Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Material Handling and Transport interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Material Handling and Transport Interview

Q 1. Describe your experience with various material handling equipment (e.g., forklifts, conveyors, automated systems).

My experience with material handling equipment spans a wide range, encompassing both traditional and automated systems. I’ve extensively worked with forklifts – from counterbalanced to reach trucks and order pickers – understanding their operational nuances and safety protocols. I’m proficient in operating and maintaining various conveyor systems, including belt conveyors, roller conveyors, and sorters, optimizing their configurations for different product flows. Furthermore, I have significant experience with automated guided vehicles (AGVs) and automated storage and retrieval systems (AS/RS), including programming and troubleshooting. For instance, in a previous role, I led the implementation of a new AS/RS system, resulting in a 30% increase in picking efficiency. I also have hands-on experience with warehouse management systems (WMS) integrated with these automated systems, ensuring seamless data flow and real-time inventory tracking. This involved managing system integrations, data validation and reporting, improving throughput and minimizing errors.

Q 2. Explain your understanding of warehouse layout optimization for efficient material flow.

Warehouse layout optimization is crucial for efficient material flow. It’s about strategically positioning equipment and storage areas to minimize travel time, reduce congestion, and maximize space utilization. Think of it like designing a well-organized city – efficient roads (aisles), strategically placed buildings (storage areas), and well-planned traffic management (material handling procedures). My approach involves analyzing the product flow, considering factors such as frequency of access, storage requirements, and order picking methods. For example, fast-moving items should be located close to shipping docks and picking areas, minimizing travel distance. I utilize tools like simulation software to model different layouts and evaluate their performance before implementation. This data-driven approach ensures an optimized design that addresses throughput, operational costs, and safety considerations. A successful optimization project I oversaw involved redesigning a warehouse layout, which reduced order fulfillment time by 25% and increased throughput by 15%.

Q 3. How would you improve the efficiency of a warehouse receiving process?

Improving warehouse receiving efficiency requires a systematic approach. First, I’d focus on streamlining the receiving process itself. This involves implementing clear procedures, utilizing barcodes and RFID technology for accurate item identification and tracking, and deploying well-trained personnel. Second, I’d optimize the receiving dock layout – ensuring sufficient space for unloading trucks, staging areas for incoming goods, and easy access to inspection and storage areas. Third, I’d implement a robust inventory management system that integrates with the receiving process, providing real-time updates on incoming shipments and inventory levels. Finally, I’d employ metrics to continuously monitor receiving efficiency, identifying bottlenecks and areas for improvement. In a past project, implementing a barcode scanning system during receiving reduced processing time per shipment by 40%, minimizing errors and speeding up the entire process.

Q 4. What are your strategies for managing inventory levels and preventing stockouts?

Managing inventory levels and preventing stockouts requires a balanced approach, combining forecasting techniques with real-time monitoring and responsive adjustments. Forecasting methods, such as moving averages and exponential smoothing, can help predict future demand. Real-time monitoring through a WMS provides accurate visibility into current stock levels. A key strategy is establishing safety stock levels – a buffer of inventory that accounts for unexpected demand fluctuations or supply chain disruptions. Regular inventory reviews, analyzing sales data and lead times, are crucial for adjusting safety stock levels and ordering points. I also advocate for collaborative relationships with suppliers, establishing reliable lead times and communication channels to ensure timely replenishment. Implementing a just-in-time (JIT) inventory system is another strategy that minimizes storage costs and waste, but requires careful coordination and planning.

Q 5. Describe your experience with different inventory management systems (e.g., FIFO, LIFO).

I have extensive experience with various inventory management systems. FIFO (First-In, First-Out) is best for perishable goods or items with short shelf lives – ensuring older items are used before they expire. LIFO (Last-In, First-Out) is more appropriate for non-perishable goods where the cost of goods sold is relevant, although it can lead to challenges in inventory valuation. I’ve also worked with FEFO (First-Expired, First-Out) for products with expiry dates. The choice of system depends greatly on the specific product characteristics and business requirements. Implementing and managing these systems involves careful tracking and documentation, ensuring accurate inventory levels and cost accounting. The choice of system should be dictated by factors such as product type, pricing strategies, and regulatory compliance. Effective use of barcode scanning and RFID enables efficient stock management regardless of the chosen inventory system.

Q 6. How do you ensure workplace safety in a material handling environment?

Workplace safety is paramount in material handling. My approach is multi-faceted, starting with comprehensive safety training for all personnel, covering safe operating procedures for all equipment, hazard identification, and emergency response. Regular safety inspections and audits are crucial for identifying and mitigating potential hazards. Proper maintenance of equipment is essential, preventing malfunctions and accidents. I also emphasize the use of appropriate personal protective equipment (PPE), such as safety shoes, gloves, and high-visibility vests. Clear signage, well-lit areas, and organized pathways contribute to a safer working environment. A robust reporting system for near-misses and accidents facilitates continuous improvement and proactive risk management. By prioritizing safety, we minimize the risk of injuries and create a productive and healthy work environment.

Q 7. What are your methods for tracking and managing shipments?

Tracking and managing shipments involves a combination of technology and process. I utilize Transportation Management Systems (TMS) to schedule shipments, generate shipping documents, track shipments in real-time, and manage carrier relationships. Barcodes and RFID tags provide accurate tracking of individual packages throughout the supply chain. Real-time visibility into shipment status enables proactive issue resolution. Regular communication with carriers is crucial, keeping stakeholders informed of any delays or disruptions. Key metrics, such as on-time delivery rates and transit times, are monitored to evaluate performance and identify areas for improvement. In a past role, implementing a TMS with real-time tracking reduced shipment delays by 15% and improved on-time delivery by 10%.

Q 8. How familiar are you with transportation management systems (TMS)?

Transportation Management Systems (TMS) are sophisticated software solutions designed to optimize all aspects of the transportation process. My familiarity extends to both the operational and strategic levels. I’ve worked extensively with TMS platforms to manage freight, track shipments, optimize routes, and analyze transportation costs. This includes experience with both cloud-based and on-premise solutions, and I’m proficient in integrating TMS with Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP) systems for seamless data flow. I understand the importance of selecting the right TMS based on business needs and the capabilities of different software packages, including functionalities like tendering, shipment execution, and carrier management.

For example, in a previous role, I implemented a new TMS that reduced our transportation costs by 15% within the first year by automating processes like carrier selection and shipment scheduling based on real-time data and predictive analytics.

Q 9. Explain your experience with various modes of transportation (e.g., truck, rail, air, sea).

My experience encompasses all major modes of transportation. With trucking, I’ve managed both LTL (Less-than-Truckload) and FTL (Full-Truckload) shipments, negotiating rates, selecting carriers, and optimizing delivery routes. I’m familiar with different types of trucking equipment and regulations, including ELD (Electronic Logging Device) compliance. Rail transportation experience includes managing intermodal shipments, coordinating with rail carriers, and optimizing rail networks for cost-efficiency. Air freight involves managing time-sensitive shipments, understanding hazardous materials regulations (IATA), and coordinating with airlines and ground handlers. Sea freight experience includes managing ocean containers, coordinating with shipping lines, and understanding Incoterms (International Commercial Terms) and documentation requirements. I’ve successfully managed complex multi-modal shipments, leveraging each mode’s strengths to provide optimal solutions.

For instance, I once streamlined a multi-modal project involving sea freight from Asia, rail transport across the continent, and finally, trucking to the final destination, resulting in a 10% reduction in transit time while maintaining cost efficiency.

Q 10. How do you handle unexpected delays or disruptions in the supply chain?

Unexpected delays and disruptions are inevitable in supply chain management. My approach involves a multi-pronged strategy focusing on proactive risk management, real-time monitoring, and reactive problem-solving. Proactive measures include building contingency plans, diversifying suppliers and carriers, and maintaining strong relationships with logistics providers. Real-time monitoring utilizes TMS and other tracking systems to identify potential problems early. When disruptions occur, I follow a structured process: 1) Identify the root cause of the delay; 2) Assess the impact on delivery schedules and customer commitments; 3) Explore alternative solutions, such as rerouting shipments, using alternative carriers, or negotiating with customers; 4) Communicate transparently with all stakeholders; 5) Implement corrective actions and learn from the experience to prevent future disruptions.

A recent example involved a port strike that threatened to delay crucial shipments. By proactively securing alternative ports and communicating the situation with our customers, we minimized the impact, avoiding significant financial losses and maintaining customer satisfaction.

Q 11. What are your strategies for reducing transportation costs?

Reducing transportation costs is a continuous effort. My strategies focus on several key areas: Negotiating favorable rates with carriers through volume discounts and strategic partnerships; Optimizing load factors to maximize space utilization and minimize empty miles; Implementing efficient route planning and optimization using TMS software; Consolidating shipments to leverage economies of scale; Exploring alternative modes of transportation that offer cost advantages for specific routes; Improving warehouse efficiency to minimize transportation time and costs; Utilizing fuel-efficient vehicles and implementing driver training programs to reduce fuel consumption; Employing advanced analytics to identify cost-saving opportunities and track transportation cost performance.

In a previous role, by implementing route optimization software, we reduced fuel costs by 8% and improved delivery times by 10%, proving the efficacy of this multi-faceted approach.

Q 12. Describe your experience with route optimization and planning.

Route optimization and planning are crucial for efficient and cost-effective transportation. My experience includes using various route optimization software tools and methodologies. These tools consider factors like distance, traffic conditions, delivery time windows, driver availability, and fuel costs to generate optimal routes. I understand the importance of considering different optimization algorithms and selecting the best one based on specific needs. Moreover, I’m experienced in creating and managing route plans, assigning shipments to drivers, and monitoring progress in real-time. My approach is data-driven, utilizing historical data and real-time information to improve routing efficiency continuously. I’m proficient in integrating route optimization with other transportation management functions, such as shipment scheduling and carrier selection, to achieve a holistic optimization.

For example, I once developed a custom route optimization algorithm that reduced delivery times by 12% and fuel consumption by 7% for a large-scale distribution network.

Q 13. How do you ensure timely delivery of goods?

Ensuring timely delivery requires a comprehensive approach that begins with accurate order processing and continues through meticulous shipment planning and execution. This includes selecting reliable carriers, accurately estimating transit times, proactively addressing potential delays, and employing robust tracking and monitoring systems. Effective communication with customers and internal teams is also vital for transparent updates and timely resolution of issues. Real-time tracking of shipments allows for proactive intervention if delays occur, minimizing their impact. Moreover, maintaining strong relationships with carriers is essential to ensure timely pickup and delivery of goods. The use of a TMS helps streamline this process, allowing for better forecasting and adjustments based on real-time data.

In one instance, I implemented a system that provided customers with real-time tracking information, dramatically improving transparency and confidence in our on-time delivery performance.

Q 14. What are the key performance indicators (KPIs) you monitor in material handling and transport?

Several key performance indicators (KPIs) are essential for monitoring performance in material handling and transport. These include: On-Time Delivery Rate (OTDR), which measures the percentage of shipments delivered on time; Perfect Order Rate (POR), considering on-time delivery, complete orders, and accurate documentation; Transportation Cost per Unit, highlighting efficiency in transportation expenditure; Inventory Turnover Rate, reflecting the efficiency of inventory management and its link to transportation; Delivery Lead Time, the time from order placement to delivery; Freight Spend, the overall cost of transportation; Carrier Performance, encompassing on-time pickup and delivery, damage rates, and claims; Fuel Efficiency, monitoring fuel consumption per mile or shipment; and Customer Satisfaction related to on-time delivery and responsiveness.

Regularly monitoring and analyzing these KPIs is crucial for identifying areas for improvement and ensuring the continuous optimization of material handling and transportation processes.

Q 15. How do you handle customer complaints related to deliveries or material handling issues?

Handling customer complaints regarding deliveries or material handling effectively involves a structured, empathetic approach. My first step is always active listening – truly understanding the customer’s frustration and the specifics of the issue. This means asking clarifying questions, not interrupting, and acknowledging their feelings. I then move to investigation, reviewing delivery records, tracking information, and potentially speaking with relevant personnel (drivers, warehouse staff) to pinpoint the root cause.

Once the cause is identified, I present a clear, concise explanation to the customer, avoiding technical jargon and focusing on the resolution. This might involve offering a replacement, refund, expedited delivery, or a discount, depending on the severity and nature of the problem. Following this, I implement corrective actions to prevent similar issues in the future, whether that’s retraining staff, adjusting processes, or improving communication channels. Finally, I follow up with the customer to ensure their satisfaction and to confirm the issue is fully resolved. For example, if a pallet of goods arrived damaged, I would first apologize, investigate the handling process from the warehouse to delivery, offer a replacement shipment, and then work with the warehouse team to improve pallet wrapping and securing procedures.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) spans over ten years, encompassing implementation, configuration, and daily operation. I’ve worked extensively with systems like Oracle WMS, SAP EWM, and Blue Yonder, integrating them with ERP systems and other logistics software. My responsibilities have ranged from defining system requirements and overseeing customizations to training warehouse staff and troubleshooting operational issues. I’m proficient in using WMS features such as inventory management, order fulfillment, putaway strategies (e.g., FIFO, LIFO), slotting optimization, and reporting and analytics. For instance, in my previous role, I spearheaded the implementation of a new WMS, resulting in a 15% reduction in order processing time and a 10% decrease in inventory discrepancies through improved accuracy and tracking.

I also have hands-on experience with WMS data analysis – using reports to identify bottlenecks, areas for improvement in warehouse layout or operational efficiency, and optimizing labor deployment. I understand the importance of data integrity within the WMS and the impact of accurate data on overall warehouse performance and supply chain visibility.

Q 17. Describe your experience with different types of warehousing (e.g., cross-docking, bulk storage).

My experience encompasses various warehousing methodologies, including cross-docking and bulk storage. Cross-docking, where goods are unloaded from incoming shipments and immediately loaded onto outgoing shipments, minimizing storage time, demands efficient coordination and real-time information flow. I’ve managed cross-docking operations for fast-moving consumer goods, requiring precision in scheduling, labor allocation, and product tracking to avoid delays and maintain product integrity. This involved optimizing dock space utilization, streamlining receiving and shipping procedures, and using WMS functionalities to manage real-time inventory status and direct movements.

In contrast, bulk storage, commonly used for raw materials or large-volume goods, necessitates effective space management and specialized handling equipment. I’ve overseen bulk storage facilities for agricultural products and construction materials, where safety protocols, inventory control using cyclical counting and stock rotation were crucial. This involved understanding the physical characteristics of the materials, optimizing storage layouts to maximize space efficiency, and implementing robust inventory tracking systems to minimize losses due to spoilage or damage. The key difference between these methods lies in the storage time; cross-docking aims for minimal storage, while bulk storage anticipates longer-term storage.

Q 18. How do you ensure the accuracy of inventory records?

Maintaining accurate inventory records is critical for efficient warehouse operation and financial reporting. My approach combines technological solutions with robust procedural controls. We utilize barcode scanning, RFID tagging, and WMS integration for real-time inventory tracking, reducing manual data entry errors. Regular cycle counting, where a portion of the inventory is counted and reconciled against the WMS daily, helps identify discrepancies early. This is supplemented by periodic full physical inventory counts to verify the accuracy of the system. Discrepancies are investigated, root causes identified (e.g., picking errors, data entry mistakes, damaged goods), and corrective actions implemented. This might include staff retraining, process improvements, or system adjustments. Furthermore, I implement quality control checks at every stage of the inventory process, from receiving to shipping, ensuring accuracy at each step. I also leverage WMS reporting and analytics to identify trends and potential sources of inaccuracies.

Q 19. What are your methods for managing warehouse space effectively?

Effective warehouse space management maximizes storage capacity and minimizes operational costs. This involves optimizing warehouse layout, utilizing vertical space (e.g., high-bay racking), implementing efficient slotting strategies (locating frequently accessed items in easily accessible areas), and employing advanced inventory management techniques. I’ve utilized simulations and 3D modeling software to design efficient warehouse layouts, considering factors like product size, weight, frequency of access, and order fulfillment processes. For example, I once redesigned a warehouse layout, using a combination of narrow-aisle racking and reach trucks, which increased storage capacity by 20% while maintaining efficient order picking times. Regular audits of warehouse space utilization, and analysis of order data to identify patterns and optimize stock placement are also essential for effective space management.

Q 20. Describe your experience with implementing new material handling technologies.

I have extensive experience implementing new material handling technologies to enhance warehouse efficiency and productivity. This includes the integration of automated guided vehicles (AGVs), conveyor systems, automated storage and retrieval systems (AS/RS), and warehouse execution systems (WES). My approach involves a phased implementation, beginning with a thorough needs assessment to identify areas for improvement and selecting the most suitable technologies. This is followed by detailed planning, including system design, vendor selection, integration with existing systems, and staff training. During implementation, I oversee project timelines, budgets, and risk management. Post-implementation, I monitor system performance, using key performance indicators (KPIs) to measure improvements in efficiency, productivity, and safety. For example, in a previous project, I led the implementation of an AS/RS, resulting in a 30% increase in picking efficiency and a reduction in labor costs.

Q 21. How do you ensure compliance with safety regulations and industry standards?

Ensuring compliance with safety regulations and industry standards is paramount in material handling and transport. This involves adhering to OSHA (Occupational Safety and Health Administration) regulations, ANSI (American National Standards Institute) standards, and other relevant industry-specific guidelines. This starts with a comprehensive safety program, including regular safety training for all personnel, covering topics such as forklift operation, safe lifting techniques, hazard identification and reporting, and emergency procedures. We conduct regular safety audits and inspections to identify potential hazards and ensure compliance with regulations. Personal Protective Equipment (PPE) is provided and its proper use enforced. We also maintain detailed records of safety incidents, investigations, and corrective actions. Furthermore, I stay updated on changes in legislation and industry best practices, ensuring our operations remain compliant and fostering a culture of safety and continuous improvement within the warehouse and transportation operations.

Q 22. Explain your experience with forecasting demand and planning capacity.

Forecasting demand and planning capacity are critical for efficient material handling and transportation. It involves predicting future needs based on historical data, market trends, and other relevant factors, and then aligning resources to meet that demand. This is often done using sophisticated software and statistical methods.

In my previous role at Acme Manufacturing, we utilized a time series forecasting model combined with a robust Materials Requirements Planning (MRP) system. This allowed us to predict demand for our raw materials with a high degree of accuracy. The MRP system then used this forecast to generate production schedules, ensuring we had the necessary materials on hand at the right time, minimizing stockouts and reducing storage costs. We also factored in seasonal variations and potential disruptions to the supply chain (like natural disasters or supplier delays) to create a more resilient plan.

For capacity planning, we considered factors like warehouse space, equipment availability (forklifts, conveyors, etc.), and workforce capacity. By comparing forecasted demand against available capacity, we identified potential bottlenecks and proactively addressed them through solutions like investing in new equipment, optimizing warehouse layout, or hiring additional staff. This proactive approach prevented costly delays and ensured smooth operations.

Q 23. How do you handle returns and damaged goods?

Handling returns and damaged goods is a crucial aspect of efficient logistics, impacting both cost and customer satisfaction. A well-structured returns process is essential.

My approach involves a multi-step process. First, we have a clear and easily accessible returns policy for customers. Next, we establish dedicated receiving areas for returned goods, separated from incoming shipments to avoid confusion. Upon receipt, goods are inspected for damage, and the reason for return is documented. For damaged goods, we determine the cause (e.g., manufacturing defect, damage during shipping) to inform quality control and potentially prevent future incidents. Depending on the condition, goods might be repaired, salvaged (e.g., parts used for repair), or disposed of responsibly according to environmental regulations. We also utilize a robust tracking system to monitor the entire returns process, from initial request to final disposition, providing transparency for both customers and internal stakeholders.

For example, at Beta Distribution, we implemented a barcoding system for returns, which significantly streamlined the tracking and processing of damaged goods. This reduced processing times by 30% and improved accuracy of damage reporting.

Q 24. What is your experience with lean manufacturing principles in material handling?

Lean manufacturing principles are fundamental to efficient material handling. The core idea is to eliminate waste (muda) in all aspects of the process, optimizing flow and minimizing unnecessary steps.

My experience includes implementing several lean techniques in material handling, such as:

- 5S Methodology: Organizing and maintaining a clean and efficient workplace reduces wasted time searching for materials.

- Kanban Systems: Using visual cues to manage inventory and trigger replenishment only when needed, minimizing excess stock and storage costs.

- Value Stream Mapping: Identifying and eliminating non-value-added activities in the material flow, from raw materials to finished goods.

- Kaizen Events: Conducting focused improvement workshops to continuously identify and address inefficiencies in the material handling process.

In a previous project at Gamma Company, we implemented a Kanban system for managing parts delivery to the assembly line. This reduced lead times by 20% and significantly decreased inventory holding costs.

Q 25. How would you improve communication and collaboration within a logistics team?

Effective communication and collaboration are paramount in logistics. Poor communication can lead to costly errors, delays, and frustration.

To improve communication within a logistics team, I would utilize several strategies:

- Establish clear communication channels: Define who is responsible for what information and the preferred methods of communication (e.g., email, instant messaging, daily stand-up meetings).

- Utilize collaborative platforms: Implement software that facilitates real-time tracking of shipments, inventory levels, and other key metrics. Tools like shared spreadsheets, project management software, or specialized logistics platforms can improve transparency and collaboration.

- Foster a culture of open communication: Encourage team members to share ideas, concerns, and feedback openly and without fear of retribution. This can be achieved through regular team meetings, informal communication channels, and feedback mechanisms.

- Provide training and development: Ensure team members have the skills and knowledge to communicate effectively and understand logistics processes. Training on communication skills and relevant software tools can significantly enhance team performance.

For example, at Delta Logistics, we introduced a daily stand-up meeting with a shared project management platform. This significantly improved communication and problem-solving, leading to a 15% reduction in delivery delays.

Q 26. Describe a time you had to solve a complex problem related to material handling or transportation.

During my time at Epsilon Transport, we experienced a major port strike that significantly disrupted our shipping schedule. Hundreds of containers were delayed, causing significant disruption to our customers and potentially huge financial losses.

To solve this, I first assembled a crisis management team, comprising representatives from various departments (operations, customer service, procurement). We then developed a multi-pronged approach:

- Identify affected shipments: We prioritized shipments based on urgency and customer impact.

- Explore alternative routes: We explored using alternative ports and transportation modes (rail, trucking) to circumvent the strike.

- Communicate proactively with customers: We kept customers informed about the delays and provided estimated delivery dates, managing expectations and minimizing negative impact.

- Negotiate with suppliers and carriers: We worked with our suppliers and carriers to secure alternative transport options and negotiate favorable rates.

Through decisive action and effective collaboration, we minimized the impact of the strike, limiting financial losses and preserving customer relationships. This experience highlighted the importance of contingency planning and adaptability in the face of unexpected challenges.

Q 27. What is your experience with international shipping and customs regulations?

International shipping involves navigating a complex web of regulations and documentation. My experience encompasses all aspects of this process, from export and import procedures to customs compliance.

I am familiar with Incoterms (International Commercial Terms), understanding the responsibilities of buyers and sellers at different stages of the shipping process. I have experience with the necessary documentation for international shipments, such as commercial invoices, packing lists, bills of lading, certificates of origin, and other regulatory documents depending on the specific goods and destination country. I understand the nuances of customs regulations, including tariff classification, duty calculations, and procedures for clearing goods through customs. I also have experience managing import/export licenses, permits, and other regulatory requirements.

For example, while working on a project involving the export of sensitive electronic equipment to Japan, I successfully navigated complex export control regulations and ensured all necessary documentation was in order, preventing potential delays and penalties.

Q 28. How do you stay up-to-date with the latest trends and technologies in material handling and transport?

Staying current in the rapidly evolving fields of material handling and transport requires a multi-faceted approach.

I regularly attend industry conferences and trade shows, such as MODEX and LogiMAT, to learn about the latest technologies and best practices. I subscribe to industry publications and journals, including those published by organizations like MHI (Material Handling Industry) and the CSCMP (Council of Supply Chain Management Professionals). I actively participate in online professional communities and forums, engaging with other professionals and sharing knowledge. I also pursue continuing education opportunities through online courses and webinars focused on relevant topics, such as automation, robotics, blockchain technology in supply chain, and sustainable logistics.

By constantly seeking new information and applying it to my work, I ensure I remain at the forefront of the field and can provide innovative solutions to logistical challenges.

Key Topics to Learn for Your Material Handling and Transport Interview

- Warehouse Management Systems (WMS): Understand the functionalities of various WMS software, their integration with other systems, and their role in optimizing warehouse operations. Consider practical applications like order fulfillment and inventory management.

- Inventory Control & Optimization: Explore different inventory management techniques (FIFO, LIFO, etc.), and their impact on efficiency and cost reduction. Think about real-world scenarios involving stock rotation and minimizing waste.

- Material Handling Equipment: Familiarize yourself with various equipment types (forklifts, conveyors, automated guided vehicles – AGVs), their capabilities, safety protocols, and maintenance requirements. Discuss practical applications and potential challenges in their operation.

- Supply Chain Management Principles: Understand the key elements of a robust supply chain, including procurement, transportation, warehousing, and delivery. Analyze how improvements in material handling impact overall supply chain efficiency.

- Logistics and Transportation Planning: Learn about route optimization, transportation modes (road, rail, sea, air), and the factors influencing transportation choices (cost, speed, reliability). Consider real-world scenarios involving delivery scheduling and fleet management.

- Safety Regulations and Compliance: Understand relevant health and safety regulations pertaining to material handling and transportation, including OSHA standards and best practices for accident prevention. Discuss practical application of safety procedures in various work environments.

- Lean Principles and Kaizen: Explore how Lean methodologies can be applied to improve efficiency and reduce waste in material handling and transportation processes. Consider practical examples of implementing Kaizen events to improve workflows.

Next Steps

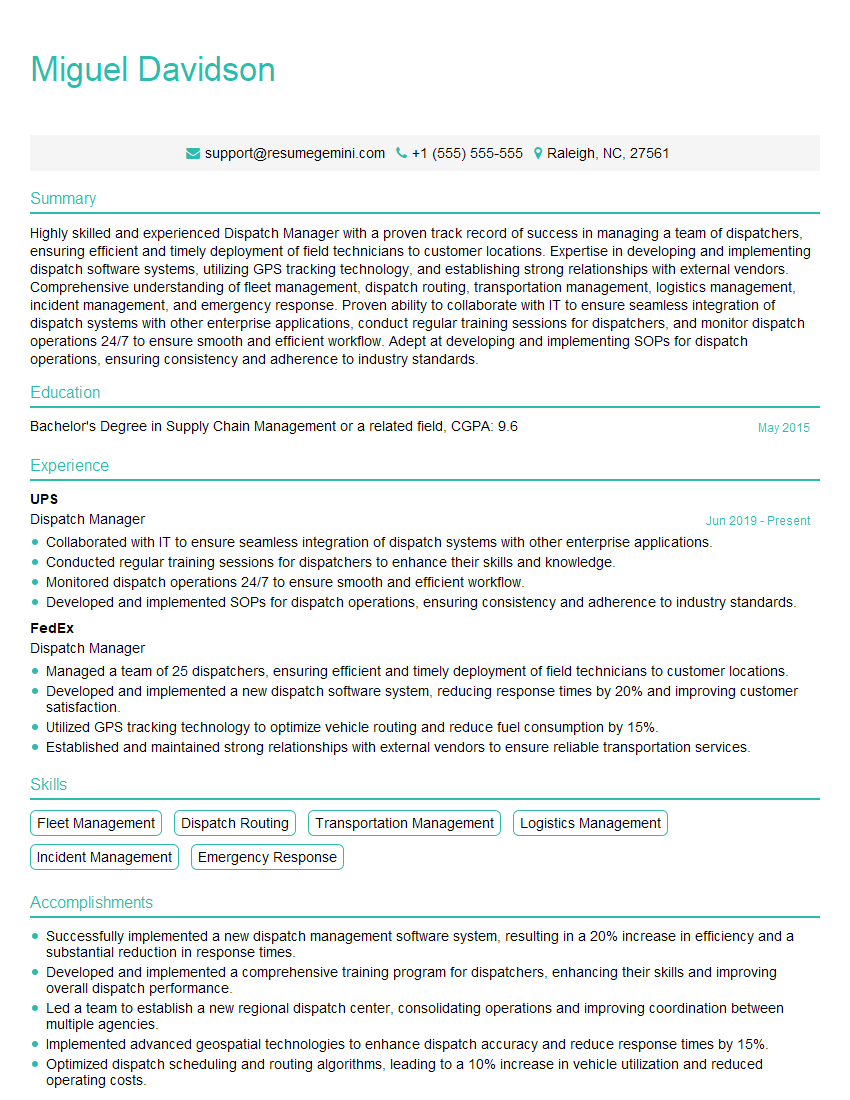

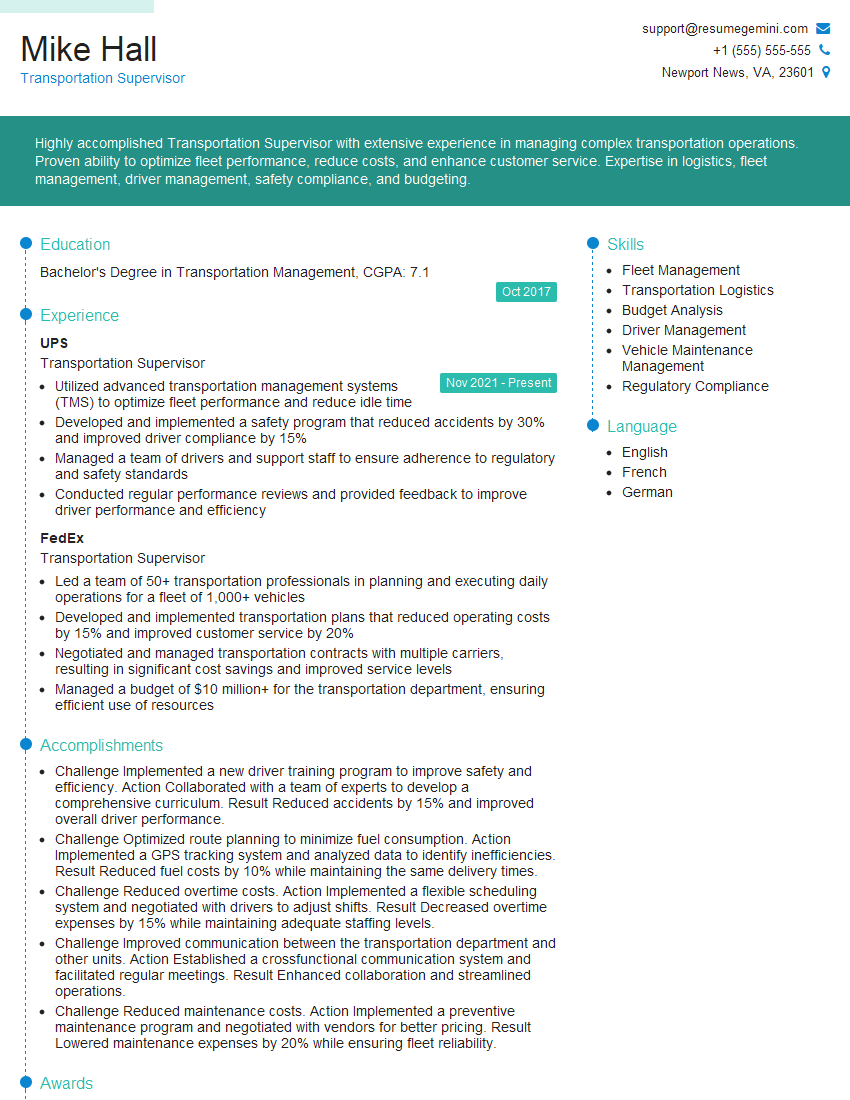

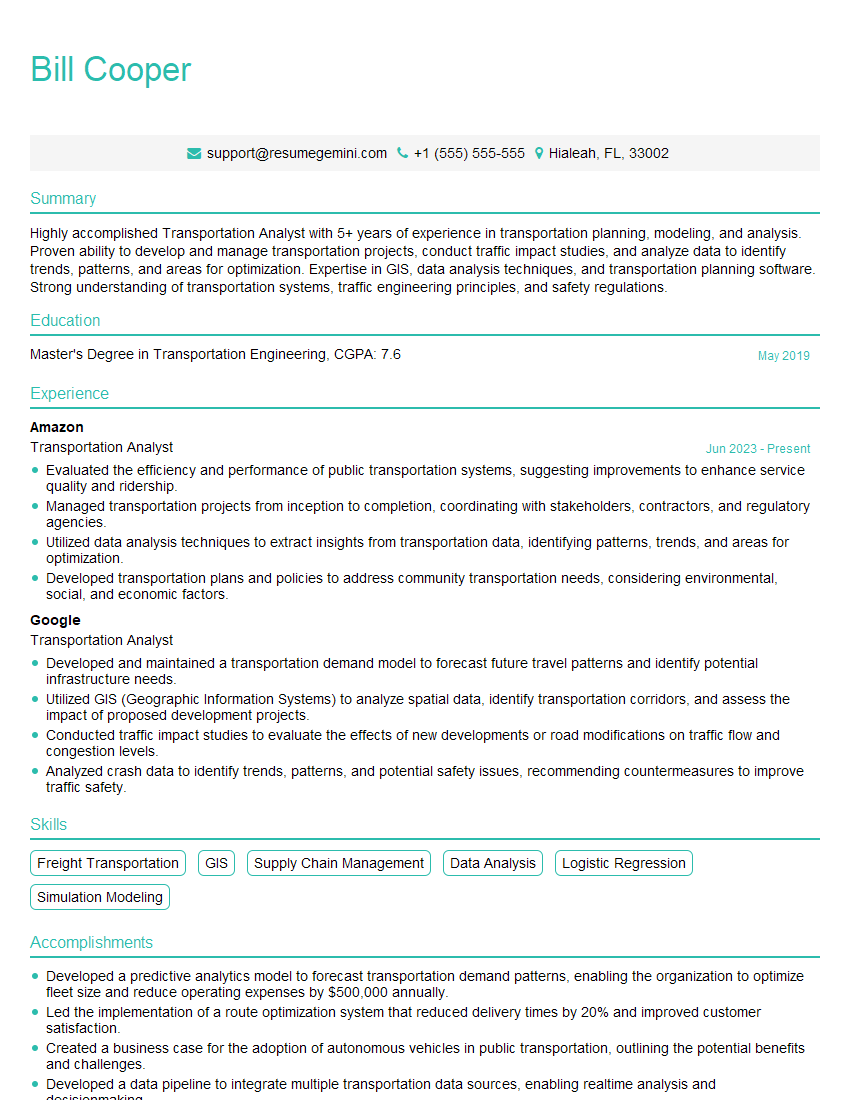

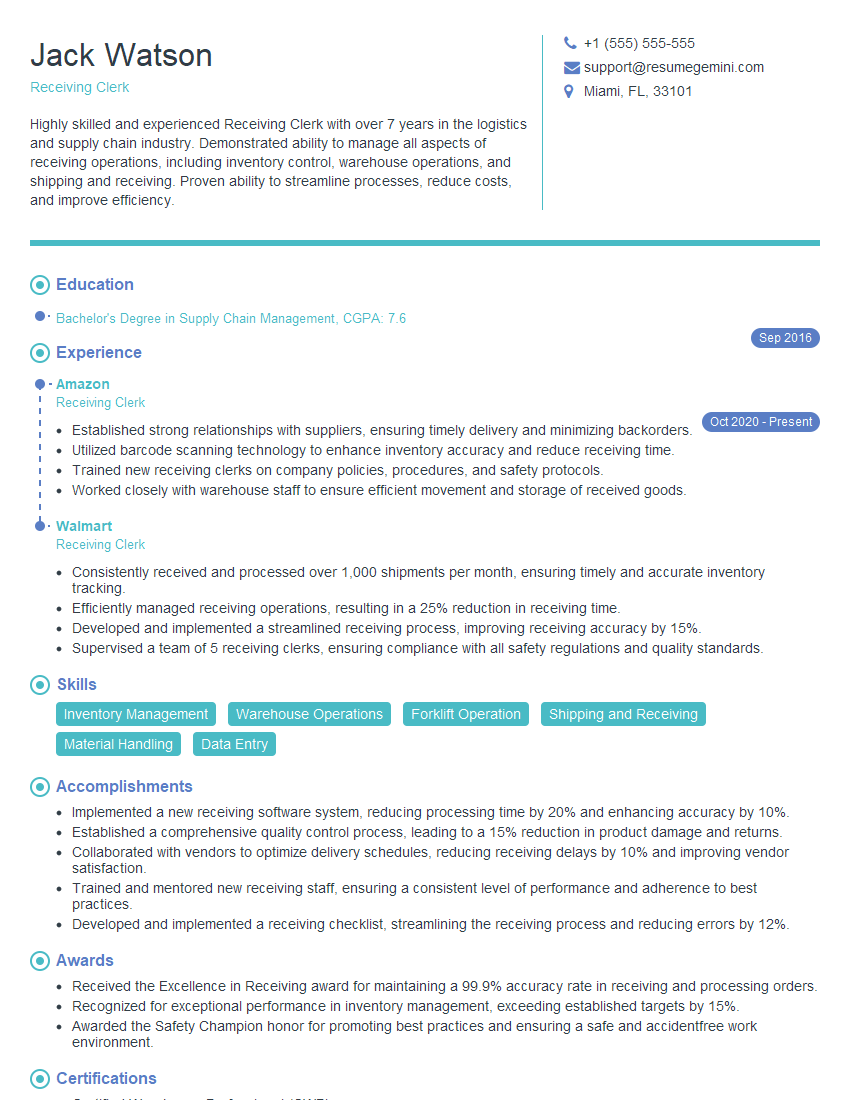

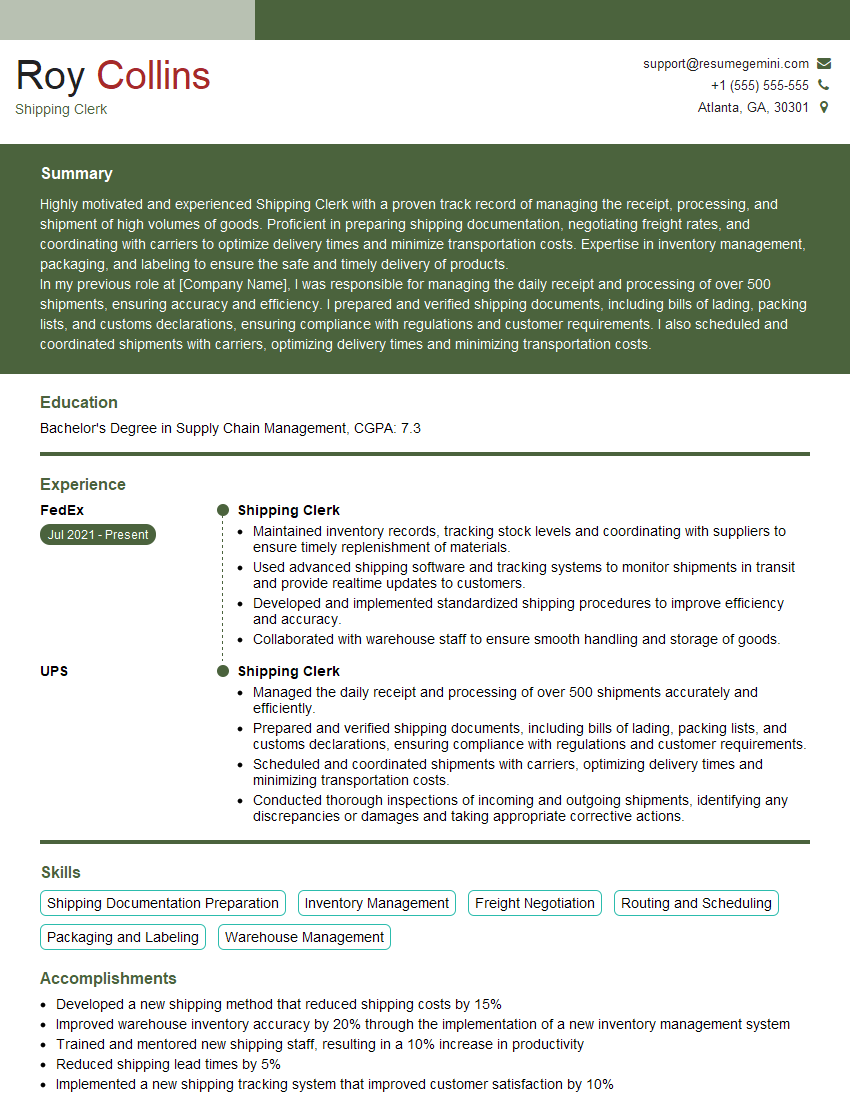

Mastering Material Handling and Transport opens doors to exciting career opportunities in a constantly evolving industry. To stand out, a strong, ATS-friendly resume is crucial. This is where ResumeGemini can help! ResumeGemini provides a powerful platform to create a professional and impactful resume that highlights your skills and experience effectively. We offer examples of resumes specifically tailored to Material Handling and Transport roles to guide you. Invest in your future – build a resume that gets noticed!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO