Preparation is the key to success in any interview. In this post, we’ll explore crucial Hand and Machine Embroidery interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Hand and Machine Embroidery Interview

Q 1. What are the different types of embroidery stitches you are proficient in?

My proficiency in embroidery stitches spans a wide range, encompassing both hand and machine embroidery techniques. In hand embroidery, I’m adept at various stitches including:

- Basic stitches: Running stitch, backstitch, stem stitch, satin stitch, French knots.

- More advanced stitches: Chain stitch, lazy daisy stitch, seed stitch, couching, and various filling stitches like detached chain stitch.

For machine embroidery, my expertise extends to utilizing built-in stitches and creating custom designs. This includes understanding and applying different stitch types such as:

- Fill stitches: Satin, dense satin, and various pattern fills (e.g., diagonal, zigzag).

- Outline stitches: Running stitch, zigzag, and specialized decorative stitches.

- Appliqué stitches: Tack down stitches and decorative edge stitches for securing fabric appliqués.

I’m constantly expanding my stitch repertoire, exploring new techniques and experimenting with stitch combinations to achieve unique effects.

Q 2. Describe your experience with various embroidery machines (e.g., single-head, multi-head).

My experience with embroidery machines encompasses both single-head and multi-head machines. I’ve worked extensively with single-head machines, from basic home models to professional-grade machines with advanced features like automatic thread trimming and multiple needle positions. This experience has given me a solid understanding of machine mechanics, thread tension, and stitch regulation.

My work with multi-head machines, primarily in a production environment, has honed my skills in efficient design setup, managing multiple heads simultaneously, and troubleshooting complex production issues. Understanding the intricacies of each machine type, from the basic mechanical components to advanced software features, is crucial for effective operation and efficient production workflows.

For instance, I’ve successfully managed projects involving six-head machines, requiring careful design planning and coordination to achieve consistent embroidery across all heads. This involved optimizing thread paths, fabric placement, and machine settings to minimize downtime and ensure high-quality output.

Q 3. Explain the process of digitizing embroidery designs.

Digitizing embroidery designs involves translating a visual image or sketch into a stitch file that an embroidery machine can understand. This process typically involves the use of specialized software.

The steps are generally as follows:

- Image Import and Preparation: The design is imported into the software, cleaned up (removing unwanted elements), and optimized for stitching. This might involve adjusting colors, removing extraneous details, or separating the design into different color areas.

- Stitch Type Selection: Appropriate stitch types are chosen for different areas of the design—for instance, satin stitches for filled areas and running stitches for outlines. Different stitch types affect the density and overall appearance of the embroidery.

- Stitch Density and Underlay Selection: The stitch density is carefully controlled. Higher density means denser stitching which is more durable, but also slower. Underlays may be added for stability on certain fabrics.

- Color Separation: The design is separated into different color sections, each with its own stitch file. The software creates a sequence that dictates the order of color changes during stitching.

- Simulation and Optimization: The software simulates the stitching process, allowing for adjustments to stitch density, underlay, jump stitches, and other settings to optimize the design for the desired effect and machine capabilities.

- File Export: The finalized design is exported as a stitch file, typically in formats like .DST, .EXP, or .PES, which are compatible with various embroidery machines.

Precision and attention to detail are crucial in digitizing, as errors can lead to stitching problems or even damage to the machine or fabric.

Q 4. How do you troubleshoot common machine embroidery problems (e.g., thread breaks, skipped stitches)?

Troubleshooting machine embroidery problems requires a systematic approach. Let’s address thread breaks and skipped stitches:

- Thread Breaks:

- Check thread tension: Improper thread tension is a primary culprit. Adjust the tension dials on the machine, ensuring it’s balanced between the upper and lower tensions. Too tight or too loose can cause breaks.

- Inspect the thread path: Ensure the thread is not snagged or tangled anywhere along its path from the spool to the needle.

- Examine the needle: Bent or damaged needles are common causes. Replace the needle with a new one of the correct type and size for the fabric.

- Check the bobbin: A poorly wound or damaged bobbin can cause thread breaks. Use high-quality bobbins and wind them correctly.

- Skipped Stitches:

- Check the needle: A dull or incorrectly sized needle can skip stitches. Use a sharp needle appropriate for the fabric weight and thread.

- Review the stitch settings: Incorrect stitch length or speed can lead to skipped stitches. Adjust the settings according to the fabric and design.

- Inspect the feed dogs: Ensure that the feed dogs are clean and functioning correctly to move the fabric smoothly under the needle.

- Check the bobbin tension: Improper bobbin tension also contributes to skipped stitches. Ensure it’s properly adjusted.

Often, a combination of factors contributes to the problem. A methodical process of elimination helps pinpoint the root cause.

Q 5. What are the key differences between hand and machine embroidery in terms of techniques and results?

Hand and machine embroidery differ significantly in techniques and results. Hand embroidery offers unparalleled control and precision, allowing for intricate detailing and unique textural effects impossible to replicate with a machine. The process is slower, but the results often exhibit a unique, handcrafted quality.

Machine embroidery, conversely, is faster and better suited for large-scale projects or designs requiring consistency and speed. While it may lack the subtle nuances of hand embroidery, it offers unmatched efficiency and repeatability. The stitches are generally more consistent and precise, but might lack some of the artistic freedom of hand-stitching.

Think of it like painting: hand embroidery is like working with fine brushes and pigments, allowing for immense detail and personal expression. Machine embroidery is more like using an airbrush—capable of quick, large-scale work with a consistent finish, yet limited in the subtleties it can produce.

Q 6. How do you select the appropriate needle and thread for different fabrics and embroidery techniques?

Selecting the right needle and thread is crucial for successful embroidery. The choice depends on the fabric and the embroidery technique.

Needles: Needle size is denoted by numbers (e.g., 75/11, 90/14); smaller numbers indicate finer needles. Different fabrics need different needle sizes: delicate fabrics require finer needles to avoid damage, while heavier fabrics need sturdier needles. There are also needles specifically designed for different types of threads (e.g., metallic threads). For example, a size 75/11 needle is usually appropriate for lightweight cotton fabrics and embroidery floss, while a size 90/14 is better for denim or canvas.

Thread: The thread’s weight and fiber content also play a crucial role. Embroidery floss is a common choice, but there are other options like rayon, metallic threads, or cotton threads, depending on the desired effect and fabric. For instance, rayon thread produces a beautiful sheen, while metallic threads add a glamorous touch but may require specialized needles.

A good rule of thumb is to match the weight of the thread to the weight of the fabric to avoid creating tension imbalances or excessive bulk in the embroidery.

Q 7. Explain your understanding of hooping techniques and their importance in embroidery.

Hooping, the process of securing fabric in a hoop or frame, is paramount in machine embroidery. Proper hooping ensures the fabric is taut and smooth during stitching, preventing puckering, wrinkles, and inconsistent stitching.

There are various hooping techniques, but the fundamental principle is to achieve even tension across the entire fabric area to be embroidered. Using the wrong hoop size can also lead to fabric damage.

Techniques: Often, an embroidery hoop consists of an inner and outer ring; the fabric is placed between them, with the outer ring tightening the inner ring against the fabric. It is crucial to ensure that the fabric isn’t overly stretched or strained, as this will distort the design and possibly damage the fabric. Some machines have advanced hoop systems with sensors to aid in accurate hooping.

Importance: Poor hooping is a common source of many embroidery problems. A loose hoop can lead to skipped stitches, puckering, and distorted designs. An overly tight hoop can cause fabric damage, needle breakage, and thread breakage. Therefore, mastering various hooping techniques is essential for producing high-quality embroidery.

Q 8. How do you maintain and care for your embroidery equipment?

Maintaining embroidery equipment is crucial for longevity and consistent performance. For hand embroidery, this involves regular cleaning of needles (using a needle threader helps prevent damage), proper storage of threads (organized by color and type, away from direct sunlight and moisture), and keeping scissors sharp. For machine embroidery, preventative maintenance is key. This includes regularly lubricating moving parts according to the manufacturer’s instructions, cleaning the bobbin area and hook assembly to remove lint and debris, and ensuring the tension is correctly adjusted. Think of it like maintaining a car – regular check-ups prevent costly repairs down the line. I also perform a monthly deep clean of my machine, removing the needle plate and cleaning underneath.

For example, I always use a lint brush to remove fluff before and after each embroidery session on my machine, this prevents thread breakage and ensures even stitching.

Q 9. Describe your experience with different embroidery software (e.g., Wilcom, Pulse).

My experience with embroidery software spans several programs, including Wilcom and Pulse. Wilcom, a powerful industry standard, excels in its comprehensive features for digitizing and editing complex designs. Its capabilities in color separation and stitch optimization are invaluable for large-scale projects. I’ve used it extensively for creating detailed designs with intricate stitching and multiple color changes. Pulse, on the other hand, offers a more intuitive interface, making it excellent for quicker designs and simpler projects. It’s a great tool for rapid prototyping and smaller-scale projects where speed and ease of use are prioritized. The choice of software really depends on the project’s complexity and the desired outcome. For example, I might use Pulse for a quick personalized birthday patch but choose Wilcom for a detailed garment design destined for mass production.

Q 10. How do you manage large embroidery projects and meet deadlines?

Managing large embroidery projects and meeting deadlines requires meticulous planning and efficient workflow. I begin by breaking down the project into smaller, manageable tasks, creating a detailed timeline with realistic deadlines for each step. This includes digitizing the design (if necessary), sourcing materials, preparing the fabric, and, of course, the embroidery process itself. Using project management tools, like a Kanban board or spreadsheet, helps me track progress and identify any potential bottlenecks. For example, for a recent large corporate logo embroidery project, I created a detailed schedule that included buffer time for unexpected delays. This ensured on-time delivery and prevented last-minute rushes. Prioritization and communication with clients are also vital; keeping them informed about progress and addressing any concerns proactively helps ensure a smooth process.

Q 11. Explain your process for creating an embroidery design from scratch.

Creating an embroidery design from scratch involves several steps. It typically begins with sketching or digitally creating the initial concept. Next, I refine the design, focusing on stitch types, density, and color placement to ensure the final design is both aesthetically pleasing and structurally sound for embroidery. For example, I might sketch a floral design on paper, then digitally trace and refine it in software, selecting appropriate stitches like satin stitch for petals and fill stitches for leaves. After this, I digitize the design, converting the artwork into a stitch file compatible with my embroidery machine or suitable for hand embroidery. Finally, I test the design on a sample fabric before committing to the final piece. This process allows for adjustments to stitch density, color, and placement, ensuring the final product meets my standards.

Q 12. How do you ensure color accuracy and consistency in your embroidery work?

Maintaining color accuracy and consistency is critical for high-quality embroidery. For machine embroidery, I meticulously select threads that closely match the design’s digital color palette. I also perform color tests on a scrap piece of the target fabric before beginning the main embroidery. For hand embroidery, I select threads from a well-organized collection, ensuring that the shades used maintain consistency throughout the project. Accurate lighting is crucial in both cases – natural daylight is ideal, but consistent artificial lighting is also necessary to avoid color distortion. Color management software also aids in ensuring consistency between the digital design and the final embroidered piece. For example, I always use a color chart to reference thread numbers and cross-reference them with my digital design palette, this minimizes discrepancies in color.

Q 13. Describe your experience working with different fabric types (e.g., cotton, silk, linen).

Experience with various fabric types is essential for successful embroidery. Different fabrics require different needle sizes, thread types, and stitch densities. Cotton, for example, is a sturdy and versatile fabric that handles various embroidery techniques well. Silk, however, is more delicate and requires a finer needle and lighter stitching to prevent damage. Linen, with its characteristic texture, can sometimes require adjustments in tension and stitch density to achieve even stitching. Understanding the properties of each fabric type is crucial for selecting the appropriate techniques and avoiding issues like puckering or thread breakage. For example, I might use a smaller needle and a looser tension for silk to prevent the fabric from being pulled or damaged.

Q 14. How do you handle complex embroidery designs with multiple colors and layers?

Complex embroidery designs with multiple colors and layers demand careful planning and execution. For machine embroidery, I use software’s color separation and layer management features to efficiently organize the stitching sequence. This ensures that colors are stitched in the correct order, preventing color overlap and ensuring a clean finish. For hand embroidery, I typically work in layers, completing one color or section before moving to the next, using a stabilizer (like water-soluble stabilizer) to maintain the fabric’s structure. Careful consideration of stitch types and density is crucial, preventing overlapping stitches and maintaining clear separation between colors and layers. For example, I might use a running stitch for outlining a design before filling it with satin stitch to create a layered effect that also prevents the colors from bleeding into each other.

Q 15. What are your strategies for managing thread tension in both hand and machine embroidery?

Managing thread tension is crucial for achieving even stitches and preventing puckering or loose threads in both hand and machine embroidery. It’s like finding the ‘Goldilocks’ zone – not too tight, not too loose, but just right.

Hand Embroidery: Consistent tension is achieved through practice and mindful control. I adjust tension by slightly pulling on the needle thread as I stitch, ensuring it’s taut but not overly stretched. Using a consistent stitch length also helps. For instance, when working with delicate fabrics, I might use a slightly looser tension to avoid damaging the fabric, while thicker fabrics can handle firmer tension.

Machine Embroidery: Machine embroidery offers more control through machine settings. I start by selecting the correct needle and thread type for the fabric. Then, I adjust the machine’s tension dial, often starting at the manufacturer’s recommended setting and making minor adjustments based on the fabric and thread. If the top thread is breaking frequently, the tension is likely too tight; if stitches are loose or loops form on the back, the tension is too loose. I also use techniques like pre-wound bobbins and proper bobbin placement to ensure smooth thread flow and consistent tension. Testing on a scrap of the fabric before starting the project is crucial.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you adapt your techniques for different embroidery applications (e.g., apparel, home décor)?

Adapting embroidery techniques for different applications involves understanding the fabric’s properties and the desired outcome. The embroidery on a delicate silk blouse requires a different approach than that on a sturdy canvas tote bag.

- Apparel: For apparel, I prioritize using lightweight, tear-away stabilizers or water-soluble stabilizers to avoid stiffness or bulk. I also consider the drape and stretch of the fabric, choosing stitches that complement its movement. Fine details are emphasized, and the thread weight and type are chosen carefully to maintain a high-quality finish that withstands washing and wear.

- Home Décor: Home décor projects, like wall hangings or pillow covers, often utilize heavier fabrics and allow for more robust embroidery techniques. I may use tear-away stabilizer or even a cut-away stabilizer for intricate designs. Here, the focus is on creating a visually striking piece that lasts. I might even incorporate different textures and embellishments, such as beads or sequins, to add interest.

For example, a delicate floral pattern on a linen tablecloth would be done with a different type of thread and stitch than a bold geometric design on a canvas tote bag. The choice of stabilizer is also crucial—a water-soluble stabilizer is ideal for apparel to avoid leaving a residue, while a heavier cut-away stabilizer might be preferred for a canvas tote.

Q 17. How familiar are you with various stabilizer types and their applications?

My familiarity with stabilizers is extensive. Choosing the right stabilizer is paramount for achieving professional results, much like selecting the right foundation for a building.

- Tear-away: Easily removed after embroidery, perfect for projects where a smooth surface is desired, such as lightweight apparel.

- Cut-away: Remains in place after embroidery, offering extra support for dense designs or difficult-to-manage fabrics like knits.

- Water-soluble: Dissolves in water, ideal for delicate fabrics where removing a stabilizer without causing damage is crucial.

- Wash-away: Similar to water-soluble but requires washing rather than dissolving in water.

- Sticky: Adhesive-backed stabilizers provide excellent support, especially useful for fabrics that might shift during embroidery.

I often combine stabilizer types. For example, I might use a wash-away stabilizer underneath a sticky stabilizer for extra support when embroidering a design on a very sheer fabric.

Q 18. Describe your experience with different embroidery techniques (e.g., free-motion, appliqué, shadow work).

My embroidery repertoire encompasses a wide range of techniques, each with its unique appeal and application.

- Free-motion embroidery: This technique involves moving the fabric freely under the needle, allowing for organic, flowing designs. It’s like drawing with a sewing machine! I use this often for creating unique backgrounds or filling in areas of a design.

- Appliqué: This involves attaching fabric shapes to a background fabric. Precision is key here, and I use a variety of techniques—from blanket stitch to satin stitch—to secure the appliqué pieces neatly. It’s perfect for creating dimensional and detailed pieces.

- Shadow work: This technique uses layers of fabric and stitching to create depth and shading, resulting in beautifully textured designs. I often combine it with other techniques, such as appliqué, for truly stunning results. It’s like sculpting with fabric and thread.

Each technique demands a different level of skill and attention to detail, and I adapt my approach based on the project’s requirements and my desired aesthetic.

Q 19. How do you ensure quality control in your embroidery process?

Quality control is an ongoing process, not a single step. I employ a multi-faceted approach:

- Pre-embroidery Checks: Before starting, I meticulously check the design for accuracy, ensuring proper digitization (for machine embroidery) or a clear pattern (for hand embroidery). I also prepare the fabric, stabilizer, and thread, checking for any defects.

- Process Monitoring: During embroidery, I regularly inspect the work to ensure even stitching, consistent tension, and the absence of flaws. I address any issues immediately.

- Post-embroidery Inspection: Once the embroidery is complete, I carefully examine the finished piece, checking for any loose threads, uneven stitching, or imperfections. I may press the finished piece to enhance its appearance and ensure the embroidery lies flat.

For example, if I notice puckering during machine embroidery, I immediately stop and adjust the machine tension or stabilizer. After hand embroidery, I carefully trim any stray threads and use a small, sharp pair of scissors to remove any excess stabilizer.

Q 20. Describe your problem-solving approach when faced with unexpected embroidery challenges.

My problem-solving approach is systematic and methodical. I approach embroidery challenges by:

- Identifying the Problem: Carefully examine the issue – Is it a tension problem? A needle issue? A stabilizer problem? A design error?

- Research and Analysis: Consult my resources (books, online forums, experienced embroiderers) to find potential solutions and gather information about the specific problem.

- Experimentation: Try different solutions systematically, starting with the simplest and safest options. Keep detailed notes on what worked and what didn’t.

- Refine and Repeat: If the initial solution isn’t fully effective, refine my approach based on the results of the experimentation. Iterate until the issue is resolved.

For example, if stitches are skipping on my machine, I systematically check the needle for damage, the bobbin case for obstructions, and the tension settings before considering more complex solutions.

Q 21. What are your strengths and weaknesses as an embroiderer?

My strengths lie in my attention to detail, my adaptability to different techniques and materials, and my ability to troubleshoot effectively. I am patient and persistent, and I strive for perfection in my work. My experience allows me to anticipate and prevent many common embroidery problems.

A weakness, if I had to pinpoint one, would be my tendency to be perfectionistic. Sometimes, this can slow down my process. However, I’m actively working on balancing my desire for excellence with efficient time management.

Q 22. How do you stay updated with the latest trends and techniques in embroidery?

Staying current in the dynamic world of embroidery requires a multi-pronged approach. I actively engage with several key resources to ensure my techniques and knowledge remain sharp. This includes subscribing to embroidery magazines like Embroidery and Threads, which feature articles on new stitches, designs, and industry trends. I also regularly attend workshops and conferences, both online and in-person, hosted by organizations like the Embroiderers’ Guild. These events offer invaluable opportunities to learn from master embroiderers and network with fellow professionals. Further, I actively participate in online communities, forums, and social media groups dedicated to embroidery. These platforms are a rich source of inspiration, tutorials, and discussions about the latest innovations in materials and techniques. Finally, I regularly review design blogs and online portfolios to see what other artists are creating and how they are pushing the boundaries of the craft.

Q 23. Are you familiar with industrial embroidery practices?

Yes, I’m very familiar with industrial embroidery practices. My experience extends beyond hand embroidery to encompass a strong understanding of computerized embroidery machines, including Tajima, Barudan, and Melco. I understand the intricacies of digitizing embroidery designs for machine production, including the importance of stitch density, underlay, and jump stitches for optimal results. I’ve worked with various types of industrial embroidery machines, understanding their capabilities and limitations in terms of fabric types, thread counts, and design complexity. For example, I’ve worked on projects requiring high-speed production using multi-needle machines for items like logo embroidery on apparel or large-scale designs on upholstery. I am also adept at troubleshooting machine malfunctions and maintaining equipment to ensure efficient workflow. This knowledge allows me to bridge the gap between hand-crafted designs and the efficient production techniques needed for large-scale projects.

Q 24. Explain your experience working under pressure and meeting tight deadlines.

Working under pressure and meeting tight deadlines is something I’ve honed over years of experience. I thrive in fast-paced environments. For example, I once had to embroider 50 custom-designed handkerchiefs for a wedding in just two weeks. To manage this, I first prioritized tasks, creating a detailed schedule that allocated specific time slots for each stage – from design transfer to finishing. I also utilized efficient techniques like using multiple embroidery hoops simultaneously when possible. Communication was key; I maintained consistent contact with the client to manage expectations and address any concerns promptly. Ultimately, not only did I deliver all the handkerchiefs on time, but I also received positive feedback on the quality of the work. My approach involves prioritizing, meticulous planning, effective time management, and clear communication to ensure successful project completion under pressure.

Q 25. Describe your ability to adapt to different work environments and team dynamics.

Adaptability is crucial in the embroidery field. I’ve worked in various settings, from small artisan studios to larger-scale production facilities. This has provided me with experience working both independently and as part of a collaborative team. In smaller studios, I’ve been responsible for managing my own projects from start to finish. In larger settings, I’ve learned to effectively communicate with designers, technicians, and other team members to ensure seamless project execution. My ability to adapt to diverse work environments stems from my strong communication skills and willingness to learn and embrace new challenges. I’m comfortable taking direction, offering constructive input, and adjusting my approach based on team dynamics and project requirements. For instance, working with a team on a large-scale project meant learning to divide tasks effectively and coordinating schedules to deliver a high-quality, cohesive final product.

Q 26. What are your salary expectations for this role?

My salary expectations for this role are in the range of [Insert Salary Range] annually. This is based on my experience, skills, and the specific requirements of this position. I am open to discussing this further based on the details of the benefits package and overall compensation structure.

Q 27. How do you handle constructive criticism and feedback on your embroidery work?

I view constructive criticism as an invaluable opportunity for growth. I actively seek feedback on my embroidery work, seeing it not as personal judgment but as a chance to refine my skills and improve my techniques. For example, if I receive feedback that a particular stitch needs to be more consistent, I analyze my process, identify the source of the inconsistency (e.g., tension, stitch placement), and practice to correct it. I also appreciate feedback on design choices and overall aesthetic aspects, viewing it as a path to better understanding client preferences and developing stronger design sense. I actively listen, ask clarifying questions, and document feedback to ensure I learn from every suggestion. My approach is to use criticism to improve and perfect my work, not to feel discouraged.

Q 28. What are your long-term career goals in the field of embroidery?

My long-term career goals involve becoming a recognized expert in my field, specializing in a particular niche within embroidery – perhaps combining traditional techniques with modern technology or focusing on sustainable practices. I envision myself leading workshops, teaching others, and possibly even creating my own line of embroidery designs and patterns. I am committed to continually advancing my skills and knowledge, pushing the boundaries of what’s possible in embroidery, and sharing my passion with others.

Key Topics to Learn for Hand and Machine Embroidery Interview

- Hand Embroidery Techniques: Understanding various stitches (e.g., running stitch, backstitch, satin stitch, French knots), their applications, and choosing appropriate stitches for different fabrics and designs. Consider the historical context and evolution of these techniques.

- Machine Embroidery Techniques: Familiarity with different machine embroidery techniques, including free-motion embroidery, appliqué, and using various embroidery feet. Understand the importance of proper digitizing and hooping techniques to achieve high-quality results. Explore different machine types and their capabilities.

- Fabric Selection and Preparation: Knowledge of different fabric types, their suitability for hand and machine embroidery, and appropriate pre-treatment methods (e.g., stabilizer selection, pre-washing). This includes understanding how fabric choice affects stitch selection and overall project outcome.

- Design and Pattern Creation: Ability to create or adapt embroidery designs, understanding design principles like balance, proportion, and color theory. This includes sketching, transferring designs, and modifying patterns for different applications.

- Thread Selection and Management: Understanding different types of embroidery threads (e.g., cotton, rayon, silk), their properties, and appropriate applications. Proper thread management techniques for both hand and machine embroidery are crucial for efficient and high-quality results.

- Troubleshooting and Problem-Solving: Experience in identifying and resolving common embroidery issues, such as thread breakage, tension problems, skipped stitches, and puckering. Demonstrating a proactive approach to problem-solving is highly valuable.

- Embroidery Software and Digitizing (for Machine Embroidery): Understanding the basics of embroidery software, such as digitizing designs, editing stitch density, and optimizing for different machines. This includes familiarity with common file formats used in machine embroidery.

- Health and Safety: Awareness of appropriate safety measures and ergonomic practices to prevent injuries during hand and machine embroidery work. This is important for maintaining a long and healthy career in this field.

Next Steps

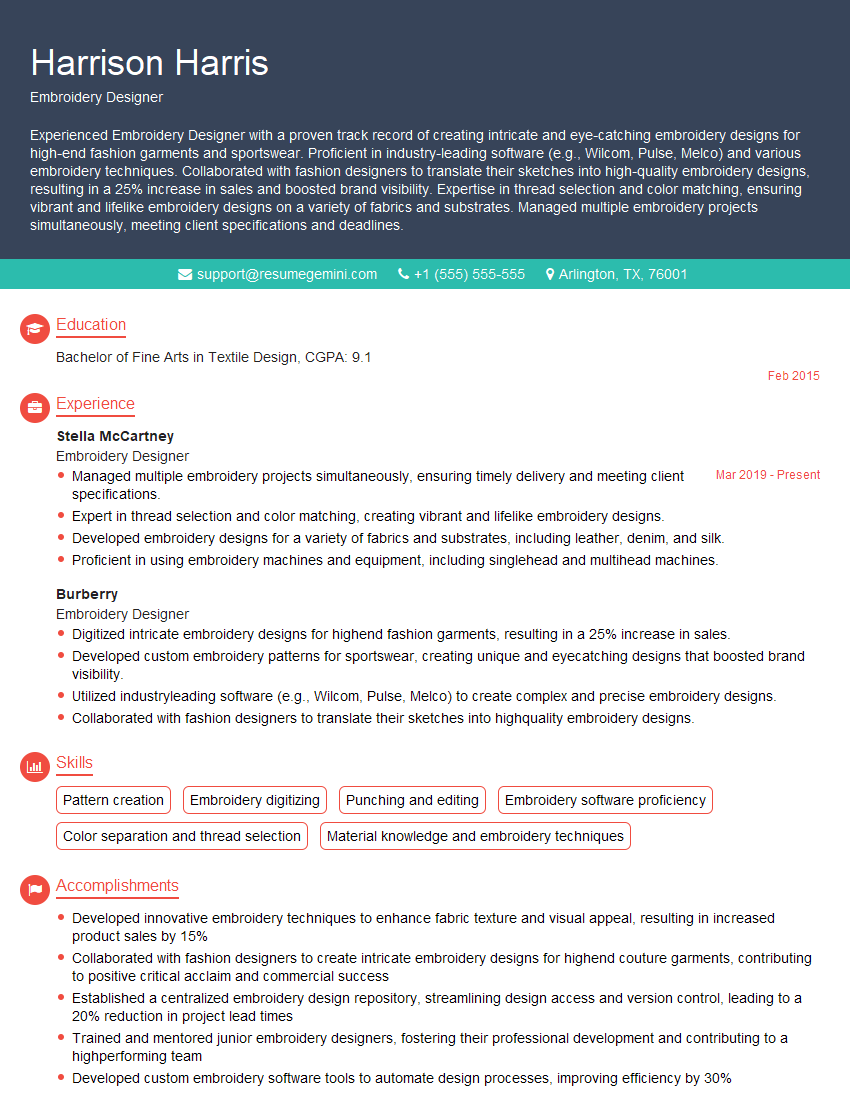

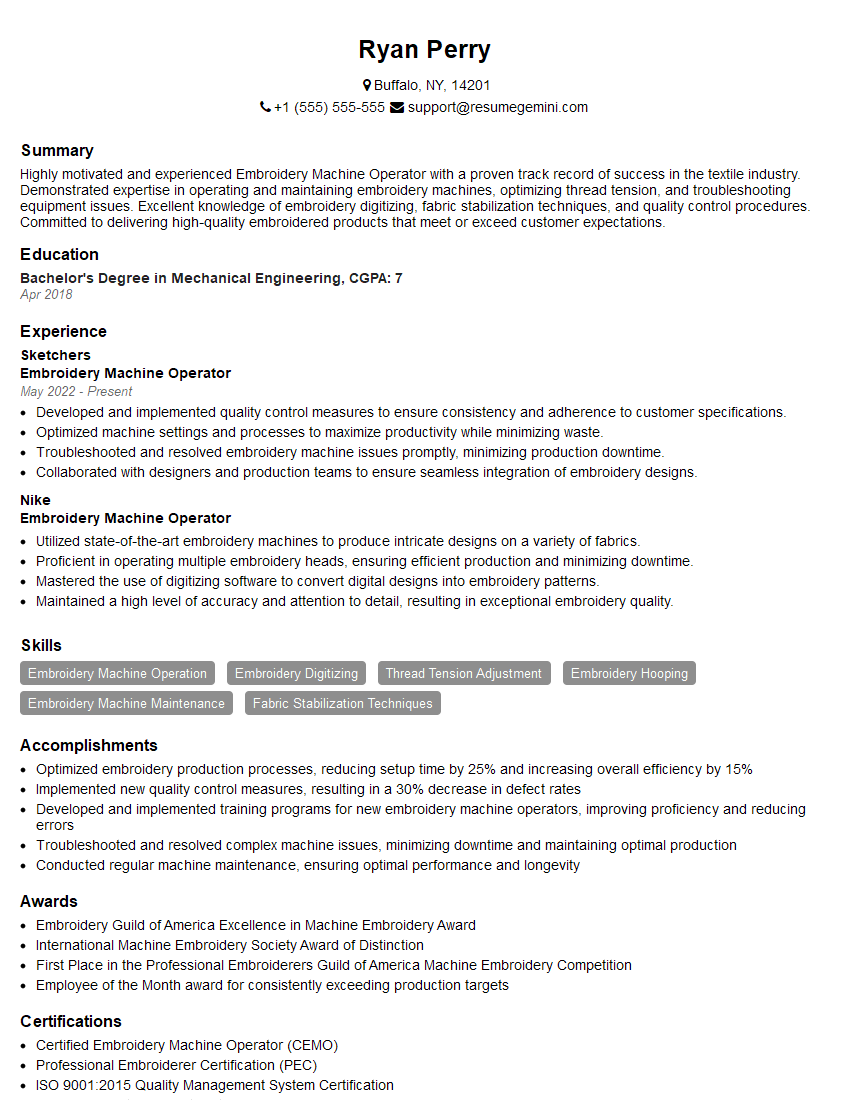

Mastering hand and machine embroidery opens doors to diverse and rewarding career paths, from freelance work to roles in fashion design, textile art, and even teaching. To maximize your job prospects, create a compelling, ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional resume tailored to the embroidery industry. Examples of resumes tailored to Hand and Machine Embroidery are available to help you get started. Invest the time to craft a strong resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO