The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Cutting Tools interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Cutting Tools Interview

Q 1. Explain the different types of cutting tool materials and their applications.

Cutting tool materials are chosen based on the required hardness, wear resistance, and temperature resistance for the specific machining operation. The selection significantly impacts tool life and surface finish.

- High-speed steel (HSS): A versatile material offering good strength and toughness, suitable for a wide range of materials and applications. Think of it as the ‘workhorse’ of cutting tools. It’s commonly used in drills, taps, and end mills for less demanding applications.

- Cemented carbides (Ceramics): These are significantly harder and more wear-resistant than HSS, making them ideal for machining tougher materials like hardened steels and cast iron. Their higher hardness allows for higher cutting speeds and feeds, leading to increased productivity. Think of them as specialized tools for tougher jobs.

- Ceramics: Even harder than carbides, ceramics excel in high-speed, high-temperature machining. They’re brittle, though, so require careful handling and are typically used in specialized applications, such as finishing operations on difficult-to-machine materials.

- Cubic Boron Nitride (CBN): Extremely hard, CBN is used for machining hardened steels and other superalloys where carbide tools would fail prematurely. This is a top-tier material, used when the hardest materials need to be machined efficiently.

- Polycrystalline Diamond (PCD): The hardest material, PCD is best for machining non-ferrous materials such as aluminum, graphite, and composites at very high speeds. Think of it as the ultimate precision tool for specific materials.

The choice depends heavily on the workpiece material, the desired surface finish, the required machining speed, and the overall cost considerations. For example, HSS is cost-effective for mild steel, while CBN is necessary for machining hardened tool steel.

Q 2. Describe the various cutting tool geometries and their impact on machining performance.

Cutting tool geometry refers to the shape and angles of the cutting edges. These angles significantly influence cutting forces, chip formation, surface finish, and tool life. A well-designed geometry optimizes the cutting process for efficiency and quality.

- Rake angle: The angle between the tool face and the direction of cutting. A positive rake angle reduces cutting forces, while a negative rake angle increases strength and wear resistance.

- Clearance angle: The angle between the tool flank and the machined surface. It prevents rubbing and ensures smooth cutting action.

- Relief angle: The angle between the tool flank and the workpiece surface. It minimizes friction and helps reduce wear.

- Lip angle: Affects chip flow and breaking, influencing surface finish.

- Nose radius: Smooths the cutting action and reduces surface roughness.

For instance, a sharp nose radius is crucial for fine finishing operations, while a larger nose radius can be more robust for roughing operations. Selecting the correct geometry requires careful consideration of the material being machined and the desired machining outcome.

Q 3. What are the factors influencing tool wear and how can it be minimized?

Tool wear is a gradual degradation of the cutting tool’s material during machining, leading to reduced tool life, poor surface finish, and dimensional inaccuracies. Several factors contribute to this wear:

- Abrasive wear: Caused by hard particles in the workpiece material scratching the tool’s surface.

- Adhesive wear: Occurs when the tool and workpiece materials stick together, leading to material transfer and tool surface damage.

- Diffusion wear: Material transfer between the tool and workpiece due to high temperatures at the cutting edge.

- Flank wear: Wear on the tool flank (the surface of the tool not involved in the cutting action), usually leading to loss of cutting edge sharpness.

- Crater wear: Wear on the rake face (cutting edge) due to the high temperatures and stresses during chip formation.

Minimizing tool wear involves selecting appropriate tool materials, optimizing cutting parameters, and using suitable cutting fluids. Regular tool inspection and timely replacement are also crucial. Using proper cutting fluids, for example, can significantly reduce adhesive wear by providing lubrication and cooling at the cutting zone.

Q 4. Explain the concept of cutting speed, feed rate, and depth of cut.

Cutting speed, feed rate, and depth of cut are the three fundamental parameters that define the machining process. They are interrelated and must be chosen carefully to optimize material removal rate (MRR), surface finish, and tool life.

- Cutting speed (V): The rotational speed of the cutting tool (usually measured in meters per minute or feet per minute). Higher cutting speeds typically increase MRR but can also lead to increased tool wear and heat generation. Think of it like driving fast, you get there quicker, but wear and tear increases.

- Feed rate (f): The amount of material removed per revolution of the tool. Higher feed rates increase MRR but can also lead to increased cutting forces, tool wear and reduced surface finish. This is akin to the accelerator pedal in a car.

- Depth of cut (d): The depth of material removed in a single pass. Increasing the depth of cut increases the MRR but also increases the cutting forces and tool wear.

The optimal combination of these parameters depends on the specific material being machined, the cutting tool material, and the desired surface finish. Incorrect selection can lead to inefficient machining, tool breakage, or poor surface quality.

Q 5. How do you select the appropriate cutting tool for a specific material and machining operation?

Selecting the right cutting tool is crucial for efficient and effective machining. The process involves considering several factors:

- Workpiece material: Hardness, strength, machinability.

- Machining operation: Turning, milling, drilling, etc. Each operation requires specific tool geometries and materials.

- Desired surface finish: Roughing or finishing operations require different tools.

- Required accuracy: Tolerance requirements influence tool selection.

- Available machining power: Limits cutting parameters like cutting speed and feed rate.

For example, machining hardened steel might require a CBN tool, while aluminum could be machined effectively with a PCD tool. Choosing the wrong tool can lead to tool breakage, poor surface finish, or inaccurate dimensions.

A step-by-step selection process might involve:

- Identify the workpiece material and its properties.

- Determine the machining operation.

- Specify the desired surface finish and tolerances.

- Consult tool catalogs and manufacturers’ recommendations based on the above.

- Conduct trial cuts to fine-tune cutting parameters.

Q 6. Describe different types of cutting fluids and their functions.

Cutting fluids, also known as coolants or lubricants, are used to improve machining performance by reducing friction, heat, and wear. They also aid in chip removal and improve surface finish.

- Oil-based fluids: Offer excellent lubrication, reducing friction and wear, particularly suitable for high-speed machining. They tend to be less effective at cooling.

- Water-based fluids (water-miscible fluids): Provide good cooling and are often more environmentally friendly than oil-based fluids. They may have lower lubricating properties.

- Synthetic fluids: Offer a combination of good cooling and lubrication and are often designed for specific applications.

- Minimum Quantity Lubrication (MQL): Uses very small amounts of cutting fluid, increasing environmental friendliness and reducing waste, but requires careful control.

The choice of cutting fluid depends on factors such as workpiece material, machining operation, and environmental concerns. Water-based fluids are common for general purpose machining, while oil-based fluids are often used for heavier cutting operations or when enhanced lubrication is paramount.

Q 7. Explain the importance of tool clamping and its effect on machining accuracy.

Proper tool clamping is essential for ensuring the accuracy and stability of the machining process. Insecure clamping can lead to tool deflection, vibration, chatter, and ultimately, inaccurate machining and poor surface finish.

Several factors influence the effectiveness of tool clamping:

- Clamping force: The clamping mechanism must provide sufficient force to hold the tool securely in place without causing deformation or damage.

- Clamping system design: The design must minimize vibration and ensure even clamping pressure across the tool interface.

- Toolholder compatibility: The toolholder and the cutting tool must be compatible to ensure secure and accurate mounting.

- Regular maintenance: The clamping system should be inspected and maintained regularly to ensure continued effectiveness.

Imagine trying to write with a pencil that keeps slipping; the result would be unreadable. Similarly, a loosely clamped cutting tool will produce an inaccurate and potentially damaged part. Proper clamping is essential for repeatability and maintaining tolerances.

Q 8. What are the common methods for measuring tool wear?

Measuring tool wear is crucial for maintaining machining efficiency and preventing costly part failures. Several methods exist, each with its strengths and weaknesses. These methods often involve direct measurement or indirect assessment of the tool’s condition.

- Direct Measurement: This involves physically measuring the tool’s dimensions using tools like calipers or optical measuring equipment. We can measure flank wear (wear on the tool’s flank), crater wear (wear on the rake face), and nose radius wear. For example, we might use a microscope with a calibrated scale to precisely measure flank wear in millimeters.

- Indirect Measurement: This involves measuring parameters that indirectly reflect tool wear. This could include monitoring the cutting forces, surface roughness of the machined part, or the tool’s vibration. An increase in cutting forces, often monitored using a dynamometer, can signify increased tool wear.

- Visual Inspection: A quick initial check involves visual inspection under magnification. This allows for the detection of chipping, cracks, or significant wear. This method isn’t very precise but is a useful initial step.

The choice of method depends on the specific application, the type of cutting tool, and the available equipment. For instance, a high-precision machining operation might necessitate precise direct measurements, while less critical operations might rely more on indirect measurements or visual inspection.

Q 9. How do you troubleshoot common cutting tool problems during machining?

Troubleshooting cutting tool problems requires a systematic approach. Let’s imagine a scenario where you’re experiencing poor surface finish.

- Identify the Problem: Precisely define the problem. Is it poor surface finish, broken tools, excessive vibration, or dimensional inaccuracy? Document the issue with photos or measurements.

- Analyze the Process Parameters: Examine the machining parameters – cutting speed, feed rate, depth of cut, and coolant usage. Are they optimized for the chosen material and tool? For example, using too high a feed rate with a worn tool can lead to poor surface finish.

- Examine the Tool: Inspect the cutting tool itself for signs of wear, chipping, or damage. Is it properly sharpened? Is the tool material appropriate for the work material?

- Check Workpiece and Fixturing: Ensure the workpiece is properly secured in the fixture, and that the fixture itself is rigid enough to prevent vibrations. Workpiece imperfections can also contribute to cutting tool problems.

- Adjust Parameters: Based on your analysis, adjust the process parameters. Reducing the feed rate might improve surface finish, while changing the cutting tool might be necessary if it’s severely worn or damaged.

For example, if you are facing excessive tool breakage, you might need to reduce the depth of cut or increase the cutting speed to optimize the cutting process.

Q 10. What are the safety precautions when using cutting tools?

Safety is paramount when using cutting tools. These are sharp, high-speed tools, and even a minor mishap can have severe consequences.

- Proper PPE: Always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and cut-resistant gloves. Depending on the operation, a face shield or apron might also be necessary.

- Machine Guarding: Ensure all machine guards are in place and functioning correctly. These guards prevent accidental contact with moving parts.

- Secure Workholding: Properly secure the workpiece to prevent it from moving unexpectedly during the cutting operation. A poorly clamped workpiece can lead to tool breakage or injury.

- Tool Handling: Handle cutting tools with care. Avoid dropping them, and use appropriate storage methods to prevent damage or accidental injury. Never leave tools lying around.

- Machine Operation: Only operate the machine after receiving proper training. Always follow the manufacturer’s instructions.

- Emergency Procedures: Be aware of the emergency stop procedures and know how to respond to any unexpected situations.

Remember: a moment of carelessness can lead to a lifetime of regret. Prioritize safety in every aspect of the cutting process.

Q 11. Explain the difference between HSS, carbide, and ceramic cutting tools.

High-speed steel (HSS), carbide, and ceramic are common cutting tool materials, each with distinct properties and applications.

- High-Speed Steel (HSS): HSS tools are relatively inexpensive and offer good versatility. Their toughness makes them suitable for a variety of materials, but their hardness is lower than carbide, limiting their speed and life when cutting harder materials.

- Carbide: Carbide tools are significantly harder and more wear-resistant than HSS. This allows for higher cutting speeds and longer tool life, especially when machining harder materials like steel and cast iron. However, they’re more brittle and prone to chipping.

- Ceramic: Ceramic tools boast the highest hardness and wear resistance, ideal for machining very hard materials or at extremely high speeds. Their brittleness limits their application to specific operations. They tend to be more expensive.

The choice depends on factors like the material being machined, the desired machining parameters, and the cost considerations. For example, HSS might be preferred for occasional light-duty machining of softer metals, while carbide would be the go-to choice for high-volume production of tougher metals. Ceramics find their niche in specialized high-precision applications.

Q 12. Describe the process of tool sharpening or reconditioning.

Tool sharpening or reconditioning extends the life of cutting tools and improves machining performance. The process depends on the tool material and the type of wear.

- Grinding: For HSS tools, grinding is commonly used to remove worn material and restore the cutting edges. This involves using grinding wheels with appropriate grit size and coolant to prevent overheating and damage.

- Honing and Lapping: These finer finishing processes are used to create a sharp cutting edge and improve surface finish. Honing uses abrasive stones, while lapping uses very fine abrasive compounds.

- Electro-discharge Grinding (EDM): For complex geometries or hard materials, EDM can be used to precisely remove material and sharpen the cutting edges. This is a non-contact method, minimizing the risk of tool damage.

Proper sharpening techniques are crucial to maintain the tool’s geometry and performance. Improper grinding can lead to premature failure. For carbide tools, specialized grinding wheels and techniques are necessary to prevent chipping and cracking.

Q 13. How does chip formation affect machining efficiency?

Chip formation significantly impacts machining efficiency. The type of chip produced – continuous, discontinuous, or built-up edge – affects surface finish, tool life, and overall process efficiency.

- Continuous Chips: These are long, ribbon-like chips typically formed when machining ductile materials at high cutting speeds. While easier to manage, they can wrap around the tool and cause damage.

- Discontinuous Chips: These are short, fragmented chips formed when machining brittle materials or at low cutting speeds. These chips are easier to manage but can lead to poor surface finish.

- Built-up Edge (BUE): This is a layer of work material that adheres to the tool’s cutting edge. BUE degrades surface finish and can lead to rapid tool wear.

Optimizing cutting parameters and using appropriate coolants can influence chip formation. For instance, using a high cutting speed with proper coolant can help produce continuous chips in ductile materials, leading to better surface finish and higher efficiency. Conversely, discontinuous chip formation, while less efficient, is often preferred for brittle materials to prevent tool chipping. Understanding chip formation is fundamental to selecting the optimal cutting parameters.

Q 14. What is the role of cutting tool coatings?

Cutting tool coatings play a crucial role in enhancing the performance and life of cutting tools. These thin layers of material significantly improve the tool’s wear resistance, reduce friction, and enhance heat dissipation.

- Increased Wear Resistance: Coatings like TiN (Titanium Nitride), TiCN (Titanium Carbonitride), and TiAlN (Titanium Aluminum Nitride) create a hard, wear-resistant surface, reducing flank and crater wear.

- Reduced Friction: Coatings can lower the coefficient of friction between the tool and the workpiece, reducing cutting forces and improving surface finish. This leads to reduced energy consumption.

- Improved Heat Dissipation: Coatings can improve heat transfer away from the cutting edge, allowing for higher cutting speeds and longer tool life. This is crucial for minimizing thermal damage.

The choice of coating depends on the application and the material being machined. For example, TiN is a common choice for general-purpose applications, while TiAlN is preferred for applications requiring higher hardness and temperature resistance. Coatings can significantly enhance the overall efficiency and cost-effectiveness of the machining process.

Q 15. Explain the concept of tool life and its importance in manufacturing.

Tool life refers to the duration a cutting tool can effectively perform its intended machining operation before requiring sharpening, replacement, or becoming unusable due to wear or breakage. It’s a crucial factor in manufacturing because it directly impacts production costs, efficiency, and product quality. A longer tool life translates to lower costs associated with tool replacement, reduced downtime for tool changes, and a more consistent machining process, leading to higher-quality parts.

Think of it like the lifespan of a chef’s knife. A high-quality knife, properly maintained, will last much longer and produce cleaner cuts than a cheap one. Similarly, in manufacturing, a well-chosen and properly used cutting tool will significantly extend its operational life, leading to substantial savings.

Factors affecting tool life include cutting speed, feed rate, depth of cut, workpiece material, cutting fluid, and the tool material itself. Optimizing these parameters is essential for maximizing tool life and minimizing production costs.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the advantages and disadvantages of using different types of cutting fluids?

Cutting fluids, also known as coolants or lubricants, play a vital role in machining processes. They offer several advantages and disadvantages depending on their type (e.g., oil-based, water-based, or synthetic).

- Advantages of using cutting fluids:

- Improved tool life: They reduce friction and heat generated during cutting, thus extending tool life.

- Enhanced surface finish: They help to lubricate the cutting zone, resulting in a smoother surface finish on the workpiece.

- Better chip removal: They help to wash away chips from the cutting zone, preventing chip build-up and improving machining efficiency.

- Reduced wear on machine tools: They can help protect machine components from wear and corrosion.

- Disadvantages of using cutting fluids:

- Environmental concerns: Some cutting fluids, especially oil-based ones, can be harmful to the environment and require careful disposal.

- Cost: Cutting fluids can represent a significant operating expense.

- Mist and fumes: The use of certain cutting fluids can generate mists and fumes, which can be hazardous to operators’ health and require proper ventilation.

- Fire hazard: Oil-based cutting fluids pose a fire risk if not handled correctly.

The choice of cutting fluid depends on the specific application, considering factors such as the material being machined, the type of machining operation, and environmental considerations. A thorough risk assessment is crucial before selecting a cutting fluid.

Q 17. How do you calculate the machining time for a given operation?

Calculating machining time requires a precise understanding of the operation’s parameters. The basic formula is:

Machining Time = (Length of Cut / Feed Rate) + Approach Time + Retract TimeLet’s break it down:

- Length of Cut: The total distance the tool travels during the cutting process. This is often determined by the dimensions of the workpiece and the specific machining operation.

- Feed Rate: The speed at which the tool advances into the workpiece per revolution or per minute. It’s usually expressed in units like mm/rev or mm/min.

- Approach Time: The time taken for the tool to approach the workpiece before engaging in the cutting operation.

- Retract Time: The time taken for the tool to retract from the workpiece after completing the cutting operation.

Example: Imagine milling a 100mm long slot with a feed rate of 0.2 mm/rev and a spindle speed of 1000 rpm. The length of cut is 100 mm. The feed rate in mm/min would be 0.2 mm/rev * 1000 rev/min = 200 mm/min. Machining time (excluding approach and retract) would be 100 mm / 200 mm/min = 0.5 minutes. Approach and retract times would need to be added based on the machine setup.

Accurate calculations require careful consideration of all factors, including tool geometry, cutting conditions, and machine capabilities. Software packages often automate these calculations for complex parts.

Q 18. Describe various CNC machining processes (e.g., milling, turning, drilling).

CNC machining encompasses a range of processes, each with its unique applications and characteristics:

- Milling: This process uses rotating cutting tools to remove material from a workpiece, creating features like slots, pockets, and complex shapes. Different milling operations exist, including face milling, end milling, and profile milling, depending on the tool and its orientation to the workpiece.

- Turning: In turning, a rotating workpiece is shaped by a stationary cutting tool. This is commonly used to create cylindrical parts, shafts, and other rotational components. Operations like facing, turning, and boring are frequently employed.

- Drilling: This process utilizes a rotating drill bit to create holes in a workpiece. Various drill bit designs are used depending on the material and the desired hole size and type.

These are just a few examples; other CNC machining processes include grinding, broaching, and wire EDM. The choice of process depends on the desired part geometry, the material properties, and the available equipment.

CNC machining offers high precision, repeatability, and automation, making it a cornerstone of modern manufacturing.

Q 19. Explain the importance of proper tool storage and handling.

Proper tool storage and handling are crucial for maintaining cutting tool performance and extending their lifespan. Neglecting these aspects can lead to premature tool wear, damage, and costly replacements.

- Storage: Tools should be stored in a clean, dry, and controlled environment to prevent corrosion and damage. Individual tool storage, ideally in a designated tool crib with appropriate racks and holders, protects cutting edges from impacts and maintains organization.

- Handling: Tools should be handled with care, avoiding dropping or striking them against hard surfaces. Using appropriate handling equipment, such as magnetic holders or protective cases, minimizes risk of damage. Cleanliness is also essential – removing chips and debris from tools after each use is crucial.

Imagine storing expensive, delicate surgical instruments carelessly – the result would be damaged, unusable tools. The same principle applies to cutting tools; proper storage and handling are investments in productivity and cost-effectiveness.

Q 20. What are the effects of vibration on machining accuracy and tool life?

Vibration during machining significantly impacts both accuracy and tool life. Excessive vibration leads to:

- Reduced Accuracy: Vibrations cause chatter marks on the machined surface, reducing dimensional accuracy and surface finish. The resulting part may not meet specifications, requiring rework or scrapping.

- Shorter Tool Life: Vibration accelerates tool wear and can cause premature tool breakage. This is due to the increased stress and strain on the cutting edges, leading to more rapid wear and potential fracture.

Sources of vibration can include machine imbalances, insufficient rigidity in the machine structure, or improper clamping of the workpiece. Minimizing vibration involves ensuring proper machine maintenance, using rigid fixturing, selecting appropriate cutting parameters, and optimizing the machining process to reduce resonance frequencies.

Think of it like trying to carve intricate details into wood with a shaky hand – the result would be imprecise and uneven. Similarly, vibration in machining compromises accuracy and reduces the effectiveness of the cutting tool.

Q 21. Describe different types of cutting tool holders.

Cutting tool holders are essential components that secure and position cutting tools within a machine tool. Different types cater to various machining operations and tool geometries:

- Collet Chucks: These are precision gripping devices used to hold end mills, drills, and other cylindrical tools. They offer precise concentricity and are commonly used in smaller machining centers.

- Shell Mill Holders: Designed for shell mills, these holders provide a secure connection and allow for precise adjustments of the tool’s position.

- Face Mill Holders: These are used to hold face milling cutters, ensuring proper alignment and stability during face milling operations.

- Boring Bar Holders: Used for boring operations, these holders provide rigidity and stability, crucial for achieving accurate hole diameters.

- Quick-Change Tool Holders: These allow for rapid tool changes, minimizing downtime during production runs.

The selection of a cutting tool holder depends on the specific tool, the machining operation, and the required rigidity and accuracy. The right holder ensures accurate tool positioning, minimizes vibration, and improves overall machining performance.

Q 22. How do you interpret a cutting tool catalog?

Interpreting a cutting tool catalog requires a systematic approach. Think of it like a highly specialized parts manual. You need to understand the language and the parameters involved. First, you’ll find sections organizing tools by material (e.g., carbide, high-speed steel), application (e.g., milling, turning, drilling), and geometry (e.g., insert shape, flute design). Each tool entry will list key specifications. Crucially, pay attention to:

- Cutting Material: This indicates the tool’s resistance to wear and the materials it’s designed to cut (e.g., steel, aluminum, titanium).

- Coating: Coatings like TiN or TiAlN significantly impact tool life and performance. The catalog will describe their properties and benefits.

- Geometry: This covers the tool’s shape (e.g., cutting edge angle, rake angle, relief angle). Different geometries are optimized for different machining strategies (roughing vs. finishing).

- Dimensions: Precise dimensions (diameter, length, shank size) are crucial for compatibility with your machine and workpiece.

- Recommended cutting parameters: The catalog often provides guidance on optimal cutting speed (SFM or m/min), feed rate (IPR or mm/rev), and depth of cut, usually in a chart format. Following these recommendations is key to achieving optimal results and extending tool life.

For example, if I need a carbide end mill to machine aluminum, I’d look for entries specifying aluminum compatibility, appropriate coatings for aluminum machining (like AlTiN), and an end mill geometry suitable for the desired surface finish. I would then cross-reference the tool’s dimensions with my machine’s capacity and the size of my workpiece.

Q 23. What is the difference between roughing and finishing operations?

Roughing and finishing are distinct machining operations with different objectives and tool selection criteria. Think of it like sculpting: roughing is the initial shaping, while finishing refines the form.

- Roughing: This stage focuses on rapidly removing large amounts of material from the workpiece. Tools used for roughing typically have strong, robust geometries designed to withstand high cutting forces. They prioritize material removal rate over surface finish. Expect higher feed rates and depths of cut compared to finishing. Tools often have larger inserts or more aggressive geometries. Examples include roughing end mills with a high helix angle or large diameter turning tools with positive rake angles.

- Finishing: This is the final stage, aiming for high precision and a superior surface finish. Finishing tools emphasize accuracy and fine detail. They employ smaller depths of cut, lower feed rates, and sharper cutting edges. Expect the use of sharper inserts, dedicated finishing end mills with finer pitches, and lower cutting speeds. Surface finish is prioritized. Examples include fine-grained carbide inserts, ball-nose end mills, or dedicated finishing tools with honed cutting edges.

In a real-world example, creating a precise part might start by using a roughing end mill to quickly remove excess material, followed by a finishing operation with a smaller, sharper end mill to create the final shape and surface quality.

Q 24. What are the key performance indicators (KPIs) for cutting tool performance?

Key Performance Indicators (KPIs) for cutting tools are essential for monitoring efficiency and optimizing processes. They’re like a dashboard for your machining operations.

- Tool Life: Measured in the number of parts produced or the machining time before tool failure. This directly impacts production costs.

- Material Removal Rate (MRR): The volume of material removed per unit time. A higher MRR means faster production.

- Surface Finish: Assessed using parameters like Ra (average roughness) or Rz (maximum peak-to-valley height). Determines part quality.

- Cutting Speed (Vc): The speed at which the tool rotates relative to the workpiece. Optimizing cutting speed maximizes productivity without compromising tool life.

- Feed Rate (f): The distance the tool advances per revolution. Affects surface finish and tool wear.

- Depth of Cut (d): The distance the tool penetrates the workpiece. Affects material removal rate and cutting forces.

- Tool Wear: Regular monitoring of flank wear, crater wear, and chipping helps predict tool failure and optimize tool change scheduling.

- Cost per Part: This combines all factors and helps measure the overall efficiency of your process.

Tracking these KPIs allows for data-driven decisions. For instance, if tool life is consistently short, you may need to adjust cutting parameters, improve tool selection, or investigate workpiece material properties.

Q 25. Explain the concept of tool presetting and its benefits.

Tool presetting is the process of precisely measuring and setting the cutting tool’s position relative to the machine’s coordinate system before machining begins. It’s like setting up your easel before you start painting – you want everything aligned accurately from the outset. Tools are measured with a presetter, which can be a manual or automated device. This measurement is then input to the CNC machine to compensate for any length variations among the cutting tools.

- Benefits:

- Increased Accuracy: Eliminates the need for trial-and-error adjustments in the machine, ensuring highly accurate part dimensions.

- Reduced Setup Time: Presetting dramatically decreases the time required for job setups, significantly boosting production efficiency.

- Improved Tool Life: Properly preset tools are less prone to damage from collisions or inaccurate positioning.

- Enhanced Safety: Prevents accidental crashes and injuries during machining.

- Improved Part Consistency: Leads to consistent part quality across production runs.

In practice, imagine setting up a milling operation with multiple tools of varying lengths. Presetting each tool ensures that each will accurately reach its programmed position, even when using different tools in rapid succession. This minimizes setup time and reduces the risk of tool breakage or scrap parts.

Q 26. Describe your experience with different CAD/CAM software for toolpath generation.

My experience encompasses several leading CAD/CAM software packages for toolpath generation. I’m proficient in Mastercam, Fusion 360, and Siemens NX CAM. These software packages allow for the design of complex toolpaths which would be difficult or impossible to produce manually.

My workflow typically involves importing the part model into the chosen software, selecting appropriate cutting tools from the tool library (often referencing a cutting tool catalog), defining machining strategies (roughing and finishing passes), and then using the software’s features to generate efficient and collision-free toolpaths. I often consider factors like tool engagement, step-over, and stock removal strategies to optimize the process. I also leverage the simulation capabilities of the software to verify the generated toolpaths before executing them on the CNC machine, preventing potential errors and damage. This simulation ensures the toolpaths are collision-free and are optimized for the particular characteristics of the workpiece and the tools selected.

For instance, in Mastercam, I frequently use dynamic milling strategies to generate efficient toolpaths for complex 3D shapes. In Fusion 360, I appreciate its ease of use and integration with its CAD modeling capabilities. My experience allows me to tailor the toolpath generation process to the specific needs of the project and machine capabilities, ensuring efficient and productive machining.

Q 27. How do you handle unexpected tool breakage during machining?

Unexpected tool breakage is a serious issue in machining that necessitates a swift and methodical response. The immediate priority is to stop the machine to prevent further damage. It is paramount to prevent damage to the CNC machine itself.

The next step involves a thorough investigation to determine the cause of the breakage. This might involve examining the broken tool, assessing the machining parameters (cutting speed, feed rate, depth of cut), and checking the condition of the workpiece. Possible causes include excessive cutting forces, improper tool selection, inadequate clamping, or workpiece defects. Was the tooling worn?

Once the cause is identified, corrective actions can be implemented, such as adjusting cutting parameters, selecting a more robust tool, improving clamping methods, or addressing workpiece issues. The machine will need to be inspected for damage, and any damaged components will need to be repaired or replaced before machining resumes.

Finally, preventative measures should be implemented to reduce the likelihood of future breakages. This might involve implementing regular tool condition monitoring, improving machine maintenance procedures, or refining the machining process itself. Documentation is crucial. All instances of tool breakage should be documented to identify trends and facilitate continuous improvement.

Q 28. What are your strategies for continuous improvement in cutting tool performance?

Continuous improvement in cutting tool performance is an ongoing process requiring a data-driven approach and a commitment to innovation. I use a combination of strategies to enhance performance.

- Data Analysis: Regularly analyzing KPIs like tool life, MRR, surface finish, and cost per part helps identify areas for improvement. Trends in tool wear can be tracked and analyzed to identify potential issues.

- Experimentation: Systematic experimentation with different cutting tools, parameters (speed, feed, depth), and cutting fluids can optimize the process and maximize efficiency. This might involve a formal design of experiments (DOE) approach to systematically test variables.

- Tool Management: Implementing a robust tool management system (including proper storage, handling, and identification) extends tool life and minimizes errors.

- Workpiece Analysis: Understanding the workpiece material properties (hardness, toughness) is critical for selecting appropriate tools and cutting parameters. Improper consideration of workpiece material can lead to tool breakage and poor surface finish.

- Stay Current with Technology: Staying informed on the latest cutting tool technologies, materials, and machining techniques is essential for continuous improvement. Attending industry events and reading technical publications are important aspects of staying current.

- Collaboration: Collaboration with cutting tool suppliers, other engineers, and machinists allows for the sharing of best practices and knowledge. Access to technical expertise, new products, and different perspectives helps identify new strategies.

For example, if data analysis reveals consistent chipping on a particular tool, I’d investigate the cutting parameters, the tool geometry, and the workpiece material to identify and correct the issue. By continuously evaluating and refining our approach, we can maximize efficiency, improve quality, and reduce costs. This continuous improvement mindset is crucial for competitiveness in manufacturing.

Key Topics to Learn for Cutting Tools Interview

- Cutting Tool Materials & Properties: Understanding the characteristics of different materials (e.g., high-speed steel, carbide, ceramic) and their impact on performance, wear resistance, and application suitability.

- Cutting Tool Geometry: Mastering concepts like rake angle, clearance angle, relief angle, and their influence on chip formation, surface finish, and tool life. Practical application involves analyzing cutting tool designs for specific machining operations.

- Machining Processes & Tool Selection: Connecting the appropriate cutting tool to various machining processes (e.g., turning, milling, drilling, grinding). This includes understanding speed, feed, and depth of cut parameters and their optimization for different materials and tools.

- Tool Wear Mechanisms & Monitoring: Identifying common wear mechanisms (e.g., abrasive wear, adhesive wear, fracture) and understanding the importance of tool condition monitoring techniques (e.g., visual inspection, sensor-based monitoring) to prevent catastrophic failures and optimize tool life.

- Coolant Selection & Application: Understanding the role of coolants in machining, including their types, properties, and selection criteria based on the material being machined and the cutting tool used. Practical application involves troubleshooting coolant-related issues.

- Cutting Tool Coatings & Surface Treatments: Exploring various coatings (e.g., TiN, TiAlN, DLC) and their impact on tool performance, wear resistance, and surface finish. This includes understanding the application and limitations of different coating technologies.

- Troubleshooting & Problem Solving: Developing a systematic approach to diagnosing and resolving common machining problems related to cutting tools, including surface defects, tool breakage, and dimensional inaccuracies.

Next Steps

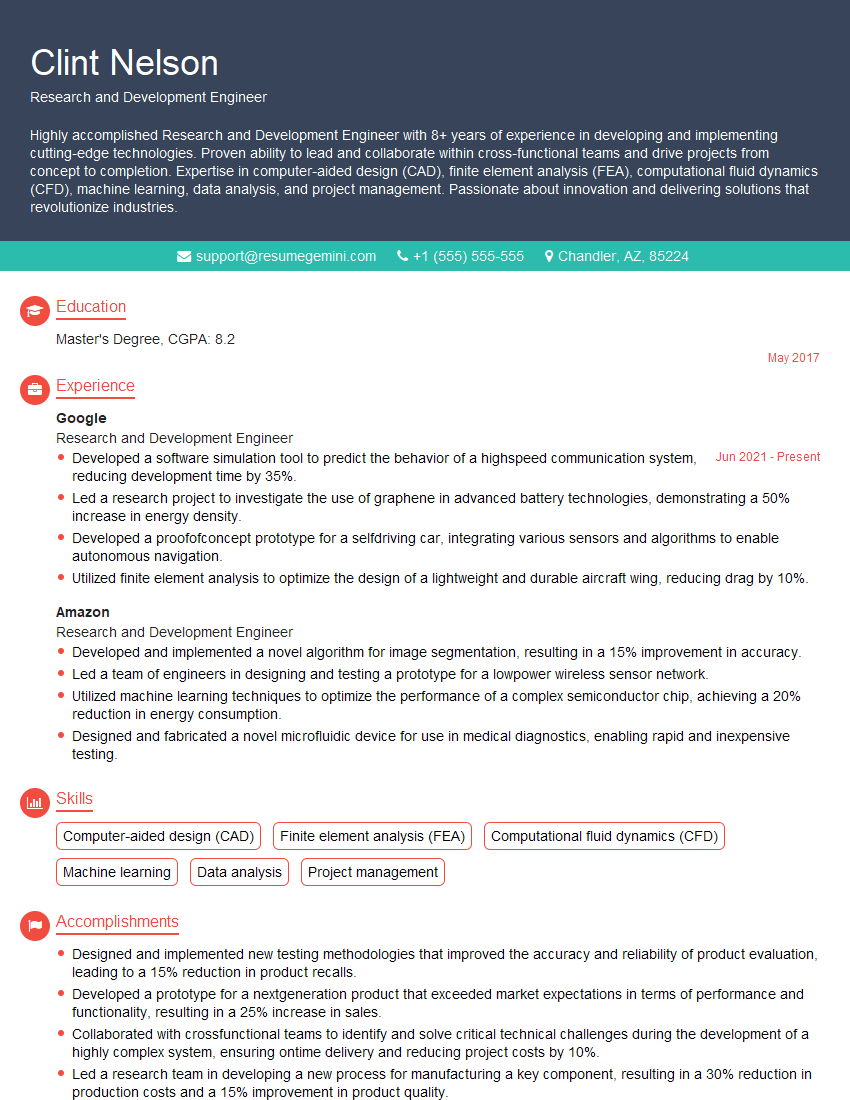

Mastering the principles of cutting tools is crucial for advancing your career in manufacturing and engineering. A strong understanding of these concepts will significantly enhance your problem-solving abilities and open doors to more challenging and rewarding roles. To maximize your job prospects, it’s essential to create a resume that effectively communicates your skills and experience to Applicant Tracking Systems (ATS). We strongly recommend using ResumeGemini to build a professional, ATS-friendly resume. ResumeGemini offers a user-friendly platform and provides examples of resumes tailored to the Cutting Tools industry, helping you present yourself in the best possible light to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO