Unlock your full potential by mastering the most common Aviation Refueling interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Aviation Refueling Interview

Q 1. What are the different types of aviation fuel and their properties?

Aviation fuel is categorized primarily into Jet A and Jet A-1, with minor variations like Jet B. These fuels are highly refined kerosene-based products designed for specific performance characteristics in aircraft engines.

- Jet A: This is the most common type, suitable for a wide range of aircraft and operating temperatures. It’s a colorless to straw-colored liquid, characterized by its low freezing point (-40°C or -40°F), making it suitable for diverse climates. Its density and energy content are carefully controlled for efficient combustion.

- Jet A-1: Very similar to Jet A, with the key difference being that it also meets the more stringent specifications for thermal oxidative stability. This means it resists the formation of deposits in fuel systems, which is critical for engine longevity.

- Jet B: This is a wide-cut naphtha-based fuel used primarily in colder climates. Its lower freezing point (-50°C or -58°F) allows for reliable operation in extreme cold, however, it is less common than Jet A and Jet A-1 due to its lower energy density.

The key properties of all these fuels include their freezing point, flash point (the temperature at which it ignites), density, and energy content (heat of combustion). These properties are rigorously tested and monitored to ensure engine safety and efficiency.

Q 2. Explain the process of pre-flight fuel checks.

Pre-flight fuel checks are crucial to ensure a safe flight. They involve verifying the fuel type, quantity, and condition before any flight. These checks, performed by both ground crews and pilots, usually follow a standardized checklist.

- Visual Inspection: Check for any leaks, damage to the fuel tanks or lines, or signs of contamination.

- Fuel Quantity Check: Use fuel gauges, dipsticks (less common on modern aircraft), or computer systems to ascertain the fuel level in each tank. This often involves comparing the reading against flight planning requirements.

- Fuel Type Verification: Confirm the fuel dispensed matches the aircraft’s requirements by checking fuel receipts, tank markings, and associated documentation. Incorrect fueling is a significant safety hazard.

- Cross-checking: Multiple crew members often cross-check each other’s readings to minimize errors. A second pair of eyes is critical for safety.

For example, a pilot might visually inspect the fuel filler caps, then check the fuel quantity indicated on the electronic flight instrument system (EFIS) and finally, cross-check this information against the refueling documentation provided by ground crew. Any discrepancies require immediate investigation before flight.

Q 3. Describe the safety procedures involved in aircraft refueling.

Aviation refueling safety is paramount due to the flammability of the fuel. Strict procedures are followed to mitigate risks. These include:

- Grounding: Both the aircraft and the refueling equipment must be properly grounded to prevent static electricity buildup, which could ignite fuel vapors.

- No Smoking/Open Flames: A strict no-smoking policy is enforced in the refueling area. All ignition sources are eliminated to minimize fire hazards.

- Proper PPE: Refuelers wear personal protective equipment (PPE), including flame-resistant clothing, safety glasses, and gloves.

- Spill Prevention & Control: Procedures are in place to prevent spills, including careful handling, use of overfill prevention devices, and the presence of spill kits and absorbent materials.

- Communication: Clear communication between ground crews and pilots is vital, ensuring everyone understands the refueling plan, quantity, and fuel type.

- Emergency Response Plan: A well-defined emergency response plan must be readily accessible and understood by all involved personnel in case of a fire or spill.

Think of it like handling highly flammable liquids – extreme caution is mandatory, with each step meticulously followed to ensure safety.

Q 4. How do you ensure the correct grade of fuel is dispensed?

Ensuring the correct fuel grade is crucial. Several methods are used to guarantee accuracy:

- Visual Inspection: Refuelers visually check the fuel tank markings and the fuel delivery documents to ensure consistency.

- Fuel Manifold: Modern facilities use fuel manifolds, which are interconnected systems ensuring that the right grade is routed to the designated aircraft tank.

- Fuel Quality Testing: Regular sampling and testing of the fuel are carried out to verify its quality and composition. This usually takes place at the fuel storage facility before delivery.

- Electronic Fuel Management Systems: Many airports utilize electronic systems that track and manage the fuel dispensing process, minimizing the chance of human error.

- Documentation: Detailed records are maintained throughout the entire process, tracking the fuel type, amount delivered, and the aircraft receiving it. This documentation allows for tracing any issues that may arise.

For instance, a pre-flight checklist will confirm the aircraft’s requirements, followed by cross-referencing it with the fuel truck’s markings and documentation before and after refueling is completed.

Q 5. What are the potential hazards associated with aviation refueling?

Aviation refueling carries several potential hazards:

- Fire: The most significant hazard is fire, due to the flammability of jet fuel. Static electricity, sparks, or open flames can all ignite fuel vapors.

- Fuel Spills: Spills create fire hazards and environmental pollution. They can also cause slippery surfaces, leading to slips and falls.

- Fumes: Inhalation of fuel fumes can cause headaches, dizziness, and respiratory problems.

- Ingestion: Accidental ingestion of fuel can be toxic and dangerous.

- Equipment Malfunction: Failures in refueling equipment can lead to spills, fires, or injuries.

- Human Error: Human errors, such as dispensing the incorrect fuel grade, are a significant cause of accidents.

These hazards highlight the need for stringent safety procedures and well-trained personnel to minimize risks.

Q 6. What are the emergency procedures in case of a fuel spill?

In case of a fuel spill, immediate action is crucial. The emergency procedures typically include:

- Evacuation: Evacuate the immediate area to prevent exposure to fuel fumes and fire risks. This includes personnel and any nearby aircraft.

- Contain the Spill: Use absorbent materials (spill pads, booms) to contain the spread of the fuel.

- Notification: Immediately notify airport emergency services, fire department, and relevant authorities.

- Ventilation: Ensure adequate ventilation to dissipate fuel vapors.

- Ignition Source Removal: Eliminate any potential ignition sources. Turn off any equipment or vehicles in the vicinity.

- Cleanup: Follow established cleanup procedures, potentially involving specialized contractors to handle the fuel spill and dispose of it safely.

A well-rehearsed emergency plan and readily available emergency equipment are critical for responding to fuel spills efficiently and safely.

Q 7. How do you calculate the required fuel quantity for a flight?

Calculating required fuel quantity involves several factors:

- Trip Fuel: This is the fuel consumed during the flight itself. It’s calculated using flight planning software or charts, considering factors like flight distance, aircraft weight, altitude, wind conditions, and fuel consumption rates for the aircraft type.

- Reserve Fuel: This extra fuel accounts for unexpected delays, diversions, holding patterns, and unforeseen circumstances. Regulations often mandate minimum reserve fuel requirements based on flight conditions and location.

- Taxi Fuel: This covers the fuel used for taxiing on the ground before takeoff and after landing. It is estimated based on the airport layout and taxi time.

- Contingency Fuel: This additional fuel provides a buffer for unforeseen issues that might arise during the flight, such as unexpected headwinds or engine issues. This is a less formal component and varies based on the pilot’s judgment and company guidelines.

The total fuel required is the sum of these components: Total Fuel = Trip Fuel + Reserve Fuel + Taxi Fuel + Contingency Fuel. Flight planning software and fuel management tools aid in accurately calculating this quantity, which is then input into the pre-flight checklist. For example, a flight from New York to Los Angeles might require 20,000 lbs of trip fuel, 3,000 lbs of reserve fuel, 500 lbs of taxi fuel, and 1000 lbs of contingency fuel. The total would be 24,500 lbs. The exact amounts depend on the flight specifics.

Q 8. What is the role of Ground Support Equipment (GSE) in refueling?

Ground Support Equipment (GSE) plays a crucial role in aviation refueling, encompassing all the equipment necessary to safely and efficiently transfer fuel from storage tanks to aircraft. This includes hydrant systems, fuel trucks, dispensers, meters, and various safety and monitoring tools. Think of GSE as the ‘muscles’ of the refueling operation, providing the physical means to move and dispense the fuel.

- Hydrant Dispensers: These are connected to underground pipelines distributing fuel directly from storage to the aircraft, minimizing the need for large fuel trucks and enhancing safety. Imagine it as a water fountain for airplanes, providing a constant, controlled flow of fuel.

- Fuel Trucks: These are mobile units carrying large quantities of fuel, which are necessary at airports lacking hydrant systems or for remote locations on the airfield. They’re like mobile gas stations for the airplanes.

- Fuel Dispensers: These are the nozzles connected to trucks or hydrants that deliver the fuel into the aircraft tanks. These need to be precise and have safety interlocks preventing spills or incorrect fueling.

- Meters and Flow Monitors: These are vital for accurate fuel measurement and monitoring of the flow rate throughout the refueling process ensuring the pilot gets exactly the amount of fuel required. Without them, efficient tracking would be impossible.

- Safety Equipment: This includes grounding equipment (to prevent static electricity buildup), spill containment systems, and personal protective equipment (PPE) for personnel. Safety is the highest priority!

Q 9. Explain the different types of refueling systems used at airports.

Airports use several refueling systems, each tailored to their specific needs and infrastructure. The choice depends on factors like airport size, fuel storage capacity, and operational requirements.

- Hydrant Fueling System: This system uses an underground network of pipelines connected to bulk storage tanks. Fuel is dispensed directly from the hydrant to the aircraft via a dispenser. It’s efficient, reduces the risk of spills, and keeps the airfield cleaner. Think of it as an advanced and safer underground water distribution network for fuel.

- Overwing Fueling: This is the traditional method, involving fuel trucks that drive alongside aircraft and connect a dispenser to the aircraft’s wing-mounted fuel tanks. It’s more flexible and adaptable to different airfield sizes but carries a higher risk of spills.

- Combination Systems: Some airports utilize a combination of hydrant and overwing systems, leveraging the advantages of both. They provide flexibility and redundancy for different aircraft types and locations.

Q 10. How do you maintain accurate fuel records and documentation?

Accurate fuel records are paramount in aviation refueling, ensuring safety, efficiency, and compliance. We achieve this through a combination of manual and automated systems.

- Pre-flight Planning: We use flight plans to estimate the required fuel based on the aircraft type, planned route, weather conditions, and reserve fuel requirements. This ensures sufficient fuel is readily available.

- Fuel Quantity Measurement: During refueling, sophisticated meters precisely record the fuel quantity dispensed. We continuously cross-check digital readings with physical gauges to avoid any discrepancies.

- Fuel Delivery Documentation: Detailed forms or software record the aircraft registration, fuel type, quantity, dispensing time, refueler ID, and the signatures of all personnel involved. This leaves a complete auditable trail.

- Post-flight Reconciliation: After the flight, the actual fuel consumption is compared to the planned uplift, and any discrepancies are investigated and documented. This helps identify potential issues and improve future predictions.

This entire process helps maintain a transparent, accurate, and auditable record of all fuel transactions.

Q 11. What are the regulations and standards governing aviation refueling?

Aviation refueling is governed by stringent regulations and standards aimed at ensuring safety, security, and environmental protection. These standards vary slightly across countries but generally align with international best practices.

- ICAO (International Civil Aviation Organization): ICAO publishes Annex 3 (Meteorology) and other related documents providing global standards. These offer guidance on operational aspects of fuel handling, safety, and quality control.

- National Aviation Authorities (e.g., FAA, EASA): Each nation has its own regulatory body establishing detailed regulations for aviation fuel handling within its jurisdiction. These often include detailed requirements for fuel quality testing, personnel training, and emergency response procedures.

- Industry Best Practices: Organizations like the International Air Transport Association (IATA) issue recommendations and guidelines that are often adopted by airports and airlines to supplement regulations and enhance safety procedures.

Non-compliance with these regulations can result in significant penalties and compromise the safety of operations.

Q 12. Describe your experience with fuel quality control measures.

Fuel quality control is critical in aviation refueling, as contaminated fuel can severely damage aircraft engines. My experience involves implementing and overseeing the following measures:

- Regular Fuel Testing: We conduct routine tests on fuel samples to check for water content, particulate matter, and other contaminants. These tests adhere to strict international standards.

- Fuel Filtration: All fuel systems include filters that remove potential contaminants before the fuel reaches the aircraft. We regularly inspect and replace these filters to maintain their effectiveness.

- Fuel Storage Management: Proper storage techniques, including maintaining tank cleanliness and preventing ingress of water or debris, are crucial. We carefully monitor storage tanks to ensure appropriate conditions.

- Personnel Training: Refueling personnel receive comprehensive training on fuel quality control procedures, including identifying potential contamination sources and responding appropriately to spills or contamination incidents. Regular refresher courses help maintain high competency levels.

Maintaining the highest fuel quality standards ensures the safety and reliability of aircraft operations.

Q 13. How do you handle discrepancies between planned and actual fuel uplift?

Discrepancies between planned and actual fuel uplift require a thorough investigation to identify the root cause and prevent future occurrences. Here’s how we address them:

- Review Fuel Calculation: We meticulously re-examine the initial fuel calculations, considering factors such as weather changes, actual flight route, and weight changes.

- Inspect Fueling Records: We carefully scrutinize all fuel dispensing records, including meter readings, documentation, and personnel signatures, looking for any anomalies.

- Investigate Possible Errors: We look for possible errors in meter calibration, fuel leaks, or human errors during the fueling process. We interview the refueling crew to gather more information.

- Implement Corrective Actions: Based on our findings, we implement necessary corrective actions, which might involve recalibrating equipment, refining procedures, or providing additional training. We document these actions completely.

- Report and Document Findings: We meticulously document all findings, conclusions, and corrective actions. This information is used to improve future fuel management practices and prevent similar discrepancies.

By systematically investigating discrepancies, we learn from our mistakes and improve our operational efficiency and safety.

Q 14. What are the common causes of fuel contamination and how can they be prevented?

Fuel contamination is a significant concern in aviation refueling. Several factors can lead to contamination, and proactive prevention measures are crucial. Common causes include:

- Water Ingress: Water contamination is a major concern, arising from rain, condensation within storage tanks, or leakage into underground pipelines. This can lead to corrosion and microbial growth.

- Particulate Matter: Dust, debris, or other foreign particles can enter fuel systems during storage, transportation, or dispensing. This can clog filters and damage engine components.

- Microbial Growth: Microorganisms can thrive in fuel, particularly in the presence of water. This can lead to fuel degradation and clogging of filters.

- Cross-contamination: Mixing different fuel types can result in adverse chemical reactions. Stringent procedures are required to prevent the wrong fuel being added.

Prevention strategies include:

- Regular Fuel Testing: Frequent testing ensures early detection of contaminants.

- Proper Storage Practices: Maintaining clean storage tanks and preventing water ingress is critical.

- Effective Filtration Systems: Regular maintenance and replacement of filters remove contaminants.

- Strict Quality Control Procedures: Adhering to strict procedures minimizes the risk of cross-contamination or other errors.

- Regular Training for Personnel: This ensures staff know how to identify, report, and handle any potential contamination.

Q 15. How familiar are you with fuel hydrant systems?

Fuel hydrant systems are my area of expertise. These systems are essentially underground pipelines that distribute fuel from a central storage facility to various aircraft fueling points on an airfield. Think of them as the arteries of an airport’s fuel network. They significantly improve efficiency by eliminating the need for individual fuel trucks to transport fuel from storage tanks to aircraft, reducing the time and resources required for fueling. My familiarity extends to their design, maintenance, operation, and troubleshooting, encompassing various aspects such as pressure regulation, leak detection, and safety protocols.

I have experience working with hydrant systems employing different materials (e.g., steel, aluminum) and configurations to handle various fuel types (Jet A, Jet A-1, avgas). I’m also familiar with the various components, including booster pumps, filter separators, pressure gauges, and shut-off valves that ensure the safe and efficient distribution of fuel.

For example, during my time at [Previous Company Name], I was responsible for the preventative maintenance and troubleshooting of a significant hydrant fueling system, resulting in a 15% reduction in downtime due to unforeseen issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of fuel delivery systems (e.g., overwing, underwing).

Overwing and underwing refueling are two primary methods for delivering fuel to aircraft. Overwing refueling involves connecting the fuel hose directly to the aircraft’s refueling receptacle located on the wing, while underwing refueling utilizes a receptacle located under the aircraft’s wing. Both methods require a high level of precision and adherence to safety protocols.

My experience encompasses both methods, including the operation of various refueling equipment such as: mobile refueling units (MRUs), which are self-contained units that can be driven to the aircraft and use different types of fueling nozzles depending on the aircraft type; and hydrant dispenser systems connected to the underground fuel network, providing a more efficient method especially at busy airports. I’m well-versed in the different procedures and safety precautions necessary for each method, considering factors such as aircraft type, fuel type, and environmental conditions.

I’ve successfully managed fuel deliveries using both methods in various weather conditions, always prioritizing safety and efficiency. In one instance, I quickly adapted to an unexpected change in weather by utilizing a specific overwing method that minimized exposure to strong winds and successfully refueled an aircraft under time constraints.

Q 17. Explain the importance of static electricity grounding during refueling.

Static electricity grounding is absolutely critical during refueling to prevent the buildup of static charges that could lead to a spark and potentially ignite flammable fuel vapors. The process involves connecting a grounding cable from the aircraft to the refueling unit before fuel transfer begins and disconnecting the cable after refueling is complete. This creates a path to ground, discharging any static electricity that may build up during fuel transfer.

Failing to properly ground during refueling poses a significant safety hazard. The potential for a fire or explosion is extremely high. I’ve always stressed the importance of this procedure to my team and implemented strict adherence to grounding protocols in all refueling operations. In fact, at my previous role I established and trained teams on visual and procedural checks to ensure proper grounding procedures were followed, eliminating the risk of potential incidents related to static discharge.

Q 18. What are the signs of fuel leaks and how should they be addressed?

Fuel leaks are a serious safety concern and can manifest in several ways, including visible fuel spills, the smell of fuel, unusual pressure fluctuations in the fuel system, and even unusual sounds or vibrations around fuel lines. Immediate action is essential if any leak is suspected.

My approach to addressing a fuel leak begins with securing the area, which includes stopping the fuel flow immediately and clearing the area of personnel. I then conduct a thorough inspection of the affected area to determine the source and extent of the leak. This frequently involves visual checks, pressure testing, and sometimes the use of specialized leak detection equipment.

Once the source of the leak is identified, corrective actions are undertaken, ranging from tightening connections to replacing damaged components or sections of fuel lines. After repairs, a thorough pressure test is performed to ensure that the leak is completely resolved. The procedure followed is strictly in accordance with safety regulations and relevant documentation. Reporting the incident and following up with appropriate corrective actions are critical.

Q 19. How do you manage fuel delivery in adverse weather conditions?

Refueling in adverse weather conditions requires extra precautions and careful planning. High winds, heavy rain, snow, or icing can all create hazards. Strong winds can make handling fuel hoses difficult and increase the risk of spills, while rain and snow can obscure visibility and make the refueling area slippery.

My approach focuses on risk mitigation. This includes assessing the weather conditions and determining if it’s safe to proceed with refueling. If the conditions are too hazardous, refueling will be postponed until they improve. If refueling can proceed, procedures are adjusted to account for the weather. For example, additional personnel might be deployed to help secure hoses in high winds, and additional measures are taken to ensure personnel and aircraft safety.

I have a record of successful refueling operations in a variety of challenging weather conditions, always prioritizing safety and following established guidelines and risk assessments. It’s about making informed decisions and taking appropriate steps to ensure the safety of personnel and equipment.

Q 20. What is your experience with fuel tank gauging and measuring?

Fuel tank gauging and measuring involve accurately determining the quantity of fuel in an aircraft’s tanks. This is crucial for flight planning, fuel management, and ensuring safe takeoff and landing weights. Accurate measurements are accomplished through various methods including sight gauges (visual indication of fuel level), dipsticks (manual measurement), and electronic fuel quantity indicating systems (more advanced systems that provide digital readouts).

My experience encompasses all of these methods. I am proficient in using both manual and electronic gauging systems, understanding their limitations and ensuring accurate readings. I’m also adept at interpreting the data from fuel gauging systems, recognizing potential errors or inconsistencies and taking appropriate corrective actions. For instance, I once identified an error in an electronic fuel gauging system during pre-flight checks, preventing a potential fuel imbalance issue which could have compromised flight safety.

Q 21. How do you ensure the integrity of fuel lines and connections?

Ensuring the integrity of fuel lines and connections is paramount to prevent fuel leaks and maintain safety. This requires a multi-faceted approach encompassing regular inspections, preventative maintenance, and adherence to strict quality control measures.

Regular inspections involve visually checking fuel lines for cracks, kinks, corrosion, or other signs of damage. These are often carried out as part of a pre-flight check or routine maintenance. Preventative maintenance includes regularly replacing worn or damaged components, such as hoses, clamps, and fittings. The use of proper materials and techniques during installation and maintenance is crucial. Any repairs or replacements must adhere to strict standards. Finally, routine pressure testing of fuel lines helps identify leaks before they become a significant safety hazard. I am very familiar with all these procedures and have a strong history of maintaining a high level of fuel line integrity in my previous roles.

Q 22. What are the procedures for handling fuel spills and environmental cleanup?

Fuel spills during aircraft refueling are a serious safety and environmental hazard. Our procedures prioritize immediate containment, preventing further spread, and then thorough cleanup to minimize environmental impact.

- Immediate Action: The first step is to immediately stop the fueling operation and secure the area. We use absorbent materials like spill pads and booms to contain the spill, preventing it from entering drains or waterways. This rapid response is crucial to limit the spread.

- Containment and Recovery: Once contained, we utilize specialized equipment like vacuum trucks to recover the spilled fuel. Smaller spills might be handled with absorbent pads and shovels, properly disposed of as hazardous waste.

- Environmental Remediation: After recovery, the affected area needs thorough cleaning. This often involves washing with specialized detergents, followed by careful inspection to ensure no residual fuel remains. Soil samples might be taken for testing, depending on the severity of the spill. All waste is disposed of according to strict environmental regulations.

- Reporting and Investigation: A detailed report of the spill, including the cause, quantity spilled, cleanup methods, and any environmental impact is documented. An internal investigation follows to identify contributing factors and implement corrective actions to prevent future occurrences.

For example, I once handled a minor spill during a high-wind event. Quick action with spill pads and immediate communication with airport authorities prevented the spill from reaching a nearby storm drain. The thorough cleanup ensured no environmental damage.

Q 23. What is your understanding of the relevant safety regulations (e.g., FAA, ICAO)?

My understanding of aviation refueling safety regulations is extensive, encompassing both FAA (Federal Aviation Administration) and ICAO (International Civil Aviation Organization) standards. These regulations cover numerous aspects, from fuel quality control and handling procedures to personnel training and emergency response planning.

- Fuel Quality: Regulations strictly define acceptable fuel grades and quality parameters. We meticulously check fuel samples to ensure compliance and prevent the use of contaminated fuel, safeguarding aircraft engines. For example, water contamination can severely damage an engine.

- Ground Handling Procedures: Detailed procedures govern all aspects of refueling, including pre-flight inspections of equipment, bonding and grounding techniques to prevent static electricity buildup, and the safe handling of fuel hoses and nozzles. These procedures are designed to prevent fires and explosions.

- Personnel Training: Refuelers undergo rigorous training, including familiarization with safety regulations, emergency response protocols, and hazard identification and risk assessment. Regular refresher courses ensure personnel stay updated with best practices.

- Emergency Response: Emergency response plans are crucial. These plans detail procedures to handle spills, fires, or other incidents, including communication protocols, emergency equipment, and evacuation procedures.

Non-compliance with these regulations can lead to significant penalties, operational disruptions, and even severe accidents, making adherence paramount.

Q 24. Describe your experience with fuel transfer operations.

I possess extensive experience in various fuel transfer operations, including:

- Hydrant Fueling: I’m proficient in connecting to underground hydrant systems, ensuring proper pressure and flow rates for efficient and safe fueling.

- Truck Fueling: I have significant experience with conventional fuel truck operations, managing fuel transfer from trucks to aircraft using various nozzle types and monitoring fuel levels throughout the process. I’m familiar with the different types of fuel trucks, from smaller units to larger, high-capacity vehicles.

- Overwing Fueling: I’m well-versed in safely and efficiently refueling aircraft directly from a fuel truck, understanding the importance of grounding and bonding procedures and using correct nozzle sizes for the aircraft.

- Fuel Quality Control: My experience extends to sampling and testing fuel for quality before and during fueling, ensuring compliance with aviation standards.

I’ve worked on various aircraft types, from small general aviation aircraft to large commercial airliners, adapting my techniques to the specific requirements of each.

Q 25. What are your troubleshooting skills regarding common refueling equipment malfunctions?

Troubleshooting refueling equipment malfunctions requires a systematic approach. My experience allows me to quickly identify and resolve common issues.

- Nozzle Malfunctions: Issues such as nozzle clogging can be addressed by cleaning or replacing the nozzle. I can diagnose issues with the internal valves and mechanisms, often involving simple repairs or component replacements.

- Pump Problems: Low flow rates or complete pump failure can point to problems with the pump motor, pressure sensors, or filters. I can diagnose electrical issues, check for blockages, and carry out necessary repairs or replacements.

- Hose Issues: Leaks or damage to hoses often require immediate replacement. I’m trained to identify potential weak points, assess the severity of the damage, and replace hoses appropriately.

- Metering System Problems: Inaccurate fuel readings might indicate a problem with the flow meter, which might require recalibration or replacement. This ensures accurate billing and prevents fuel shortages.

A crucial part of troubleshooting is proper documentation, allowing for maintenance planning and preventing recurring problems. I maintain detailed records of all repairs and maintenance performed.

Q 26. How do you communicate effectively with pilots and other ground crew members during refueling?

Effective communication is paramount during refueling. I utilize clear and concise language, avoiding jargon, and confirming understanding at every step.

- Pre-Refueling Briefing: Before commencing, I confirm the aircraft type, fuel type, and quantity required with the pilot or designated representative. I also discuss any potential hazards or special considerations.

- Visual Cues: I use hand signals to communicate with the pilot during the fueling process, ensuring both parties are aware of the refueling status and any potential concerns.

- Clear and Concise Reporting: I regularly update the pilot on the fueling progress, reporting fuel levels and any unexpected issues promptly and professionally.

- Post-Refueling Confirmation: Once fueling is complete, I verify the quantity dispensed, confirming it matches the requested amount with the pilot or ground crew. Any discrepancies are immediately addressed.

I have found that using clear, simple language, combined with visual cues and regular updates, helps to prevent misunderstandings and ensures a safe and efficient refueling process.

Q 27. How do you prioritize tasks during peak refueling periods?

During peak refueling periods, efficient task prioritization is essential. I use a combination of techniques to manage multiple aircraft refueling requests effectively.

- Prioritize based on urgency: Aircraft with imminent departure times or operational constraints take precedence. I determine aircraft priority based on flight schedules and operational necessities.

- Optimize fuel truck assignments: I coordinate fuel truck deployment to ensure efficient movement and minimize idle time. This reduces wait times and improves turnaround speed for each aircraft.

- Coordinate with ground crew: Effective communication with other ground crew members helps to anticipate potential delays and adjust the refueling schedule accordingly, ensuring a smooth workflow.

- Continuous monitoring: I constantly monitor the progress of each fueling operation, making adjustments as needed to maintain efficiency and prevent bottlenecks. This dynamic approach allows for efficient handling of fluctuating demands.

Using a combination of these strategies allows me to successfully handle peak refueling periods with minimal delays and ensure smooth airport operations.

Q 28. Explain your understanding of aviation fuel pricing and invoicing.

Aviation fuel pricing is complex, influenced by several factors including global crude oil prices, market demand, taxes, and delivery costs. Invoicing reflects these complexities.

- Price Determination: Fuel prices are often set daily or even hourly based on market fluctuations. They are typically quoted in US dollars per gallon or liter, and specific contracts may stipulate different price adjustment mechanisms.

- Volume Discounts: Larger fuel purchases often qualify for volume discounts, reflecting economies of scale. This aspect is reflected in the final invoice.

- Delivery Costs: Transporting fuel to the airport adds to the overall cost. These costs depend on distance, mode of transport, and any additional handling charges.

- Taxes and Fees: Various taxes and airport fees are included in the final price. These vary by location and can be a significant component of the overall cost.

- Invoicing: Invoices typically include detailed information such as the date, aircraft details, fuel type, quantity, price per unit, taxes, delivery charges, and total amount due. Detailed records ensure transparency and accountability.

Understanding these factors is vital for accurate cost estimation and managing fuel budgets effectively. I’m experienced in reviewing invoices to ensure accuracy and address any discrepancies promptly.

Key Topics to Learn for Your Aviation Refueling Interview

- Fueling Procedures and Regulations: Understand the intricacies of different fueling methods (overwing, hydrant), safety protocols (FOD prevention, grounding procedures), and relevant FAA regulations.

- Fuel Quality Control: Learn about fuel testing, contamination prevention, and the importance of maintaining fuel quality throughout the refueling process. Practical application includes understanding how to identify and address potential fuel contamination issues.

- Aircraft Specifics and Fuel Systems: Familiarize yourself with the various aircraft types and their unique fuel systems. This includes understanding fuel tank capacities, pressure points, and potential hazards specific to different aircraft models.

- Safety and Emergency Procedures: Master emergency response protocols, including spill containment, fire suppression, and communication procedures in case of incidents during refueling operations.

- Refueling Equipment and Maintenance: Gain a working knowledge of the different types of refueling equipment, their maintenance requirements, and troubleshooting common malfunctions. Practical application could involve describing a scenario where equipment malfunctioned and how you solved it.

- Teamwork and Communication: Highlight your ability to effectively communicate and collaborate within a team environment, crucial for coordinated and safe refueling operations.

- Risk Management and Hazard Identification: Demonstrate your understanding of hazard identification, risk assessment, and mitigation strategies within the aviation refueling context. This could include examples of how you proactively prevented potential hazards.

Next Steps

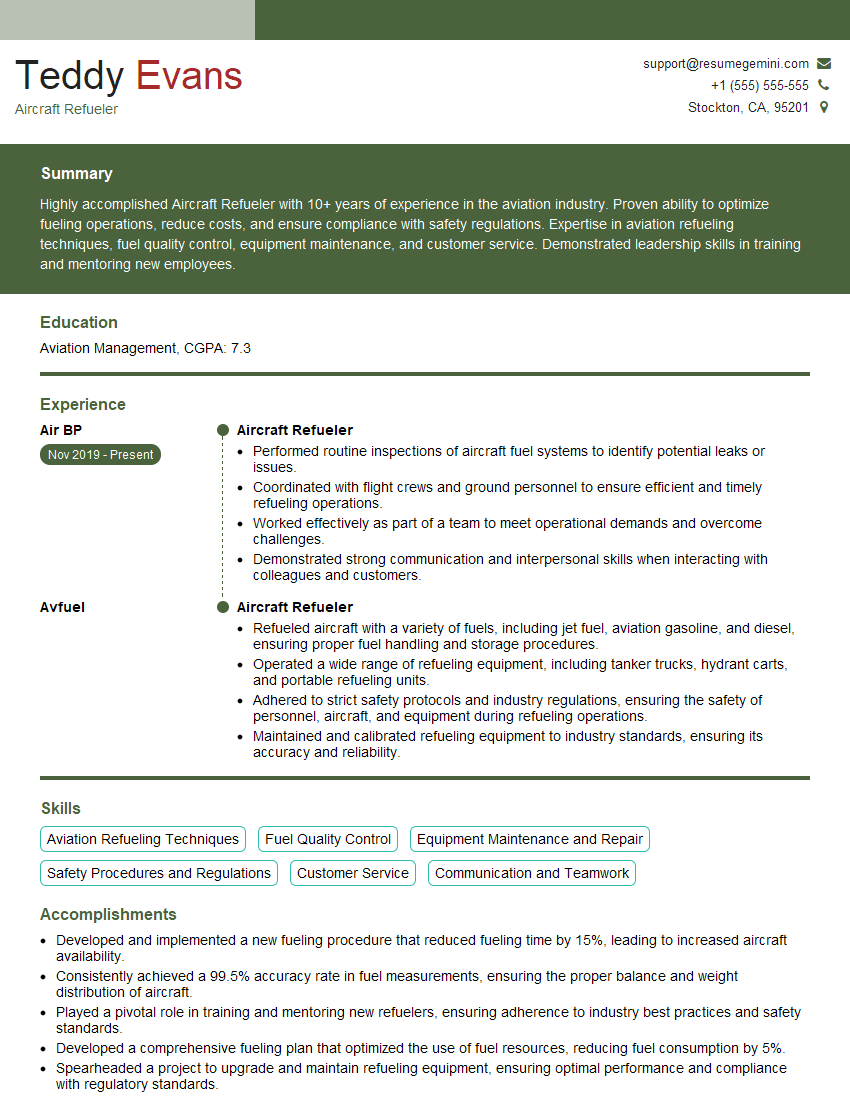

Mastering aviation refueling opens doors to a rewarding career with excellent growth potential in a dynamic and essential industry. To maximize your job prospects, invest time in creating an ATS-friendly resume that effectively showcases your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to the aviation refueling industry, to give you a head start in presenting your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO