Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Fiber Arts and Textile Design interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Fiber Arts and Textile Design Interview

Q 1. Explain your experience with various textile dyeing techniques.

My experience with textile dyeing techniques is extensive, encompassing both natural and synthetic dyes. I’m proficient in various methods, each offering unique aesthetic and practical advantages.

Vat dyeing: This process, ideal for producing deep, vibrant, and colorfast results, involves reducing insoluble dye to a soluble form, dyeing the fiber, and then re-oxidizing the dye to trap the color within the fiber. I’ve used this extensively for cotton and linen, achieving rich indigo shades, for example.

Reactive dyeing: A popular choice for cellulosic fibers (cotton, rayon), reactive dyes form a strong chemical bond with the fiber, creating very washfast colors. I often use this technique for achieving bright, saturated hues in my designs.

Acid dyeing: Primarily employed for protein fibers like wool and silk, acid dyes require an acidic dye bath to achieve optimal color fixation. The range of colors achievable is exceptional and the process offers a luxurious hand feel.

Natural dyeing: I have a passion for natural dyeing using plant materials like madder root, indigo, and turmeric. This approach offers unique, earthy color palettes and aligns with sustainable practices. Understanding the properties of different plant materials and their interaction with different fibers is key to success in this area. For example, I recently experimented with using avocado pits to achieve a beautiful range of browns and greens on wool.

My approach to dyeing prioritizes colorfastness and ecological considerations. I always meticulously prepare fibers, accurately control dye baths, and select dyeing methods appropriate for the specific fiber and desired effect.

Q 2. Describe your proficiency in different weaving structures (plain, twill, satin).

My understanding of weaving structures extends to various fundamental and more complex weaves. Plain, twill, and satin weaves form the foundation of many textile designs and mastering them allows for diverse aesthetic and performance outcomes.

Plain weave: The simplest weave, characterized by a one-over-one-under arrangement of warp and weft yarns. It is known for its durability and even surface texture. I often utilize plain weave as a base for creating more intricate designs or when strength and simplicity are paramount.

Twill weave: This weave produces diagonal lines due to the pattern of yarn interlacing (e.g., two-over-one-under or three-over-one-under). This creates a more textured surface and offers increased strength and stability compared to plain weave. Twills are excellent for garments, upholstery, and home furnishings due to their ability to drape nicely or resist wear and tear.

Satin weave: This weave features long floats (where one yarn is laid over several other yarns) and creates a lustrous, smooth surface. The characteristic sheen of satin results from the minimal yarn interlacings, which reflect light efficiently. I’ve utilized satin weaves in projects requiring luxurious feel and drape, such as linings or evening wear.

Beyond these fundamental structures, I’m familiar with more complex weaves like basket weave, jacquard, and double cloth, all of which add to my versatility as a designer.

Q 3. What software programs are you proficient in for textile design (e.g., Adobe Illustrator, Photoshop)?

I’m proficient in several software programs vital for textile design and pattern creation. My expertise encompasses both raster and vector-based applications.

Adobe Illustrator: I leverage Illustrator for creating precise vector graphics, ideal for designing repeatable patterns, developing technical drawings for weaving or knitting, and generating scalable artwork for printing.

Adobe Photoshop: Photoshop is crucial for manipulating images, adjusting color balances, creating realistic fabric simulations, and preparing artwork for digital printing. I use it to refine designs, create color palettes, and manipulate textures.

Other programs: I also have experience with specialized textile design software such as [mention any specialized software used, if any]. This allows me to explore different design capabilities and experiment with different design processes.

My software skills are essential for bringing my creative vision to life efficiently and professionally, allowing for seamless transition from concept to production.

Q 4. Discuss your knowledge of different fiber types (natural and synthetic) and their properties.

My knowledge of fiber types is fundamental to my design process. Understanding the properties of different fibers – both natural and synthetic – allows me to make informed decisions about material selection, ensuring optimal performance and aesthetic outcomes.

Natural Fibers: Cotton (absorbent, breathable), linen (strong, durable), wool (warm, insulating), silk (luxurious, smooth), and cashmere (soft, luxurious) are a few examples. Each fiber’s unique characteristics – strength, elasticity, drape, luster, and absorbency – dictate its suitability for different applications.

Synthetic Fibers: Nylon (strong, elastic), polyester (durable, wrinkle-resistant), acrylic (soft, warm), and rayon (drapable, versatile) provide designers with a vast range of options. I consider their properties in relation to the end-use of the textile, like moisture-wicking properties of polyester for sportswear or the soft hand of acrylic for blankets.

I always consider factors like fiber sourcing, sustainability, and the ethical implications of my material choices when selecting fibers for my projects. For example, I prioritize using organic cotton whenever possible to minimize environmental impact.

Q 5. How do you approach color theory in your textile designs?

Color theory is integral to my textile design process. My approach involves understanding color relationships, harmonies, and contrasts to create visually appealing and impactful designs. I use several tools and approaches:

Color wheels: These are essential for exploring color harmonies – analogous, complementary, triadic, etc. I use them to create balanced color palettes that convey specific moods and aesthetics. For example, a design using analogous colors might feel calm and peaceful, while a complementary scheme could be striking and vibrant.

Color psychology: I’m aware of the emotional and cultural associations of various colors. This knowledge informs my choices, ensuring that the color palette aligns with the intended purpose and audience of the design.

Color mixing and experimentation: I frequently experiment with mixing different dyes to achieve unique and nuanced colors, going beyond commercially available shades. I document my color experiments to develop a comprehensive library of custom colors.

Ultimately, my goal is to use color strategically to enhance the overall design, communicating a specific message or mood through a carefully chosen palette.

Q 6. Explain your understanding of textile printing methods (screen printing, digital printing, etc.).

My knowledge of textile printing methods encompasses various techniques, each with its own advantages and limitations. The choice depends on factors like design complexity, fabric type, production volume, and budget.

Screen printing: This traditional method involves creating stencils (screens) for each color in the design. It’s ideal for producing bold, high-opacity prints, especially on a larger scale. I’ve utilized this technique extensively for creating vibrant designs on cotton and linen.

Digital printing: This modern method uses inkjet technology to print directly onto fabric. It’s excellent for intricate designs with subtle color gradations and photorealistic images. The process offers greater flexibility and precision, ideal for smaller runs or custom designs.

Other methods: I have familiarity with other printing methods like block printing (using carved wooden blocks), discharge printing (removing color from a dyed fabric), and batik (wax-resist dyeing). Each method adds unique textures and visual effects to the finished product. For example, I recently used block printing to create a limited-edition collection of scarves using hand-carved wooden blocks.

My approach considers the relationship between the printing technique, the fabric, and the design to achieve the most aesthetically pleasing and durable outcome.

Q 7. Describe your experience with knitting and crochet techniques.

I possess a strong foundation in both knitting and crochet techniques, allowing me to create three-dimensional textile structures with varied textures and forms. My expertise extends beyond basic stitches to more complex patterns and techniques.

Knitting: I am proficient in various knitting techniques including stockinette, garter stitch, seed stitch, cables, colorwork (fair isle, intarsia), and lace. I am comfortable working with different yarn weights and needles to achieve specific textures and garment structures. For example, I recently designed a sweater using a complex cable pattern.

Crochet: My crochet skills include basic stitches like single crochet, double crochet, treble crochet, as well as more advanced techniques like Tunisian crochet, filet crochet, and amigurumi (creating small three-dimensional figures). I use crochet to create both functional and decorative items.

I frequently combine knitting and crochet in my projects, layering different textures and techniques to achieve unique and complex designs. My understanding of stitch construction and pattern design allows for the creation of both simple and intricate textile objects.

Q 8. How familiar are you with textile finishing processes?

Textile finishing is the crucial final stage of fabric production, transforming raw materials into marketable textiles. It encompasses a wide array of processes aimed at enhancing the fabric’s appearance, feel, performance, and durability. My familiarity extends across various techniques, including:

- Mechanical Finishing: Processes like calendaring (improving smoothness and luster), shearing (removing fuzz), and raising (creating a fuzzy surface like fleece). I’ve worked extensively with calendaring to achieve specific hand-feels for different garments, from crisp cotton shirts to soft, drapey scarves.

- Chemical Finishing: This involves treatments that alter the fabric’s properties. Examples include mercerization (increasing cotton’s luster and strength), dyeing (adding color), printing (applying patterns), and water-repellent treatments. I’ve successfully implemented durable water-repellent finishes on outdoor jackets, significantly enhancing their practicality.

- Finishing for Specific Properties: This includes flame-retardant treatments for safety textiles, anti-microbial treatments for hygiene, and wrinkle-resistant finishes for easy-care garments. I’ve developed a line of bedding using antimicrobial finishes, responding directly to consumer demand for healthier sleep environments.

Understanding these processes is crucial for effective design, as the finishing techniques significantly impact the final product’s aesthetics and functionality. For example, choosing the wrong dyeing process can compromise colorfastness, and an inappropriate water-repellent finish can stiffen a fabric and reduce its comfort.

Q 9. How do you manage deadlines and prioritize tasks in a fast-paced design environment?

Deadlines are a constant in textile design, demanding efficient time management. My approach is a blend of proactive planning and adaptable execution. I begin by breaking down large projects into smaller, manageable tasks, assigning each a realistic timeframe. I use project management tools to track progress and identify potential bottlenecks.

Prioritization is key. I employ a method that weighs task urgency and importance. Urgent and important tasks get immediate attention; important but less urgent tasks are scheduled strategically; and less important tasks are delegated or postponed if possible. For instance, during a recent rush order for a new line of scarves, I prioritized the most complex dye-print designs while delegating simpler tasks like packaging and labeling to the team.

Regular communication with the team and clients is crucial for keeping the project on track and adjusting the schedule as needed. Flexibility is also important; I understand that unforeseen issues may arise and am adept at quickly re-prioritizing tasks to address them effectively.

Q 10. Describe your process for translating design concepts into technical specifications.

Translating design concepts into technical specifications requires a meticulous approach. I start with a detailed sketch or digital rendering of my design, specifying color palettes, textures, patterns, and overall aesthetic. Then, I delve into the technical aspects, considering factors like:

- Fiber content: Selecting the appropriate fibers (cotton, silk, wool, synthetics, blends) based on desired properties like drape, strength, and comfort.

- Yarn construction: Specifying the yarn type (spun, filament) and structure (ply, twist) to achieve the desired texture and weight.

- Fabric construction: Detailing the weave structure (plain, twill, satin), knit structure (jersey, rib), or non-woven structure to achieve specific visual and tactile properties.

- Finishing processes: Clearly documenting the finishing techniques necessary to achieve the desired final look and feel, including dyeing, printing, and other treatments. I often provide examples and reference swatches for clarity.

I meticulously document all these specifications in a comprehensive technical design document, which includes detailed sketches, fabric swatches, and precise measurements. This ensures that the production team can accurately interpret the design vision and execute it flawlessly. For example, when designing a jacquard-woven tapestry, I would provide detailed schematics outlining the warp and weft yarns, their sequence, and the desired pattern repeat. This avoids costly mistakes during production.

Q 11. How do you handle constructive criticism on your designs?

Constructive criticism is invaluable for design growth. I approach it as an opportunity for learning and improvement, rather than a personal attack. I actively listen to the feedback, asking clarifying questions to ensure I fully understand the points raised. I then analyze the criticism, separating subjective opinions from objective observations.

For example, if a client criticizes the color palette as ‘too muted,’ I’ll analyze if this is a valid point based on the target market and the overall design concept. If the feedback is valid and aligned with the project’s objectives, I’ll revise the design accordingly. However, if it is a matter of personal preference and contradicts the design intent, I will respectfully explain my design rationale while being open to exploring alternative solutions that might address the concern without compromising the core concept.

Documenting feedback and revisions is essential. It allows me to track my progress and to learn from past critiques, enhancing my future design processes and decision-making.

Q 12. Explain your approach to incorporating sustainability into your textile designs.

Sustainability is paramount in my design philosophy. It’s not just a trend but an ethical imperative. My approach involves integrating sustainable practices throughout the design process, from fiber selection to end-of-life considerations.

Fiber Selection: I prioritize using organically grown, recycled, or sustainably sourced fibers like organic cotton, recycled polyester, Tencel, or hemp. These choices minimize environmental impact compared to conventionally grown fibers. I frequently research innovative materials and technologies that prioritize sustainability and biodegradability.

Production Processes: I advocate for low-impact dyeing and finishing techniques that minimize water and energy consumption and reduce the use of harmful chemicals. I work with manufacturers who share my commitment to ethical production practices and fair labor standards.

Design for Durability and Longevity: Designing for longevity means creating pieces that are high quality, timeless in style, and easily repairable, thus reducing textile waste. I often incorporate design elements that encourage upcycling or repurposing after the garment’s initial use. This reduces reliance on fast fashion and promotes circularity.

Transparency and Traceability: I believe in transparent sourcing and production processes, providing customers with clear information about the origins of the materials and the methods used to create their garments. This ensures ethical and sustainable practices are demonstrably part of the brand’s identity.

Q 13. How do you stay current with the latest trends in the textile industry?

Staying current in the dynamic textile industry requires a multifaceted approach. I actively engage with industry publications such as Textile View, Fashion United, and Surface Design Journal. These resources provide insights into emerging trends, new technologies, and innovative materials.

I attend industry trade shows like Première Vision and Heimtextil, connecting with manufacturers, suppliers, and other designers. These events offer a firsthand look at the latest fabrics, technologies, and design aesthetics.

Online platforms such as Pinterest, Instagram, and specialized design websites are invaluable for tracking emerging trends and discovering inspiration. Following key influencers and industry leaders on social media keeps me informed about the latest innovations and stylistic shifts.

Networking with other designers and professionals in the industry is crucial. This enables me to learn from their experiences, stay abreast of industry developments, and discover new opportunities for collaboration. Continuous learning, through workshops, online courses, and self-study, further enhances my expertise and keeps my creative vision sharp.

Q 14. Describe your experience with CAD software for textile design.

I possess extensive experience using CAD software for textile design, primarily Adobe Illustrator and Photoshop, alongside specialized programs such as Lectra. These tools are indispensable for creating intricate designs, generating technical specifications, and visualizing the final product.

In Adobe Illustrator, I create precise vector graphics for repeating patterns, surface designs, and detailed technical drawings. Photoshop allows me to manipulate images, experiment with color palettes, and create realistic renderings of my designs.

My proficiency in Lectra enables me to seamlessly transition from design concepts to production-ready files, creating digital repeats, generating cutting patterns, and managing the entire design workflow in an efficient and streamlined manner. I’ve successfully used Lectra to streamline the design and manufacturing processes for several large-scale projects, enhancing efficiency and reducing production errors. The software’s advanced tools significantly aid in producing high-quality, marketable products that precisely meet specifications.

Q 15. Explain your understanding of textile manufacturing processes.

Textile manufacturing is a multifaceted process that transforms raw materials into finished fabrics. It generally involves several key stages, each with its own unique techniques and machinery. Think of it like a delicious recipe – you need the right ingredients and steps to get the desired outcome.

- Fiber Production: This initial stage involves cultivating, harvesting, and processing natural fibers like cotton, wool, silk, or flax; or manufacturing synthetic fibers like polyester, nylon, or acrylic. This often includes cleaning, combing, and spinning the fibers into yarns.

- Yarn Manufacturing: Yarns are created by twisting or plying together individual fibers. Different spinning methods (e.g., ring spinning, open-end spinning) influence the yarn’s properties like strength and texture. Imagine knitting – the yarn is the foundation of your project.

- Fabric Formation: This is where yarns are interlaced to create fabrics. The primary methods include weaving (interlacing warp and weft yarns), knitting (interlooping yarns), and non-woven techniques (bonding fibers mechanically or chemically). This stage dictates the fabric’s structure, drape, and overall feel.

- Finishing Processes: Once the fabric is made, it undergoes finishing treatments to improve its properties. This may include bleaching, dyeing, printing, calendaring (pressing), and other treatments to enhance color, texture, and durability. Think of it as the finishing touches on a piece of art.

The specific processes employed depend on the desired end-product – a simple cotton t-shirt will undergo a different manufacturing process than a complex jacquard woven tapestry. Understanding these stages is crucial for effective textile design, allowing designers to make informed decisions regarding material selection, structural design, and final aesthetics.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe a time you had to problem-solve a technical challenge in a textile project.

In a recent project designing a performance fabric for sportswear, we encountered significant challenges with achieving the desired level of moisture-wicking while maintaining fabric strength and durability. Our initial prototype, using a standard polyester blend, did not effectively wick away sweat. The solution wasn’t simply switching materials but rather finding the optimal blend and weave structure.

We systematically tested various blends of polyester and nylon fibers with different yarn counts and weave patterns. We utilized a tensile strength testing machine to measure the durability of the different fabric samples and a sweat wicking test to determine how well moisture was transported away from the fabric. Through a series of iterative tests and adjustments, we optimized the fabric composition, yarn structure, and weave pattern. Ultimately, we achieved a fabric that met all performance criteria: excellent moisture-wicking, high durability, and a comfortable hand feel.

This experience highlighted the importance of rigorous testing, collaboration with technical experts, and iterative design processes in addressing complex textile challenges.

Q 17. How familiar are you with different types of textile machinery?

My familiarity with textile machinery is extensive, encompassing both traditional and advanced technologies. I have practical experience operating and troubleshooting various machines. This extends from basic spinning and weaving equipment to more sophisticated machinery like:

- Spinning Machinery: Ring spinning frames, open-end spinning machines, air-jet spinning machines. I understand the differences in yarn quality and production rates these machines offer.

- Weaving Machinery: Various loom types, including shuttle looms, rapier looms, and air-jet looms. I understand the different weaving patterns and fabric structures achievable with each.

- Knitting Machinery: Circular knitting machines, flat knitting machines, and their capabilities in creating different knit structures.

- Dyeing and Finishing Machinery: Jet dyeing machines, continuous dyeing ranges, and various printing machines. I’m familiar with the impact different processing techniques have on the final product.

This knowledge allows me to anticipate challenges in the manufacturing process, make informed material choices, and effectively communicate with manufacturers to bring my designs to life.

Q 18. How do you collaborate with other team members in a design project?

Collaboration is paramount in textile design. I believe in open communication and a shared understanding of project goals from the outset. My collaborative approach involves:

- Regular Meetings: I schedule regular meetings to discuss progress, address challenges, and ensure everyone is on the same page.

- Open Communication: I maintain open channels for communication, encouraging feedback and suggestions from all team members.

- Shared Design Files: I utilize cloud-based platforms to share design files and updates, fostering transparency and easy access for everyone.

- Respectful Feedback: I provide constructive feedback to my colleagues, fostering an environment of mutual respect and growth.

In a recent project, working with a team including pattern makers, and sample technicians, this collaborative approach allowed us to integrate different perspectives and expertise. It helped avoid costly mistakes and deliver a high-quality final product on schedule.

Q 19. What are your strengths and weaknesses as a textile designer?

My strengths lie in my creative problem-solving skills, my deep understanding of textile manufacturing processes, and my ability to translate design concepts into practical, manufacturable products. I am adept at color theory, print design, and surface ornamentation techniques. I’m also a highly effective communicator and collaborator.

A potential area for development is my time management skills, particularly when juggling multiple projects simultaneously. I’m actively working on improving this through project management techniques and prioritizing tasks effectively. I view this as an ongoing process of improvement rather than a weakness.

Q 20. Describe your experience with creating textile samples.

Creating textile samples is an integral part of my design process. It’s where concepts become tangible realities. My approach involves:

- Initial Sketches and Mood Boards: I begin with sketches, mood boards, and color palettes to define the direction of the project.

- Material Selection: I carefully select the appropriate yarns, fabrics, and embellishments to meet the design criteria and manufacturing constraints.

- Sample Creation: I create a range of samples, experimenting with different techniques and variations of the design. This may involve hand-weaving, knitting, dyeing, printing, and other relevant techniques.

- Iteration and Refinement: Based on feedback and testing, I refine the samples, making adjustments to color, texture, pattern, and structure until the desired result is achieved.

- Documentation: I meticulously document the sample-making process, including material specifications, production techniques, and cost estimations.

This systematic process allows for thorough evaluation and refinement of designs before moving to full-scale production, minimizing potential issues and ensuring a high-quality final product.

Q 21. How do you manage your time effectively during the design process?

Effective time management is crucial in textile design. I utilize a project management approach to prioritize tasks and maintain a productive workflow. This includes:

- Project Breakdown: I break down large projects into smaller, manageable tasks with clear deadlines.

- Prioritization: I prioritize tasks based on urgency and importance, focusing on critical path activities first.

- Time Blocking: I allocate specific time blocks for different tasks to maintain focus and avoid multitasking.

- Regular Review: I regularly review my progress, adjusting the schedule as needed to account for unexpected delays or challenges.

- Tools and Techniques: I utilize project management software and time-tracking apps to help me stay organized and monitor my progress.

By employing these strategies, I ensure that projects are completed on time and within budget, maintaining a high level of quality throughout the design process.

Q 22. What inspires your textile designs?

My textile designs are inspired by a multitude of sources, constantly evolving and intertwining. Nature plays a significant role; I find endless inspiration in the intricate patterns of leaves, the textures of bark, the subtle color gradations of a sunset. I’m also deeply influenced by global cultures and their rich textile traditions. For example, the vibrant ikat weaving of Indonesia or the intricate embroidery of South America often sparks ideas for new color palettes and structural approaches. Finally, contemporary art, architecture, and even music can profoundly impact my creative process, leading to unexpected and exciting design solutions.

For instance, a recent collection was inspired by the microscopic structure of a seashell, translating its organic curves and fractal patterns into a series of woven tapestries. Another project drew inspiration from the rhythmic energy of jazz music, resulting in a collection of fabrics with dynamic, flowing lines and unexpected color juxtapositions.

Q 23. How do you ensure quality control in your textile designs?

Quality control in textile design is a multifaceted process that begins long before the final product. It involves meticulous attention to detail at every stage, from initial concept development to final production. I utilize a rigorous system encompassing several key steps.

- Yarn Selection & Testing: I carefully select yarns based on their fiber content, strength, and suitability for the intended design. This includes testing for colorfastness and durability.

- Prototype Development: Creating several prototypes allows for iterative refinement of the design, addressing potential issues with drape, texture, and structural integrity. This also enables testing different weaving or knitting techniques to achieve the desired outcome.

- Color Matching & Calibration: Ensuring precise color matching across different batches of fabric is crucial for consistency. This involves working closely with dyers and utilizing color management systems to maintain accuracy.

- Quality Checks at Each Stage of Production: Regular inspections throughout the manufacturing process, including yarn preparation, weaving/knitting, finishing, and packaging, ensure adherence to quality standards. This often involves collaborating with skilled artisans and factory personnel.

- Final Inspection: A thorough final inspection of the finished product is conducted to check for any defects and ensure that the final product meets the design specifications and quality standards.

This structured approach helps ensure a high level of quality and consistency in my designs.

Q 24. Describe your knowledge of textile industry standards and regulations.

My understanding of textile industry standards and regulations is comprehensive. I’m familiar with various certifications, including OEKO-TEX Standard 100 (which guarantees the absence of harmful substances), GOTS (Global Organic Textile Standard) for organic cotton, and various standards related to workplace safety and environmental compliance. I’m also aware of the relevant legislation concerning product labeling and consumer protection in various markets. These standards are critical for ethical and sustainable design practices.

For example, I understand the importance of adhering to specific colorfastness standards to ensure that the fabric maintains its color even after repeated washing. This knowledge allows me to choose appropriate dyes and pre-treatments. Additionally, I am aware of the regulations surrounding the use of specific chemicals in dyeing and finishing processes, prioritizing environmentally friendly options whenever possible. Knowledge of these standards ensures not only the high quality of the final product but also its safety and sustainability.

Q 25. What are your salary expectations?

My salary expectations are commensurate with my experience and expertise in the field of textile design. Based on my research of comparable roles and my unique skillset, I am targeting a salary range between [Insert Salary Range] annually.

Q 26. Why are you interested in this specific role?

I’m highly interested in this specific role because of [Company Name]’s reputation for innovation and its commitment to [mention specific company values or projects that resonate with you]. The opportunity to work on [mention specific projects or aspects of the role] within a collaborative and creative team aligns perfectly with my career goals. I’m particularly drawn to [mention a specific aspect of the company culture or working style that appeals to you]. My skills and experience in [mention specific skills] are ideally suited to contribute meaningfully to your team’s success.

Q 27. Where do you see yourself in five years?

In five years, I see myself as a significant contributor to [Company Name]’s design team, having taken on greater responsibilities and leadership roles. I aim to have further developed my expertise in [mention specific area of expertise you wish to develop], possibly through mentoring junior designers or spearheading innovative projects. I envision myself being recognized as a leading voice within the company for sustainable and ethical design practices.

Q 28. Do you have any questions for us?

Yes, I do have a few questions. Firstly, could you elaborate on the company’s current focus in terms of sustainable textile production? Secondly, what opportunities are there for professional development and skill enhancement within the company? Finally, can you describe the team dynamic and collaborative work environment?

Key Topics to Learn for Your Fiber Arts and Textile Design Interview

- Fiber Properties & Selection: Understanding the characteristics of natural and synthetic fibers (strength, drape, texture, etc.) and their suitability for different applications. Consider how you’d select fibers for a specific project and justify your choices.

- Dyeing & Printing Techniques: Familiarize yourself with various dyeing methods (e.g., natural dyeing, reactive dyeing) and printing techniques (e.g., screen printing, digital printing). Be prepared to discuss the pros and cons of each and their impact on the final product.

- Textile Design Principles: Master concepts like color theory, pattern design, composition, and texture. Think about how these principles influence the aesthetic and functionality of textiles.

- Weaving & Knitting Techniques: Demonstrate understanding of basic weaving and knitting structures, their applications, and how variations in these structures affect the final fabric’s properties. Be ready to discuss different types of looms and knitting machines.

- Sustainability & Ethical Production: Showcase your awareness of eco-friendly materials, sustainable practices in textile production, and ethical considerations within the industry. Discuss your approach to minimizing environmental impact.

- Textile Technology & Innovation: Explore advancements in textile manufacturing, digital design tools, and emerging technologies impacting the field. Discuss your understanding of trends and future directions.

- Problem-Solving & Design Process: Be prepared to discuss your design process, from initial concept to final product. Highlight your ability to troubleshoot challenges and adapt to changing requirements.

Next Steps

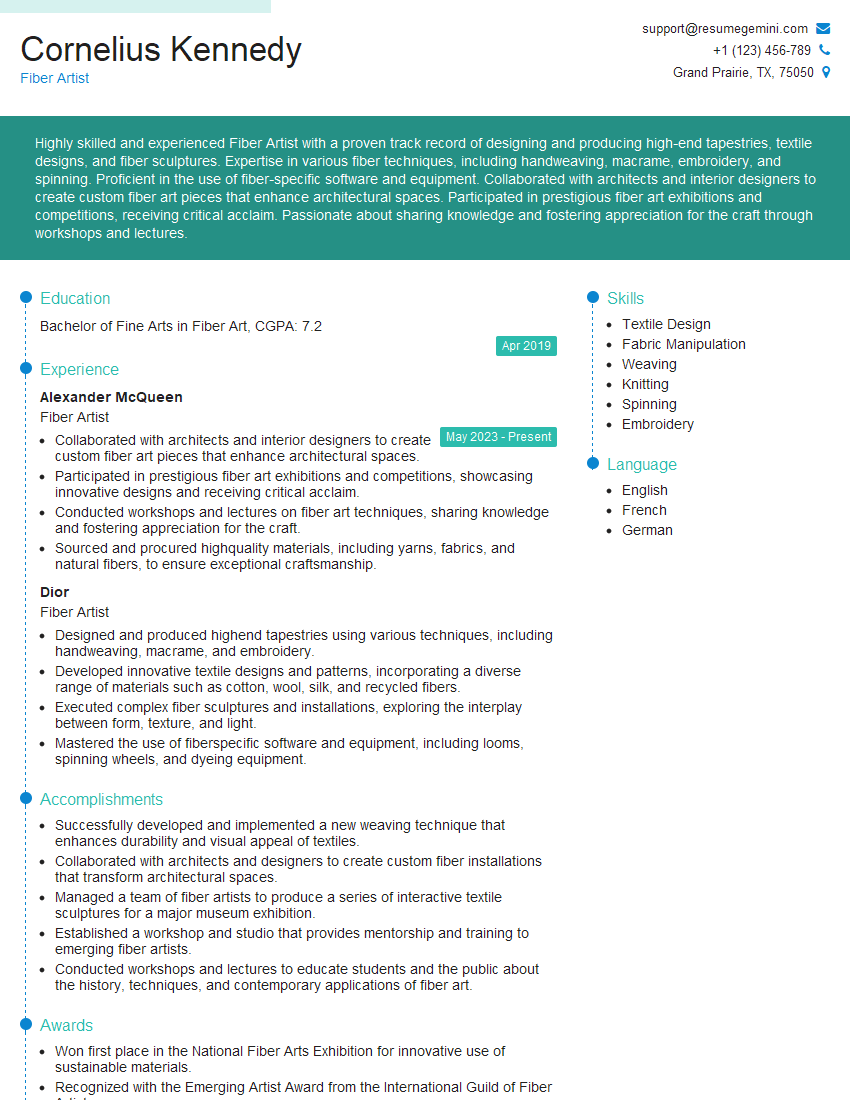

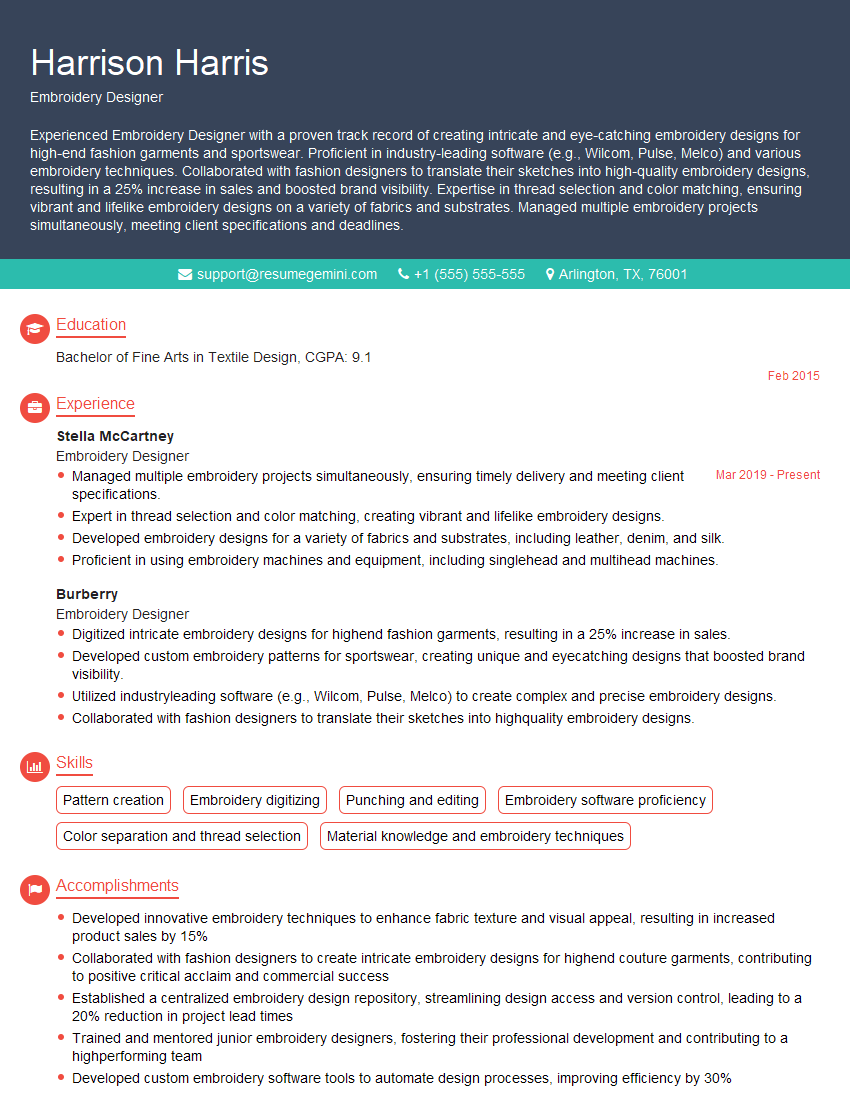

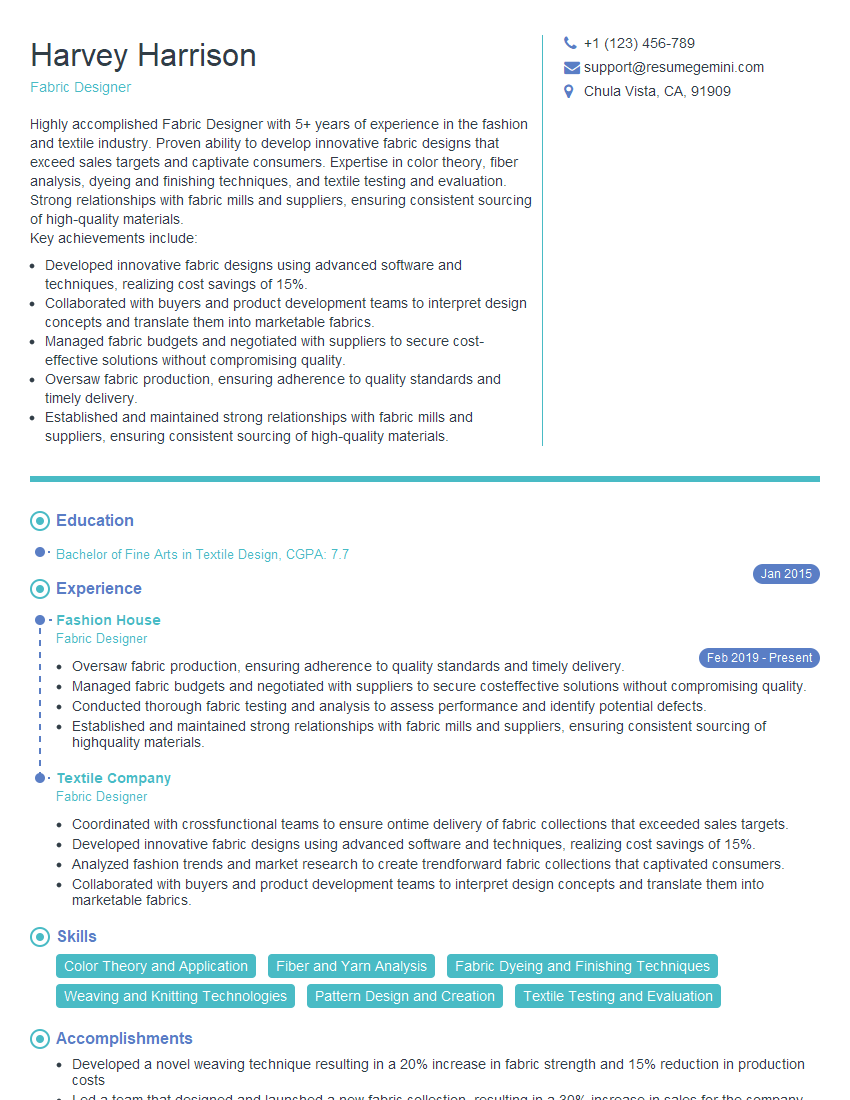

Mastering Fiber Arts and Textile Design opens doors to exciting and fulfilling careers. To stand out, a strong, ATS-friendly resume is crucial. ResumeGemini can help you craft a compelling resume that highlights your skills and experience effectively. ResumeGemini offers a streamlined process and provides examples of resumes tailored to Fiber Arts and Textile Design, ensuring your application makes a lasting impression. Invest time in creating a professional resume; it’s a key step towards securing your dream role.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO