Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Prinergy Workflow interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Prinergy Workflow Interview

Q 1. Explain the architecture of the Prinergy Workflow system.

Prinergy Workflow’s architecture is a client-server model, designed for scalability and robustness. At its core is a central database that manages all job information, resources, and configurations. Clients, such as the user interface (typically accessed through a web browser) and various prepress applications, connect to this database to interact with the workflow. The server handles job processing, managing the flow of data through various modules and connected devices like imposition software, color management tools, and output devices. Think of it like an orchestra conductor, meticulously guiding each instrument (application/device) to produce a harmonious symphony (the final printed product).

The system is modular, allowing customization. Different components can be added or removed based on the specific needs of the print shop. This flexibility ensures that the system can adapt to various workflows and printing processes.

For example, a large print shop might use multiple servers to handle different aspects of the workflow, ensuring high availability and preventing bottlenecks. Smaller print shops might use a single server system, keeping things simple and efficient.

Q 2. Describe the role of the Prinergy Workflow in a typical print production environment.

In a typical print production environment, Prinergy Workflow acts as the central nervous system, automating and streamlining the entire process. From job submission to final output, it manages all aspects of prepress, providing a single platform for collaboration and control.

- Job Scheduling and Tracking: Prinergy automates job routing, ensuring tasks are completed in the correct order and within deadlines.

- Automated Processes: It automates tasks such as preflighting, imposition, color management, and proofing, reducing manual intervention and errors.

- Resource Management: It optimizes resource allocation, efficiently using printing devices and personnel.

- Collaboration and Communication: It facilitates collaboration among team members, providing a centralized platform for communication and job status updates.

- Version Control: It enables version tracking, allowing quick access to different job revisions.

Imagine trying to manage a large print job without Prinergy. You’d be juggling numerous applications, spreadsheets, and manual processes. Prinergy simplifies this immensely, making the production flow much smoother and more efficient.

Q 3. How do you handle job submissions and tracking in Prinergy Workflow?

Job submission in Prinergy is usually done through the user interface, either by uploading files directly or by integrating with other software. The system provides various options for submitting jobs, including hot folders for automated submission and drag-and-drop functionality for manual submission.

Tracking is handled through a sophisticated job tracking system that provides real-time visibility into the job status. Users can monitor the progress of each job, identify potential bottlenecks, and receive notifications of important events, such as job completion or errors. Detailed reports are generated, providing valuable data for analysis and process optimization.

For example, a user can see the exact stage a job is in (e.g., ‘Preflighting,’ ‘Imposing,’ ‘Outputting’) and access real-time statistics, like the number of pages processed or the estimated time remaining for completion. This level of transparency is invaluable for efficient production management.

Q 4. What are the different modules within Prinergy Workflow, and what are their functions?

Prinergy Workflow comprises several key modules, each with specific functions:

- Job Creation and Submission: This module facilitates the initial setup and submission of jobs into the workflow.

- Preflight: This module performs automated checks on submitted files to ensure they meet the required specifications, preventing problems downstream.

- Imposition: This module arranges pages for printing on sheets or rolls, based on predefined templates.

- Color Management: This module manages color profiles, ensuring accurate and consistent color reproduction.

- Proofing: This module creates digital proofs for review and approval.

- Output Management: This module handles the routing of jobs to the appropriate output devices.

- Job Tracking and Reporting: This module tracks job progress, generates reports, and provides real-time visibility into the production process.

Each module is interconnected, forming a seamless workflow. For instance, the preflight module ensures that a job is suitable for imposition before moving on to the next step. This integration minimizes errors and maximizes efficiency.

Q 5. Explain the concept of imposition and how it’s managed in Prinergy.

Imposition is the process of arranging pages on a sheet or roll for printing. In Prinergy, this is managed through the imposition module, using either built-in templates or custom created ones. The software automatically handles the complex calculations needed for efficient sheet utilization, reducing waste and maximizing productivity.

Different imposition schemes cater to different printing methods and sheet sizes. For example, a book might require a specific imposition scheme for signatures, while a brochure might use a different scheme optimized for folding. Prinergy allows users to select or create templates tailored to their specific requirements, allowing flexibility and control over the imposition process. Using pre-built templates speeds up the imposition considerably for standardized formats.

For example, if you’re printing a 16-page booklet, Prinergy’s imposition module will automatically arrange the pages on a sheet in a way that minimizes waste and allows for efficient folding and binding after printing. Without automation, this task would be time-consuming and prone to errors.

Q 6. How do you manage color profiles and color management within Prinergy?

Prinergy’s color management capabilities are crucial for achieving accurate and consistent color reproduction across different devices and media. It utilizes ICC profiles to manage color conversions throughout the workflow. These profiles define the color characteristics of different input and output devices, allowing Prinergy to accurately translate colors from the source file to the final printed output.

The system allows for defining color spaces, assigning profiles to specific devices, and performing color conversions based on chosen intents (e.g., perceptual, absolute colorimetric). This ensures that the colors seen on screen closely match the printed output. Prinergy supports various color management standards and workflows, providing the flexibility needed for diverse print environments.

A key aspect is the ability to manage and assign profiles to different parts of the production chain: input (scanner, camera, etc.), output (different printers), and proofing devices. Mismatched profiles can lead to significant color discrepancies. Prinergy helps to avoid such issues through rigorous profile management and color conversion.

Q 7. Describe your experience with Prinergy’s proofing capabilities.

Prinergy offers robust proofing capabilities, allowing for the creation of soft and hard proofs. Soft proofing provides a digital representation of the final printed output, allowing for review and approval before actual printing. This reduces waste and speeds up the production cycle. Soft proofing capabilities are integrated into the workflow, and often involve the generation of PDF files that reflect the intended color and output characteristics.

For hard proofing, Prinergy can manage and integrate with devices that generate physical proofs, allowing for more accurate representation of the final product for color-critical work, Prinergy’s proofing capabilities also includes the ability to compare various versions of a proof and highlight any differences. This is crucial for ensuring that the final output matches the client’s expectations. For example, if a client wants to compare the initial proof with the final, revised version, Prinergy allows for an easy visual comparison highlighting the changes made.

My experience with Prinergy’s proofing capabilities has been positive, significantly reducing the need for multiple rounds of revisions and ensuring client satisfaction.

Q 8. How do you troubleshoot common Prinergy Workflow errors?

Troubleshooting Prinergy Workflow errors involves a systematic approach. I start by examining the error logs – Prinergy provides detailed logs indicating the source and nature of the problem. These logs often contain error codes that can be referenced in the Prinergy documentation or online support resources. Common errors stem from file issues (incorrect formats, missing fonts, corrupt images), resource conflicts (insufficient disk space, network connectivity problems), or configuration problems (incorrect settings in the workflow definition).

My process typically involves:

- Checking the Prinergy logs: This is the first step; I analyze the timestamp, error code, and associated job information.

- Verifying the input files: I inspect the job’s source files to ensure they meet Prinergy’s requirements – correct file formats, embedded profiles, and adequate resolution.

- Checking server resources: I monitor server resource usage (CPU, memory, disk space) to identify potential bottlenecks.

- Reviewing the workflow definition: I carefully examine the workflow steps to identify any misconfigurations or conflicts.

- Testing with a simple job: If the issue is unclear, I create a very basic job to isolate the problem. If the simple job works, the problem lies within the original job’s files or configuration.

- Contacting support (if necessary): If I can’t resolve the issue, I’ll leverage Kodak’s support resources, forums, or direct support channels, providing them with the error logs and detailed descriptions.

For example, a common error I’ve encountered is a ‘missing font’ error. This is usually solved by ensuring that all fonts used in the input files are installed on the Prinergy server and correctly mapped within the workflow.

Q 9. Explain the process of creating and managing templates in Prinergy.

Creating and managing templates in Prinergy is crucial for maintaining consistency and efficiency. Templates pre-define the settings for a job, including imposition, color profiles, output settings, and job properties. This eliminates repetitive tasks and reduces the chance of errors.

The process typically involves:

- Creating a new template: This involves defining the imposition scheme (how pages are arranged on a sheet), selecting color profiles (for accurate color reproduction), specifying output settings (resolution, color space, etc.), and adding any necessary pre-flight checks.

- Defining variables: Templates can incorporate variables, allowing for flexibility. For instance, you can create a variable for the job name, allowing the name to be automatically populated during job creation.

- Testing the template: It’s vital to thoroughly test the template with sample jobs to ensure it works as expected before putting it into regular use.

- Managing and updating templates: Prinergy allows for version control of templates. This is critical for keeping track of changes and maintaining consistency.

- Using the templates: Once created, templates can be easily selected when submitting new jobs, significantly speeding up the process.

For instance, I created a template for a specific magazine layout, pre-setting the imposition, color profiles, and bleed settings. This ensures all issues of the magazine are consistently produced.

Q 10. How do you handle job revisions and updates in Prinergy Workflow?

Handling job revisions and updates in Prinergy involves leveraging its versioning capabilities and workflow flexibility. This is typically triggered by client requests for changes or corrections after initial job submission.

The process typically involves:

- Creating a new revision: Instead of directly modifying the original job, I create a new revision, preserving the original job’s data. This maintains a clear history of changes.

- Utilizing the ‘Job Properties’: I modify relevant job properties such as the version number or description within the Job Properties panel to differentiate revisions.

- Updating input files: I replace the old files with revised files. Prinergy automatically recognizes this change and processes the updated job.

- Modifying the workflow: If changes require adjustments to the workflow itself (such as different output settings), this is done within the workflow definition and the revised job will use the updated workflow.

- Proofing and approval: The revised job typically undergoes a new proofing process before final output, ensuring all changes are correct.

For example, if a client requested a change in font for a particular page, I would create a new revision, update the relevant file, and then process the revised job using the same template. The history of changes is clearly documented within Prinergy.

Q 11. Describe your experience with automated workflows in Prinergy.

My experience with automated workflows in Prinergy is extensive. I’ve designed and implemented numerous automated workflows to streamline various aspects of the printing process, reducing manual intervention and improving turnaround times.

Automated workflows I’ve implemented include:

- Automated pre-flight checks: Automated checks for missing fonts, incorrect color spaces, low-resolution images, and other potential issues are essential. This reduces errors and saves time. I’ve used JDF (Job Definition Format) to trigger these checks automatically.

- Automated imposition: Prinergy allows setting up automatic imposition using the integrated tools, minimizing manual imposition steps.

- Automated job routing: This directs jobs automatically to specific output devices based on predefined criteria like job type, color mode, or paper size.

- Integration with MIS systems: This automates the flow of job information between Prinergy and management systems, reducing data entry and ensuring data consistency.

For example, I automated a workflow for business cards. The system automatically received the order details from our online store, created the job in Prinergy with the correct imposition, and sent the ready-to-print files directly to the press.

Q 12. How do you ensure the quality control of jobs processed through Prinergy?

Ensuring quality control in Prinergy relies on a multi-layered approach, combining automated checks and manual verification.

My quality control processes include:

- Pre-flight checks: Automated pre-flight checks are fundamental, catching many errors before processing begins. This includes checks for missing fonts, color profile discrepancies, and resolution issues.

- Soft proofing: Prinergy allows for soft proofing, providing a digital preview of the output, allowing for visual verification.

- Hard proofing: Producing hard proofs (printed samples) is essential for critical jobs, especially where color accuracy is paramount.

- Automated color management: Correct color profiles are critical; I meticulously set up color profiles and use Prinergy’s color management features to ensure accurate color reproduction.

- Post-flight checks: After processing, I review the job status and logs for any errors or warnings.

- Visual Inspection: A final visual inspection of the final output for any defects.

For example, before sending a job to a high-end press, I always create a hard proof using the same paper stock and ink profile to verify the color accuracy and overall quality.

Q 13. Explain your experience with integrating Prinergy with other MIS systems.

Integrating Prinergy with other MIS (Management Information Systems) is crucial for efficient workflow and data management. I have extensive experience integrating Prinergy with various MIS systems using industry-standard interfaces.

My integration experience includes:

- JDF/JMF (Job Definition Format/Job Messaging Format): I leverage JDF/JMF for seamless data exchange between Prinergy and MIS systems. This allows for automated job creation, status updates, and data tracking.

- API (Application Programming Interface): I’ve worked with Prinergy’s APIs to create custom integrations and automate specific tasks not directly supported by the standard interfaces.

- Database connections: I’ve established database connections between Prinergy and other systems to exchange job data, customer information, and other relevant details.

For instance, I integrated Prinergy with a client’s MIS system to automate the entire job tracking process. This automated job creation, status updates, and the generation of reports, which significantly improved their efficiency and tracking.

Q 14. Describe the process of setting up and configuring a new Prinergy server.

Setting up and configuring a new Prinergy server is a complex process requiring careful planning and execution. This involves several key steps:

The process typically involves:

- Hardware preparation: This includes selecting appropriate server hardware with sufficient processing power, memory, and disk space to handle the anticipated workload. Redundancy is typically essential for high-availability setups.

- Software installation: Installing the Prinergy software involves following Kodak’s installation guidelines precisely. This usually requires database setup as well.

- Network configuration: Configuring the network settings (IP address, subnet mask, gateway) is crucial for connectivity.

- Database configuration: Configuring the database (typically SQL Server or Oracle) is a key part; this involves setting up database users, permissions, and connection strings.

- Workflow configuration: This is a significant task that needs careful planning. It involves setting up pre-flight checks, color profiles, output devices, and templates. I always thoroughly test each part of the configuration.

- User and security setup: Creating user accounts and setting access permissions is vital for security and managing access.

- Testing and validation: Extensive testing is crucial to ensure stability and functionality before deployment.

For example, in a recent project, I carefully planned the server hardware configuration, optimizing for both performance and scalability, anticipating future growth. I also implemented robust security measures during setup to protect sensitive job data and maintain data integrity.

Q 15. How do you manage user access and permissions in Prinergy Workflow?

Managing user access and permissions in Prinergy Workflow is crucial for security and workflow efficiency. It’s all done through the Prinergy system’s robust user management tools. Think of it like assigning keys and access levels to a building – different users need different levels of access.

Firstly, you define user groups, which are collections of users with similar roles and permissions. For example, you might have a ‘Prepress Operators’ group, a ‘Proofreaders’ group, and a ‘Management’ group. Each group is then assigned specific permissions, granting them access to only the functionalities they need. This prevents unauthorized access to sensitive data or actions.

Secondly, you assign individual users to these groups. This way, adding or removing a user’s access is as simple as adding or removing them from the relevant group. For example, a new prepress operator is added to the ‘Prepress Operators’ group, automatically inheriting the group’s permissions.

Thirdly, you can fine-tune permissions at the individual level. Even within a group, you might need to give specific users additional or restricted access. For instance, a senior prepress operator might have permission to approve jobs while others only have access to process them.

Finally, regular audits of user permissions are essential to maintain security. Periodically reviewing and updating permissions ensures that only authorized individuals have access to sensitive data and functions, preventing any potential security risks. This entire process is managed through the Prinergy administration interface, making it intuitive and efficient.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with Prinergy’s job ticketing and reporting features.

Prinergy’s job ticketing and reporting features are invaluable for tracking projects, managing resources, and analyzing workflow performance. Think of them as a detailed logbook and performance dashboard for your entire print production.

Job ticketing in Prinergy allows for detailed job information input before a job even begins. This includes client details, job specifications, deadlines, and special instructions. This organized tracking system minimizes confusion and ensures everyone is on the same page. I’ve used this feature extensively to generate custom job tickets for complex projects, including unique identification numbers, barcodes, and even pre-populated fields based on client preferences.

Reporting, on the other hand, provides a powerful analysis of your workflow’s efficiency. Prinergy offers a range of pre-built reports, such as job turnaround times, resource utilization, and error rates. I’ve personally used these reports to identify bottlenecks in our workflow, optimize resource allocation, and make data-driven decisions to improve our overall efficiency. The custom report generation option allows me to build tailored reports for specific clients, or to track specific metrics of interest. For instance, a customized report might show the time spent on preflight checks for a specific client over a quarter. This level of insight helps us proactively address areas for improvement.

Q 17. How do you optimize Prinergy Workflow for speed and efficiency?

Optimizing Prinergy Workflow for speed and efficiency is a continuous process involving several key strategies. It’s like fine-tuning a well-oiled machine to make it run even smoother and faster.

- Streamlining Job Processes: Carefully examining and refining the workflow steps is crucial. This could involve automating repetitive tasks using hot folders, scripting, or other automation tools. For example, we automated the imposition process for a specific type of brochure, significantly reducing turnaround time.

- Hardware Optimization: Ensuring your hardware (servers, RIPs, etc.) meets the demands of your workload is paramount. This involves monitoring system performance, upgrading components when necessary, and optimizing network bandwidth. We once saw a dramatic improvement in processing speed after upgrading our RIP servers.

- Efficient Preflighting: Implementing rigorous preflight checks catches errors early, preventing costly reprints and delays. Customizing preflight profiles for different job types ensures only relevant checks are performed, saving time and resources.

- User Training and Best Practices: Well-trained operators using efficient work practices contribute significantly to workflow speed. Regular training and clear guidelines ensure everyone is working optimally.

- Regular Maintenance: Performing regular system maintenance, including database backups and software updates, prevents unexpected downtime and performance issues.

A holistic approach, combining these strategies, yields the best results. It requires a blend of technical knowledge, process optimization skills, and consistent monitoring.

Q 18. Describe your experience with different imposition methods available in Prinergy.

Prinergy offers a variety of imposition methods to suit different printing requirements. Choosing the right method depends on the job specifications, substrate, and desired output. Think of it like choosing the right tools for different carpentry tasks – you wouldn’t use a hammer to screw in a screw.

Automated Imposition: Prinergy’s automated imposition tools offer quick and efficient solutions for common jobs. I often use these for standard brochures, booklets, and other publications where the imposition is straightforward. These tools are incredibly helpful for repetitive jobs, saving considerable time and reducing errors.

Manual Imposition: For complex jobs with intricate layouts, manual imposition provides the flexibility needed for precise control. I’ve used this for jobs requiring unique arrangements or those involving intricate die-cuts or special finishing techniques. While more time-consuming, the manual approach allows for a high degree of customization.

Custom Imposition Templates: For frequently repeated job types, creating and saving custom imposition templates is extremely beneficial. This speeds up the process significantly for standardized jobs by automatically applying a pre-defined imposition scheme. I’ve created many custom templates for common jobs, drastically reducing setup time.

Third-Party Imposition Software Integration: Prinergy also seamlessly integrates with some third-party imposition software solutions. This is useful when specialized imposition requirements exceed the capabilities of Prinergy’s built-in tools. This is very advantageous for specific applications requiring higher accuracy or advanced features.

Q 19. How do you handle large-format printing jobs within Prinergy Workflow?

Handling large-format printing jobs in Prinergy Workflow requires careful planning and optimized settings. The key is to ensure the workflow is designed to handle the unique demands of these jobs. Think of it as preparing for a large-scale construction project – careful planning and resource allocation are crucial for success.

First, appropriate RIP settings are needed. High-resolution output requires sufficient processing power and memory. Optimizing RIP settings for large files can help prevent crashes and maintain a smooth workflow. I always start by checking system resources and adjusting settings as needed, particularly the memory allocation.

Next, efficient file handling is crucial. Large files can slow down the workflow significantly. We use file compression techniques where possible and optimize the file transfer process. Employing appropriate network infrastructure can improve file transfer speed substantially.

Lastly, efficient imposition techniques are essential. Large-format jobs often involve complex arrangements and may require careful planning of tiles and page layouts. The right imposition method can dramatically impact productivity. Using automation and custom templates for standard layouts is key.

Furthermore, monitoring the job progress is essential to proactively address potential issues. Having the ability to track the progress of large-format jobs aids quick identification and resolution of any bottlenecks. This minimizes downtime and ensures jobs are completed on schedule.

Q 20. What is your experience with Prinergy’s preflight capabilities?

Prinergy’s preflight capabilities are crucial for ensuring print quality and preventing costly errors. Think of it as a comprehensive quality control check before production begins.

Prinergy offers a range of preflight checks, from verifying color profiles and font embedding to detecting missing images and low-resolution files. The system allows me to customize these checks to fit the specific needs of the job. For example, I’ve configured preflight profiles for different types of jobs – one for high-resolution images, another for web-based files, ensuring only relevant checks are performed.

Automated preflighting saves significant time and prevents errors that could lead to reprints and delays. Identifying issues early in the workflow dramatically reduces waste. For example, automatically detecting a missing font prevents the job from reaching the press only to be halted by the missing asset.

Furthermore, the detailed reporting from Prinergy’s preflight function is extremely helpful. Detailed reports allow us to analyze error trends and identify areas for improvement in our prepress workflow. We often use this data to update our preflight profiles, our processes and even enhance operator training.

Q 21. How do you use Prinergy’s tools to manage and resolve print-related issues?

Prinergy provides a suite of tools for managing and resolving print-related issues, acting as a central hub for troubleshooting and problem-solving. Think of it as a command center for addressing any hiccups during the print production process.

Job Tracking: Prinergy’s job tracking tools allow me to monitor the progress of each job in real-time, identifying potential problems early. If a job is delayed or encounters an error, I can quickly pinpoint the issue and take corrective action. I’ve used this extensively to troubleshoot jobs that experience slowdowns or unexpected errors. The system often provides clear clues as to the source of the problem.

Error Reporting: Prinergy’s detailed error reports provide specific information about the nature of any issues encountered, streamlining troubleshooting. Knowing the exact error message helps me quickly identify the cause and find the best solution. This saves time and minimizes downtime compared to trial-and-error approaches.

Remote Diagnostics: In some cases, remote diagnostic tools are extremely helpful. These tools allow technicians to access and analyze the Prinergy system remotely, identifying issues that may not be apparent locally. We utilize this functionality to diagnose and resolve complex issues without on-site visits, saving time and expenses. This is especially useful for addressing issues with remote RIP servers.

Log Files: Prinergy maintains detailed log files that provide a record of every action performed within the system. These log files are invaluable for analyzing past problems and identifying recurring issues. This helps proactively implement preventative measures in the future, enhancing the stability and reliability of the system.

Q 22. Explain your experience using the Prinergy Connect module.

Prinergy Connect is a crucial module for streamlining communication and automating processes between prepress and print production. It acts as a bridge, allowing for seamless data transfer and job management between different systems and departments. My experience involves extensively utilizing Connect to integrate Prinergy with our MIS (Management Information System) and various client-side systems. This automated the submission of jobs, reduced manual data entry errors, and dramatically sped up turnaround times. For instance, we integrated Connect with our customer’s web-to-print platform. This allowed clients to upload files, select options, and receive automated proofing, all without manual intervention on our end. This improved customer experience and internal efficiency substantially.

Another key aspect of my Connect experience is troubleshooting integration issues. For example, we encountered challenges with data mapping between the MIS system and Prinergy. By thoroughly understanding both systems’ data structures and utilizing Connect’s flexible configuration options, we successfully mapped all critical data points, resolving the issue and ensuring data integrity.

Q 23. Describe your experience with the Prinergy’s archiving and retrieval system.

Prinergy’s archiving and retrieval system is essential for long-term data management and efficient job recall. I’ve utilized this extensively, managing terabytes of data across numerous projects and clients. The system allows for both online and offline archiving, ensuring data security and accessibility. Think of it as a highly organized digital library for all your print jobs. Each job is meticulously archived, preserving all its associated files, metadata, and production history. This allows for easy retrieval of past projects, crucial for reprint orders or client requests for job details.

One specific example was a client requiring a reprint of a brochure after several years. Using Prinergy’s archive, I quickly located the project, accessed the original files, and initiated the reprint process, minimizing the time and effort needed. The system’s robust search capabilities and detailed metadata tags made this retrieval incredibly efficient. Beyond individual job retrieval, the system supports comprehensive reporting, providing insights into historical data for capacity planning and resource allocation.

Q 24. How do you maintain and update Prinergy Workflow software and configurations?

Maintaining and updating Prinergy involves a multi-faceted approach. It starts with proactive monitoring of the system’s health, using built-in tools to check for errors and warnings. Regular software updates are critical; these often include bug fixes, performance enhancements, and new features. We follow a structured approach, carefully testing updates in a staging environment before deploying them to the production system. This ensures minimal disruption to workflows. This includes updating not just the core software but also connected modules like Connect and any custom plugins or integrations.

Configuration maintenance is equally vital. We regularly review and optimize the system’s settings, such as job ticket configurations, imposition presets, and color profiles, to ensure optimal performance and efficiency. This involves collaborating with the print production team to gather feedback and fine-tune configurations based on their needs. Documentation is key – we maintain detailed records of all software versions, configurations, and changes, making troubleshooting easier and ensuring a smooth transition during upgrades or issues.

Q 25. Describe your experience with migrating from a previous workflow system to Prinergy.

Migrating from our previous workflow system to Prinergy was a significant undertaking, but ultimately very rewarding. The process involved several key phases. First, a thorough assessment of our existing workflow and data was performed to identify what needed to be migrated and how. Data migration was a critical step, requiring careful planning and execution to ensure data integrity. We used Prinergy’s migration tools and developed custom scripts where necessary to move data effectively. The migration was staged, allowing us to migrate data in manageable chunks and test thoroughly before moving to the next phase.

Training was also a critical aspect. The team received comprehensive training on Prinergy’s functionality, ensuring a smooth transition. Finally, post-migration support was crucial to address any unexpected issues and fine-tune the system. This whole process taught us the importance of meticulous planning, robust testing, and effective communication within the team. The result was a more streamlined and efficient workflow, significantly improving our productivity and reducing errors.

Q 26. How familiar are you with the different Prinergy Workflow configurations and options?

I’m highly familiar with various Prinergy Workflow configurations and options. This includes different server architectures (standalone, clustered), database configurations, and the various modules available. I’ve worked with both large-scale installations serving multiple printing presses and smaller, more specialized setups. I understand the trade-offs between different configurations, and can select the optimal setup based on specific needs. For example, the choice between a clustered architecture and a standalone server depends on factors like scalability requirements, redundancy needs, and budget.

My experience also extends to configuring various aspects of the workflow, from job ticket design and imposition settings to color management profiles and output device configurations. I understand the impact of these configurations on printing quality, efficiency, and overall production costs. This includes optimizing the workflow for different print types, such as offset, digital, and large-format printing, recognizing the unique requirements of each.

Q 27. Explain your understanding of Prinergy’s security features and best practices.

Prinergy’s security features are essential for protecting sensitive data and ensuring the integrity of the workflow. Key features include user authentication and authorization, data encryption, and access control. We implement robust security protocols, including strong passwords, multi-factor authentication, and regular security audits. Data encryption is critical, especially when dealing with confidential client information. Access control ensures that only authorized personnel have access to specific functions and data within the system.

Best practices include regularly updating the software to patch security vulnerabilities, implementing strict access control policies, and providing regular security awareness training to all users. We also adhere to industry best practices, such as regular backups and disaster recovery planning to ensure business continuity. By combining these technical measures with a strong security culture, we maintain a secure and reliable printing workflow.

Q 28. What are some common challenges you’ve faced using Prinergy Workflow, and how did you resolve them?

One common challenge was integrating Prinergy with legacy systems, where data formats or communication protocols were incompatible. We resolved this through careful data mapping, custom scripting, and close collaboration with the vendors of the legacy systems. Another challenge was optimizing the workflow for high-volume production. We tackled this by fine-tuning system configurations, optimizing job ticket settings, and streamlining the production processes. This included implementing automated tasks and improving the efficiency of various stages of the workflow.

Performance bottlenecks were another issue, sometimes caused by large files or inefficient processes. We addressed these by optimizing server resources, upgrading hardware when needed, and improving job processing parameters. In each instance, a methodical approach involving thorough analysis, testing, and collaboration with the team proved effective in addressing these challenges. The key is proactive monitoring and a willingness to adapt and optimize the system based on real-world demands.

Key Topics to Learn for Your Prinergy Workflow Interview

- Workflow Basics: Understanding the core components of the Prinergy Workflow system, including job creation, processing, and output. This includes a solid grasp of the overall architecture and how different modules interact.

- Job Ticket Creation and Management: Learn how to efficiently create and manage job tickets, ensuring accuracy and consistency in pre-press operations. Practical application involves understanding the various options and settings within a job ticket and their impact on the final output.

- Imposition and Preflight: Mastering imposition techniques and preflight checks is crucial. Explore different imposition strategies and how to identify and resolve preflight errors to guarantee quality and efficiency.

- Color Management: Understand the importance of color profiles and how Prinergy handles color conversions. Practical application involves troubleshooting color discrepancies and ensuring color consistency across different output devices.

- Automation and Scripting (if applicable): Explore the automation capabilities within Prinergy Workflow, including scripting options (if relevant to the role). This demonstrates advanced problem-solving and efficiency.

- Troubleshooting and Problem Solving: Develop your ability to diagnose and resolve common issues within the Prinergy Workflow system. This often involves understanding error messages and logs.

- Integration with other systems: Familiarize yourself with how Prinergy integrates with other MIS and pre-press software. This showcases a broader understanding of the print production process.

Next Steps

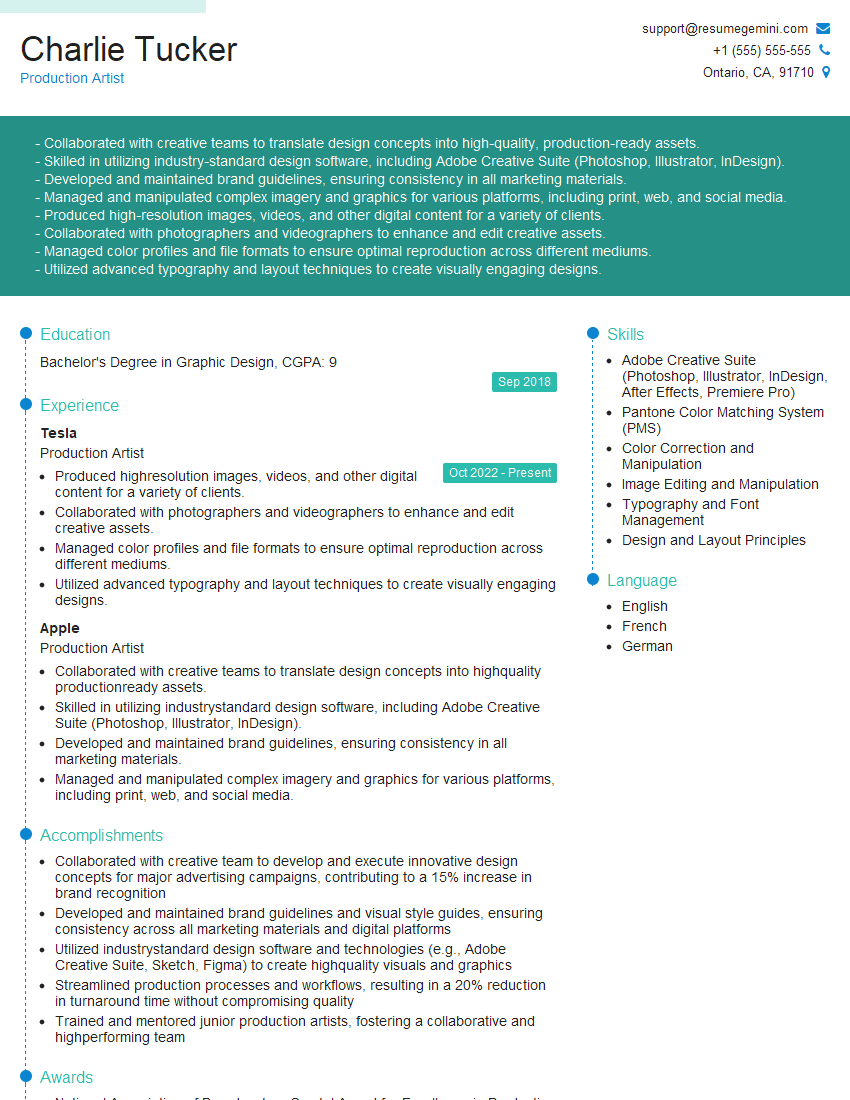

Mastering Prinergy Workflow significantly enhances your marketability and opens doors to exciting opportunities in the print and publishing industries. A strong understanding of this system demonstrates valuable technical skills and efficiency. To increase your chances of landing your dream job, invest time in crafting a compelling, ATS-friendly resume that highlights your Prinergy expertise. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to ensure your resume is optimized for Applicant Tracking Systems (ATS), significantly boosting your visibility to potential employers. Examples of resumes tailored to Prinergy Workflow positions are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hi, I’m Jay, we have a few potential clients that are interested in your services, thought you might be a good fit. I’d love to talk about the details, when do you have time to talk?

Best,

Jay

Founder | CEO