Are you ready to stand out in your next interview? Understanding and preparing for Warping and Weaving Techniques interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Warping and Weaving Techniques Interview

Q 1. Describe the different types of warping techniques.

Warping is the process of preparing the lengthwise yarns (warp) for weaving. Different techniques cater to various needs in terms of yarn type, fabric complexity, and loom type.

- Direct warping: The simplest method, where the yarn is wound directly onto the warp beam. Suitable for simpler fabrics and smaller quantities.

- Sectional warping: Yarn is wound onto several smaller beams first, then these sections are joined to create the full warp. This is efficient for longer warps and allows for easier handling.

- Cone warping: Yarn cones are used as the source, and the warp is wound directly from these cones onto the beam. This reduces yarn tangling and is suitable for fine or delicate yarns.

- Drum warping: A large drum is used to wind the warp, enabling the creation of very long warps efficiently.

- Computerized warping: Modern technology utilizes computer-controlled warping machines offering precision and automation, ideal for complex designs and high-volume production.

The choice of warping method depends on factors like the yarn count, fabric design, loom type, and production scale. For instance, a fine silk saree might necessitate cone warping for its delicate nature, while a heavy duty canvas might be warped directly onto the beam.

Q 2. Explain the process of beaming yarn for weaving.

Beaming involves winding the prepared warp onto a warp beam, a large cylindrical device that feeds the warp threads to the loom during weaving. The process ensures even tension and minimizes yarn breakage.

- Preparation: The warped yarn (either from a direct, sectional, or other method) is carefully inspected for knots or imperfections.

- Securing the yarn: The beginning of the warp is secured to the warp beam using various methods such as lease sticks or a warp-winding device.

- Winding the yarn: The warp is wound onto the beam at a controlled tension to avoid unevenness. This tension is crucial for consistent fabric quality.

- Tension control: Modern beaming machines incorporate sophisticated tension control systems using sensors and brakes to maintain consistent tension. In manual processes, experience is key to judge and adjust tension.

- Warp beam preparation for weaving: The beam is then fitted onto the loom, ready for the weaving process. The warp ends are then passed through the heddles and reed of the loom.

Improper beaming can lead to weaving defects like uneven fabric density and warp breakage. A well-beamed warp is essential for efficient and high-quality weaving.

Q 3. What are the common types of weaving structures?

Weaving structures determine the appearance, drape, and strength of the fabric. They are defined by how the warp and weft yarns interlace.

- Plain weave: The simplest structure, where the warp and weft yarns interlace alternately over and under each other. This creates a basic, strong, and versatile fabric.

- Twill weave: Characterized by diagonal lines created by a pattern of warp and weft interlacing that isn’t strictly over-one-under-one. Examples include denim and gabardine.

- Satin weave: Creates a smooth, lustrous surface with long floats (where a warp or weft yarn passes over several other yarns). Silk charmeuse is a common example.

- Damask weave: A complex weave used to create intricate patterns, often featuring raised motifs. Commonly found in table linens.

- Pile weaves: Creates a raised surface, such as in velvet, corduroy, and terry cloth. Extra yarns are looped or knotted to create the pile.

Understanding different weave structures allows weavers to choose the appropriate structure to achieve desired properties in the finished fabric. For example, a twill weave is chosen for its durability in denim jeans, whereas satin weave is selected for the smoothness and shine of a silk scarf.

Q 4. How do you troubleshoot a broken warp thread?

A broken warp thread is a common problem in weaving. Quick and effective troubleshooting is key to prevent further damage and maintain weaving efficiency.

- Identify the broken thread: Locate the exact point of breakage in the warp.

- Secure the broken ends: Secure both ends of the broken thread to prevent them from unraveling further. This might involve tying a knot or using a small clamp.

- Repair the warp thread: This usually involves splicing in a new section of yarn, carefully matching the color and thickness. Precise splicing is crucial to avoid visible imperfections.

- Reinsert the thread: Carefully re-thread the repaired section through the heddles and reed, ensuring proper alignment.

- Check tension: Make sure the tension of the repaired section is consistent with the rest of the warp.

Ignoring a broken warp thread can lead to more damage, affecting the overall fabric integrity. Knowing how to address this effectively is vital to a weaver’s skillset. In complex weaves, this process requires greater precision and may involve the assistance of specialized tools.

Q 5. Describe the different types of looms and their applications.

Looms are the machines used for weaving. Different loom types are suited to varying production scales and fabric types.

- Hand looms: Simple looms operated manually, excellent for small-scale production, artistic expression, and experimental weaving. They offer greater control but are slower and less efficient.

- Table looms: Larger than hand looms, still manually operated but offering greater warp capacity, often used for home weaving and small-scale production.

- Floor looms: Larger, more sophisticated floor-standing looms that offer significant warp capacity and increased efficiency. They are suitable for heavier fabrics and larger production runs.

- Jacquard looms: Utilize punched cards or electronic controls to create complex patterns, essential for intricate designs, such as tapestries and damasks. They automate the lifting of individual warp threads.

- Industrial looms: High-speed, automated looms used for mass production of fabrics. These are highly efficient but require significant investment and specialized expertise.

The choice of loom depends on factors such as the scale of production, the complexity of the fabric design, the type of yarn being used, and the weaver’s skill level and budget. A tapestry weaver would use a jacquard loom, while a small home weaver might opt for a table loom.

Q 6. What are the key factors affecting fabric quality in weaving?

Several factors contribute to the overall quality of woven fabrics. Understanding these factors is essential for producing high-quality textiles.

- Yarn quality: The fiber type, yarn count, and twist all influence the fabric’s strength, drape, and appearance. Fine, even yarns produce a smoother, higher-quality fabric.

- Warp and weft density: A higher density (more yarns per inch) results in a stronger, more durable, and often more expensive fabric. This affects both drape and durability.

- Weaving tension: Consistent weaving tension is crucial for an even fabric structure, preventing distortions and imperfections. Uneven tension leads to irregular fabric.

- Weaving technique: The chosen weave structure significantly impacts the final product’s look, feel, and durability. Careful execution is essential for high quality.

- Finishing processes: Post-weaving treatments, such as washing, scouring, and dyeing, further influence the fabric’s final properties. These processes can enhance the softness, color, and durability of the fabric.

For example, using high-quality combed cotton yarns, a dense weave structure, and precise weaving tension will yield a superior quality cotton shirting compared to using lower quality yarns and a loose weave.

Q 7. How do you calculate warp and weft density?

Warp and weft density, expressed as ends per inch (EPI) and picks per inch (PPI), respectively, determine the number of warp and weft yarns within a one-inch section of fabric.

EPI (Ends Per Inch): This refers to the number of warp yarns packed within one inch of fabric. It is determined by counting the warp yarns in a one-inch section.

PPI (Picks Per Inch): This refers to the number of weft yarns packed within one inch of fabric. It is determined by counting the weft yarns in a one-inch section.

Calculating density is typically done using a fabric measuring device or by directly counting the yarns under a magnifying glass. It’s critical to measure in multiple locations to ensure accuracy, as density may slightly vary across the fabric.

Example: If a fabric has 30 warp yarns and 25 weft yarns in a one-inch section, the density is 30 EPI and 25 PPI. A higher EPI and PPI generally indicates a denser, heavier fabric with increased durability and often a smoother finish.

Q 8. Explain the concept of shedding, picking, and beating-up in weaving.

Shedding, picking, and beating-up are the three fundamental movements in weaving, creating the fabric structure. Imagine weaving as a three-step dance between warp and weft yarns.

Shedding: This is the first step, where the warp yarns (the lengthwise yarns) are separated to form a space, or shed, between them. This allows the weft yarn (the crosswise yarn) to pass through. Think of it like parting your hair – you create a space to weave a ribbon through. Different shedding mechanisms exist, like those using heddles (individual harnesses that raise and lower warp yarns) or a Jacquard loom (offering intricate pattern control).

Picking: Once the shed is formed, the picking process introduces the weft yarn across the width of the loom, passing it through the open shed. The weft yarn might be inserted using a shuttle (traditional method), a rapier (a mechanical arm), or a projectile. Imagine threading a needle and pulling it through the parted hair.

Beating-up: Finally, the newly inserted weft yarn is pushed tightly against the previously woven weft yarns, compacting the fabric and creating a dense, even structure. A reed (a comb-like structure) or similar mechanism is used to beat-up the weft. This is like pressing down on the woven ribbon to ensure it is snugly in place.

These three steps – shedding, picking, and beating-up – are repeated thousands of times to create a woven fabric. The speed and precision of these movements significantly influence the fabric’s quality, appearance, and strength.

Q 9. What are the common yarn faults that occur during warping?

Warping, the process of preparing the warp yarns, is crucial for successful weaving. Several yarn faults can occur during this stage, potentially impacting the final fabric quality.

- Slubs: Thickened areas in the yarn due to uneven spinning. They result in uneven texture and potential breakage.

- Neps: Small entangled masses of fibers. These create imperfections in the fabric’s surface, causing unsightly lumps.

- Ends broken or missing: These are simply broken or missing yarns in the warp, resulting in missing sections or fabric flaws.

- False twists: Unintended twists or kinks in the yarn, creating visual irregularities and potential weakening.

- Uneven tension: Inconsistent tension in the warp yarns leads to distorted fabric and may cause the loom to malfunction.

Careful yarn inspection before warping, proper tension control during the warping process, and using appropriate warping equipment are crucial to minimise these faults. A consistent and smooth warp is essential for high-quality woven fabric.

Q 10. How do you identify and correct weaving defects?

Identifying and correcting weaving defects requires a keen eye and understanding of the weaving process. Many defects originate from issues with the warp, weft, or loom settings.

Common Defects and Solutions:

- Broken ends: Look for missing warp yarns; mend them with a needle and thread or replace the damaged section.

- Missed picks: Spaces or gaps in the weft; use a weft repair device or hand-weave the missing section.

- Loose or tight fabric: Adjust loom tension settings or check for inconsistent weft insertion.

- Slack selvages: Uneven edges; readjust the loom’s selvage settings or adjust warp tension.

- Fabric imperfections: Uneven texture or color; investigate warp and weft yarn faults or loom malfunctions.

Systematic inspection of the woven fabric throughout the process is crucial, catching defects early minimizes wasted materials and effort. Documenting defects allows for better identification of root causes and process improvement.

Q 11. Describe the process of setting up a loom for a specific fabric design.

Setting up a loom for a specific fabric design involves several steps. It’s like preparing a canvas for a painting, but much more intricate.

- Warping: Prepare the warp yarns according to the design, considering yarn type, color, and required length.

- Heddle setup (if applicable): Thread the heddles according to the chosen weave structure to control the shedding pattern. This is where the design truly takes shape, as it determines how the warp yarns will be raised and lowered to form the shed.

- Reed setup: Position the warp yarns within the reed, ensuring even spacing and preventing yarn damage.

- Weft preparation: Prepare the weft yarn in a way that is readily accessible to the shuttle or other weft insertion system. For complex designs this may involve multiple colors or patterns.

- Design implementation: On more advanced looms like Jacquard looms, the design is programmed into a computer system that controls the heddle movement, allowing for intricate patterns.

- Trial run: Weave a small test piece to ensure the loom is correctly set up and the chosen fabric design is accurately reproduced.

This process requires precision and expertise. A single error can affect the entire fabric, emphasizing the importance of careful planning and execution. Each step is interlinked, making the process a fascinating interplay of mechanics and design.

Q 12. What safety precautions are essential when operating weaving machinery?

Operating weaving machinery demands stringent safety precautions to prevent accidents. The machinery is powerful and moving parts can cause serious injury.

- Personal Protective Equipment (PPE): Always wear eye protection, hearing protection, and appropriate clothing to prevent injuries from flying debris or moving parts.

- Machine guarding: Ensure all safety guards are in place and functioning correctly to prevent access to dangerous moving parts.

- Lockout/Tagout procedures: Before maintenance or cleaning, follow lockout/tagout procedures to prevent accidental starts.

- Training: Proper training on the operation and maintenance of the specific machinery is essential. Never operate machinery without proper training and authorization.

- Emergency stops: Familiarize yourself with the location and operation of emergency stop buttons and other safety mechanisms.

- Regular inspections: Regularly inspect machinery for wear and tear, damaged parts, and potential hazards. Report any issues immediately.

A safe working environment is paramount. Adhering to these safety measures is not just a best practice; it’s crucial for the well-being of all personnel.

Q 13. How do you maintain and troubleshoot weaving machinery?

Maintaining and troubleshooting weaving machinery is vital for preventing breakdowns and ensuring quality fabric production. Regular maintenance is key to prolonging the lifespan of the equipment and preventing unexpected issues during operation.

Maintenance:

- Regular lubrication: Keep moving parts lubricated according to the manufacturer’s recommendations. This reduces friction and wear.

- Cleaning: Regularly remove lint and debris to prevent buildup, which can impact the performance of the machine.

- Inspection: Regularly inspect the machine for worn parts or potential problems, addressing them before they become major issues.

- Calibration: Periodically calibrate the machine’s settings (e.g., tension controls) to maintain consistent fabric production.

Troubleshooting:

- Identify the problem: Observe the machine’s behavior, listen for unusual sounds, and check for visible damage.

- Consult manuals: Refer to the manufacturer’s manuals for troubleshooting guides and repair procedures.

- Systematic approach: If the problem persists, use a systematic approach, checking components one by one to locate the fault.

- Seek expert assistance: If you cannot resolve the issue, consult with experienced technicians or engineers.

Preventative maintenance is far more efficient than reactive repairs; regular care extends the life and efficiency of your equipment and reduces downtime.

Q 14. Explain the difference between plain weave, twill weave, and satin weave.

Plain weave, twill weave, and satin weave are three basic weave structures, each producing a unique fabric texture and appearance. Think of them as the fundamental building blocks of woven fabrics.

Plain weave: This is the simplest weave structure, where the weft yarn passes alternately over and under the warp yarns. It creates a stable, even fabric, perfect for everyday applications like sheets or shirts. Imagine a checkerboard pattern.

Twill weave: This weave structure creates diagonal lines on the fabric’s surface due to a pattern where the weft yarn passes over more than one warp yarn before going under. This produces a more textured, diagonal fabric with a certain strength and drape. Think of denim jeans.

Satin weave: This weave structure produces a smooth, lustrous surface characterized by long floats (where the weft yarn passes over several warp yarns before going under). This results in a luxurious fabric often used for clothing and bedding. Think of satin sheets.

Each weave structure offers unique properties: plain weave is durable and simple; twill weave is durable and has a characteristic diagonal pattern; satin weave is lustrous and smooth. The choice of weave structure greatly impacts the final fabric’s properties and aesthetic appeal.

Q 15. What are the advantages and disadvantages of different weaving techniques?

Different weaving techniques offer unique advantages and disadvantages, impacting the final fabric’s characteristics. Let’s explore some key examples:

- Plain Weave: Simple, strong, and versatile. Advantages: Easy to produce, cost-effective, suitable for various materials. Disadvantages: Can lack texture, potentially less draping than other weaves.

- Twill Weave: Creates diagonal lines, offering durability and texture. Advantages: Strong, good drape, visually appealing. Disadvantages: More complex to weave than plain weave, slightly more yarn consumption.

- Satin Weave: Characterized by a smooth, lustrous surface. Advantages: Luxurious feel, excellent drape. Disadvantages: Less durable than twill or plain weave, susceptible to snags, more complex to weave.

- Jacquard Weave: Allows for intricate patterns and designs. Advantages: Highly detailed designs, visually stunning. Disadvantages: Complex and specialized looms required, higher production costs.

The choice of weaving technique depends on the desired fabric properties (strength, drape, texture, appearance), the available resources (loom type, yarn quality), and the intended application of the fabric.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage yarn tension during warping and weaving?

Managing yarn tension is crucial for consistent fabric quality and avoiding defects. During warping, even tension is achieved using a variety of methods, including:

- Using a warping board or mill: These tools help distribute tension evenly across all warp yarns.

- Employing lease sticks: These prevent warp yarns from tangling and maintain spacing.

- Utilizing tensioning devices on the loom: These help control the tension of the warp yarns during weaving.

During weaving, consistent tension is maintained by carefully monitoring the yarn supply and adjusting the tensioning devices on the loom. Inconsistent tension can lead to broken warps, uneven fabric structure, and overall poor quality. Think of it like playing a musical instrument – each string needs the right tension to create beautiful music; likewise, each warp yarn needs appropriate tension for a beautiful fabric.

Q 17. Describe the process of preparing warp yarns for weaving.

Preparing warp yarns is a crucial step involving several procedures:

- Warping: The process of winding the warp yarns onto a beam or a warping reel in the correct order and under even tension. This ensures that the yarns are evenly spaced and ready to be placed on the loom.

- Sizing: Applying a sizing agent to the warp yarns. This strengthens the yarns, reduces abrasion during weaving, and makes them easier to handle. The choice of sizing depends on the yarn fiber type and fabric characteristics.

- Beaming: Winding the prepared warp yarns onto a loom beam, which is a large cylindrical structure used to hold the warp yarns on the loom. This requires careful tension control to avoid unevenness in the final fabric.

- Drawing-in: Threading the warp yarns through the heddles and reed on the loom, preparing them for weaving. This requires precision to ensure each yarn is correctly placed.

Each step is vital for successful weaving; skipping or neglecting any step can lead to weaving problems and fabric defects. Think of this as preparing ingredients for baking a cake – each step must be followed carefully to achieve the desired outcome.

Q 18. How do you select the appropriate loom for a specific fabric?

Loom selection depends greatly on the desired fabric and the scale of production. Factors to consider include:

- Fabric complexity: Simple fabrics like plain weave can be woven on basic looms, whereas intricate designs may require sophisticated jacquard looms.

- Yarn type and weight: Heavier yarns may require looms with more robust construction.

- Production volume: Small-scale production may use simple hand looms, while large-scale production necessitates industrial looms.

- Budget: Looms range in price from affordable hand looms to expensive industrial models.

For example, a lightweight silk scarf might be woven on a small table loom, while a heavy tapestry might require a floor loom with a larger capacity. Matching the loom to the project is essential for efficient and successful weaving.

Q 19. What are the different types of weaving selvedges?

Selvedges are the finished edges of woven fabric, crucial for preventing unraveling. Several types exist:

- Simple Selvedge: Created by the loom’s mechanism, it’s a basic, often slightly tighter edge.

- Bound Selvedge: Created by weaving an extra weft yarn around the edge to secure it. This results in a clean and durable finish.

- Fringed Selvedge: The warp ends are left loose, creating a fringe. Often seen in decorative fabrics.

- Herringbone Selvedge: A decorative selvedge with a distinctive zigzag pattern.

The choice of selvedge depends on the fabric’s intended use and aesthetic requirements. A sturdy bound selvedge is ideal for upholstery, while a fringed selvedge is more appropriate for shawls.

Q 20. Explain the importance of weft insertion in weaving.

Weft insertion is the process of interlacing the weft yarn across the warp yarns, creating the fabric’s structure. It’s the core of weaving and dictates the fabric’s texture, pattern, and overall integrity. Without proper weft insertion, the warp yarns would remain separate and the fabric wouldn’t exist.

Different weft insertion methods exist, including:

- Shuttle weaving: A traditional method using a shuttle to carry the weft yarn.

- Projectile weaving: Uses a projectile to shoot the weft across the warp.

- Air-jet weaving: Air jets propel the weft yarn across the warp.

The method chosen depends on the desired fabric characteristics and the production scale. Consistent weft insertion is critical for consistent fabric quality.

Q 21. How do you calculate the required amount of warp yarn for a given fabric?

Calculating warp yarn requirements involves several steps:

- Determine the fabric width: This is the final width of the woven fabric.

- Determine the warp threads per inch (EPI): This depends on the fabric type and desired density.

- Calculate the total number of warp threads: Multiply the fabric width by the EPI.

- Determine the length of the warp: This considers the fabric length plus additional warp for selvedges and waste.

- Calculate total warp yarn length: Multiply the total number of warp threads by the warp length.

- Account for yarn shrinkage: Consider the shrinkage of the yarn during weaving and add a percentage to account for it.

For example: If your fabric is 24 inches wide, you have 20 EPI, and the fabric is 36 inches long, then the total warp yarn needed would be (24 * 20) * (36 + allowance for selvedge and waste). Always add extra yarn to account for potential breakage and waste during weaving.

Q 22. Describe the process of inspecting woven fabric for defects.

Inspecting woven fabric for defects is crucial for quality control. It involves a systematic examination of the fabric for any imperfections that might affect its appearance, strength, or overall performance. This process typically involves visual inspection, often aided by magnification tools, and sometimes involves specialized testing equipment.

- Visual Inspection: This is the primary method, focusing on identifying things like broken or missing warp or weft yarns (ends or picks), slubs (thickened areas of yarn), neps (small knots of tangled fibers), mispicks (incorrectly interlaced weft yarns), and other irregularities in the weave structure. I often look for patterns in defects; a consistently repeating problem points to a loom setting issue.

- Magnification: A magnifying glass or even a microscope can help reveal tiny imperfections like thin places in the yarns or slight inconsistencies in the weave that might be missed with the naked eye.

- Specialized Testing: Depending on the fabric’s intended use, additional testing may be done to assess strength, abrasion resistance, or other relevant properties.

For example, a slight weft mispick in a fine silk might be acceptable for a scarf, but completely unacceptable in a parachute. The level of acceptable imperfection depends entirely on the final application.

Q 23. What are the common causes of warp breakage?

Warp breakage, the snapping of lengthwise yarns, is a common problem in weaving. Several factors contribute to it:

- Yarn Quality: Weak or damaged yarns are prone to breakage. Improperly spun or poorly treated yarns are particularly vulnerable.

- Tension: Excessive tension on the warp yarns can cause them to break. Incorrectly set warp tension is a frequent culprit.

- Loom Setting: Improperly adjusted loom parts, such as the reed or heddles, can put undue stress on the warp, leading to breakage. A poorly maintained loom will also contribute to this.

- Knots and Slubs: Knots or slubs in the warp yarn act as stress points, making them more susceptible to breaking.

- Environmental Factors: Extreme humidity or dryness can affect yarn strength, increasing the likelihood of breakage.

- Abrasion: Friction from the reed, heddles, or shuttles can gradually weaken and break yarns.

Identifying the cause requires careful observation. For example, frequent breakage at a specific point on the loom suggests a problem with that section’s setup or mechanics. Consistent breakage in a particular yarn lot suggests a quality issue with the yarn itself.

Q 24. How do you adjust the loom settings to achieve the desired fabric quality?

Adjusting loom settings to achieve desired fabric quality is a skill honed through experience. It involves manipulating several parameters to control the fabric’s density, drape, and overall aesthetic.

- Warp Tension: This controls the tightness of the warp yarns, influencing the fabric’s density and drape. Too much tension leads to breakage; too little leads to loose fabric.

- Weft Tension: This controls the tightness of the weft yarns, affecting the fabric’s surface texture and strength. Improper tension can result in inconsistent fabric density or uneven surface.

- Reed Spacing: The reed’s spacing determines the fabric’s density, influencing its weight and drape. A closer reed spacing results in a denser fabric.

- Beat-up Force: This is the force with which the weft is pushed into place after each pick, influencing the compactness of the fabric. Too little force results in loose fabric, while too much can damage yarns.

- Heddle Sequence: The order in which the heddles lift determines the weave pattern and consequently the fabric’s aesthetic qualities. Changing the sequence entirely changes the fabric’s texture and look.

Achieving the right balance requires trial and error, careful observation, and a deep understanding of how each parameter interacts with others. For example, increasing warp tension might require adjusting the beat-up to prevent damaging the yarns.

Q 25. Explain the concept of reed and its role in weaving.

The reed is a crucial component of the loom. It’s essentially a comb-like structure with evenly spaced teeth, used to beat the newly inserted weft yarn into place, aligning the weft threads and creating a compact fabric structure.

Its role is multifaceted:

- Beat-up: The primary function is to compact the woven fabric by forcefully pushing each weft thread against the previously inserted ones. This creates a smooth, even fabric surface.

- Warp Control: The reed also helps maintain the correct spacing and alignment of the warp yarns. It prevents the warp threads from shifting or becoming tangled during the weaving process.

- Density Control: The density of the fabric is directly influenced by the spacing between the reed’s teeth; closer spacing leads to tighter fabric.

Imagine the reed as a meticulously organized lineup ensuring that all the weft threads neatly and accurately join the already set warp threads. The reed’s integrity is vital for the fabric’s quality and consistency.

Q 26. How do you calculate the number of warp ends per inch?

Calculating the number of warp ends per inch (EPI) is fundamental in weaving. It directly impacts the fabric’s density and appearance.

The calculation is straightforward:

EPI = Total number of warp ends / Fabric width in inches

For example, if you have a total of 200 warp ends and the fabric is 20 inches wide, the EPI is 10. That is, there are 10 warp ends per inch of fabric.

Accurate EPI measurement is essential to meet design requirements. Incorrect EPI can result in fabric that’s either too loose or too tight. Therefore, precise measurement and calculation are imperative for quality control.

Q 27. Describe different types of heddles and their applications.

Heddles are an essential part of the loom, responsible for lifting and separating the warp yarns to allow the shuttle to pass through. Different types cater to various weaving techniques and fabric structures.

- Simple Heddles: These are the most basic type, with a single eyelet for each warp yarn. They are suitable for simple plain weaves.

- Double Heddles: These have two eyelets, allowing for more complex weaves, enabling the creation of various patterns and textures.

- Jacquard Heddles: These are controlled by a complex system of punched cards or computer software, enabling the creation of intricate and highly detailed woven designs. This allows for elaborate and very finely detailed designs.

- Leno Heddles: These are used in Leno weaving, a technique that creates open, gauze-like fabrics. They create the distinctive open and airy fabric structure.

The choice of heddle type depends on the desired weave structure and complexity of the design. For a simple cotton sheet, simple heddles are sufficient. For a highly patterned tapestry, a Jacquard system is necessary.

Q 28. What are the different types of shuttles used in weaving?

Shuttles are used to carry the weft yarn across the warp yarns. Various types exist, each with its own characteristics and advantages:

- Plain Shuttles: These are the most common type, with a simple box-like shape. They are versatile and suitable for most weaving applications.

- Flying Shuttles: Used in high-speed looms, these are propelled across the warp yarns mechanically. They significantly increase weaving speed, often essential in industrial settings.

- Boat Shuttles: These are used in hand weaving and are characterized by their boat-like shape, allowing for the storage of a larger amount of weft yarn.

- Picker Shuttles: These are utilized on automatic looms and use picking sticks to propel the shuttle across the warp.

The selection of a shuttle depends on the type of loom and the weaving process. A hand weaver might use a boat shuttle for its yarn capacity, while an industrial loom might use a flying shuttle to maximize production.

Key Topics to Learn for Warping and Weaving Techniques Interview

- Warping Preparation: Understanding different warping methods (e.g., direct warping, sectional warping), calculations for warp length and beam size, and troubleshooting common warping issues.

- Weaving Techniques: Proficiency in various weaving structures (plain weave, twill, satin, jacquard), understanding shed formation, beat-up mechanisms, and their impact on fabric properties.

- Yarn Selection and Properties: Knowledge of yarn types (natural and synthetic fibers), their suitability for different weaving techniques, and the effect of yarn characteristics on fabric drape and strength.

- Loom Operation and Maintenance: Familiarization with different loom types (e.g., shuttle loom, rapier loom, air-jet loom), their operation principles, and routine maintenance procedures to ensure efficient weaving.

- Fabric Design and Pattern Creation: Understanding the relationship between warp and weft arrangements and their effect on the final fabric design, utilizing software or manual drafting techniques.

- Quality Control and Troubleshooting: Identifying and resolving weaving defects (e.g., broken ends, mispicks, slubs), implementing quality control measures throughout the weaving process.

- Health and Safety: Awareness of safety protocols and procedures related to loom operation, yarn handling, and working within a textile manufacturing environment.

- Production Planning and Efficiency: Understanding production scheduling, optimizing loom utilization, and minimizing downtime to increase efficiency.

Next Steps

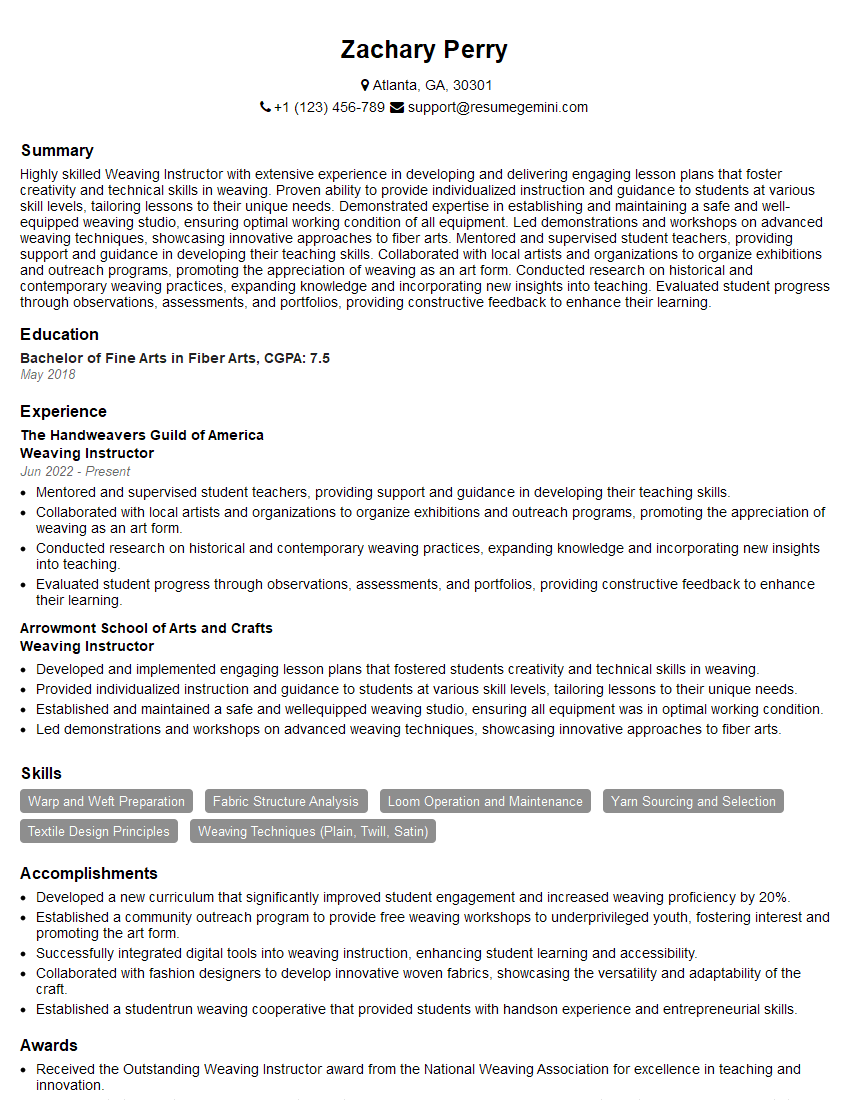

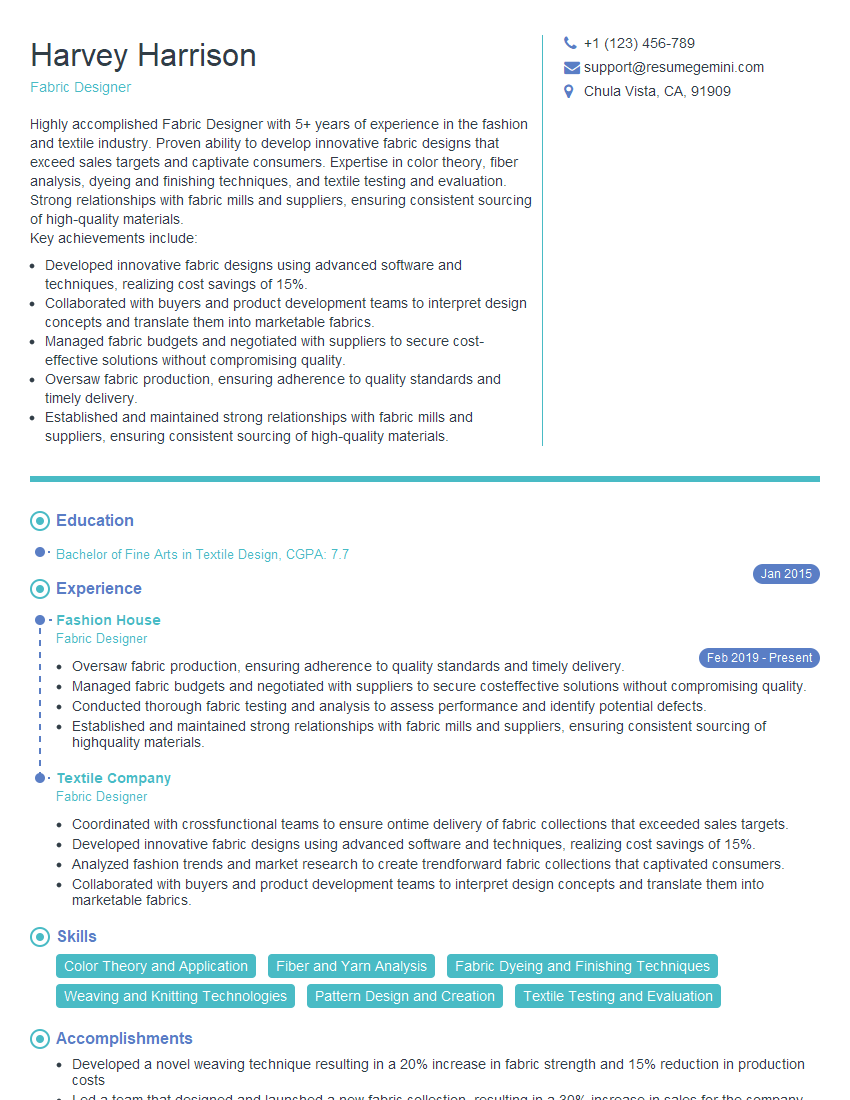

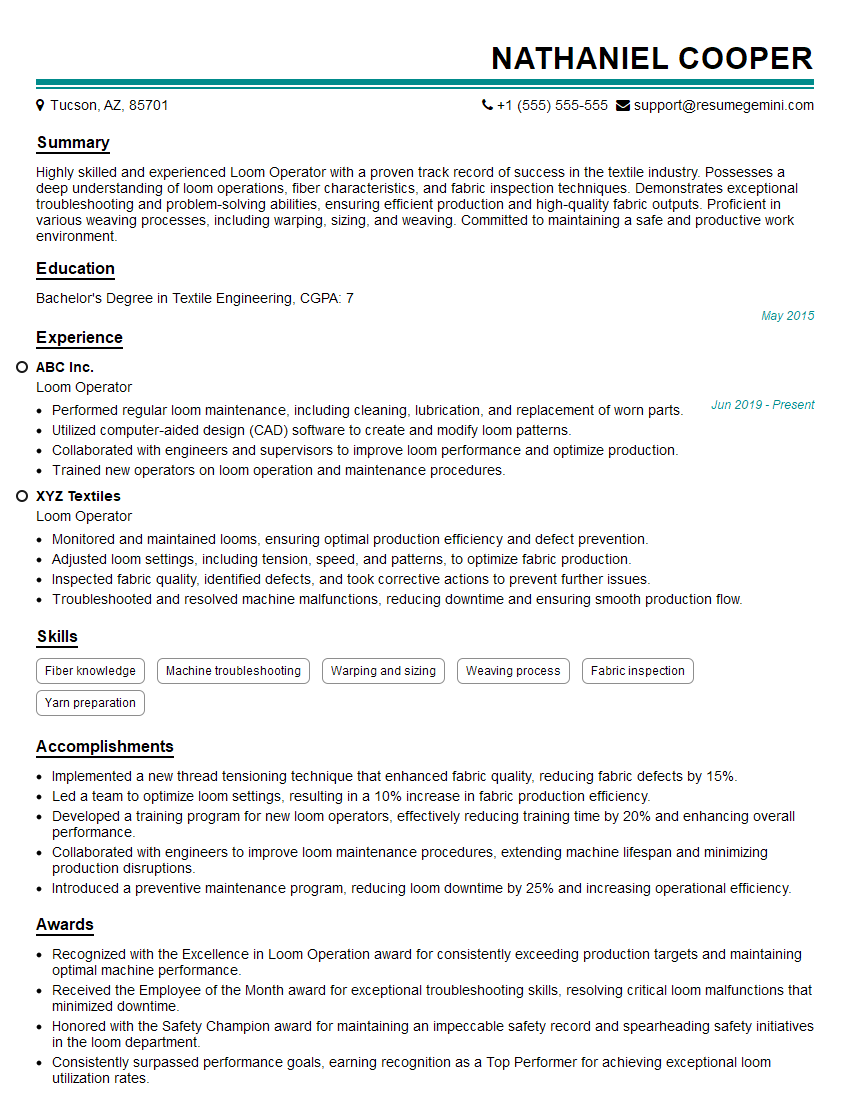

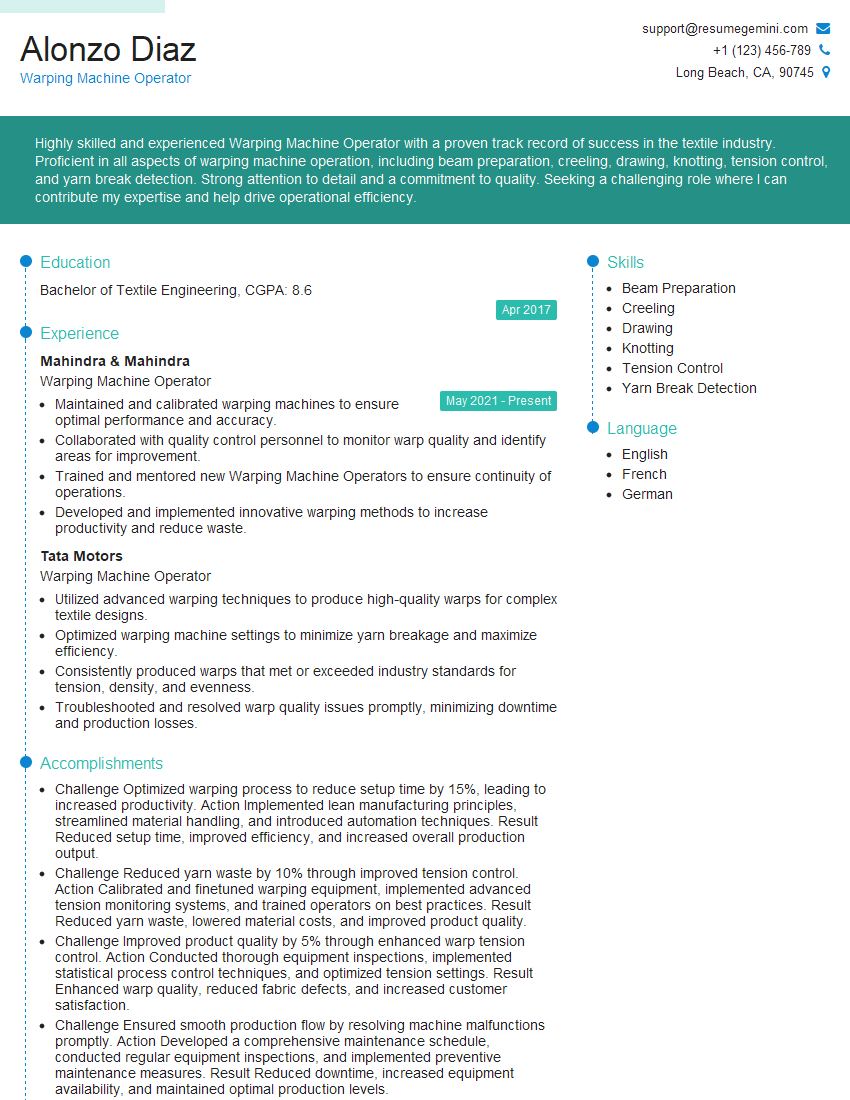

Mastering warping and weaving techniques opens doors to exciting career opportunities in the textile industry, offering roles with increasing responsibility and earning potential. To stand out, create a compelling resume that highlights your skills and experience effectively. An ATS-friendly resume is crucial for maximizing your job prospects. ResumeGemini is a valuable tool to help you build a professional and impactful resume tailored to your specific experience. Examples of resumes tailored to Warping and Weaving Techniques are available to guide you in showcasing your abilities effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO