The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Maintenance Request Processing interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Maintenance Request Processing Interview

Q 1. Describe your experience with different CMMS (Computerized Maintenance Management System) software.

Throughout my career, I’ve worked extensively with several CMMS platforms, each offering unique features and functionalities. My experience includes using both cloud-based systems like UpKeep and Fiix, and on-premise solutions such as IBM Maximo. With UpKeep, I particularly appreciated its user-friendly interface and mobile accessibility, making it ideal for quick request submissions and on-the-go updates. Fiix’s strong reporting capabilities proved invaluable for analyzing maintenance trends and optimizing resource allocation. On the other hand, IBM Maximo, while more complex, provided a highly customizable and robust solution for managing large-scale maintenance operations, especially useful in a heavily regulated environment. My experience spans implementing these systems, customizing workflows, training users, and leveraging their analytical tools to improve overall maintenance efficiency. For example, in one role, we migrated from a paper-based system to UpKeep, resulting in a 30% reduction in response times to maintenance requests. This was achieved through streamlined workflows, automated notifications, and improved communication among technicians.

Q 2. Explain the process of prioritizing maintenance requests.

Prioritizing maintenance requests involves a multi-faceted approach, balancing urgency, impact, and cost. We often employ a system that combines several factors. First, urgency is categorized – critical, high, medium, low – based on the potential for safety hazards, operational downtime, or significant financial loss. A critical failure in a primary piece of equipment, for instance, would take precedence over a minor cosmetic issue. Secondly, we consider the impact – how many people or processes are affected. A broken elevator impacting a high-rise building would be prioritized higher than a malfunctioning coffee machine in a small office. Finally, we consider the cost – both the cost of repair and the cost of inaction. Sometimes, delaying a less urgent but expensive repair might be strategically sound to align with budget considerations. We use a weighted scoring system to combine these factors, creating a clear priority list. For example, a critical issue with high impact and high cost would receive the highest score and immediate attention. This system ensures that resources are allocated effectively and that the most impactful repairs are addressed first.

Q 3. How do you handle urgent maintenance requests?

Handling urgent maintenance requests requires a rapid and coordinated response. Upon receiving an urgent request, the first step is to quickly assess the situation and its potential impact. This often involves contacting the requestor directly to gather more information. Next, we dispatch the most appropriate technician, considering their skillset and availability. Sometimes this might require pulling a technician from another assignment if absolutely necessary. We also leverage real-time communication tools to keep all involved parties informed of the progress, including estimated arrival times and updates on the repair process. During the repair itself, we focus on the most efficient and safe resolution, even if it means temporarily using a workaround until a permanent solution can be implemented. For instance, if a critical server is down, we might prioritize getting a backup server online temporarily while the primary server is being repaired. After completion, we conduct a thorough follow-up to document the issue, the resolution, and any preventative measures needed to avoid future occurrences.

Q 4. What metrics do you use to track maintenance request efficiency?

Tracking maintenance request efficiency involves several key metrics. We monitor Mean Time To Repair (MTTR), which measures the average time taken to resolve a maintenance request. A lower MTTR indicates greater efficiency. We also track Mean Time Between Failures (MTBF), indicating the average time between equipment failures. A higher MTBF suggests better preventative maintenance practices. First Call Resolution (FCR) rate measures the percentage of requests resolved on the first attempt, highlighting the effectiveness of our diagnostic and repair processes. Finally, we monitor backlog, representing the number of outstanding requests. A consistent low backlog demonstrates efficient request processing. We use dashboards and reporting tools within our CMMS to visualize these metrics and identify areas for improvement. For example, if MTTR for a specific equipment type is consistently high, we can investigate whether additional training for technicians, better spare parts management, or improved diagnostic tools are needed.

Q 5. How do you ensure accurate documentation of maintenance requests?

Accurate documentation is crucial for efficient maintenance request processing. Our process relies on a well-defined system within the CMMS. Each request includes detailed information: problem description, location, priority level, assigned technician, repair timeline, photos/videos (if applicable), and a clear record of all actions taken. We use standardized templates and checklists to ensure consistency and completeness of the information. All communication regarding the request – emails, phone calls, notes from technicians – is also logged in the system. Regular audits are performed to ensure data integrity and accuracy. This detailed documentation provides valuable data for future analysis, preventative maintenance scheduling, and troubleshooting similar issues. Imagine a situation where a similar issue arises six months later. Access to detailed records allows for faster resolution since previous solutions and challenges are readily available, saving time and resources.

Q 6. Describe your experience with preventative maintenance scheduling.

Preventative maintenance scheduling is a core element of our strategy to minimize equipment downtime and extend its lifespan. We use the CMMS to build a comprehensive schedule based on manufacturers’ recommendations, historical data on equipment failures, and criticality assessments. We consider factors such as operating hours, environmental conditions, and the frequency of previous repairs to determine optimal maintenance intervals. The schedule includes various tasks – inspections, lubrication, cleaning, component replacements – tailored to specific equipment types. We allocate tasks to technicians based on their skills and availability. The CMMS provides automated reminders and alerts, ensuring adherence to the schedule. Regular reviews of the preventative maintenance program, analyzing its effectiveness, are crucial. For instance, if a particular preventative task consistently fails to prevent future failures, we might adjust the frequency, modify the task itself, or explore alternative approaches.

Q 7. How do you handle conflicting maintenance requests?

Handling conflicting maintenance requests necessitates careful planning and prioritization. When two or more requests compete for the same technician or equipment, we revert to our established prioritization system. The request with the highest priority, as determined by the urgency, impact, and cost factors, takes precedence. We communicate transparently with all requestors regarding the scheduling adjustments, providing rationale for the prioritization decisions. In some cases, it might be possible to adjust the schedule or combine related tasks to optimize resource utilization. If adjustments aren’t possible, we may need to allocate additional resources (e.g., an additional technician) or explore alternative solutions. Transparency and proactive communication are essential to avoid frustration and ensure all stakeholders understand the reasons behind the scheduling choices. In situations of extreme conflict, we engage management to aid in resolving the conflict and re-evaluating the request prioritization system itself, if necessary.

Q 8. How do you communicate with tenants or employees regarding maintenance requests?

Effective communication is paramount in maintenance request processing. I typically use a multi-pronged approach depending on the situation and tenant/employee preference. For routine requests, a user-friendly online portal is ideal. This allows for easy submission, tracking, and updates. I also utilize email confirmations and updates, ensuring everyone remains informed of the request status. For more urgent or complex issues, a direct phone call provides immediate clarification and allows for a more personal touch. In cases needing in-person communication, I’ll schedule a visit to discuss the issue and solution firsthand.

For example, if a tenant reports a leaky faucet through our online portal, I immediately acknowledge receipt, provide an estimated timeframe for repair, and then send further updates as the work progresses. If a critical issue like a power outage arises, a phone call is used to establish immediate contact and deploy the necessary personnel.

Q 9. What is your experience with generating maintenance reports?

Generating comprehensive maintenance reports is crucial for tracking performance, identifying trends, and improving operational efficiency. My experience includes using various software solutions to generate reports summarizing request volume, completion times, cost analysis, and technician performance metrics. I’m proficient in creating both standard reports, like monthly summaries, and custom reports tailored to specific needs, such as analyzing the frequency of specific types of repairs in a particular building.

For instance, I might generate a report showing that plumbing issues in Building A are significantly higher than in Building B, prompting further investigation into the root cause and preventative maintenance strategies. These reports are essential for justifying budget allocations and improving our overall maintenance planning.

Q 10. How do you manage a large volume of maintenance requests?

Managing a high volume of maintenance requests necessitates a structured and organized approach. This involves using a Computerized Maintenance Management System (CMMS), a software specifically designed to streamline maintenance operations. A CMMS allows for efficient prioritization of requests based on urgency and impact. It also facilitates task assignment to technicians, tracks progress, and generates reports. Furthermore, I employ a system of categorization and tagging to swiftly identify recurring issues or patterns, allowing for proactive solutions and preventative maintenance.

Think of it like an orchestra conductor managing multiple musicians. The CMMS is the score, providing structure and organization. Prioritization ensures that the most pressing issues are addressed first, much like a conductor focusing on the crucial sections of a symphony. Regular reporting acts as performance feedback, allowing for continuous improvement.

Q 11. Describe your experience with troubleshooting maintenance issues.

Troubleshooting is a significant part of maintenance work. My approach is systematic and methodical. It starts with gathering information from the requester – what’s the problem, when did it start, what has been tried already? Next, I utilize visual inspection, technical manuals, and diagnostic tools to pinpoint the root cause. This may involve testing electrical circuits, checking plumbing systems, or inspecting HVAC components. I then develop a solution, ensuring it addresses the underlying problem, not just the symptoms. My experience allows me to identify patterns and common issues, significantly reducing troubleshooting time.

For example, if a tenant reports intermittent power outages in their apartment, I wouldn’t just reset the circuit breaker. I’d systematically check the wiring, outlets, and appliances to identify the faulty component. This ensures a long-term fix and prevents recurrence.

Q 12. How do you ensure all maintenance requests are completed on time?

Ensuring timely completion of maintenance requests requires careful planning and execution. I prioritize requests based on urgency and impact, using a system that assigns realistic deadlines. Regular follow-ups with technicians are crucial to monitor progress and address any roadblocks. Effective communication with tenants keeps them informed and manages expectations. We use the CMMS to track Key Performance Indicators (KPIs) like average resolution times and on-time completion rates, allowing for continuous improvement and identification of bottlenecks.

We might set Service Level Agreements (SLAs) to ensure that urgent requests, such as plumbing leaks or electrical hazards, are addressed within a specific timeframe, while routine requests have slightly longer deadlines. This ensures efficient resource allocation and satisfies tenant needs.

Q 13. How do you handle maintenance requests outside of normal working hours?

Handling requests outside normal working hours necessitates a robust on-call system. This typically involves a designated team of technicians who are available for emergencies. The system should clearly define escalation procedures and communication protocols. We use a dedicated phone line and potentially a messaging system to ensure rapid response. The CMMS is configured to log and track these after-hours requests separately, allowing for analysis of emergency occurrences and resource planning.

For instance, a burst pipe at 2 am requires immediate attention, activating our on-call technician. The system ensures that the issue is documented, addressed promptly, and then integrated into the regular workflow for follow-up, such as repairs and potential preventative measures.

Q 14. What is your experience with inventory management related to maintenance?

Effective inventory management is essential for efficient maintenance operations. I have experience using inventory management software integrated with the CMMS to track the quantity, location, and condition of all maintenance supplies and parts. This includes regular stock checks, automated reordering systems, and cost tracking. This minimizes downtime caused by missing parts and optimizes procurement costs. It also aids in waste reduction by optimizing stock levels and preventing unnecessary purchases.

For example, tracking the number of specific HVAC filters and their usage allows for proactive ordering, preventing delays due to shortages. Regular stock checks also identify items nearing expiry or those which are damaged, thus reducing waste and ensuring the use of quality materials.

Q 15. Explain your approach to resolving customer complaints related to maintenance.

My approach to resolving customer complaints related to maintenance is methodical and customer-centric. It begins with active listening to fully understand the issue from the customer’s perspective. I aim to empathize with their frustration and assure them that their concern is being taken seriously.

Next, I meticulously document the complaint, including details such as the location, nature of the problem, urgency, and any relevant contact information. This detailed documentation ensures clear communication and efficient tracking throughout the resolution process.

Following documentation, I prioritize the complaint based on urgency and impact. Critical issues, like plumbing leaks or electrical malfunctions, receive immediate attention, while less urgent issues are handled according to a predetermined schedule. I then assign the issue to the appropriate technician or team, ensuring they possess the necessary skills and resources. Regular updates are provided to the customer, keeping them informed of progress and anticipated resolution time.

Finally, upon completion of the repair or maintenance, I follow up with the customer to confirm their satisfaction and address any remaining concerns. This feedback loop is crucial for continuous improvement and identifying potential systemic problems. For example, if a similar complaint arises multiple times, it might indicate a need for preventative maintenance or process improvements.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with different types of maintenance (preventive, corrective, etc.)?

I’m very familiar with various types of maintenance, including preventative, corrective, predictive, and scheduled maintenance. Each plays a critical role in maintaining optimal operational efficiency and extending the lifespan of assets.

- Preventive Maintenance (PM): This involves regularly scheduled inspections and servicing to prevent equipment failures. Think of it like changing your car’s oil – it’s proactive and prevents larger, more costly repairs down the line. Examples include regularly cleaning HVAC filters or lubricating machinery.

- Corrective Maintenance (CM): This addresses equipment failures after they occur. It’s reactive, dealing with the problem once it arises. For instance, repairing a broken refrigerator compressor after it stops working.

- Predictive Maintenance (PdM): This utilizes technology like sensors and data analytics to anticipate potential failures before they happen. By monitoring equipment performance and identifying patterns, we can schedule maintenance proactively, minimizing downtime and optimizing maintenance schedules. An example is using vibration sensors on machinery to predict bearing failures.

- Scheduled Maintenance: This is a planned maintenance activity performed at predefined intervals or based on usage. It combines elements of preventive and corrective maintenance based on a well-defined schedule for asset maintenance and management. For example, periodic inspections of fire safety equipment or annual HVAC system checkups.

Q 17. How do you identify and address recurring maintenance issues?

Identifying and addressing recurring maintenance issues requires a systematic approach. The first step is tracking maintenance requests using a robust system, which allows us to identify patterns and trends.

Once recurring issues are identified, a root cause analysis (RCA) is conducted. This involves systematically investigating the underlying cause of the problem, rather than just addressing the symptoms. Techniques like the ‘5 Whys’ can be used to drill down to the root cause. For example, if we repeatedly receive complaints about low water pressure in a specific building, we’d investigate factors like pipe corrosion, pump efficiency, or water main pressure.

Following the RCA, appropriate corrective actions are implemented, which may involve repairs, upgrades, or changes to operational procedures. For example, we might replace corroded pipes, upgrade a faulty pump, or implement a preventative maintenance schedule for regular pipe inspections. Finally, we monitor the effectiveness of the corrective actions to ensure the problem is resolved and doesn’t reappear. This involves regular tracking and analysis of maintenance requests to ensure the problem is definitively resolved and doesn’t reappear.

Q 18. Describe your experience with using mobile applications for maintenance requests.

I have extensive experience using mobile applications for maintenance requests. These apps significantly streamline the process, improving communication and efficiency.

Features I find most valuable include the ability for customers to easily submit requests with photos and descriptions, real-time tracking of requests, direct communication between customers and technicians, and automated notifications for updates and scheduling. For example, a tenant can submit a maintenance request for a leaky faucet through an app, upload a photo, and receive immediate acknowledgement and estimated time of arrival from a technician. The app allows for the technician to confirm completion and the customer to rate the service.

Furthermore, mobile apps often integrate with the back-end maintenance management system, providing a centralized platform for managing all requests, scheduling tasks, and generating reports. This integration provides an efficient, transparent, and comprehensive overview of all maintenance activities.

Q 19. How do you collaborate with other departments to resolve maintenance issues?

Effective collaboration with other departments is essential for resolving maintenance issues efficiently. I regularly collaborate with departments such as procurement for sourcing necessary parts, engineering for complex technical issues, and accounting for budget approvals and cost tracking.

For example, if a major HVAC system malfunction requires a replacement part, I would collaborate with procurement to expedite the ordering process. If the issue is technically complex and requires specialized expertise, I would consult with engineering. And, I would work with the accounting department to ensure the necessary budget is allocated and to monitor expenses related to the repair.

Clear and consistent communication is key to this collaboration. I ensure all parties involved have the necessary information, understand their roles and responsibilities, and are kept updated on progress. This collaborative approach ensures timely resolution and optimized resource allocation.

Q 20. How do you ensure compliance with safety regulations during maintenance tasks?

Ensuring compliance with safety regulations during maintenance tasks is paramount. My approach involves several key steps.

First, all technicians are thoroughly trained on relevant safety regulations and procedures, including the use of personal protective equipment (PPE), proper lockout/tagout procedures for electrical and mechanical equipment, and hazard identification and risk assessment.

Secondly, I ensure that all maintenance tasks are planned and executed according to established safety protocols. This includes regular safety inspections of work areas and equipment, and the use of appropriate safety equipment and procedures.

Thirdly, I maintain comprehensive documentation of safety training, inspections, and incident reports. This documentation provides a clear record of compliance and facilitates continuous improvement of safety practices. Finally, I promote a strong safety culture by encouraging open communication and proactive reporting of safety concerns. For instance, before any major maintenance task, a detailed safety plan is developed and approved, and the work is overseen to ensure adherence to safety protocols. This includes making sure work permits are properly issued.

Q 21. Describe your experience with budgeting and cost control for maintenance activities.

My experience with budgeting and cost control for maintenance activities includes developing and managing maintenance budgets, tracking expenses, and identifying cost-saving opportunities.

I begin by creating a detailed budget that considers factors such as the type and frequency of maintenance, costs of materials and labor, and potential unforeseen expenses. This budget is regularly reviewed and updated based on actual expenses and changing needs.

To ensure cost control, I track expenses carefully and identify potential areas for savings. This might involve negotiating better prices with suppliers, optimizing maintenance schedules to reduce downtime, and implementing preventative maintenance programs to reduce the need for costly repairs. For example, by implementing a predictive maintenance program for our HVAC systems, we have been able to proactively identify and fix minor issues before they become major and costly breakdowns.

Regular reporting and analysis of maintenance costs provide insights into spending patterns, allowing for informed decisions about resource allocation and future budget planning. By leveraging data-driven insights, we can make strategic decisions to enhance efficiency and cost-effectiveness of maintenance operations.

Q 22. What is your experience with data analysis related to maintenance performance?

Data analysis is crucial for optimizing maintenance performance. I leverage data to identify trends, predict potential failures, and improve resource allocation. My experience involves analyzing historical maintenance data to pinpoint recurring issues, assess the effectiveness of preventative maintenance programs, and measure technician performance. For example, I might analyze the frequency of requests for a specific piece of equipment to determine if preventative maintenance is insufficient or if the equipment itself needs to be replaced. I use tools like Excel, SQL, and specialized CMMS (Computerized Maintenance Management System) software to analyze data, creating visualizations like charts and dashboards to communicate key findings to stakeholders. This data-driven approach helps us make informed decisions regarding budget allocation, staffing, and preventative maintenance schedules, ultimately leading to cost savings and improved efficiency.

Specifically, I’ve used statistical methods like regression analysis to predict equipment failure rates based on factors like age and usage. This allows for proactive maintenance, preventing costly downtime.

Q 23. How do you utilize technology to improve maintenance request processing?

Technology significantly enhances maintenance request processing. We utilize a CMMS, which centralizes all requests, tracks their status, manages work orders, and schedules maintenance activities. This system automates many manual tasks, reducing errors and improving response times. For instance, our CMMS integrates with our building access system, enabling technicians to gain access seamlessly. Furthermore, mobile applications allow technicians to access and update work orders in real-time, improving communication and accountability. We also use data analytics dashboards within the CMMS to monitor key performance indicators (KPIs) like request resolution time and technician productivity. This data drives continuous improvement initiatives.

Beyond the CMMS, we utilize other technologies like IoT (Internet of Things) sensors on critical equipment. These sensors monitor equipment health and provide early warnings of potential problems, enabling proactive maintenance and minimizing unexpected failures. Imagine sensors on HVAC units alerting us to potential issues before they lead to a system failure, allowing us to schedule maintenance during off-peak hours. This improves uptime and reduces disruptions to building occupants.

Q 24. How do you handle requests that require specialized skills or equipment?

Requests requiring specialized skills or equipment are handled through a multi-step process. First, the request is carefully reviewed to identify the specific expertise and equipment needed. Then, we consult our internal team to determine if we have the necessary resources in-house. If not, we engage external contractors or vendors with the required expertise. Our CMMS facilitates this process, providing a structured workflow for subcontractor management, including bidding, scheduling, and payment processing. We maintain a pre-qualified vendor database, ensuring that all outsourced work meets our quality standards. Clear communication channels are established with both internal and external personnel to ensure transparency and efficient resolution of the request.

For example, a request involving complex HVAC repairs might require a specialized contractor with certification in handling refrigerants. We would leverage our pre-qualified vendor list, obtain multiple quotes, and then select the best contractor based on price, reputation, and availability. The entire process is meticulously documented within our CMMS, maintaining a comprehensive audit trail.

Q 25. How do you manage escalated maintenance requests?

Escalated maintenance requests, typically those involving critical system failures or significant safety hazards, require immediate attention. Our process begins with identifying the severity of the issue and assigning it a priority level. Senior management is immediately notified of critical issues. A dedicated team is responsible for coordinating the response, assigning skilled technicians, and securing necessary resources. We use a structured escalation matrix, outlining the reporting hierarchy and communication protocols. Regular updates are provided to stakeholders throughout the resolution process, ensuring transparency and minimizing disruption.

Effective communication is paramount. We utilize various communication tools including email, phone calls, and even on-site meetings to keep everyone informed and aligned. After the issue is resolved, a thorough root cause analysis is performed to prevent similar incidents in the future. This analysis is documented, and recommendations are implemented to improve our maintenance processes and prevent future escalation.

Q 26. Describe a time you had to prioritize multiple urgent maintenance requests.

During a severe winter storm, we experienced multiple urgent maintenance requests simultaneously: a burst pipe in a critical building zone, a power outage affecting several offices, and a malfunctioning HVAC system in a server room. To prioritize, we used a risk assessment matrix, evaluating the potential impact of each issue on building operations and safety. The server room HVAC malfunction was prioritized highest due to the risk of data loss, followed by the burst pipe to prevent water damage, and then the office power outage.

We mobilized multiple teams, assigning each a specific task based on their expertise. The CMMS was critical in coordinating resources and tracking progress. Clear communication was maintained throughout the process, keeping all stakeholders updated on the status of each request. Through efficient coordination and effective prioritization, we managed to resolve all issues within a reasonable timeframe, minimizing disruption and preventing significant damage. This experience reinforced the importance of proactive planning, thorough risk assessment, and robust communication in managing multiple urgent requests.

Q 27. Explain your experience with different maintenance request tracking methods.

I have experience with various maintenance request tracking methods, ranging from simple spreadsheets to sophisticated CMMS software. In my earlier roles, I used spreadsheets to log requests, track their status, and generate basic reports. While functional for smaller organizations, this approach lacked the features and scalability of a dedicated CMMS. Spreadsheets are prone to errors, difficult to share and collaborate on, and don’t offer advanced analytics or reporting.

Currently, we utilize a robust CMMS, which provides significant advantages. The system automates work order generation, tracks progress, manages inventory, and generates comprehensive reports. The CMMS offers functionalities such as automated notifications, real-time dashboards for monitoring KPIs, and integration with other business systems. Moreover, it enables efficient collaboration among technicians, supervisors, and other stakeholders. The shift from spreadsheets to a CMMS has significantly improved our efficiency, reduced errors, and enhanced our ability to analyze maintenance performance data. The CMMS has been a crucial tool in our move towards data-driven decision-making in maintenance management.

Key Topics to Learn for Maintenance Request Processing Interview

- Understanding the Maintenance Request Lifecycle: From initial submission to completion, grasp the entire process, including prioritization, assignment, and closure.

- Request Categorization and Prioritization: Learn how to effectively categorize requests (e.g., urgent, routine, preventative) and prioritize based on urgency and impact.

- Using CMMS (Computerized Maintenance Management Systems): Familiarize yourself with various CMMS software and their functionalities in managing maintenance requests. Practice navigating interfaces and data entry.

- Communication and Collaboration: Master effective communication with technicians, residents/tenants, and supervisors. Understand the importance of clear and concise reporting.

- Data Analysis and Reporting: Learn how to generate reports on maintenance request trends, identify areas for improvement, and track key performance indicators (KPIs).

- Problem-solving and Troubleshooting: Develop your ability to analyze problems described in requests, identify potential solutions, and escalate complex issues appropriately.

- Workflow Optimization: Explore strategies for streamlining the maintenance request process, reducing turnaround times, and improving efficiency.

- Compliance and Regulations: Understand relevant safety regulations and compliance requirements related to maintenance and repair procedures.

Next Steps

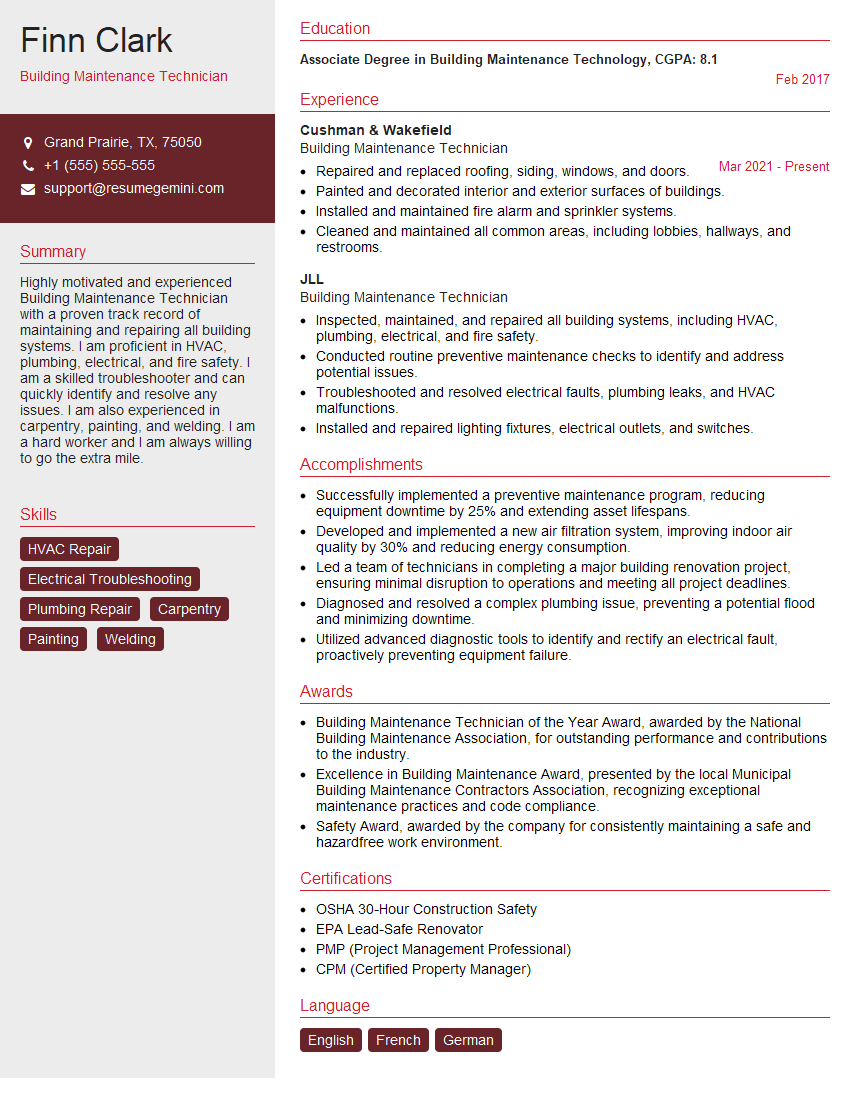

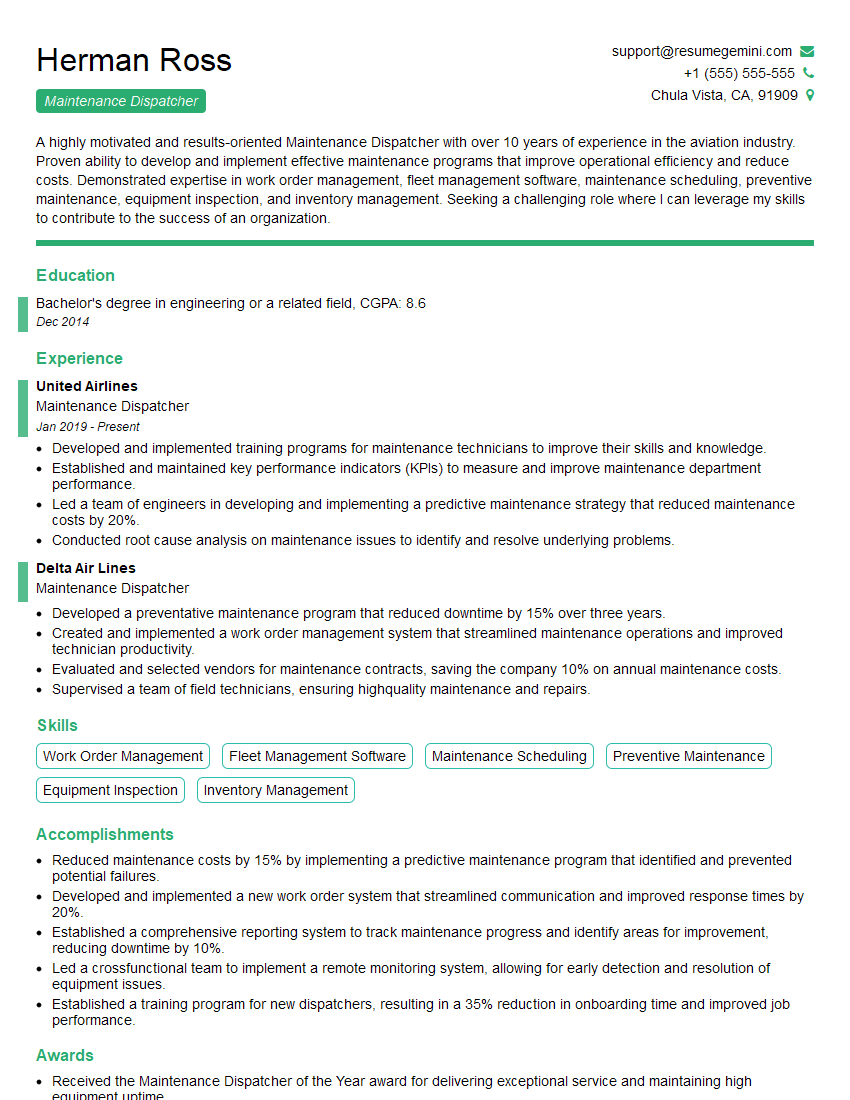

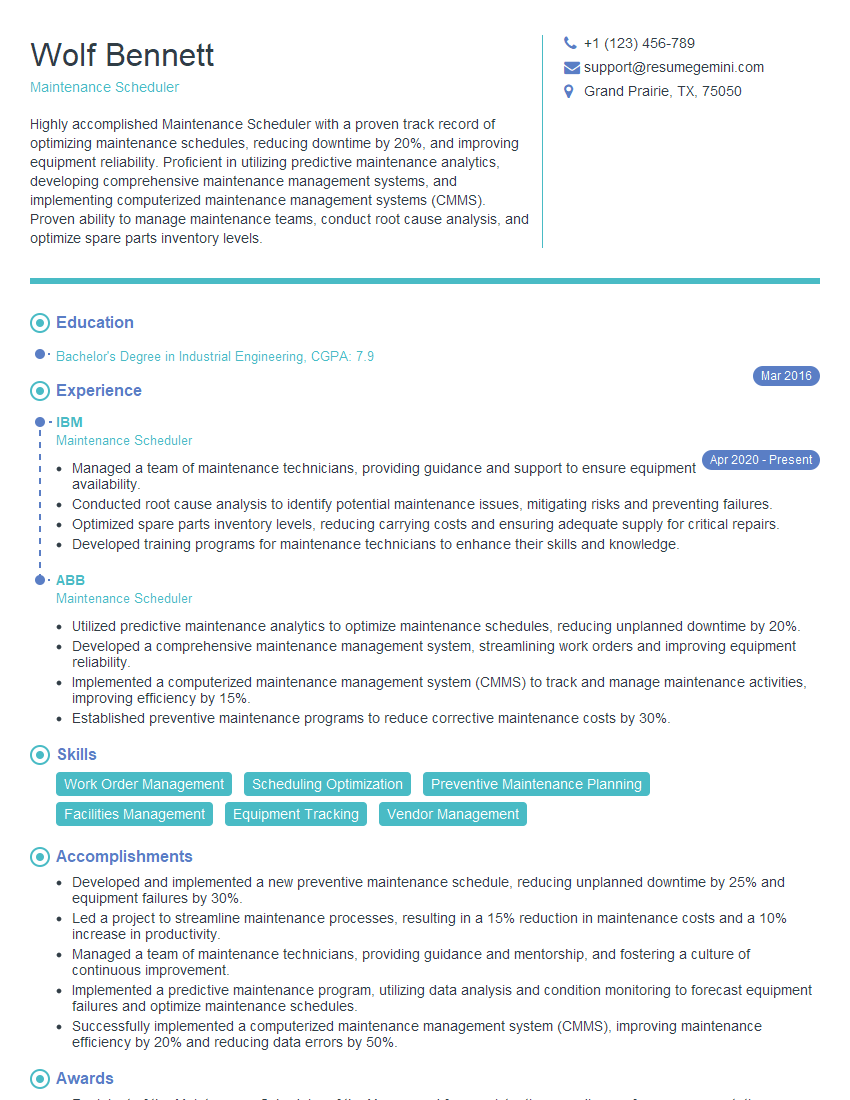

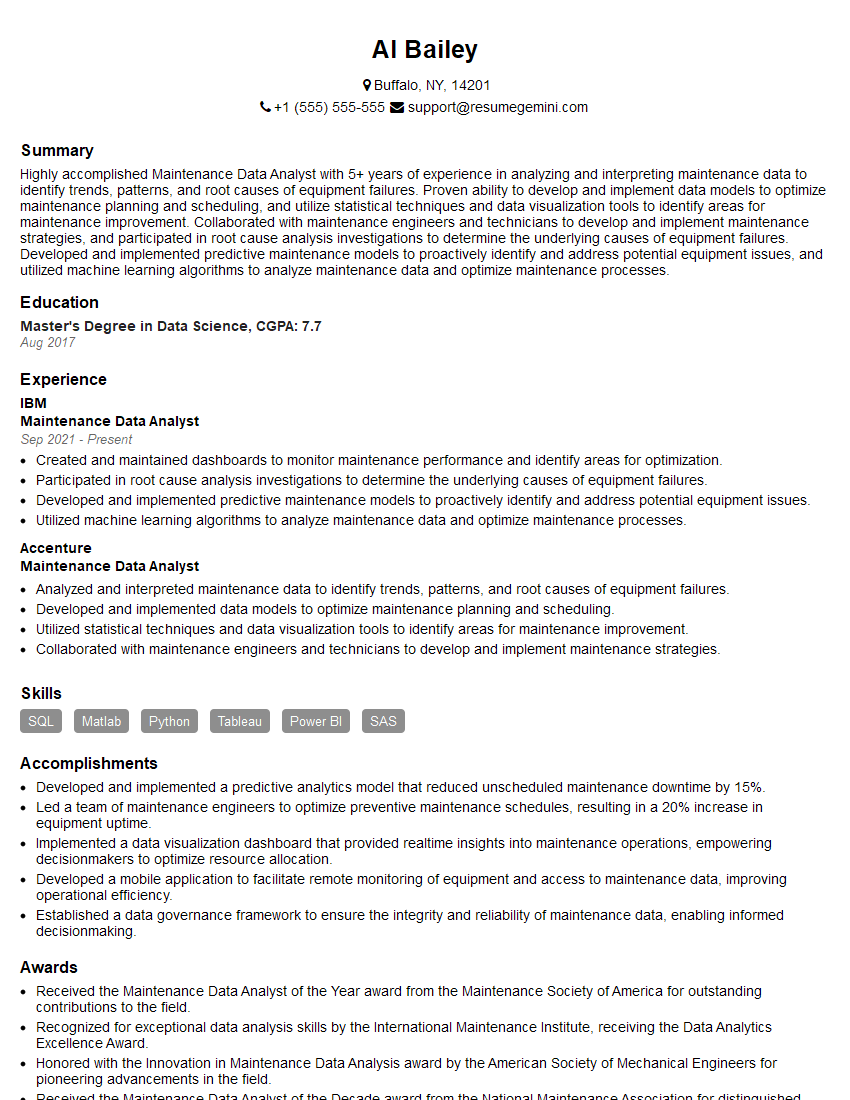

Mastering Maintenance Request Processing opens doors to exciting career opportunities in facilities management, property management, and other related fields. A strong understanding of this process demonstrates valuable organizational, communication, and problem-solving skills highly sought after by employers. To maximize your job prospects, it’s crucial to create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored to Maintenance Request Processing to guide you in crafting a compelling application that showcases your abilities. Take the next step towards your dream job today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO