. Describe your experience with different types of sanding machines (e.g., belt sanders, orbital sanders).

I’ve extensive experience with various sanding machines. Belt sanders are excellent for removing large amounts of material quickly, perfect for shaping wood or metal. Their power and efficiency are unmatched for heavy-duty tasks but require careful handling to avoid gouging. Orbital sanders provide a finer finish and are less likely to create uneven surfaces. They’re great for smoothing surfaces and preparing for painting. I’ve also used smaller, more specialized sanders, such as palm sanders for detailed work, and random orbital sanders that blend speed and fine finish. Each machine has its strengths and weaknesses; selecting the right one for the task at hand is critical. My experience spans various applications, from furniture finishing to metal fabrication, and I’m familiar with a wide range of abrasive types and grits, ensuring I select the optimal equipment and approach for any project.

Q 15. How do you calibrate and maintain sanding equipment for precision work?

Calibrating and maintaining sanding equipment for precision work is crucial for achieving consistent surface finishes. It involves a multi-step process focusing on both the machine and the abrasive. For example, with belt sanders, ensuring the belt is properly tracked and tensioned is paramount. Incorrect tracking leads to uneven sanding, while insufficient tension causes slippage and poor results. Regularly checking and adjusting the tracking mechanism, often using adjustment screws, is essential. Tension is usually managed by adjusting a lever or knob; the manufacturer’s manual provides precise instructions.

Maintaining the abrasive itself is equally important. For precision work, using fine-grit abrasives and regularly changing them prevents clogging and scratching. Clogged abrasives lead to uneven sanding and potentially damage the workpiece. The frequency of abrasive changes depends on the material being sanded and the desired finish, but it’s always better to err on the side of caution and replace them more frequently than necessary for optimal results. Furthermore, regular cleaning of the sander’s dust collection system is vital to maintain its efficiency and prevent overheating.

Precision also demands regular inspection of the sanding platen (for random orbital sanders) or drum (for drum sanders) for wear and tear. Scratches or damage to these components can transfer to the workpiece. Consider replacing them if significant wear is detected. Finally, always reference the manufacturer’s recommended maintenance schedule for detailed instructions tailored to your specific model of sanding equipment.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the common causes of sanding defects and how do you prevent them?

Sanding defects can stem from various causes, including improper abrasive selection, incorrect sanding technique, machine malfunction, and insufficient dust collection. For instance, using too coarse of a grit at the beginning of a project can leave deep scratches that are difficult to remove later. Conversely, starting with too fine a grit will result in excessive sanding time and possible material removal issues. Another common problem is uneven pressure application, leading to variations in surface finish. Consistent, light pressure is usually best.

Machine malfunction is another major factor. A misaligned belt sander or a worn-out sanding pad on a random orbital sander will create uneven surfaces. Regular maintenance, as previously discussed, mitigates these issues. Finally, inadequate dust collection causes the abrasive to clog, leading to scratching and an inconsistent finish. Using proper dust collection systems and regularly cleaning them is critical. Preventing defects requires careful planning, which includes selecting the appropriate grit, maintaining the equipment, and employing the correct sanding technique for the specific material being worked on.

Think of it like baking a cake: If you don’t use the right ingredients (abrasive) or follow the recipe (sanding technique), you won’t get the desired result. Careful attention to all aspects of the process – from equipment maintenance to the final sanding technique – ensures high-quality results.

Q 17. How do you maintain a clean and organized work area while operating sanding equipment?

Maintaining a clean and organized work area is essential for both efficiency and safety when operating sanding equipment. A cluttered workspace increases the risk of accidents, such as tripping over tools or cords. It also hinders smooth workflow. Before starting any sanding operation, clear the immediate work area of unnecessary items. This includes tools, materials, and anything that could interfere with the equipment or create a safety hazard.

Proper dust collection is a critical part of maintaining a clean workspace. Sanding generates significant amounts of fine dust, which can be harmful to both health and the environment. Ensure that your equipment is properly equipped with dust collection systems and that these systems are functioning correctly. Regularly empty and clean the dust collection bags or containers. In addition to dust collection, use appropriate personal protective equipment (PPE) such as respirators and safety glasses.

After completing the sanding operation, clean the work area thoroughly, removing all sanding dust and debris. Store tools and materials properly, keeping the workspace organized and ready for the next task. This systematic approach minimizes cleaning time and prevents accidents. Organizing and maintaining a clean work area is an investment in efficiency and safety.

Q 18. Describe your experience working with different materials (wood, metal, plastic, etc.) using sanding equipment.

My experience encompasses sanding various materials, each requiring a tailored approach. With wood, the selection of grit and sanding technique are crucial to achieving the desired finish, from smooth to textured. For example, coarse grits are used for initial shaping and removing imperfections, followed by progressively finer grits for achieving a smooth surface. Different wood types (hardwoods vs. softwoods) also require adjustments in technique and abrasive selection. Hardwoods, such as oak, require more attention and finer grits to prevent tear-out. Softwoods are generally easier to sand.

Sanding metal requires different abrasives and techniques compared to wood. Often, metal sanding involves removing rust, paint, or other coatings before achieving a smooth surface. Appropriate safety precautions, such as eye protection, are paramount due to the potential for sparks and flying debris. Abrasive selection depends on the specific metal and its hardness. Plastics are another material that demands careful consideration. Using excessive pressure can cause melting or deformation. Selecting appropriate grits and minimizing pressure are essential to avoid damage.

In each case, understanding the material’s properties is key to selecting the right abrasive, speed, and pressure. I’ve consistently adapted my approach to ensure the optimal result for different materials, always prioritizing safety and precision.

Q 19. What are the environmental considerations related to sanding operations (e.g., dust, noise)?

Sanding operations present significant environmental considerations, primarily dust and noise pollution. Fine dust particles generated during sanding can be inhaled, causing respiratory problems. This necessitates the use of effective dust collection systems, often incorporating HEPA filters to capture even the finest particles. Regular maintenance of these systems is crucial to ensure their effectiveness. Moreover, proper ventilation is essential to prevent dust accumulation in the work area.

Noise pollution is another significant concern. Sanding equipment can generate high noise levels, potentially causing hearing damage if prolonged exposure occurs. Using hearing protection, such as earplugs or earmuffs, is mandatory. In addition, choosing quieter sanding equipment when possible is an important consideration. Minimizing noise and dust pollution through careful planning and the use of appropriate equipment and safety measures is vital for both worker health and environmental responsibility.

Q 20. How do you ensure compliance with safety regulations related to sanding equipment?

Ensuring compliance with safety regulations is a top priority in my work. This starts with understanding and adhering to all relevant OSHA (or equivalent local regulations) standards related to sanding equipment. This includes regular inspection of the equipment for any damage or malfunction, ensuring all safety guards are in place and functioning correctly. Proper personal protective equipment (PPE) is always used, including respirators to prevent dust inhalation, safety glasses to protect the eyes from flying debris, and hearing protection to reduce noise exposure.

Furthermore, proper training and understanding of the equipment’s operational procedures are vital. This involves understanding how to safely start and stop the equipment, avoiding unsafe practices, and knowing what to do in case of emergencies. Regular maintenance, documented appropriately, helps ensure the continued safety of both the equipment and the operator. Compliance with safety regulations isn’t just about following rules; it’s a commitment to a safe and productive work environment.

Q 21. What is your experience with troubleshooting pneumatic and electric sanding equipment?

I possess significant experience troubleshooting both pneumatic and electric sanding equipment. With pneumatic sanders, common issues include air leaks, low air pressure, and hose blockages. Air leaks can often be identified by listening for hissing sounds or using soapy water to detect escaping air. Low air pressure can be addressed by checking the air compressor and its pressure settings. Hose blockages may require cleaning or replacement of the hose. With electric sanders, problems frequently arise from worn-out brushes, faulty switches, and power cord issues.

Troubleshooting often begins with a visual inspection of the equipment for any obvious problems, followed by systematic checks of the power supply and other components. Using multimeters and other diagnostic tools helps pinpoint the exact source of the problem. For instance, a multimeter can be used to test the continuity of the power cord and the voltage supplied to the motor. Knowledge of electrical circuits is essential for safe and effective troubleshooting of electric equipment. My approach to troubleshooting is methodical, starting with the simplest solutions and progressively moving toward more complex repairs.

Experience has taught me the importance of patience, careful diagnosis, and systematic troubleshooting. This approach allows for efficient repair, minimizes downtime, and ultimately ensures the safe and effective operation of sanding equipment.

Q 22. Describe your experience with computerized numerical control (CNC) sanding machines.

My experience with CNC sanding machines spans several years, encompassing both operation and maintenance. I’ve worked extensively with machines from leading manufacturers, including [mention specific brands if comfortable, otherwise omit], utilizing their programming interfaces to create complex sanding profiles for various materials. This includes generating G-code, setting up tool paths, and optimizing cutting parameters for different applications. For example, I once worked on a project where we needed to create a precisely contoured surface on a large batch of automotive parts. Using a CNC sander, I programmed the machine to achieve the desired surface finish within tight tolerances, significantly improving efficiency compared to manual methods. I am proficient in troubleshooting CNC-specific issues such as axis misalignment, tool wear detection and compensation, and interpreting error codes generated by the machine’s control system. I also understand the importance of regular preventative maintenance to ensure optimal performance and longevity of these sophisticated machines.

Q 23. How do you diagnose and repair mechanical and electrical problems in sanding equipment?

Diagnosing and repairing mechanical and electrical problems in sanding equipment requires a systematic approach. I begin by carefully observing the malfunctioning equipment. Is there a noise, vibration, or unusual smell? Are there any visible signs of damage or wear? Then, I consult the machine’s technical manual and schematics to identify the components involved in the process. For mechanical issues, this might involve inspecting belts, bearings, motors, and sanding drums for wear, misalignment, or damage. For example, a noisy bearing might indicate the need for lubrication or replacement. For electrical issues, I use multimeters to check voltage, current, and continuity in circuits, identifying faulty wiring, switches, or motor controllers. A systematic testing process is essential to pinpoint the root cause. Once the problem is identified, the repair process is undertaken. This may involve replacing faulty components, repairing wiring, or adjusting mechanical settings. After the repair, thorough testing is performed to verify the machine’s functionality and safety before returning it to service.

Q 24. What is your experience with different types of sanding processes (e.g., hand sanding, machine sanding)?

My experience encompasses a wide range of sanding processes, from basic hand sanding to the operation of sophisticated automated systems. Hand sanding, while seemingly simple, requires skill and precision to achieve a consistent finish. I’m experienced with various hand sanding techniques for different materials and desired finishes, using different grits of sandpaper appropriately. Machine sanding offers greater efficiency and precision for high-volume or complex applications. I’m familiar with belt sanders, disc sanders, orbital sanders, and automated CNC sanders, each suited to different tasks. For example, belt sanders are ideal for removing large amounts of material, while orbital sanders are better for finer finishing. Selecting the right machine and process for a given job is crucial to achieve optimal results, minimizing material waste and maximizing productivity. My experience allows me to assess the requirements of a particular task and recommend the most appropriate sanding method and equipment.

Q 25. How do you interpret technical manuals and schematics for sanding equipment?

Interpreting technical manuals and schematics is fundamental to effective sanding equipment maintenance. I approach this task systematically. First, I familiarize myself with the overall system layout, identifying major components and their interconnections. Schematics provide a visual representation of the electrical circuits and hydraulic systems, allowing me to trace signals and identify potential points of failure. The technical manual provides detailed information on components, troubleshooting procedures, safety precautions, and maintenance schedules. For example, a schematic might show the wiring diagram for a motor control circuit, while the manual describes the specific torque and amperage specifications for the motor. I use these documents to diagnose problems, plan repairs, and perform preventative maintenance. My ability to quickly and accurately interpret these documents is critical to efficient and effective problem-solving.

Q 26. Explain the importance of regular lubrication and maintenance of sanding equipment.

Regular lubrication and maintenance are crucial for the longevity and efficiency of sanding equipment. Lubrication reduces friction, minimizing wear and tear on moving parts such as bearings, gears, and shafts, and extending their lifespan. This prevents premature failure and costly repairs. A well-lubricated machine also operates more smoothly, producing a better surface finish. Maintenance includes regular inspection of components, cleaning of dust and debris, and replacement of worn parts. For example, neglecting to lubricate bearings can lead to premature failure, resulting in costly downtime and repairs. A regular maintenance schedule based on the manufacturer’s recommendations ensures that the equipment is functioning optimally and safely. I’ve seen firsthand the significant difference between well-maintained equipment and neglected equipment; the former consistently delivers high-quality work with minimal downtime, while the latter is prone to frequent breakdowns and costly repairs.

Q 27. How do you manage inventory for sanding supplies and consumables?

Effective inventory management for sanding supplies and consumables is essential for maintaining a smooth operation. I utilize a combination of methods, including a computerized inventory system to track stock levels, order points, and usage history. This allows me to anticipate demand and order supplies proactively, preventing stockouts that can halt production. I also perform regular physical inventory checks to verify stock levels and identify any discrepancies. I work closely with suppliers to negotiate favorable pricing and ensure timely delivery. The key is to find the balance between maintaining sufficient stock to meet demand and avoiding excessive inventory that ties up capital. This includes considering factors such as storage space, shelf life of consumables, and potential obsolescence of certain items. Efficient inventory management not only ensures uninterrupted production but also minimizes waste and optimizes costs.

Key Topics to Learn for Sanding Equipment Maintenance and Operation Interview

- Safety Procedures and Regulations: Understanding and adhering to all safety protocols related to sanding equipment operation and maintenance, including lockout/tagout procedures and personal protective equipment (PPE) usage.

- Equipment Operation: Practical knowledge of operating various types of sanding equipment, including belt sanders, disc sanders, orbital sanders, and specialized industrial sanding machines. This includes understanding speed adjustments, abrasive selection, and dust collection systems.

- Preventive Maintenance: Proficiency in performing routine maintenance tasks such as lubrication, cleaning, belt changes, and inspections to prevent breakdowns and ensure optimal performance. Knowing the manufacturer’s recommended maintenance schedules is crucial.

- Troubleshooting and Repair: Ability to diagnose common malfunctions, perform basic repairs, and identify when professional assistance is needed. Understanding the workings of different components (motors, belts, bearings, etc.) is vital.

- Abrasive Selection and Application: Knowledge of different abrasive types (sandpaper grits, polishing compounds) and their appropriate applications for various materials and surface finishes. Understanding the impact of grit selection on surface quality.

- Dust Collection and Control: Familiarity with dust collection systems and their importance in maintaining a safe and clean work environment. Understanding the principles of dust suppression and disposal methods.

- Quality Control and Inspection: Ability to inspect finished surfaces for quality, identify defects, and understand the relationship between sanding techniques and final product quality.

Next Steps

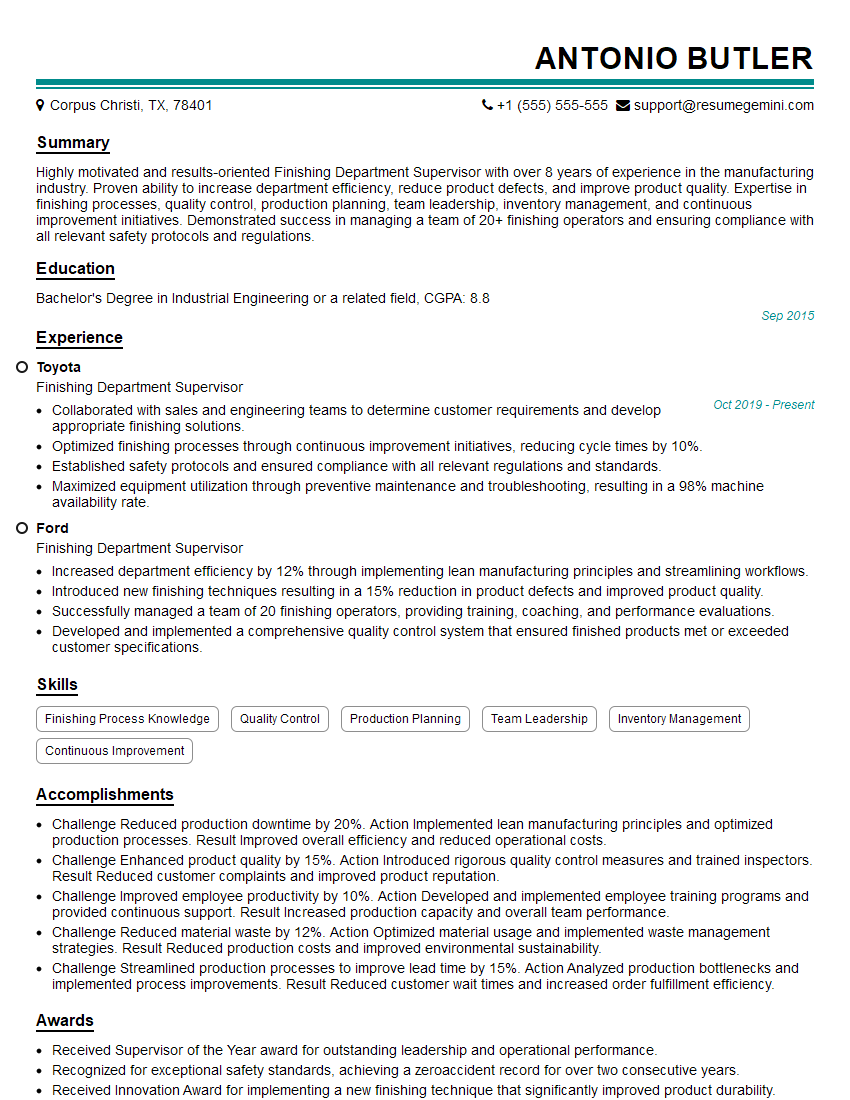

Mastering Sanding Equipment Maintenance and Operation opens doors to a rewarding career with excellent growth potential. Your expertise in this field will be highly sought after in various industries. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by potential employers. ResumeGemini is a trusted resource that can help you build a professional and impactful resume that stands out. They provide examples of resumes tailored to Sanding Equipment Maintenance and Operation to guide you through the process. Invest time in crafting a strong resume—it’s your first impression and a significant step towards securing your dream job.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO