The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Bolt Assembly interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Bolt Assembly Interview

Q 1. What are the different types of bolts used in assembly?

The world of bolts is surprisingly diverse! Choosing the right bolt depends heavily on the application. Here are some common types:

- Machine Bolts: These are typically used with nuts and washers, offering a strong and reliable fastening solution for a wide range of applications. Think of them as the workhorses of the bolt world.

- Carriage Bolts: These have a rounded head and are often used in applications where a smooth, finished look is desired. They’re frequently found in wooden structures or where the bolt head is visible.

- Hex Bolts: Characterized by their hexagonal head, hex bolts offer excellent grip for wrenches, making them ideal for high-torque applications. Their strength and versatility make them extremely common.

- Eye Bolts: These bolts have a loop or eye at the end, designed for lifting or attaching a load. Safety is paramount here, so proper load ratings must be considered.

- Shoulder Bolts: These have a cylindrical shoulder beneath the head, useful when precise positioning is needed. They’re often seen in mechanical assemblies where alignment is critical.

- Set Screws: These don’t use nuts; instead, they are tightened directly into a threaded hole, often used to secure components onto a shaft.

The choice depends on factors such as material strength required, aesthetic considerations, ease of installation, and the nature of the joint.

Q 2. Explain the torque specifications and their importance.

Torque specifications are crucial; they dictate the amount of rotational force applied to tighten a bolt. Think of it like this: too little torque, and the joint might loosen and fail; too much, and you risk stripping the threads or damaging the materials. Torque specifications are usually given in pound-feet (lb-ft) or Newton-meters (Nm).

The importance stems from ensuring the joint’s integrity. Proper torque prevents loosening due to vibration or stress, ensuring the parts remain securely fastened. Incorrect torque can lead to catastrophic failures in various applications, from minor inconveniences to major safety hazards in automotive, aerospace, and industrial settings.

Torque specifications are usually found in engineering drawings, assembly manuals, or manufacturer’s documentation. Always consult these documents to avoid potentially disastrous mistakes.

Q 3. Describe the process of tightening bolts to prevent stripping.

Preventing bolt stripping requires careful attention to technique. Here’s a step-by-step process:

- Use the Correct Tool: Choose a wrench or socket that precisely fits the bolt head. Using an ill-fitting tool can easily damage the bolt.

- Apply Lubricant: A thin layer of appropriate lubricant reduces friction and allows for more controlled tightening, lessening the chances of stripping.

- Gradual Tightening: Tighten the bolt in stages, not with one forceful turn. This ensures even pressure distribution and avoids stress concentrations.

- Torque Wrench (When Necessary): For critical applications, a torque wrench is indispensable. It ensures that the bolt is tightened to the precise torque specification, eliminating guesswork and preventing over-tightening.

- Check for Alignment: Before tightening, ensure that the components are properly aligned to prevent binding and uneven stress on the bolt.

Think of it like this: gradually increasing the pressure is like slowly inflating a balloon—controlled and steady. A sudden burst of force is akin to popping the balloon—a stripped bolt.

Q 4. How do you identify and address a stripped bolt?

Identifying a stripped bolt is relatively straightforward – you’ll notice the threads are damaged or worn, making it difficult to tighten or hold the nut securely. The bolt might spin freely without tightening.

Addressing a stripped bolt depends on the severity and location:

- Minor Stripping: Sometimes, a slightly stripped bolt can be salvaged using a thread repair kit or helicoil insert. These restore the threads, providing a new secure fastening point.

- Severe Stripping: If the damage is extensive, the bolt needs replacing. It’s crucial to use a replacement bolt with the correct specifications.

- Strategic Replacement: Consider if the location of the stripped bolt allows for replacing the entire component rather than just the bolt. Sometimes this is a more efficient and reliable solution.

Prevention is always better than cure. Careful tightening techniques and using appropriately sized tools minimize the risk of stripped bolts.

Q 5. What are the common causes of bolt failure?

Bolt failure can stem from several factors, often working in combination:

- Over-tightening: This is a primary cause; excessive torque stresses the bolt beyond its yield strength, leading to fracture or stripping.

- Corrosion: Rust and other forms of corrosion weaken the bolt’s material, reducing its strength and making it susceptible to failure.

- Fatigue: Repeated cyclic loading, such as vibrations in machinery, gradually weakens the bolt until it fails.

- Improper Lubrication: Lack of lubrication increases friction and leads to uneven stress distribution and premature failure.

- Incorrect Bolt Selection: Using a bolt with inadequate strength or improper material for the application can lead to failure under stress.

- Environmental Factors: Extreme temperatures or corrosive environments can accelerate bolt degradation and failure.

Understanding these causes is essential for implementing preventative measures and ensuring reliable bolted joints.

Q 6. Explain the importance of proper bolt lubrication.

Proper bolt lubrication is critical for several reasons:

- Reduced Friction: Lubrication minimizes friction between the bolt threads and mating surfaces. This allows for more even torque distribution, reducing the risk of over-tightening and stripping.

- Improved Torque Accuracy: With less friction, the torque wrench provides a more accurate measure of the applied force.

- Corrosion Prevention: Lubricants act as a barrier, protecting the bolt from environmental factors that can lead to corrosion and premature failure.

- Easier Assembly and Disassembly: Lubrication makes it easier to assemble and disassemble bolted joints, saving time and effort.

The type of lubricant depends on the application and environmental conditions; some common choices include anti-seize compounds, specialized thread locking fluids, or even simple grease. Consult relevant standards and specifications for guidance.

Q 7. How do you ensure the correct bolt is used for a specific application?

Ensuring the correct bolt is used involves a multi-step process:

- Consult Engineering Drawings: These drawings explicitly state the bolt’s material, grade, size, and length. This is the primary source of information.

- Material Compatibility: The bolt material must be compatible with the materials being fastened to prevent galvanic corrosion.

- Strength Requirements: The bolt’s tensile strength must meet or exceed the load requirements of the application. Using a weaker bolt is a recipe for disaster.

- Thread Type and Pitch: The bolt’s thread type (e.g., metric or unified) and pitch must match the threaded hole. Incompatible threads can lead to cross-threading and failure.

- Length and Grip: The bolt must be long enough to provide sufficient grip length when tightened. Insufficient grip weakens the joint significantly.

Using incorrect bolts can lead to loosening, failure, and safety hazards. Always double-check specifications; accuracy is non-negotiable when dealing with critical fastening.

Q 8. Describe your experience with different types of bolt tightening tools.

My experience encompasses a wide range of bolt tightening tools, from simple hand tools to sophisticated power tools. I’m proficient with various wrenches, including open-end, box-end, combination, and socket wrenches, selecting the appropriate type based on the bolt size, accessibility, and required torque. For higher torque applications, I’ve extensively used torque wrenches – both mechanical and electronic – ensuring precise tightening to prevent over-tightening or under-tightening. My experience also includes pneumatic and hydraulic impact wrenches for high-volume or difficult-to-access applications. I understand the importance of calibrating torque wrenches regularly to maintain accuracy and prevent damage. For instance, during assembly of a large-scale industrial structure, we used hydraulic torque wrenches to guarantee the consistent tension of critical bolts that would experience high stress and strain.

- Hand Wrenches: Essential for smaller bolts and situations where precision is key.

- Torque Wrenches: Crucial for ensuring the correct amount of tension on the bolt, preventing damage.

- Impact Wrenches: Ideal for high-volume applications and those involving stubborn fasteners.

Q 9. What safety precautions do you follow when working with bolts?

Safety is paramount in any bolt assembly operation. My safety protocols begin with a thorough risk assessment of the job, identifying potential hazards like falling objects, pinched fingers, or electrical shocks. I always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and steel-toed boots. When working with power tools, I ensure the area is clear of obstructions and that the tools are in good working order and properly maintained. I never attempt to force a bolt; instead, I use the correct tool and technique to avoid injury. Furthermore, I’m always aware of my surroundings and follow all company safety regulations and procedures. For example, while working on an overhead structure, we implemented fall protection systems in addition to all standard PPE.

- PPE: Safety glasses, gloves, and steel-toed boots are mandatory.

- Tool Inspection: Always check tools for damage before use.

- Safe Work Practices: Follow all company safety procedures and guidelines.

Q 10. How do you handle damaged or defective bolts?

Damaged or defective bolts are never reused. Identifying a damaged bolt involves careful visual inspection for signs of bending, cracking, galling (surface damage), or significant corrosion. Even minor damage can compromise the bolt’s strength and integrity, potentially leading to failure. If a bolt shows any signs of damage, it is immediately discarded and replaced with a new one that meets the specified material and dimensional requirements. I maintain detailed records of all rejected bolts, including their serial numbers, condition, and the reason for rejection. This meticulous documentation is crucial for quality control and traceability. For instance, during a critical aircraft maintenance project, a single damaged bolt was discovered and subsequently documented. The meticulous process meant it never threatened the structural integrity.

- Visual Inspection: Check for bending, cracking, galling, or corrosion.

- Replacement: Damaged bolts are always replaced with new, compliant parts.

- Documentation: Maintain records of all rejected bolts.

Q 11. Explain your experience with bolt assembly procedures and documentation.

My experience with bolt assembly procedures and documentation is extensive. I’m familiar with various industry standards and specifications, ensuring adherence to best practices throughout the process. I meticulously follow assembly drawings, torque specifications, and lubrication requirements. Each step is documented thoroughly, including the type and size of bolts, torque values applied, and any deviations from the planned procedure. This documentation ensures traceability and allows for easy troubleshooting or analysis in case of issues. For example, on a recent project assembling a complex robotic system, detailed documentation of each step, including torque values and bolt identification numbers, allowed us to perform future repairs and maintenance in an organized manner.

- Adherence to Standards: Following relevant industry standards and specifications.

- Meticulous Documentation: Recording each step of the assembly process.

- Traceability: Ensuring easy tracking of components and processes.

Q 12. What are the different types of bolt head designs?

Bolt head designs vary significantly depending on the application and required functionality. Some common types include:

- Hexagonal Head: The most common type, offering six flat sides for wrench engagement.

- Square Head: Similar to hexagonal, but with four sides, often used in less demanding applications.

- Fillister Head: A low-profile head with a cylindrical top, often used where head clearance is limited.

- Button Head: A very low-profile head with a rounded top.

- Pan Head: A slightly countersunk head with a domed top.

- Countersunk Head: A head that sits flush with or slightly below the surface.

The choice of head design is crucial for factors like accessibility, torque transfer, and the overall aesthetic of the assembly. For instance, countersunk heads are ideal for applications requiring a flush surface, whereas hexagonal heads provide a better grip for wrenches.

Q 13. How do you determine the correct bolt length for a given application?

Determining the correct bolt length is crucial for proper function and safety. It’s more than just ensuring the bolt reaches through the components; sufficient thread engagement is vital. This involves considering the thickness of the materials being joined, the type of nut and washer used, and the required thread engagement length. The general rule is to have at least two-thirds of the bolt’s threaded portion engaged in the material. To calculate the precise length, I would typically refer to engineering drawings and specifications and account for all factors (thread length, material thickness, head height, nut thickness, washer thickness). For example, while working on a bridge structure, the bolt length was critical to ensure sufficient structural integrity, and miscalculation could have jeopardized safety.

- Material Thickness: The total thickness of the materials being joined.

- Thread Engagement: Ensuring sufficient thread engagement for adequate strength.

- Engineering Drawings: Referencing detailed assembly drawings and specifications.

Q 14. Explain the concept of preload in bolt tightening.

Preload in bolt tightening refers to the initial tension applied to the bolt before any external load is applied. It’s a crucial concept because it’s this preload that primarily resists the external forces acting on the joint. Think of it like stretching a rubber band; the tension you put in it before attaching it to objects is what holds those objects together. By creating this preload, we effectively clamp the joined parts together, increasing the friction and preventing relative movement between the components. Insufficient preload can lead to loosening and failure under load, while excessive preload can damage the components or the bolt itself. Achieving the correct preload depends on factors like bolt material, size, and the desired clamping force and requires careful torque control.

- Clamping Force: The force that holds the joined components together.

- Torque Control: Precise tightening to achieve the correct preload.

- Material Properties: Bolt material and component characteristics influence the required preload.

Q 15. Describe your experience working with automated bolt tightening systems.

My experience with automated bolt tightening systems spans over eight years, encompassing various applications from automotive manufacturing to heavy machinery assembly. I’ve worked extensively with systems ranging from simple, single-spindle units to complex, multi-spindle robotic systems capable of handling diverse bolt sizes and tightening torques. I’m proficient in programming and troubleshooting these systems, ensuring optimal performance and consistent torque accuracy. For example, in a recent project involving the assembly of engine blocks, I integrated a new automated system that reduced assembly time by 30% while simultaneously improving torque consistency and eliminating human error in the process. This involved careful calibration of the system’s torque sensors and fine-tuning the tightening sequences to optimize for speed and accuracy.

My expertise also extends to integrating these automated systems into larger manufacturing processes, ensuring seamless data transfer and integration with other quality control systems. I’m familiar with various communication protocols, including ProfiNet and EtherCAT, enabling efficient data acquisition and analysis for process optimization.

Career Expert Tips:

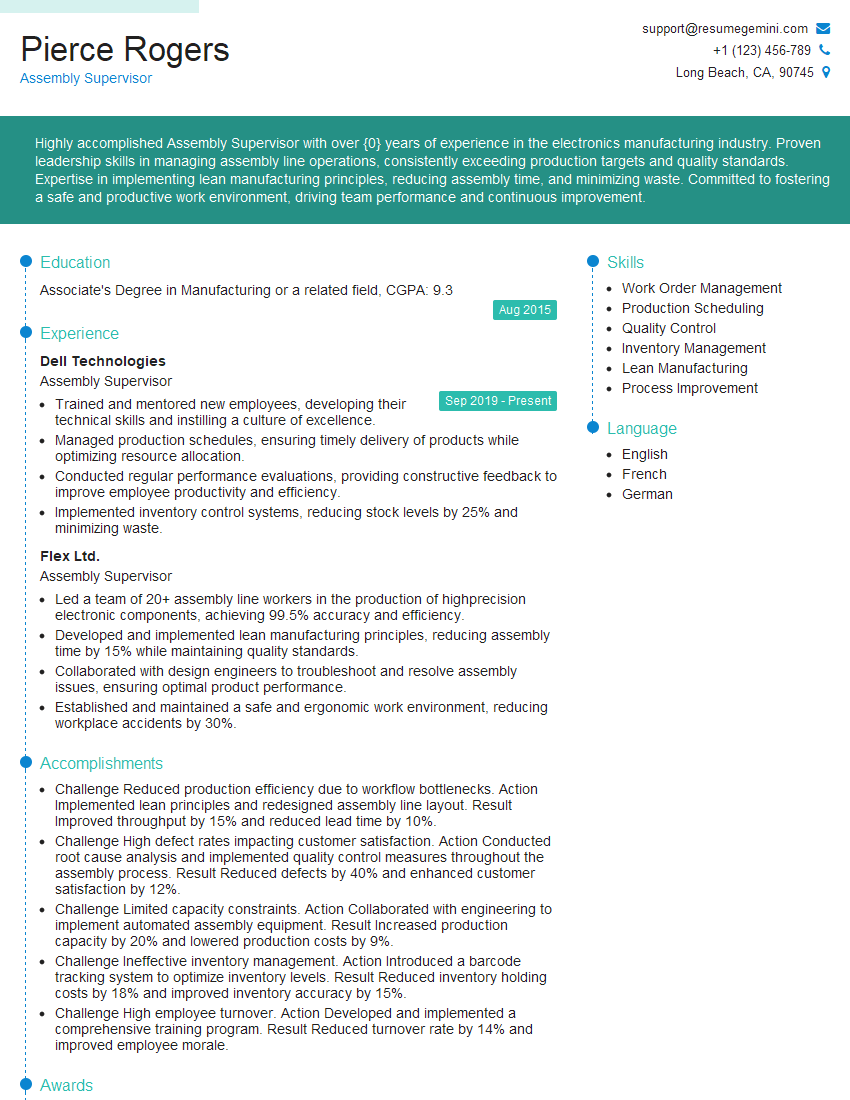

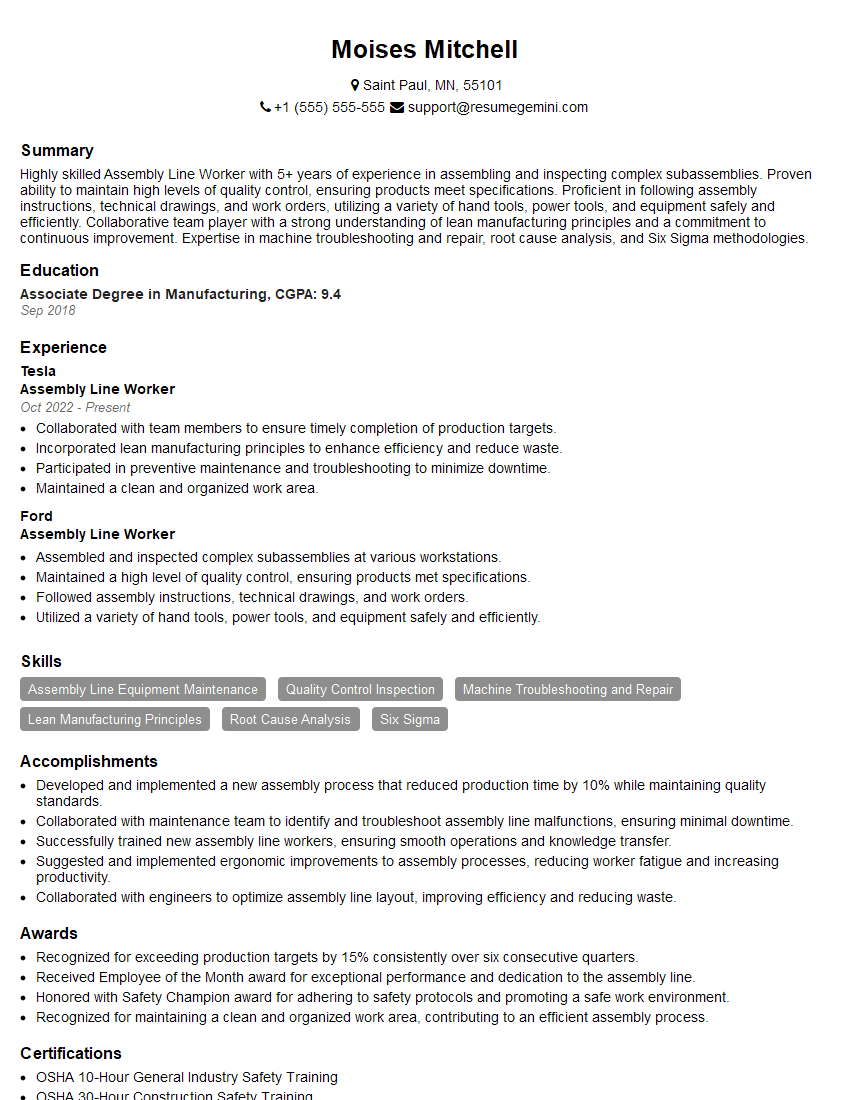

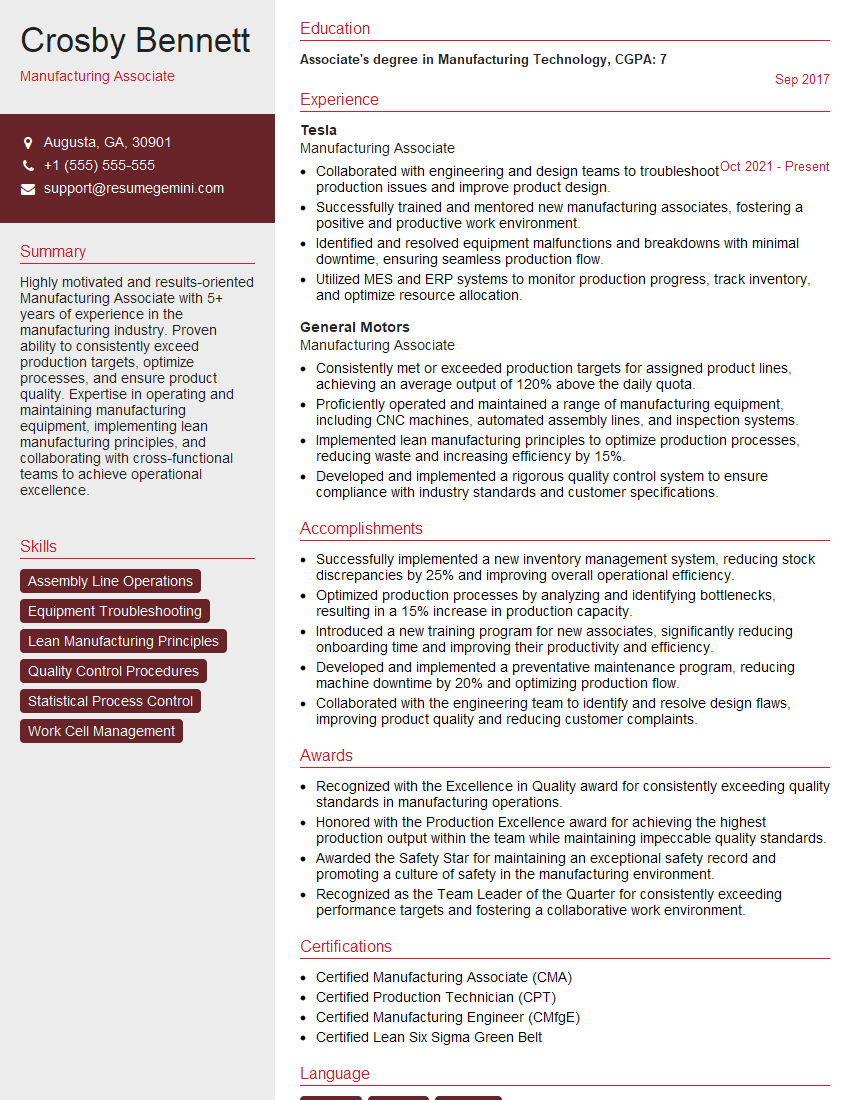

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you identify and resolve discrepancies in bolt assembly?

Identifying discrepancies in bolt assembly requires a multi-faceted approach. It starts with a thorough understanding of the assembly specifications, including required torque values, preload requirements, and material properties. I use a combination of methods to pinpoint inconsistencies. This includes visual inspection for damaged bolts or misaligned components, torque verification using calibrated torque wrenches or digital systems, and non-destructive testing techniques like ultrasonic testing to assess the integrity of the bolt and its connection. Discrepancies are often caused by human error, faulty equipment, or material defects.

Resolving these discrepancies involves systematic troubleshooting. For instance, if torque values are consistently low, I’d check the tightening tools for calibration issues, inspect bolts for defects, and investigate potential issues with the clamping surfaces or joint geometry. If the issue stems from a systematic problem with the tightening process, it may require adjustments to the automated system’s parameters or even a redesign of the assembly process. Thorough documentation throughout this entire process is vital for future reference and preventing recurrence.

Q 17. What is your experience with different types of bolt materials?

My experience encompasses a wide range of bolt materials, including carbon steel, stainless steel (various grades), alloy steel, and even specialized materials like titanium or inconel for high-temperature or corrosive environments. Understanding the properties of each material is crucial for selecting appropriate tightening procedures. For instance, stainless steel bolts might require higher torque values to achieve the same preload as carbon steel bolts due to their higher yield strength. Similarly, the risk of galling (metal-to-metal seizure) needs to be considered when using certain stainless steel alloys.

I’m adept at reading material specifications and interpreting data sheets to select the correct bolt material based on the specific application demands. This ensures the assembly can withstand anticipated loads and environmental conditions. I’ve used my knowledge of material properties to solve several challenges related to bolt failure in the field, often tracing it back to an inappropriate material choice for the given environment.

Q 18. How do you maintain the quality of bolt assembly work?

Maintaining quality in bolt assembly is a continuous process, starting with meticulous planning and extending to rigorous testing and monitoring. It begins with using high-quality materials and reliable equipment. Regular calibration of torque wrenches and automated systems is essential to ensure consistent tightening to specifications. I always adhere to strict quality control protocols, including 100% inspection for critical assemblies, statistical sampling for high-volume production, and detailed documentation of every step in the process.

Further quality assurance measures include implementing preventative maintenance schedules for equipment, operator training programs focusing on proper techniques and safety, and proactive investigation of any reported defects. By closely monitoring key metrics such as torque values, tightening times, and failure rates, I can identify potential problems early and take corrective actions to minimize defects and ensure long-term product reliability.

Q 19. What are some common challenges in bolt assembly, and how do you overcome them?

Common challenges in bolt assembly often involve issues with inconsistent torque, damaged threads, improper preload, and material incompatibility. Inconsistent torque can result from faulty equipment, operator error, or variations in material properties. Damaged threads may lead to premature failure and require careful inspection and replacement of affected bolts. Insufficient preload, which is the clamping force exerted on the joint, can result in loosening and potential failure of the assembly under load. Finally, using incompatible materials can lead to galling or corrosion, compromising the integrity of the connection.

I tackle these issues using a multi-pronged approach. For inconsistent torque, I thoroughly check equipment calibration and operator training, sometimes adding additional process controls. Damaged threads require careful examination of the cause (e.g., cross-threading, improper lubrication) and replacement with correctly sized and lubricated bolts. To ensure adequate preload, I may need to adjust the tightening procedure or use specialized techniques like angle tightening. Material incompatibility requires selecting compatible materials based on compatibility charts and environmental conditions.

Q 20. Explain your experience with preventative maintenance of bolt tightening equipment.

Preventative maintenance of bolt tightening equipment is crucial for ensuring its reliability and accuracy. My experience includes developing and implementing comprehensive maintenance schedules that cover routine checks, lubrication, and calibration. This involves regular inspection of torque wrenches for damage or wear, verification of calibration accuracy using traceable standards, and lubrication of moving parts to minimize friction and wear. Automated systems require more involved maintenance, including software updates, sensor checks, and periodic system diagnostics.

I create detailed maintenance logs, tracking all servicing activities and calibration results. This allows me to identify trends and predict potential failures, minimizing downtime and ensuring the long-term performance of the equipment. Following a well-defined maintenance schedule and meticulous record-keeping is essential to prevent costly breakdowns and ensure the quality of our bolt assembly processes. For example, we instituted a predictive maintenance program on our automated system using vibration sensors, which led to a 50% reduction in unexpected downtime.

Q 21. Describe a time you had to troubleshoot a bolt assembly issue.

In one instance, we experienced a significant increase in bolt failures on a large-scale assembly line. Initial investigations pointed to inconsistent torque values, but after thorough examination, we discovered the problem wasn’t with the tightening tools themselves, but rather with the lubrication used on the bolts. The lubricant had degraded over time, leading to increased friction and premature bolt failure. This caused a significant reduction in the effective torque applied, despite readings showing the expected torque values.

The solution involved switching to a high-quality, long-lasting lubricant and implementing stricter inventory management procedures for lubrication supplies. We also revised our assembly process to incorporate a more thorough lubrication step. After addressing these issues, the rate of bolt failures dropped dramatically, highlighting the importance of considering all aspects of the assembly process, including seemingly minor elements like lubrication.

Q 22. How familiar are you with different bolt standards (e.g., ISO, ANSI)?

My familiarity with bolt standards is extensive. I have practical experience working with both ISO and ANSI standards, understanding their nuances and how they impact bolt selection, material specifications, and tightening procedures. For instance, ISO metric bolts utilize a different thread profile and tolerance system compared to their UNC (Unified National Coarse) or UNF (Unified National Fine) ANSI counterparts. This requires careful attention to ensure compatibility and avoid issues like cross-threading or insufficient clamping force. I understand the significance of various grades, such as ISO 8.8 or ANSI Grade 5, which directly correlate to the bolt’s tensile strength and its ability to withstand operational loads. I frequently consult relevant standards documents to ensure compliance and best practices are followed in any given project.

- ISO standards: Offer a comprehensive system for specifying dimensions, material properties, and tolerances for bolts.

- ANSI standards: Provide similar specifications, but with variations in thread profiles and grading systems.

Understanding these differences is crucial for selecting the appropriate bolt for a specific application, ensuring structural integrity and preventing failures.

Q 23. How do you ensure the consistency of torque applied to bolts?

Ensuring consistent torque is paramount for reliable bolt assembly. Inconsistent torque can lead to insufficient clamping force (resulting in loosening and potential failure) or over-tightening (causing bolt damage or component distortion). We use calibrated torque wrenches, regularly checked and certified for accuracy. Beyond the tools, the process itself is critical. This includes:

- Proper wrench selection: Choosing a wrench with the appropriate size and drive type for the specific bolt.

- Lubrication: Consistent application of lubricant to the bolt threads and under the bolt head reduces friction and ensures accurate torque readings.

- Operator training: Thorough training on proper torque wrench usage, including understanding the different types of torque wrenches (beam, click-type, electronic), is crucial to prevent errors.

- Regular calibration: Torque wrenches need regular calibration to maintain accuracy. We have a rigorous schedule for this to ensure reliability.

- Torque monitoring and recording: In critical applications, we use electronic torque wrenches that record each tightening event. This data is then analyzed to track trends and identify potential issues. We also use torque management systems that allow real-time monitoring and alerts for deviations from pre-set parameters.

Imagine building a car engine – inconsistent tightening of the head bolts could lead to a catastrophic failure. Consistent torque ensures every joint is secure and contributes to the overall system’s reliability and longevity.

Q 24. Describe your experience with statistical process control (SPC) in bolt assembly.

Statistical Process Control (SPC) is integral to our bolt assembly processes. We employ control charts (e.g., X-bar and R charts) to monitor torque values, ensuring they remain within predetermined acceptable limits. This allows us to identify trends and variations early on, preventing problems before they escalate. For example, if we notice a sudden increase in the variation of torque readings, we investigate the cause – this could be anything from a faulty torque wrench to a change in lubrication procedures or even operator fatigue. Data from these charts helps us optimize our processes, reducing waste and improving consistency. We use software specifically designed for SPC analysis to streamline data collection and interpretation, generating detailed reports that track key metrics and identify areas for improvement.

SPC isn’t just about reacting to problems; it’s about proactively improving our processes. By continuously monitoring and analyzing data, we identify potential sources of variation and implement corrective actions, resulting in more robust and reliable assembly procedures.

Q 25. How do you ensure traceability in bolt assembly processes?

Traceability in bolt assembly is essential, particularly in industries with stringent quality and safety requirements. We achieve this through a comprehensive system of documentation and identification. Each bolt batch is clearly identified with lot numbers, which are recorded throughout the entire process – from procurement to final assembly. We use barcodes or RFID tags to track individual bolts or components whenever feasible. Detailed records of torque values, operator IDs, and timestamps are logged and stored electronically. This data is readily accessible for audits or in case of any future investigation. In essence, we create a detailed audit trail for every bolt used, allowing us to quickly pinpoint the source of any issue if one arises. For example, if a bolt fails in service, we can trace it back to the specific batch, allowing us to investigate the root cause and prevent similar incidents.

Q 26. What are the effects of incorrect bolt tightening?

Incorrect bolt tightening can have serious consequences, ranging from minor inconvenience to catastrophic failure. The effects depend on whether the bolt is under-tightened or over-tightened:

- Under-tightening: Results in insufficient clamping force, leading to loosened joints, vibrations, leaks (in fluid systems), and ultimately, part failure. Think of a loose wheel on a car – it’s dangerous and unreliable.

- Over-tightening: Can cause the bolt to yield or even fracture, potentially damaging the threads, the mating parts, or even stripping the bolt head. This can lead to stress concentrations, premature component fatigue and failure.

In critical applications such as aerospace or automotive industries, incorrect tightening can result in safety hazards or even fatalities. Therefore, precise torque control is not just a best practice but an absolute necessity.

Q 27. How do you ensure compliance with safety regulations during bolt assembly?

Ensuring compliance with safety regulations during bolt assembly is a top priority. This involves adherence to relevant industry standards and regulations (OSHA, ISO, etc.), using approved safety equipment (e.g., safety glasses, gloves), and implementing safe work practices. We provide comprehensive training to all personnel involved in bolt assembly, covering aspects such as correct torque wrench usage, hazard identification and risk assessment, and emergency procedures. Regular safety inspections are conducted to identify and mitigate potential hazards. Furthermore, we maintain meticulous records of safety training and inspections to demonstrate compliance to auditors. We also ensure that the materials used are sourced from reputable suppliers who comply with relevant material specifications and safety standards. Safety is not just a checkbox item; it is an integral part of our culture and integrated into every aspect of our operations.

Key Topics to Learn for Bolt Assembly Interview

- Bolt Types and Specifications: Understanding various bolt types (e.g., hex bolts, carriage bolts, machine screws), their material properties (e.g., strength, corrosion resistance), and size designations (e.g., UNC, UNF).

- Torque and Tension: Grasping the relationship between applied torque and bolt tension, and the importance of achieving proper tension for secure assembly. This includes understanding torque wrenches and their calibration.

- Fastener Selection: Knowing how to select the appropriate bolt and nut for a given application based on factors such as load requirements, material compatibility, and environmental conditions.

- Assembly Techniques and Procedures: Mastering proper assembly techniques, including lubrication, sequence of tightening, and the prevention of cross-threading. Understanding the implications of improper assembly.

- Troubleshooting Common Problems: Identifying and resolving issues such as stripped threads, broken bolts, and insufficient clamping force. This involves diagnostic skills and problem-solving.

- Safety Procedures: Understanding and adhering to relevant safety protocols during the assembly process, including the use of personal protective equipment (PPE).

- Quality Control and Inspection: Familiarizing yourself with quality control measures for ensuring proper bolt assembly and identifying potential defects.

Next Steps

Mastering Bolt Assembly is crucial for career advancement in numerous manufacturing and engineering fields. A strong understanding of these principles demonstrates valuable practical skills and problem-solving abilities, making you a highly sought-after candidate. To maximize your job prospects, it’s essential to create an ATS-friendly resume that highlights your skills and experience effectively. We strongly encourage you to utilize ResumeGemini to build a professional and compelling resume. ResumeGemini offers a streamlined process and provides examples of resumes tailored to the Bolt Assembly field to help you present your qualifications in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

I Redesigned Spongebob Squarepants and his main characters of my artwork.

https://www.deviantart.com/reimaginesponge/art/Redesigned-Spongebob-characters-1223583608

IT gave me an insight and words to use and be able to think of examples

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO